SUBARU LEGACY 1999 Service Repair Manual

LEGACY 1999

SUBARU

SUBARU

https://www.carmanualsonline.info/img/17/57435/w960_57435-0.png

SUBARU LEGACY 1999 Service Repair Manual

Page 1 of 1456

1. Front Catalytic Converter

A: REMOVAL

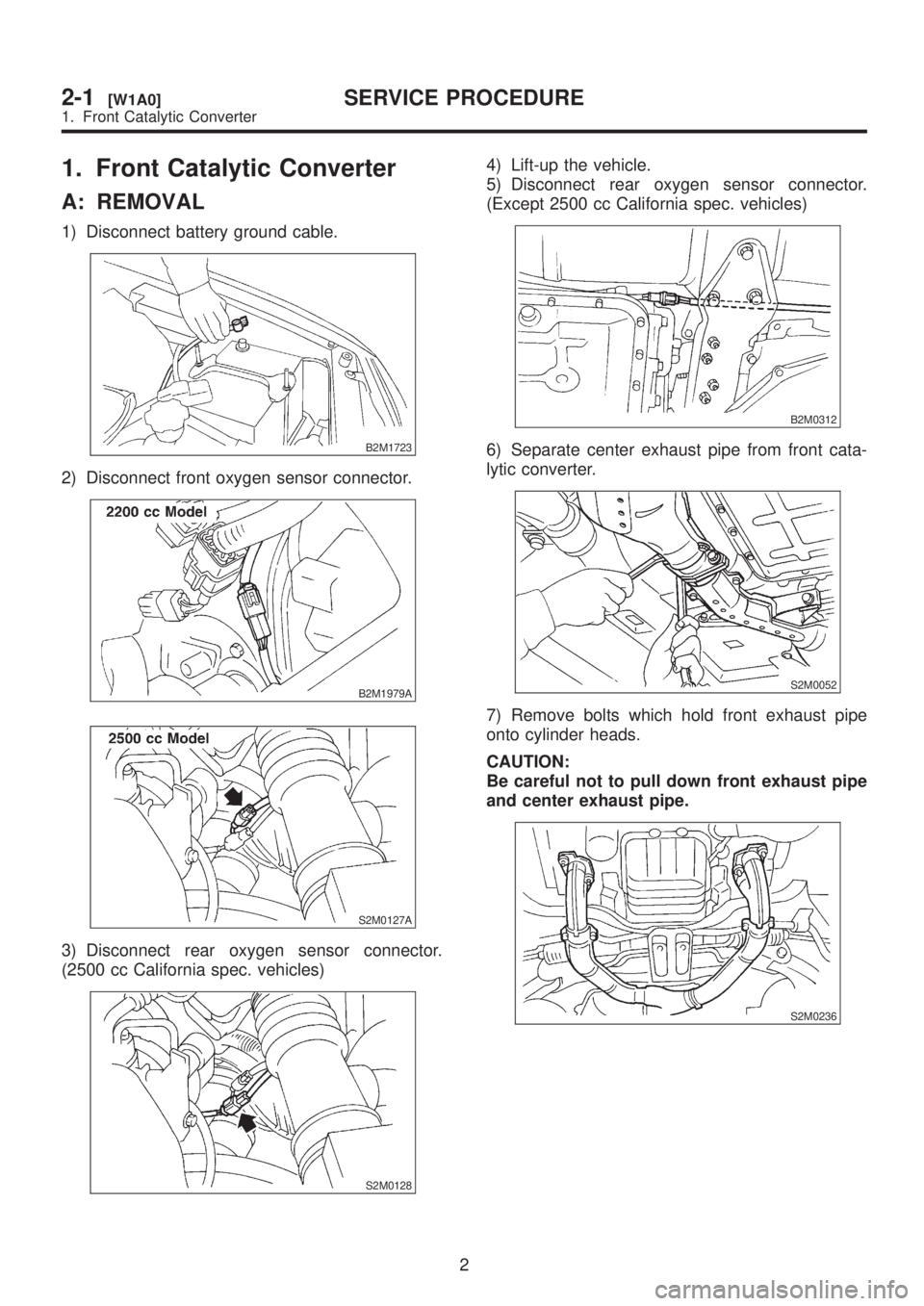

1) Disconnect battery ground cable.

B2M1723

2) Disconnect front oxygen sensor connector.

B2M1979A

S2M0127A

3) Disconnect rear oxygen sensor connector.

(2500 cc California spec. vehicles)

S2M0128

4) Lift-up the vehicle.

5) Disconnect rear oxygen sensor connector.

(Except 2500 cc California spec. vehicles)

B2M0312

6) Separate center exhaust pipe from front cata-

lytic converter.

S2M0052

7) Remove bolts which hold front exhaust pipe

onto cylinder heads.

CAUTION:

Be careful not to pull down front exhaust pipe

and center exhaust pipe.

S2M0236

2

2-1[W1A0]SERVICE PROCEDURE

1. Front Catalytic Converter

Page 3 of 1456

7) Connect front oxygen sensor connector.

B2M1979A

S2M0127A

8) Connect battery ground cable.

B2M1723

2. Rear Catalytic Converter

A: REMOVAL

1) Disconnect battery ground cable.

B2M1723

2) Lift-up the vehicle.

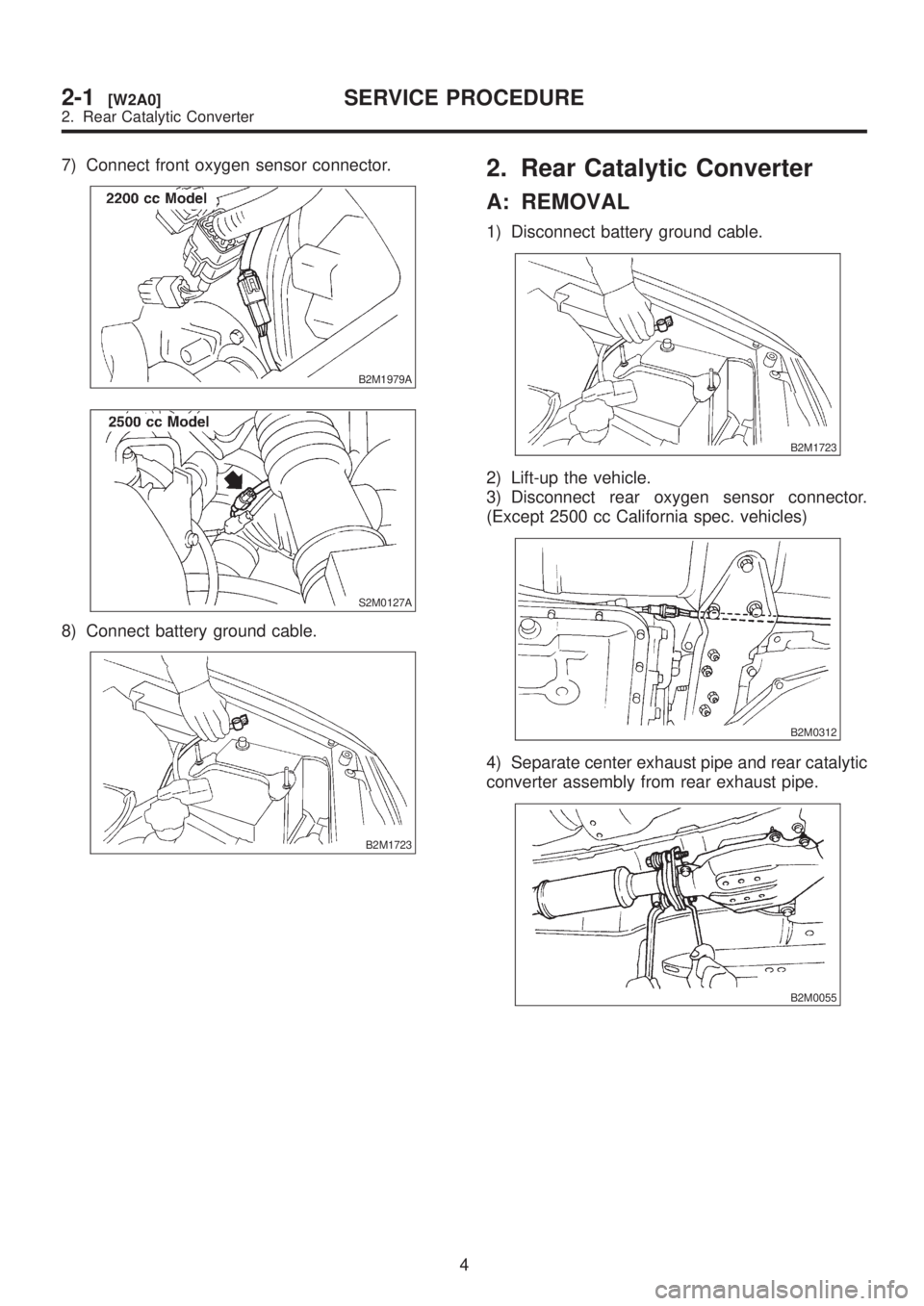

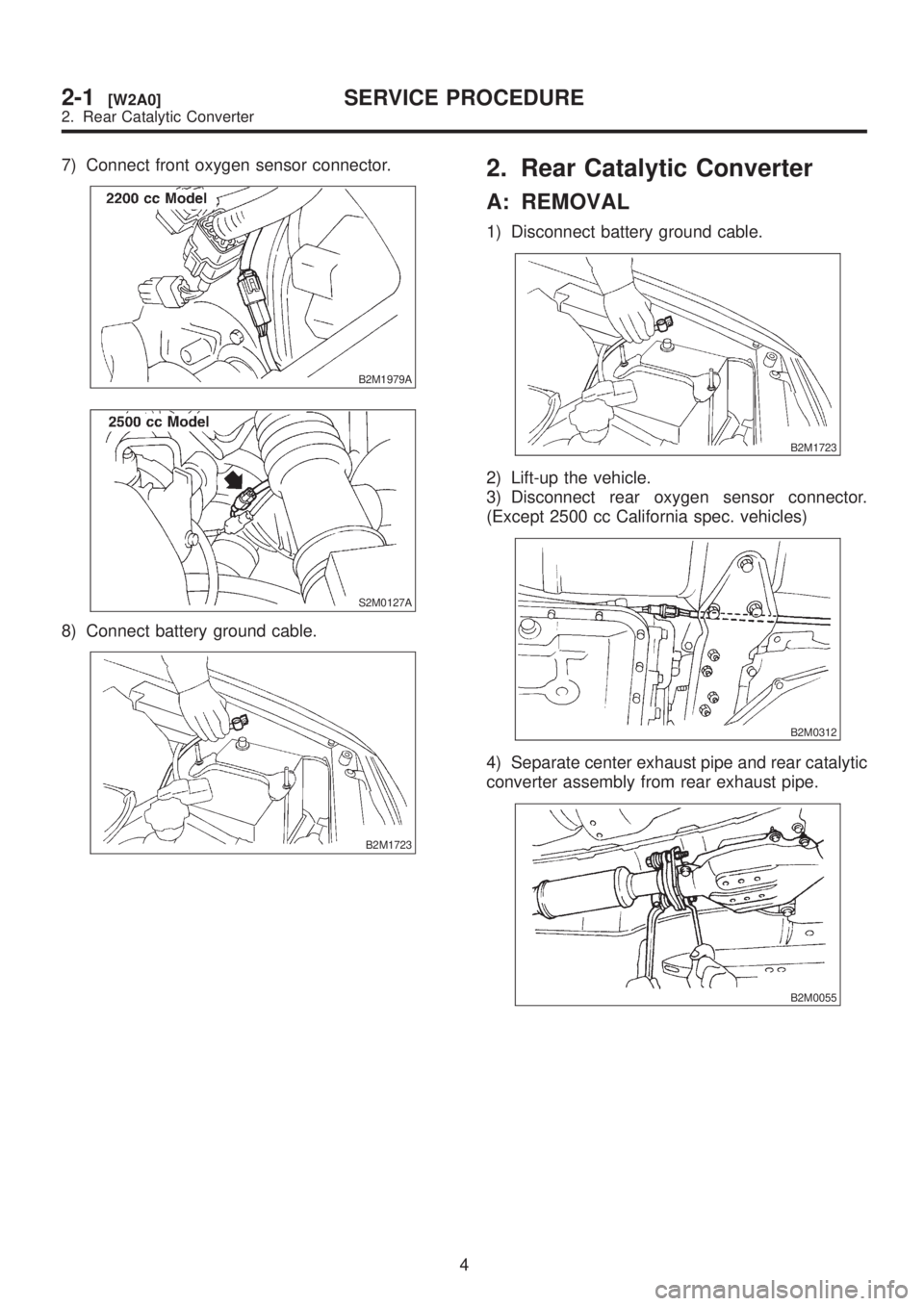

3) Disconnect rear oxygen sensor connector.

(Except 2500 cc California spec. vehicles)

B2M0312

4) Separate center exhaust pipe and rear catalytic

converter assembly from rear exhaust pipe.

B2M0055

4

2-1[W2A0]SERVICE PROCEDURE

2. Rear Catalytic Converter

Page 4 of 1456

7) Connect front oxygen sensor connector.

B2M1979A

S2M0127A

8) Connect battery ground cable.

B2M1723

2. Rear Catalytic Converter

A: REMOVAL

1) Disconnect battery ground cable.

B2M1723

2) Lift-up the vehicle.

3) Disconnect rear oxygen sensor connector.

(Except 2500 cc California spec. vehicles)

B2M0312

4) Separate center exhaust pipe and rear catalytic

converter assembly from rear exhaust pipe.

B2M0055

4

2-1[W2A0]SERVICE PROCEDURE

2. Rear Catalytic Converter

Page 6 of 1456

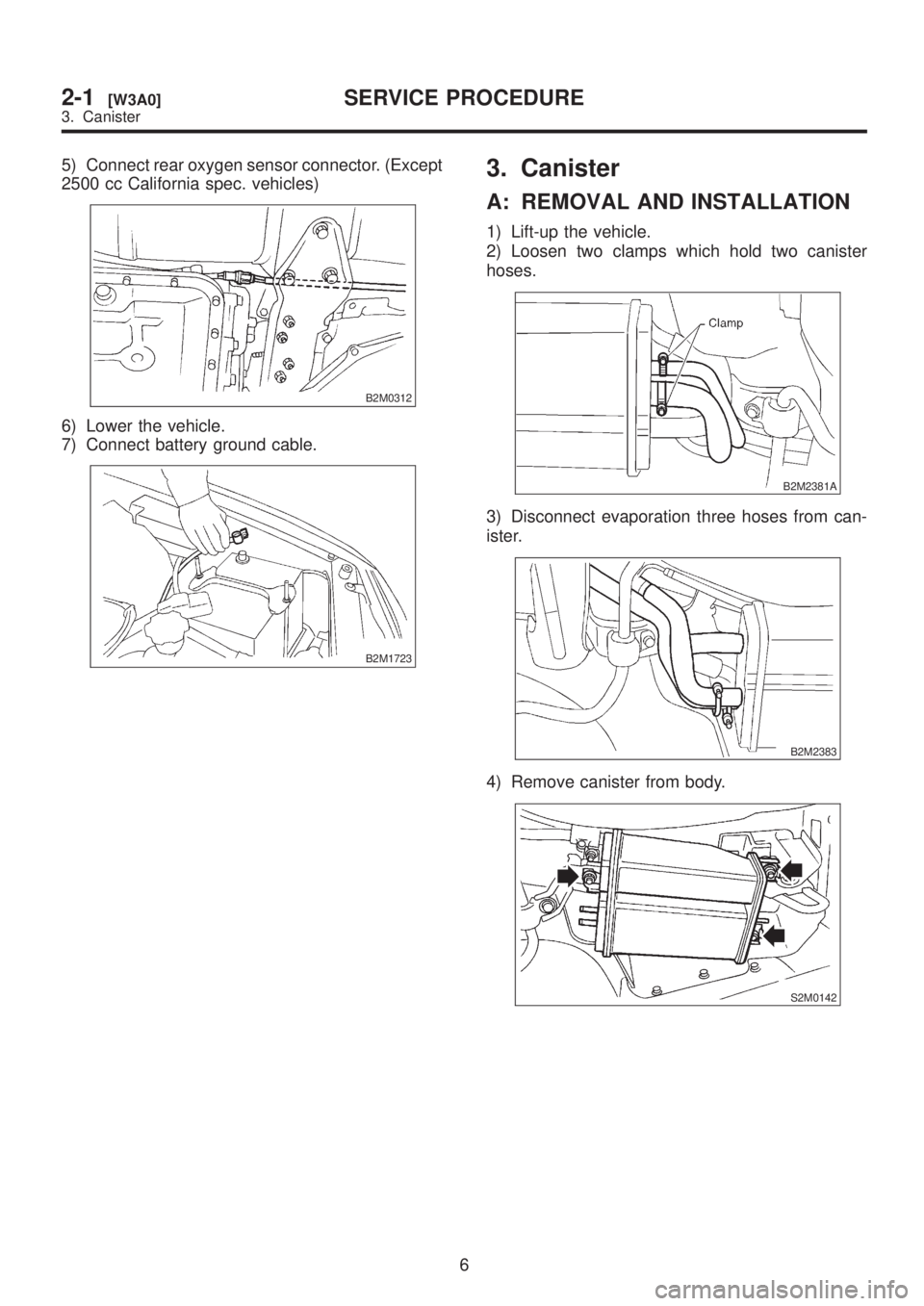

5) Connect rear oxygen sensor connector. (Except

2500 cc California spec. vehicles)

B2M0312

6) Lower the vehicle.

7) Connect battery ground cable.

B2M1723

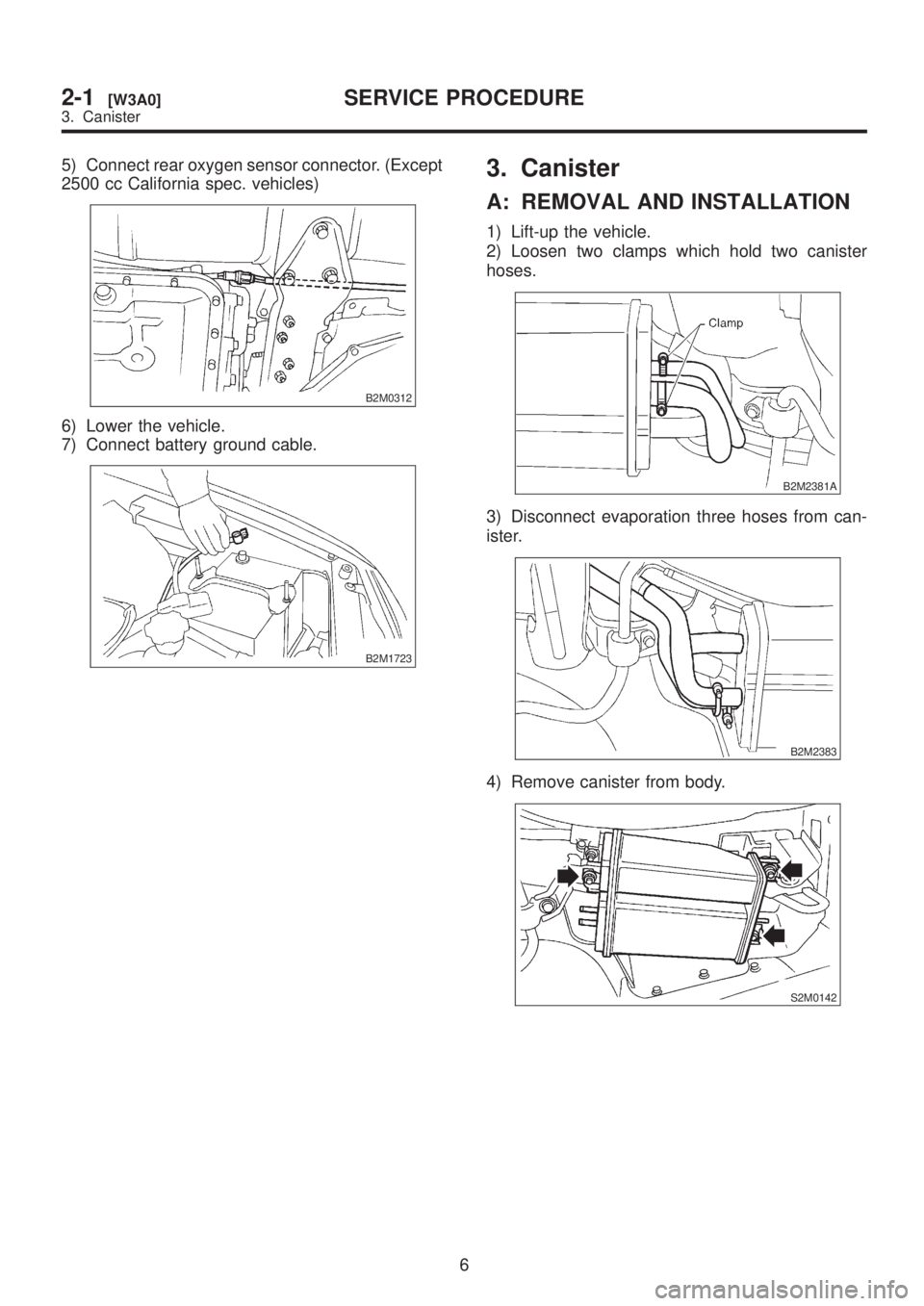

3. Canister

A: REMOVAL AND INSTALLATION

1) Lift-up the vehicle.

2) Loosen two clamps which hold two canister

hoses.

B2M2381A

3) Disconnect evaporation three hoses from can-

ister.

B2M2383

4) Remove canister from body.

S2M0142

6

2-1[W3A0]SERVICE PROCEDURE

3. Canister

Page 7 of 1456

5) Connect rear oxygen sensor connector. (Except

2500 cc California spec. vehicles)

B2M0312

6) Lower the vehicle.

7) Connect battery ground cable.

B2M1723

3. Canister

A: REMOVAL AND INSTALLATION

1) Lift-up the vehicle.

2) Loosen two clamps which hold two canister

hoses.

B2M2381A

3) Disconnect evaporation three hoses from can-

ister.

B2M2383

4) Remove canister from body.

S2M0142

6

2-1[W3A0]SERVICE PROCEDURE

3. Canister

Page 8 of 1456

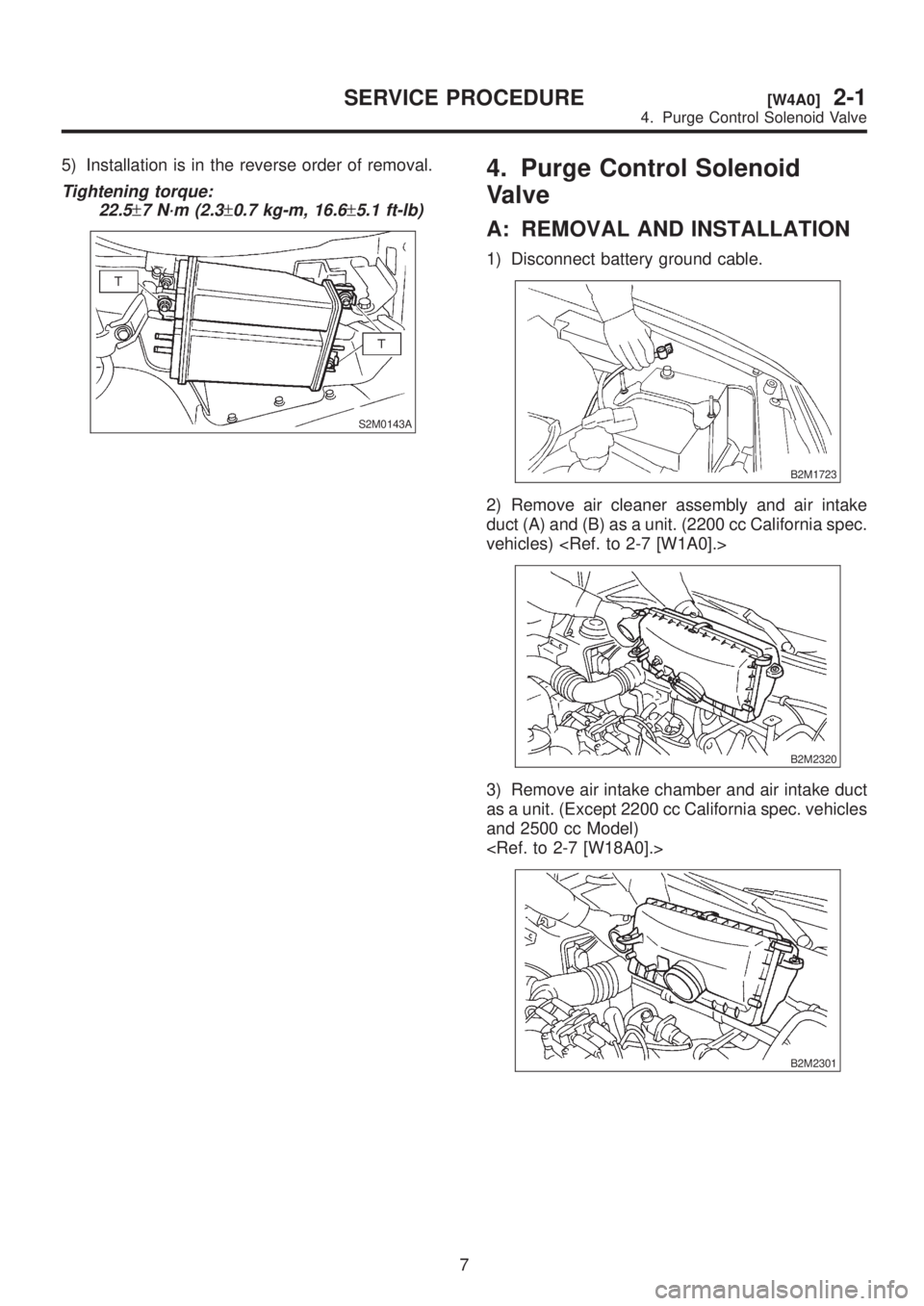

5) Installation is in the reverse order of removal.

Tightening torque:

22.5

±7 N´m (2.3±0.7 kg-m, 16.6±5.1 ft-lb)

S2M0143A

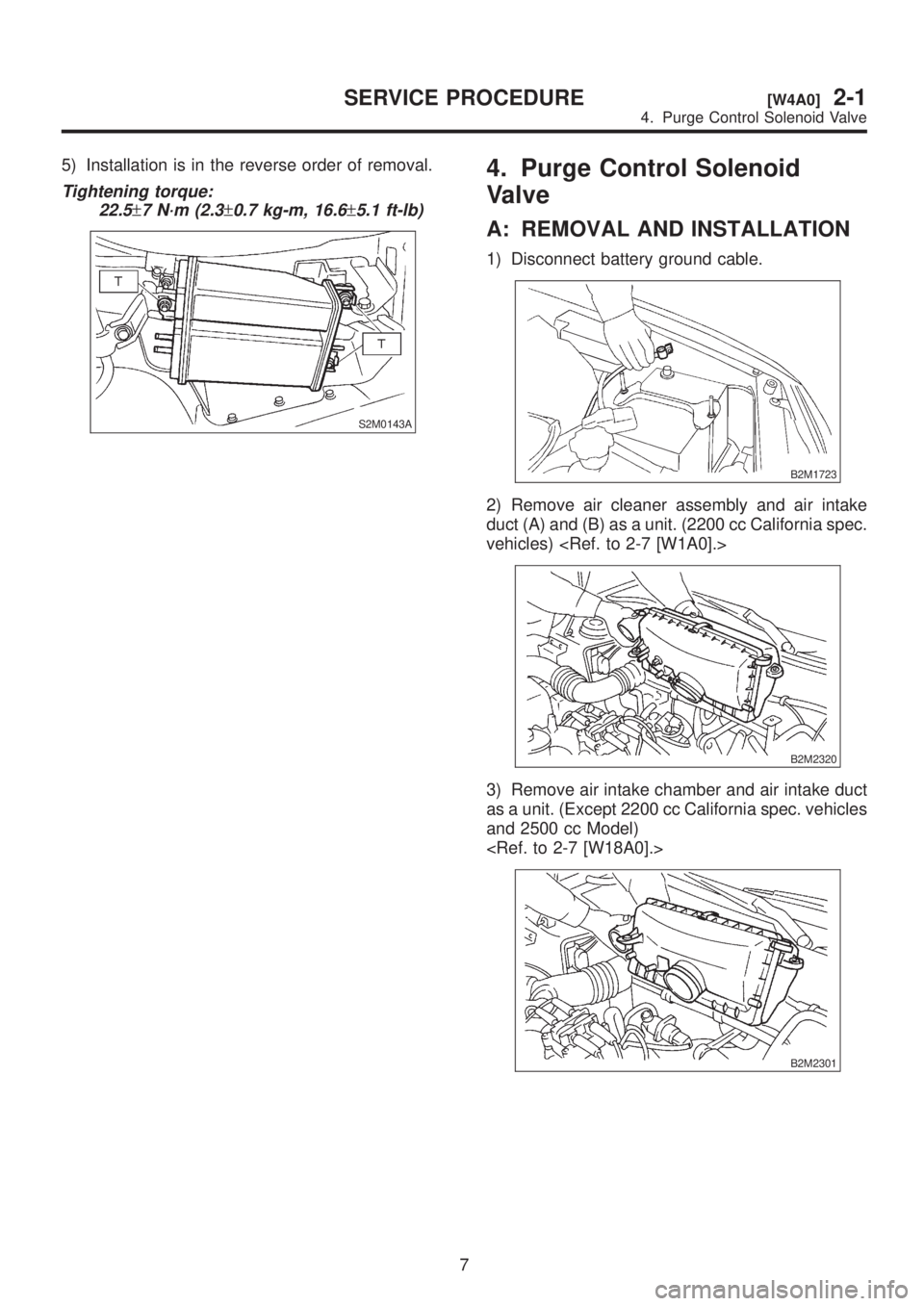

4. Purge Control Solenoid

Valve

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

B2M1723

2) Remove air cleaner assembly and air intake

duct (A) and (B) as a unit. (2200 cc California spec.

vehicles)

B2M2320

3) Remove air intake chamber and air intake duct

as a unit. (Except 2200 cc California spec. vehicles

and 2500 cc Model)

B2M2301

7

[W4A0]2-1SERVICE PROCEDURE

4. Purge Control Solenoid Valve

Page 9 of 1456

5) Installation is in the reverse order of removal.

Tightening torque:

22.5

±7 N´m (2.3±0.7 kg-m, 16.6±5.1 ft-lb)

S2M0143A

4. Purge Control Solenoid

Valve

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

B2M1723

2) Remove air cleaner assembly and air intake

duct (A) and (B) as a unit. (2200 cc California spec.

vehicles)

B2M2320

3) Remove air intake chamber and air intake duct

as a unit. (Except 2200 cc California spec. vehicles

and 2500 cc Model)

B2M2301

7

[W4A0]2-1SERVICE PROCEDURE

4. Purge Control Solenoid Valve

Page 13 of 1456

7. EGR Solenoid Valve (2500 cc

Model)

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

B2M1723

2) Remove air intake chamber.

[W18A0].>

B2M1679

3) Disconnect vacuum hoses from EGR solenoid

valve.

4) Disconnect connector from EGR solenoid

valve.

S2M0058A

5) Remove bolt which installs EGR solenoid valve

onto intake manifold.

S2M0059

6) Installation is in the reverse order of removal.

Tightening torque:

15.7

±1.5 N´m (1.6±0.15 kg-m, 11.6±1.1

ft-lb)

10

2-1[W7A0]SERVICE PROCEDURE

7. EGR Solenoid Valve (2500 cc Model)

Page 14 of 1456

8. Fuel Temperature Sensor

A: REMOVAL

1) Release fuel pressure.

2) Remove fuel filler cap.

B2M1746

3) Disconnect battery ground cable.

B2M1723

4) Disconnect fuel delivery hose (A), return hose

(B) and jet pump hose (C).

B2M0954E

5) Remove nuts which install fuel pump assembly

onto fuel tank.

B2M0955

6) Take off fuel pump assembly from fuel tank.

B2M0956

7) Disconnect connector from fuel pump bracket.

S2M0145

8) Remove main fuel level sensor from fuel pump

assembly.

NOTE:

Fuel temperature sensor is a unit with fuel pump.

If replacing it, replace as a fuel pump.

S2M0855

11

[W8A0]2-1SERVICE PROCEDURE

8. Fuel Temperature Sensor

Page 15 of 1456

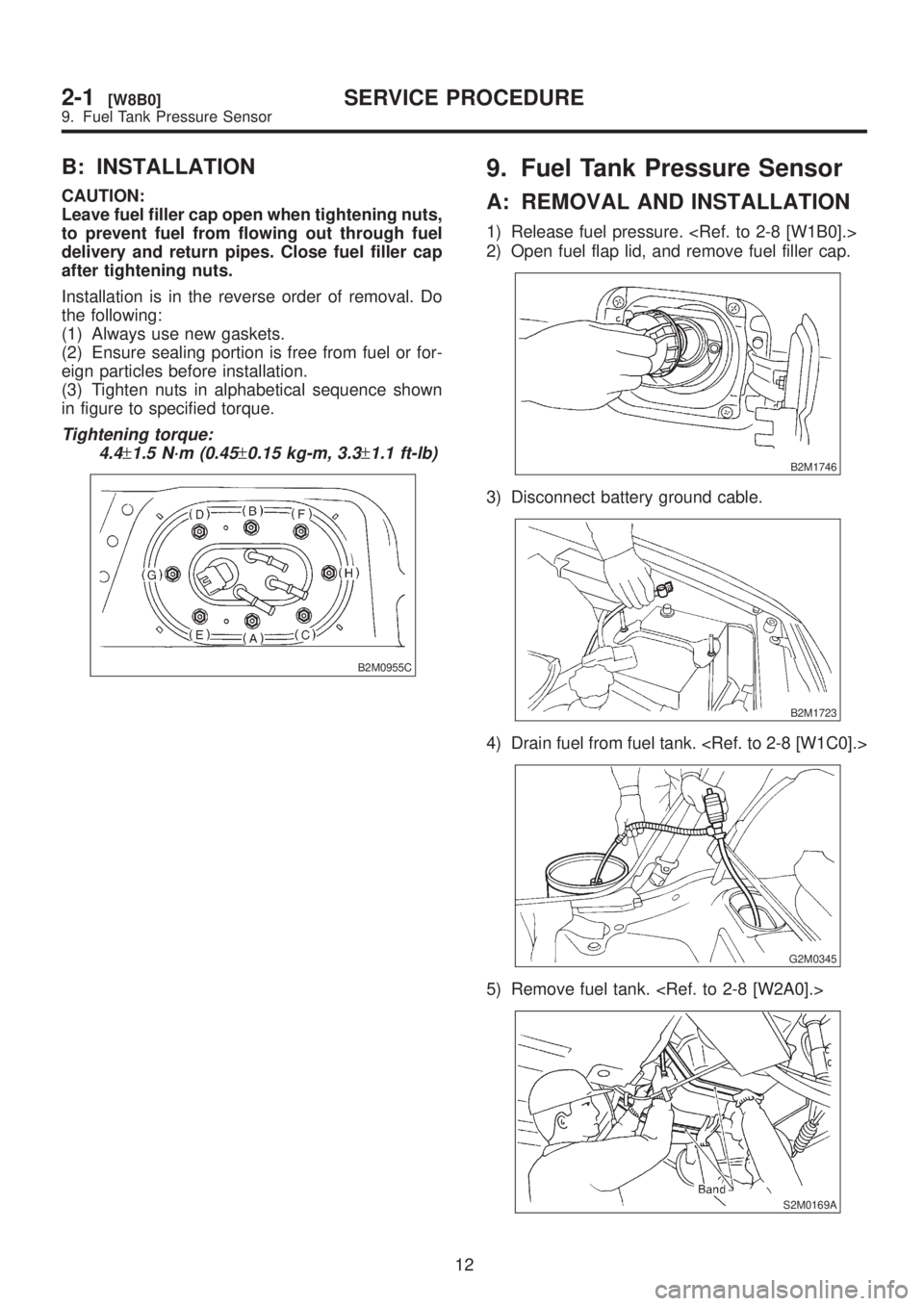

B: INSTALLATION

CAUTION:

Leave fuel filler cap open when tightening nuts,

to prevent fuel from flowing out through fuel

delivery and return pipes. Close fuel filler cap

after tightening nuts.

Installation is in the reverse order of removal. Do

the following:

(1) Always use new gaskets.

(2) Ensure sealing portion is free from fuel or for-

eign particles before installation.

(3) Tighten nuts in alphabetical sequence shown

in figure to specified torque.

Tightening torque:

4.4

±1.5 N´m (0.45±0.15 kg-m, 3.3±1.1 ft-lb)

B2M0955C

9. Fuel Tank Pressure Sensor

A: REMOVAL AND INSTALLATION

1) Release fuel pressure.

2) Open fuel flap lid, and remove fuel filler cap.

B2M1746

3) Disconnect battery ground cable.

B2M1723

4) Drain fuel from fuel tank.

G2M0345

5) Remove fuel tank.

S2M0169A

12

2-1[W8B0]SERVICE PROCEDURE

9. Fuel Tank Pressure Sensor

![SUBARU LEGACY 1999 Service Repair Manual 7. EGR Solenoid Valve (2500 cc

Model)

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

B2M1723

2) Remove air intake chamber. <Ref. to 2-7

[W18A0].>

B2M1679

3) Disconnect vacuum hoses fr SUBARU LEGACY 1999 Service Repair Manual 7. EGR Solenoid Valve (2500 cc

Model)

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

B2M1723

2) Remove air intake chamber. <Ref. to 2-7

[W18A0].>

B2M1679

3) Disconnect vacuum hoses fr](/img/17/57435/w960_57435-12.png)

![SUBARU LEGACY 1999 Service Repair Manual 8. Fuel Temperature Sensor

A: REMOVAL

1) Release fuel pressure. <Ref. to 2-8 [W1B0].>

2) Remove fuel filler cap.

B2M1746

3) Disconnect battery ground cable.

B2M1723

4) Disconnect fuel delivery hose (A SUBARU LEGACY 1999 Service Repair Manual 8. Fuel Temperature Sensor

A: REMOVAL

1) Release fuel pressure. <Ref. to 2-8 [W1B0].>

2) Remove fuel filler cap.

B2M1746

3) Disconnect battery ground cable.

B2M1723

4) Disconnect fuel delivery hose (A](/img/17/57435/w960_57435-13.png)