sunroof SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 1057 of 1456

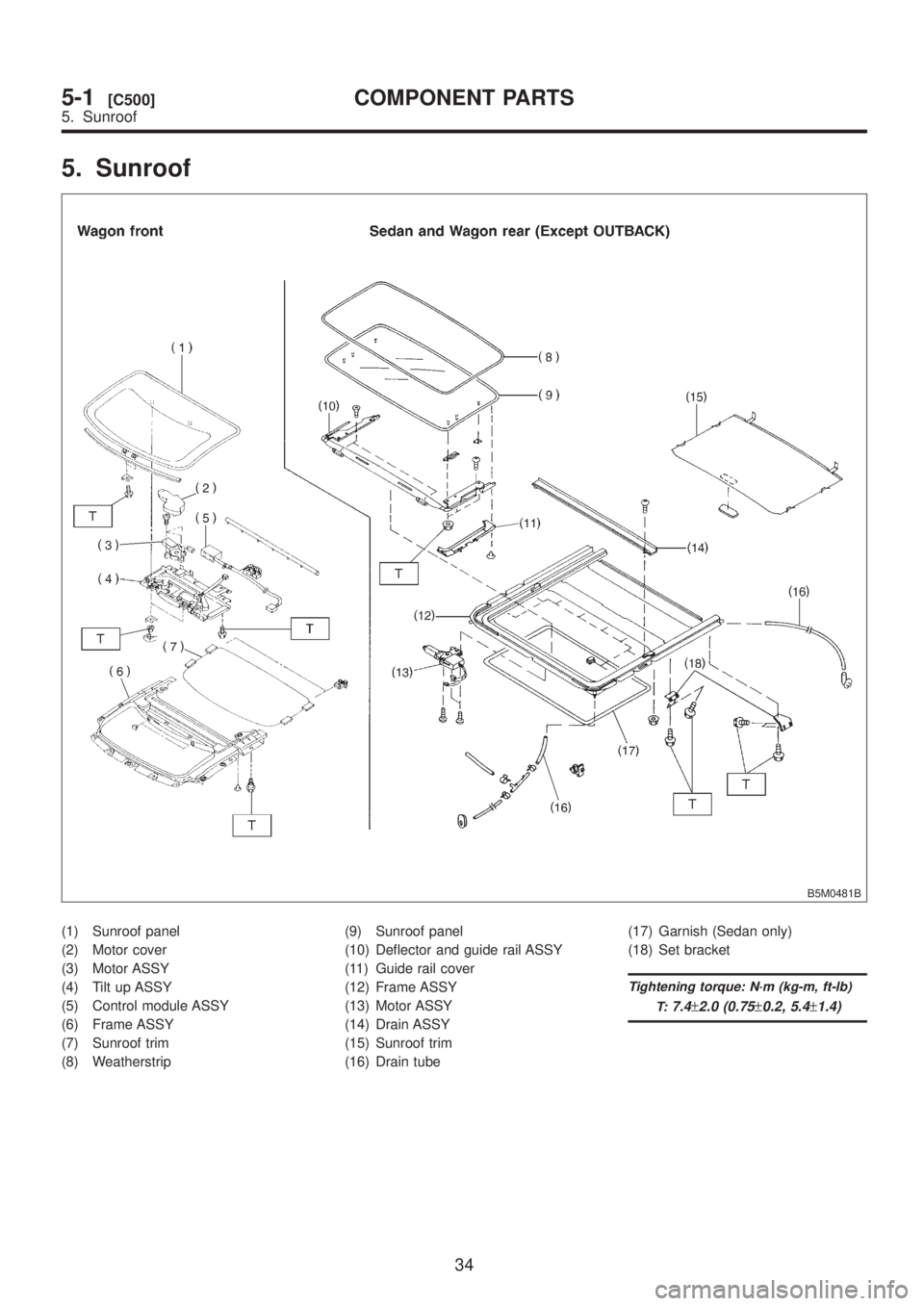

5. Sunroof

B5M0481B

(1) Sunroof panel

(2) Motor cover

(3) Motor ASSY

(4) Tilt up ASSY

(5) Control module ASSY

(6) Frame ASSY

(7) Sunroof trim

(8) Weatherstrip(9) Sunroof panel

(10) Deflector and guide rail ASSY

(11) Guide rail cover

(12) Frame ASSY

(13) Motor ASSY

(14) Drain ASSY

(15) Sunroof trim

(16) Drain tube(17) Garnish (Sedan only)

(18) Set bracket

Tightening torque: N´m (kg-m, ft-lb)

T:

7.4±2.0 (0.75±0.2, 5.4±1.4)

34

5-1[C500]COMPONENT PARTS

5. Sunroof

Page 1086 of 1456

16. Sunroof

A: REMOVAL AND INSTALLATION

1. SEDAN AND WAGON REAR (EXCEPT

OUTBACK)

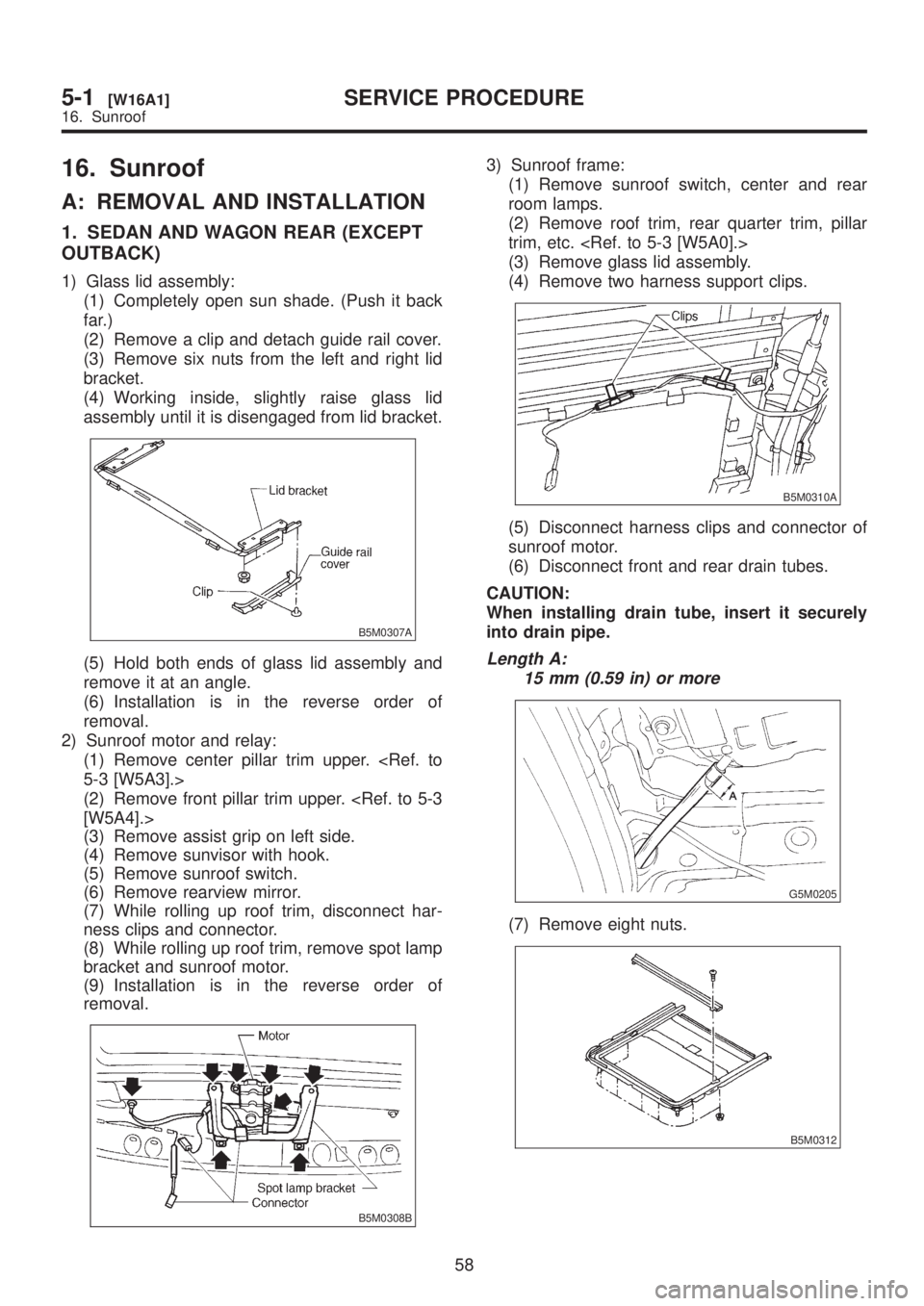

1) Glass lid assembly:

(1) Completely open sun shade. (Push it back

far.)

(2) Remove a clip and detach guide rail cover.

(3) Remove six nuts from the left and right lid

bracket.

(4) Working inside, slightly raise glass lid

assembly until it is disengaged from lid bracket.

B5M0307A

(5) Hold both ends of glass lid assembly and

remove it at an angle.

(6) Installation is in the reverse order of

removal.

2) Sunroof motor and relay:

(1) Remove center pillar trim upper.

(2) Remove front pillar trim upper.

(3) Remove assist grip on left side.

(4) Remove sunvisor with hook.

(5) Remove sunroof switch.

(6) Remove rearview mirror.

(7) While rolling up roof trim, disconnect har-

ness clips and connector.

(8) While rolling up roof trim, remove spot lamp

bracket and sunroof motor.

(9) Installation is in the reverse order of

removal.

B5M0308B

3) Sunroof frame:

(1) Remove sunroof switch, center and rear

room lamps.

(2) Remove roof trim, rear quarter trim, pillar

trim, etc.

(3) Remove glass lid assembly.

(4) Remove two harness support clips.

B5M0310A

(5) Disconnect harness clips and connector of

sunroof motor.

(6) Disconnect front and rear drain tubes.

CAUTION:

When installing drain tube, insert it securely

into drain pipe.

Length A:

15 mm (0.59 in) or more

G5M0205

(7) Remove eight nuts.

B5M0312

58

5-1[W16A1]SERVICE PROCEDURE

16. Sunroof

Page 1087 of 1456

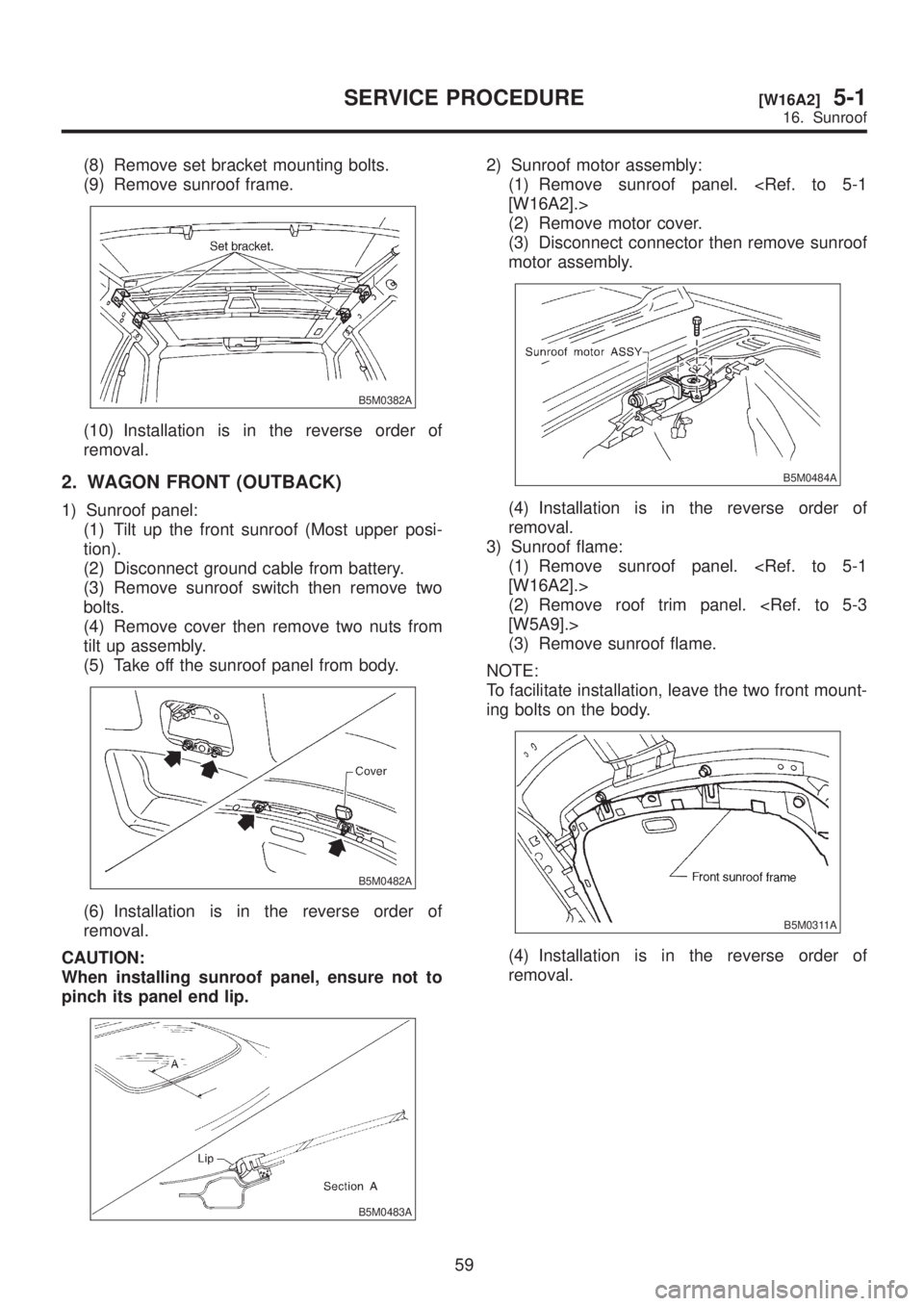

(8) Remove set bracket mounting bolts.

(9) Remove sunroof frame.

B5M0382A

(10) Installation is in the reverse order of

removal.

2. WAGON FRONT (OUTBACK)

1) Sunroof panel:

(1) Tilt up the front sunroof (Most upper posi-

tion).

(2) Disconnect ground cable from battery.

(3) Remove sunroof switch then remove two

bolts.

(4) Remove cover then remove two nuts from

tilt up assembly.

(5) Take off the sunroof panel from body.

B5M0482A

(6) Installation is in the reverse order of

removal.

CAUTION:

When installing sunroof panel, ensure not to

pinch its panel end lip.

B5M0483A

2) Sunroof motor assembly:

(1) Remove sunroof panel.

(2) Remove motor cover.

(3) Disconnect connector then remove sunroof

motor assembly.

B5M0484A

(4) Installation is in the reverse order of

removal.

3) Sunroof flame:

(1) Remove sunroof panel.

(2) Remove roof trim panel.

(3) Remove sunroof flame.

NOTE:

To facilitate installation, leave the two front mount-

ing bolts on the body.

B5M0311A

(4) Installation is in the reverse order of

removal.

59

[W16A2]5-1SERVICE PROCEDURE

16. Sunroof

Page 1088 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 4) Tilt up assembly:

(1) Remove sunroof flame. <Ref. to 5-1

[W16A2].>

(2) Remove tilt up assembly.

B5M0485A

(3) Installation is in the reverse order of

removal.

B: ADJUSTMENT

1. SEDAN AND WAGON REAR ( SUBARU LEGACY 1999 Service Repair Manual 4) Tilt up assembly:

(1) Remove sunroof flame. <Ref. to 5-1

[W16A2].>

(2) Remove tilt up assembly.

B5M0485A

(3) Installation is in the reverse order of

removal.

B: ADJUSTMENT

1. SEDAN AND WAGON REAR (](/img/17/57435/w960_57435-1087.png)

4) Tilt up assembly:

(1) Remove sunroof flame.

(2) Remove tilt up assembly.

B5M0485A

(3) Installation is in the reverse order of

removal.

B: ADJUSTMENT

1. SEDAN AND WAGON REAR (EXCEPT

OUTBACK)

1) Alignment of height between glass lid assembly

and roof panel:

(1) Remove guide rail cover.

(2) Loosen nuts and adjust height by adding

(Max: two pieces) and extracting (Max: one

piece) shim(s) (Standard: one piece) between

glass lid assembly and lid bracket.

Difference in height between glass lid assem-

bly and roof panel:

0

±0.5 mm (0±0.020 in)

B5M0314B

B5M0315B

2) Alignment of glass lid assembly with roof panel:

(1) Remove guide rail cover.

(2) Loosen nuts and move glass lid assembly

to either side to adjust front, rear, right, and left

side partitions.

Partition clearance:

7.0

±0.5 mm (0.276±0.020 in)

B5M0316A

3) Checking for movement of glass lid assembly

itself:

(1) Before installing sunroof motor, check glass

lid assembly for movement.

(2) Place a cloth on glass lid assembly and sun

shade, and attach a spring scale to glass lid

assembly edge using the cloth.

B5M0317

(3) Pull spring scale to measure force required

to move glass lid assembly.

Force required to move glass lid assembly

and sun shade trim:

Less than 196 N (20 kg, 44 lb)

Considerable effort is required to start glass lid

assembly moving, so take scale reading while

glass lid assembly is moving smoothly.

(4) If force required exceeds specifications,

check the following points:

IGlass lid assembly, sun shade and deflector and

guide rail assembly for improper installation

ICable for seizure

60

5-1[W16B1]SERVICE PROCEDURE

16. Sunroof

Page 1089 of 1456

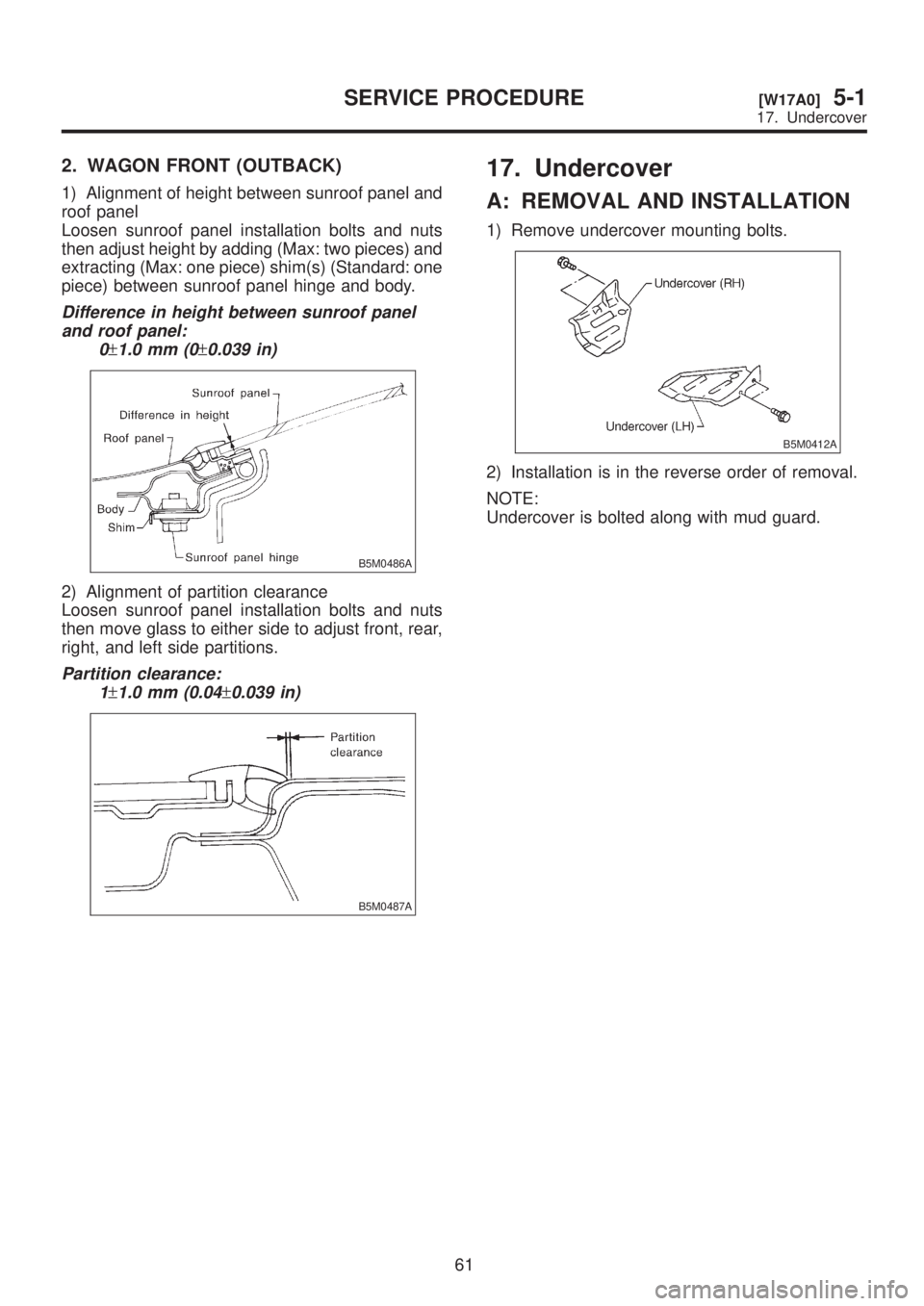

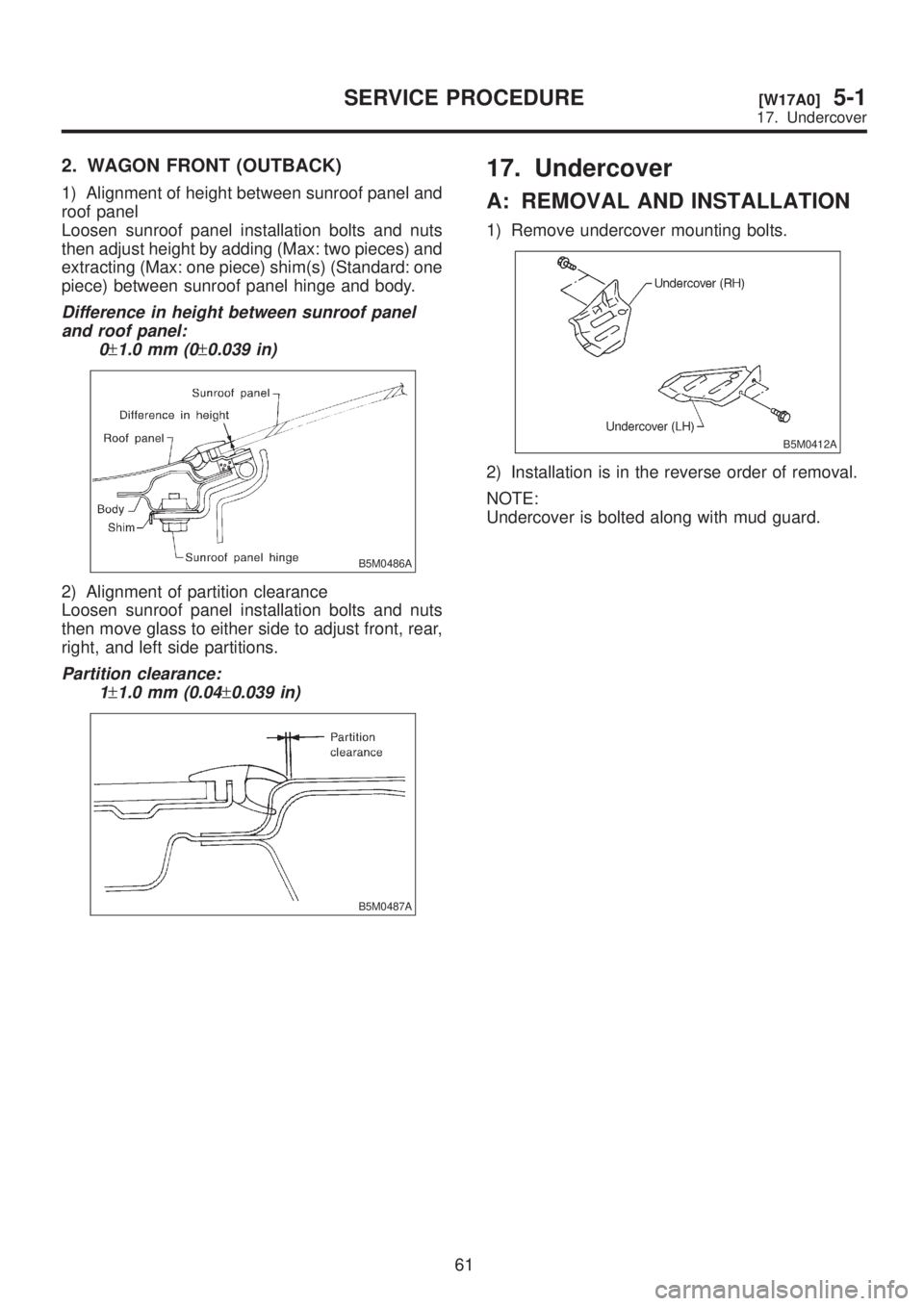

2. WAGON FRONT (OUTBACK)

1) Alignment of height between sunroof panel and

roof panel

Loosen sunroof panel installation bolts and nuts

then adjust height by adding (Max: two pieces) and

extracting (Max: one piece) shim(s) (Standard: one

piece) between sunroof panel hinge and body.

Difference in height between sunroof panel

and roof panel:

0

±1.0 mm (0±0.039 in)

B5M0486A

2) Alignment of partition clearance

Loosen sunroof panel installation bolts and nuts

then move glass to either side to adjust front, rear,

right, and left side partitions.

Partition clearance:

1

±1.0 mm (0.04±0.039 in)

B5M0487A

17. Undercover

A: REMOVAL AND INSTALLATION

1) Remove undercover mounting bolts.

B5M0412A

2) Installation is in the reverse order of removal.

NOTE:

Undercover is bolted along with mud guard.

61

[W17A0]5-1SERVICE PROCEDURE

17. Undercover

Page 1090 of 1456

2. WAGON FRONT (OUTBACK)

1) Alignment of height between sunroof panel and

roof panel

Loosen sunroof panel installation bolts and nuts

then adjust height by adding (Max: two pieces) and

extracting (Max: one piece) shim(s) (Standard: one

piece) between sunroof panel hinge and body.

Difference in height between sunroof panel

and roof panel:

0

±1.0 mm (0±0.039 in)

B5M0486A

2) Alignment of partition clearance

Loosen sunroof panel installation bolts and nuts

then move glass to either side to adjust front, rear,

right, and left side partitions.

Partition clearance:

1

±1.0 mm (0.04±0.039 in)

B5M0487A

17. Undercover

A: REMOVAL AND INSTALLATION

1) Remove undercover mounting bolts.

B5M0412A

2) Installation is in the reverse order of removal.

NOTE:

Undercover is bolted along with mud guard.

61

[W17A0]5-1SERVICE PROCEDURE

17. Undercover

Page 1099 of 1456

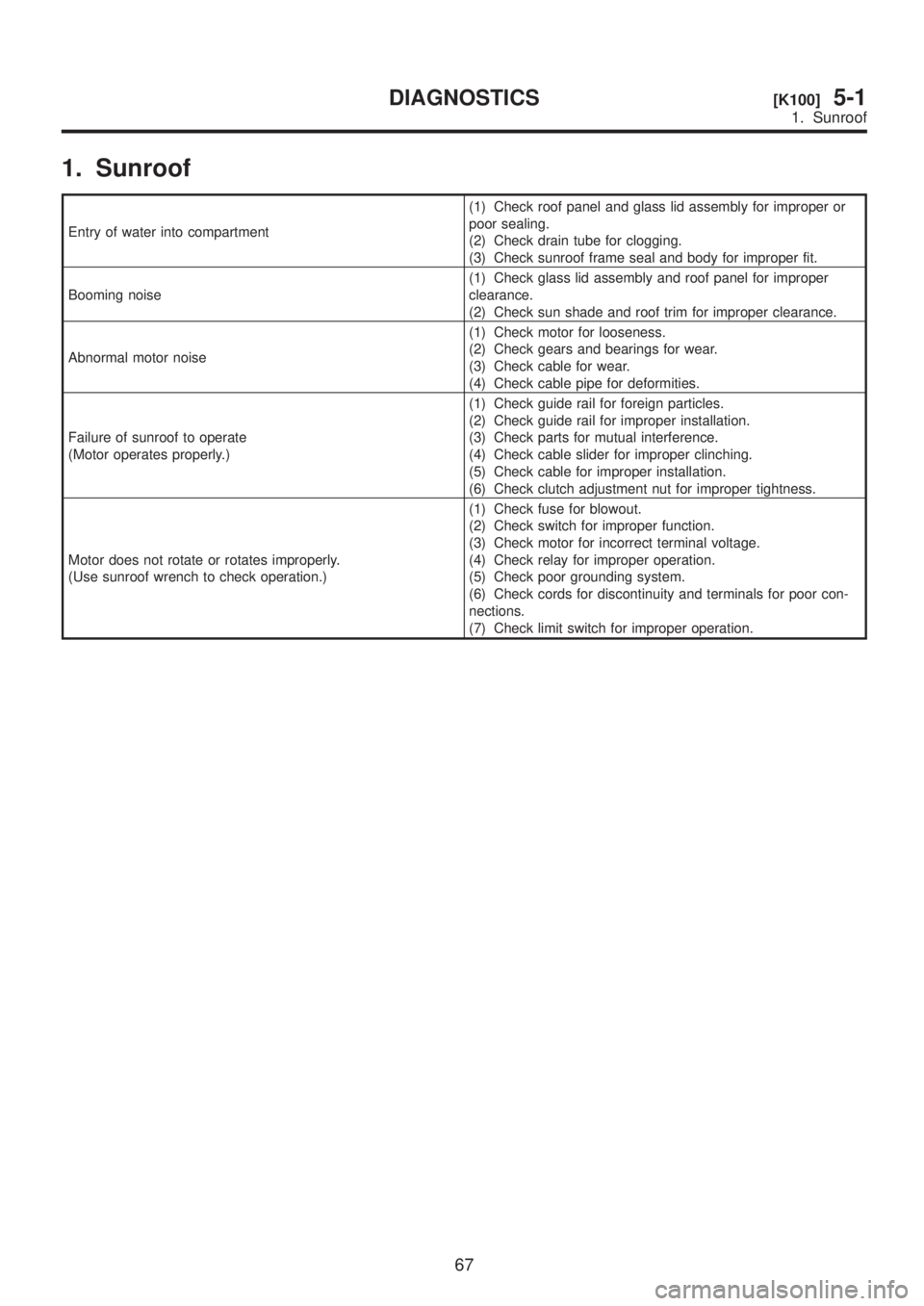

1. Sunroof

Entry of water into compartment(1) Check roof panel and glass lid assembly for improper or

poor sealing.

(2) Check drain tube for clogging.

(3) Check sunroof frame seal and body for improper fit.

Booming noise(1) Check glass lid assembly and roof panel for improper

clearance.

(2) Check sun shade and roof trim for improper clearance.

Abnormal motor noise(1) Check motor for looseness.

(2) Check gears and bearings for wear.

(3) Check cable for wear.

(4) Check cable pipe for deformities.

Failure of sunroof to operate

(Motor operates properly.)(1) Check guide rail for foreign particles.

(2) Check guide rail for improper installation.

(3) Check parts for mutual interference.

(4) Check cable slider for improper clinching.

(5) Check cable for improper installation.

(6) Check clutch adjustment nut for improper tightness.

Motor does not rotate or rotates improperly.

(Use sunroof wrench to check operation.)(1) Check fuse for blowout.

(2) Check switch for improper function.

(3) Check motor for incorrect terminal voltage.

(4) Check relay for improper operation.

(5) Check poor grounding system.

(6) Check cords for discontinuity and terminals for poor con-

nections.

(7) Check limit switch for improper operation.

67

[K100]5-1DIAGNOSTICS

1. Sunroof

Page 1267 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 20. Sunroof

A: REMOVAL AND INSTALLATION

1. SUNROOF AND SUNROOF MOTOR

<Ref. to 5-1 [W1600].> as for removal and instal-

lation of sunroof system.

2. SUNROOF SWITCH

NOTE:

The sunroof switch is installed SUBARU LEGACY 1999 Service Repair Manual 20. Sunroof

A: REMOVAL AND INSTALLATION

1. SUNROOF AND SUNROOF MOTOR

<Ref. to 5-1 [W1600].> as for removal and instal-

lation of sunroof system.

2. SUNROOF SWITCH

NOTE:

The sunroof switch is installed](/img/17/57435/w960_57435-1266.png)

20. Sunroof

A: REMOVAL AND INSTALLATION

1. SUNROOF AND SUNROOF MOTOR

lation of sunroof system.

2. SUNROOF SWITCH

NOTE:

The sunroof switch is installed in spot light body.

1) Pry spot light lens off using a screwdriver.

2) Remove screws which secure spot light body.

3) Remove spot light body while disconnecting

connectors.

4) Remove screw which secures sunroof switch,

and then remove sunroof switch.

B6M0141A

5) Installation is in the reverse order of removal.

B: INSPECTION

1. SUNROOF SWITCH

Set sunroof switch to each position and check con-

tinuity between terminals as indicated in table

below:

B6M0142A

B6M0861A

37

[W20B1]6-2SERVICE PROCEDURE

20. Sunroof

Page 1268 of 1456

2. SUNROOF MOTOR

1) Apply battery voltage between 1-pin connector

(Except OUTBACK) or terminal No. 1 (OUTBACK)

and body ground wire.

2) Make sure that sunroof motor moves when con-

necting terminals as described below:

Except OUTBACK

IConnect between terminals No. 3 and 4 (OPEN)

IConnect between terminals No. 6 and 4

(CLOSE)

IConnect between terminals No. 5 and 4 (TILT

UP)

IConnect between terminals No. 2 and 4 (TILT

DOWN)

OUTBACK (Rear)

IConnect between terminals No. 2 and 3 (OPEN)

IConnect between terminals No. 6 and 3

(CLOSE)

B6M0893A

OUTBACK (Front)

IConnect between terminals No. 1 and 2 (TILT

UP)

IConnect between terminals No. 2 and 1 (TILT

DOWN)

B6M0788B

3. SUNROOF RELAY

Check continuity between terminals as indicated in

table below, when battery voltage is applied

between terminals No. 1 and No. 2.

When current

flows.Between terminals

No. 3 and No. 4Continuity exists.

When current

does not flow.Between terminals

No. 3 and No. 4Continuity does not

exist.

Between terminals

No. 1 and No. 2Continuity exists.

B6M0785A

38

6-2[W20B2]SERVICE PROCEDURE

20. Sunroof

Page 1284 of 1456

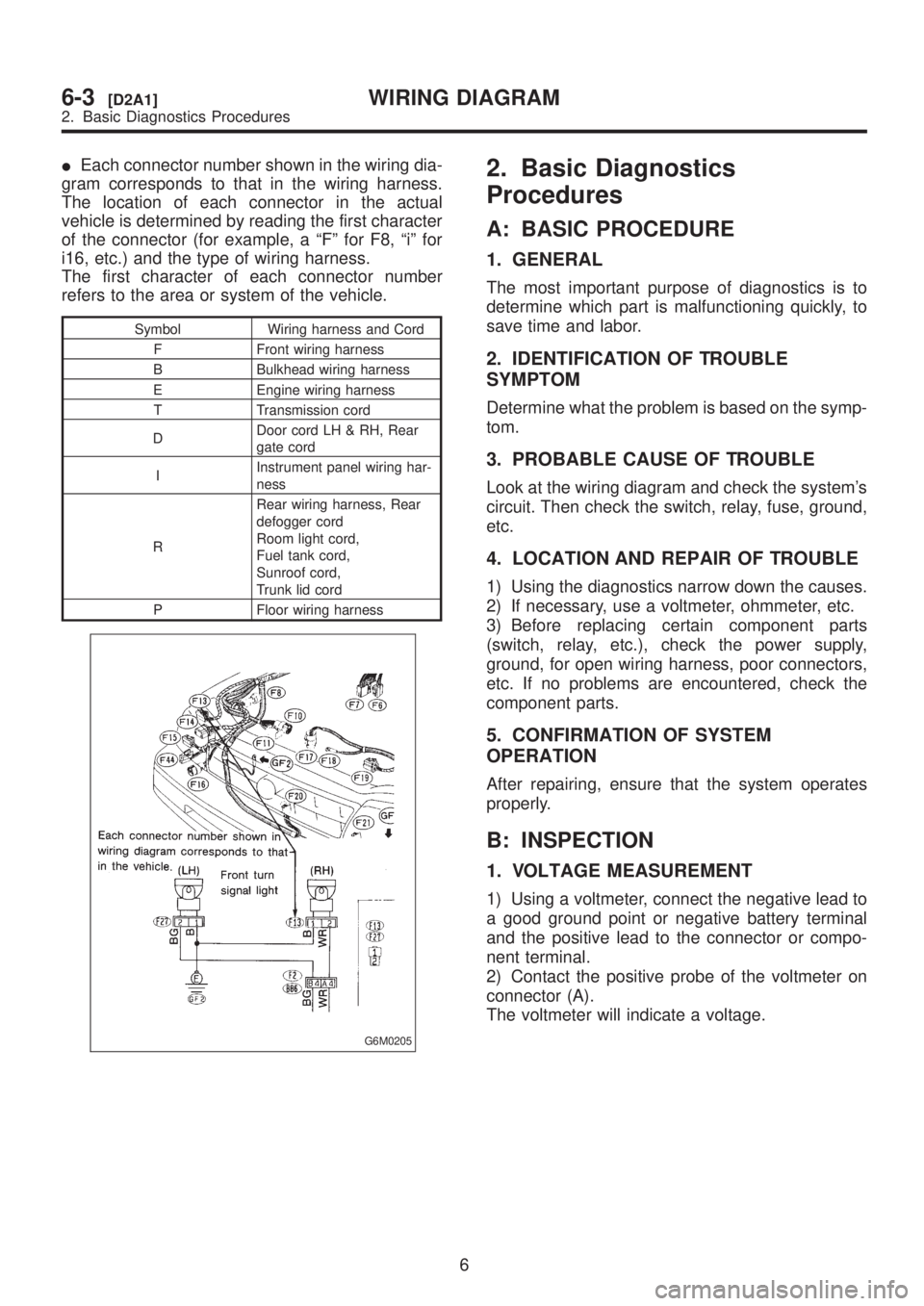

IEach connector number shown in the wiring dia-

gram corresponds to that in the wiring harness.

The location of each connector in the actual

vehicle is determined by reading the first character

of the connector (for example, a ªFº for F8, ªiº for

i16, etc.) and the type of wiring harness.

The first character of each connector number

refers to the area or system of the vehicle.

Symbol Wiring harness and Cord

F Front wiring harness

B Bulkhead wiring harness

E Engine wiring harness

T Transmission cord

DDoor cord LH & RH, Rear

gate cord

IInstrument panel wiring har-

ness

RRear wiring harness, Rear

defogger cord

Room light cord,

Fuel tank cord,

Sunroof cord,

Trunk lid cord

P Floor wiring harness

G6M0205

2. Basic Diagnostics

Procedures

A: BASIC PROCEDURE

1. GENERAL

The most important purpose of diagnostics is to

determine which part is malfunctioning quickly, to

save time and labor.

2. IDENTIFICATION OF TROUBLE

SYMPTOM

Determine what the problem is based on the symp-

tom.

3. PROBABLE CAUSE OF TROUBLE

Look at the wiring diagram and check the system's

circuit. Then check the switch, relay, fuse, ground,

etc.

4. LOCATION AND REPAIR OF TROUBLE

1) Using the diagnostics narrow down the causes.

2) If necessary, use a voltmeter, ohmmeter, etc.

3) Before replacing certain component parts

(switch, relay, etc.), check the power supply,

ground, for open wiring harness, poor connectors,

etc. If no problems are encountered, check the

component parts.

5. CONFIRMATION OF SYSTEM

OPERATION

After repairing, ensure that the system operates

properly.

B: INSPECTION

1. VOLTAGE MEASUREMENT

1) Using a voltmeter, connect the negative lead to

a good ground point or negative battery terminal

and the positive lead to the connector or compo-

nent terminal.

2) Contact the positive probe of the voltmeter on

connector (A).

The voltmeter will indicate a voltage.

6

6-3[D2A1]WIRING DIAGRAM

2. Basic Diagnostics Procedures