charging SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 127 of 1456

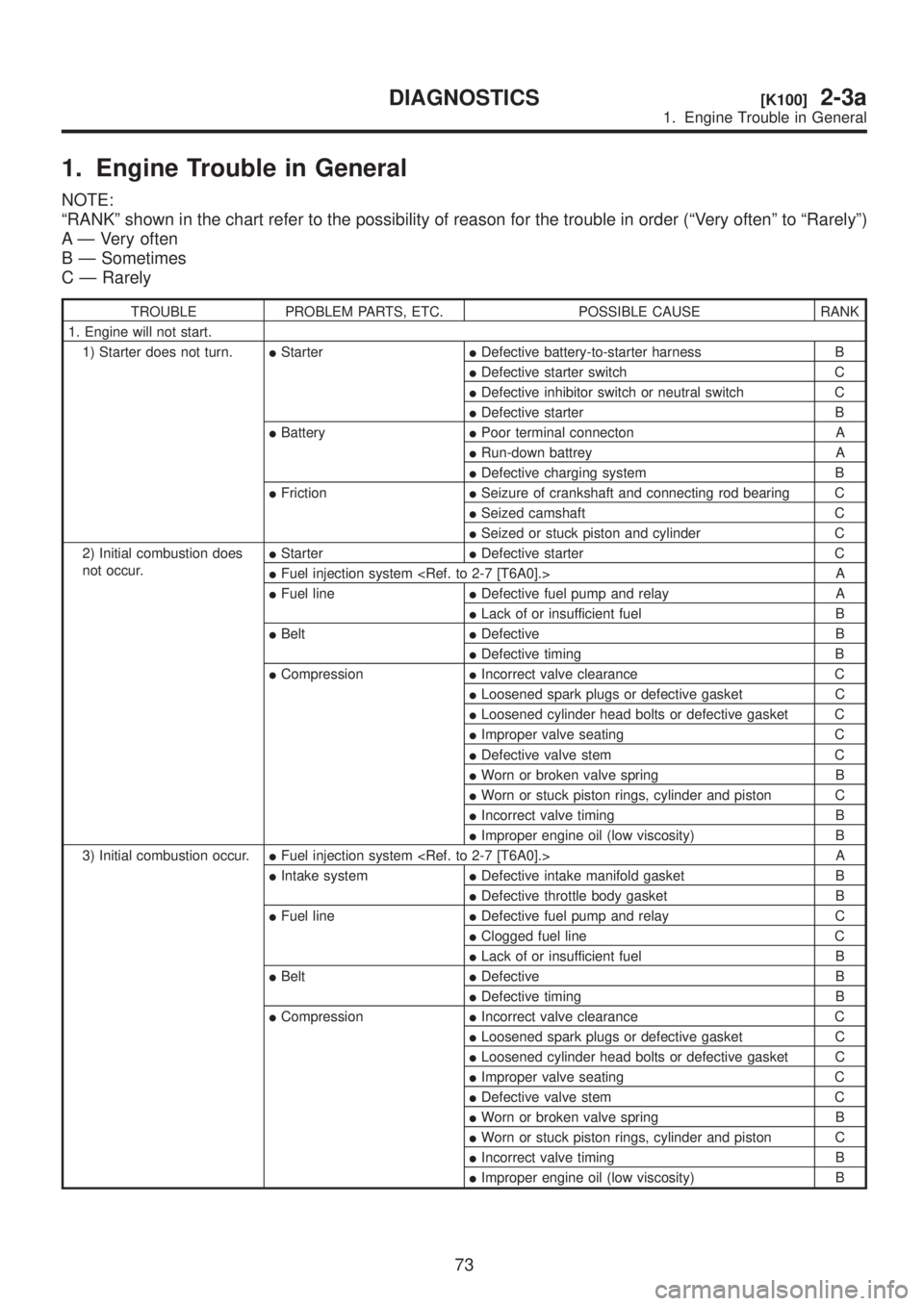

1. Engine Trouble in General

NOTE:

ªRANKº shown in the chart refer to the possibility of reason for the trouble in order (ªVery oftenº to ªRarelyº)

A Ð Very often

B Ð Sometimes

C Ð Rarely

TROUBLE PROBLEM PARTS, ETC. POSSIBLE CAUSE RANK

1. Engine will not start.

1) Starter does not turn.IStarterIDefective battery-to-starter harness B

IDefective starter switch C

IDefective inhibitor switch or neutral switch C

IDefective starter B

IBatteryIPoor terminal connecton A

IRun-down battrey A

IDefective charging system B

IFrictionISeizure of crankshaft and connecting rod bearing C

ISeized camshaft C

ISeized or stuck piston and cylinder C

2) Initial combustion does

not occur.IStarterIDefective starter C

IFuel injection system

IFuel lineIDefective fuel pump and relay A

ILack of or insufficient fuel B

IBeltIDefective B

IDefective timing B

ICompressionIIncorrect valve clearance C

ILoosened spark plugs or defective gasket C

ILoosened cylinder head bolts or defective gasket C

IImproper valve seating C

IDefective valve stem C

IWorn or broken valve spring B

IWorn or stuck piston rings, cylinder and piston C

IIncorrect valve timing B

IImproper engine oil (low viscosity) B

3) Initial combustion occur.IFuel injection system

IIntake systemIDefective intake manifold gasket B

IDefective throttle body gasket B

IFuel lineIDefective fuel pump and relay C

IClogged fuel line C

ILack of or insufficient fuel B

IBeltIDefective B

IDefective timing B

ICompressionIIncorrect valve clearance C

ILoosened spark plugs or defective gasket C

ILoosened cylinder head bolts or defective gasket C

IImproper valve seating C

IDefective valve stem C

IWorn or broken valve spring B

IWorn or stuck piston rings, cylinder and piston C

IIncorrect valve timing B

IImproper engine oil (low viscosity) B

73

[K100]2-3aDIAGNOSTICS

1. Engine Trouble in General

Page 202 of 1456

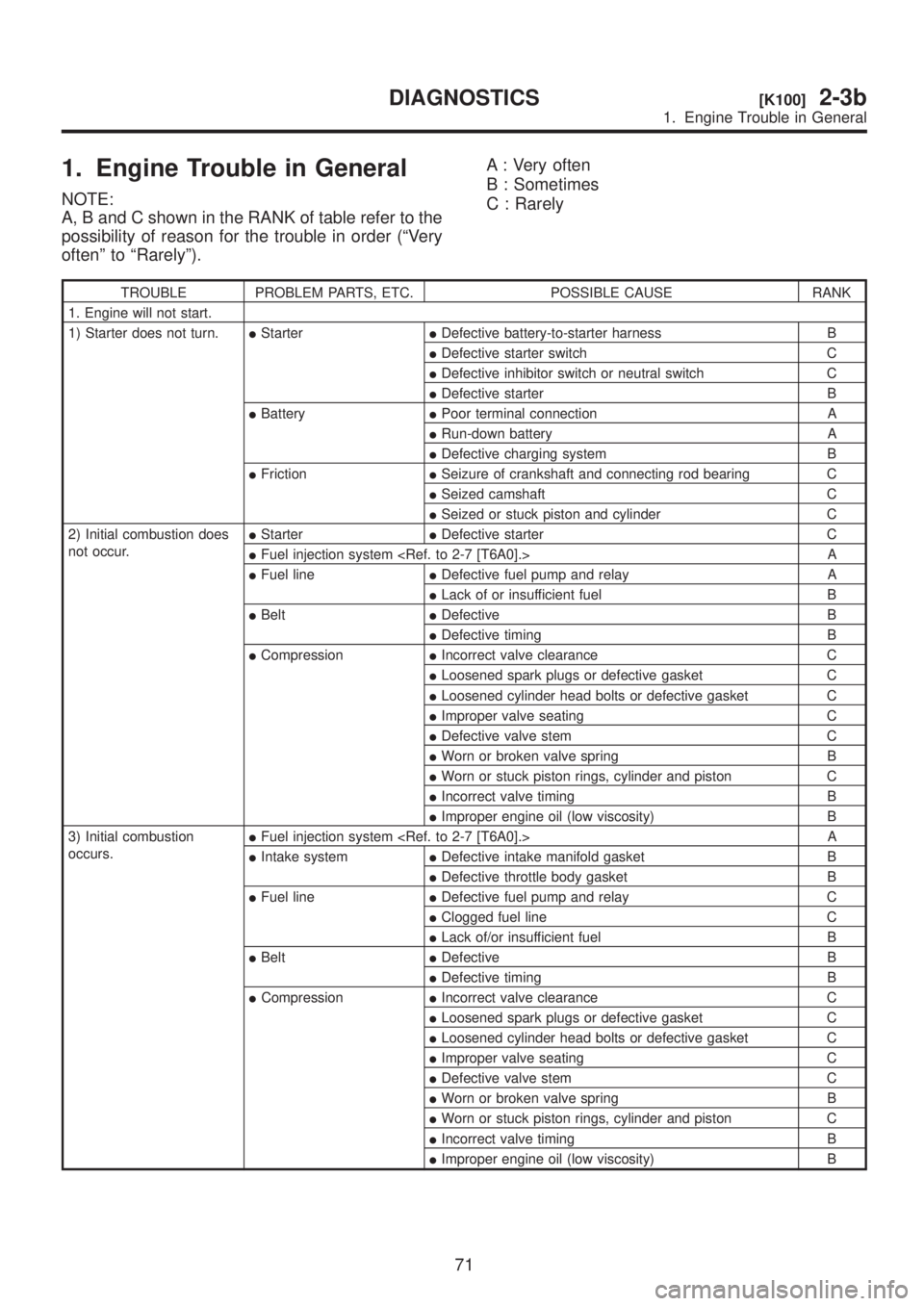

1. Engine Trouble in General

NOTE:

A, B and C shown in the RANK of table refer to the

possibility of reason for the trouble in order (ªVery

oftenº to ªRarelyº).A : Very often

B : Sometimes

C : Rarely

TROUBLE PROBLEM PARTS, ETC. POSSIBLE CAUSE RANK

1. Engine will not start.

1) Starter does not turn.IStarterIDefective battery-to-starter harness B

IDefective starter switch C

IDefective inhibitor switch or neutral switch C

IDefective starter B

IBatteryIPoor terminal connection A

IRun-down battery A

IDefective charging system B

IFrictionISeizure of crankshaft and connecting rod bearing C

ISeized camshaft C

ISeized or stuck piston and cylinder C

2) Initial combustion does

not occur.IStarterIDefective starter C

IFuel injection system

IFuel lineIDefective fuel pump and relay A

ILack of or insufficient fuel B

IBeltIDefective B

IDefective timing B

ICompressionIIncorrect valve clearance C

ILoosened spark plugs or defective gasket C

ILoosened cylinder head bolts or defective gasket C

IImproper valve seating C

IDefective valve stem C

IWorn or broken valve spring B

IWorn or stuck piston rings, cylinder and piston C

IIncorrect valve timing B

IImproper engine oil (low viscosity) B

3) Initial combustion

occurs.IFuel injection system

IIntake systemIDefective intake manifold gasket B

IDefective throttle body gasket B

IFuel lineIDefective fuel pump and relay C

IClogged fuel line C

ILack of/or insufficient fuel B

IBeltIDefective B

IDefective timing B

ICompressionIIncorrect valve clearance C

ILoosened spark plugs or defective gasket C

ILoosened cylinder head bolts or defective gasket C

IImproper valve seating C

IDefective valve stem C

IWorn or broken valve spring B

IWorn or stuck piston rings, cylinder and piston C

IIncorrect valve timing B

IImproper engine oil (low viscosity) B

71

[K100]2-3bDIAGNOSTICS

1. Engine Trouble in General

Page 986 of 1456

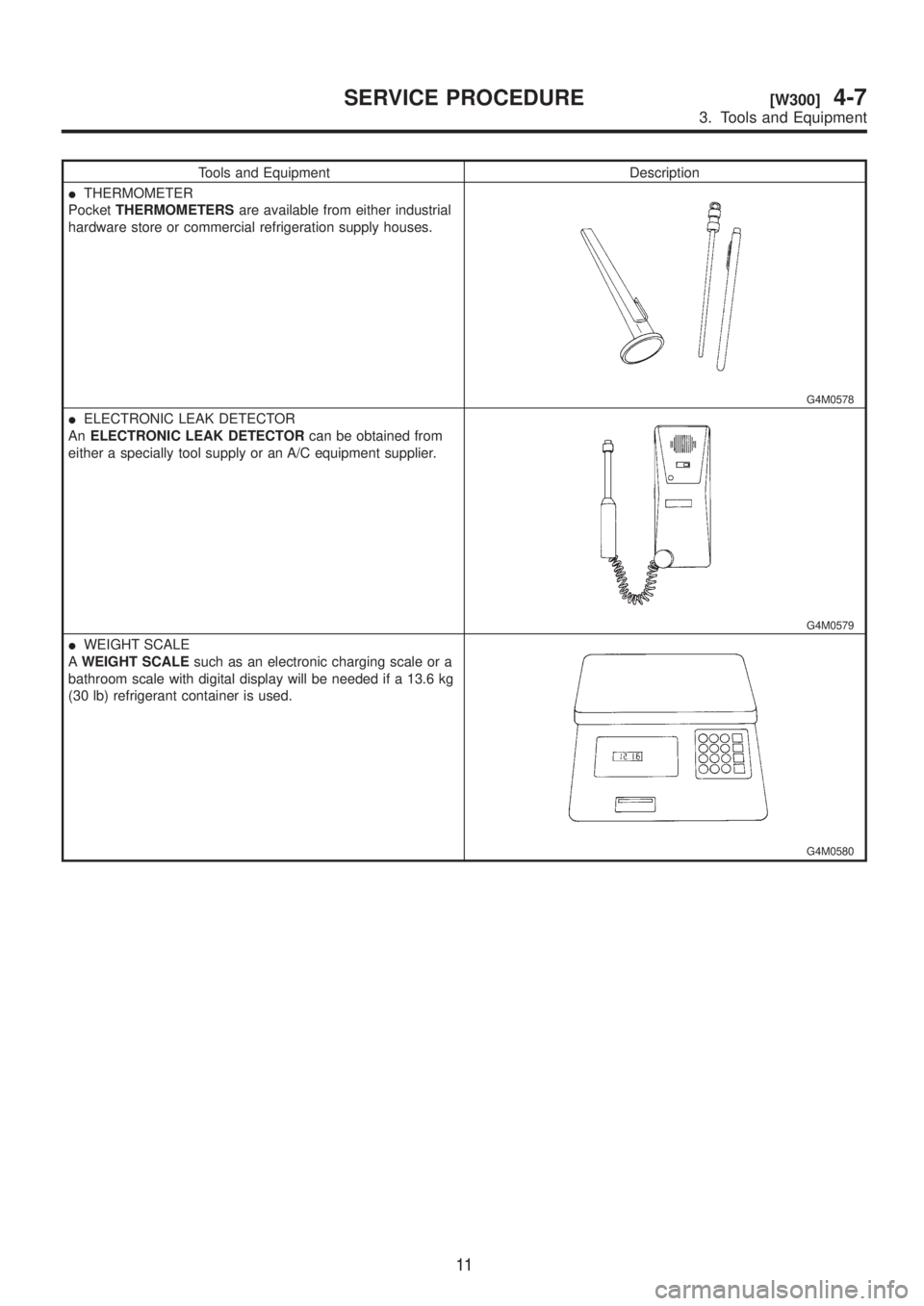

Tools and Equipment Description

ITHERMOMETER

PocketTHERMOMETERSare available from either industrial

hardware store or commercial refrigeration supply houses.

G4M0578

IELECTRONIC LEAK DETECTOR

AnELECTRONIC LEAK DETECTORcan be obtained from

either a specially tool supply or an A/C equipment supplier.

G4M0579

IWEIGHT SCALE

AWEIGHT SCALEsuch as an electronic charging scale or a

bathroom scale with digital display will be needed if a 13.6 kg

(30 lb) refrigerant container is used.

G4M0580

11

[W300]4-7SERVICE PROCEDURE

3. Tools and Equipment

Page 990 of 1456

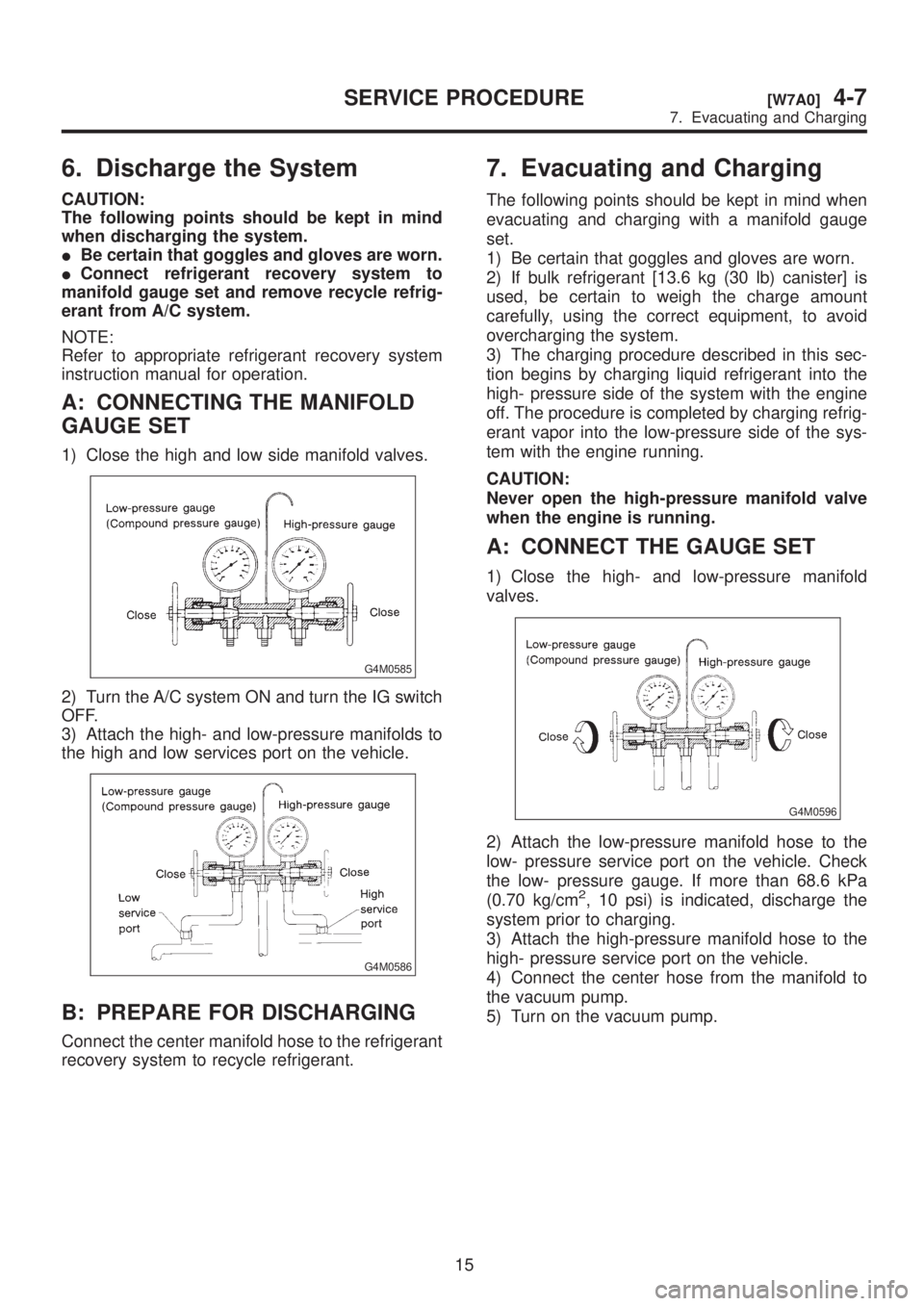

6. Discharge the System

CAUTION:

The following points should be kept in mind

when discharging the system.

IBe certain that goggles and gloves are worn.

IConnect refrigerant recovery system to

manifold gauge set and remove recycle refrig-

erant from A/C system.

NOTE:

Refer to appropriate refrigerant recovery system

instruction manual for operation.

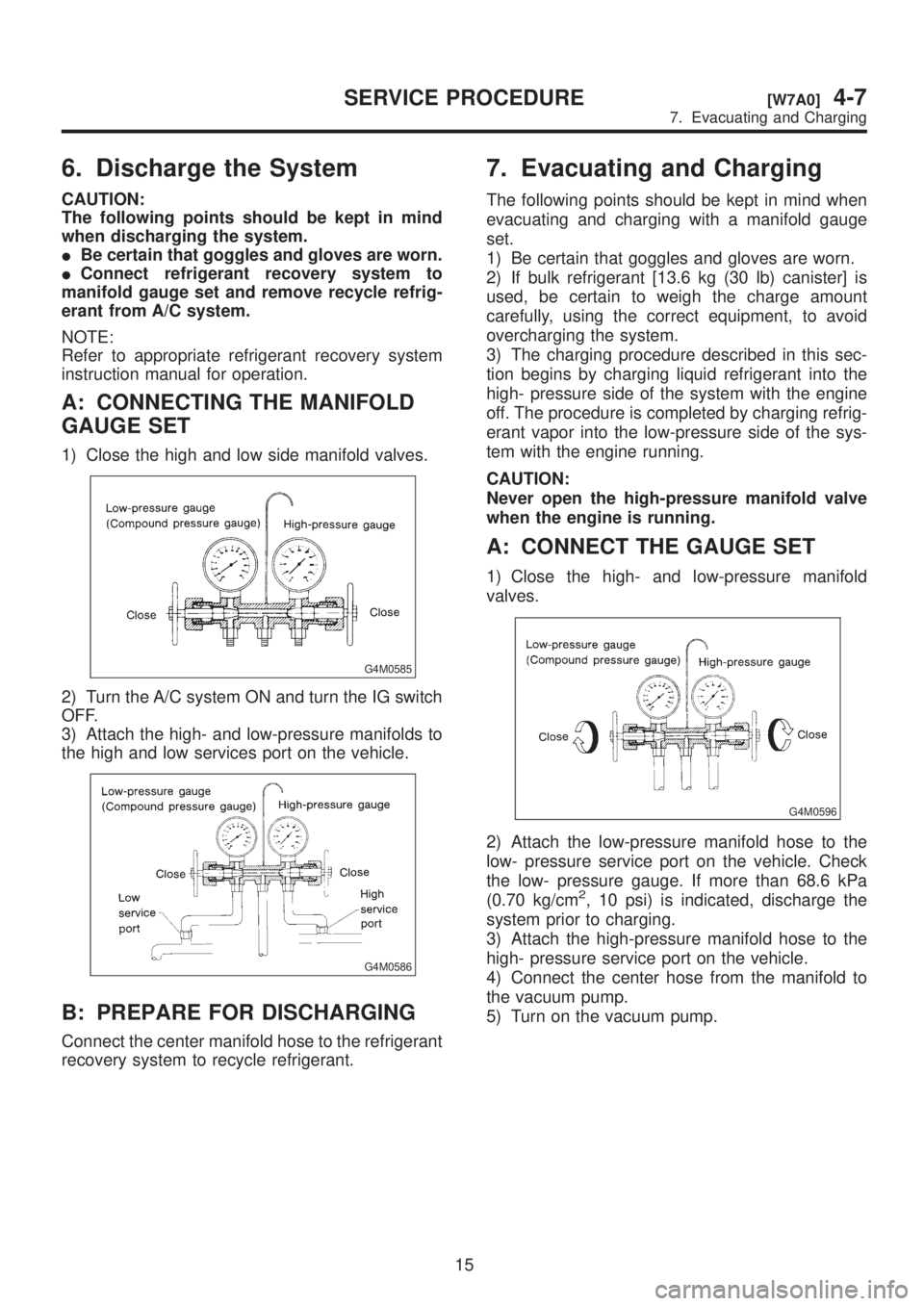

A: CONNECTING THE MANIFOLD

GAUGE SET

1) Close the high and low side manifold valves.

G4M0585

2) Turn the A/C system ON and turn the IG switch

OFF.

3) Attach the high- and low-pressure manifolds to

the high and low services port on the vehicle.

G4M0586

B: PREPARE FOR DISCHARGING

Connect the center manifold hose to the refrigerant

recovery system to recycle refrigerant.

7. Evacuating and Charging

The following points should be kept in mind when

evacuating and charging with a manifold gauge

set.

1) Be certain that goggles and gloves are worn.

2) If bulk refrigerant [13.6 kg (30 lb) canister] is

used, be certain to weigh the charge amount

carefully, using the correct equipment, to avoid

overcharging the system.

3) The charging procedure described in this sec-

tion begins by charging liquid refrigerant into the

high- pressure side of the system with the engine

off. The procedure is completed by charging refrig-

erant vapor into the low-pressure side of the sys-

tem with the engine running.

CAUTION:

Never open the high-pressure manifold valve

when the engine is running.

A: CONNECT THE GAUGE SET

1) Close the high- and low-pressure manifold

valves.

G4M0596

2) Attach the low-pressure manifold hose to the

low- pressure service port on the vehicle. Check

the low- pressure gauge. If more than 68.6 kPa

(0.70 kg/cm

2, 10 psi) is indicated, discharge the

system prior to charging.

3) Attach the high-pressure manifold hose to the

high- pressure service port on the vehicle.

4) Connect the center hose from the manifold to

the vacuum pump.

5) Turn on the vacuum pump.

15

[W7A0]4-7SERVICE PROCEDURE

7. Evacuating and Charging

Page 991 of 1456

6. Discharge the System

CAUTION:

The following points should be kept in mind

when discharging the system.

IBe certain that goggles and gloves are worn.

IConnect refrigerant recovery system to

manifold gauge set and remove recycle refrig-

erant from A/C system.

NOTE:

Refer to appropriate refrigerant recovery system

instruction manual for operation.

A: CONNECTING THE MANIFOLD

GAUGE SET

1) Close the high and low side manifold valves.

G4M0585

2) Turn the A/C system ON and turn the IG switch

OFF.

3) Attach the high- and low-pressure manifolds to

the high and low services port on the vehicle.

G4M0586

B: PREPARE FOR DISCHARGING

Connect the center manifold hose to the refrigerant

recovery system to recycle refrigerant.

7. Evacuating and Charging

The following points should be kept in mind when

evacuating and charging with a manifold gauge

set.

1) Be certain that goggles and gloves are worn.

2) If bulk refrigerant [13.6 kg (30 lb) canister] is

used, be certain to weigh the charge amount

carefully, using the correct equipment, to avoid

overcharging the system.

3) The charging procedure described in this sec-

tion begins by charging liquid refrigerant into the

high- pressure side of the system with the engine

off. The procedure is completed by charging refrig-

erant vapor into the low-pressure side of the sys-

tem with the engine running.

CAUTION:

Never open the high-pressure manifold valve

when the engine is running.

A: CONNECT THE GAUGE SET

1) Close the high- and low-pressure manifold

valves.

G4M0596

2) Attach the low-pressure manifold hose to the

low- pressure service port on the vehicle. Check

the low- pressure gauge. If more than 68.6 kPa

(0.70 kg/cm

2, 10 psi) is indicated, discharge the

system prior to charging.

3) Attach the high-pressure manifold hose to the

high- pressure service port on the vehicle.

4) Connect the center hose from the manifold to

the vacuum pump.

5) Turn on the vacuum pump.

15

[W7A0]4-7SERVICE PROCEDURE

7. Evacuating and Charging

Page 992 of 1456

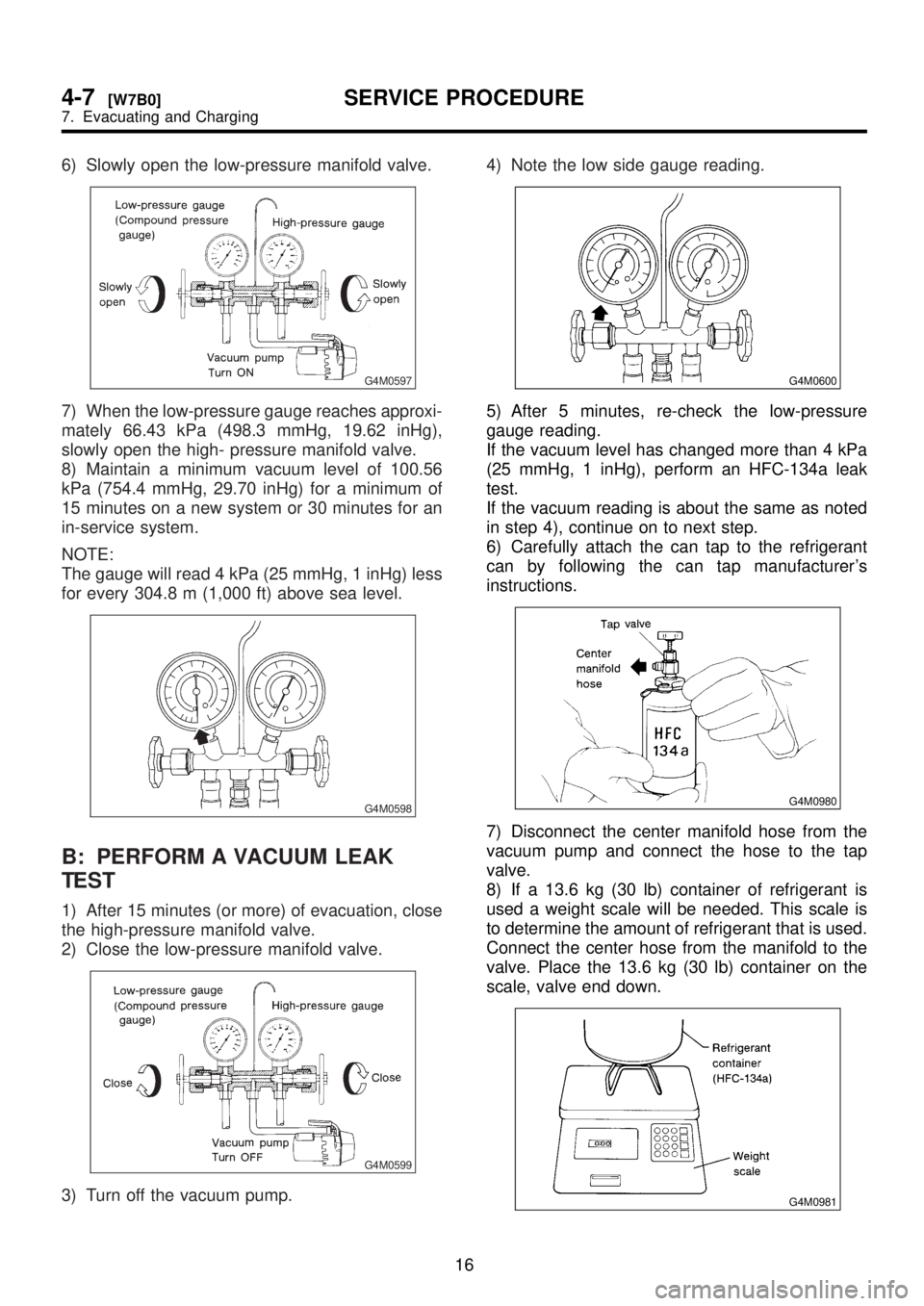

6) Slowly open the low-pressure manifold valve.

G4M0597

7) When the low-pressure gauge reaches approxi-

mately 66.43 kPa (498.3 mmHg, 19.62 inHg),

slowly open the high- pressure manifold valve.

8) Maintain a minimum vacuum level of 100.56

kPa (754.4 mmHg, 29.70 inHg) for a minimum of

15 minutes on a new system or 30 minutes for an

in-service system.

NOTE:

The gauge will read 4 kPa (25 mmHg, 1 inHg) less

for every 304.8 m (1,000 ft) above sea level.

G4M0598

B: PERFORM A VACUUM LEAK

TEST

1) After 15 minutes (or more) of evacuation, close

the high-pressure manifold valve.

2) Close the low-pressure manifold valve.

G4M0599

3) Turn off the vacuum pump.4) Note the low side gauge reading.

G4M0600

5) After 5 minutes, re-check the low-pressure

gauge reading.

If the vacuum level has changed more than 4 kPa

(25 mmHg, 1 inHg), perform an HFC-134a leak

test.

If the vacuum reading is about the same as noted

in step 4), continue on to next step.

6) Carefully attach the can tap to the refrigerant

can by following the can tap manufacturer's

instructions.

G4M0980

7) Disconnect the center manifold hose from the

vacuum pump and connect the hose to the tap

valve.

8) If a 13.6 kg (30 lb) container of refrigerant is

used a weight scale will be needed. This scale is

to determine the amount of refrigerant that is used.

Connect the center hose from the manifold to the

valve. Place the 13.6 kg (30 lb) container on the

scale, valve end down.

G4M0981

16

4-7[W7B0]SERVICE PROCEDURE

7. Evacuating and Charging

Page 993 of 1456

C: PURGE THE CENTER HOSE

CAUTION:

Be certain that goggles and gloves are worn.

1) Verify that all three hose connections are tight

at the manifold gauge set.

G4M0603

2) Open the valve on the HFC-134a source.

3) Loosen the center hose connection at the mani-

fold and allow the HFC-134a to escape for no more

than two or three seconds, then quickly retighten

the hose fitting at the manifold.

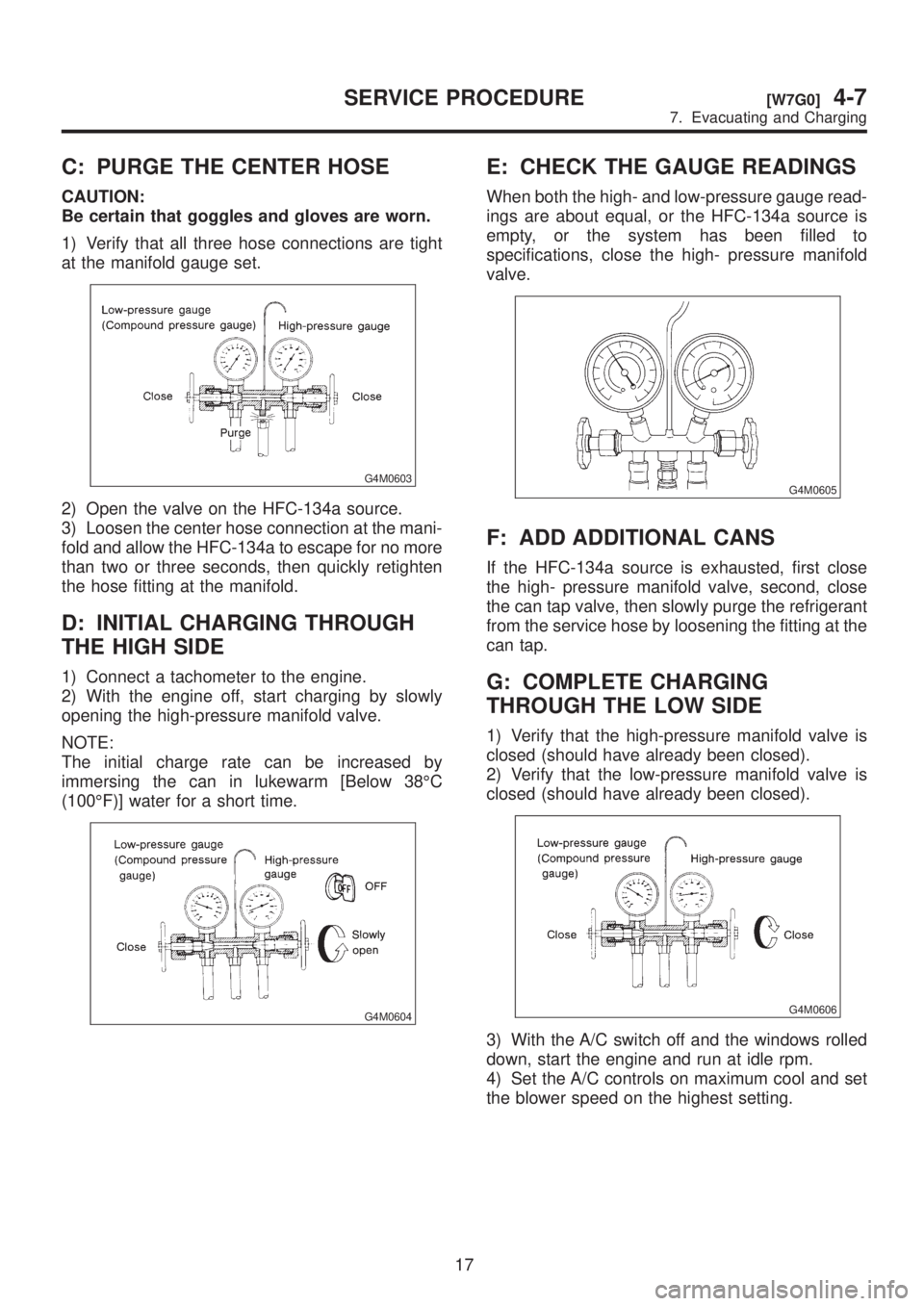

D: INITIAL CHARGING THROUGH

THE HIGH SIDE

1) Connect a tachometer to the engine.

2) With the engine off, start charging by slowly

opening the high-pressure manifold valve.

NOTE:

The initial charge rate can be increased by

immersing the can in lukewarm [Below 38ÉC

(100ÉF)] water for a short time.

G4M0604

E: CHECK THE GAUGE READINGS

When both the high- and low-pressure gauge read-

ings are about equal, or the HFC-134a source is

empty, or the system has been filled to

specifications, close the high- pressure manifold

valve.

G4M0605

F: ADD ADDITIONAL CANS

If the HFC-134a source is exhausted, first close

the high- pressure manifold valve, second, close

the can tap valve, then slowly purge the refrigerant

from the service hose by loosening the fitting at the

can tap.

G: COMPLETE CHARGING

THROUGH THE LOW SIDE

1) Verify that the high-pressure manifold valve is

closed (should have already been closed).

2) Verify that the low-pressure manifold valve is

closed (should have already been closed).

G4M0606

3) With the A/C switch off and the windows rolled

down, start the engine and run at idle rpm.

4) Set the A/C controls on maximum cool and set

the blower speed on the highest setting.

17

[W7G0]4-7SERVICE PROCEDURE

7. Evacuating and Charging

Page 994 of 1456

5) Quickly turn the A/C switch on-off-on-off a few

times to prevent initial compressor damage due to

ªload shock.º Finish this operation with the A/C

switch in the ON position.

G4M0607

6) Raise engine rpm to approximately 1,500 rpm.

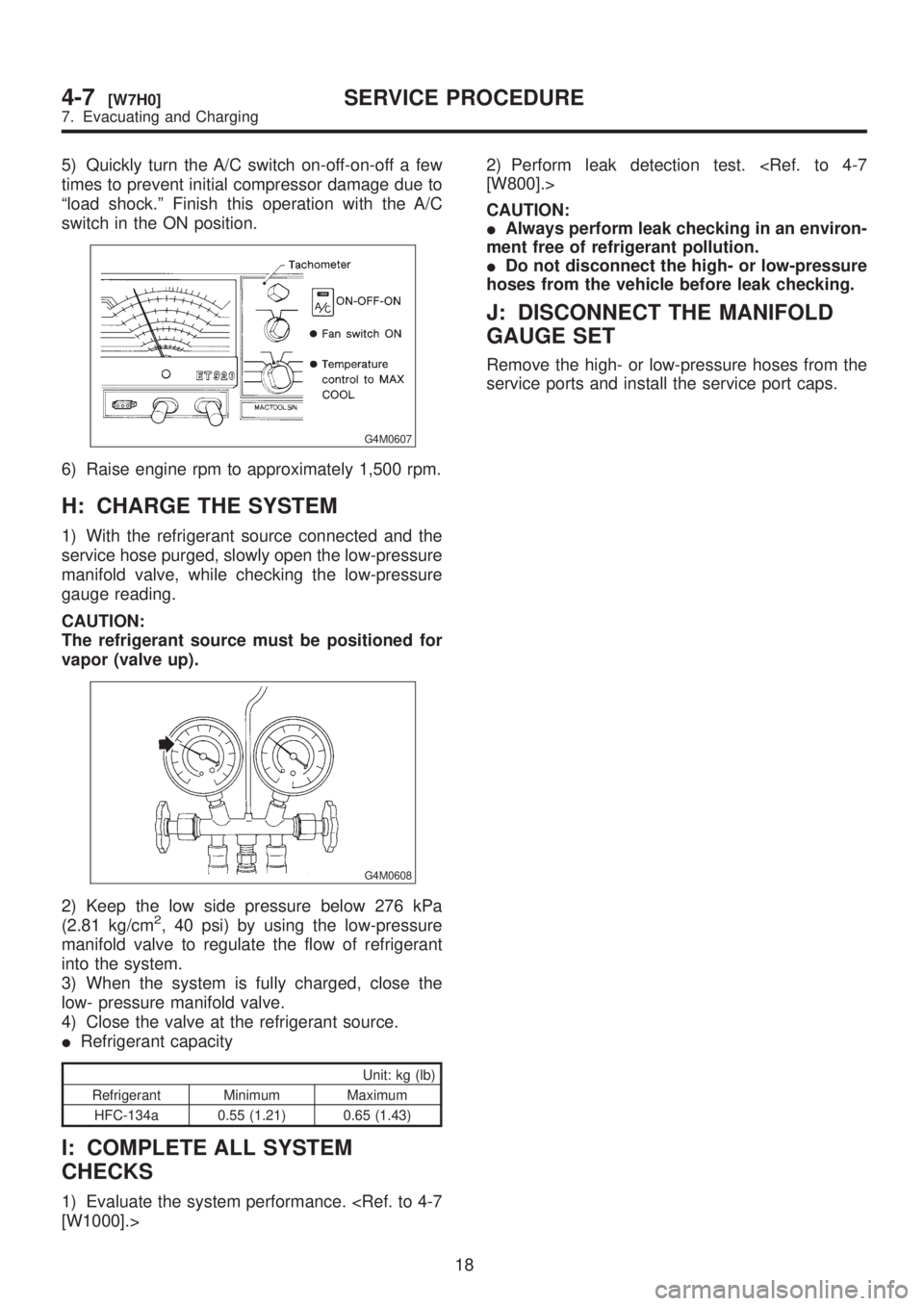

H: CHARGE THE SYSTEM

1) With the refrigerant source connected and the

service hose purged, slowly open the low-pressure

manifold valve, while checking the low-pressure

gauge reading.

CAUTION:

The refrigerant source must be positioned for

vapor (valve up).

G4M0608

2) Keep the low side pressure below 276 kPa

(2.81 kg/cm2, 40 psi) by using the low-pressure

manifold valve to regulate the flow of refrigerant

into the system.

3) When the system is fully charged, close the

low- pressure manifold valve.

4) Close the valve at the refrigerant source.

IRefrigerant capacity

Unit: kg (lb)

Refrigerant Minimum Maximum

HFC-134a 0.55 (1.21) 0.65 (1.43)

I: COMPLETE ALL SYSTEM

CHECKS

1) Evaluate the system performance.

CAUTION:

IAlways perform leak checking in an environ-

ment free of refrigerant pollution.

IDo not disconnect the high- or low-pressure

hoses from the vehicle before leak checking.

J: DISCONNECT THE MANIFOLD

GAUGE SET

Remove the high- or low-pressure hoses from the

service ports and install the service port caps.

18

4-7[W7H0]SERVICE PROCEDURE

7. Evacuating and Charging

Page 995 of 1456

8. Leak Testing

A: INSPECTION

The following points should be kept in mind when

conducting a refrigerant leak test.

1) The A/C system to be tested must have an

adequate refrigerant charge to begin with.

2) The area where the leak test is conducted must

be free of wind and drafts, with still air being the

ideal condition.

3) The atmosphere where the leak test is con-

ducted must be free of refrigerant contamination.

4) Operate the A/C system for approx. 10 minutes,

then turn the engine off an begin the leak test.

5) Refrigerant gas is heavier than air, therefore

always hold the probe below the connection being

tested.

6) When checking for a leak along a length of

hose or tube, the leak detector probe must be

moved slowly, approx. 25 mm (1 in) per second

making sure probe does not come in contact with

the component being tested.

7) When checking for a leak at a certain point, the

leak detector probe must be held at that point for

at least 5 seconds.

1. CHECK THE SYSTEM PRESSURE

With gauges connected to the A/C system, operate

the A/C and confirm that the high side pressure is

above 690 kPa (7.03 kg/cm

2, 100 psi). If not,

evacuate and charge the system before leak

checking (refer to evacuation and charging sec-

tions).

G4M0609

2. CLEAN CONNECTIONS BEFORE

TESTING

Before testing, use a clean shop towel to wipe off

refrigerant oil, dirt, or foreign material from all of the

connections and components to be tested.

NOTE:

Since refrigerant oil absorbs refrigerant, excess oil

on or near a connection may falsely signal a leak.

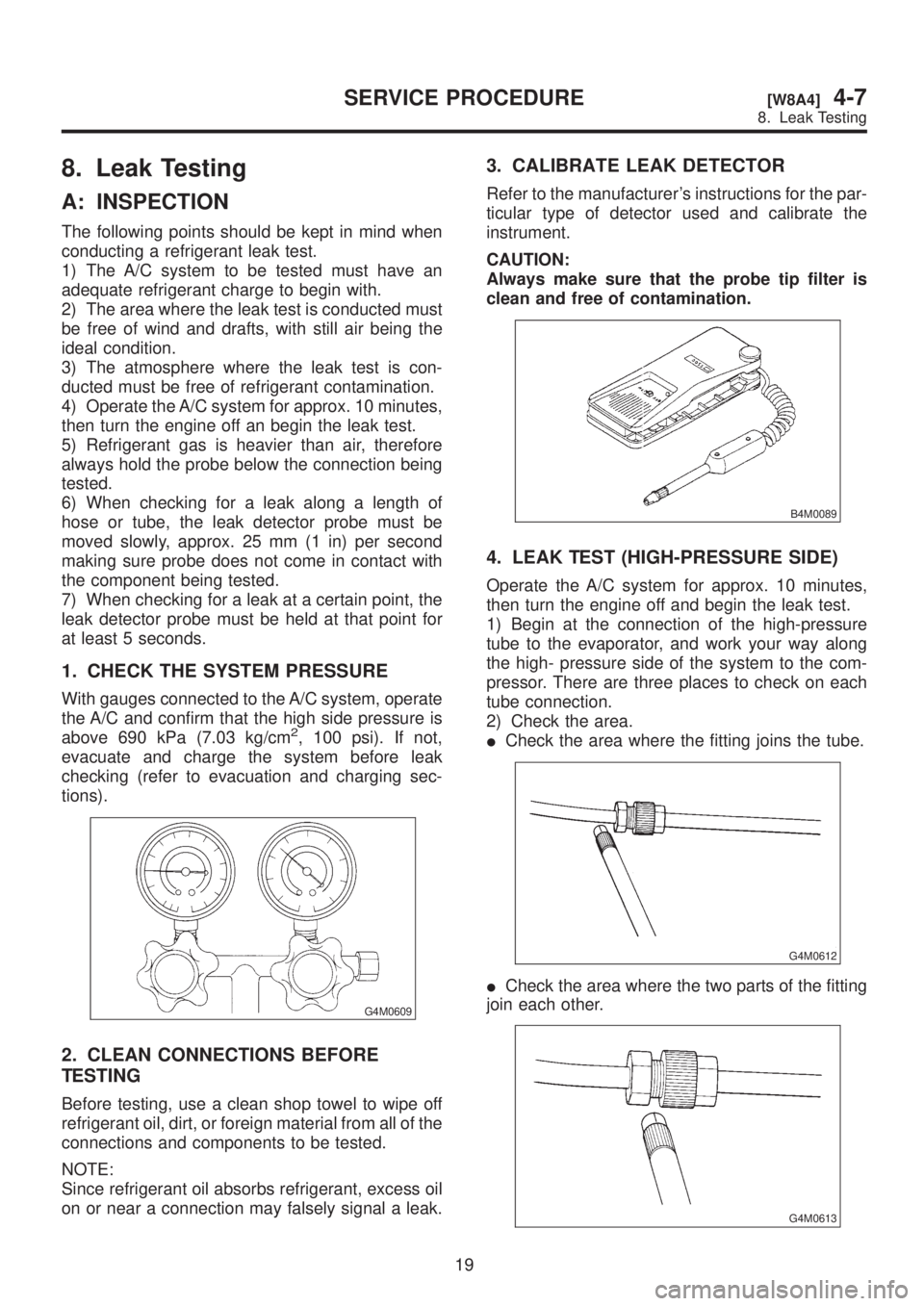

3. CALIBRATE LEAK DETECTOR

Refer to the manufacturer's instructions for the par-

ticular type of detector used and calibrate the

instrument.

CAUTION:

Always make sure that the probe tip filter is

clean and free of contamination.

B4M0089

4. LEAK TEST (HIGH-PRESSURE SIDE)

Operate the A/C system for approx. 10 minutes,

then turn the engine off and begin the leak test.

1) Begin at the connection of the high-pressure

tube to the evaporator, and work your way along

the high- pressure side of the system to the com-

pressor. There are three places to check on each

tube connection.

2) Check the area.

ICheck the area where the fitting joins the tube.

G4M0612

ICheck the area where the two parts of the fitting

join each other.

G4M0613

19

[W8A4]4-7SERVICE PROCEDURE

8. Leak Testing

Page 1001 of 1456

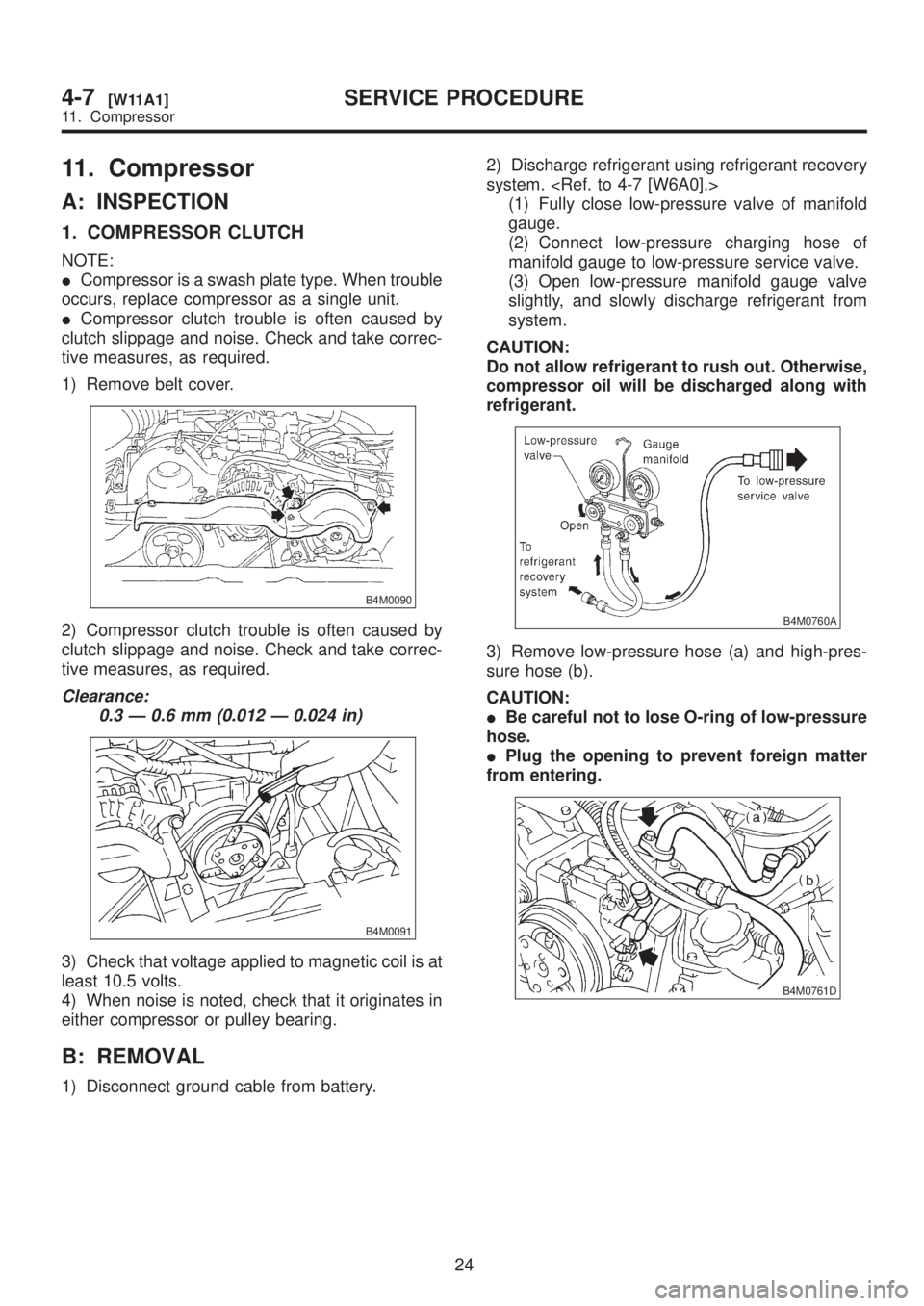

11. Compressor

A: INSPECTION

1. COMPRESSOR CLUTCH

NOTE:

ICompressor is a swash plate type. When trouble

occurs, replace compressor as a single unit.

ICompressor clutch trouble is often caused by

clutch slippage and noise. Check and take correc-

tive measures, as required.

1) Remove belt cover.

B4M0090

2) Compressor clutch trouble is often caused by

clutch slippage and noise. Check and take correc-

tive measures, as required.

Clearance:

0.3 Ð 0.6 mm (0.012 Ð 0.024 in)

B4M0091

3) Check that voltage applied to magnetic coil is at

least 10.5 volts.

4) When noise is noted, check that it originates in

either compressor or pulley bearing.

B: REMOVAL

1) Disconnect ground cable from battery.2) Discharge refrigerant using refrigerant recovery

system.

(1) Fully close low-pressure valve of manifold

gauge.

(2) Connect low-pressure charging hose of

manifold gauge to low-pressure service valve.

(3) Open low-pressure manifold gauge valve

slightly, and slowly discharge refrigerant from

system.

CAUTION:

Do not allow refrigerant to rush out. Otherwise,

compressor oil will be discharged along with

refrigerant.

B4M0760A

3) Remove low-pressure hose (a) and high-pres-

sure hose (b).

CAUTION:

IBe careful not to lose O-ring of low-pressure

hose.

IPlug the opening to prevent foreign matter

from entering.

B4M0761D

24

4-7[W11A1]SERVICE PROCEDURE

11. Compressor