tire type SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 417 of 1456

5) Depress clutch pedal to assure there is no

abnormality in the clutch system.

G2M0236

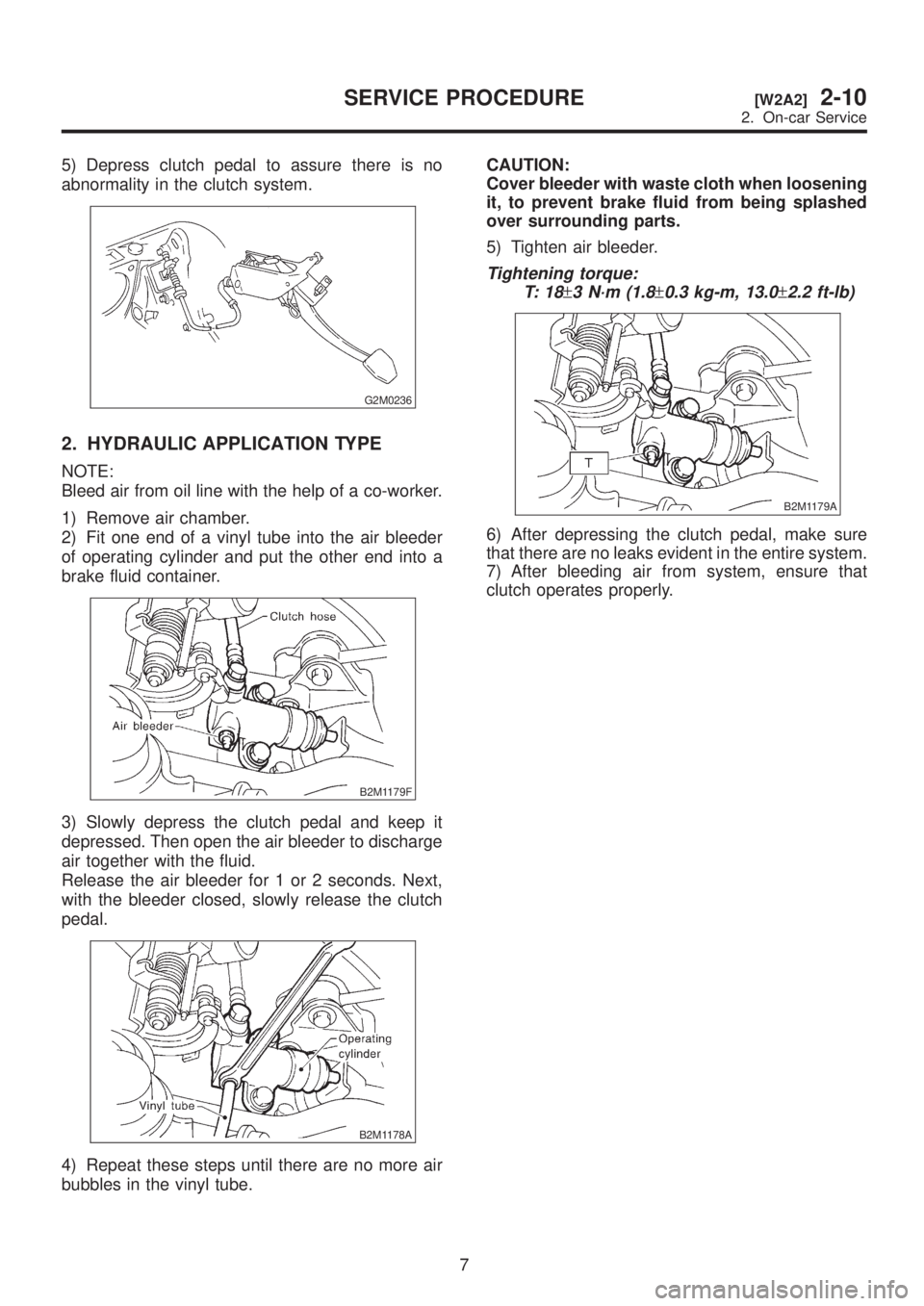

2. HYDRAULIC APPLICATION TYPE

NOTE:

Bleed air from oil line with the help of a co-worker.

1) Remove air chamber.

2) Fit one end of a vinyl tube into the air bleeder

of operating cylinder and put the other end into a

brake fluid container.

B2M1179F

3) Slowly depress the clutch pedal and keep it

depressed. Then open the air bleeder to discharge

air together with the fluid.

Release the air bleeder for 1 or 2 seconds. Next,

with the bleeder closed, slowly release the clutch

pedal.

B2M1178A

4) Repeat these steps until there are no more air

bubbles in the vinyl tube.CAUTION:

Cover bleeder with waste cloth when loosening

it, to prevent brake fluid from being splashed

over surrounding parts.

5) Tighten air bleeder.

Tightening torque:

T: 1 8

±3 N´m (1.8±0.3 kg-m, 13.0±2.2 ft-lb)

B2M1179A

6) After depressing the clutch pedal, make sure

that there are no leaks evident in the entire system.

7) After bleeding air from system, ensure that

clutch operates properly.

7

[W2A2]2-10SERVICE PROCEDURE

2. On-car Service

Page 652 of 1456

2. Rear Differential

A: SPECIFICATIONS

Type of gearHypoid

MT AT

2200 cc 2500 cc 2200 cc 2500 cc

Gear ratio (Number of gear teeth) 3.900 (39/10) 4.111 (37/9) 4.111 (37/9) 4.444 (40/9)

Oil capacity 0.8(0.8 US qt, 0.7 Imp qt)

Rear differential gear oil GL-5

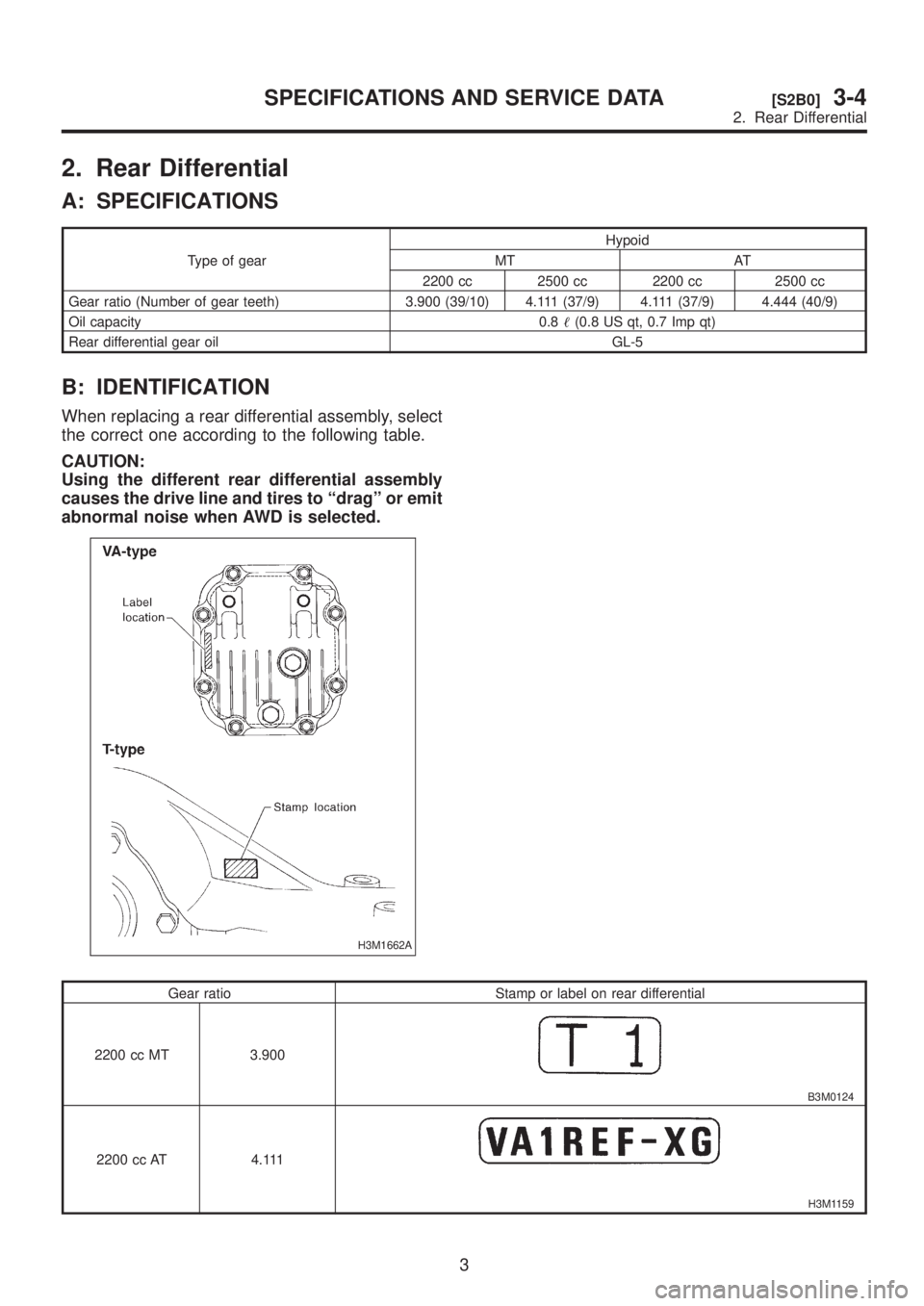

B: IDENTIFICATION

When replacing a rear differential assembly, select

the correct one according to the following table.

CAUTION:

Using the different rear differential assembly

causes the drive line and tires to ªdragº or emit

abnormal noise when AWD is selected.

H3M1662A

Gear ratio Stamp or label on rear differential

2200 cc MT 3.900

B3M0124

2200 cc AT 4.111

H3M1159

3

[S2B0]3-4SPECIFICATIONS AND SERVICE DATA

2. Rear Differential

Page 735 of 1456

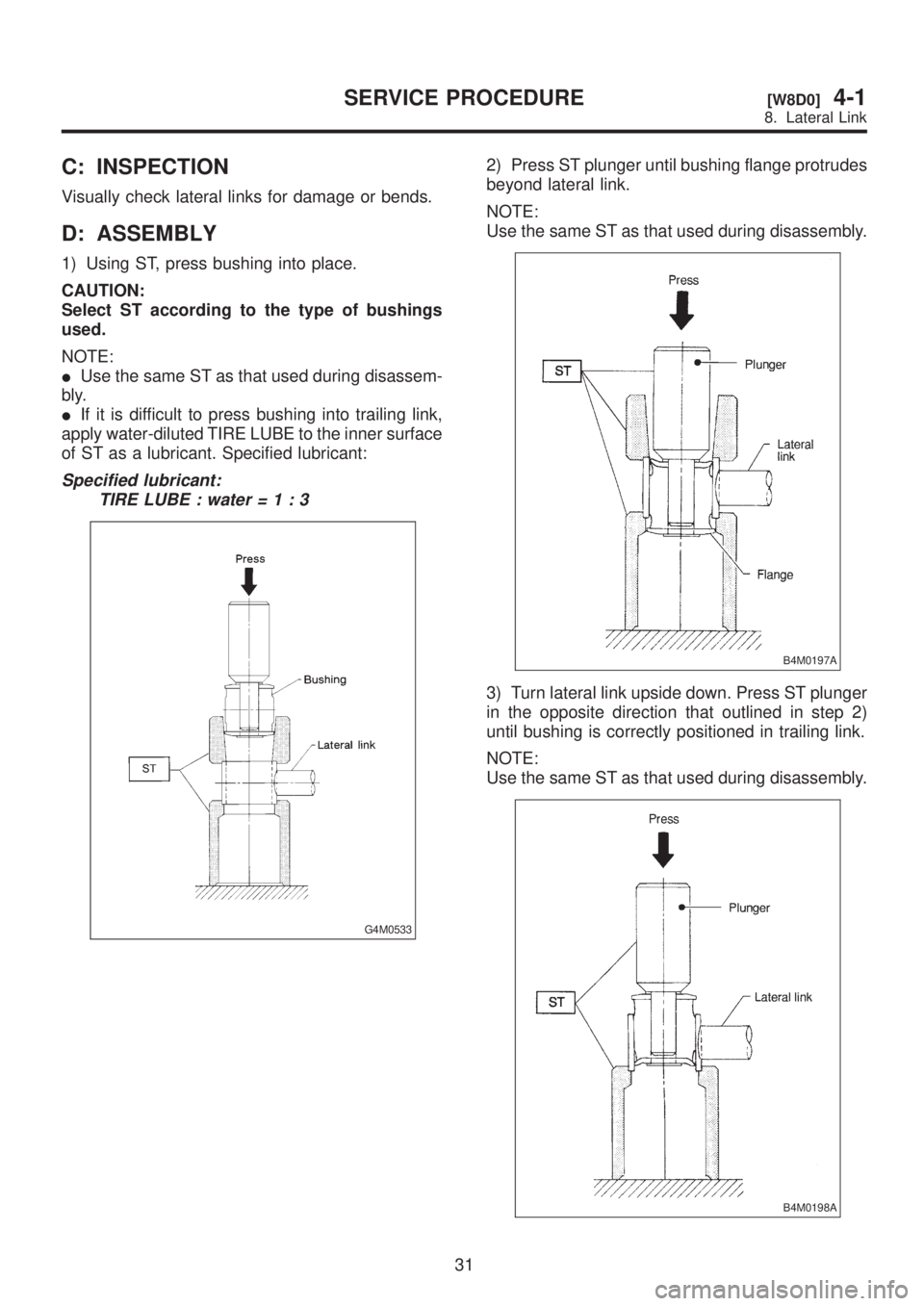

C: INSPECTION

Visually check lateral links for damage or bends.

D: ASSEMBLY

1) Using ST, press bushing into place.

CAUTION:

Select ST according to the type of bushings

used.

NOTE:

IUse the same ST as that used during disassem-

bly.

IIf it is difficult to press bushing into trailing link,

apply water-diluted TIRE LUBE to the inner surface

of ST as a lubricant. Specified lubricant:

Specified lubricant:

TIRE LUBE : water=1:3

G4M0533

2) Press ST plunger until bushing flange protrudes

beyond lateral link.

NOTE:

Use the same ST as that used during disassembly.

B4M0197A

3) Turn lateral link upside down. Press ST plunger

in the opposite direction that outlined in step 2)

until bushing is correctly positioned in trailing link.

NOTE:

Use the same ST as that used during disassembly.

B4M0198A

31

[W8D0]4-1SERVICE PROCEDURE

8. Lateral Link

Page 745 of 1456

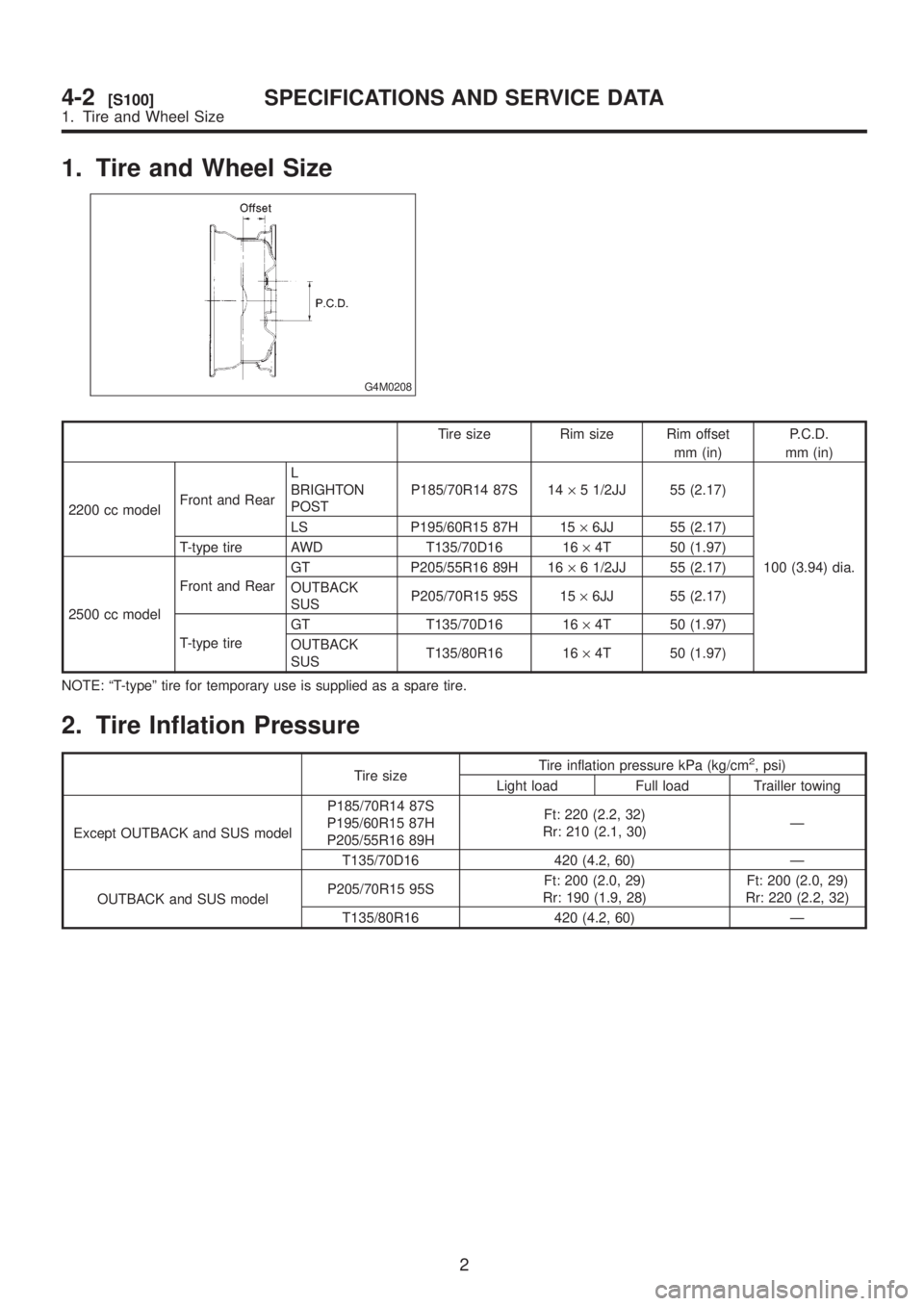

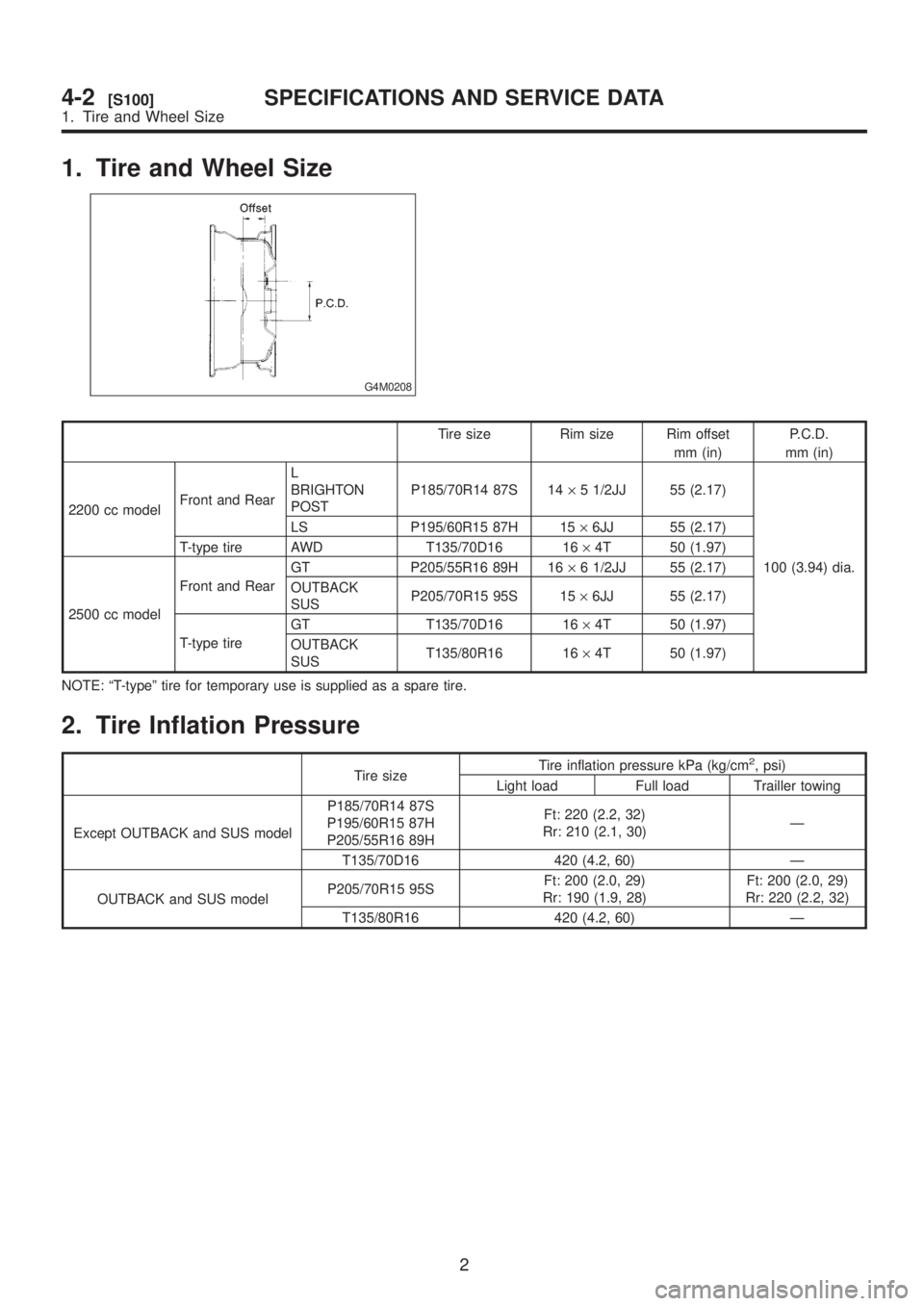

1. Tire and Wheel Size

G4M0208

Tire size Rim size Rim offset

mm (in)P.C.D.

mm (in)

2200 cc modelFront and RearL

BRIGHTON

POSTP185/70R14 87S 14´5 1/2JJ 55 (2.17)

100 (3.94) dia. LS P195/60R15 87H 15´6JJ 55 (2.17)

T-type tire AWD T135/70D16 16´4T 50 (1.97)

2500 cc modelFront and RearGT P205/55R16 89H 16´6 1/2JJ 55 (2.17)

OUTBACK

SUSP205/70R15 95S 15´6JJ 55 (2.17)

T-type tireGT T135/70D16 16´4T 50 (1.97)

OUTBACK

SUST135/80R16 16´4T 50 (1.97)

NOTE: ªT-typeº tire for temporary use is supplied as a spare tire.

2. Tire Inflation Pressure

Tire sizeTire inflation pressure kPa (kg/cm

2, psi)

Light load Full load Trailler towing

Except OUTBACK and SUS modelP185/70R14 87S

P195/60R15 87H

P205/55R16 89HFt: 220 (2.2, 32)

Rr: 210 (2.1, 30)Ð

T135/70D16 420 (4.2, 60) Ð

OUTBACK and SUS modelP205/70R15 95SFt: 200 (2.0, 29)

Rr: 190 (1.9, 28)Ft: 200 (2.0, 29)

Rr: 220 (2.2, 32)

T135/80R16 420 (4.2, 60) Ð

2

4-2[S100]SPECIFICATIONS AND SERVICE DATA

1. Tire and Wheel Size

Page 746 of 1456

1. Tire and Wheel Size

G4M0208

Tire size Rim size Rim offset

mm (in)P.C.D.

mm (in)

2200 cc modelFront and RearL

BRIGHTON

POSTP185/70R14 87S 14´5 1/2JJ 55 (2.17)

100 (3.94) dia. LS P195/60R15 87H 15´6JJ 55 (2.17)

T-type tire AWD T135/70D16 16´4T 50 (1.97)

2500 cc modelFront and RearGT P205/55R16 89H 16´6 1/2JJ 55 (2.17)

OUTBACK

SUSP205/70R15 95S 15´6JJ 55 (2.17)

T-type tireGT T135/70D16 16´4T 50 (1.97)

OUTBACK

SUST135/80R16 16´4T 50 (1.97)

NOTE: ªT-typeº tire for temporary use is supplied as a spare tire.

2. Tire Inflation Pressure

Tire sizeTire inflation pressure kPa (kg/cm

2, psi)

Light load Full load Trailler towing

Except OUTBACK and SUS modelP185/70R14 87S

P195/60R15 87H

P205/55R16 89HFt: 220 (2.2, 32)

Rr: 210 (2.1, 30)Ð

T135/70D16 420 (4.2, 60) Ð

OUTBACK and SUS modelP205/70R15 95SFt: 200 (2.0, 29)

Rr: 190 (1.9, 28)Ft: 200 (2.0, 29)

Rr: 220 (2.2, 32)

T135/80R16 420 (4.2, 60) Ð

2

4-2[S100]SPECIFICATIONS AND SERVICE DATA

1. Tire and Wheel Size

Page 788 of 1456

8. Aluminum Wheel

A: INSPECTION

Inspection for aluminum wheels is basically the

same as the one for steel wheels. However, check

the rim flange for cracks or damage, and replace

(not repair) aluminum wheel if air leakage is found.

B: PRECAUTIONS

Aluminum wheels are easily scratched. To main-

tain their appearance and safety, do the following:

1) Do not damage aluminum wheels during

removal, disassembly, installation, wheel

balancing, etc. After removing aluminum wheels,

place them on a rubber mat, etc.

2) While vehicle is being driven, be careful not to

ride over sharp obstacles or allow aluminum

wheels to contact the shoulder of the road.

3) When installing tire chain, be sure to install it

properly not to have a slack; otherwise it may hit

wheel while driving.

4) When washing aluminum wheel, use neutral

synthetic detergent and water. Avoid using the

cleanser including abrasive, hard brushes or an

automatic car washer.

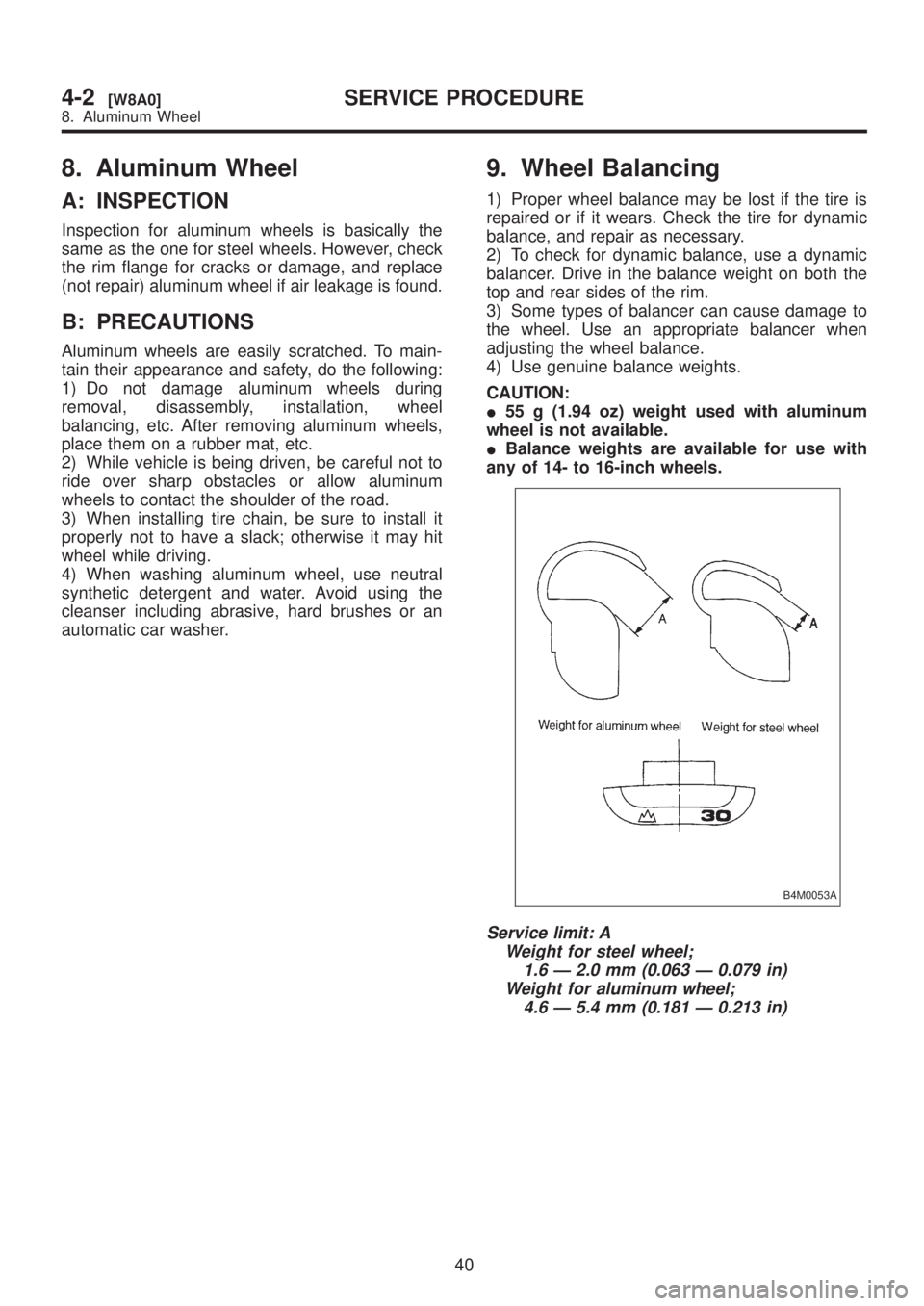

9. Wheel Balancing

1) Proper wheel balance may be lost if the tire is

repaired or if it wears. Check the tire for dynamic

balance, and repair as necessary.

2) To check for dynamic balance, use a dynamic

balancer. Drive in the balance weight on both the

top and rear sides of the rim.

3) Some types of balancer can cause damage to

the wheel. Use an appropriate balancer when

adjusting the wheel balance.

4) Use genuine balance weights.

CAUTION:

I55 g (1.94 oz) weight used with aluminum

wheel is not available.

IBalance weights are available for use with

any of 14- to 16-inch wheels.

B4M0053A

Service limit: A

Weight for steel wheel;

1.6 Ð 2.0 mm (0.063 Ð 0.079 in)

Weight for aluminum wheel;

4.6 Ð 5.4 mm (0.181 Ð 0.213 in)

40

4-2[W8A0]SERVICE PROCEDURE

8. Aluminum Wheel

Page 789 of 1456

8. Aluminum Wheel

A: INSPECTION

Inspection for aluminum wheels is basically the

same as the one for steel wheels. However, check

the rim flange for cracks or damage, and replace

(not repair) aluminum wheel if air leakage is found.

B: PRECAUTIONS

Aluminum wheels are easily scratched. To main-

tain their appearance and safety, do the following:

1) Do not damage aluminum wheels during

removal, disassembly, installation, wheel

balancing, etc. After removing aluminum wheels,

place them on a rubber mat, etc.

2) While vehicle is being driven, be careful not to

ride over sharp obstacles or allow aluminum

wheels to contact the shoulder of the road.

3) When installing tire chain, be sure to install it

properly not to have a slack; otherwise it may hit

wheel while driving.

4) When washing aluminum wheel, use neutral

synthetic detergent and water. Avoid using the

cleanser including abrasive, hard brushes or an

automatic car washer.

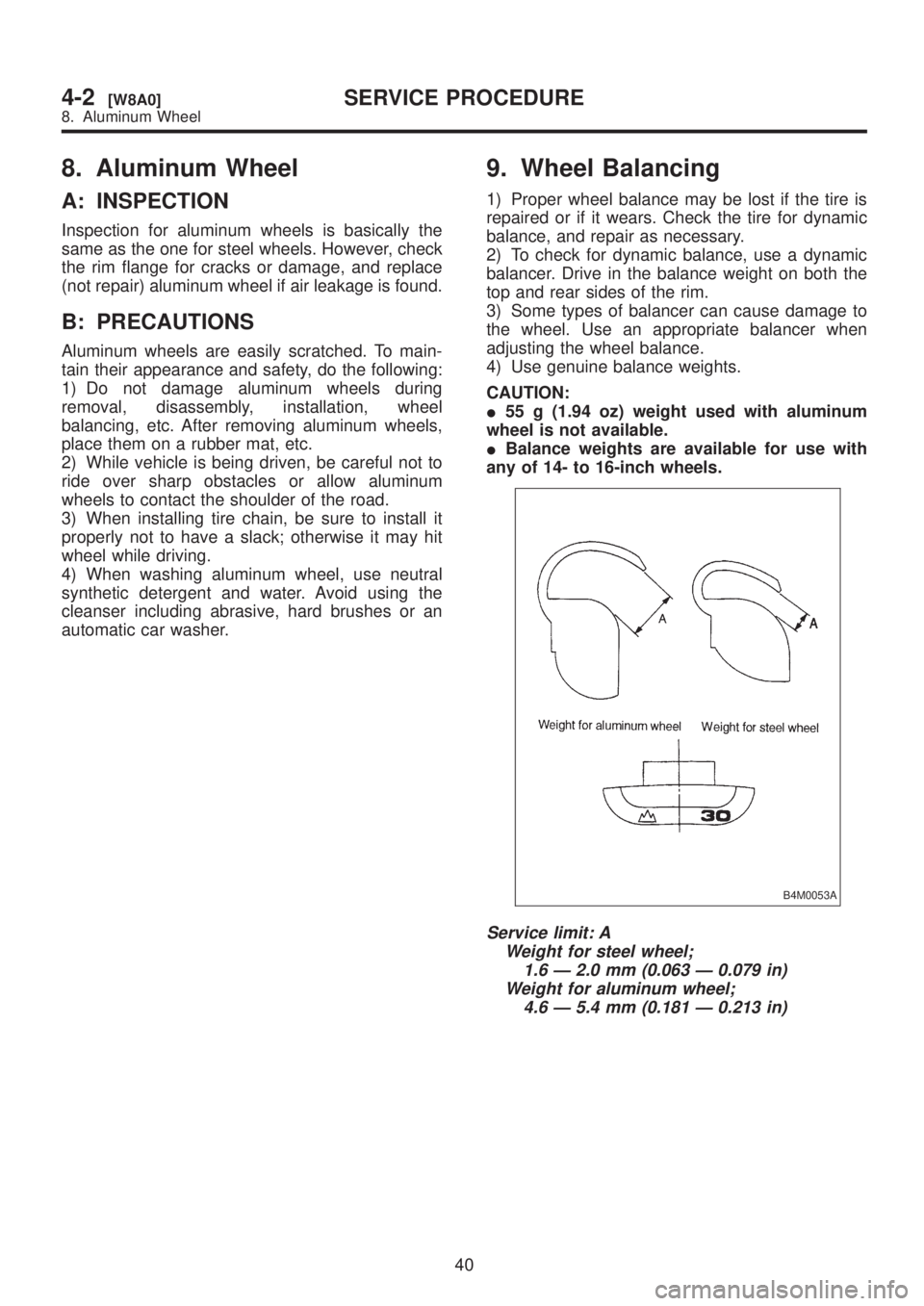

9. Wheel Balancing

1) Proper wheel balance may be lost if the tire is

repaired or if it wears. Check the tire for dynamic

balance, and repair as necessary.

2) To check for dynamic balance, use a dynamic

balancer. Drive in the balance weight on both the

top and rear sides of the rim.

3) Some types of balancer can cause damage to

the wheel. Use an appropriate balancer when

adjusting the wheel balance.

4) Use genuine balance weights.

CAUTION:

I55 g (1.94 oz) weight used with aluminum

wheel is not available.

IBalance weights are available for use with

any of 14- to 16-inch wheels.

B4M0053A

Service limit: A

Weight for steel wheel;

1.6 Ð 2.0 mm (0.063 Ð 0.079 in)

Weight for aluminum wheel;

4.6 Ð 5.4 mm (0.181 Ð 0.213 in)

40

4-2[W8A0]SERVICE PROCEDURE

8. Aluminum Wheel

Page 792 of 1456

12. ªT-typeº Tire

ªT-typeº tire for temporary use is prepared as a

spare tire.

CAUTION:

IKeep the inflation pressure at 420 kPa (4.2

kg/cm

2, 60 psi) at all times.

IWhen the wear indicator appears on the

tread surface, replace the tire with a new one.

IDo not use a tire chain with the ªT-typeº tire.

Because of the smaller tire size, a tire chain will

not fit properly and will result in damage to the

vehicle and the tire.

IDo not drive at a speed greater than 80 km/h

(50 MPH).

IDrive as slowly as possible and avoid pass-

ing over bumps.

IReplace with a conventional tire as soon as

possible since this ªT-typeº tire is only for tem-

porary use.

42

4-2[W1200]SERVICE PROCEDURE

12. ªT-typeº Tire

Page 793 of 1456

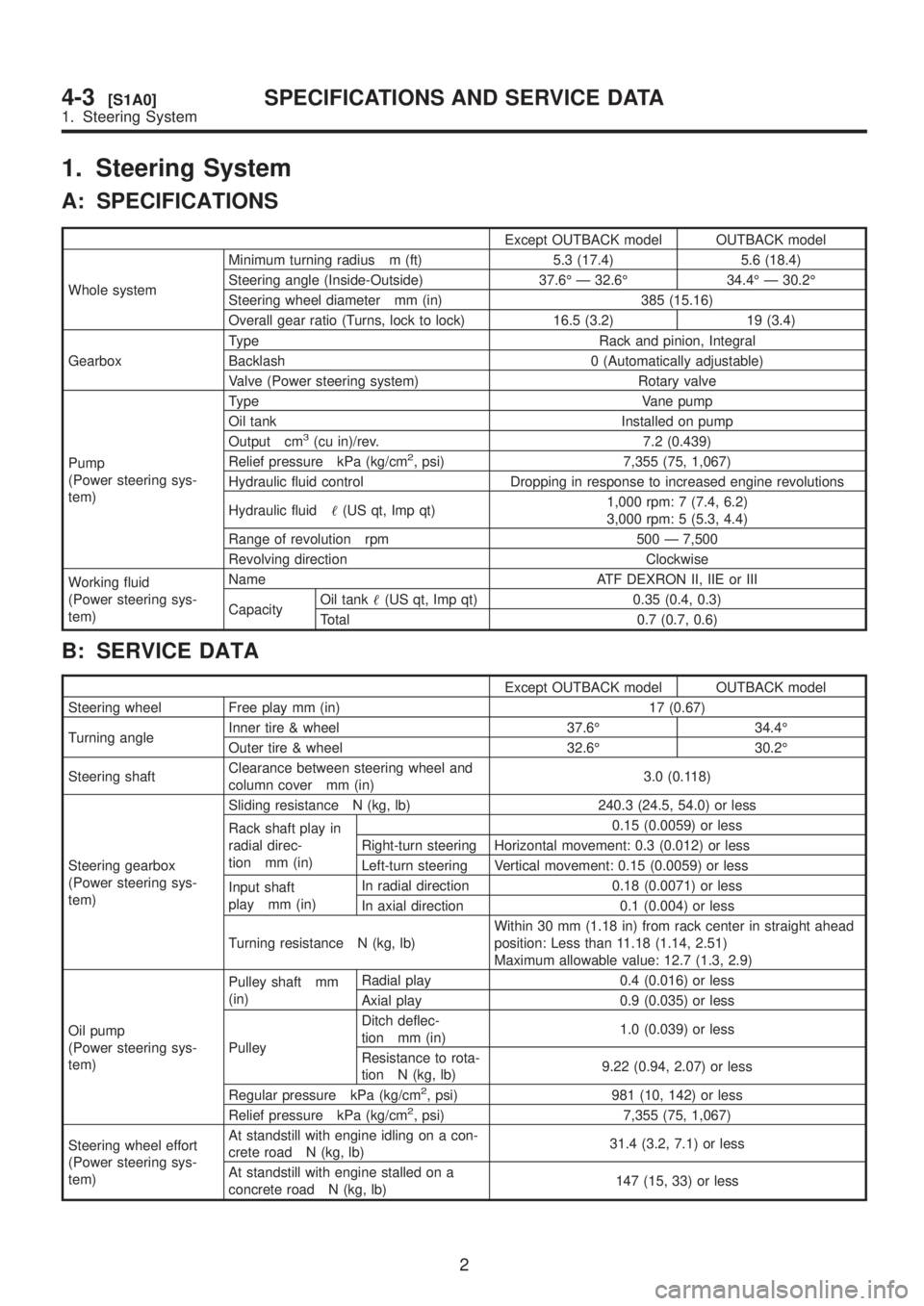

1. Steering System

A: SPECIFICATIONS

Except OUTBACK model OUTBACK model

Whole systemMinimum turning radius m (ft) 5.3 (17.4) 5.6 (18.4)

Steering angle (Inside-Outside) 37.6É Ð 32.6É 34.4É Ð 30.2É

Steering wheel diameter mm (in) 385 (15.16)

Overall gear ratio (Turns, lock to lock) 16.5 (3.2) 19 (3.4)

GearboxType Rack and pinion, Integral

Backlash 0 (Automatically adjustable)

Valve (Power steering system) Rotary valve

Pump

(Power steering sys-

tem)Type Vane pump

Oil tank Installed on pump

Output cm

3(cu in)/rev. 7.2 (0.439)

Relief pressure kPa (kg/cm2, psi) 7,355 (75, 1,067)

Hydraulic fluid control Dropping in response to increased engine revolutions

Hydraulic fluid(US qt, Imp qt)1,000 rpm: 7 (7.4, 6.2)

3,000 rpm: 5 (5.3, 4.4)

Range of revolution rpm 500 Ð 7,500

Revolving direction Clockwise

Working fluid

(Power steering sys-

tem)Name ATF DEXRON II, IIE or III

CapacityOil tank(US qt, Imp qt) 0.35 (0.4, 0.3)

Total 0.7 (0.7, 0.6)

B: SERVICE DATA

Except OUTBACK model OUTBACK model

Steering wheel Free play mm (in) 17 (0.67)

Turning angleInner tire & wheel 37.6É 34.4É

Outer tire & wheel 32.6É 30.2É

Steering shaftClearance between steering wheel and

column cover mm (in)3.0 (0.118)

Steering gearbox

(Power steering sys-

tem)Sliding resistance N (kg, lb) 240.3 (24.5, 54.0) or less

Rack shaft play in

radial direc-

tion mm (in)0.15 (0.0059) or less

Right-turn steering Horizontal movement: 0.3 (0.012) or less

Left-turn steering Vertical movement: 0.15 (0.0059) or less

Input shaft

play mm (in)In radial direction 0.18 (0.0071) or less

In axial direction 0.1 (0.004) or less

Turning resistance N (kg, lb)Within 30 mm (1.18 in) from rack center in straight ahead

position: Less than 11.18 (1.14, 2.51)

Maximum allowable value: 12.7 (1.3, 2.9)

Oil pump

(Power steering sys-

tem)Pulley shaft mm

(in)Radial play 0.4 (0.016) or less

Axial play 0.9 (0.035) or less

PulleyDitch deflec-

tion mm (in)1.0 (0.039) or less

Resistance to rota-

tion N (kg, lb)9.22 (0.94, 2.07) or less

Regular pressure kPa (kg/cm

2, psi) 981 (10, 142) or less

Relief pressure kPa (kg/cm2, psi) 7,355 (75, 1,067)

Steering wheel effort

(Power steering sys-

tem)At standstill with engine idling on a con-

crete road N (kg, lb)31.4 (3.2, 7.1) or less

At standstill with engine stalled on a

concrete road N (kg, lb)147 (15, 33) or less

2

4-3[S1A0]SPECIFICATIONS AND SERVICE DATA

1. Steering System

Page 1231 of 1456

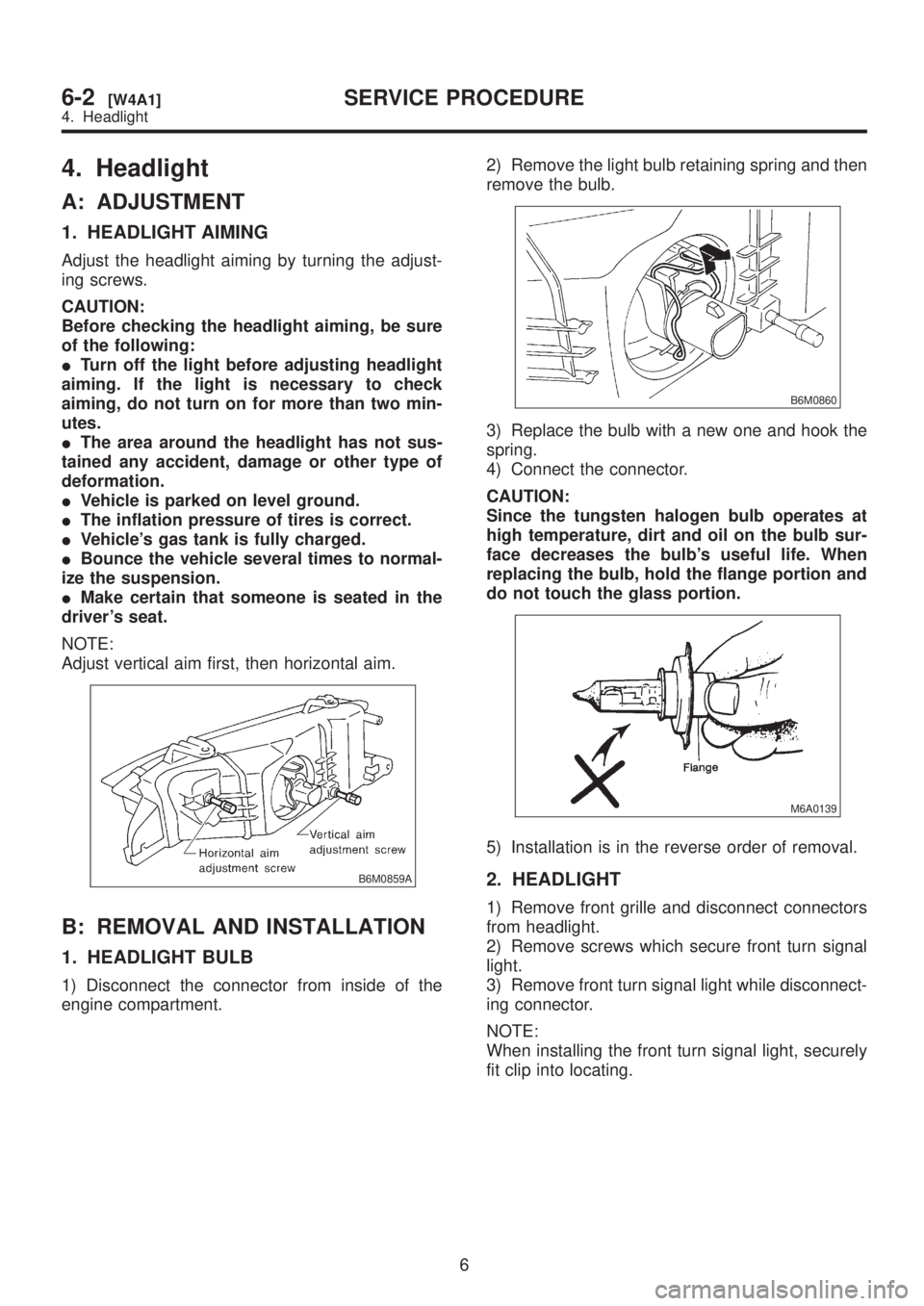

4. Headlight

A: ADJUSTMENT

1. HEADLIGHT AIMING

Adjust the headlight aiming by turning the adjust-

ing screws.

CAUTION:

Before checking the headlight aiming, be sure

of the following:

ITurn off the light before adjusting headlight

aiming. If the light is necessary to check

aiming, do not turn on for more than two min-

utes.

IThe area around the headlight has not sus-

tained any accident, damage or other type of

deformation.

IVehicle is parked on level ground.

IThe inflation pressure of tires is correct.

IVehicle's gas tank is fully charged.

IBounce the vehicle several times to normal-

ize the suspension.

IMake certain that someone is seated in the

driver's seat.

NOTE:

Adjust vertical aim first, then horizontal aim.

B6M0859A

B: REMOVAL AND INSTALLATION

1. HEADLIGHT BULB

1) Disconnect the connector from inside of the

engine compartment.2) Remove the light bulb retaining spring and then

remove the bulb.

B6M0860

3) Replace the bulb with a new one and hook the

spring.

4) Connect the connector.

CAUTION:

Since the tungsten halogen bulb operates at

high temperature, dirt and oil on the bulb sur-

face decreases the bulb's useful life. When

replacing the bulb, hold the flange portion and

do not touch the glass portion.

M6A0139

5) Installation is in the reverse order of removal.

2. HEADLIGHT

1) Remove front grille and disconnect connectors

from headlight.

2) Remove screws which secure front turn signal

light.

3) Remove front turn signal light while disconnect-

ing connector.

NOTE:

When installing the front turn signal light, securely

fit clip into locating.

6

6-2[W4A1]SERVICE PROCEDURE

4. Headlight