low oil pressure SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 40 of 1456

Diagnosis of engine condition by measurement of manifold vacuum

Vacuum gauge indication Possible engine condition

1. Needle is steady but lower than normal position. This ten-

dency becomes more evident as engine temperature rises.Leakage around intake manifold gasket or disconnection or

damaged vacuum hose

2. When engine speed is reduced slowly from higher speed,

needle stops temporarily when it is lowering or becomes

steady above normal position.Back pressure too high, or exhaust system clogged

3. Needle intermittently drops to position lower than normal

position.Leakage around cylinder

4. Needle drops suddenly and intermittently from normal posi-

tion.Sticky valves

5. When engine speed is gradually increased, needle begins

to vibrate rapidly at certain speed, and then vibration

increases as engine speed increases.Weak or broken valve springs

6. Needle vibrates above and below normal position in narrow

range.Defective ignition system or throttle chamber idle adjustment

6. Engine Oil Pressure

A: MEASUREMENT

1) Disconnect battery ground cable.

2) Remove generator from bracket.

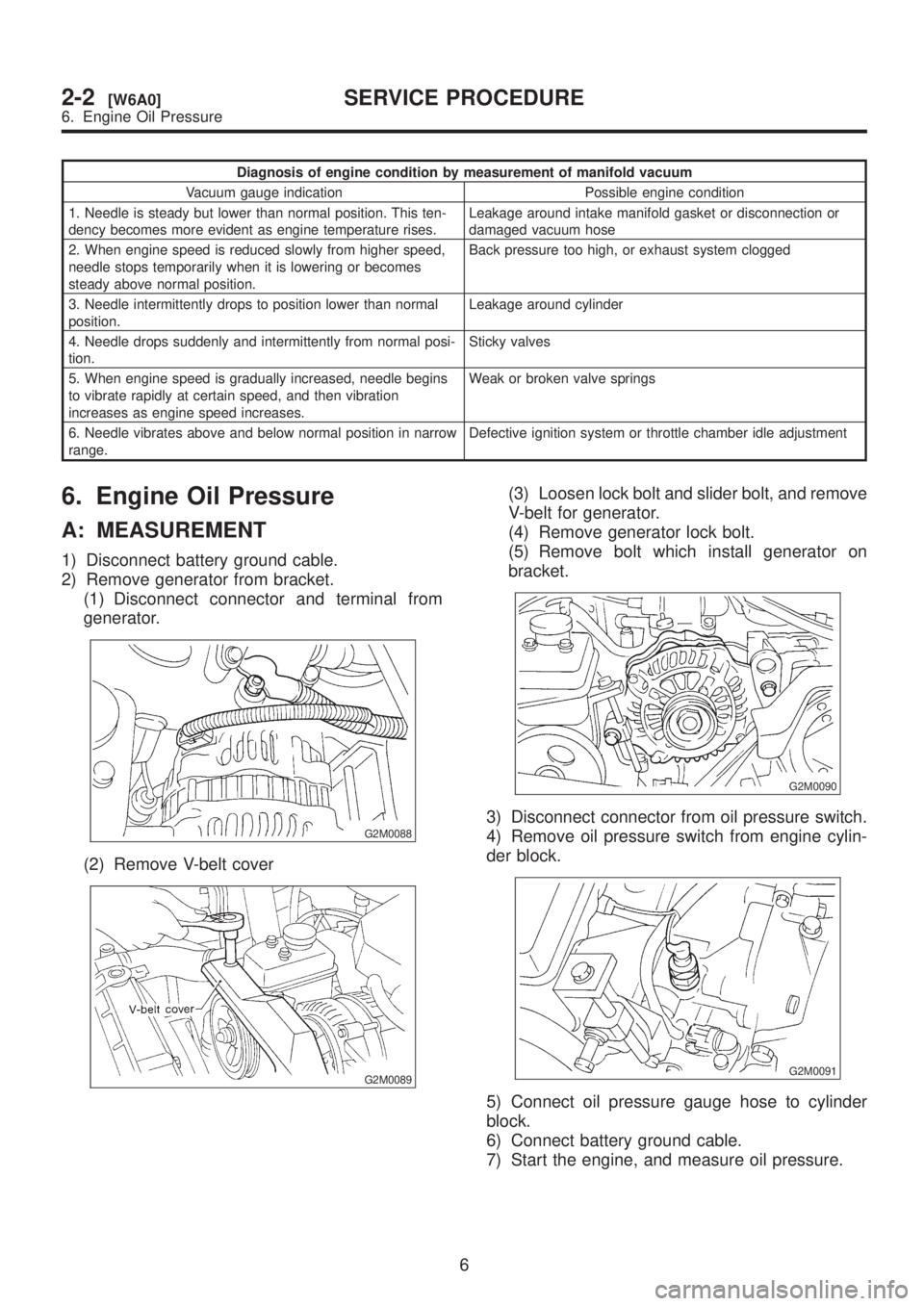

(1) Disconnect connector and terminal from

generator.

G2M0088

(2) Remove V-belt cover

G2M0089

(3) Loosen lock bolt and slider bolt, and remove

V-belt for generator.

(4) Remove generator lock bolt.

(5) Remove bolt which install generator on

bracket.

G2M0090

3) Disconnect connector from oil pressure switch.

4) Remove oil pressure switch from engine cylin-

der block.

G2M0091

5) Connect oil pressure gauge hose to cylinder

block.

6) Connect battery ground cable.

7) Start the engine, and measure oil pressure.

6

2-2[W6A0]SERVICE PROCEDURE

6. Engine Oil Pressure

Page 41 of 1456

Diagnosis of engine condition by measurement of manifold vacuum

Vacuum gauge indication Possible engine condition

1. Needle is steady but lower than normal position. This ten-

dency becomes more evident as engine temperature rises.Leakage around intake manifold gasket or disconnection or

damaged vacuum hose

2. When engine speed is reduced slowly from higher speed,

needle stops temporarily when it is lowering or becomes

steady above normal position.Back pressure too high, or exhaust system clogged

3. Needle intermittently drops to position lower than normal

position.Leakage around cylinder

4. Needle drops suddenly and intermittently from normal posi-

tion.Sticky valves

5. When engine speed is gradually increased, needle begins

to vibrate rapidly at certain speed, and then vibration

increases as engine speed increases.Weak or broken valve springs

6. Needle vibrates above and below normal position in narrow

range.Defective ignition system or throttle chamber idle adjustment

6. Engine Oil Pressure

A: MEASUREMENT

1) Disconnect battery ground cable.

2) Remove generator from bracket.

(1) Disconnect connector and terminal from

generator.

G2M0088

(2) Remove V-belt cover

G2M0089

(3) Loosen lock bolt and slider bolt, and remove

V-belt for generator.

(4) Remove generator lock bolt.

(5) Remove bolt which install generator on

bracket.

G2M0090

3) Disconnect connector from oil pressure switch.

4) Remove oil pressure switch from engine cylin-

der block.

G2M0091

5) Connect oil pressure gauge hose to cylinder

block.

6) Connect battery ground cable.

7) Start the engine, and measure oil pressure.

6

2-2[W6A0]SERVICE PROCEDURE

6. Engine Oil Pressure

Page 42 of 1456

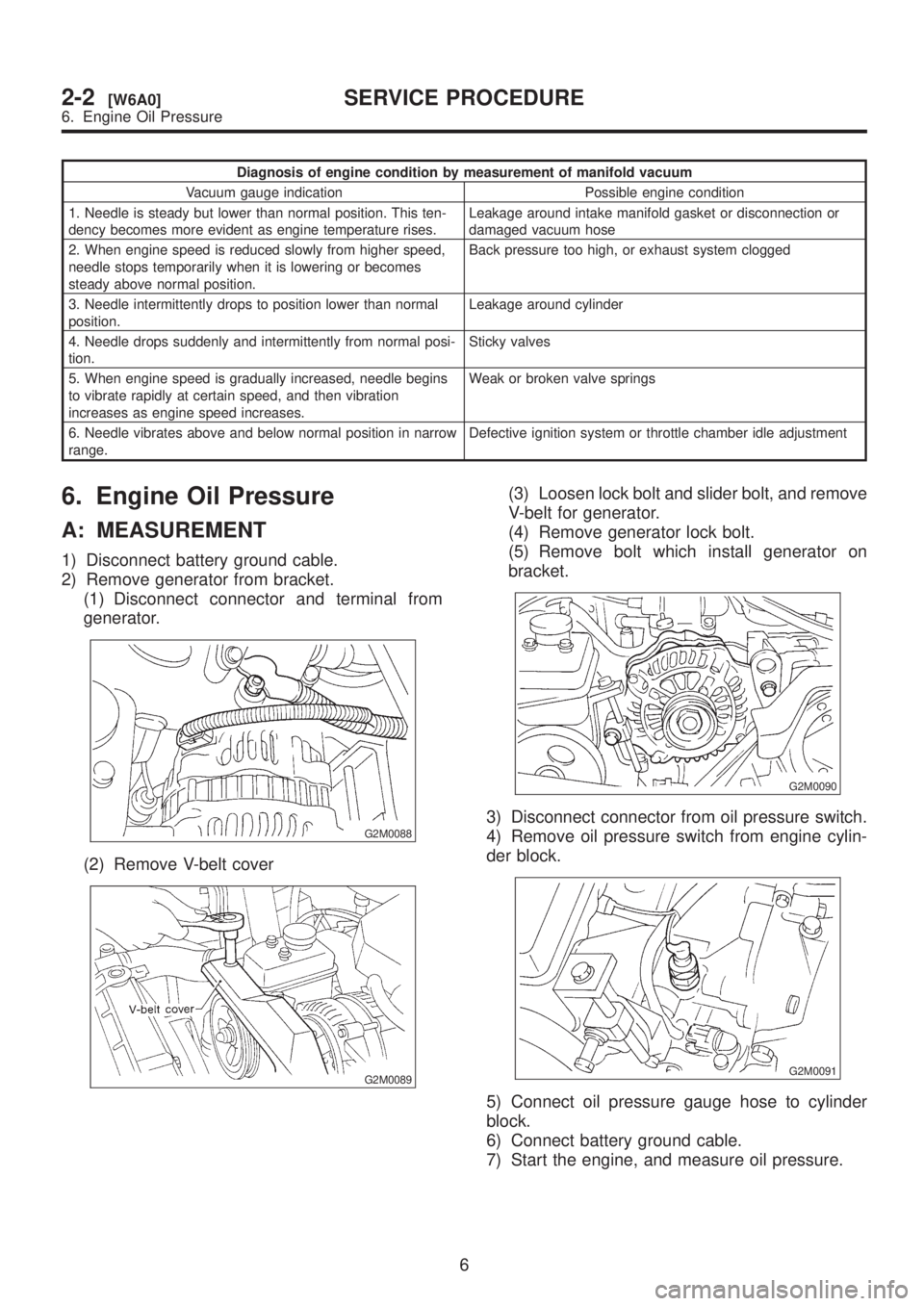

S2M0242

Oil pressure:

98 kPa (1.0 kg/cm2,14 psi) or more at 800

rpm

294 kPa (3.0 kg/cm

2, 43 psi) or more at

5,000 rpm

CAUTION:

IIf oil pressure is out of specification, check

oil pump, oil filter and lubrication line.

IIf oil pressure warning light is turned ON and

oil pressure is in specification, replace oil pres-

sure switch.

NOTE:

The specified data is based on an engine oil tem-

perature of 80ÉC (176ÉF).

8) After measuring oil pressure, install oil pressure

switch.

Tightening torque:

25

±3 N´m (2.5±0.3 kg-m, 18.1±2.2 ft-lb)

9) Install generator and V-belt in the reverse order

of removal, and adjust the V-belt deflection.

7. Valve Clearance

A: INSPECTION

1. 2200 cc MODEL

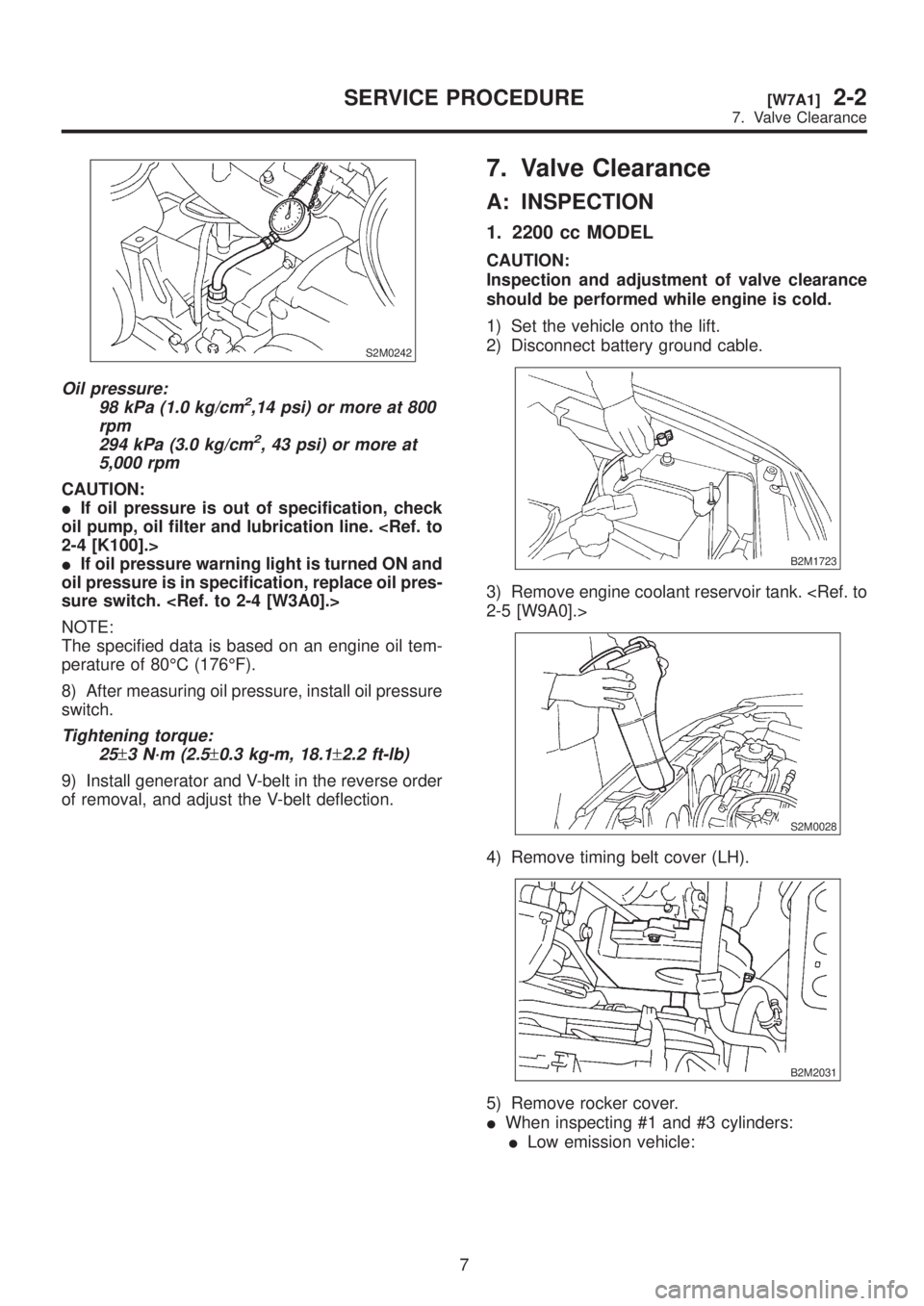

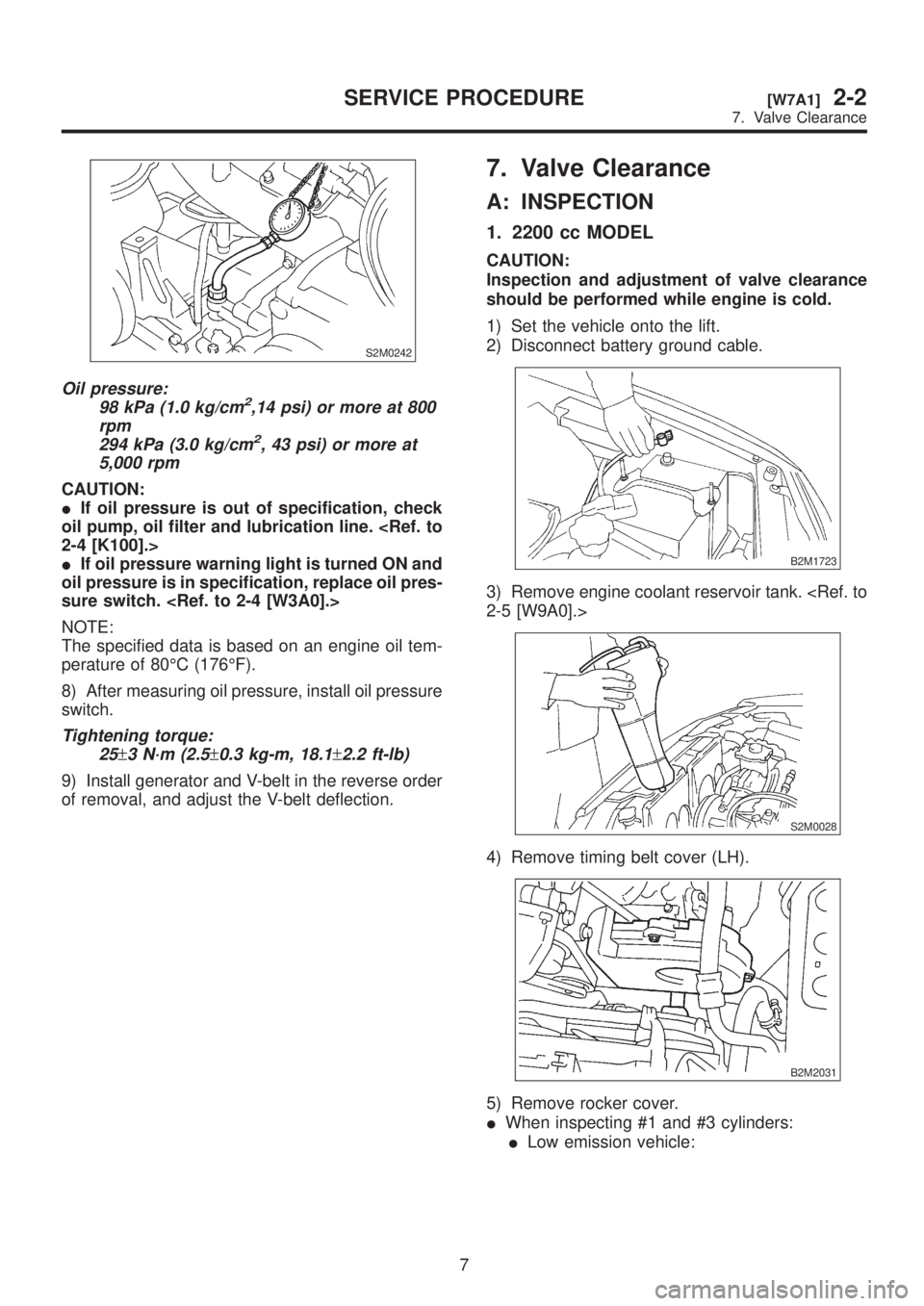

CAUTION:

Inspection and adjustment of valve clearance

should be performed while engine is cold.

1) Set the vehicle onto the lift.

2) Disconnect battery ground cable.

B2M1723

3) Remove engine coolant reservoir tank.

S2M0028

4) Remove timing belt cover (LH).

B2M2031

5) Remove rocker cover.

IWhen inspecting #1 and #3 cylinders:

ILow emission vehicle:

7

[W7A1]2-2SERVICE PROCEDURE

7. Valve Clearance

Page 43 of 1456

S2M0242

Oil pressure:

98 kPa (1.0 kg/cm2,14 psi) or more at 800

rpm

294 kPa (3.0 kg/cm

2, 43 psi) or more at

5,000 rpm

CAUTION:

IIf oil pressure is out of specification, check

oil pump, oil filter and lubrication line.

IIf oil pressure warning light is turned ON and

oil pressure is in specification, replace oil pres-

sure switch.

NOTE:

The specified data is based on an engine oil tem-

perature of 80ÉC (176ÉF).

8) After measuring oil pressure, install oil pressure

switch.

Tightening torque:

25

±3 N´m (2.5±0.3 kg-m, 18.1±2.2 ft-lb)

9) Install generator and V-belt in the reverse order

of removal, and adjust the V-belt deflection.

7. Valve Clearance

A: INSPECTION

1. 2200 cc MODEL

CAUTION:

Inspection and adjustment of valve clearance

should be performed while engine is cold.

1) Set the vehicle onto the lift.

2) Disconnect battery ground cable.

B2M1723

3) Remove engine coolant reservoir tank.

S2M0028

4) Remove timing belt cover (LH).

B2M2031

5) Remove rocker cover.

IWhen inspecting #1 and #3 cylinders:

ILow emission vehicle:

7

[W7A1]2-2SERVICE PROCEDURE

7. Valve Clearance

Page 71 of 1456

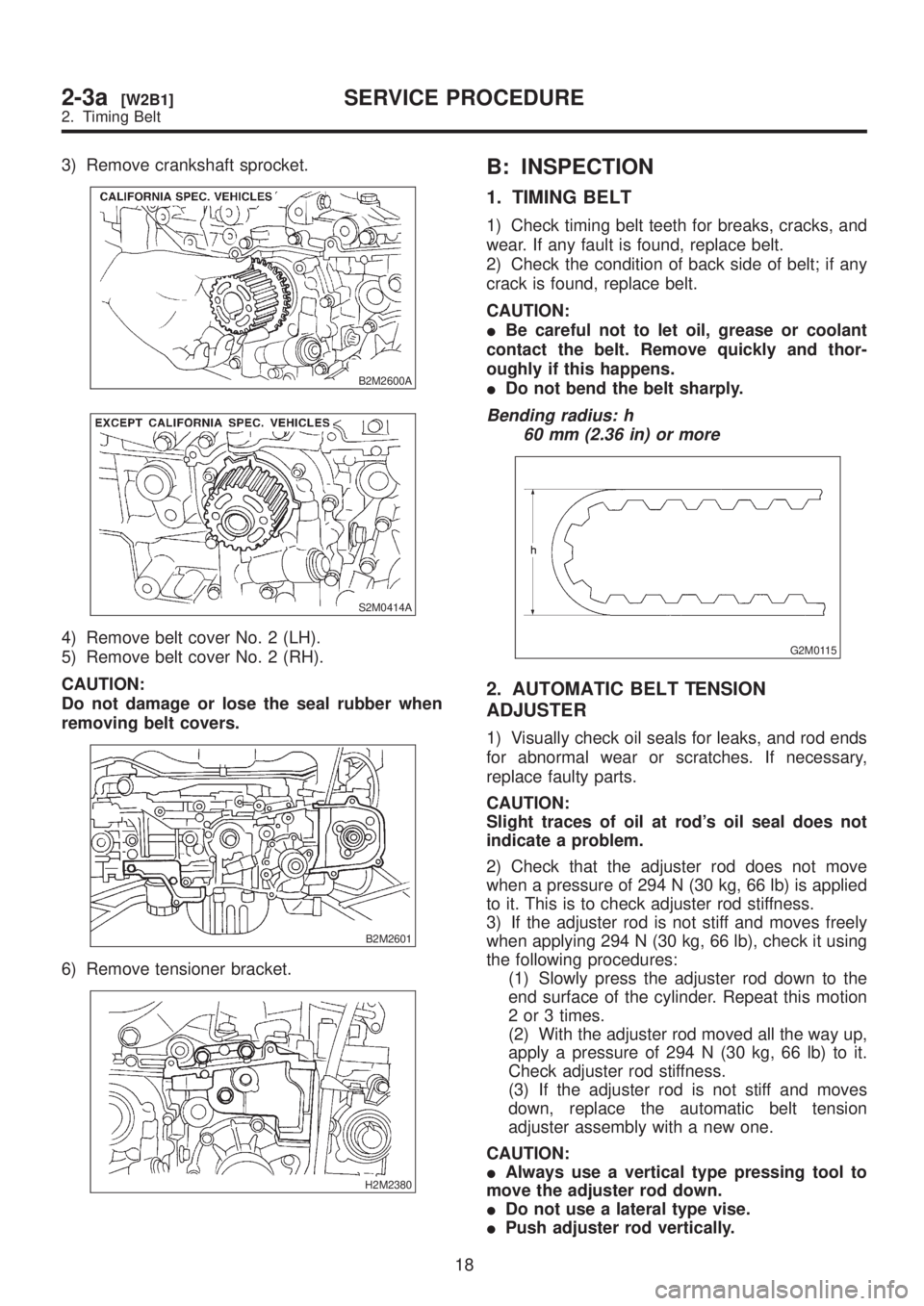

3) Remove crankshaft sprocket.

B2M2600A

S2M0414A

4) Remove belt cover No. 2 (LH).

5) Remove belt cover No. 2 (RH).

CAUTION:

Do not damage or lose the seal rubber when

removing belt covers.

B2M2601

6) Remove tensioner bracket.

H2M2380

B: INSPECTION

1. TIMING BELT

1) Check timing belt teeth for breaks, cracks, and

wear. If any fault is found, replace belt.

2) Check the condition of back side of belt; if any

crack is found, replace belt.

CAUTION:

IBe careful not to let oil, grease or coolant

contact the belt. Remove quickly and thor-

oughly if this happens.

IDo not bend the belt sharply.

Bending radius: h

60 mm (2.36 in) or more

G2M0115

2. AUTOMATIC BELT TENSION

ADJUSTER

1) Visually check oil seals for leaks, and rod ends

for abnormal wear or scratches. If necessary,

replace faulty parts.

CAUTION:

Slight traces of oil at rod's oil seal does not

indicate a problem.

2) Check that the adjuster rod does not move

when a pressure of 294 N (30 kg, 66 lb) is applied

to it. This is to check adjuster rod stiffness.

3) If the adjuster rod is not stiff and moves freely

when applying 294 N (30 kg, 66 lb), check it using

the following procedures:

(1) Slowly press the adjuster rod down to the

end surface of the cylinder. Repeat this motion

2 or 3 times.

(2) With the adjuster rod moved all the way up,

apply a pressure of 294 N (30 kg, 66 lb) to it.

Check adjuster rod stiffness.

(3) If the adjuster rod is not stiff and moves

down, replace the automatic belt tension

adjuster assembly with a new one.

CAUTION:

IAlways use a vertical type pressing tool to

move the adjuster rod down.

IDo not use a lateral type vise.

IPush adjuster rod vertically.

18

2-3a[W2B1]SERVICE PROCEDURE

2. Timing Belt

Page 94 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 5. Cylinder Head

A: REMOVAL

1. RELATED PARTS

1) Release fuel pressure. <Ref. to 2-8 [W1B0].>

2) Drain engine coolant. <Ref. to 2-5 [W1A0].>

3) Remove V-belt(s).

4) Remove generator and bracket.

5) Rem SUBARU LEGACY 1999 Service Repair Manual 5. Cylinder Head

A: REMOVAL

1. RELATED PARTS

1) Release fuel pressure. <Ref. to 2-8 [W1B0].>

2) Drain engine coolant. <Ref. to 2-5 [W1A0].>

3) Remove V-belt(s).

4) Remove generator and bracket.

5) Rem](/img/17/57435/w960_57435-93.png)

5. Cylinder Head

A: REMOVAL

1. RELATED PARTS

1) Release fuel pressure.

2) Drain engine coolant.

3) Remove V-belt(s).

4) Remove generator and bracket.

5) Remove A/C compressor and bracket. (With

A/C model)6) Disconnect spark plug cords.

7) Remove connector bracket attaching bolt.

8) Remove camshaft position sensor and cam-

shaft position sensor support.

9) Disconnect oil pressure switch connector.

10) Disconnect blow-by hose.

11) Remove intake manifold.

2. CYLINDER HEAD

B2M2627A

(1) Rocker cover

(2) Cylinder head bolt(3) Cylinder head

(4) Cylinder head gasket

1) Remove timing belt, camshaft sprocket and

related parts.

2) Remove oil level gauge guide attaching bolt

(left hand only) and oil level gauge guide.

3) Remove rocker cover.

40

2-3a[W5A1]SERVICE PROCEDURE

5. Cylinder Head

Page 104 of 1456

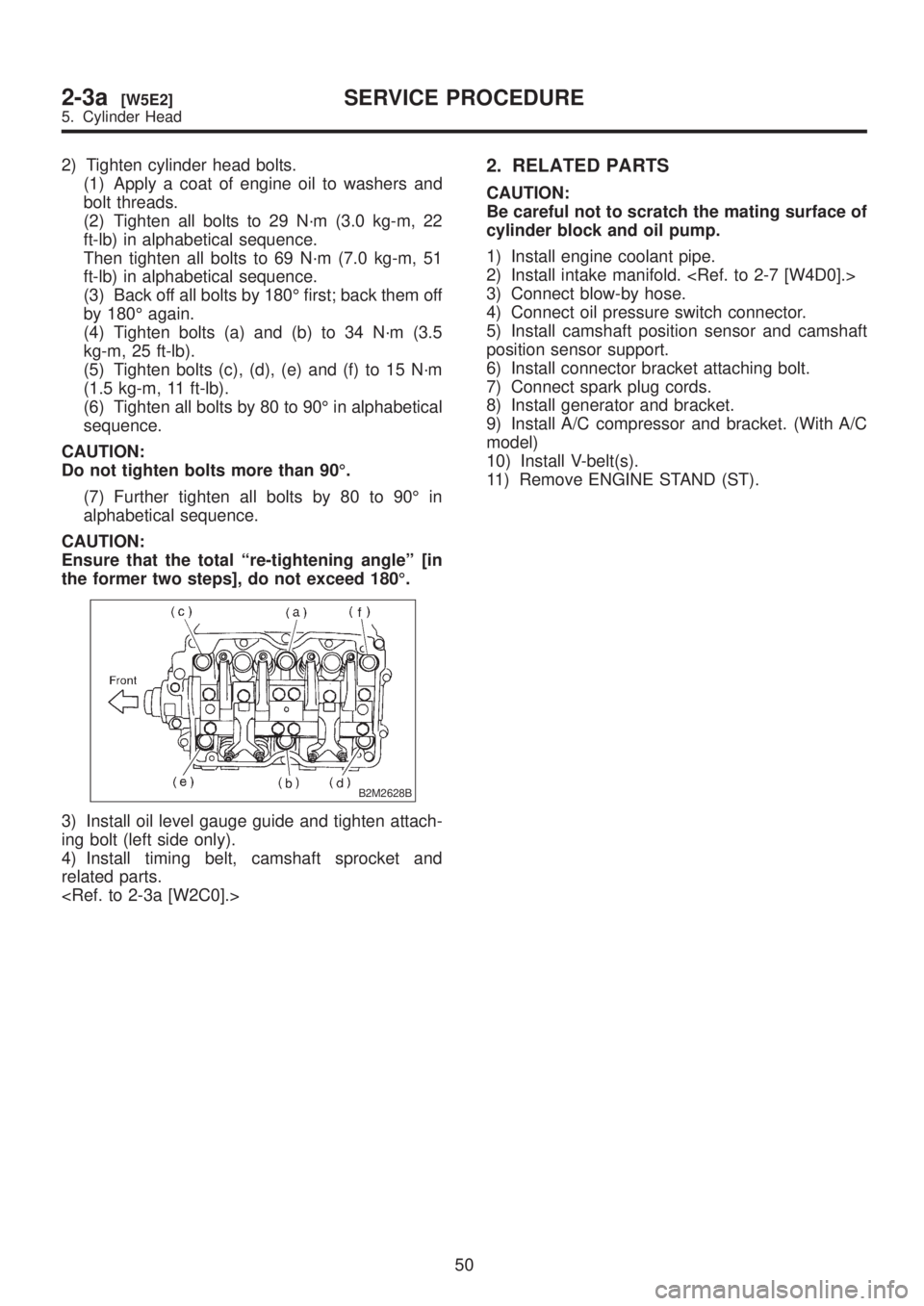

2) Tighten cylinder head bolts.

(1) Apply a coat of engine oil to washers and

bolt threads.

(2) Tighten all bolts to 29 N´m (3.0 kg-m, 22

ft-lb) in alphabetical sequence.

Then tighten all bolts to 69 N´m (7.0 kg-m, 51

ft-lb) in alphabetical sequence.

(3) Back off all bolts by 180É first; back them off

by 180É again.

(4) Tighten bolts (a) and (b) to 34 N´m (3.5

kg-m, 25 ft-lb).

(5) Tighten bolts (c), (d), (e) and (f) to 15 N´m

(1.5 kg-m, 11 ft-lb).

(6) Tighten all bolts by 80 to 90É in alphabetical

sequence.

CAUTION:

Do not tighten bolts more than 90É.

(7) Further tighten all bolts by 80 to 90É in

alphabetical sequence.

CAUTION:

Ensure that the total ªre-tightening angleº [in

the former two steps], do not exceed 180É.

B2M2628B

3) Install oil level gauge guide and tighten attach-

ing bolt (left side only).

4) Install timing belt, camshaft sprocket and

related parts.

2. RELATED PARTS

CAUTION:

Be careful not to scratch the mating surface of

cylinder block and oil pump.

1) Install engine coolant pipe.

2) Install intake manifold.

3) Connect blow-by hose.

4) Connect oil pressure switch connector.

5) Install camshaft position sensor and camshaft

position sensor support.

6) Install connector bracket attaching bolt.

7) Connect spark plug cords.

8) Install generator and bracket.

9) Install A/C compressor and bracket. (With A/C

model)

10) Install V-belt(s).

11) Remove ENGINE STAND (ST).

50

2-3a[W5E2]SERVICE PROCEDURE

5. Cylinder Head

Page 128 of 1456

![SUBARU LEGACY 1999 Service Repair Manual TROUBLE PROBLEM PARTS, ETC. POSSIBLE CAUSE RANK

4) Engine stalls after initial

combustion.Fuel injection system <Ref. to 2-7 [T6A0].> A

IIntake systemILoosened or cracked intake uct B

ILoosened or cra SUBARU LEGACY 1999 Service Repair Manual TROUBLE PROBLEM PARTS, ETC. POSSIBLE CAUSE RANK

4) Engine stalls after initial

combustion.Fuel injection system <Ref. to 2-7 [T6A0].> A

IIntake systemILoosened or cracked intake uct B

ILoosened or cra](/img/17/57435/w960_57435-127.png)

TROUBLE PROBLEM PARTS, ETC. POSSIBLE CAUSE RANK

4) Engine stalls after initial

combustion.Fuel injection system

IIntake systemILoosened or cracked intake uct B

ILoosened or cracked PCV hose C

ILoosened or cracked vacuum hose C

IDefective intake manifold gasket B

IDefective throttle body gasket B

IDirty air cleaner element C

IFuel lineIClogged fuel line C

ILack of or insufficient fuel B

IBeltIDefective B

IDefective timing B

ICompressionIIncorrect valve clearance C

ILoosened spark plugs or defective gasket C

ILoosened cylinder head bolts or defective gasket C

IImproper valve seating C

IDefective valve stem C

IWorn or broken valve spring B

IWorn or stuck piston rings, cylinder and piston C

IIncorrect valve timing B

IImproper engine oil (low viscosity) B

2. Rough idle and engine stall Fuel injection system

IIntake systemILoosened or cracked intake duct A

ILoosened or cracked PCV hose A

ILoosened or cracked vacuum hose A

IDefective intake manifold gasket B

IDefective throttle body gasket B

IDefective PCV valve C

ILoosened oil filter cap B

IDirty air cleaner element C

IFuel lineIDefective fuel pump and relay C

IClogged fuel line C

ILack of or insufficient fuel B

IBeltIDefective timing C

ICompressionIIncorrect valve clearance B

ILoosened spark plugs or defective gasket B

ILoosened cylinder head bolts or defective gasket B

IImproper valve seating B

IDefective valve stem C

IWorn or broken valve spring B

IWorn or stuck piston rings, cylinder and piston B

IIncorrect valve timing A

IImproper engine oil (low viscosity) B

ILubrication systemIIncorrect oil pressure B

IDefective rocker cover gasket C

ICooling systemIOverheating C

IOthersIMalfunction of evaporative emission control system A

IStuck or damaged throttle valve B

IAccelerator cable out of adjustment C

74

2-3a[K100]DIAGNOSTICS

1. Engine Trouble in General

Page 129 of 1456

![SUBARU LEGACY 1999 Service Repair Manual TROUBLE PROBLEM PARTS, ETC. POSSIBLE CAUSE RANK

3. Low output, hesitation and

poor accelerationIFuel injection system <Ref. to 2-7 [T6A0].> A

IIntake systemILoosened or cracked intake duct A

ILoosened SUBARU LEGACY 1999 Service Repair Manual TROUBLE PROBLEM PARTS, ETC. POSSIBLE CAUSE RANK

3. Low output, hesitation and

poor accelerationIFuel injection system <Ref. to 2-7 [T6A0].> A

IIntake systemILoosened or cracked intake duct A

ILoosened](/img/17/57435/w960_57435-128.png)

TROUBLE PROBLEM PARTS, ETC. POSSIBLE CAUSE RANK

3. Low output, hesitation and

poor accelerationIFuel injection system

IIntake systemILoosened or cracked intake duct A

ILoosened or cracked PCV hose A

ILoosened or cracked vacuum hose B

IDefective intake manifold gasket B

IDefective throttle body gasket B

IDefective PCV valve B

ILoosened oil filter cap B

IDirty air cleaner element A

IFuel lineIDefective fuel pump and relay B

IClogged fuel line B

ILack of or insufficient fuel C

IBeltIDefective timing B

ICompressionIIncorrect valve clearance B

ILoosened spark plugs or defective gasket B

ILoosened cylinder head bolts or defective gasket B

IImproper valve seating B

IDefective valve stem C

IWorn or broken valve spring B

IWorn or stuck piston rings, cylinder and piston C

IIncorrect valve timing A

IImproper engine oil (low viscosity) B

ILubrication systemIIncorrect oil pressure B

ICooling systemIOverheating C

IOver cooling C

IOthersIMalfunction of evaporative emission control system A

4. SurgingIFuel injection system

IIntake systemILoosened or cracked intake duct A

ILoosened or cracked PCV hose A

ILoosened or cracked vacuum hose A

IDefective intake manifold gasket B

IDefective throttle body gasket B

IDefective PCV valve B

ILoosened oil filter cap B

IDirty air cleaner element B

IFuel lineIDefective fuel pump and relay B

IClogged fuel line B

ILack of or insufficient fuel C

IBeltIDefective timing B

ICompressionIIncorrect valve clearance B

ILoosened spark plugs or defective gasket C

ILoosened cylinder head bolts or defective gasket C

IImproper valve seating C

IDefective valve stem C

IWorn or broken valve spring C

IWorn or stuck piston rings, cylinder and piston C

IIncorrect valve timing A

IImproper engine oil (low viscosity) B

ICooling systemIOverheating B

IOthersIMalfunction of evaporative emission control system C

75

[K100]2-3aDIAGNOSTICS

1. Engine Trouble in General

Page 132 of 1456

2. Engine Noise

Type of sound Condition Possible cause

Regular clicking soundSound increases as engine

speed increases.IValve mechanism is defective.

IIncorrect valve clearance

IWorn valve rocker

IWorn camshaft

IBroken valve spring

Heavy and dull clankOil pressure is low.IWorn crankshaft main bearing

IWorn connecting rod bearing (big end)

Oil pressure is normal.ILoose flywheel mounting bolts

IDamaged engine mounting

High-pitched clank

(Spark knock)Sound is noticeable when

accelerating with an overload.IIgnition timing advanced

IAccumulation of carbon inside combustion chamber

IWrong spark plug

IImproper gasoline

Clank when engine speed is

medium (1,000 to 2,000 rpm)Sound is reduced when fuel

injector connector of noisy cyl-

inder is disconnected.

(NOTE*)IWorn crankshaft main bearing

IWorn bearing at crankshaft end of connecting rod

Knocking sound when engine

is operating under idling speed

and engine is warmSound is reduced when fuel

injector connector of noisy cyl-

inder is disconnected.

(NOTE*)IWorn cylinder liner and piston ring

IBroken or stuck piston ring

IWorn piston pin and hole at piston end of connecting rod

Sound is not reduced if each

fuel injector connector is dis-

connected in turn. (NOTE*)IUnusually worn valve lifter

IWorn cam gear

IWorn camshaft journal bore in crankcase

Squeaky sound ÐIInsufficient generator lubrication

Rubbing sound ÐIDefective generator brush and rotor contact

Gear scream when starting

engineÐIDefective ignition starter switch

IWorn gear and starter pinion

Sound like polishing glass with

a dry clothÐILoose drive belt

IDefective engine coolant pump shaft

Hissing sound ÐILoss of compression

IAir leakage in air intake system, hoses, connections or

manifolds

Timing belt noise ÐILoose timing belt

IBelt contacting case/adjacent part

Valve tappet noise ÐIIncorrect valve clearance

NOTE*:

When disconnecting fuel injector connector, Malfunction Indicator Light (CHECK ENGINE light) illuminates and trouble code is

stored in ECM memory.

Therefore, carry out the CLEAR MEMORY MODE

necting fuel injector connector.

78

2-3a[K200]DIAGNOSTICS

2. Engine Noise