specifications SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 36 of 1456

![SUBARU LEGACY 1999 Service Repair Manual CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

<Ref. to 2-7 [T6A0].>4. Eng SUBARU LEGACY 1999 Service Repair Manual CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

<Ref. to 2-7 [T6A0].>4. Eng](/img/17/57435/w960_57435-35.png)

CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

A: MEASUREMENT

1. 2200 cc MODEL

1) After warming-up the engine, turn ignition

switch to OFF.

2) Make sure that the battery is fully charged.

3) Remove all the spark plugs.

4) Disconnect connectors from fuel injectors.

5) Fully open throttle valve.

6) Check the starter motor for satisfactory perfor-

mance and operation.

7) Hold the compression gauge tight against the

spark plug hole.

CAUTION:

When using a screw-in type compression

gauge, the screw (put into cylinder head spark

plug hole) should be less than 18 mm (0.71 in)

long.

8) Crank the engine by means of the starter motor,

and read the maximum value on the gauge when

the pointer is steady.

G2M0098

9) Perform at least two measurements per

cylinder, and make sure that the values are correct.

Compression (200 Ð 300 rpm and fully open

throttle):

Standard;

1,079 Ð 1,275 kPa (11.0 Ð 13.0 kg/cm

2,

156 Ð 185 psi)

Limit;

883 kPa (9.0 kg/cm

2, 128 psi)

Difference between cylinders;

196 kPa (2.0 kg/cm

2, 28 psi)

4

2-2[W4A1]SERVICE PROCEDURE

4. Engine Compression

Page 37 of 1456

![SUBARU LEGACY 1999 Service Repair Manual CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

<Ref. to 2-7 [T6A0].>4. Eng SUBARU LEGACY 1999 Service Repair Manual CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

<Ref. to 2-7 [T6A0].>4. Eng](/img/17/57435/w960_57435-36.png)

CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

A: MEASUREMENT

1. 2200 cc MODEL

1) After warming-up the engine, turn ignition

switch to OFF.

2) Make sure that the battery is fully charged.

3) Remove all the spark plugs.

4) Disconnect connectors from fuel injectors.

5) Fully open throttle valve.

6) Check the starter motor for satisfactory perfor-

mance and operation.

7) Hold the compression gauge tight against the

spark plug hole.

CAUTION:

When using a screw-in type compression

gauge, the screw (put into cylinder head spark

plug hole) should be less than 18 mm (0.71 in)

long.

8) Crank the engine by means of the starter motor,

and read the maximum value on the gauge when

the pointer is steady.

G2M0098

9) Perform at least two measurements per

cylinder, and make sure that the values are correct.

Compression (200 Ð 300 rpm and fully open

throttle):

Standard;

1,079 Ð 1,275 kPa (11.0 Ð 13.0 kg/cm

2,

156 Ð 185 psi)

Limit;

883 kPa (9.0 kg/cm

2, 128 psi)

Difference between cylinders;

196 kPa (2.0 kg/cm

2, 28 psi)

4

2-2[W4A1]SERVICE PROCEDURE

4. Engine Compression

Page 54 of 1456

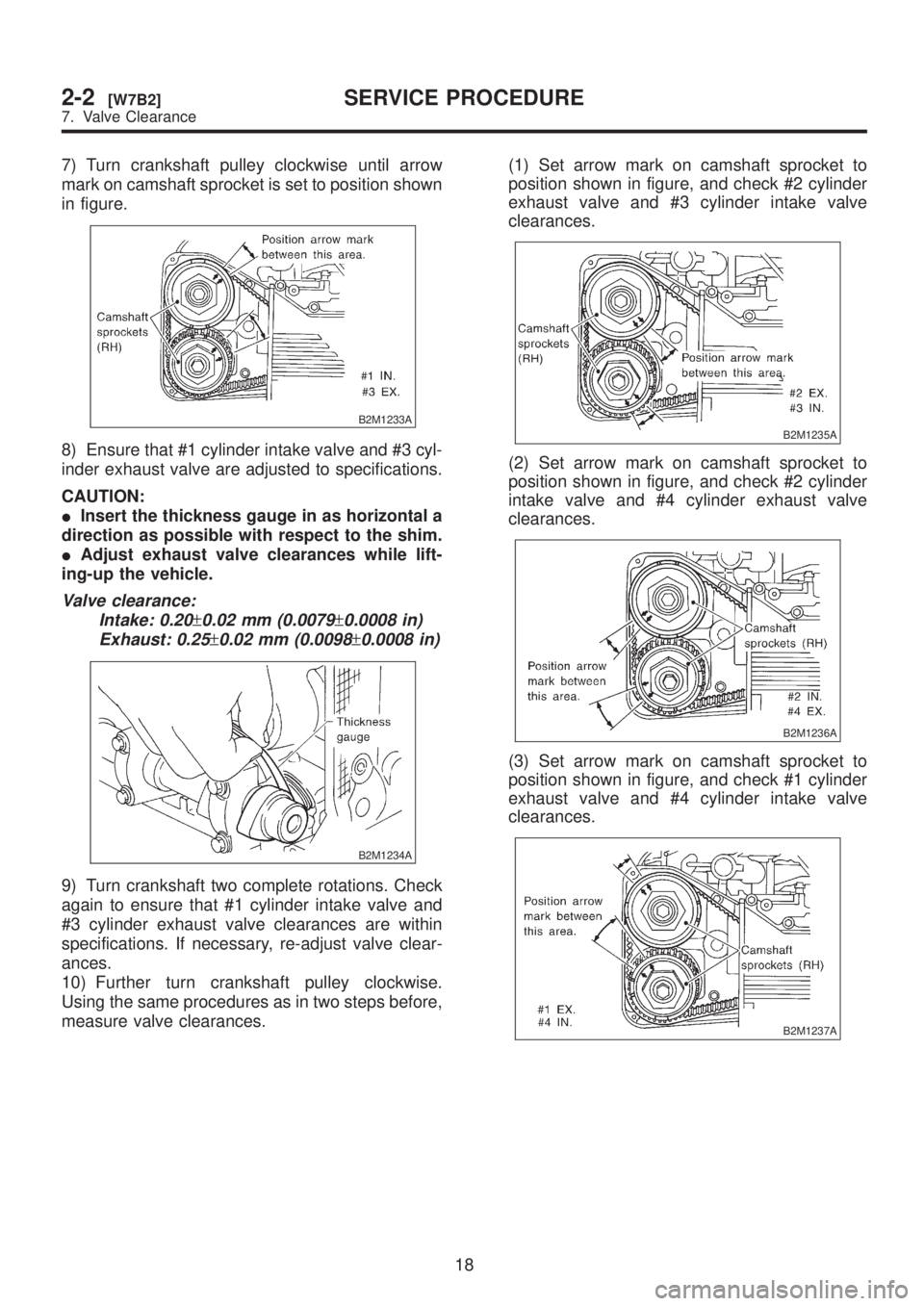

7) Turn crankshaft pulley clockwise until arrow

mark on camshaft sprocket is set to position shown

in figure.

B2M1233A

8) Ensure that #1 cylinder intake valve and #3 cyl-

inder exhaust valve are adjusted to specifications.

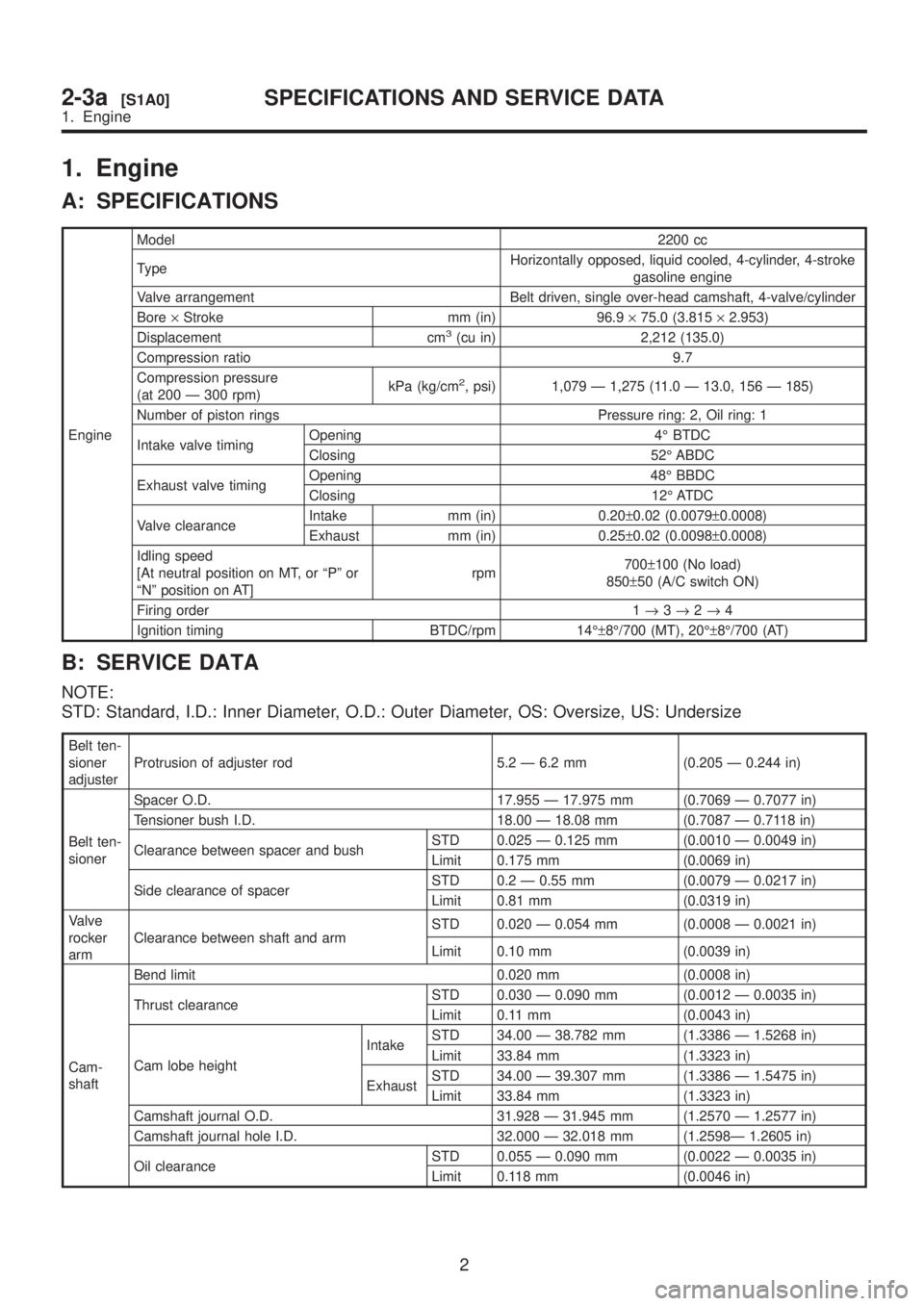

CAUTION:

IInsert the thickness gauge in as horizontal a

direction as possible with respect to the shim.

IAdjust exhaust valve clearances while lift-

ing-up the vehicle.

Valve clearance:

Intake: 0.20

±0.02 mm (0.0079±0.0008 in)

Exhaust: 0.25

±0.02 mm (0.0098±0.0008 in)

B2M1234A

9) Turn crankshaft two complete rotations. Check

again to ensure that #1 cylinder intake valve and

#3 cylinder exhaust valve clearances are within

specifications. If necessary, re-adjust valve clear-

ances.

10) Further turn crankshaft pulley clockwise.

Using the same procedures as in two steps before,

measure valve clearances.(1) Set arrow mark on camshaft sprocket to

position shown in figure, and check #2 cylinder

exhaust valve and #3 cylinder intake valve

clearances.

B2M1235A

(2) Set arrow mark on camshaft sprocket to

position shown in figure, and check #2 cylinder

intake valve and #4 cylinder exhaust valve

clearances.

B2M1236A

(3) Set arrow mark on camshaft sprocket to

position shown in figure, and check #1 cylinder

exhaust valve and #4 cylinder intake valve

clearances.

B2M1237A

18

2-2[W7B2]SERVICE PROCEDURE

7. Valve Clearance

Page 55 of 1456

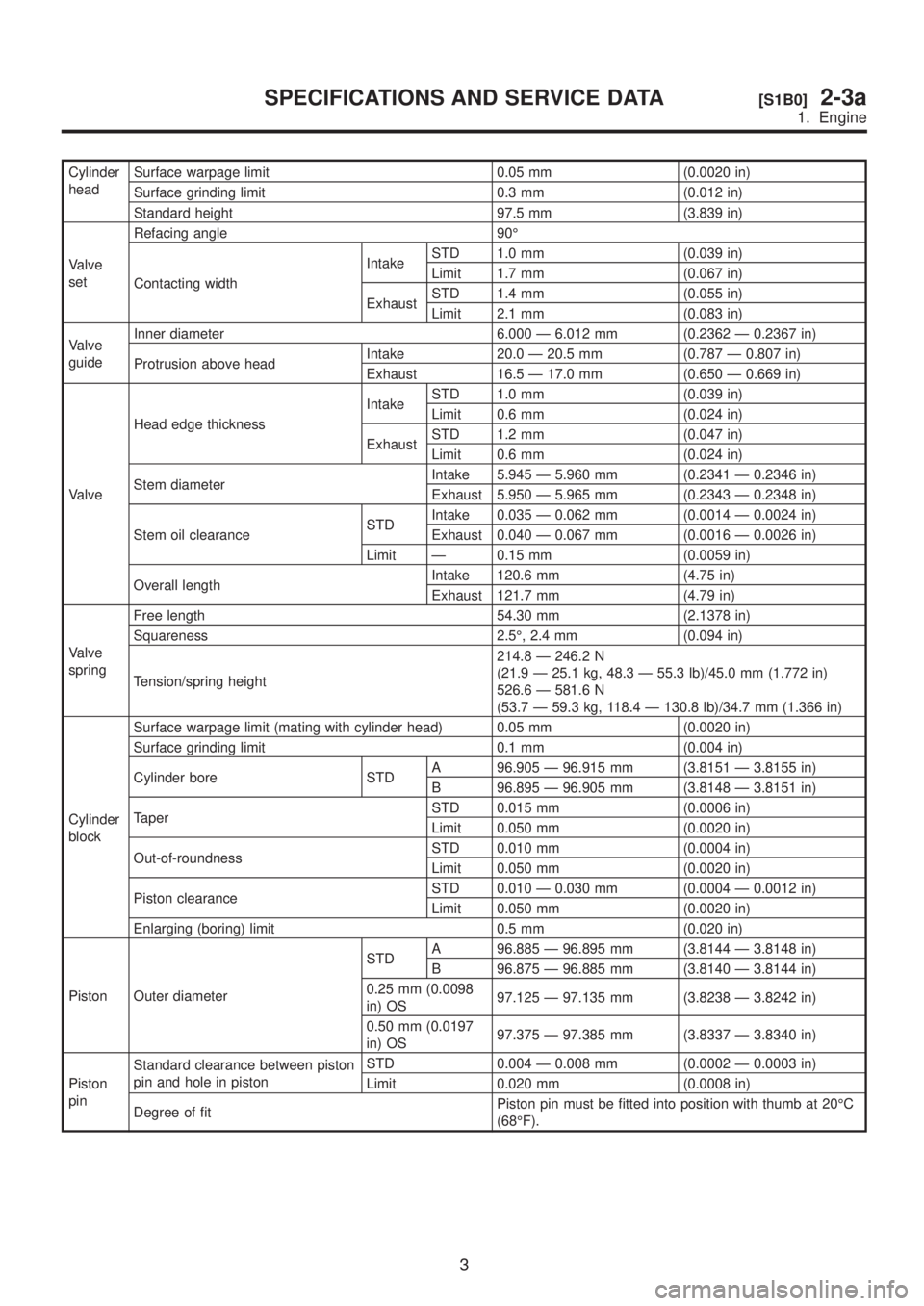

1. Engine

A: SPECIFICATIONS

EngineModel2200 cc

TypeHorizontally opposed, liquid cooled, 4-cylinder, 4-stroke

gasoline engine

Valve arrangement Belt driven, single over-head camshaft, 4-valve/cylinder

Bore´Stroke mm (in) 96.9´75.0 (3.815´2.953)

Displacement cm

3(cu in) 2,212 (135.0)

Compression ratio 9.7

Compression pressure

(at 200 Ð 300 rpm)kPa (kg/cm

2, psi) 1,079 Ð 1,275 (11.0 Ð 13.0, 156 Ð 185)

Number of piston rings Pressure ring: 2, Oil ring: 1

Intake valve timingOpening 4É BTDC

Closing 52É ABDC

Exhaust valve timingOpening 48É BBDC

Closing 12É ATDC

Valve clearanceIntake mm (in) 0.20±0.02 (0.0079±0.0008)

Exhaust mm (in) 0.25±0.02 (0.0098±0.0008)

Idling speed

[At neutral position on MT, or ªPº or

ªNº position on AT]rpm700±100 (No load)

850±50 (A/C switch ON)

Firing order 1®3®2®4

Ignition timing BTDC/rpm 14ɱ8É/700 (MT), 20ɱ8É/700 (AT)

B: SERVICE DATA

NOTE:

STD: Standard, I.D.: Inner Diameter, O.D.: Outer Diameter, OS: Oversize, US: Undersize

Belt ten-

sioner

adjusterProtrusion of adjuster rod 5.2 Ð 6.2 mm (0.205 Ð 0.244 in)

Belt ten-

sionerSpacer O.D. 17.955 Ð 17.975 mm (0.7069 Ð 0.7077 in)

Tensioner bush I.D. 18.00 Ð 18.08 mm (0.7087 Ð 0.7118 in)

Clearance between spacer and bushSTD 0.025 Ð 0.125 mm (0.0010 Ð 0.0049 in)

Limit 0.175 mm (0.0069 in)

Side clearance of spacerSTD 0.2 Ð 0.55 mm (0.0079 Ð 0.0217 in)

Limit 0.81 mm (0.0319 in)

Valve

rocker

armClearance between shaft and armSTD 0.020 Ð 0.054 mm (0.0008 Ð 0.0021 in)

Limit 0.10 mm (0.0039 in)

Cam-

shaftBend limit 0.020 mm (0.0008 in)

Thrust clearanceSTD 0.030 Ð 0.090 mm (0.0012 Ð 0.0035 in)

Limit 0.11 mm (0.0043 in)

Cam lobe heightIntakeSTD 34.00 Ð 38.782 mm (1.3386 Ð 1.5268 in)

Limit 33.84 mm (1.3323 in)

ExhaustSTD 34.00 Ð 39.307 mm (1.3386 Ð 1.5475 in)

Limit 33.84 mm (1.3323 in)

Camshaft journal O.D. 31.928 Ð 31.945 mm (1.2570 Ð 1.2577 in)

Camshaft journal hole I.D. 32.000 Ð 32.018 mm (1.2598Ð 1.2605 in)

Oil clearanceSTD 0.055 Ð 0.090 mm (0.0022 Ð 0.0035 in)

Limit 0.118 mm (0.0046 in)

2

2-3a[S1A0]SPECIFICATIONS AND SERVICE DATA

1. Engine

Page 56 of 1456

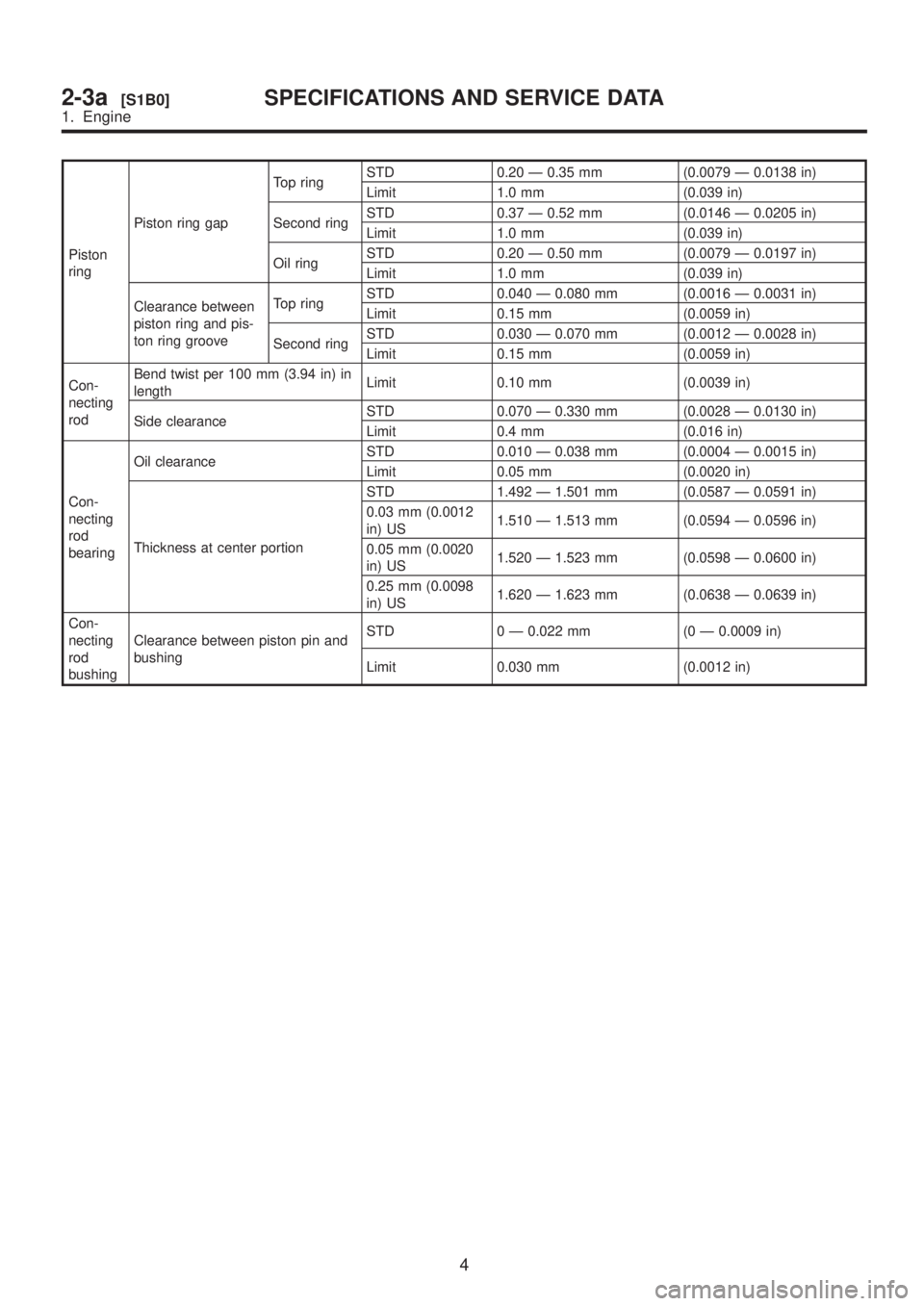

Cylinder

headSurface warpage limit 0.05 mm (0.0020 in)

Surface grinding limit 0.3 mm (0.012 in)

Standard height 97.5 mm (3.839 in)

Valve

setRefacing angle 90É

Contacting widthIntakeSTD 1.0 mm (0.039 in)

Limit 1.7 mm (0.067 in)

ExhaustSTD 1.4 mm (0.055 in)

Limit 2.1 mm (0.083 in)

Valve

guideInner diameter 6.000 Ð 6.012 mm (0.2362 Ð 0.2367 in)

Protrusion above headIntake 20.0 Ð 20.5 mm (0.787 Ð 0.807 in)

Exhaust 16.5 Ð 17.0 mm (0.650 Ð 0.669 in)

ValveHead edge thicknessIntakeSTD 1.0 mm (0.039 in)

Limit 0.6 mm (0.024 in)

ExhaustSTD 1.2 mm (0.047 in)

Limit 0.6 mm (0.024 in)

Stem diameterIntake 5.945 Ð 5.960 mm (0.2341 Ð 0.2346 in)

Exhaust 5.950 Ð 5.965 mm (0.2343 Ð 0.2348 in)

Stem oil clearanceSTDIntake 0.035 Ð 0.062 mm (0.0014 Ð 0.0024 in)

Exhaust 0.040 Ð 0.067 mm (0.0016 Ð 0.0026 in)

Limit Ð 0.15 mm (0.0059 in)

Overall lengthIntake 120.6 mm (4.75 in)

Exhaust 121.7 mm (4.79 in)

Valve

springFree length 54.30 mm (2.1378 in)

Squareness 2.5É, 2.4 mm (0.094 in)

Tension/spring height214.8 Ð 246.2 N

(21.9 Ð 25.1 kg, 48.3 Ð 55.3 lb)/45.0 mm (1.772 in)

526.6 Ð 581.6 N

(53.7 Ð 59.3 kg, 118.4 Ð 130.8 lb)/34.7 mm (1.366 in)

Cylinder

blockSurface warpage limit (mating with cylinder head) 0.05 mm (0.0020 in)

Surface grinding limit 0.1 mm (0.004 in)

Cylinder bore STDA 96.905 Ð 96.915 mm (3.8151 Ð 3.8155 in)

B 96.895 Ð 96.905 mm (3.8148 Ð 3.8151 in)

TaperSTD 0.015 mm (0.0006 in)

Limit 0.050 mm (0.0020 in)

Out-of-roundnessSTD 0.010 mm (0.0004 in)

Limit 0.050 mm (0.0020 in)

Piston clearanceSTD 0.010 Ð 0.030 mm (0.0004 Ð 0.0012 in)

Limit 0.050 mm (0.0020 in)

Enlarging (boring) limit 0.5 mm (0.020 in)

Piston Outer diameterSTDA 96.885 Ð 96.895 mm (3.8144 Ð 3.8148 in)

B 96.875 Ð 96.885 mm (3.8140 Ð 3.8144 in)

0.25 mm (0.0098

in) OS97.125 Ð 97.135 mm (3.8238 Ð 3.8242 in)

0.50 mm (0.0197

in) OS97.375 Ð 97.385 mm (3.8337 Ð 3.8340 in)

Piston

pinStandard clearance between piston

pin and hole in pistonSTD 0.004 Ð 0.008 mm (0.0002 Ð 0.0003 in)

Limit 0.020 mm (0.0008 in)

Degree of fitPiston pin must be fitted into position with thumb at 20ÉC

(68ÉF).

3

[S1B0]2-3aSPECIFICATIONS AND SERVICE DATA

1. Engine

Page 57 of 1456

Piston

ringPiston ring gapTop ringSTD 0.20 Ð 0.35 mm (0.0079 Ð 0.0138 in)

Limit 1.0 mm (0.039 in)

Second ringSTD 0.37 Ð 0.52 mm (0.0146 Ð 0.0205 in)

Limit 1.0 mm (0.039 in)

Oil ringSTD 0.20 Ð 0.50 mm (0.0079 Ð 0.0197 in)

Limit 1.0 mm (0.039 in)

Clearance between

piston ring and pis-

ton ring grooveTop ringSTD 0.040 Ð 0.080 mm (0.0016 Ð 0.0031 in)

Limit 0.15 mm (0.0059 in)

Second ringSTD 0.030 Ð 0.070 mm (0.0012 Ð 0.0028 in)

Limit 0.15 mm (0.0059 in)

Con-

necting

rodBend twist per 100 mm (3.94 in) in

lengthLimit 0.10 mm (0.0039 in)

Side clearanceSTD 0.070 Ð 0.330 mm (0.0028 Ð 0.0130 in)

Limit 0.4 mm (0.016 in)

Con-

necting

rod

bearingOil clearanceSTD 0.010 Ð 0.038 mm (0.0004 Ð 0.0015 in)

Limit 0.05 mm (0.0020 in)

Thickness at center portionSTD 1.492 Ð 1.501 mm (0.0587 Ð 0.0591 in)

0.03 mm (0.0012

in) US1.510 Ð 1.513 mm (0.0594 Ð 0.0596 in)

0.05 mm (0.0020

in) US1.520 Ð 1.523 mm (0.0598 Ð 0.0600 in)

0.25 mm (0.0098

in) US1.620 Ð 1.623 mm (0.0638 Ð 0.0639 in)

Con-

necting

rod

bushingClearance between piston pin and

bushingSTD 0 Ð 0.022 mm (0 Ð 0.0009 in)

Limit 0.030 mm (0.0012 in)

4

2-3a[S1B0]SPECIFICATIONS AND SERVICE DATA

1. Engine

Page 58 of 1456

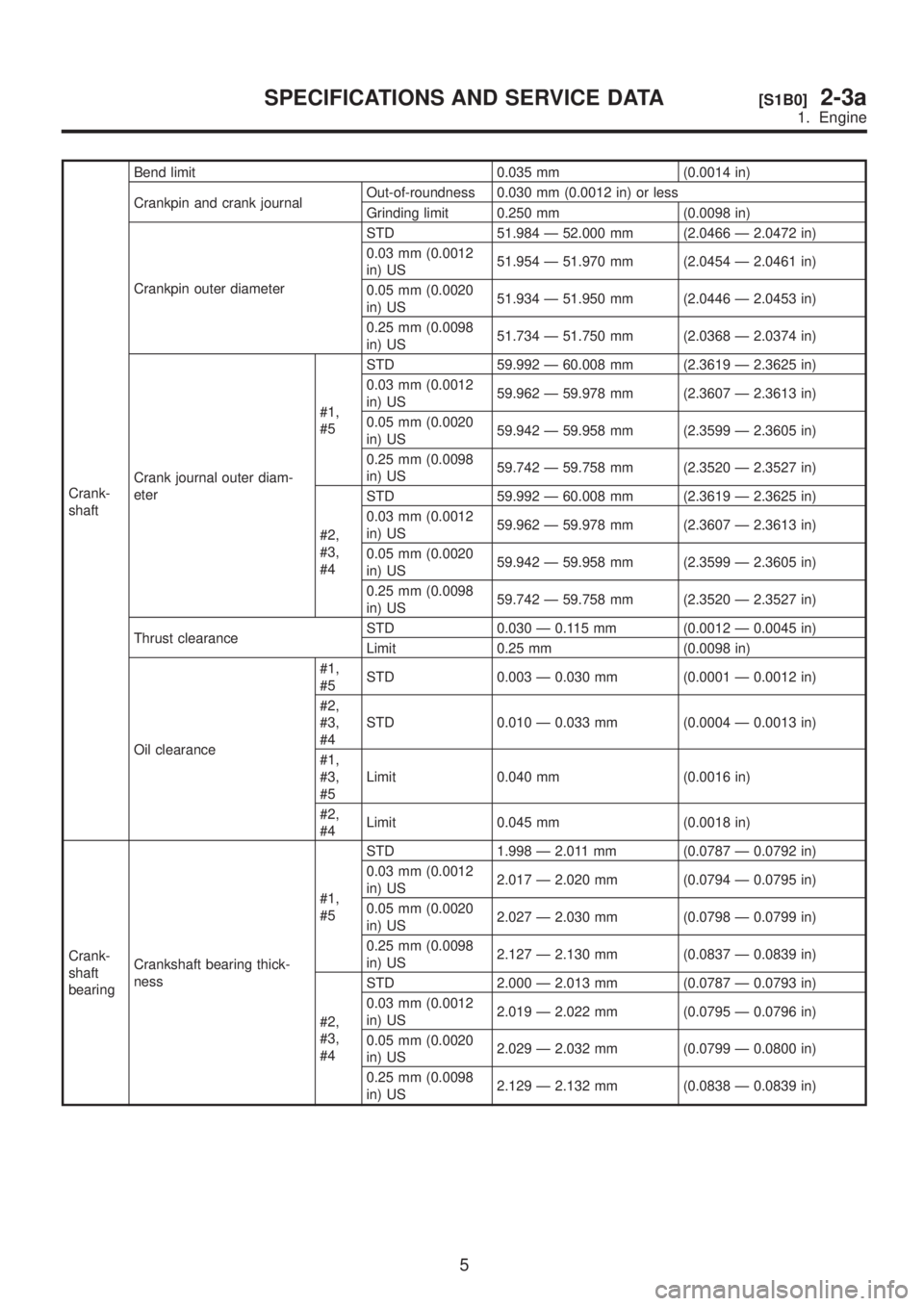

Crank-

shaftBend limit 0.035 mm (0.0014 in)

Crankpin and crank journalOut-of-roundness 0.030 mm (0.0012 in) or less

Grinding limit 0.250 mm (0.0098 in)

Crankpin outer diameterSTD 51.984 Ð 52.000 mm (2.0466 Ð 2.0472 in)

0.03 mm (0.0012

in) US51.954 Ð 51.970 mm (2.0454 Ð 2.0461 in)

0.05 mm (0.0020

in) US51.934 Ð 51.950 mm (2.0446 Ð 2.0453 in)

0.25 mm (0.0098

in) US51.734 Ð 51.750 mm (2.0368 Ð 2.0374 in)

Crank journal outer diam-

eter#1,

#5STD 59.992 Ð 60.008 mm (2.3619 Ð 2.3625 in)

0.03 mm (0.0012

in) US59.962 Ð 59.978 mm (2.3607 Ð 2.3613 in)

0.05 mm (0.0020

in) US59.942 Ð 59.958 mm (2.3599 Ð 2.3605 in)

0.25 mm (0.0098

in) US59.742 Ð 59.758 mm (2.3520 Ð 2.3527 in)

#2,

#3,

#4STD 59.992 Ð 60.008 mm (2.3619 Ð 2.3625 in)

0.03 mm (0.0012

in) US59.962 Ð 59.978 mm (2.3607 Ð 2.3613 in)

0.05 mm (0.0020

in) US59.942 Ð 59.958 mm (2.3599 Ð 2.3605 in)

0.25 mm (0.0098

in) US59.742 Ð 59.758 mm (2.3520 Ð 2.3527 in)

Thrust clearanceSTD 0.030 Ð 0.115 mm (0.0012 Ð 0.0045 in)

Limit 0.25 mm (0.0098 in)

Oil clearance#1,

#5STD 0.003 Ð 0.030 mm (0.0001 Ð 0.0012 in)

#2,

#3,

#4STD 0.010 Ð 0.033 mm (0.0004 Ð 0.0013 in)

#1,

#3,

#5Limit 0.040 mm (0.0016 in)

#2,

#4Limit 0.045 mm (0.0018 in)

Crank-

shaft

bearingCrankshaft bearing thick-

ness#1,

#5STD 1.998 Ð 2.011 mm (0.0787 Ð 0.0792 in)

0.03 mm (0.0012

in) US2.017 Ð 2.020 mm (0.0794 Ð 0.0795 in)

0.05 mm (0.0020

in) US2.027 Ð 2.030 mm (0.0798 Ð 0.0799 in)

0.25 mm (0.0098

in) US2.127 Ð 2.130 mm (0.0837 Ð 0.0839 in)

#2,

#3,

#4STD 2.000 Ð 2.013 mm (0.0787 Ð 0.0793 in)

0.03 mm (0.0012

in) US2.019 Ð 2.022 mm (0.0795 Ð 0.0796 in)

0.05 mm (0.0020

in) US2.029 Ð 2.032 mm (0.0799 Ð 0.0800 in)

0.25 mm (0.0098

in) US2.129 Ð 2.132 mm (0.0838 Ð 0.0839 in)

5

[S1B0]2-3aSPECIFICATIONS AND SERVICE DATA

1. Engine

Page 72 of 1456

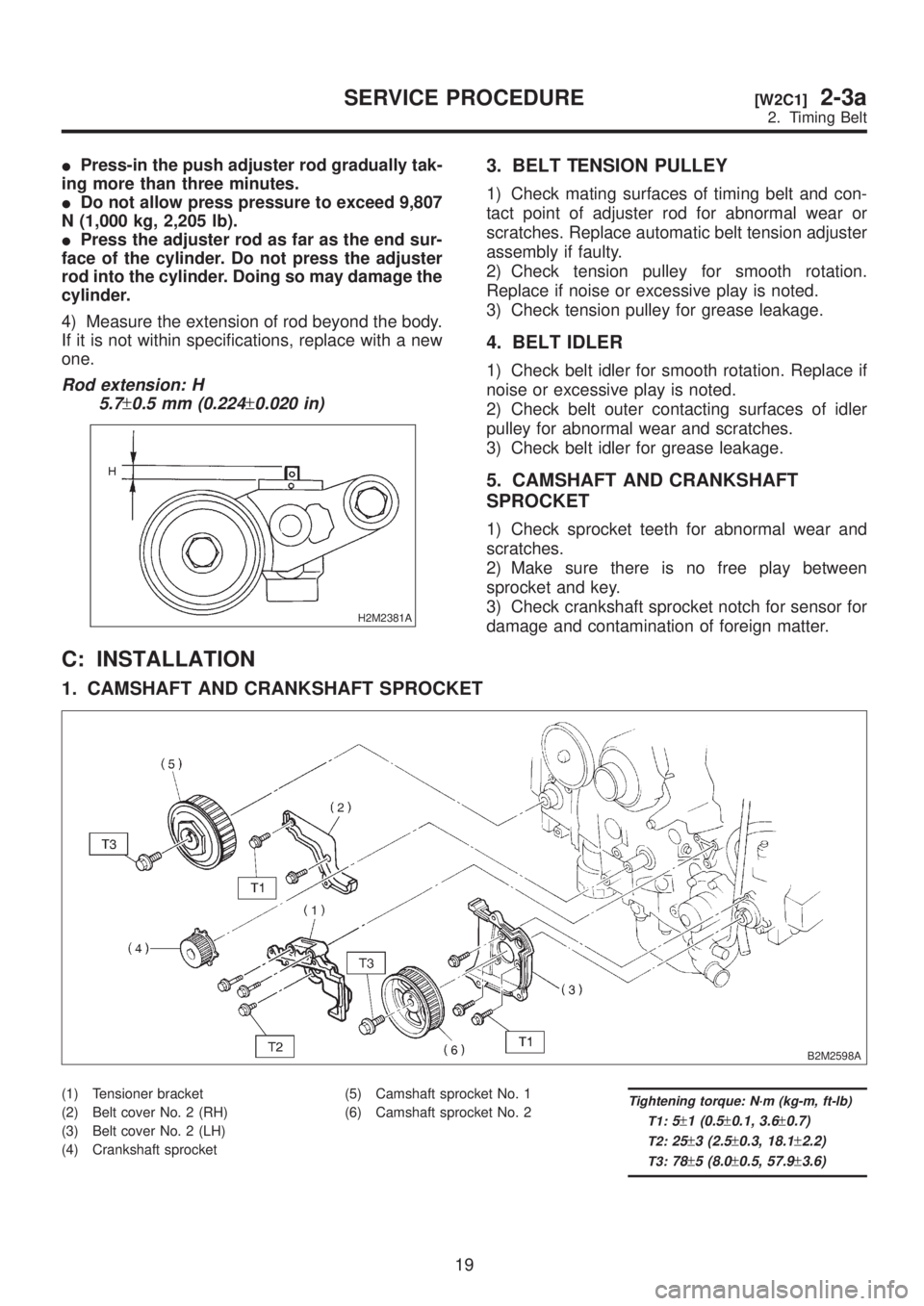

IPress-in the push adjuster rod gradually tak-

ing more than three minutes.

IDo not allow press pressure to exceed 9,807

N (1,000 kg, 2,205 lb).

IPress the adjuster rod as far as the end sur-

face of the cylinder. Do not press the adjuster

rod into the cylinder. Doing so may damage the

cylinder.

4) Measure the extension of rod beyond the body.

If it is not within specifications, replace with a new

one.

Rod extension: H

5.7

±0.5 mm (0.224±0.020 in)

H2M2381A

3. BELT TENSION PULLEY

1) Check mating surfaces of timing belt and con-

tact point of adjuster rod for abnormal wear or

scratches. Replace automatic belt tension adjuster

assembly if faulty.

2) Check tension pulley for smooth rotation.

Replace if noise or excessive play is noted.

3) Check tension pulley for grease leakage.

4. BELT IDLER

1) Check belt idler for smooth rotation. Replace if

noise or excessive play is noted.

2) Check belt outer contacting surfaces of idler

pulley for abnormal wear and scratches.

3) Check belt idler for grease leakage.

5. CAMSHAFT AND CRANKSHAFT

SPROCKET

1) Check sprocket teeth for abnormal wear and

scratches.

2) Make sure there is no free play between

sprocket and key.

3) Check crankshaft sprocket notch for sensor for

damage and contamination of foreign matter.

C: INSTALLATION

1. CAMSHAFT AND CRANKSHAFT SPROCKET

B2M2598A

(1) Tensioner bracket

(2) Belt cover No. 2 (RH)

(3) Belt cover No. 2 (LH)

(4) Crankshaft sprocket(5) Camshaft sprocket No. 1

(6) Camshaft sprocket No. 2Tightening torque: N´m (kg-m, ft-lb)

T1:

5±1 (0.5±0.1, 3.6±0.7)

T2:25±3 (2.5±0.3, 18.1±2.2)

T3:78±5 (8.0±0.5, 57.9±3.6)

19

[W2C1]2-3aSERVICE PROCEDURE

2. Timing Belt

Page 83 of 1456

C: INSPECTION

1. VALVE ROCKER ARM

1) Measure inside diameter of valve rocker arm

and outside diameter of valve rocker shaft, and

determine the difference between the two (= oil

clearance).

Clearance between arm and shaft:

Standard

0.020 Ð 0.054 mm (0.0008 Ð 0.0021 in)

Limit

0.10 mm (0.0039 in)

IIf oil clearance exceeds specifications, replace

valve rocker arm or shaft.

NOTE:

Replace valve rocker arm or shaft, whichever

shows greater amount of wear.

Rocker arm inside diameter:

22.020 Ð 22.041 mm (0.8669 Ð 0.8678 in)

Rocker shaft diameter:

21.987 Ð 22.000 mm (0.8656 Ð 0.8661 in)

B2M0072

B2M0073

2) Measure inside diameter of rocker shaft sup-

port and outside diameter of valve rocker shaft,

and determine the difference between the two (=

oil clearance).

Clearance between support and shaft:

Standard

0.005 Ð 0.039 mm (0.0002 Ð 0.0015 in)

Limit

0.05 mm (0.0020 in)

IIf oil clearance exceeds specifications, replace

rocker shaft support or shaft.

NOTE:

Replace rocker shaft support or shaft, whichever

shows greater amount of wear.

Rocker shaft support inside diameter:

22.005 Ð 22.026 mm (0.8663 Ð 0.8672 in)

Rocker shaft diameter:

21.987 Ð 22.000 mm (0.8656 Ð 0.8661 in)

3) If cam or valve contact surface of valve rocker

arm is worn or dented excessively, replace valve

rocker arm.

4) Check that valve rocker arm roller rotates

smoothly. If not, replace valve rocker arm.

2. INTAKE AND EXHAUST VALVE

ROCKER SHAFT

Visually check oil relief valve of shaft end for any

of the following abnormalities.

IBreaks in check ball body

IForeign particles caught in valve spring

IOil leakage at check ball

CAUTION:

Repair or replace valve rocker shaft as neces-

sary.

29

[W3C2]2-3aSERVICE PROCEDURE

3. Valve Rocker Assembly

Page 89 of 1456

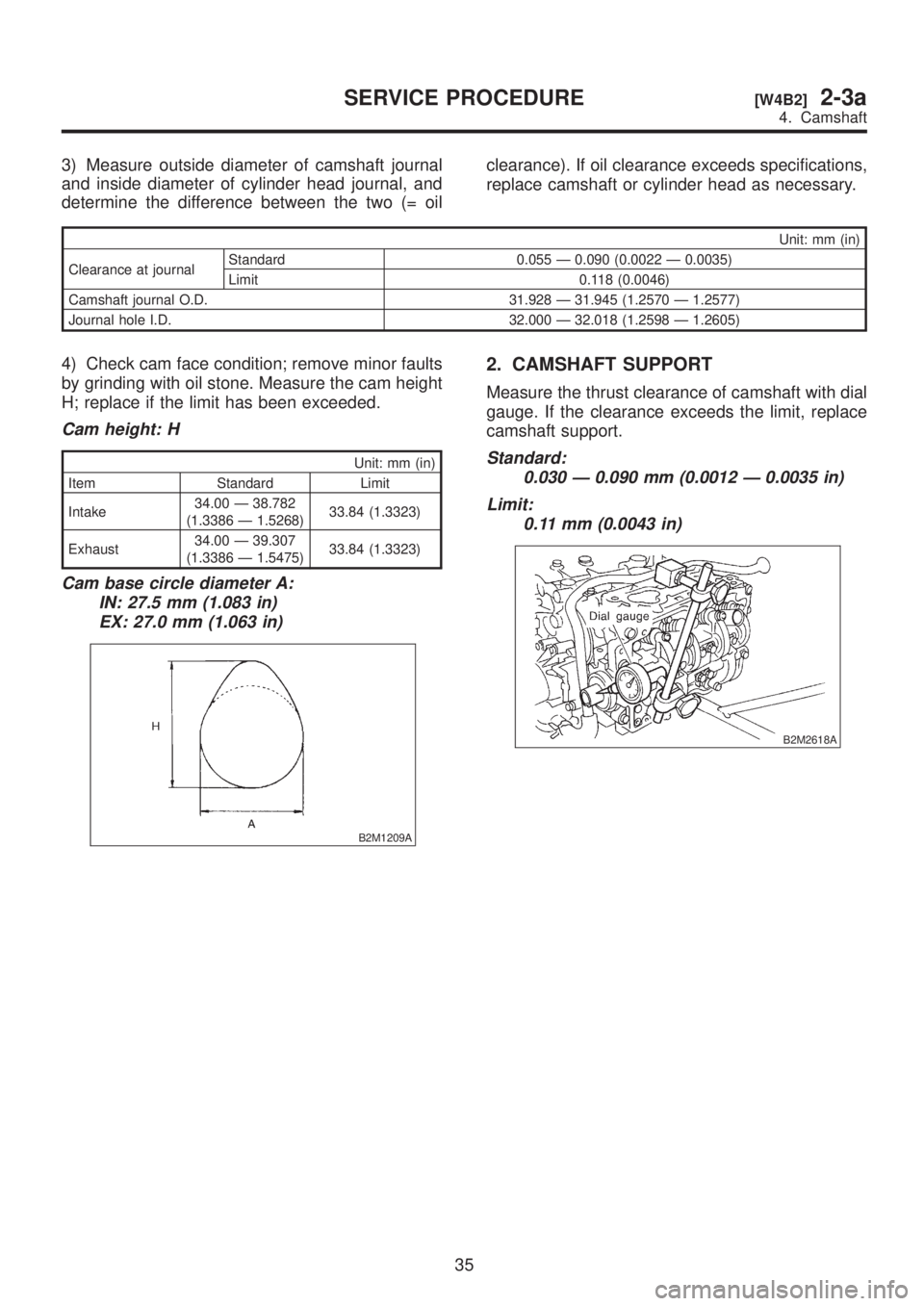

3) Measure outside diameter of camshaft journal

and inside diameter of cylinder head journal, and

determine the difference between the two (= oilclearance). If oil clearance exceeds specifications,

replace camshaft or cylinder head as necessary.

Unit: mm (in)

Clearance at journalStandard 0.055 Ð 0.090 (0.0022 Ð 0.0035)

Limit 0.118 (0.0046)

Camshaft journal O.D. 31.928 Ð 31.945 (1.2570 Ð 1.2577)

Journal hole I.D. 32.000 Ð 32.018 (1.2598 Ð 1.2605)

4) Check cam face condition; remove minor faults

by grinding with oil stone. Measure the cam height

H; replace if the limit has been exceeded.

Cam height: H

Unit: mm (in)

Item Standard Limit

Intake34.00 Ð 38.782

(1.3386 Ð 1.5268)33.84 (1.3323)

Exhaust34.00 Ð 39.307

(1.3386 Ð 1.5475)33.84 (1.3323)

Cam base circle diameter A:

IN: 27.5 mm (1.083 in)

EX: 27.0 mm (1.063 in)

B2M1209A

2. CAMSHAFT SUPPORT

Measure the thrust clearance of camshaft with dial

gauge. If the clearance exceeds the limit, replace

camshaft support.

Standard:

0.030 Ð 0.090 mm (0.0012 Ð 0.0035 in)

Limit:

0.11 mm (0.0043 in)

B2M2618A

35

[W4B2]2-3aSERVICE PROCEDURE

4. Camshaft