brake SUBARU LEGACY 1999 Service Service Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 580 of 1456

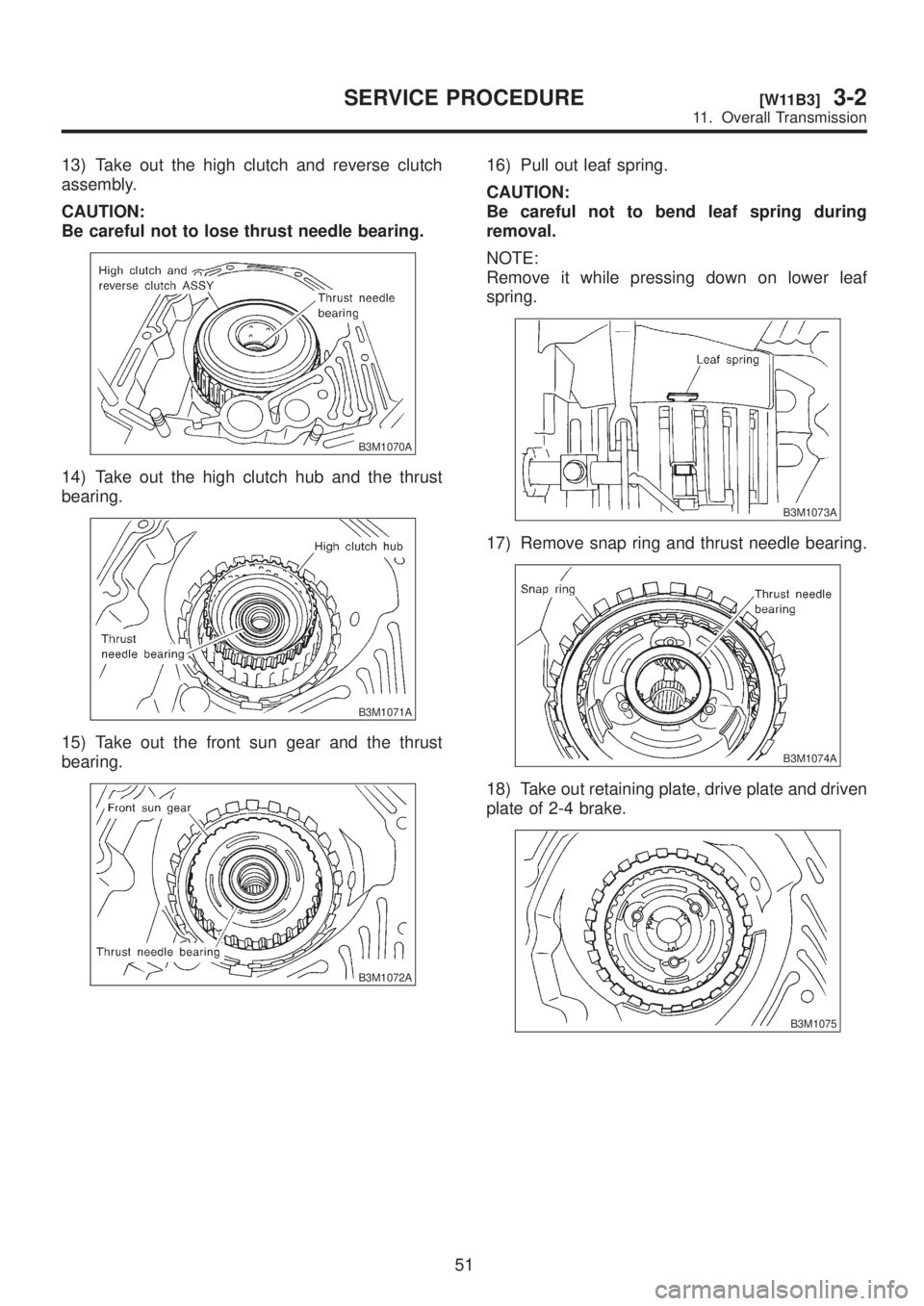

13) Take out the high clutch and reverse clutch

assembly.

CAUTION:

Be careful not to lose thrust needle bearing.

B3M1070A

14) Take out the high clutch hub and the thrust

bearing.

B3M1071A

15) Take out the front sun gear and the thrust

bearing.

B3M1072A

16) Pull out leaf spring.

CAUTION:

Be careful not to bend leaf spring during

removal.

NOTE:

Remove it while pressing down on lower leaf

spring.

B3M1073A

17) Remove snap ring and thrust needle bearing.

B3M1074A

18) Take out retaining plate, drive plate and driven

plate of 2-4 brake.

B3M1075

51

[W11B3]3-2SERVICE PROCEDURE

11. Overall Transmission

Page 581 of 1456

19) Take out the thrust needle bearing, planetary

gear assembly and the low clutch assembly.

B3M1076A

20) Remove snap ring.

B3M1077A

21) Take out 2-4 brake return spring.

B3M1078A

22) Take out 2-4 brake piston and piston retainer.

CAUTION:

When removing the brake piston 2-4 and piston

retainer, be careful not to rub or bump them

against the transmission case.

B3M1079A

23) Separate 2-4 brake piston and piston retainer.

B3M1080A

24) Pull out leaf spring.

CAUTION:

Be careful not to bend leaf spring during

removal.

B3M0956A

25) Remove snap ring.

B3M1081A

26) Take out retaining plate, drive plate, driven

plate and dish plate.

B3M1082

52

3-2[W11B3]SERVICE PROCEDURE

11. Overall Transmission

Page 582 of 1456

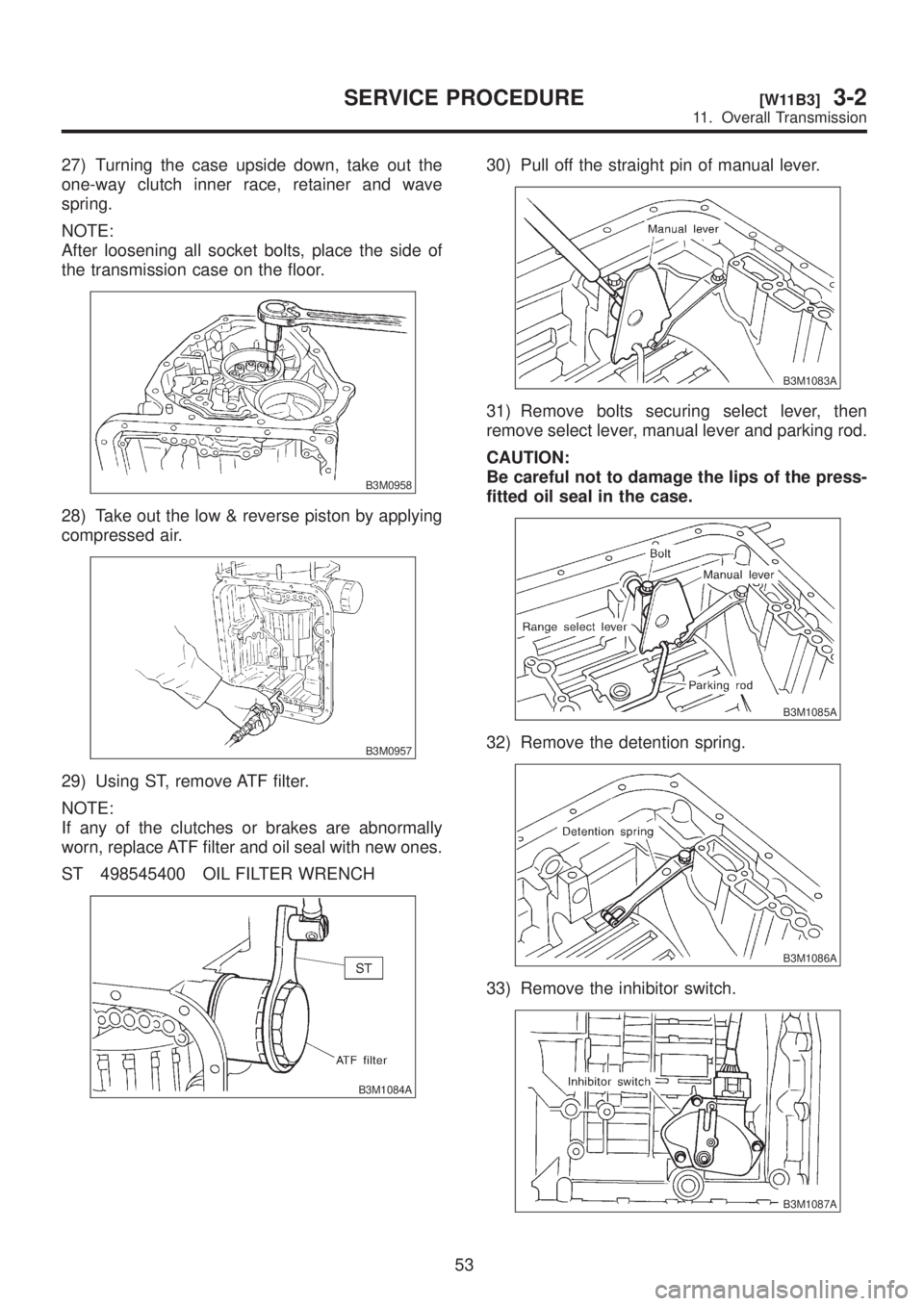

27) Turning the case upside down, take out the

one-way clutch inner race, retainer and wave

spring.

NOTE:

After loosening all socket bolts, place the side of

the transmission case on the floor.

B3M0958

28) Take out the low & reverse piston by applying

compressed air.

B3M0957

29) Using ST, remove ATF filter.

NOTE:

If any of the clutches or brakes are abnormally

worn, replace ATF filter and oil seal with new ones.

ST 498545400 OIL FILTER WRENCH

B3M1084A

30) Pull off the straight pin of manual lever.

B3M1083A

31) Remove bolts securing select lever, then

remove select lever, manual lever and parking rod.

CAUTION:

Be careful not to damage the lips of the press-

fitted oil seal in the case.

B3M1085A

32) Remove the detention spring.

B3M1086A

33) Remove the inhibitor switch.

B3M1087A

53

[W11B3]3-2SERVICE PROCEDURE

11. Overall Transmission

Page 591 of 1456

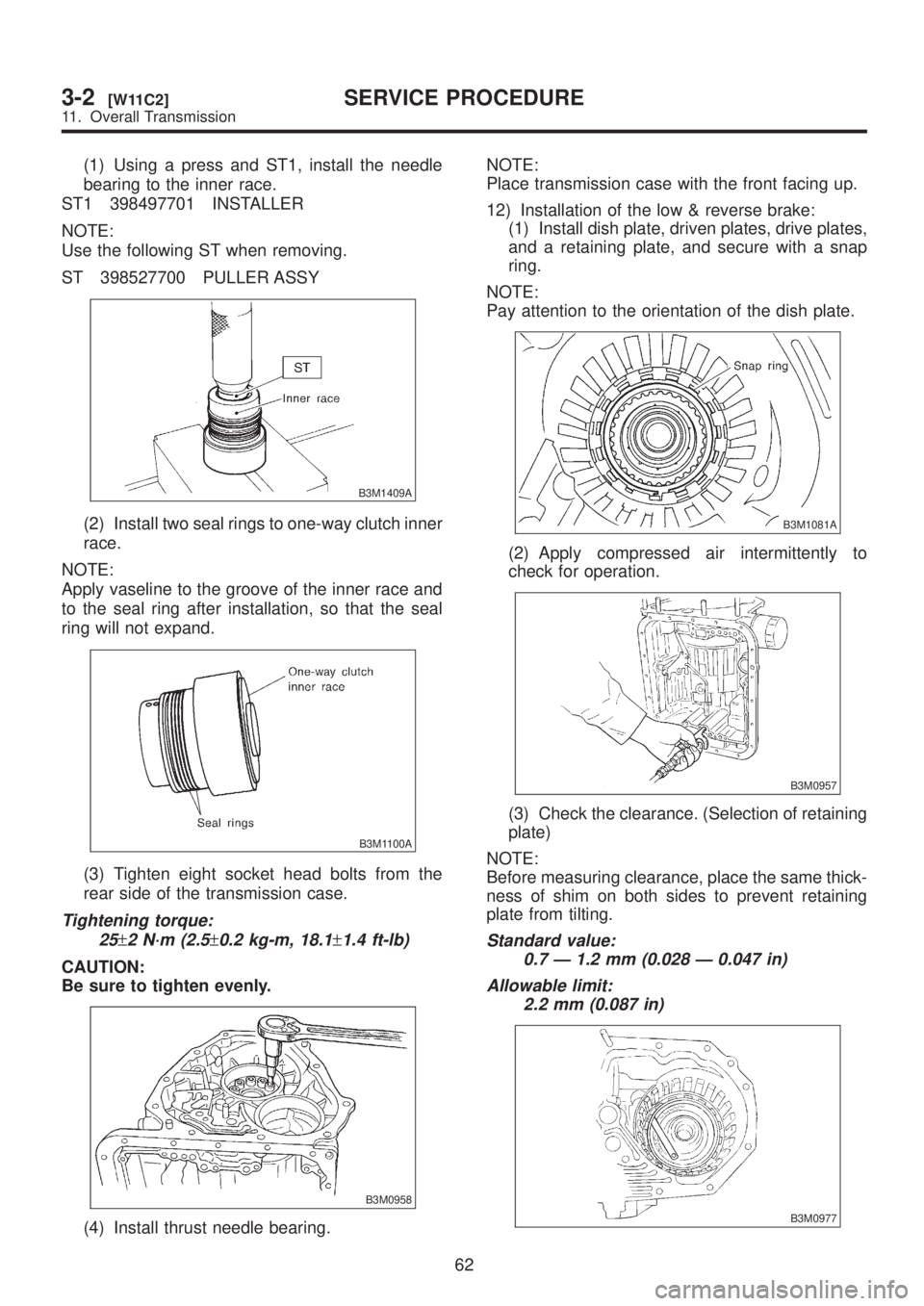

(1) Using a press and ST1, install the needle

bearing to the inner race.

ST1 398497701 INSTALLER

NOTE:

Use the following ST when removing.

ST 398527700 PULLER ASSY

B3M1409A

(2) Install two seal rings to one-way clutch inner

race.

NOTE:

Apply vaseline to the groove of the inner race and

to the seal ring after installation, so that the seal

ring will not expand.

B3M1100A

(3) Tighten eight socket head bolts from the

rear side of the transmission case.

Tightening torque:

25

±2 N´m (2.5±0.2 kg-m, 18.1±1.4 ft-lb)

CAUTION:

Be sure to tighten evenly.

B3M0958

(4) Install thrust needle bearing.NOTE:

Place transmission case with the front facing up.

12) Installation of the low & reverse brake:

(1) Install dish plate, driven plates, drive plates,

and a retaining plate, and secure with a snap

ring.

NOTE:

Pay attention to the orientation of the dish plate.

B3M1081A

(2) Apply compressed air intermittently to

check for operation.

B3M0957

(3) Check the clearance. (Selection of retaining

plate)

NOTE:

Before measuring clearance, place the same thick-

ness of shim on both sides to prevent retaining

plate from tilting.

Standard value:

0.7 Ð 1.2 mm (0.028 Ð 0.047 in)

Allowable limit:

2.2 mm (0.087 in)

B3M0977

62

3-2[W11C2]SERVICE PROCEDURE

11. Overall Transmission

Page 592 of 1456

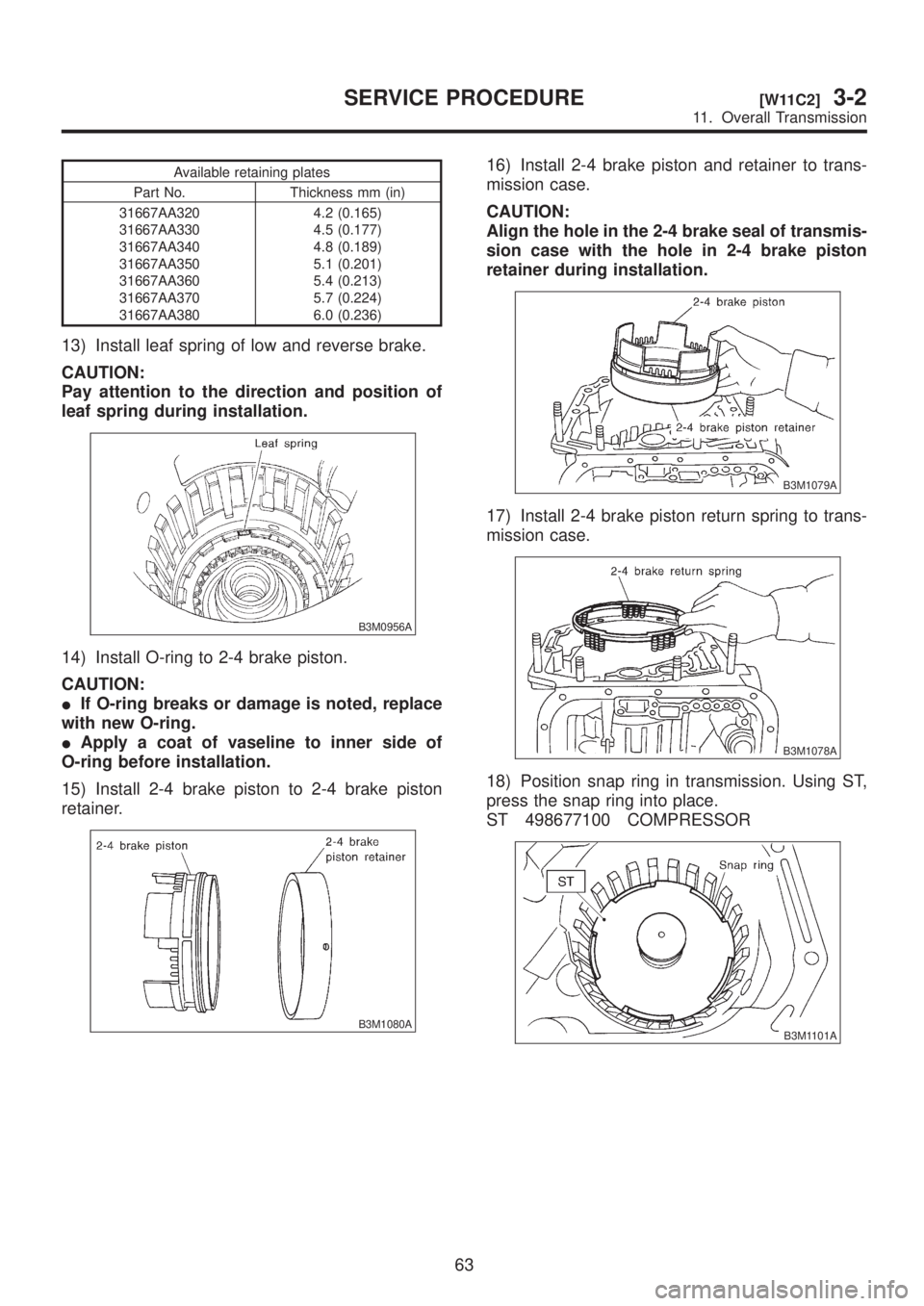

Available retaining plates

Part No. Thickness mm (in)

31667AA320

31667AA330

31667AA340

31667AA350

31667AA360

31667AA370

31667AA3804.2 (0.165)

4.5 (0.177)

4.8 (0.189)

5.1 (0.201)

5.4 (0.213)

5.7 (0.224)

6.0 (0.236)

13) Install leaf spring of low and reverse brake.

CAUTION:

Pay attention to the direction and position of

leaf spring during installation.

B3M0956A

14) Install O-ring to 2-4 brake piston.

CAUTION:

IIf O-ring breaks or damage is noted, replace

with new O-ring.

IApply a coat of vaseline to inner side of

O-ring before installation.

15) Install 2-4 brake piston to 2-4 brake piston

retainer.

B3M1080A

16) Install 2-4 brake piston and retainer to trans-

mission case.

CAUTION:

Align the hole in the 2-4 brake seal of transmis-

sion case with the hole in 2-4 brake piston

retainer during installation.

B3M1079A

17) Install 2-4 brake piston return spring to trans-

mission case.

B3M1078A

18) Position snap ring in transmission. Using ST,

press the snap ring into place.

ST 498677100 COMPRESSOR

B3M1101A

63

[W11C2]3-2SERVICE PROCEDURE

11. Overall Transmission

Page 593 of 1456

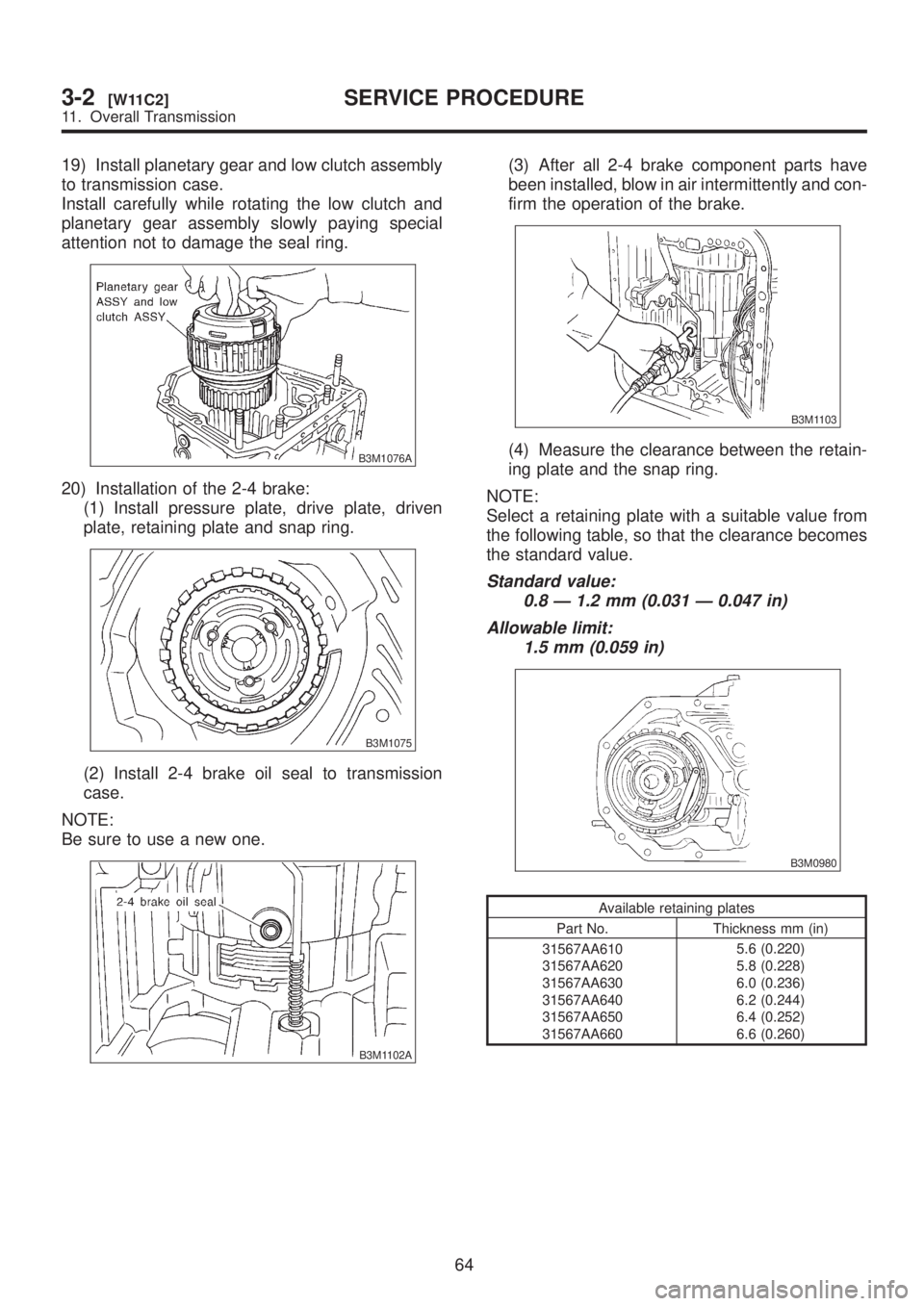

19) Install planetary gear and low clutch assembly

to transmission case.

Install carefully while rotating the low clutch and

planetary gear assembly slowly paying special

attention not to damage the seal ring.

B3M1076A

20) Installation of the 2-4 brake:

(1) Install pressure plate, drive plate, driven

plate, retaining plate and snap ring.

B3M1075

(2) Install 2-4 brake oil seal to transmission

case.

NOTE:

Be sure to use a new one.

B3M1102A

(3) After all 2-4 brake component parts have

been installed, blow in air intermittently and con-

firm the operation of the brake.

B3M1103

(4) Measure the clearance between the retain-

ing plate and the snap ring.

NOTE:

Select a retaining plate with a suitable value from

the following table, so that the clearance becomes

the standard value.

Standard value:

0.8 Ð 1.2 mm (0.031 Ð 0.047 in)

Allowable limit:

1.5 mm (0.059 in)

B3M0980

Available retaining plates

Part No. Thickness mm (in)

31567AA610

31567AA620

31567AA630

31567AA640

31567AA650

31567AA6605.6 (0.220)

5.8 (0.228)

6.0 (0.236)

6.2 (0.244)

6.4 (0.252)

6.6 (0.260)

64

3-2[W11C2]SERVICE PROCEDURE

11. Overall Transmission

Page 594 of 1456

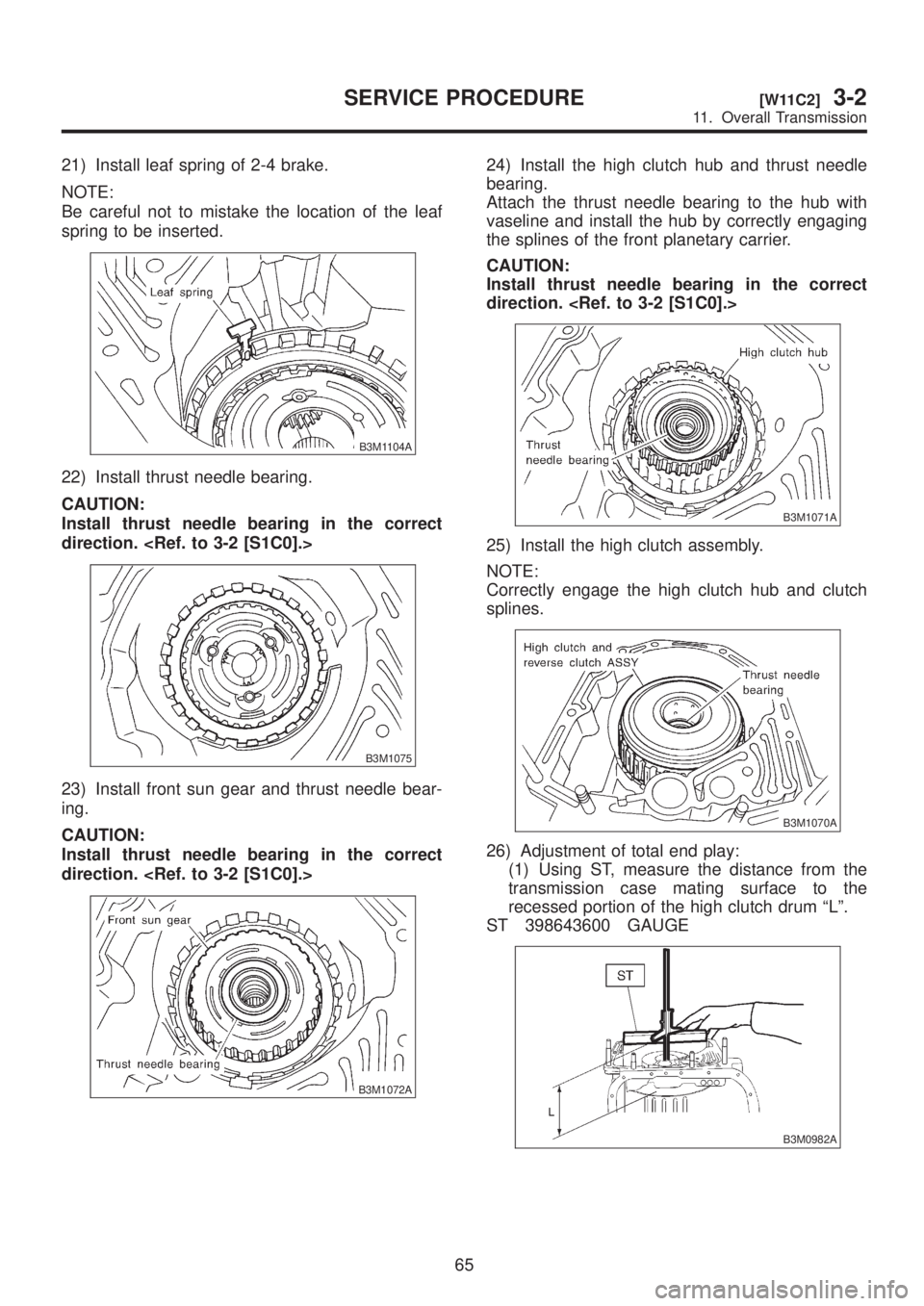

21) Install leaf spring of 2-4 brake.

NOTE:

Be careful not to mistake the location of the leaf

spring to be inserted.

B3M1104A

22) Install thrust needle bearing.

CAUTION:

Install thrust needle bearing in the correct

direction.

B3M1075

23) Install front sun gear and thrust needle bear-

ing.

CAUTION:

Install thrust needle bearing in the correct

direction.

B3M1072A

24) Install the high clutch hub and thrust needle

bearing.

Attach the thrust needle bearing to the hub with

vaseline and install the hub by correctly engaging

the splines of the front planetary carrier.

CAUTION:

Install thrust needle bearing in the correct

direction.

B3M1071A

25) Install the high clutch assembly.

NOTE:

Correctly engage the high clutch hub and clutch

splines.

B3M1070A

26) Adjustment of total end play:

(1) Using ST, measure the distance from the

transmission case mating surface to the

recessed portion of the high clutch drum ªLº.

ST 398643600 GAUGE

B3M0982A

65

[W11C2]3-2SERVICE PROCEDURE

11. Overall Transmission

Page 596 of 1456

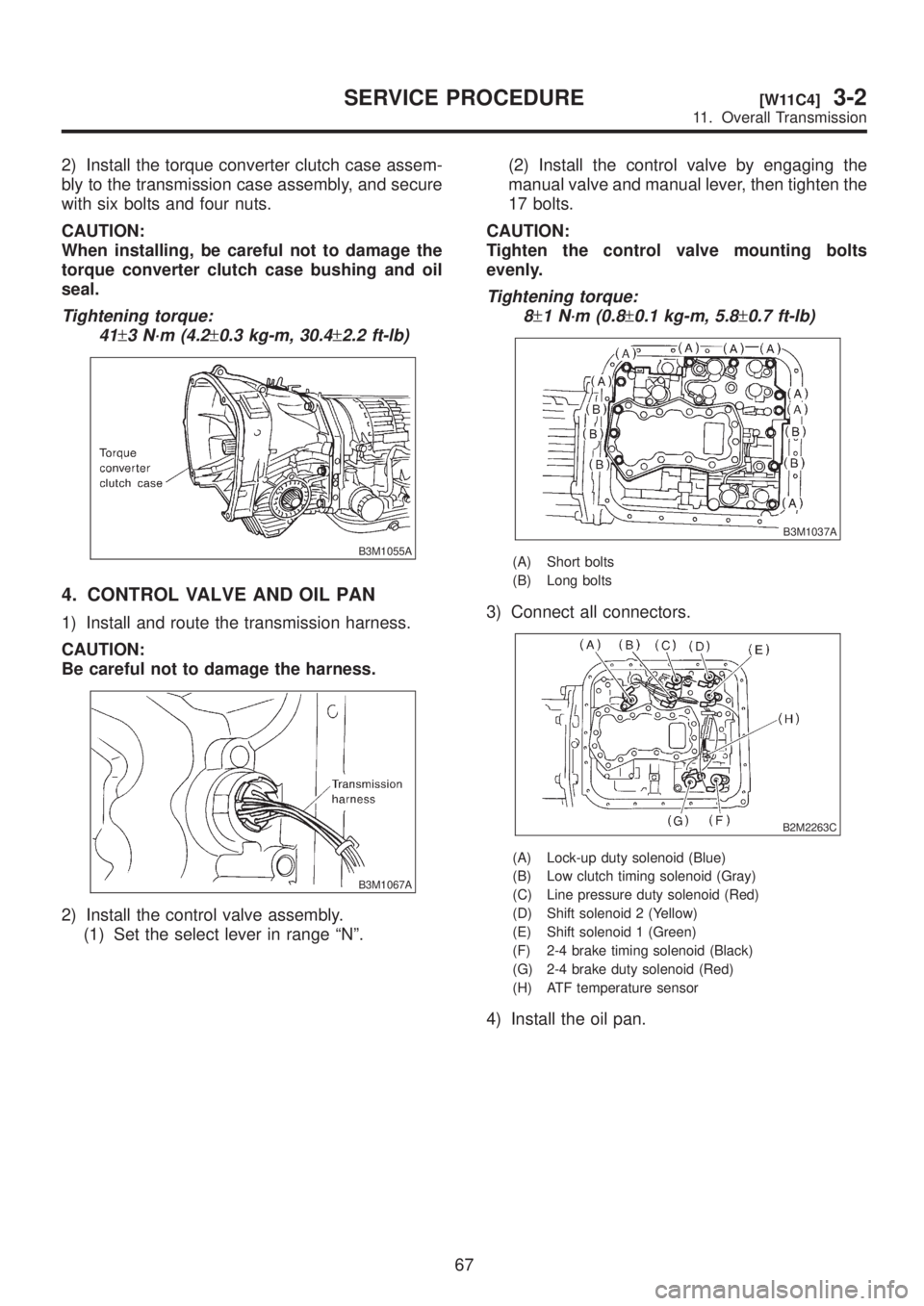

2) Install the torque converter clutch case assem-

bly to the transmission case assembly, and secure

with six bolts and four nuts.

CAUTION:

When installing, be careful not to damage the

torque converter clutch case bushing and oil

seal.

Tightening torque:

41

±3 N´m (4.2±0.3 kg-m, 30.4±2.2 ft-lb)

B3M1055A

4. CONTROL VALVE AND OIL PAN

1) Install and route the transmission harness.

CAUTION:

Be careful not to damage the harness.

B3M1067A

2) Install the control valve assembly.

(1) Set the select lever in range ªNº.(2) Install the control valve by engaging the

manual valve and manual lever, then tighten the

17 bolts.

CAUTION:

Tighten the control valve mounting bolts

evenly.

Tightening torque:

8

±1 N´m (0.8±0.1 kg-m, 5.8±0.7 ft-lb)

B3M1037A

(A) Short bolts

(B) Long bolts

3) Connect all connectors.

B2M2263C

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 2 (Yellow)

(E) Shift solenoid 1 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid (Red)

(H) ATF temperature sensor

4) Install the oil pan.

67

[W11C4]3-2SERVICE PROCEDURE

11. Overall Transmission

Page 605 of 1456

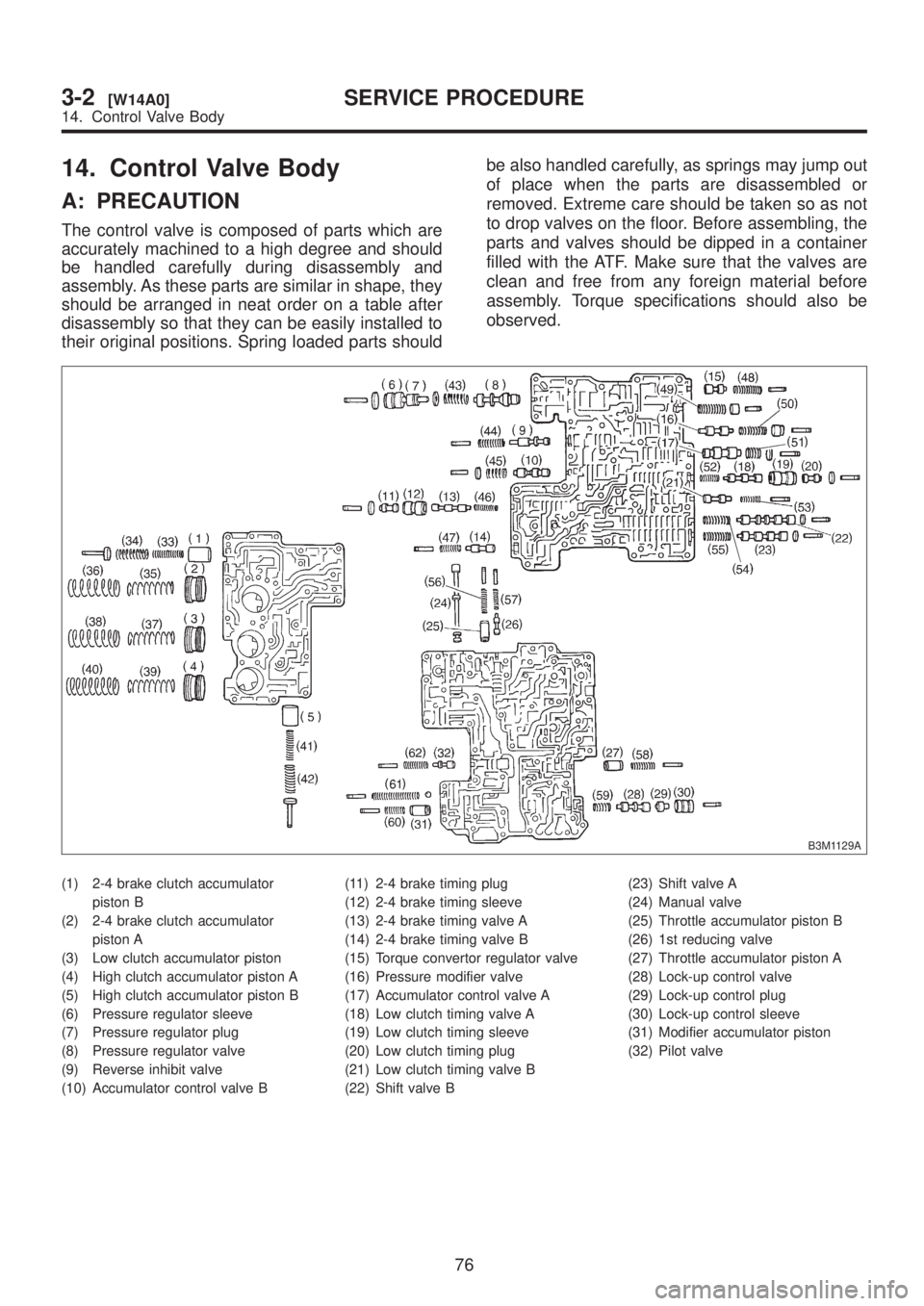

14. Control Valve Body

A: PRECAUTION

The control valve is composed of parts which are

accurately machined to a high degree and should

be handled carefully during disassembly and

assembly. As these parts are similar in shape, they

should be arranged in neat order on a table after

disassembly so that they can be easily installed to

their original positions. Spring loaded parts shouldbe also handled carefully, as springs may jump out

of place when the parts are disassembled or

removed. Extreme care should be taken so as not

to drop valves on the floor. Before assembling, the

parts and valves should be dipped in a container

filled with the ATF. Make sure that the valves are

clean and free from any foreign material before

assembly. Torque specifications should also be

observed.

B3M1129A

(1) 2-4 brake clutch accumulator

piston B

(2) 2-4 brake clutch accumulator

piston A

(3) Low clutch accumulator piston

(4) High clutch accumulator piston A

(5) High clutch accumulator piston B

(6) Pressure regulator sleeve

(7) Pressure regulator plug

(8) Pressure regulator valve

(9) Reverse inhibit valve

(10) Accumulator control valve B(11) 2-4 brake timing plug

(12) 2-4 brake timing sleeve

(13) 2-4 brake timing valve A

(14) 2-4 brake timing valve B

(15) Torque convertor regulator valve

(16) Pressure modifier valve

(17) Accumulator control valve A

(18) Low clutch timing valve A

(19) Low clutch timing sleeve

(20) Low clutch timing plug

(21) Low clutch timing valve B

(22) Shift valve B(23) Shift valve A

(24) Manual valve

(25) Throttle accumulator piston B

(26) 1st reducing valve

(27) Throttle accumulator piston A

(28) Lock-up control valve

(29) Lock-up control plug

(30) Lock-up control sleeve

(31) Modifier accumulator piston

(32) Pilot valve

76

3-2[W14A0]SERVICE PROCEDURE

14. Control Valve Body

Page 606 of 1456

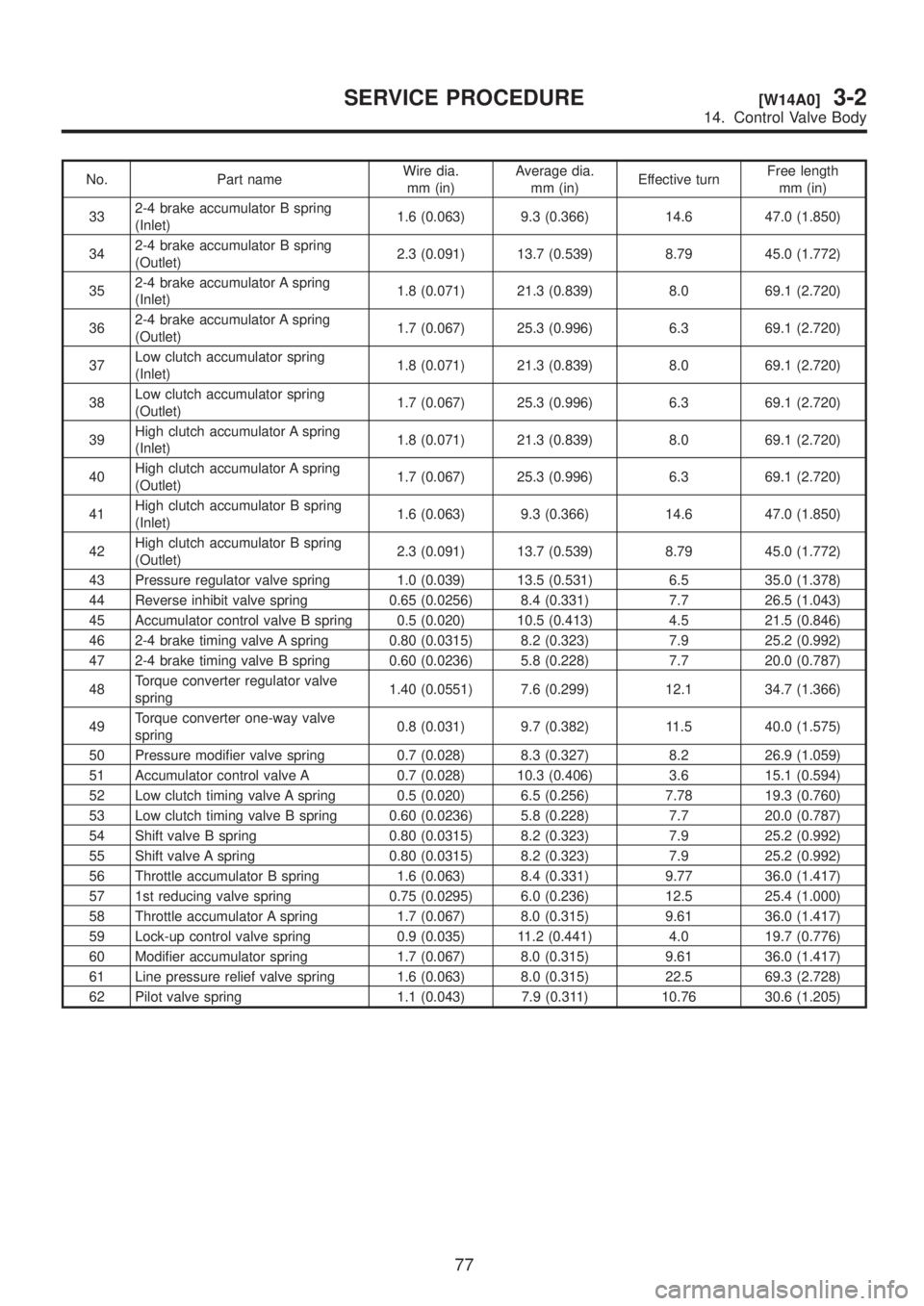

No. Part nameWire dia.

mm (in)Average dia.

mm (in)Effective turnFree length

mm (in)

332-4 brake accumulator B spring

(Inlet)1.6 (0.063) 9.3 (0.366) 14.6 47.0 (1.850)

342-4 brake accumulator B spring

(Outlet)2.3 (0.091) 13.7 (0.539) 8.79 45.0 (1.772)

352-4 brake accumulator A spring

(Inlet)1.8 (0.071) 21.3 (0.839) 8.0 69.1 (2.720)

362-4 brake accumulator A spring

(Outlet)1.7 (0.067) 25.3 (0.996) 6.3 69.1 (2.720)

37Low clutch accumulator spring

(Inlet)1.8 (0.071) 21.3 (0.839) 8.0 69.1 (2.720)

38Low clutch accumulator spring

(Outlet)1.7 (0.067) 25.3 (0.996) 6.3 69.1 (2.720)

39High clutch accumulator A spring

(Inlet)1.8 (0.071) 21.3 (0.839) 8.0 69.1 (2.720)

40High clutch accumulator A spring

(Outlet)1.7 (0.067) 25.3 (0.996) 6.3 69.1 (2.720)

41High clutch accumulator B spring

(Inlet)1.6 (0.063) 9.3 (0.366) 14.6 47.0 (1.850)

42High clutch accumulator B spring

(Outlet)2.3 (0.091) 13.7 (0.539) 8.79 45.0 (1.772)

43 Pressure regulator valve spring 1.0 (0.039) 13.5 (0.531) 6.5 35.0 (1.378)

44 Reverse inhibit valve spring 0.65 (0.0256) 8.4 (0.331) 7.7 26.5 (1.043)

45 Accumulator control valve B spring 0.5 (0.020) 10.5 (0.413) 4.5 21.5 (0.846)

46 2-4 brake timing valve A spring 0.80 (0.0315) 8.2 (0.323) 7.9 25.2 (0.992)

47 2-4 brake timing valve B spring 0.60 (0.0236) 5.8 (0.228) 7.7 20.0 (0.787)

48Torque converter regulator valve

spring1.40 (0.0551) 7.6 (0.299) 12.1 34.7 (1.366)

49Torque converter one-way valve

spring0.8 (0.031) 9.7 (0.382) 11.5 40.0 (1.575)

50 Pressure modifier valve spring 0.7 (0.028) 8.3 (0.327) 8.2 26.9 (1.059)

51 Accumulator control valve A 0.7 (0.028) 10.3 (0.406) 3.6 15.1 (0.594)

52 Low clutch timing valve A spring 0.5 (0.020) 6.5 (0.256) 7.78 19.3 (0.760)

53 Low clutch timing valve B spring 0.60 (0.0236) 5.8 (0.228) 7.7 20.0 (0.787)

54 Shift valve B spring 0.80 (0.0315) 8.2 (0.323) 7.9 25.2 (0.992)

55 Shift valve A spring 0.80 (0.0315) 8.2 (0.323) 7.9 25.2 (0.992)

56 Throttle accumulator B spring 1.6 (0.063) 8.4 (0.331) 9.77 36.0 (1.417)

57 1st reducing valve spring 0.75 (0.0295) 6.0 (0.236) 12.5 25.4 (1.000)

58 Throttle accumulator A spring 1.7 (0.067) 8.0 (0.315) 9.61 36.0 (1.417)

59 Lock-up control valve spring 0.9 (0.035) 11.2 (0.441) 4.0 19.7 (0.776)

60 Modifier accumulator spring 1.7 (0.067) 8.0 (0.315) 9.61 36.0 (1.417)

61 Line pressure relief valve spring 1.6 (0.063) 8.0 (0.315) 22.5 69.3 (2.728)

62 Pilot valve spring 1.1 (0.043) 7.9 (0.311) 10.76 30.6 (1.205)

77

[W14A0]3-2SERVICE PROCEDURE

14. Control Valve Body