ECO mode SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 33 of 1456

1. Foreword

A: GENERAL

This chapter describes major inspection and ser-

vice procedures for the engine mounted on the

body. For procedures not found in this chapter,

refer to the service procedure section in the appli-

cable chapter.

2. Ignition Timing

A: MEASUREMENT

CAUTION:

After warming-up, engine becomes very hot.

Be careful not to burn yourself during mea-

surement.

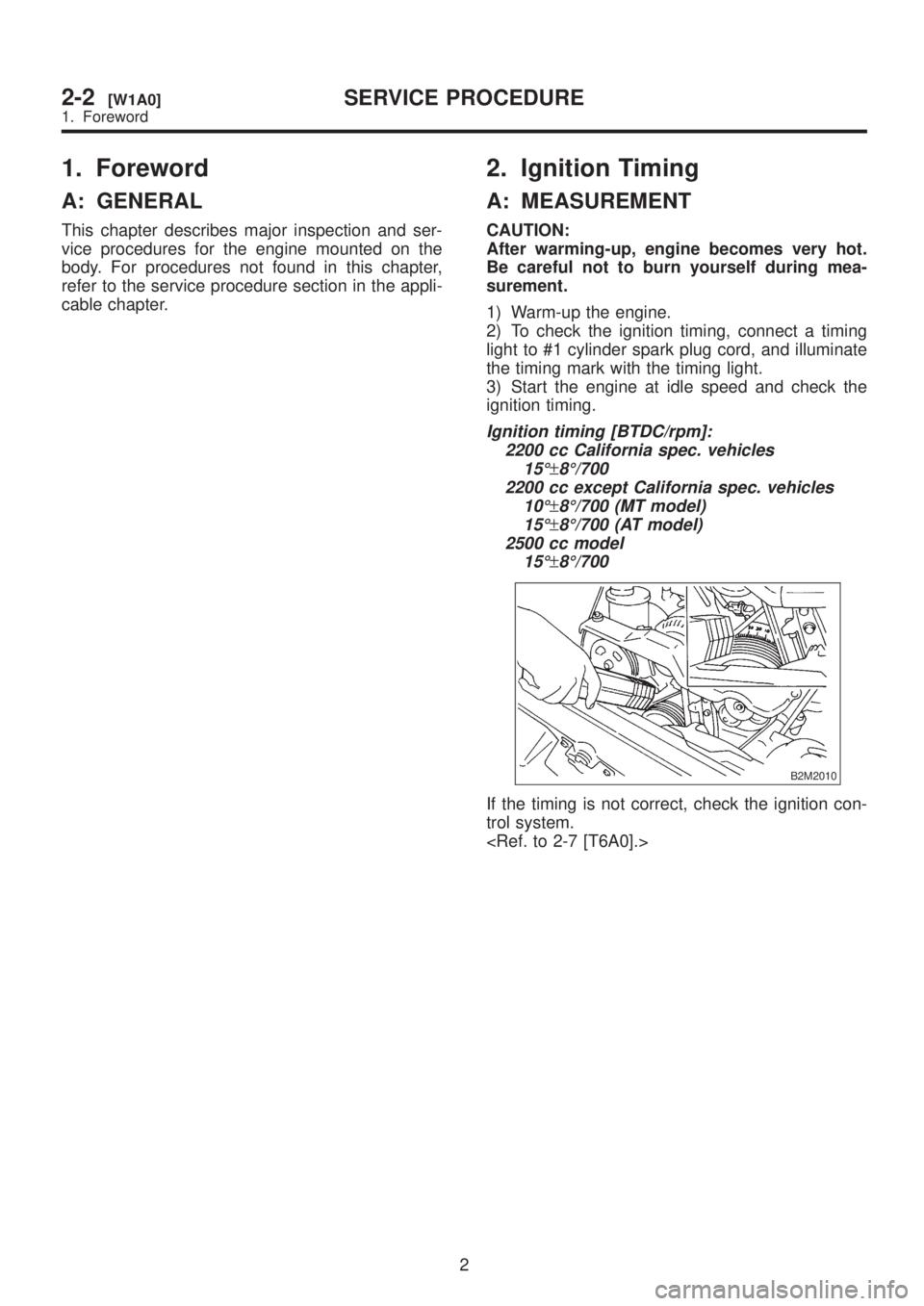

1) Warm-up the engine.

2) To check the ignition timing, connect a timing

light to #1 cylinder spark plug cord, and illuminate

the timing mark with the timing light.

3) Start the engine at idle speed and check the

ignition timing.

Ignition timing [BTDC/rpm]:

2200 cc California spec. vehicles

15É

±8É/700

2200 cc except California spec. vehicles

10É

±8É/700 (MT model)

15É

±8É/700 (AT model)

2500 cc model

15É

±8É/700

B2M2010

If the timing is not correct, check the ignition con-

trol system.

2

2-2[W1A0]SERVICE PROCEDURE

1. Foreword

Page 34 of 1456

1. Foreword

A: GENERAL

This chapter describes major inspection and ser-

vice procedures for the engine mounted on the

body. For procedures not found in this chapter,

refer to the service procedure section in the appli-

cable chapter.

2. Ignition Timing

A: MEASUREMENT

CAUTION:

After warming-up, engine becomes very hot.

Be careful not to burn yourself during mea-

surement.

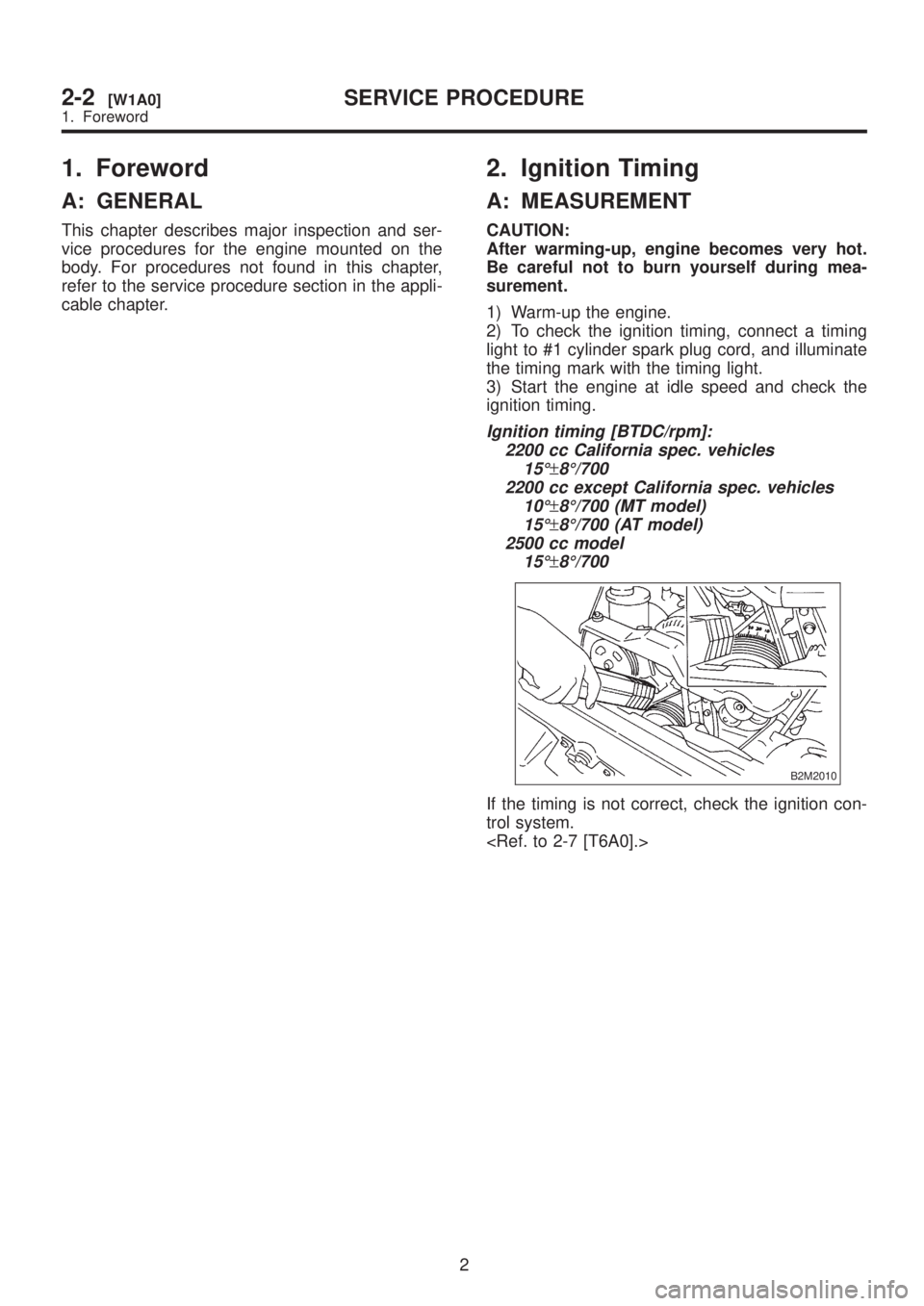

1) Warm-up the engine.

2) To check the ignition timing, connect a timing

light to #1 cylinder spark plug cord, and illuminate

the timing mark with the timing light.

3) Start the engine at idle speed and check the

ignition timing.

Ignition timing [BTDC/rpm]:

2200 cc California spec. vehicles

15É

±8É/700

2200 cc except California spec. vehicles

10É

±8É/700 (MT model)

15É

±8É/700 (AT model)

2500 cc model

15É

±8É/700

B2M2010

If the timing is not correct, check the ignition con-

trol system.

2

2-2[W1A0]SERVICE PROCEDURE

1. Foreword

Page 38 of 1456

2. 2500 cc MODEL

CAUTION:

After warming-up, engine becomes very hot.

Be careful not to burn yourself during mea-

surement.

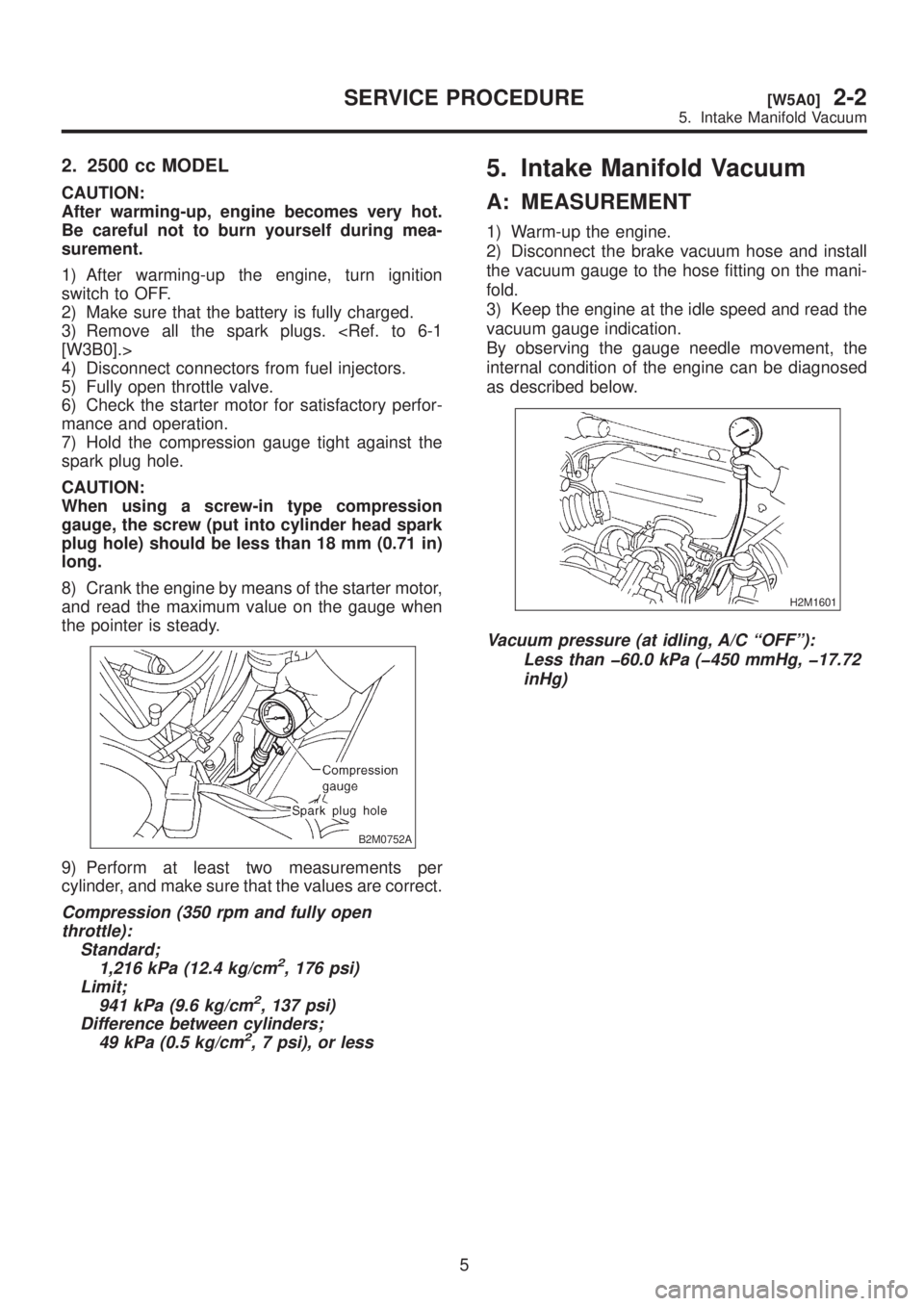

1) After warming-up the engine, turn ignition

switch to OFF.

2) Make sure that the battery is fully charged.

3) Remove all the spark plugs.

4) Disconnect connectors from fuel injectors.

5) Fully open throttle valve.

6) Check the starter motor for satisfactory perfor-

mance and operation.

7) Hold the compression gauge tight against the

spark plug hole.

CAUTION:

When using a screw-in type compression

gauge, the screw (put into cylinder head spark

plug hole) should be less than 18 mm (0.71 in)

long.

8) Crank the engine by means of the starter motor,

and read the maximum value on the gauge when

the pointer is steady.

B2M0752A

9) Perform at least two measurements per

cylinder, and make sure that the values are correct.

Compression (350 rpm and fully open

throttle):

Standard;

1,216 kPa (12.4 kg/cm

2, 176 psi)

Limit;

941 kPa (9.6 kg/cm

2, 137 psi)

Difference between cylinders;

49 kPa (0.5 kg/cm

2, 7 psi), or less

5. Intake Manifold Vacuum

A: MEASUREMENT

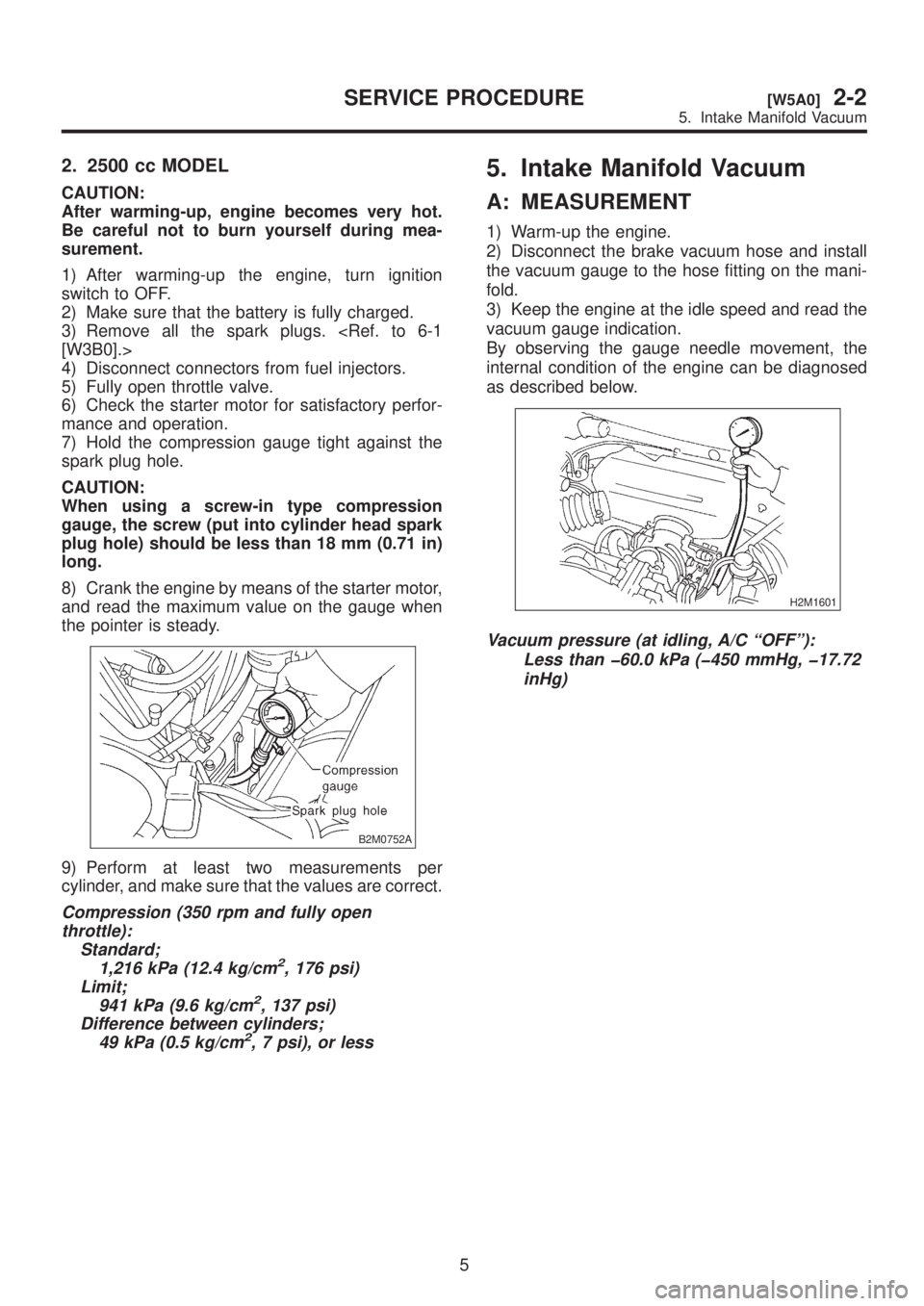

1) Warm-up the engine.

2) Disconnect the brake vacuum hose and install

the vacuum gauge to the hose fitting on the mani-

fold.

3) Keep the engine at the idle speed and read the

vacuum gauge indication.

By observing the gauge needle movement, the

internal condition of the engine can be diagnosed

as described below.

H2M1601

Vacuum pressure (at idling, A/C ªOFFº):

Less than þ60.0 kPa (þ450 mmHg, þ17.72

inHg)

5

[W5A0]2-2SERVICE PROCEDURE

5. Intake Manifold Vacuum

Page 39 of 1456

2. 2500 cc MODEL

CAUTION:

After warming-up, engine becomes very hot.

Be careful not to burn yourself during mea-

surement.

1) After warming-up the engine, turn ignition

switch to OFF.

2) Make sure that the battery is fully charged.

3) Remove all the spark plugs.

4) Disconnect connectors from fuel injectors.

5) Fully open throttle valve.

6) Check the starter motor for satisfactory perfor-

mance and operation.

7) Hold the compression gauge tight against the

spark plug hole.

CAUTION:

When using a screw-in type compression

gauge, the screw (put into cylinder head spark

plug hole) should be less than 18 mm (0.71 in)

long.

8) Crank the engine by means of the starter motor,

and read the maximum value on the gauge when

the pointer is steady.

B2M0752A

9) Perform at least two measurements per

cylinder, and make sure that the values are correct.

Compression (350 rpm and fully open

throttle):

Standard;

1,216 kPa (12.4 kg/cm

2, 176 psi)

Limit;

941 kPa (9.6 kg/cm

2, 137 psi)

Difference between cylinders;

49 kPa (0.5 kg/cm

2, 7 psi), or less

5. Intake Manifold Vacuum

A: MEASUREMENT

1) Warm-up the engine.

2) Disconnect the brake vacuum hose and install

the vacuum gauge to the hose fitting on the mani-

fold.

3) Keep the engine at the idle speed and read the

vacuum gauge indication.

By observing the gauge needle movement, the

internal condition of the engine can be diagnosed

as described below.

H2M1601

Vacuum pressure (at idling, A/C ªOFFº):

Less than þ60.0 kPa (þ450 mmHg, þ17.72

inHg)

5

[W5A0]2-2SERVICE PROCEDURE

5. Intake Manifold Vacuum

Page 50 of 1456

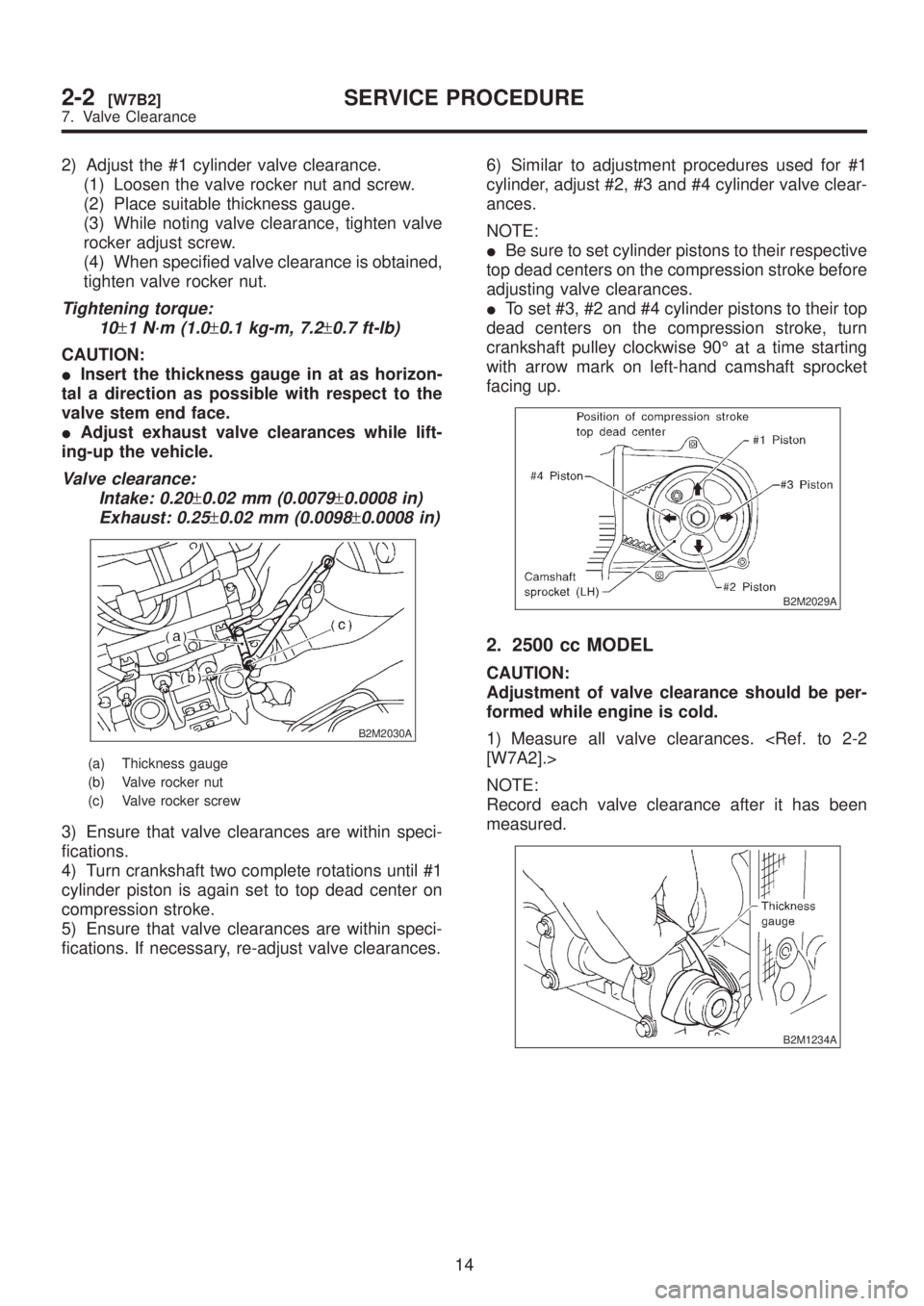

2) Adjust the #1 cylinder valve clearance.

(1) Loosen the valve rocker nut and screw.

(2) Place suitable thickness gauge.

(3) While noting valve clearance, tighten valve

rocker adjust screw.

(4) When specified valve clearance is obtained,

tighten valve rocker nut.

Tightening torque:

10

±1 N´m (1.0±0.1 kg-m, 7.2±0.7 ft-lb)

CAUTION:

IInsert the thickness gauge in at as horizon-

tal a direction as possible with respect to the

valve stem end face.

IAdjust exhaust valve clearances while lift-

ing-up the vehicle.

Valve clearance:

Intake: 0.20

±0.02 mm (0.0079±0.0008 in)

Exhaust: 0.25

±0.02 mm (0.0098±0.0008 in)

B2M2030A

(a) Thickness gauge

(b) Valve rocker nut

(c) Valve rocker screw

3) Ensure that valve clearances are within speci-

fications.

4) Turn crankshaft two complete rotations until #1

cylinder piston is again set to top dead center on

compression stroke.

5) Ensure that valve clearances are within speci-

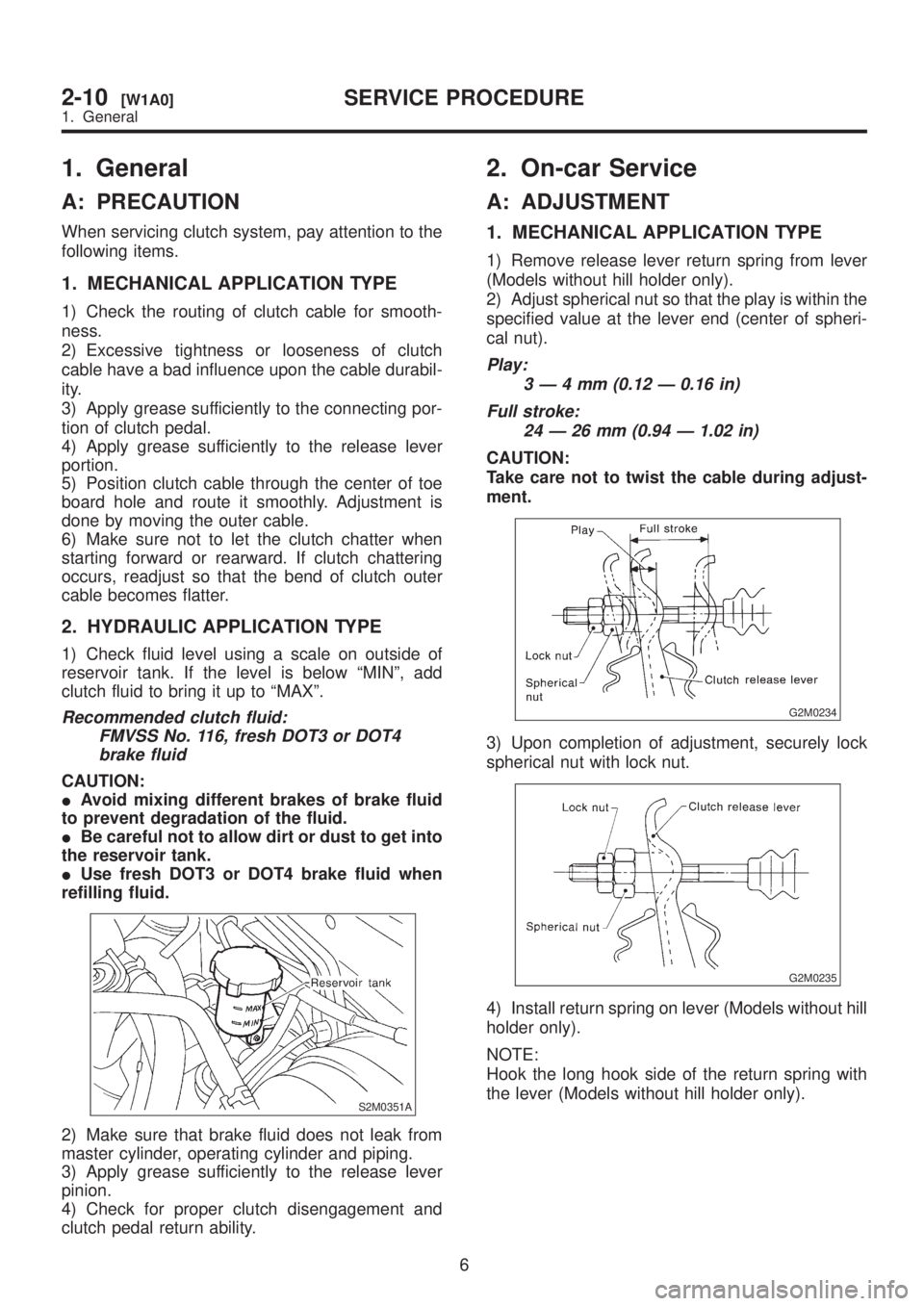

fications. If necessary, re-adjust valve clearances.6) Similar to adjustment procedures used for #1

cylinder, adjust #2, #3 and #4 cylinder valve clear-

ances.

NOTE:

IBe sure to set cylinder pistons to their respective

top dead centers on the compression stroke before

adjusting valve clearances.

ITo set #3, #2 and #4 cylinder pistons to their top

dead centers on the compression stroke, turn

crankshaft pulley clockwise 90É at a time starting

with arrow mark on left-hand camshaft sprocket

facing up.

B2M2029A

2. 2500 cc MODEL

CAUTION:

Adjustment of valve clearance should be per-

formed while engine is cold.

1) Measure all valve clearances.

NOTE:

Record each valve clearance after it has been

measured.

B2M1234A

14

2-2[W7B2]SERVICE PROCEDURE

7. Valve Clearance

Page 415 of 1456

1. General

A: PRECAUTION

When servicing clutch system, pay attention to the

following items.

1. MECHANICAL APPLICATION TYPE

1) Check the routing of clutch cable for smooth-

ness.

2) Excessive tightness or looseness of clutch

cable have a bad influence upon the cable durabil-

ity.

3) Apply grease sufficiently to the connecting por-

tion of clutch pedal.

4) Apply grease sufficiently to the release lever

portion.

5) Position clutch cable through the center of toe

board hole and route it smoothly. Adjustment is

done by moving the outer cable.

6) Make sure not to let the clutch chatter when

starting forward or rearward. If clutch chattering

occurs, readjust so that the bend of clutch outer

cable becomes flatter.

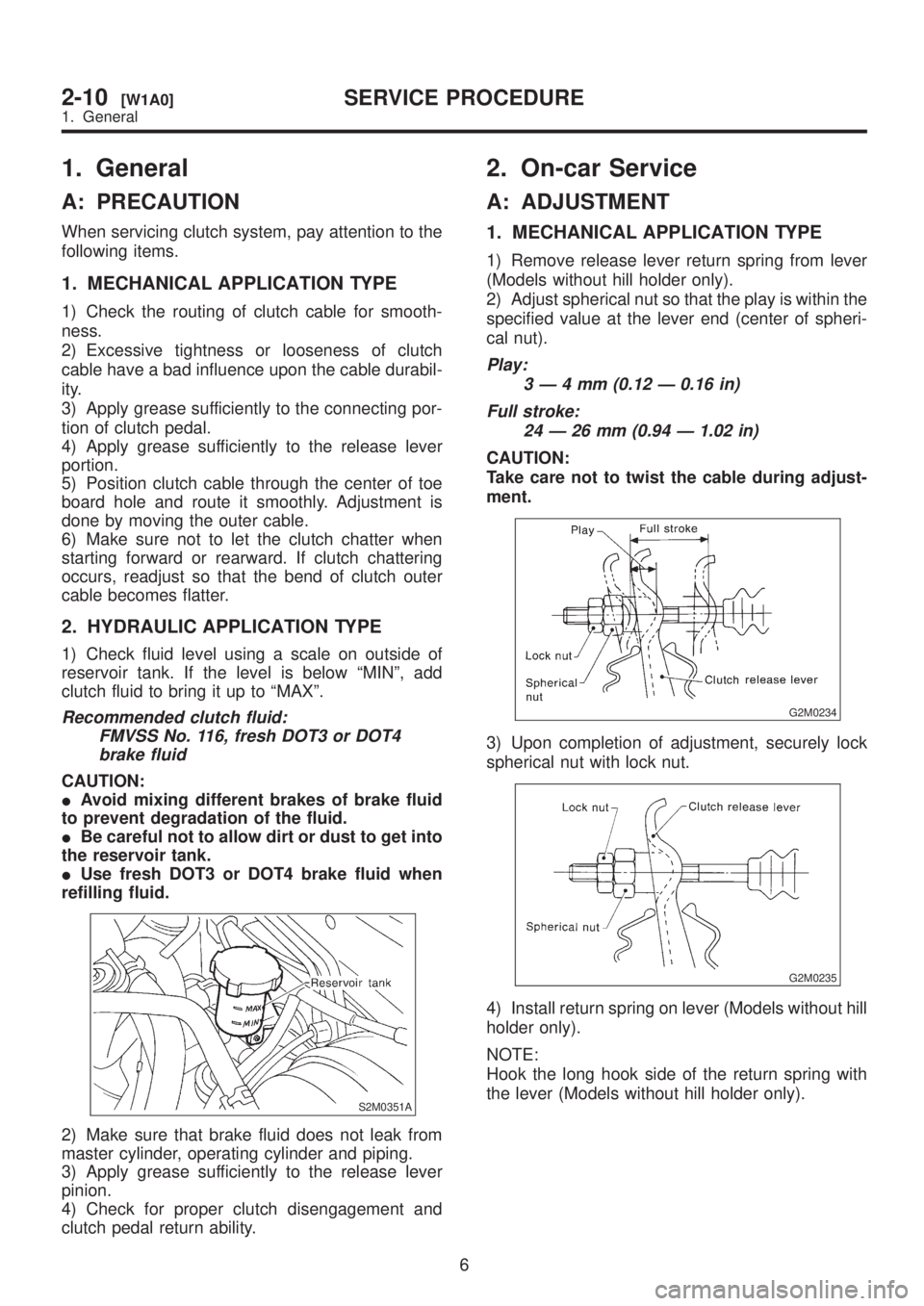

2. HYDRAULIC APPLICATION TYPE

1) Check fluid level using a scale on outside of

reservoir tank. If the level is below ªMINº, add

clutch fluid to bring it up to ªMAXº.

Recommended clutch fluid:

FMVSS No. 116, fresh DOT3 or DOT4

brake fluid

CAUTION:

IAvoid mixing different brakes of brake fluid

to prevent degradation of the fluid.

IBe careful not to allow dirt or dust to get into

the reservoir tank.

IUse fresh DOT3 or DOT4 brake fluid when

refilling fluid.

S2M0351A

2) Make sure that brake fluid does not leak from

master cylinder, operating cylinder and piping.

3) Apply grease sufficiently to the release lever

pinion.

4) Check for proper clutch disengagement and

clutch pedal return ability.

2. On-car Service

A: ADJUSTMENT

1. MECHANICAL APPLICATION TYPE

1) Remove release lever return spring from lever

(Models without hill holder only).

2) Adjust spherical nut so that the play is within the

specified value at the lever end (center of spheri-

cal nut).

Play:

3Ð4mm(0.12 Ð 0.16 in)

Full stroke:

24 Ð 26 mm (0.94 Ð 1.02 in)

CAUTION:

Take care not to twist the cable during adjust-

ment.

G2M0234

3) Upon completion of adjustment, securely lock

spherical nut with lock nut.

G2M0235

4) Install return spring on lever (Models without hill

holder only).

NOTE:

Hook the long hook side of the return spring with

the lever (Models without hill holder only).

6

2-10[W1A0]SERVICE PROCEDURE

1. General

Page 416 of 1456

1. General

A: PRECAUTION

When servicing clutch system, pay attention to the

following items.

1. MECHANICAL APPLICATION TYPE

1) Check the routing of clutch cable for smooth-

ness.

2) Excessive tightness or looseness of clutch

cable have a bad influence upon the cable durabil-

ity.

3) Apply grease sufficiently to the connecting por-

tion of clutch pedal.

4) Apply grease sufficiently to the release lever

portion.

5) Position clutch cable through the center of toe

board hole and route it smoothly. Adjustment is

done by moving the outer cable.

6) Make sure not to let the clutch chatter when

starting forward or rearward. If clutch chattering

occurs, readjust so that the bend of clutch outer

cable becomes flatter.

2. HYDRAULIC APPLICATION TYPE

1) Check fluid level using a scale on outside of

reservoir tank. If the level is below ªMINº, add

clutch fluid to bring it up to ªMAXº.

Recommended clutch fluid:

FMVSS No. 116, fresh DOT3 or DOT4

brake fluid

CAUTION:

IAvoid mixing different brakes of brake fluid

to prevent degradation of the fluid.

IBe careful not to allow dirt or dust to get into

the reservoir tank.

IUse fresh DOT3 or DOT4 brake fluid when

refilling fluid.

S2M0351A

2) Make sure that brake fluid does not leak from

master cylinder, operating cylinder and piping.

3) Apply grease sufficiently to the release lever

pinion.

4) Check for proper clutch disengagement and

clutch pedal return ability.

2. On-car Service

A: ADJUSTMENT

1. MECHANICAL APPLICATION TYPE

1) Remove release lever return spring from lever

(Models without hill holder only).

2) Adjust spherical nut so that the play is within the

specified value at the lever end (center of spheri-

cal nut).

Play:

3Ð4mm(0.12 Ð 0.16 in)

Full stroke:

24 Ð 26 mm (0.94 Ð 1.02 in)

CAUTION:

Take care not to twist the cable during adjust-

ment.

G2M0234

3) Upon completion of adjustment, securely lock

spherical nut with lock nut.

G2M0235

4) Install return spring on lever (Models without hill

holder only).

NOTE:

Hook the long hook side of the return spring with

the lever (Models without hill holder only).

6

2-10[W1A0]SERVICE PROCEDURE

1. General

Page 465 of 1456

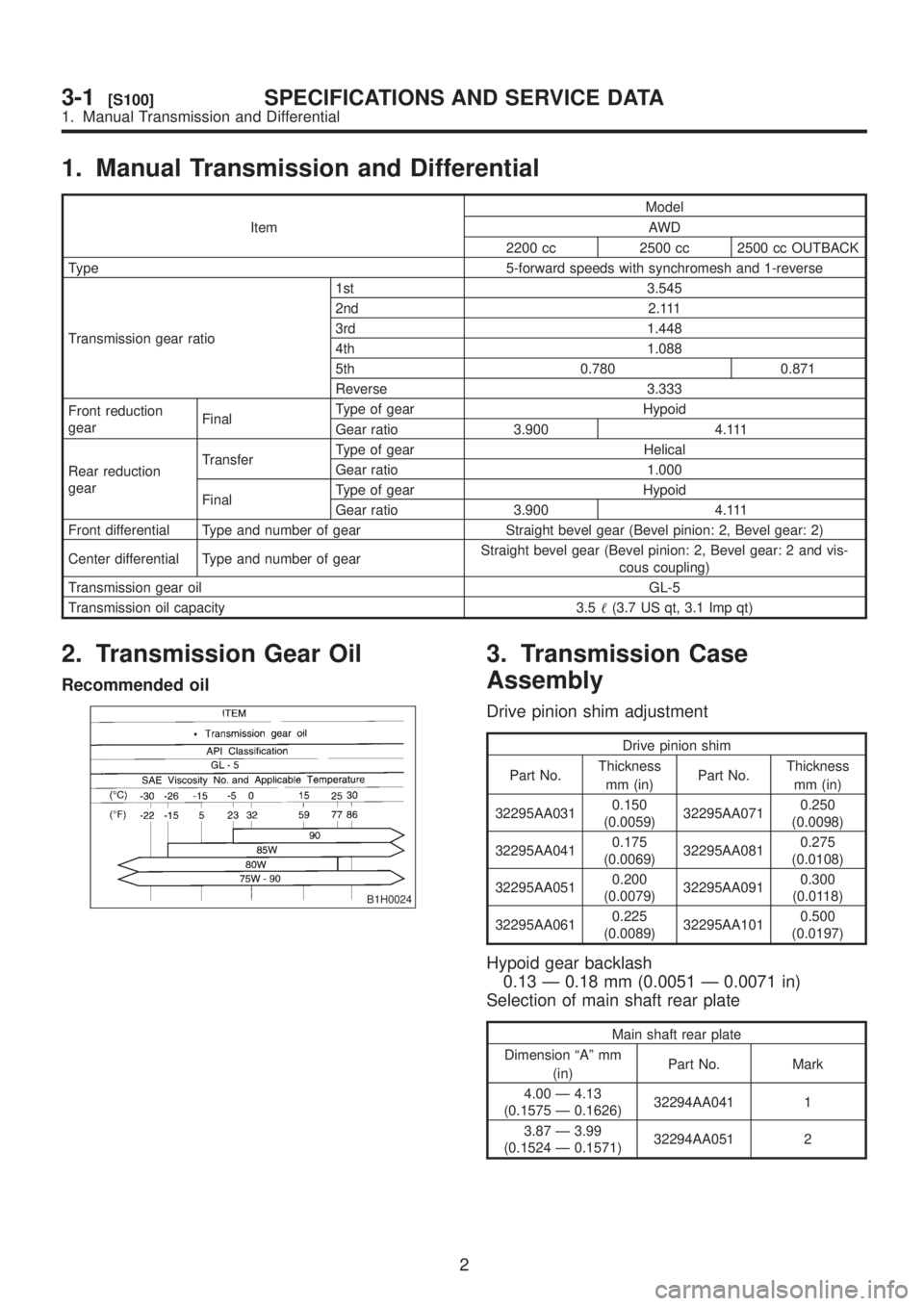

1. Manual Transmission and Differential

ItemModel

AWD

2200 cc 2500 cc 2500 cc OUTBACK

Type 5-forward speeds with synchromesh and 1-reverse

Transmission gear ratio1st 3.545

2nd 2.111

3rd 1.448

4th 1.088

5th 0.780 0.871

Reverse 3.333

Front reduction

gearFinalType of gear Hypoid

Gear ratio 3.900 4.111

Rear reduction

gearTransferType of gear Helical

Gear ratio 1.000

FinalType of gear Hypoid

Gear ratio 3.900 4.111

Front differential Type and number of gear Straight bevel gear (Bevel pinion: 2, Bevel gear: 2)

Center differential Type and number of gearStraight bevel gear (Bevel pinion: 2, Bevel gear: 2 and vis-

cous coupling)

Transmission gear oilGL-5

Transmission oil capacity 3.5(3.7 US qt, 3.1 Imp qt)

2. Transmission Gear Oil

Recommended oil

B1H0024

3. Transmission Case

Assembly

Drive pinion shim adjustment

Drive pinion shim

Part No.Thickness

mm (in)Part No.Thickness

mm (in)

32295AA0310.150

(0.0059)32295AA0710.250

(0.0098)

32295AA0410.175

(0.0069)32295AA0810.275

(0.0108)

32295AA0510.200

(0.0079)32295AA0910.300

(0.0118)

32295AA0610.225

(0.0089)32295AA1010.500

(0.0197)

Hypoid gear backlash

0.13 Ð 0.18 mm (0.0051 Ð 0.0071 in)

Selection of main shaft rear plate

Main shaft rear plate

Dimension ªAº mm

(in)Part No. Mark

4.00 Ð 4.13

(0.1575 Ð 0.1626)32294AA041 1

3.87 Ð 3.99

(0.1524 Ð 0.1571)32294AA051 2

2

3-1[S100]SPECIFICATIONS AND SERVICE DATA

1. Manual Transmission and Differential

Page 466 of 1456

1. Manual Transmission and Differential

ItemModel

AWD

2200 cc 2500 cc 2500 cc OUTBACK

Type 5-forward speeds with synchromesh and 1-reverse

Transmission gear ratio1st 3.545

2nd 2.111

3rd 1.448

4th 1.088

5th 0.780 0.871

Reverse 3.333

Front reduction

gearFinalType of gear Hypoid

Gear ratio 3.900 4.111

Rear reduction

gearTransferType of gear Helical

Gear ratio 1.000

FinalType of gear Hypoid

Gear ratio 3.900 4.111

Front differential Type and number of gear Straight bevel gear (Bevel pinion: 2, Bevel gear: 2)

Center differential Type and number of gearStraight bevel gear (Bevel pinion: 2, Bevel gear: 2 and vis-

cous coupling)

Transmission gear oilGL-5

Transmission oil capacity 3.5(3.7 US qt, 3.1 Imp qt)

2. Transmission Gear Oil

Recommended oil

B1H0024

3. Transmission Case

Assembly

Drive pinion shim adjustment

Drive pinion shim

Part No.Thickness

mm (in)Part No.Thickness

mm (in)

32295AA0310.150

(0.0059)32295AA0710.250

(0.0098)

32295AA0410.175

(0.0069)32295AA0810.275

(0.0108)

32295AA0510.200

(0.0079)32295AA0910.300

(0.0118)

32295AA0610.225

(0.0089)32295AA1010.500

(0.0197)

Hypoid gear backlash

0.13 Ð 0.18 mm (0.0051 Ð 0.0071 in)

Selection of main shaft rear plate

Main shaft rear plate

Dimension ªAº mm

(in)Part No. Mark

4.00 Ð 4.13

(0.1575 Ð 0.1626)32294AA041 1

3.87 Ð 3.99

(0.1524 Ð 0.1571)32294AA051 2

2

3-1[S100]SPECIFICATIONS AND SERVICE DATA

1. Manual Transmission and Differential

Page 467 of 1456

1. Manual Transmission and Differential

ItemModel

AWD

2200 cc 2500 cc 2500 cc OUTBACK

Type 5-forward speeds with synchromesh and 1-reverse

Transmission gear ratio1st 3.545

2nd 2.111

3rd 1.448

4th 1.088

5th 0.780 0.871

Reverse 3.333

Front reduction

gearFinalType of gear Hypoid

Gear ratio 3.900 4.111

Rear reduction

gearTransferType of gear Helical

Gear ratio 1.000

FinalType of gear Hypoid

Gear ratio 3.900 4.111

Front differential Type and number of gear Straight bevel gear (Bevel pinion: 2, Bevel gear: 2)

Center differential Type and number of gearStraight bevel gear (Bevel pinion: 2, Bevel gear: 2 and vis-

cous coupling)

Transmission gear oilGL-5

Transmission oil capacity 3.5(3.7 US qt, 3.1 Imp qt)

2. Transmission Gear Oil

Recommended oil

B1H0024

3. Transmission Case

Assembly

Drive pinion shim adjustment

Drive pinion shim

Part No.Thickness

mm (in)Part No.Thickness

mm (in)

32295AA0310.150

(0.0059)32295AA0710.250

(0.0098)

32295AA0410.175

(0.0069)32295AA0810.275

(0.0108)

32295AA0510.200

(0.0079)32295AA0910.300

(0.0118)

32295AA0610.225

(0.0089)32295AA1010.500

(0.0197)

Hypoid gear backlash

0.13 Ð 0.18 mm (0.0051 Ð 0.0071 in)

Selection of main shaft rear plate

Main shaft rear plate

Dimension ªAº mm

(in)Part No. Mark

4.00 Ð 4.13

(0.1575 Ð 0.1626)32294AA041 1

3.87 Ð 3.99

(0.1524 Ð 0.1571)32294AA051 2

2

3-1[S100]SPECIFICATIONS AND SERVICE DATA

1. Manual Transmission and Differential