refrigerant type SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 976 of 1456

1. Air Conditioning System

A: SPECIFICATIONS

Item Specifications

Type of air conditioner Reheat air-mix type

Cooling capacity (IMACA)4.885 kW

(4,200 kcal/h, 16,666 BTU/h)

RefrigerantHFC-134a (CH

2FCF3)

[0.55 Ð 0.65 kg

(1.21 Ð 1.43 lb)]

CompressorType 5-vane rotary, fix volume (DKV-14G)

Discharge 140 cm

3(8.54 cu in)/rev

Max. permissible speed 7,000 rpm

Magnet clutchType Dry, single-disc type

Power consumption 45 W

Type of belt V-Ribbed 4 PK

Pulley dia. (effective dia.) 125 mm (4.92 in)

Pulley ratio 1.064

CondenserType Corrugated fin (Multi-flow)

Core face area 0.215 m

2(2.31 sq ft)

Core thickness 19 mm (0.75 in)

Radiation area 4.7 m

2(51 sq ft)

Receiver drier Effective inner capacity 290 cm3(17.70 cu in)

Expansion valve Type Internal equalizing

EvaporatorType A-laminate

Dimensions (W´H´T)60´224´235 mm

(2.36´8.82´9.25 in)

Blower fanFan type Sirocco fan

Outer diameter´width 150´75 mm (5.91´2.95 in)

Power consumption 230 W at 12 V

Condenser fan

(Sub fan)Motor type Magnet

Power consumption 120 W at 12 V

Fan outer diameter 320 mm (12.60 in)

Radiator fan

(Main fan)Motor type Magnet

Power consumption 120 W at 12 V

Fan outer diameter 320 mm (12.60 in)

Idling speed with

F.I.C.D. in operationMPFI model850±100 rpm (700±100 rpm ªDº range in AT

model)

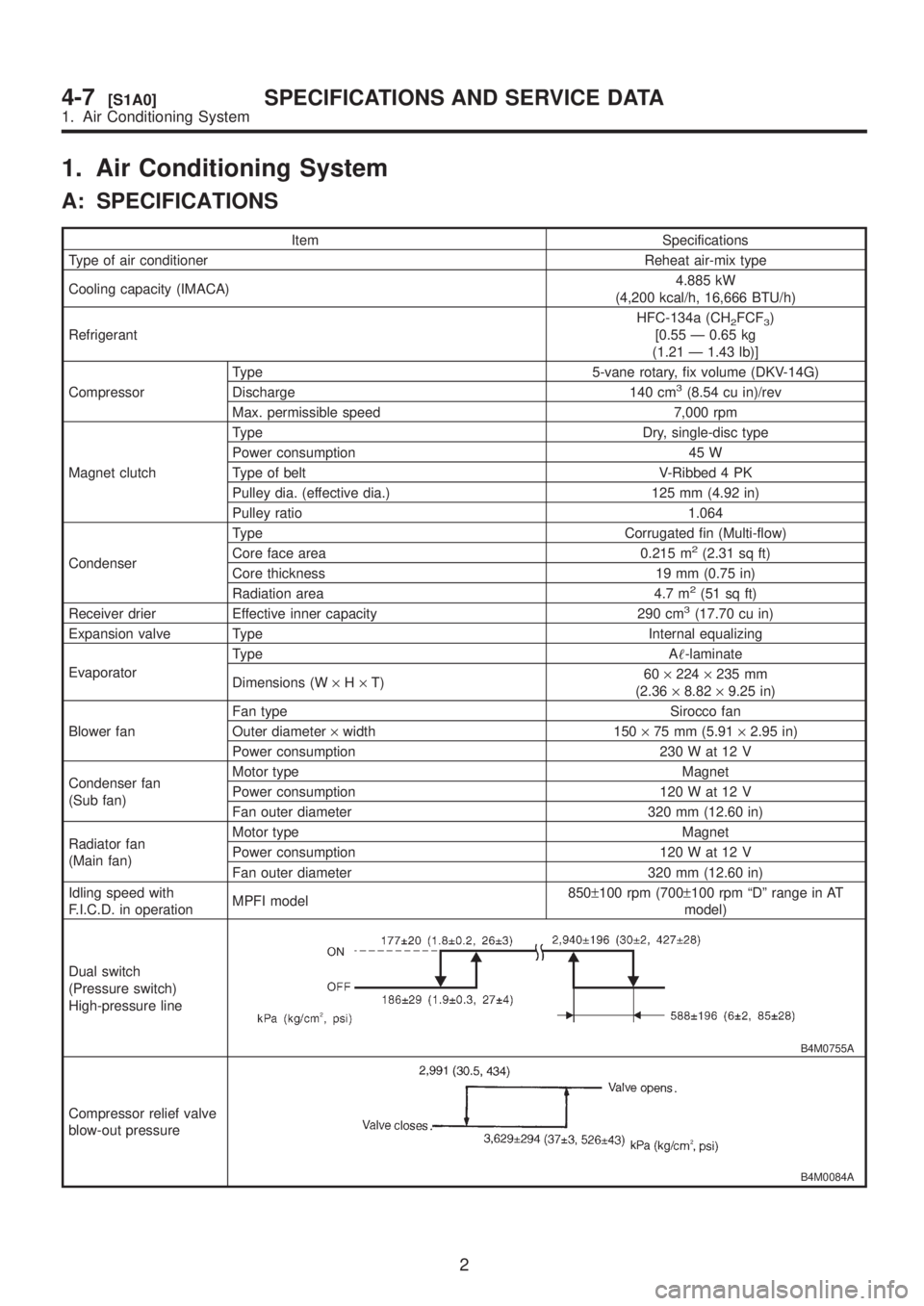

Dual switch

(Pressure switch)

High-pressure line

B4M0755A

Compressor relief valve

blow-out pressure

B4M0084A

2

4-7[S1A0]SPECIFICATIONS AND SERVICE DATA

1. Air Conditioning System

Page 981 of 1456

1. Safety Precautions

A: HFC-134a AIR CONDITIONING

SYSTEM

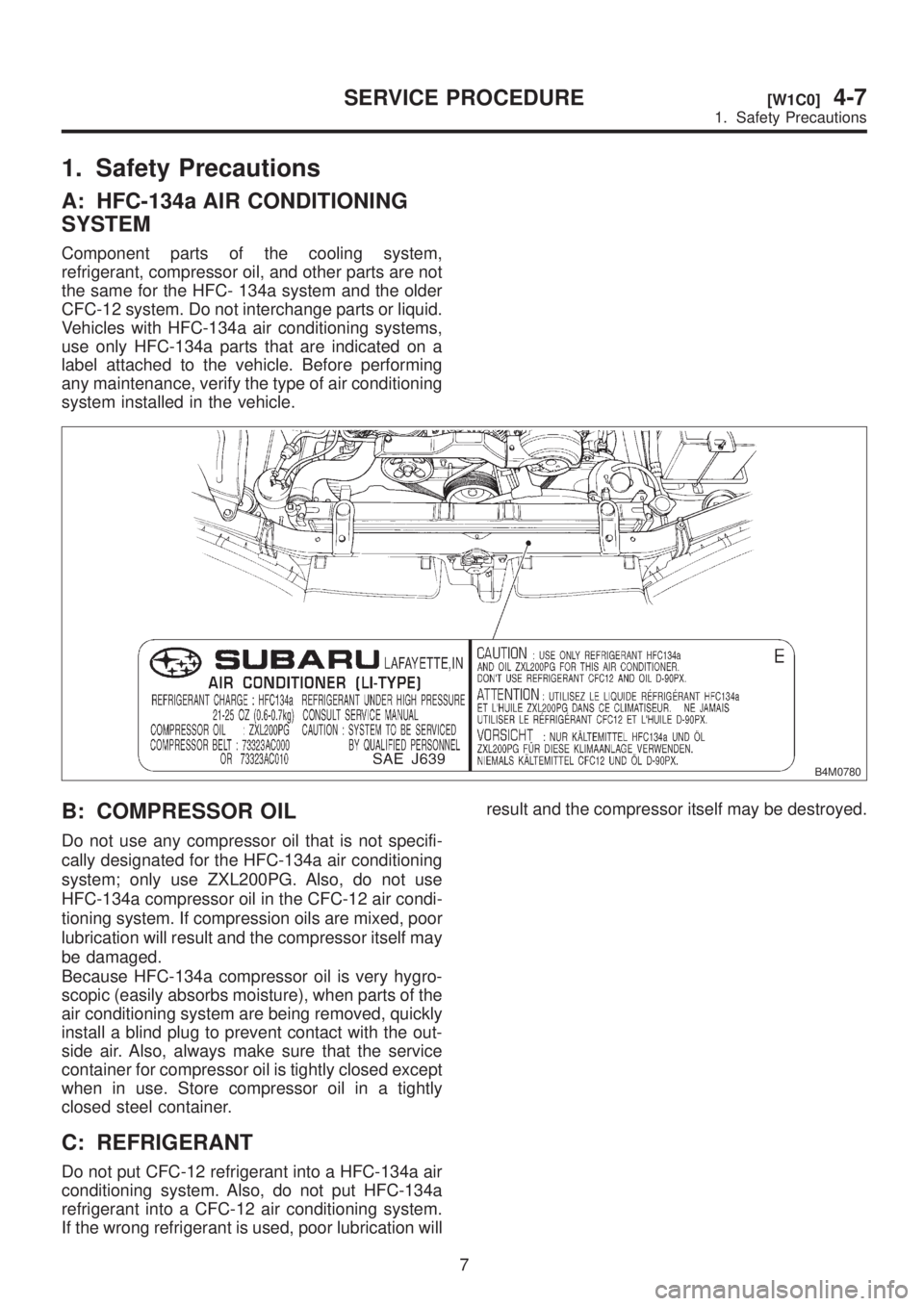

Component parts of the cooling system,

refrigerant, compressor oil, and other parts are not

the same for the HFC- 134a system and the older

CFC-12 system. Do not interchange parts or liquid.

Vehicles with HFC-134a air conditioning systems,

use only HFC-134a parts that are indicated on a

label attached to the vehicle. Before performing

any maintenance, verify the type of air conditioning

system installed in the vehicle.

B4M0780

B: COMPRESSOR OIL

Do not use any compressor oil that is not specifi-

cally designated for the HFC-134a air conditioning

system; only use ZXL200PG. Also, do not use

HFC-134a compressor oil in the CFC-12 air condi-

tioning system. If compression oils are mixed, poor

lubrication will result and the compressor itself may

be damaged.

Because HFC-134a compressor oil is very hygro-

scopic (easily absorbs moisture), when parts of the

air conditioning system are being removed, quickly

install a blind plug to prevent contact with the out-

side air. Also, always make sure that the service

container for compressor oil is tightly closed except

when in use. Store compressor oil in a tightly

closed steel container.

C: REFRIGERANT

Do not put CFC-12 refrigerant into a HFC-134a air

conditioning system. Also, do not put HFC-134a

refrigerant into a CFC-12 air conditioning system.

If the wrong refrigerant is used, poor lubrication willresult and the compressor itself may be destroyed.

7

[W1C0]4-7SERVICE PROCEDURE

1. Safety Precautions

Page 984 of 1456

3. Tools and Equipment

The following section provides information about

the tools and equipment that will be necessary to

properly service the A/C system.

Since equipment may vary slightly depending on

the manufacturer, it is important to always read and

follow the manufacturer's instructions.

CAUTION:

When working on vehicles with the HFC-134a

system, only use HFC-134a specified tools and

parts. Do not mix with CFC-12 tools and parts.

If HFC-134a and CFC-12 refrigerant or com-pressor oil is mixed, poor lubrication will result

and the compressor itself may be destroyed. In

order to help prevent mixing HFC-134a and

CFC-12 parts and liquid, the tool and screw

type and the type of service valves used are

different. The gas leak detectors for the HFC-

134a and CFC-12 systems must also not be

interchanged.

HFC-134a CFC-12

Tool & screw type Millimeter size Inch size

Valve type Quick joint type Screw-in type

Tools and Equipment Description

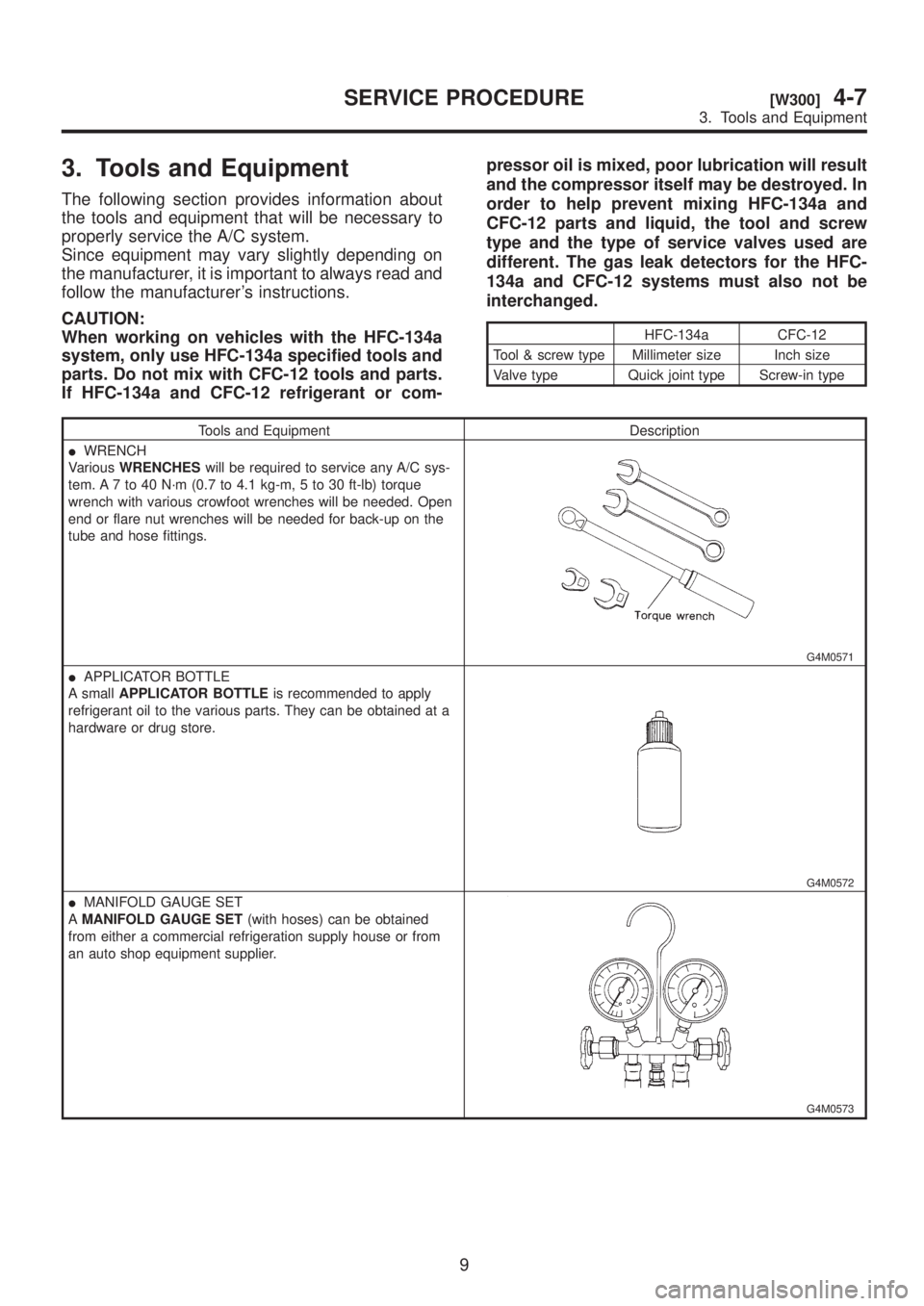

IWRENCH

VariousWRENCHESwill be required to service any A/C sys-

tem. A 7 to 40 N´m (0.7 to 4.1 kg-m, 5 to 30 ft-lb) torque

wrench with various crowfoot wrenches will be needed. Open

end or flare nut wrenches will be needed for back-up on the

tube and hose fittings.

G4M0571

IAPPLICATOR BOTTLE

A smallAPPLICATOR BOTTLEis recommended to apply

refrigerant oil to the various parts. They can be obtained at a

hardware or drug store.

G4M0572

IMANIFOLD GAUGE SET

AMANIFOLD GAUGE SET(with hoses) can be obtained

from either a commercial refrigeration supply house or from

an auto shop equipment supplier.

G4M0573

9

[W300]4-7SERVICE PROCEDURE

3. Tools and Equipment

Page 995 of 1456

8. Leak Testing

A: INSPECTION

The following points should be kept in mind when

conducting a refrigerant leak test.

1) The A/C system to be tested must have an

adequate refrigerant charge to begin with.

2) The area where the leak test is conducted must

be free of wind and drafts, with still air being the

ideal condition.

3) The atmosphere where the leak test is con-

ducted must be free of refrigerant contamination.

4) Operate the A/C system for approx. 10 minutes,

then turn the engine off an begin the leak test.

5) Refrigerant gas is heavier than air, therefore

always hold the probe below the connection being

tested.

6) When checking for a leak along a length of

hose or tube, the leak detector probe must be

moved slowly, approx. 25 mm (1 in) per second

making sure probe does not come in contact with

the component being tested.

7) When checking for a leak at a certain point, the

leak detector probe must be held at that point for

at least 5 seconds.

1. CHECK THE SYSTEM PRESSURE

With gauges connected to the A/C system, operate

the A/C and confirm that the high side pressure is

above 690 kPa (7.03 kg/cm

2, 100 psi). If not,

evacuate and charge the system before leak

checking (refer to evacuation and charging sec-

tions).

G4M0609

2. CLEAN CONNECTIONS BEFORE

TESTING

Before testing, use a clean shop towel to wipe off

refrigerant oil, dirt, or foreign material from all of the

connections and components to be tested.

NOTE:

Since refrigerant oil absorbs refrigerant, excess oil

on or near a connection may falsely signal a leak.

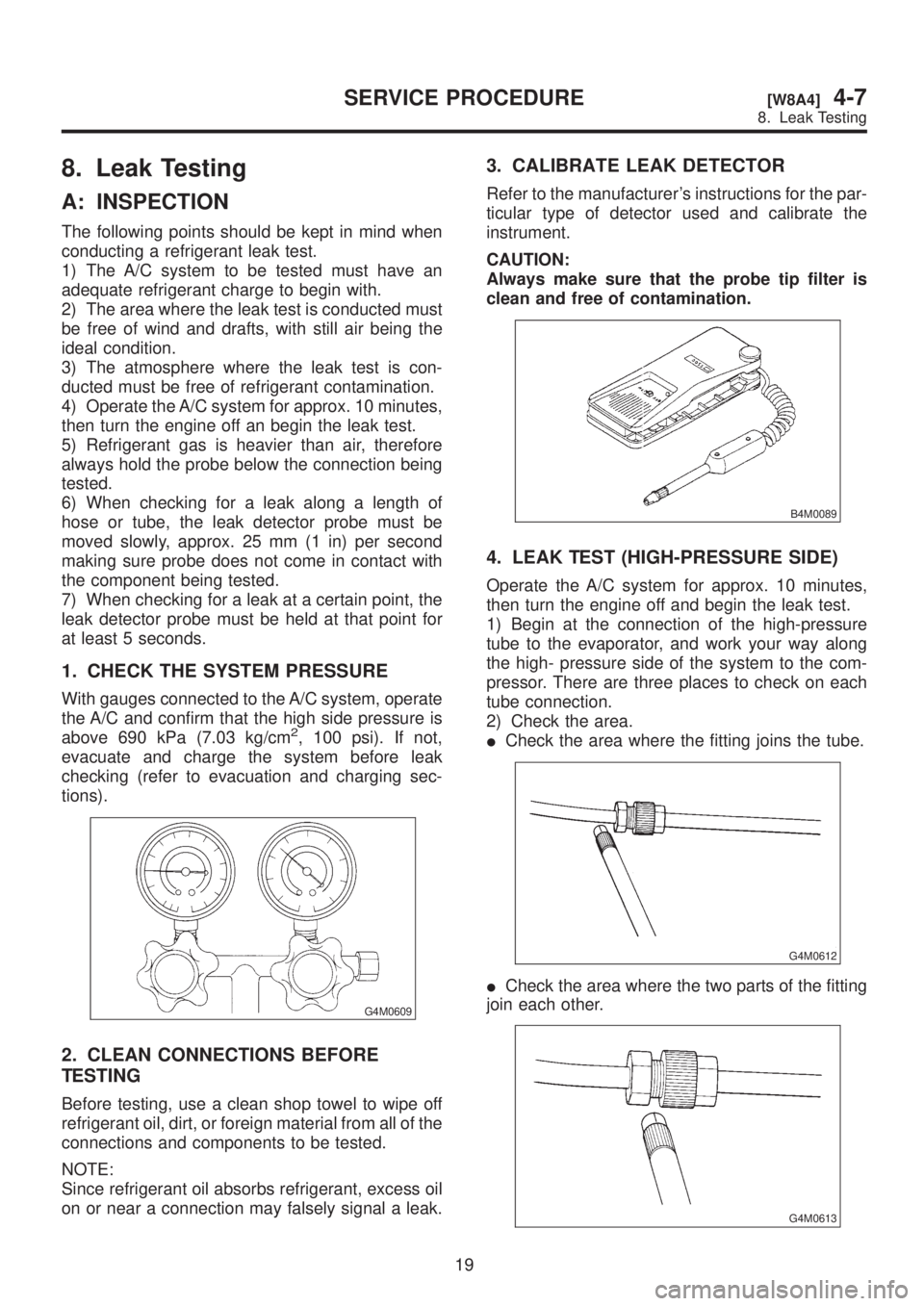

3. CALIBRATE LEAK DETECTOR

Refer to the manufacturer's instructions for the par-

ticular type of detector used and calibrate the

instrument.

CAUTION:

Always make sure that the probe tip filter is

clean and free of contamination.

B4M0089

4. LEAK TEST (HIGH-PRESSURE SIDE)

Operate the A/C system for approx. 10 minutes,

then turn the engine off and begin the leak test.

1) Begin at the connection of the high-pressure

tube to the evaporator, and work your way along

the high- pressure side of the system to the com-

pressor. There are three places to check on each

tube connection.

2) Check the area.

ICheck the area where the fitting joins the tube.

G4M0612

ICheck the area where the two parts of the fitting

join each other.

G4M0613

19

[W8A4]4-7SERVICE PROCEDURE

8. Leak Testing

Page 1001 of 1456

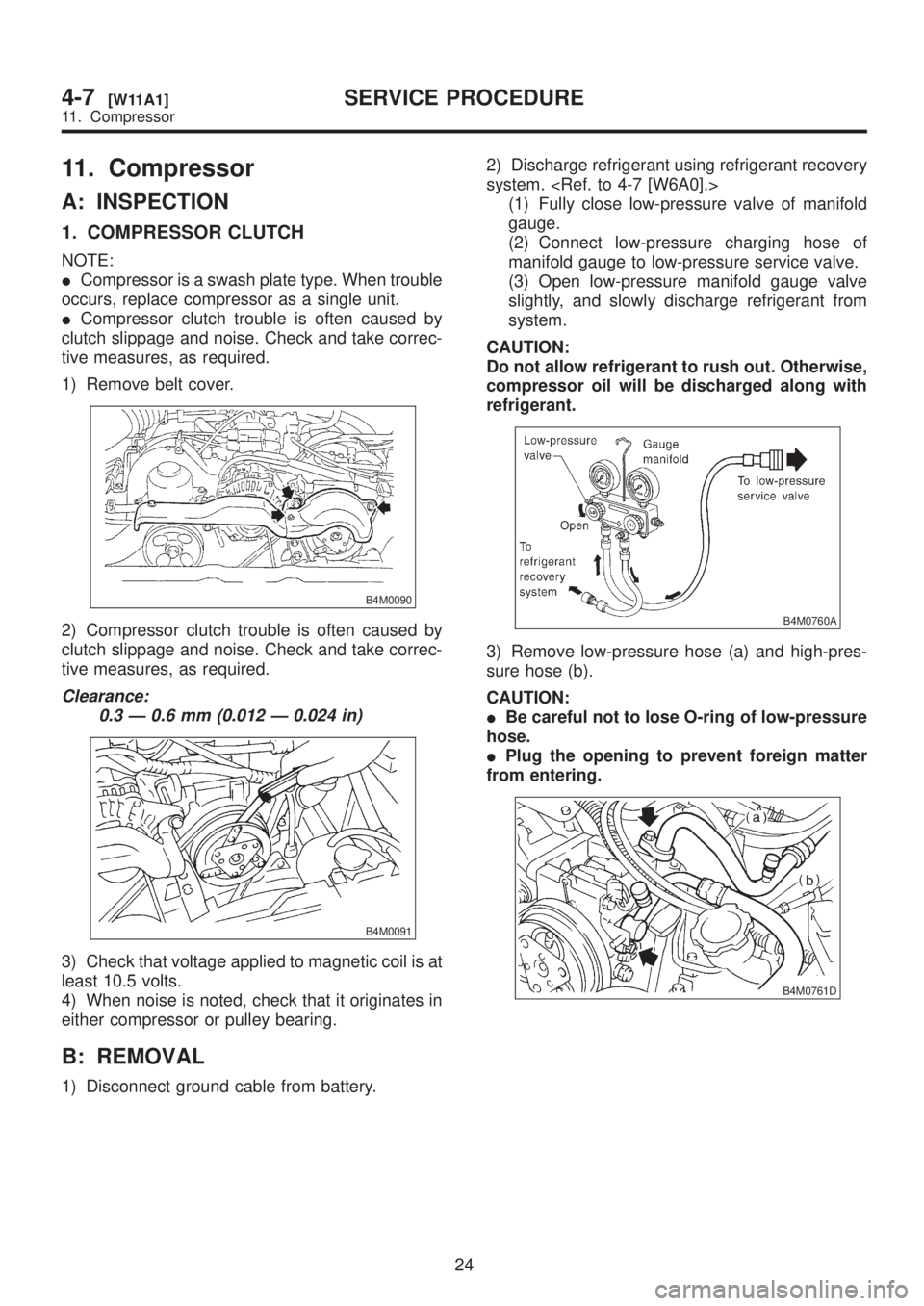

11. Compressor

A: INSPECTION

1. COMPRESSOR CLUTCH

NOTE:

ICompressor is a swash plate type. When trouble

occurs, replace compressor as a single unit.

ICompressor clutch trouble is often caused by

clutch slippage and noise. Check and take correc-

tive measures, as required.

1) Remove belt cover.

B4M0090

2) Compressor clutch trouble is often caused by

clutch slippage and noise. Check and take correc-

tive measures, as required.

Clearance:

0.3 Ð 0.6 mm (0.012 Ð 0.024 in)

B4M0091

3) Check that voltage applied to magnetic coil is at

least 10.5 volts.

4) When noise is noted, check that it originates in

either compressor or pulley bearing.

B: REMOVAL

1) Disconnect ground cable from battery.2) Discharge refrigerant using refrigerant recovery

system.

(1) Fully close low-pressure valve of manifold

gauge.

(2) Connect low-pressure charging hose of

manifold gauge to low-pressure service valve.

(3) Open low-pressure manifold gauge valve

slightly, and slowly discharge refrigerant from

system.

CAUTION:

Do not allow refrigerant to rush out. Otherwise,

compressor oil will be discharged along with

refrigerant.

B4M0760A

3) Remove low-pressure hose (a) and high-pres-

sure hose (b).

CAUTION:

IBe careful not to lose O-ring of low-pressure

hose.

IPlug the opening to prevent foreign matter

from entering.

B4M0761D

24

4-7[W11A1]SERVICE PROCEDURE

11. Compressor