transmission SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 260 of 1456

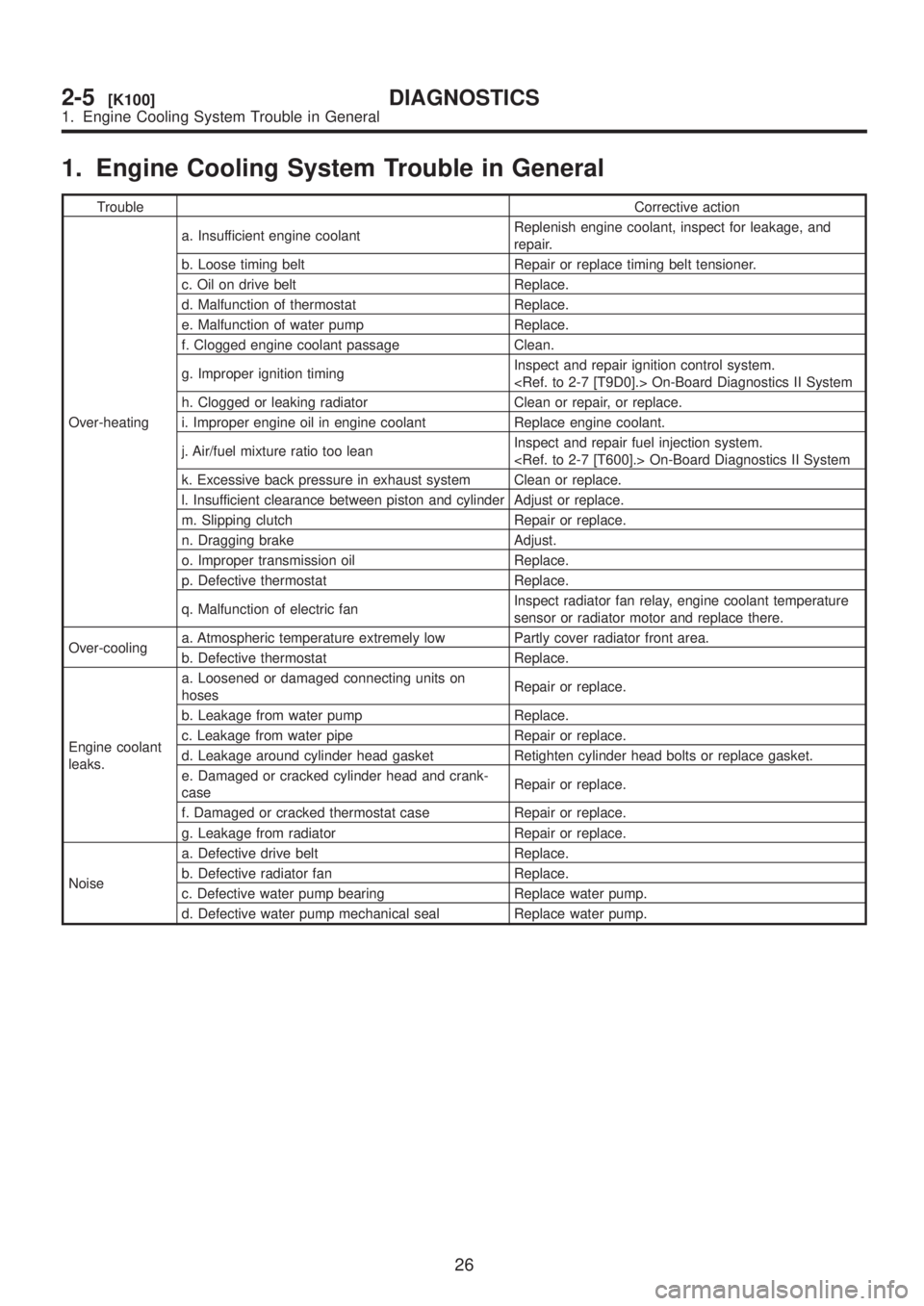

1. Engine Cooling System Trouble in General

TroubleCorrective action

Over-heatinga. Insufficient engine coolantReplenish engine coolant, inspect for leakage, and

repair.

b. Loose timing belt Repair or replace timing belt tensioner.

c. Oil on drive belt Replace.

d. Malfunction of thermostat Replace.

e. Malfunction of water pump Replace.

f. Clogged engine coolant passage Clean.

g. Improper ignition timingInspect and repair ignition control system.

h. Clogged or leaking radiator Clean or repair, or replace.

i. Improper engine oil in engine coolant Replace engine coolant.

j. Air/fuel mixture ratio too leanInspect and repair fuel injection system.

k. Excessive back pressure in exhaust system Clean or replace.

l. Insufficient clearance between piston and cylinder Adjust or replace.

m. Slipping clutch Repair or replace.

n. Dragging brake Adjust.

o. Improper transmission oil Replace.

p. Defective thermostat Replace.

q. Malfunction of electric fanInspect radiator fan relay, engine coolant temperature

sensor or radiator motor and replace there.

Over-coolinga. Atmospheric temperature extremely low Partly cover radiator front area.

b. Defective thermostat Replace.

Engine coolant

leaks.a. Loosened or damaged connecting units on

hosesRepair or replace.

b. Leakage from water pump Replace.

c. Leakage from water pipe Repair or replace.

d. Leakage around cylinder head gasket Retighten cylinder head bolts or replace gasket.

e. Damaged or cracked cylinder head and crank-

caseRepair or replace.

f. Damaged or cracked thermostat case Repair or replace.

g. Leakage from radiator Repair or replace.

Noisea. Defective drive belt Replace.

b. Defective radiator fan Replace.

c. Defective water pump bearing Replace water pump.

d. Defective water pump mechanical seal Replace water pump.

26

2-5[K100]DIAGNOSTICS

1. Engine Cooling System Trouble in General

Page 293 of 1456

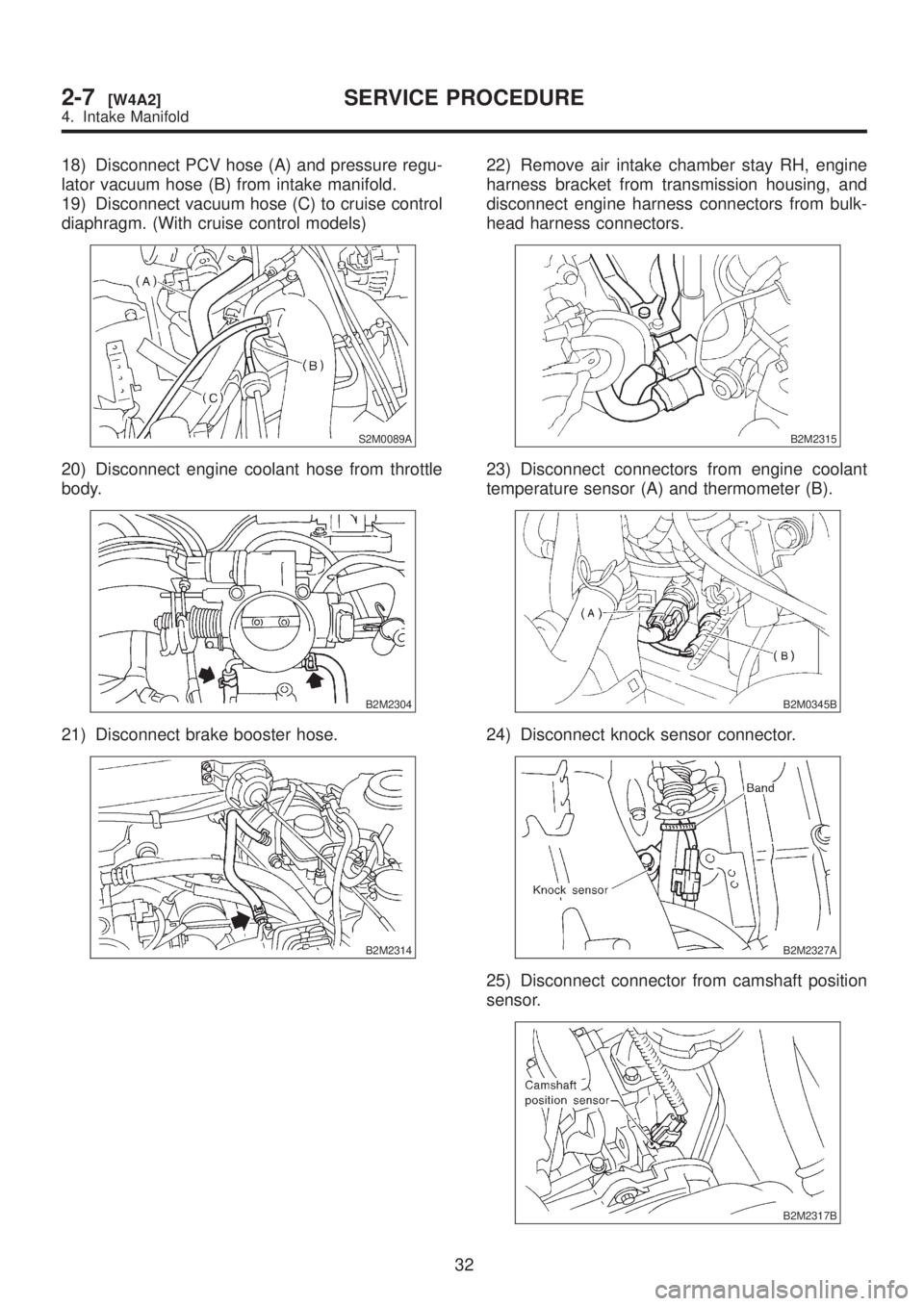

18) Disconnect PCV hose (A) and pressure regu-

lator vacuum hose (B) from intake manifold.

19) Disconnect vacuum hose (C) to cruise control

diaphragm. (With cruise control models)

S2M0089A

20) Disconnect engine coolant hose from throttle

body.

B2M2304

21) Disconnect brake booster hose.

B2M2314

22) Remove air intake chamber stay RH, engine

harness bracket from transmission housing, and

disconnect engine harness connectors from bulk-

head harness connectors.

B2M2315

23) Disconnect connectors from engine coolant

temperature sensor (A) and thermometer (B).

B2M0345B

24) Disconnect knock sensor connector.

B2M2327A

25) Disconnect connector from camshaft position

sensor.

B2M2317B

32

2-7[W4A2]SERVICE PROCEDURE

4. Intake Manifold

Page 352 of 1456

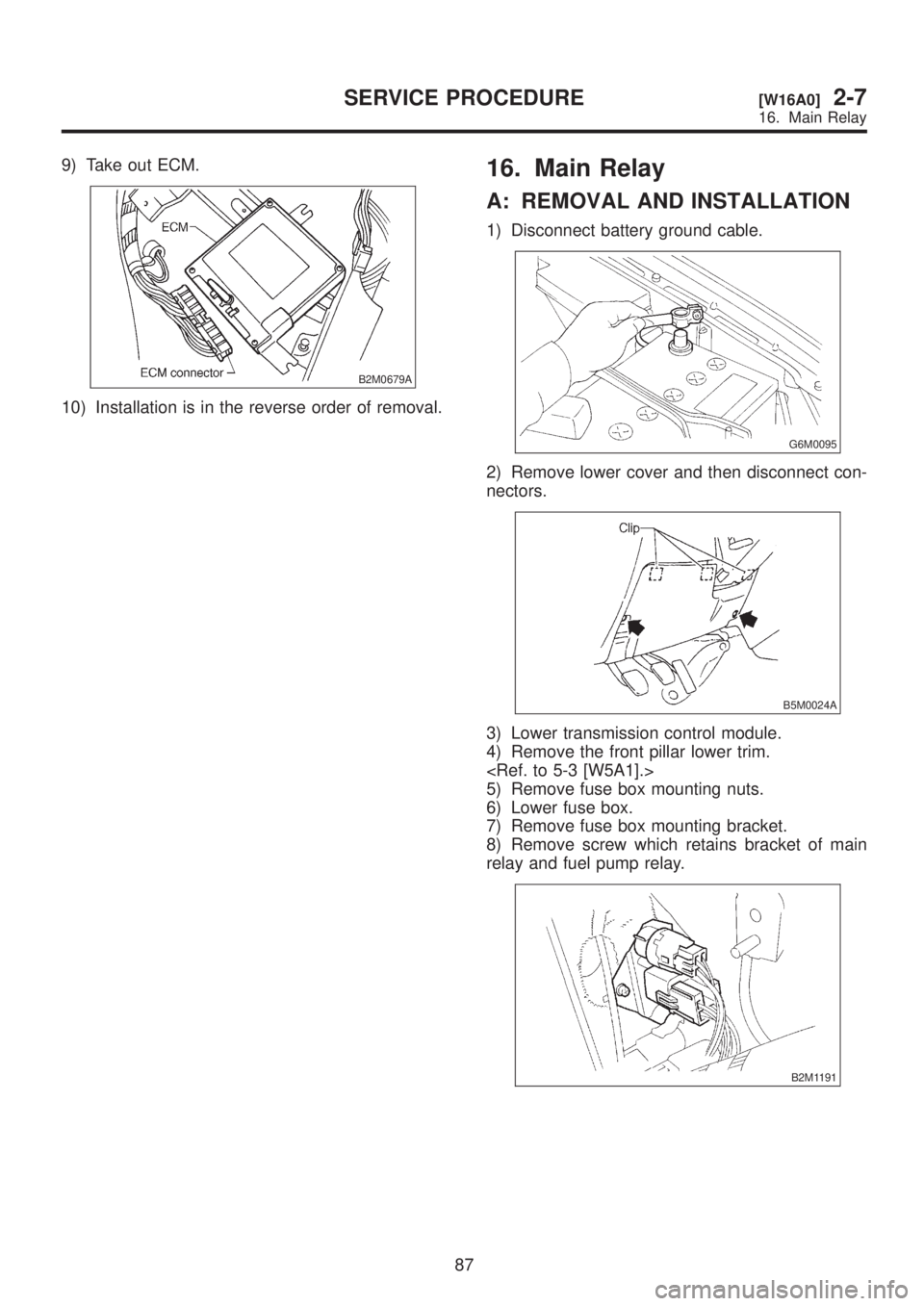

9) Take out ECM.

B2M0679A

10) Installation is in the reverse order of removal.

16. Main Relay

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

G6M0095

2) Remove lower cover and then disconnect con-

nectors.

B5M0024A

3) Lower transmission control module.

4) Remove the front pillar lower trim.

5) Remove fuse box mounting nuts.

6) Lower fuse box.

7) Remove fuse box mounting bracket.

8) Remove screw which retains bracket of main

relay and fuel pump relay.

B2M1191

87

[W16A0]2-7SERVICE PROCEDURE

16. Main Relay

Page 353 of 1456

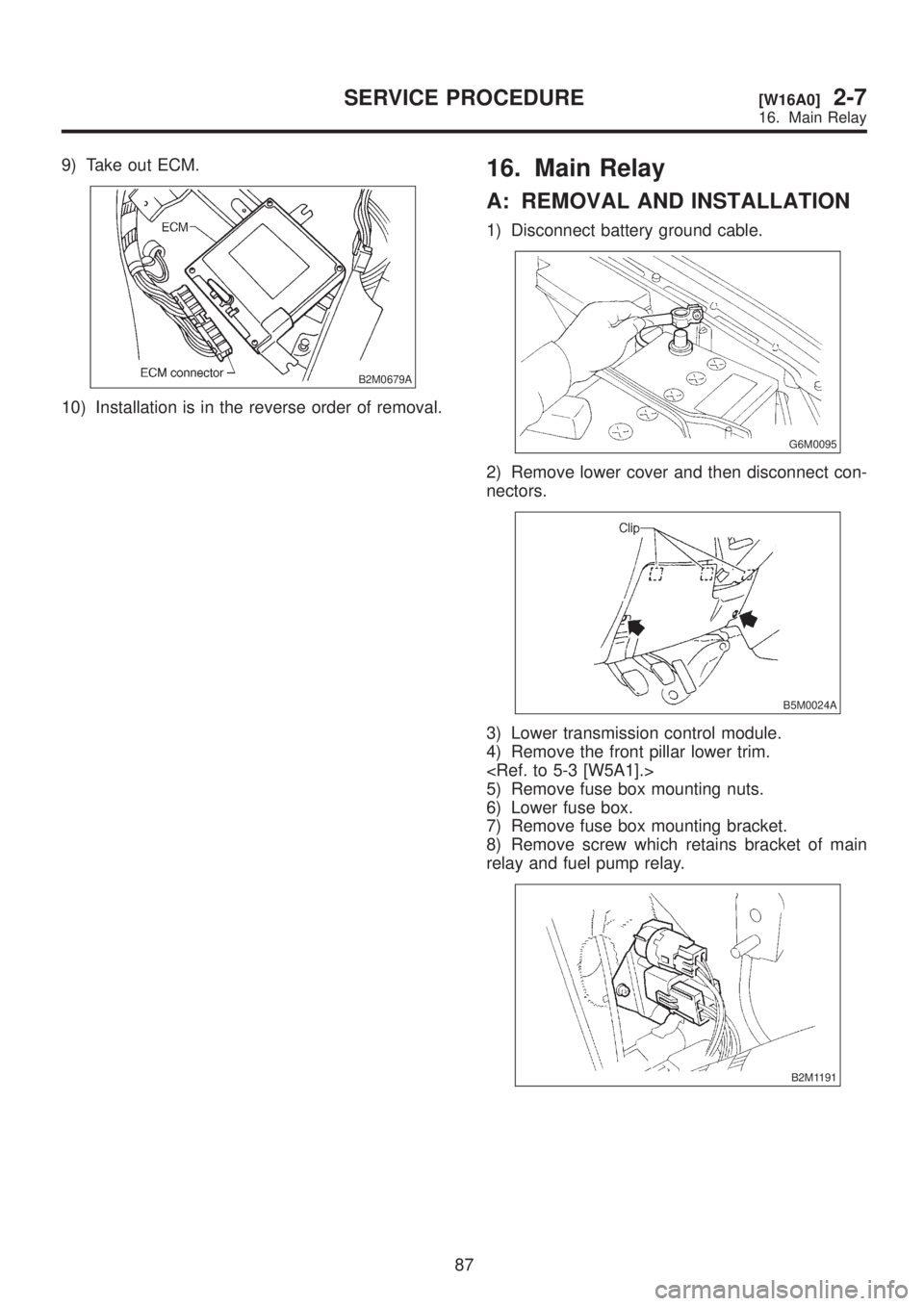

9) Take out ECM.

B2M0679A

10) Installation is in the reverse order of removal.

16. Main Relay

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

G6M0095

2) Remove lower cover and then disconnect con-

nectors.

B5M0024A

3) Lower transmission control module.

4) Remove the front pillar lower trim.

5) Remove fuse box mounting nuts.

6) Lower fuse box.

7) Remove fuse box mounting bracket.

8) Remove screw which retains bracket of main

relay and fuel pump relay.

B2M1191

87

[W16A0]2-7SERVICE PROCEDURE

16. Main Relay

Page 354 of 1456

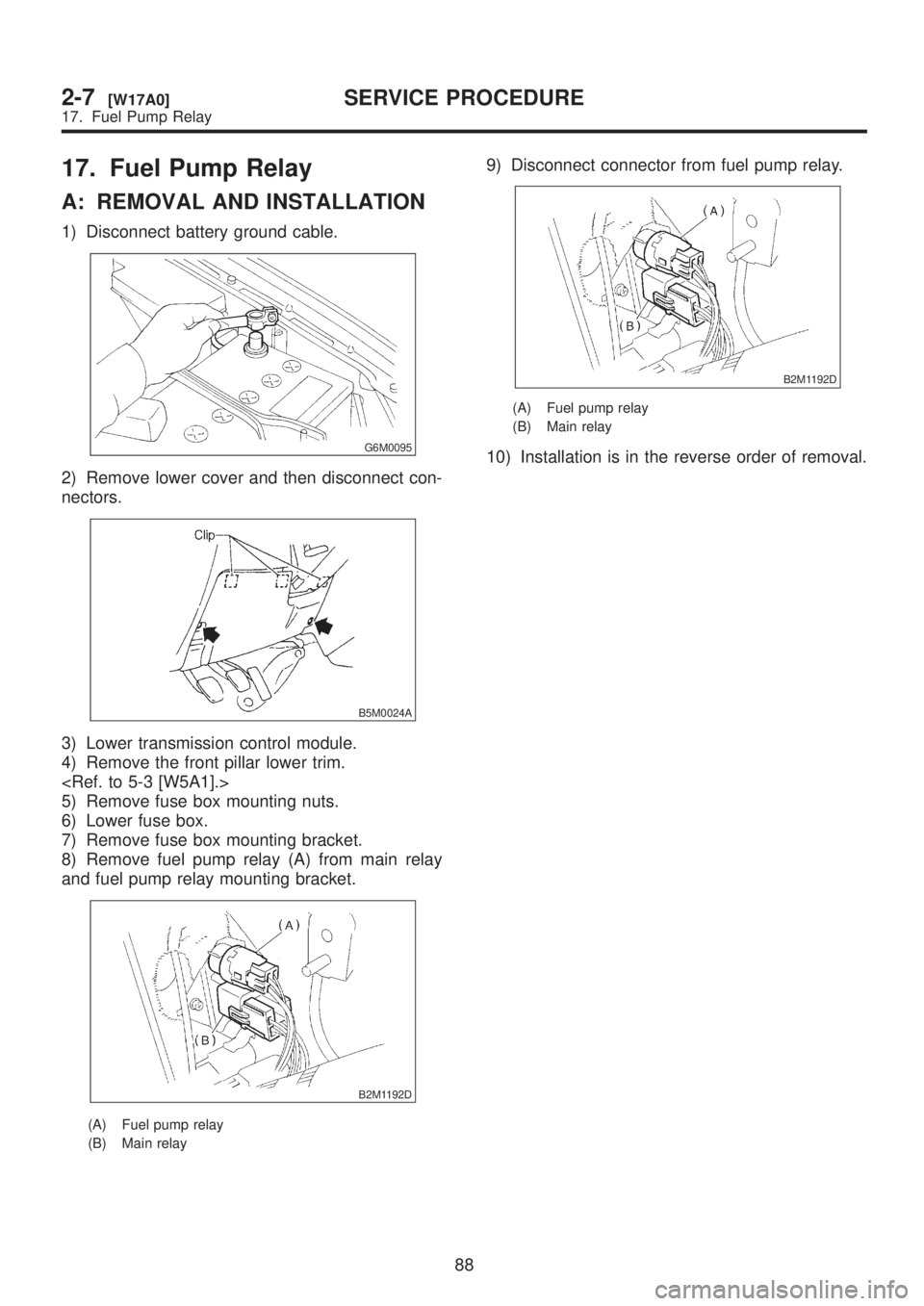

17. Fuel Pump Relay

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

G6M0095

2) Remove lower cover and then disconnect con-

nectors.

B5M0024A

3) Lower transmission control module.

4) Remove the front pillar lower trim.

5) Remove fuse box mounting nuts.

6) Lower fuse box.

7) Remove fuse box mounting bracket.

8) Remove fuel pump relay (A) from main relay

and fuel pump relay mounting bracket.

B2M1192D

(A) Fuel pump relay

(B) Main relay

9) Disconnect connector from fuel pump relay.

B2M1192D

(A) Fuel pump relay

(B) Main relay

10) Installation is in the reverse order of removal.

88

2-7[W17A0]SERVICE PROCEDURE

17. Fuel Pump Relay

Page 373 of 1456

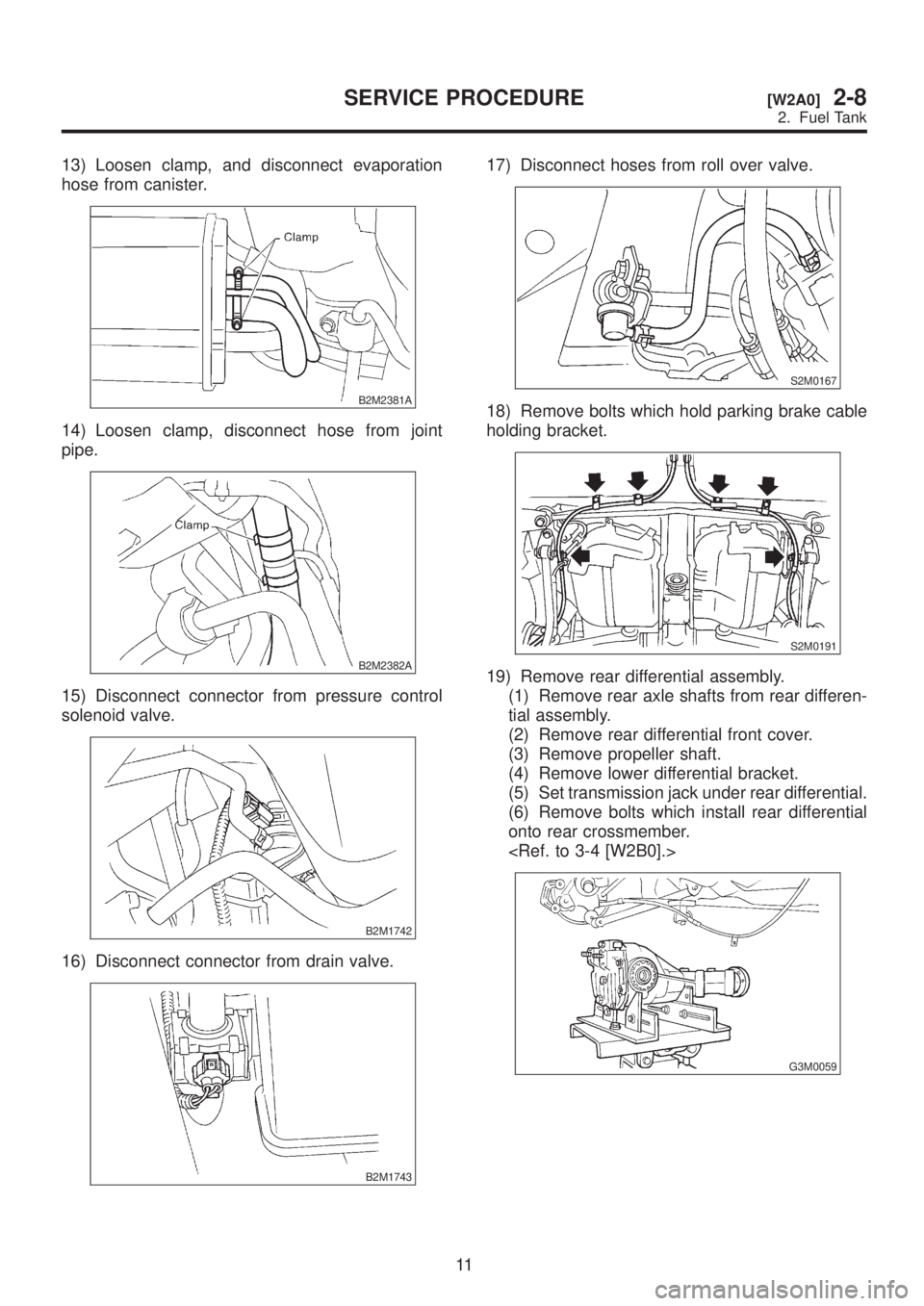

13) Loosen clamp, and disconnect evaporation

hose from canister.

B2M2381A

14) Loosen clamp, disconnect hose from joint

pipe.

B2M2382A

15) Disconnect connector from pressure control

solenoid valve.

B2M1742

16) Disconnect connector from drain valve.

B2M1743

17) Disconnect hoses from roll over valve.

S2M0167

18) Remove bolts which hold parking brake cable

holding bracket.

S2M0191

19) Remove rear differential assembly.

(1) Remove rear axle shafts from rear differen-

tial assembly.

(2) Remove rear differential front cover.

(3) Remove propeller shaft.

(4) Remove lower differential bracket.

(5) Set transmission jack under rear differential.

(6) Remove bolts which install rear differential

onto rear crossmember.

G3M0059

11

[W2A0]2-8SERVICE PROCEDURE

2. Fuel Tank

Page 418 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 3. Release Bearing and Lever

A: REMOVAL

1. MECHANICAL APPLICATION TYPE

1) Remove transmission assembly from vehicle

body.

<Ref. to 2-11 [W2B0].>

2) Remove release lever return spring (Models

without h SUBARU LEGACY 1999 Service Repair Manual 3. Release Bearing and Lever

A: REMOVAL

1. MECHANICAL APPLICATION TYPE

1) Remove transmission assembly from vehicle

body.

<Ref. to 2-11 [W2B0].>

2) Remove release lever return spring (Models

without h](/img/17/57435/w960_57435-417.png)

3. Release Bearing and Lever

A: REMOVAL

1. MECHANICAL APPLICATION TYPE

1) Remove transmission assembly from vehicle

body.

2) Remove release lever return spring (Models

without hill holder only).

3) Remove the two clips from clutch release lever

and remove release bearing.

CAUTION:

Be careful not to deform clips.

4) Remove release lever seal.

B2M0633D

(A) Release lever return spring

(B) Clip

(C) Release lever

(D) Release lever seal

(E) Retainer spring

(F) Clutch release lever

5) Remove release lever retainer spring from

release lever pivot with a screwdriver by accessing

it through clutch housing release lever hole. Then

remove release lever.

B2M0174A

2. HYDRAULIC APPLICATION TYPE

1) Remove transmission assembly from vehicle

body.

2) Remove operating cylinder.

3) Remove the two clips from clutch release lever

and remove release bearing.

CAUTION:

Be careful not to deform clips.

4) Remove release lever seal.

B2M1257G

(A) Operating cylinder

(B) Clip

(C) Clutch release lever

(D) Release bearing

(E) Release lever seal

8

2-10[W3A1]SERVICE PROCEDURE

3. Release Bearing and Lever

Page 419 of 1456

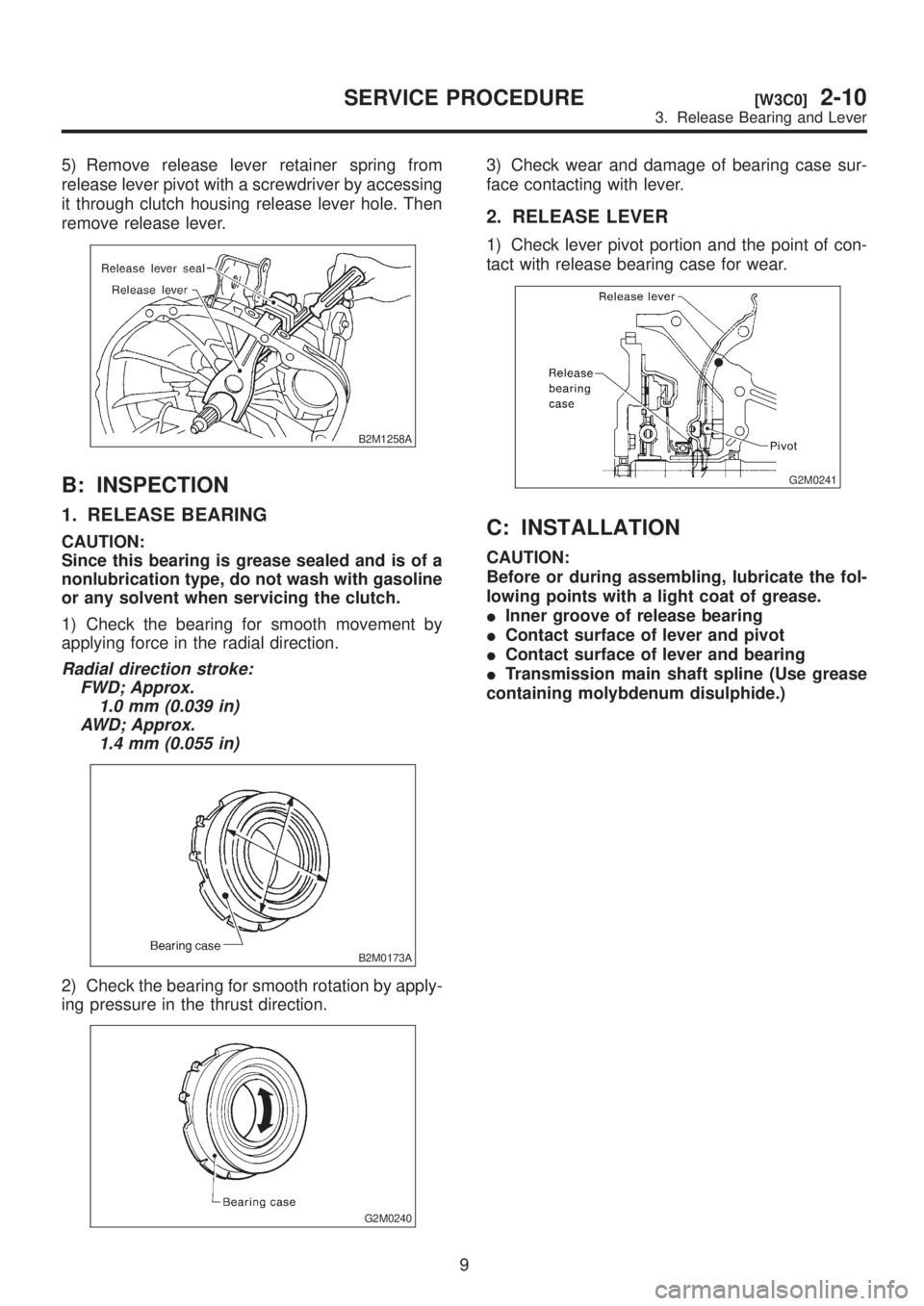

5) Remove release lever retainer spring from

release lever pivot with a screwdriver by accessing

it through clutch housing release lever hole. Then

remove release lever.

B2M1258A

B: INSPECTION

1. RELEASE BEARING

CAUTION:

Since this bearing is grease sealed and is of a

nonlubrication type, do not wash with gasoline

or any solvent when servicing the clutch.

1) Check the bearing for smooth movement by

applying force in the radial direction.

Radial direction stroke:

FWD; Approx.

1.0 mm (0.039 in)

AWD; Approx.

1.4 mm (0.055 in)

B2M0173A

2) Check the bearing for smooth rotation by apply-

ing pressure in the thrust direction.

G2M0240

3) Check wear and damage of bearing case sur-

face contacting with lever.

2. RELEASE LEVER

1) Check lever pivot portion and the point of con-

tact with release bearing case for wear.

G2M0241

C: INSTALLATION

CAUTION:

Before or during assembling, lubricate the fol-

lowing points with a light coat of grease.

IInner groove of release bearing

IContact surface of lever and pivot

IContact surface of lever and bearing

ITransmission main shaft spline (Use grease

containing molybdenum disulphide.)

9

[W3C0]2-10SERVICE PROCEDURE

3. Release Bearing and Lever

Page 420 of 1456

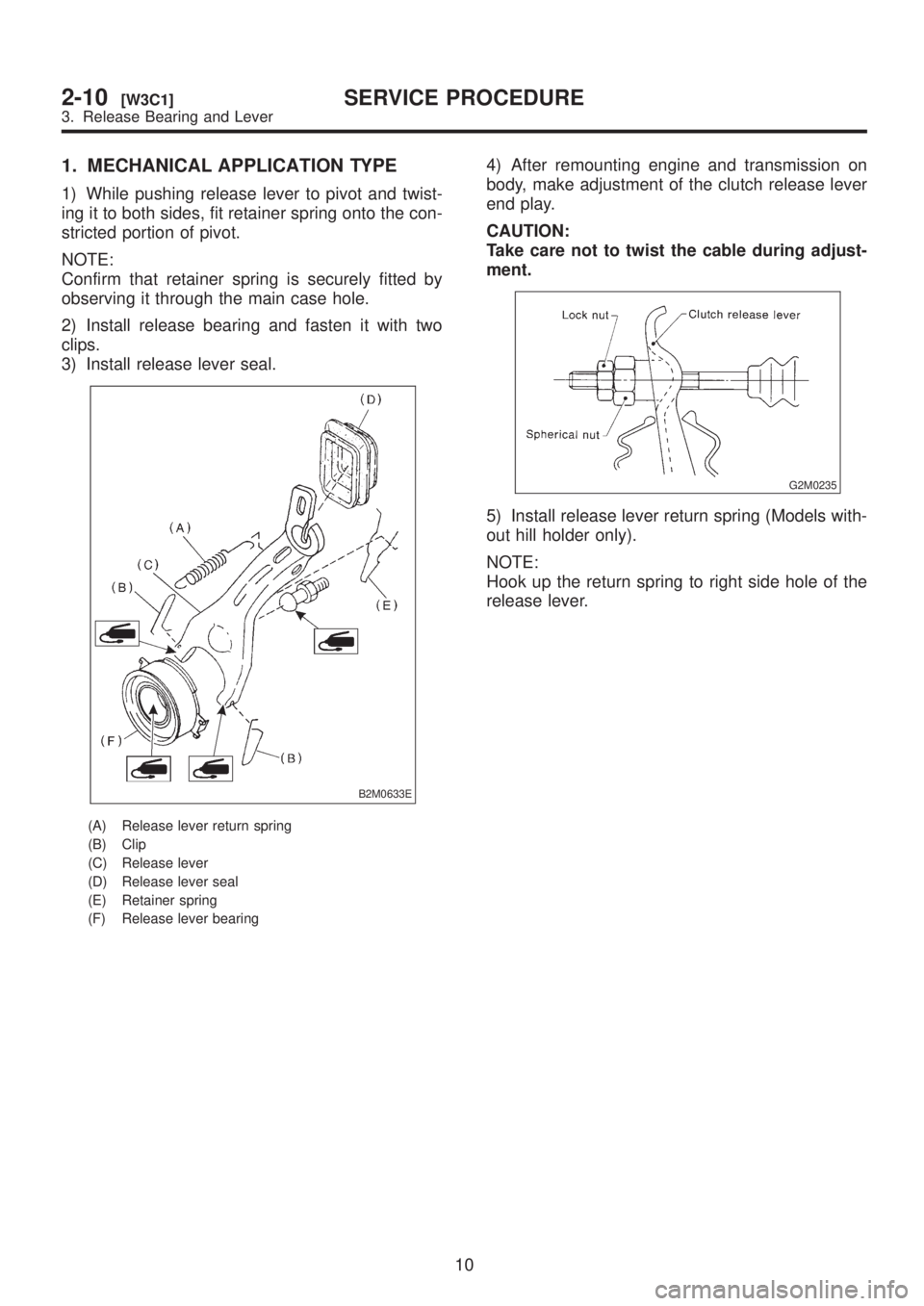

1. MECHANICAL APPLICATION TYPE

1) While pushing release lever to pivot and twist-

ing it to both sides, fit retainer spring onto the con-

stricted portion of pivot.

NOTE:

Confirm that retainer spring is securely fitted by

observing it through the main case hole.

2) Install release bearing and fasten it with two

clips.

3) Install release lever seal.

B2M0633E

(A) Release lever return spring

(B) Clip

(C) Release lever

(D) Release lever seal

(E) Retainer spring

(F) Release lever bearing

4) After remounting engine and transmission on

body, make adjustment of the clutch release lever

end play.

CAUTION:

Take care not to twist the cable during adjust-

ment.

G2M0235

5) Install release lever return spring (Models with-

out hill holder only).

NOTE:

Hook up the return spring to right side hole of the

release lever.

10

2-10[W3C1]SERVICE PROCEDURE

3. Release Bearing and Lever

Page 421 of 1456

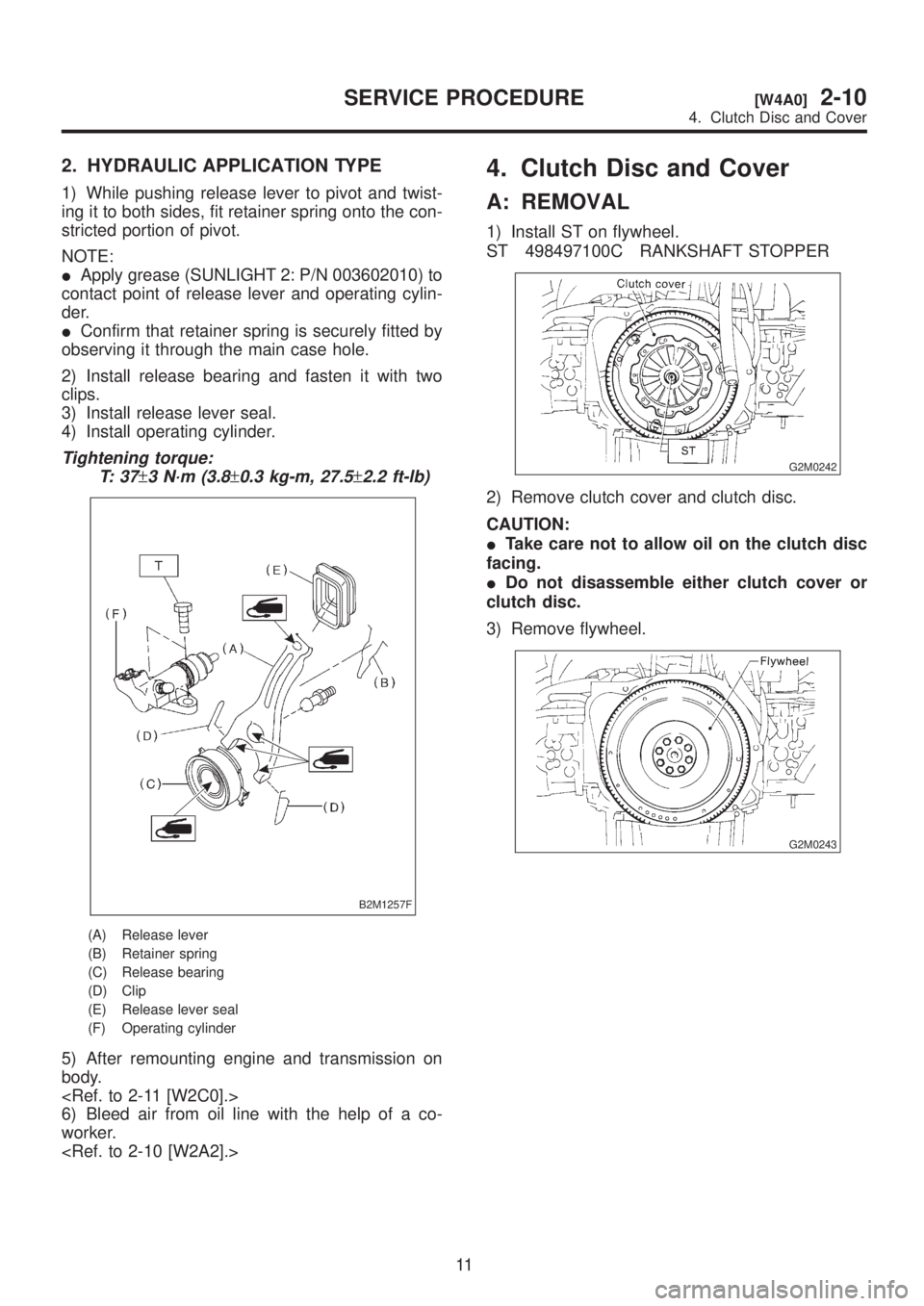

2. HYDRAULIC APPLICATION TYPE

1) While pushing release lever to pivot and twist-

ing it to both sides, fit retainer spring onto the con-

stricted portion of pivot.

NOTE:

IApply grease (SUNLIGHT 2: P/N 003602010) to

contact point of release lever and operating cylin-

der.

IConfirm that retainer spring is securely fitted by

observing it through the main case hole.

2) Install release bearing and fasten it with two

clips.

3) Install release lever seal.

4) Install operating cylinder.

Tightening torque:

T: 3 7

±3 N´m (3.8±0.3 kg-m, 27.5±2.2 ft-lb)

B2M1257F

(A) Release lever

(B) Retainer spring

(C) Release bearing

(D) Clip

(E) Release lever seal

(F) Operating cylinder

5) After remounting engine and transmission on

body.

6) Bleed air from oil line with the help of a co-

worker.

4. Clutch Disc and Cover

A: REMOVAL

1) Install ST on flywheel.

ST 498497100C RANKSHAFT STOPPER

G2M0242

2) Remove clutch cover and clutch disc.

CAUTION:

ITake care not to allow oil on the clutch disc

facing.

IDo not disassemble either clutch cover or

clutch disc.

3) Remove flywheel.

G2M0243

11

[W4A0]2-10SERVICE PROCEDURE

4. Clutch Disc and Cover