specifications SUBARU LEGACY 1999 Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 100 of 1456

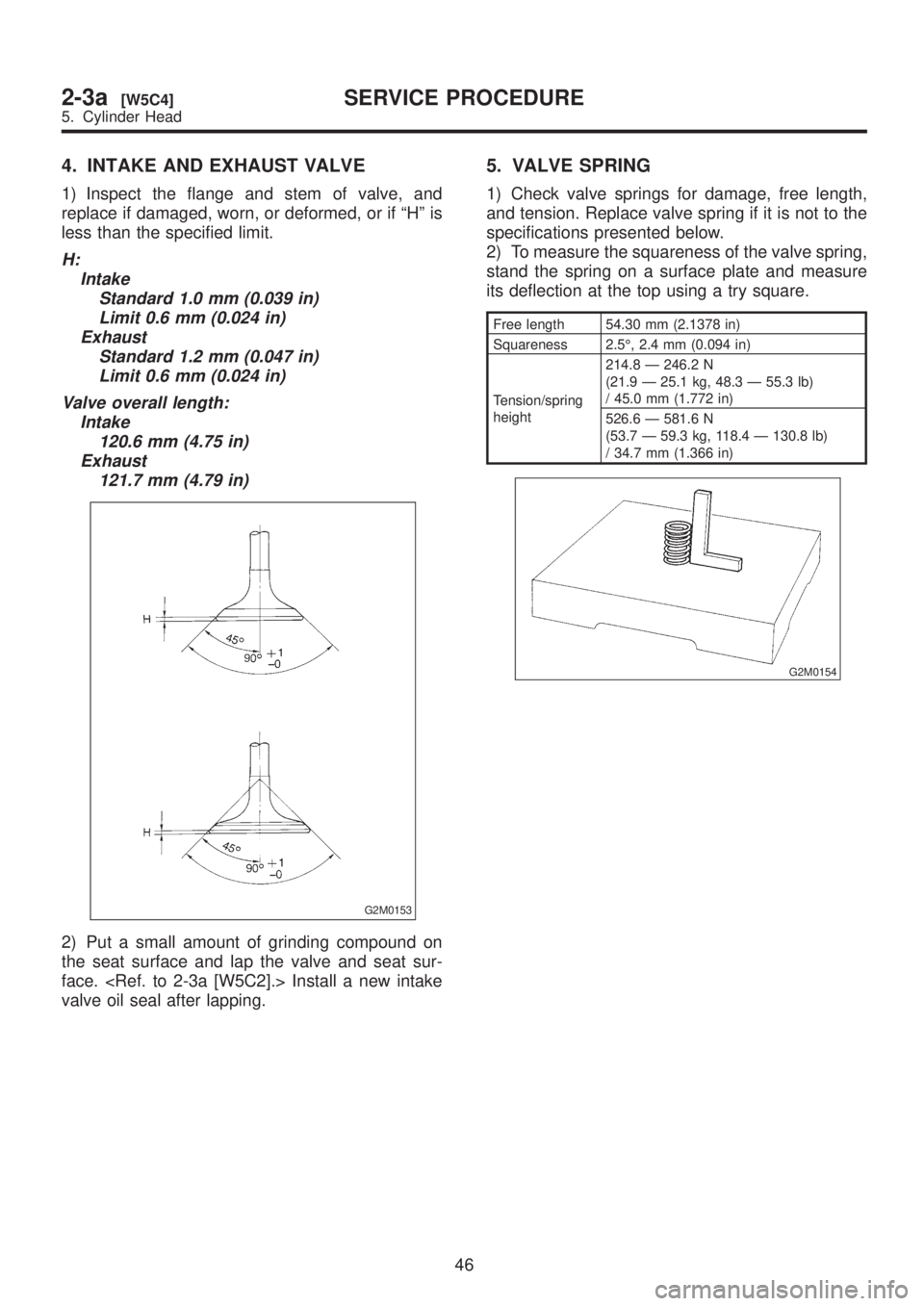

4. INTAKE AND EXHAUST VALVE

1) Inspect the flange and stem of valve, and

replace if damaged, worn, or deformed, or if ªHº is

less than the specified limit.

H:

Intake

Standard 1.0 mm (0.039 in)

Limit 0.6 mm (0.024 in)

Exhaust

Standard 1.2 mm (0.047 in)

Limit 0.6 mm (0.024 in)

Valve overall length:

Intake

120.6 mm (4.75 in)

Exhaust

121.7 mm (4.79 in)

G2M0153

2) Put a small amount of grinding compound on

the seat surface and lap the valve and seat sur-

face.

valve oil seal after lapping.

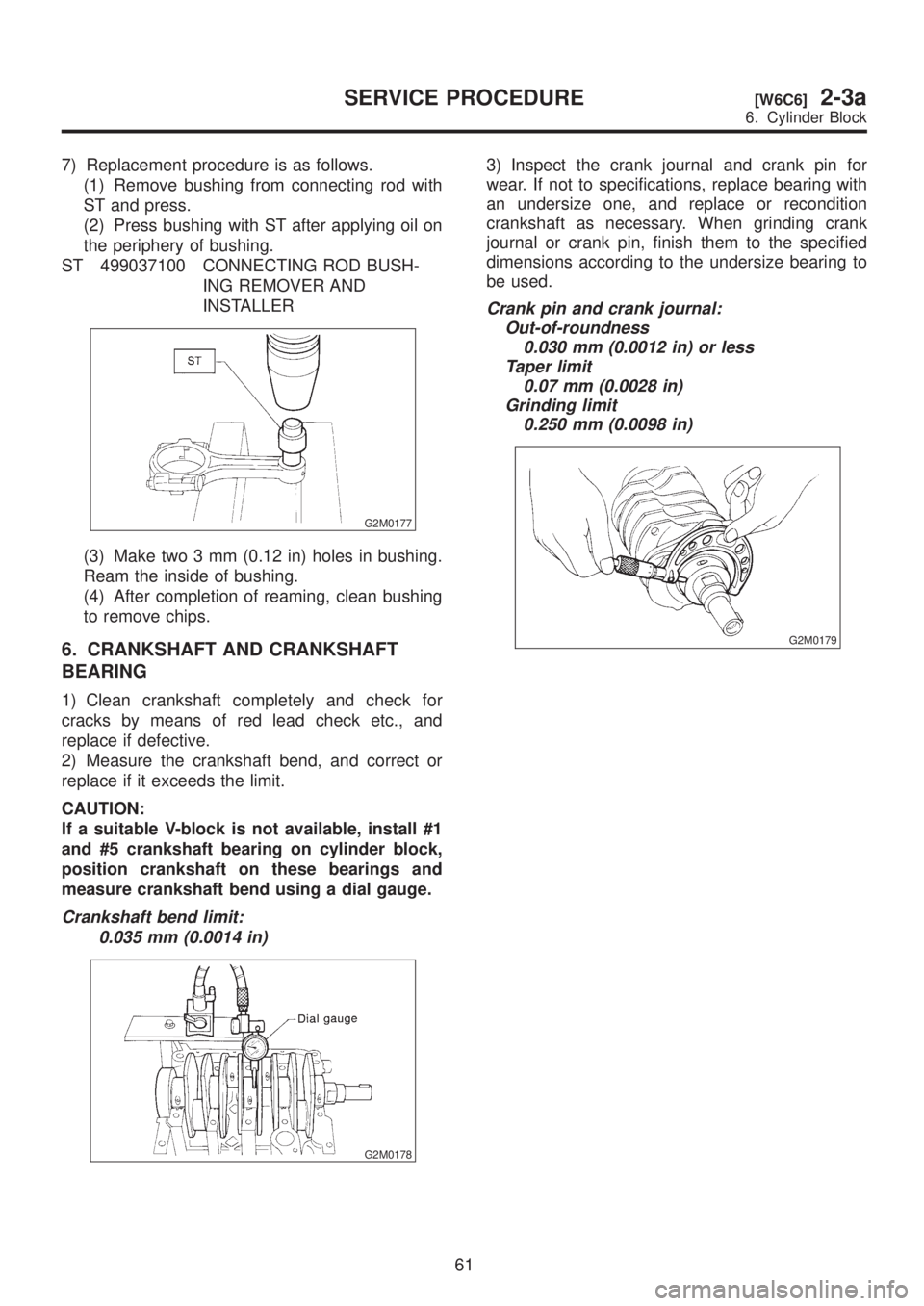

5. VALVE SPRING

1) Check valve springs for damage, free length,

and tension. Replace valve spring if it is not to the

specifications presented below.

2) To measure the squareness of the valve spring,

stand the spring on a surface plate and measure

its deflection at the top using a try square.

Free length 54.30 mm (2.1378 in)

Squareness 2.5É, 2.4 mm (0.094 in)

Tension/spring

height214.8 Ð 246.2 N

(21.9 Ð 25.1 kg, 48.3 Ð 55.3 lb)

/ 45.0 mm (1.772 in)

526.6 Ð 581.6 N

(53.7 Ð 59.3 kg, 118.4 Ð 130.8 lb)

/ 34.7 mm (1.366 in)

G2M0154

46

2-3a[W5C4]SERVICE PROCEDURE

5. Cylinder Head

Page 115 of 1456

7) Replacement procedure is as follows.

(1) Remove bushing from connecting rod with

ST and press.

(2) Press bushing with ST after applying oil on

the periphery of bushing.

ST 499037100 CONNECTING ROD BUSH-

ING REMOVER AND

INSTALLER

G2M0177

(3) Make two 3 mm (0.12 in) holes in bushing.

Ream the inside of bushing.

(4) After completion of reaming, clean bushing

to remove chips.

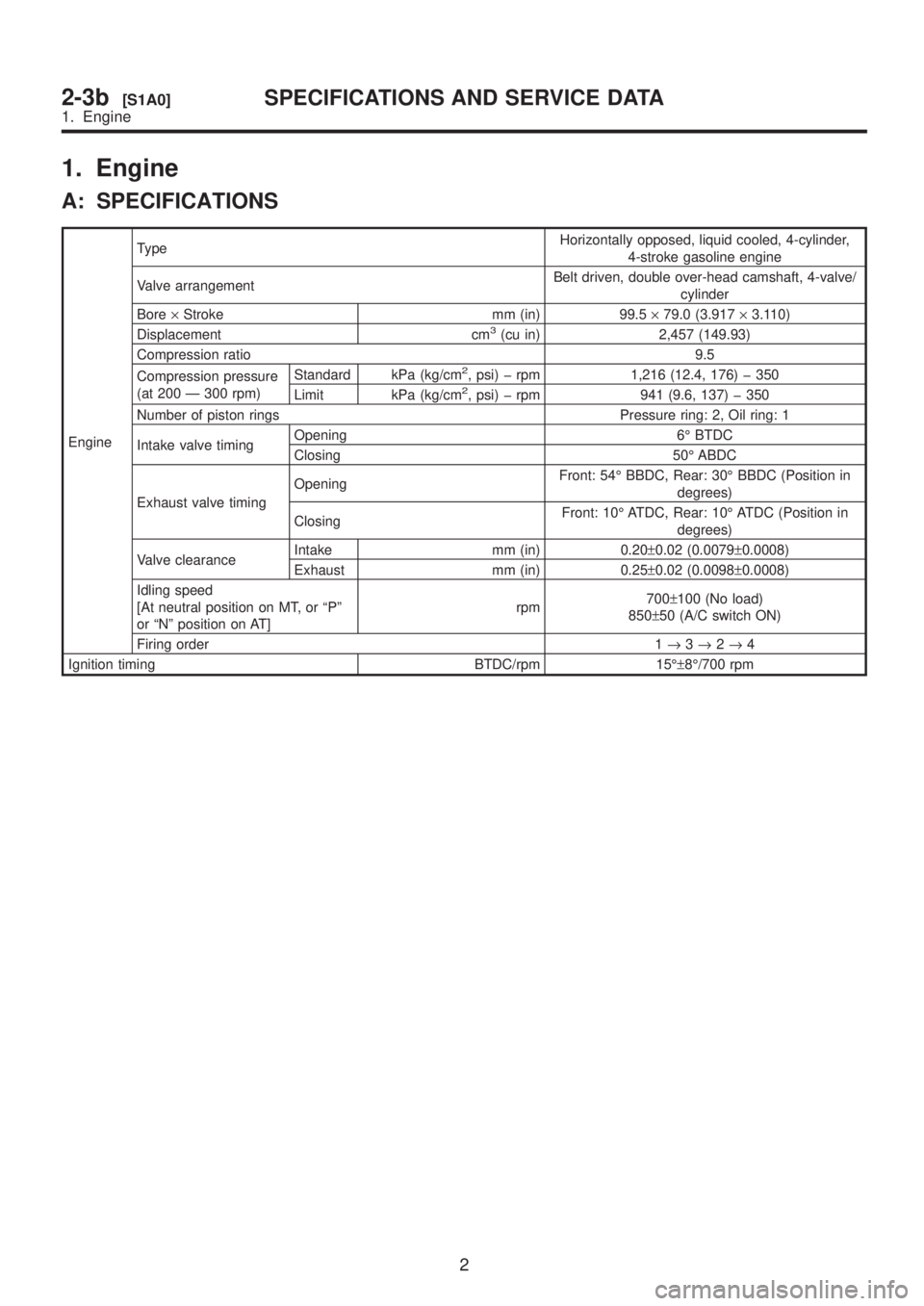

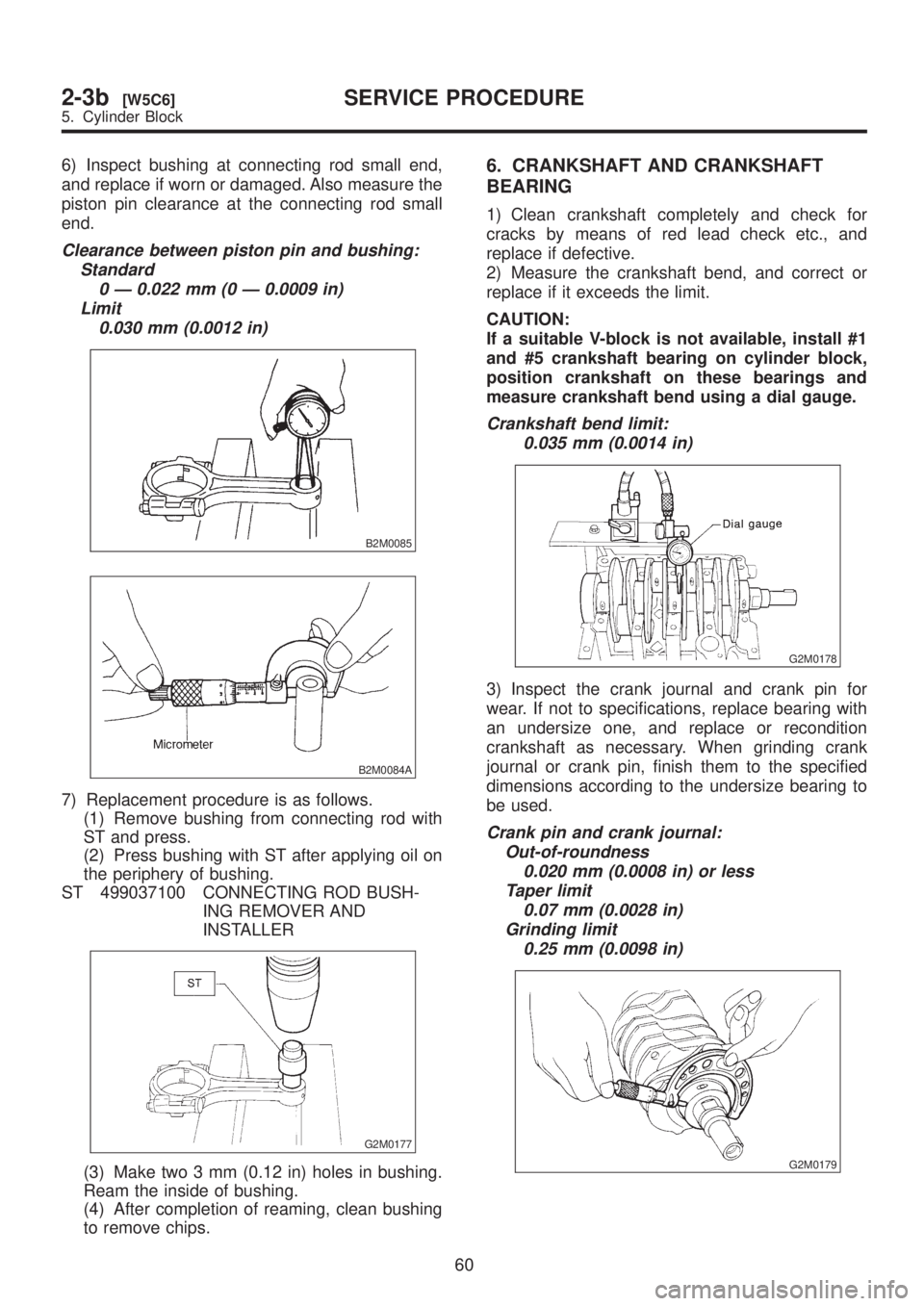

6. CRANKSHAFT AND CRANKSHAFT

BEARING

1) Clean crankshaft completely and check for

cracks by means of red lead check etc., and

replace if defective.

2) Measure the crankshaft bend, and correct or

replace if it exceeds the limit.

CAUTION:

If a suitable V-block is not available, install #1

and #5 crankshaft bearing on cylinder block,

position crankshaft on these bearings and

measure crankshaft bend using a dial gauge.

Crankshaft bend limit:

0.035 mm (0.0014 in)

G2M0178

3) Inspect the crank journal and crank pin for

wear. If not to specifications, replace bearing with

an undersize one, and replace or recondition

crankshaft as necessary. When grinding crank

journal or crank pin, finish them to the specified

dimensions according to the undersize bearing to

be used.

Crank pin and crank journal:

Out-of-roundness

0.030 mm (0.0012 in) or less

Taper limit

0.07 mm (0.0028 in)

Grinding limit

0.250 mm (0.0098 in)

G2M0179

61

[W6C6]2-3aSERVICE PROCEDURE

6. Cylinder Block

Page 133 of 1456

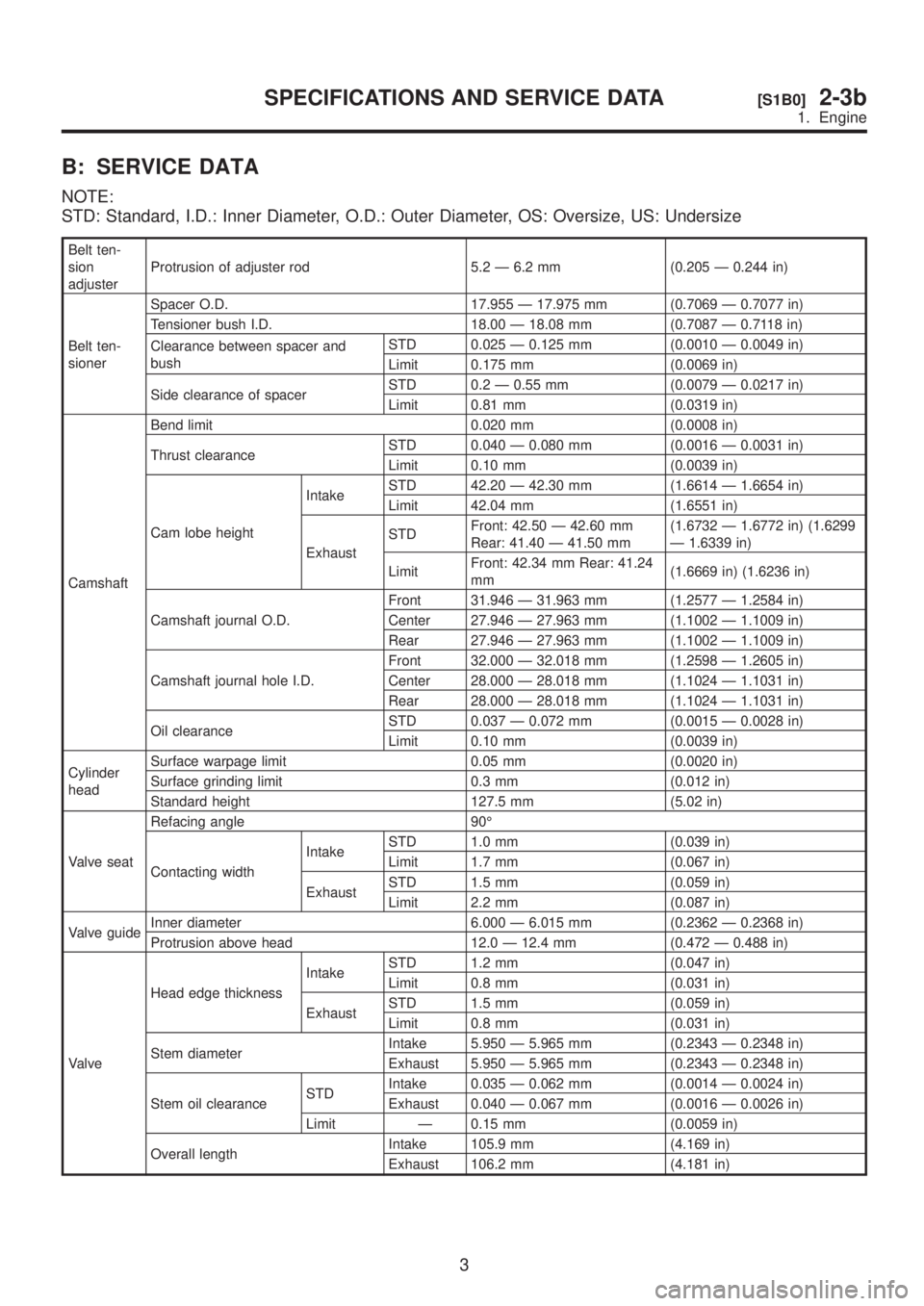

1. Engine

A: SPECIFICATIONS

EngineTypeHorizontally opposed, liquid cooled, 4-cylinder,

4-stroke gasoline engine

Valve arrangementBelt driven, double over-head camshaft, 4-valve/

cylinder

Bore´Stroke mm (in) 99.5´79.0 (3.917´3.110)

Displacement cm

3(cu in) 2,457 (149.93)

Compression ratio 9.5

Compression pressure

(at 200 Ð 300 rpm)Standard kPa (kg/cm

2, psi) þ rpm 1,216 (12.4, 176) þ 350

Limit kPa (kg/cm2, psi) þ rpm 941 (9.6, 137) þ 350

Number of piston rings Pressure ring: 2, Oil ring: 1

Intake valve timingOpening 6É BTDC

Closing 50É ABDC

Exhaust valve timingOpeningFront: 54É BBDC, Rear: 30É BBDC (Position in

degrees)

ClosingFront: 10É ATDC, Rear: 10É ATDC (Position in

degrees)

Valve clearanceIntake mm (in) 0.20±0.02 (0.0079±0.0008)

Exhaust mm (in) 0.25±0.02 (0.0098±0.0008)

Idling speed

[At neutral position on MT, or ªPº

or ªNº position on AT]rpm700±100 (No load)

850±50 (A/C switch ON)

Firing order 1®3®2®4

Ignition timing BTDC/rpm 15ɱ8É/700 rpm

2

2-3b[S1A0]SPECIFICATIONS AND SERVICE DATA

1. Engine

Page 134 of 1456

B: SERVICE DATA

NOTE:

STD: Standard, I.D.: Inner Diameter, O.D.: Outer Diameter, OS: Oversize, US: Undersize

Belt ten-

sion

adjusterProtrusion of adjuster rod 5.2 Ð 6.2 mm (0.205 Ð 0.244 in)

Belt ten-

sionerSpacer O.D. 17.955 Ð 17.975 mm (0.7069 Ð 0.7077 in)

Tensioner bush I.D. 18.00 Ð 18.08 mm (0.7087 Ð 0.7118 in)

Clearance between spacer and

bushSTD 0.025 Ð 0.125 mm (0.0010 Ð 0.0049 in)

Limit 0.175 mm (0.0069 in)

Side clearance of spacerSTD 0.2 Ð 0.55 mm (0.0079 Ð 0.0217 in)

Limit 0.81 mm (0.0319 in)

CamshaftBend limit 0.020 mm (0.0008 in)

Thrust clearanceSTD 0.040 Ð 0.080 mm (0.0016 Ð 0.0031 in)

Limit 0.10 mm (0.0039 in)

Cam lobe heightIntakeSTD 42.20 Ð 42.30 mm (1.6614 Ð 1.6654 in)

Limit 42.04 mm (1.6551 in)

ExhaustSTDFront: 42.50 Ð 42.60 mm

Rear: 41.40 Ð 41.50 mm(1.6732 Ð 1.6772 in) (1.6299

Ð 1.6339 in)

LimitFront: 42.34 mm Rear: 41.24

mm(1.6669 in) (1.6236 in)

Camshaft journal O.D.Front 31.946 Ð 31.963 mm (1.2577 Ð 1.2584 in)

Center 27.946 Ð 27.963 mm (1.1002 Ð 1.1009 in)

Rear 27.946 Ð 27.963 mm (1.1002 Ð 1.1009 in)

Camshaft journal hole I.D.Front 32.000 Ð 32.018 mm (1.2598 Ð 1.2605 in)

Center 28.000 Ð 28.018 mm (1.1024 Ð 1.1031 in)

Rear 28.000 Ð 28.018 mm (1.1024 Ð 1.1031 in)

Oil clearanceSTD 0.037 Ð 0.072 mm (0.0015 Ð 0.0028 in)

Limit 0.10 mm (0.0039 in)

Cylinder

headSurface warpage limit 0.05 mm (0.0020 in)

Surface grinding limit 0.3 mm (0.012 in)

Standard height 127.5 mm (5.02 in)

Valve seatRefacing angle 90É

Contacting widthIntakeSTD 1.0 mm (0.039 in)

Limit 1.7 mm (0.067 in)

ExhaustSTD 1.5 mm (0.059 in)

Limit 2.2 mm (0.087 in)

Valve guideInner diameter 6.000 Ð 6.015 mm (0.2362 Ð 0.2368 in)

Protrusion above head 12.0 Ð 12.4 mm (0.472 Ð 0.488 in)

ValveHead edge thicknessIntakeSTD 1.2 mm (0.047 in)

Limit 0.8 mm (0.031 in)

ExhaustSTD 1.5 mm (0.059 in)

Limit 0.8 mm (0.031 in)

Stem diameterIntake 5.950 Ð 5.965 mm (0.2343 Ð 0.2348 in)

Exhaust 5.950 Ð 5.965 mm (0.2343 Ð 0.2348 in)

Stem oil clearanceSTDIntake 0.035 Ð 0.062 mm (0.0014 Ð 0.0024 in)

Exhaust 0.040 Ð 0.067 mm (0.0016 Ð 0.0026 in)

Limit Ð 0.15 mm (0.0059 in)

Overall lengthIntake 105.9 mm (4.169 in)

Exhaust 106.2 mm (4.181 in)

3

[S1B0]2-3bSPECIFICATIONS AND SERVICE DATA

1. Engine

Page 135 of 1456

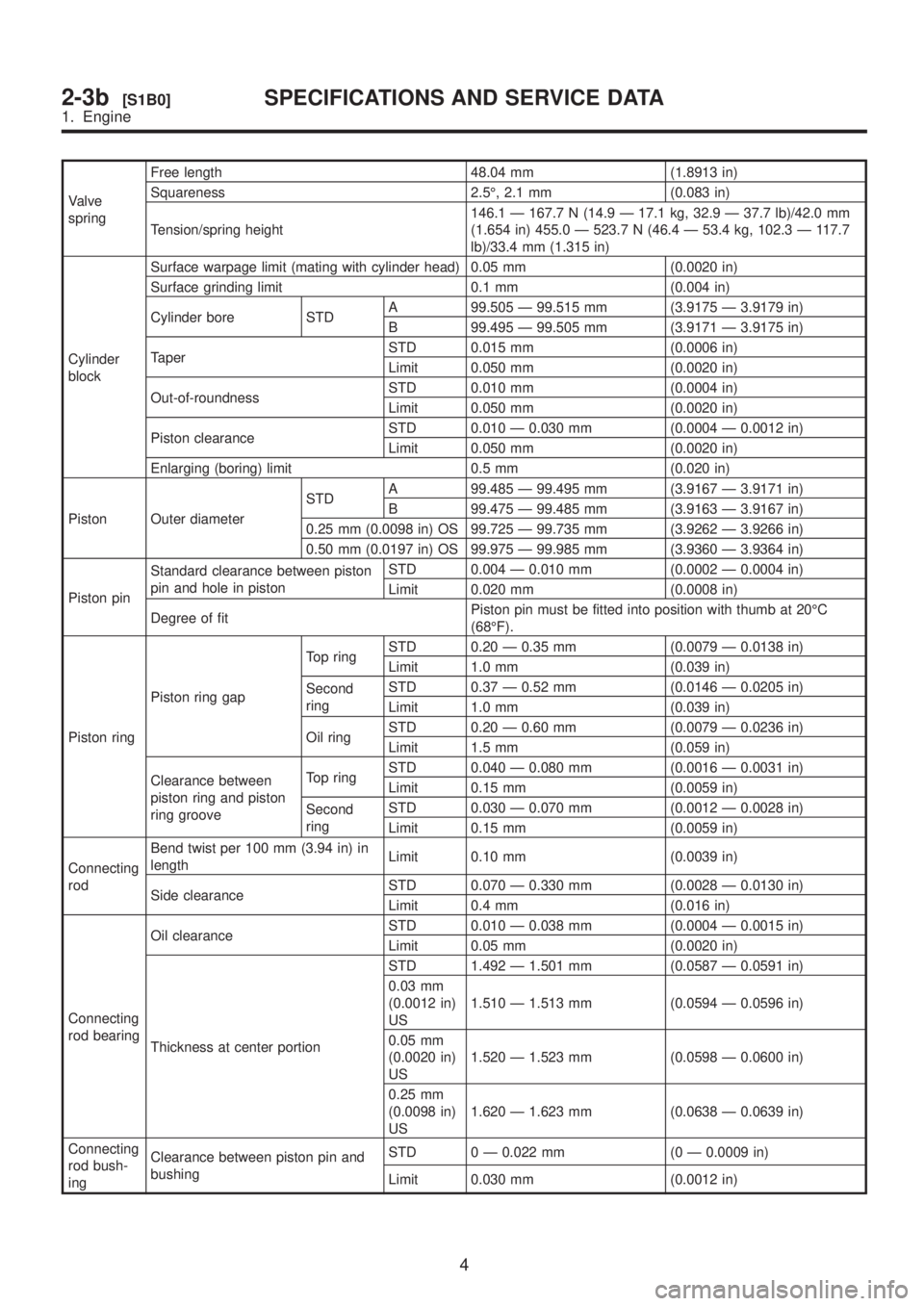

Valve

springFree length 48.04 mm (1.8913 in)

Squareness 2.5É, 2.1 mm (0.083 in)

Tension/spring height146.1 Ð 167.7 N (14.9 Ð 17.1 kg, 32.9 Ð 37.7 lb)/42.0 mm

(1.654 in) 455.0 Ð 523.7 N (46.4 Ð 53.4 kg, 102.3 Ð 117.7

lb)/33.4 mm (1.315 in)

Cylinder

blockSurface warpage limit (mating with cylinder head) 0.05 mm (0.0020 in)

Surface grinding limit 0.1 mm (0.004 in)

Cylinder bore STDA 99.505 Ð 99.515 mm (3.9175 Ð 3.9179 in)

B 99.495 Ð 99.505 mm (3.9171 Ð 3.9175 in)

TaperSTD 0.015 mm (0.0006 in)

Limit 0.050 mm (0.0020 in)

Out-of-roundnessSTD 0.010 mm (0.0004 in)

Limit 0.050 mm (0.0020 in)

Piston clearanceSTD 0.010 Ð 0.030 mm (0.0004 Ð 0.0012 in)

Limit 0.050 mm (0.0020 in)

Enlarging (boring) limit 0.5 mm (0.020 in)

Piston Outer diameterSTDA 99.485 Ð 99.495 mm (3.9167 Ð 3.9171 in)

B 99.475 Ð 99.485 mm (3.9163 Ð 3.9167 in)

0.25 mm (0.0098 in) OS 99.725 Ð 99.735 mm (3.9262 Ð 3.9266 in)

0.50 mm (0.0197 in) OS 99.975 Ð 99.985 mm (3.9360 Ð 3.9364 in)

Piston pinStandard clearance between piston

pin and hole in pistonSTD 0.004 Ð 0.010 mm (0.0002 Ð 0.0004 in)

Limit 0.020 mm (0.0008 in)

Degree of fitPiston pin must be fitted into position with thumb at 20ÉC

(68ÉF).

Piston ringPiston ring gapTop ringSTD 0.20 Ð 0.35 mm (0.0079 Ð 0.0138 in)

Limit 1.0 mm (0.039 in)

Second

ringSTD 0.37 Ð 0.52 mm (0.0146 Ð 0.0205 in)

Limit 1.0 mm (0.039 in)

Oil ringSTD 0.20 Ð 0.60 mm (0.0079 Ð 0.0236 in)

Limit 1.5 mm (0.059 in)

Clearance between

piston ring and piston

ring grooveTop ringSTD 0.040 Ð 0.080 mm (0.0016 Ð 0.0031 in)

Limit 0.15 mm (0.0059 in)

Second

ringSTD 0.030 Ð 0.070 mm (0.0012 Ð 0.0028 in)

Limit 0.15 mm (0.0059 in)

Connecting

rodBend twist per 100 mm (3.94 in) in

lengthLimit 0.10 mm (0.0039 in)

Side clearanceSTD 0.070 Ð 0.330 mm (0.0028 Ð 0.0130 in)

Limit 0.4 mm (0.016 in)

Connecting

rod bearingOil clearanceSTD 0.010 Ð 0.038 mm (0.0004 Ð 0.0015 in)

Limit 0.05 mm (0.0020 in)

Thickness at center portionSTD 1.492 Ð 1.501 mm (0.0587 Ð 0.0591 in)

0.03 mm

(0.0012 in)

US1.510 Ð 1.513 mm (0.0594 Ð 0.0596 in)

0.05 mm

(0.0020 in)

US1.520 Ð 1.523 mm (0.0598 Ð 0.0600 in)

0.25 mm

(0.0098 in)

US1.620 Ð 1.623 mm (0.0638 Ð 0.0639 in)

Connecting

rod bush-

ingClearance between piston pin and

bushingSTD 0 Ð 0.022 mm (0 Ð 0.0009 in)

Limit 0.030 mm (0.0012 in)

4

2-3b[S1B0]SPECIFICATIONS AND SERVICE DATA

1. Engine

Page 136 of 1456

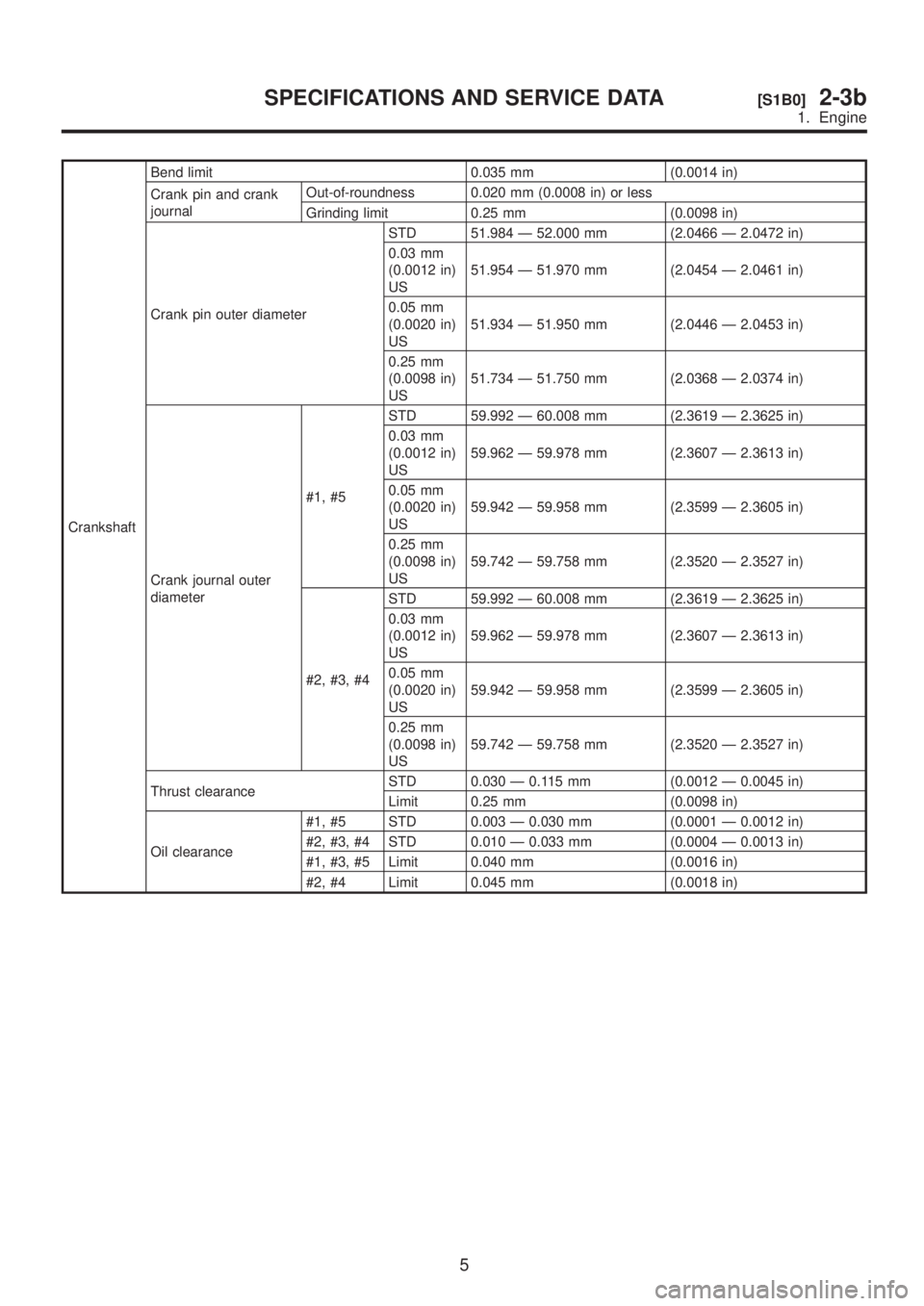

CrankshaftBend limit 0.035 mm (0.0014 in)

Crank pin and crank

journalOut-of-roundness 0.020 mm (0.0008 in) or less

Grinding limit 0.25 mm (0.0098 in)

Crank pin outer diameterSTD 51.984 Ð 52.000 mm (2.0466 Ð 2.0472 in)

0.03 mm

(0.0012 in)

US51.954 Ð 51.970 mm (2.0454 Ð 2.0461 in)

0.05 mm

(0.0020 in)

US51.934 Ð 51.950 mm (2.0446 Ð 2.0453 in)

0.25 mm

(0.0098 in)

US51.734 Ð 51.750 mm (2.0368 Ð 2.0374 in)

Crank journal outer

diameter#1, #5STD 59.992 Ð 60.008 mm (2.3619 Ð 2.3625 in)

0.03 mm

(0.0012 in)

US59.962 Ð 59.978 mm (2.3607 Ð 2.3613 in)

0.05 mm

(0.0020 in)

US59.942 Ð 59.958 mm (2.3599 Ð 2.3605 in)

0.25 mm

(0.0098 in)

US59.742 Ð 59.758 mm (2.3520 Ð 2.3527 in)

#2, #3, #4STD 59.992 Ð 60.008 mm (2.3619 Ð 2.3625 in)

0.03 mm

(0.0012 in)

US59.962 Ð 59.978 mm (2.3607 Ð 2.3613 in)

0.05 mm

(0.0020 in)

US59.942 Ð 59.958 mm (2.3599 Ð 2.3605 in)

0.25 mm

(0.0098 in)

US59.742 Ð 59.758 mm (2.3520 Ð 2.3527 in)

Thrust clearanceSTD 0.030 Ð 0.115 mm (0.0012 Ð 0.0045 in)

Limit 0.25 mm (0.0098 in)

Oil clearance#1, #5 STD 0.003 Ð 0.030 mm (0.0001 Ð 0.0012 in)

#2, #3, #4 STD 0.010 Ð 0.033 mm (0.0004 Ð 0.0013 in)

#1, #3, #5 Limit 0.040 mm (0.0016 in)

#2, #4 Limit 0.045 mm (0.0018 in)

5

[S1B0]2-3bSPECIFICATIONS AND SERVICE DATA

1. Engine

Page 137 of 1456

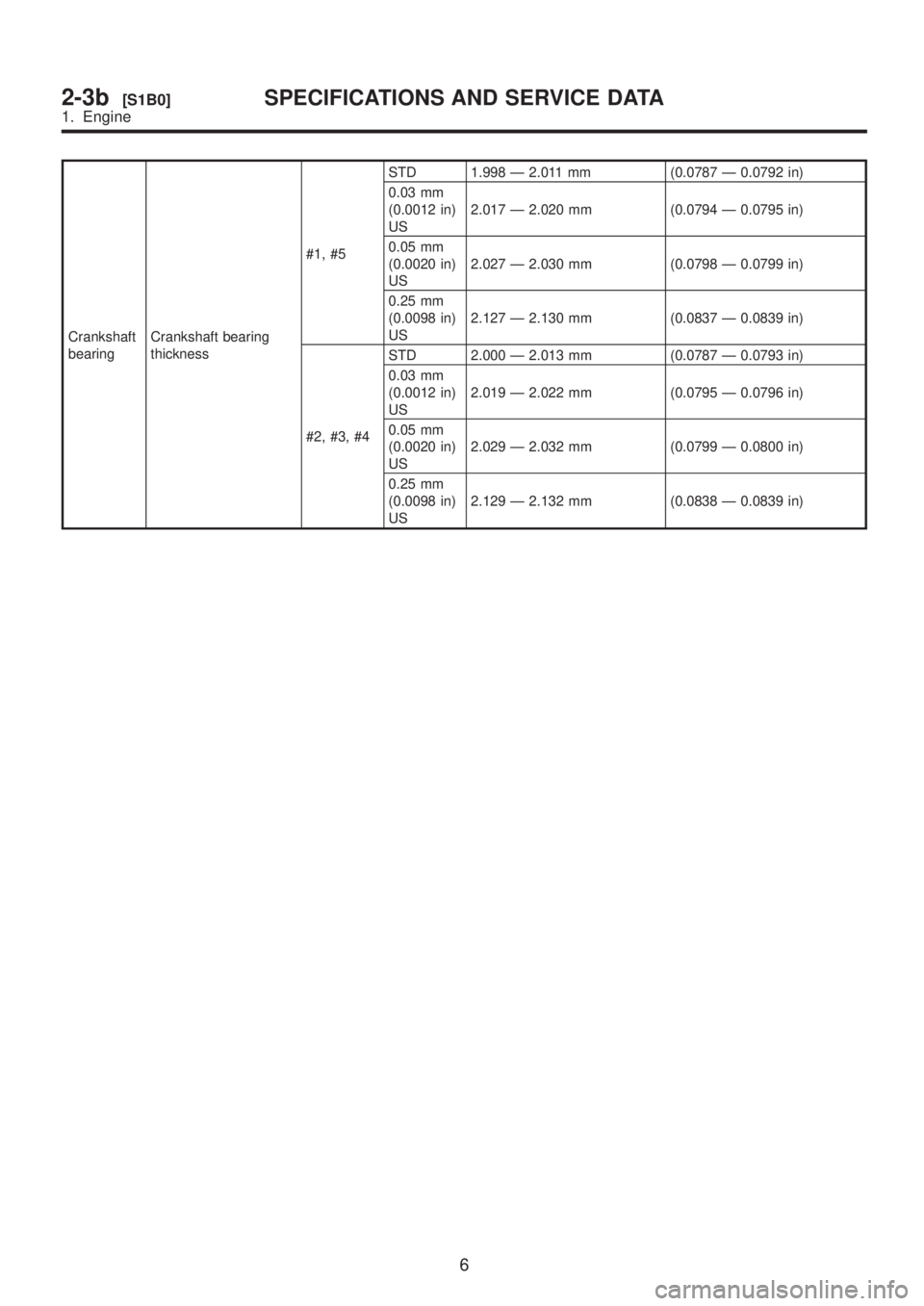

Crankshaft

bearingCrankshaft bearing

thickness#1, #5STD 1.998 Ð 2.011 mm (0.0787 Ð 0.0792 in)

0.03 mm

(0.0012 in)

US2.017 Ð 2.020 mm (0.0794 Ð 0.0795 in)

0.05 mm

(0.0020 in)

US2.027 Ð 2.030 mm (0.0798 Ð 0.0799 in)

0.25 mm

(0.0098 in)

US2.127 Ð 2.130 mm (0.0837 Ð 0.0839 in)

#2, #3, #4STD 2.000 Ð 2.013 mm (0.0787 Ð 0.0793 in)

0.03 mm

(0.0012 in)

US2.019 Ð 2.022 mm (0.0795 Ð 0.0796 in)

0.05 mm

(0.0020 in)

US2.029 Ð 2.032 mm (0.0799 Ð 0.0800 in)

0.25 mm

(0.0098 in)

US2.129 Ð 2.132 mm (0.0838 Ð 0.0839 in)

6

2-3b[S1B0]SPECIFICATIONS AND SERVICE DATA

1. Engine

Page 151 of 1456

(1) Slowly press the adjuster rod down to the

end surface of the cylinder. Repeat this motion

2 or 3 times.

(2) With the adjuster rod moved all the way up,

apply a pressure of 294 N (30 kg, 66 lb) to it.

Check adjuster rod stiffness.

(3) If the adjuster rod is not stiff and moves

down, replace the automatic belt tension

adjuster assembly with a new one.

CAUTION:

IAlways use a vertical type pressing tool to

move the adjuster rod down.

IDo not use a lateral type vise.

IPush adjuster rod vertically.

IPress-in the push adjuster rod gradually tak-

ing more than three minutes.

IDo not allow press pressure to exceed 9,807

N (1,000 kg, 2,205 lb).

IPress the adjuster rod as far as the end sur-

face of the cylinder. Do not press the adjuster

rod into the cylinder. Doing so may damage the

cylinder.

4) Measure the extension of rod beyond the body.

If it is not within specifications, replace with a new

one.

Rod extension: H

5.7

±0.5 mm (0.224±0.020 in)

H2M2381A

3. BELT TENSION PULLEY

1) Check mating surfaces of timing belt and con-

tact point of adjuster rod for abnormal wear or

scratches. Replace belt tension pulley if faulty.

2) Check belt tension pulley for smooth rotation.

Replace if noise or excessive play is noted.

3) Check belt tension pulley for grease leakage.

4. BELT IDLER

1) Check idler for smooth rotation. Replace if

noise or excessive play is noted.

2) Check outer contacting surfaces of idler pulley

for abnormal wear and scratches.

3) Check idler for grease leakage.

5. SPROCKET

1) Check sprocket teeth for abnormal wear and

scratches.

2) Make sure there is no free play between

sprocket and key.

3) Check crankshaft sprocket notch for sensor for

damage and contamination of foreign matter.

20

2-3b[W2B3]SERVICE PROCEDURE

2. Timing Belt

Page 172 of 1456

5. VALVE SPRINGS

1) Check valve springs for damage, free length,

and tension. Replace valve spring if it is not to the

specifications presented in the table.

2) To measure the squareness of the valve spring,

stand the spring on a surface plate and measure

its deflection at the top using a try square.

Valve spring

Free length 39.8 mm (1.567 in)

Tension/spring height228.5 Ð 261.8 N

(23.3 Ð 26.7 kg, 51.4 Ð 58.9

lb)/31.0 mm (1.220 in)

462.9 Ð 531.5 N

(47.2 Ð 54.2 kg, 104.1 Ð 119.5

lb)/23.2 mm (0.913 in)

Squareness 2.5É, 1.7 mm (0.067 in)

G2M0154

6. INTAKE AND EXHAUST VALVE OIL

SEAL

Replace oil seal with new one, if lip is damaged or

spring out of place, or when the surfaces of intake

valve and valve seat are reconditioned or intake

valve guide is replaced.

1) Place cylinder head on ST1.

2) Press in oil seal to the specified dimension indi-

cated in the figure by using ST2.

ST1 498267600 CYLINDER HEAD TABLE

ST2 498857100 VALVE OIL SEAL GUIDE

CAUTION:

IApply engine oil to oil seal before force-fit-

ting.

IDifferentiate between intake valve oil seal

and exhaust valve oil seal by noting their dif-

ference in color.

Color of rubber part:

Intake [Black]

Exhaust [Brown]

Color of spring part:

Intake [Silver]

Exhaust [Silver]

B2M1399A

7. VALVE LIFTER

1) Check valve lifter visually.

2) Measure outer diameter of valve lifter.

Outer diameter:

32.959 Ð 32.975 mm (1.2976 Ð 1.2982 in)

B2M1222

41

[W4C7]2-3bSERVICE PROCEDURE

4. Cylinder Head

Page 191 of 1456

6) Inspect bushing at connecting rod small end,

and replace if worn or damaged. Also measure the

piston pin clearance at the connecting rod small

end.

Clearance between piston pin and bushing:

Standard

0 Ð 0.022 mm (0 Ð 0.0009 in)

Limit

0.030 mm (0.0012 in)

B2M0085

B2M0084A

7) Replacement procedure is as follows.

(1) Remove bushing from connecting rod with

ST and press.

(2) Press bushing with ST after applying oil on

the periphery of bushing.

ST 499037100 CONNECTING ROD BUSH-

ING REMOVER AND

INSTALLER

G2M0177

(3) Make two 3 mm (0.12 in) holes in bushing.

Ream the inside of bushing.

(4) After completion of reaming, clean bushing

to remove chips.

6. CRANKSHAFT AND CRANKSHAFT

BEARING

1) Clean crankshaft completely and check for

cracks by means of red lead check etc., and

replace if defective.

2) Measure the crankshaft bend, and correct or

replace if it exceeds the limit.

CAUTION:

If a suitable V-block is not available, install #1

and #5 crankshaft bearing on cylinder block,

position crankshaft on these bearings and

measure crankshaft bend using a dial gauge.

Crankshaft bend limit:

0.035 mm (0.0014 in)

G2M0178

3) Inspect the crank journal and crank pin for

wear. If not to specifications, replace bearing with

an undersize one, and replace or recondition

crankshaft as necessary. When grinding crank

journal or crank pin, finish them to the specified

dimensions according to the undersize bearing to

be used.

Crank pin and crank journal:

Out-of-roundness

0.020 mm (0.0008 in) or less

Taper limit

0.07 mm (0.0028 in)

Grinding limit

0.25 mm (0.0098 in)

G2M0179

60

2-3b[W5C6]SERVICE PROCEDURE

5. Cylinder Block