ESP SUBARU OUTBACK 2017 6.G Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2017, Model line: OUTBACK, Model: SUBARU OUTBACK 2017 6.GPages: 610, PDF Size: 10.28 MB

Page 465 of 610

Driving tips/Trailer towing (Legacy)

Trailer towing (Legacy)

Your vehicle is neither designed nor

intended to be used for trailer towing.

Therefore, never tow a trailer with your

vehicle.

SUBARU assumes no responsibility for

injuries or vehicle damage that may result

from trailer towing, from any trailer towing

equipment or from any errors or omissions

in the instructions accompanying such

equipment. SUBARU warranties do not

apply to vehicle damage or malfunction

caused by trailer towing.

Trailer towing (Outback)

Your vehicle is designed and intended to

be used primarily as a passenger-carrying

vehicle. Towing a trailer puts additional

loads on your vehicle’s engine, drivetrain,

brakes, tires and suspension and has an

adverse effect on fuel economy and air

conditioning system cooling performance.

If you do decide to tow a trailer, your safety

and satisfaction depend upon proper use

of correct equipment and cautious opera-

tion of your vehicle. Seek the advice of

your SUBARU dealer to assist you in

purchasing a hitch and other necessary

towing equipment appropriate for your

vehicle. Do not use towing equipment

other than genuine SUBARU towing

equipment. In addition, be sure to follow

the instructions on correct installation and

use provided by SUBARU.

SUBARU assumes no responsibility for

injuries or vehicle damage that result from

trailer towing equipment, or from any

errors or omissions in the instructions

accompanying such equipment or for your

failure to follow the proper instructions.

Regularly check that the hitch mounting

bolts and nuts are tightened securely.

& Warranties and maintenance

SUBARU warranties do not apply to

vehicle damage or malfunction caused

by trailer towing. If you use your vehicle to

tow a trailer, more frequent maintenance

will be required due to the additional load.

(Refer to “Maintenance schedule under

severe driving conditions ”in the “Warranty

and Maintenance Booklet ”.)

Under no circumstances should a trailer

be towed with a new vehicle or a vehicle

with any new powertrain component (en-

gine, transmission, differential, wheel

bearings, etc.) for the first 1,000 miles

(1,600 km) of driving.

& Maximum load limits

WARNING

Never exceed the maximum load

limits explained in the following.

Exceeding the maximum load limits

could cause personal injury and/or

vehicle damage.

CAUTION

. Adequate size trailer brakes are

required when the trailer and its

cargo exceed 1,000 lbs (453 kg)

8-22

Page 468 of 610

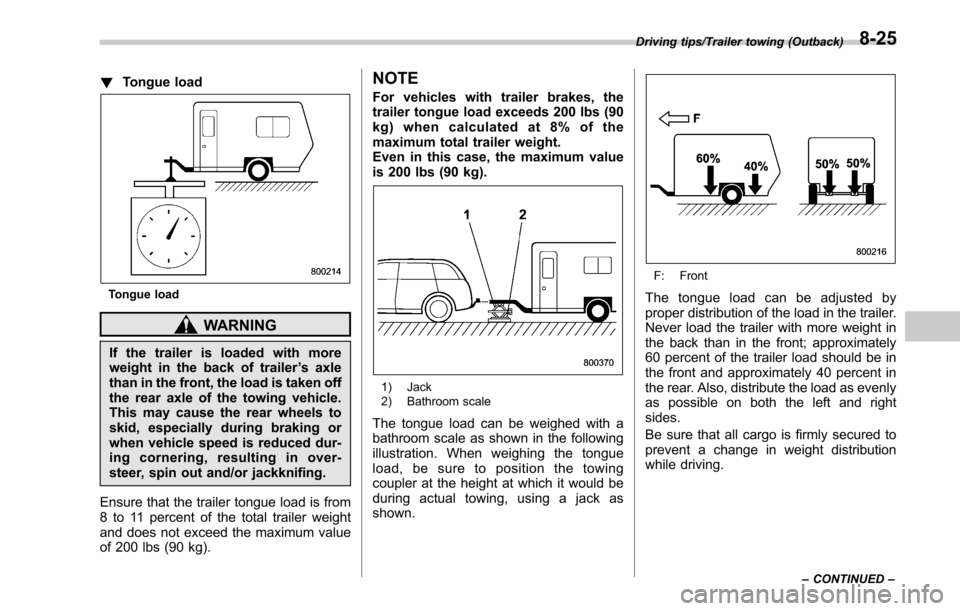

!Tongue load

Tongue load

WARNING

If the trailer is loaded with more

weight in the back of trailer ’s axle

than in the front, the load is taken off

the rear axle of the towing vehicle.

This may cause the rear wheels to

skid, especially during braking or

when vehicle speed is reduced dur-

ing cornering, resulting in over-

steer, spin out and/or jackknifing.

Ensure that the trailer tongue load is from

8 to 11 percent of the total trailer weight

and does not exceed the maximum value

of 200 lbs (90 kg).

NOTE

For vehicles with trailer brakes, the

trailer tongue load exceeds 200 lbs (90

kg) when calculated at 8% of the

maximum total trailer weight.

Even in this case, the maximum value

is 200 lbs (90 kg).

1) Jack

2) Bathroom scale

The tongue load can be weighed with a

bathroom scale as shown in the following

illustration. When weighing the tongue

load, be sure to position the towing

coupler at the height at which it would be

during actual towing, using a jack as

shown.

F: Front

The tongue load can be adjusted by

proper distribution of the load in the trailer.

Never load the trailer with more weight in

the back than in the front; approximately

60 percent of the trailer load should be in

the front and approximately 40 percent in

the rear. Also, distribute the load as evenly

as possible on both the left and right

sides.

Be sure that all cargo is firmly secured to

prevent a change in weight distribution

while driving.

Driving tips/Trailer towing (Outback)

–CONTINUED –8-25

Page 501 of 610

Appearance care/Corrosion protection

washing device.

.Clean the vehicle (including the alumi-

num wheels) with water as soon as

possible when it has been splashed with

sea water, exposed to sea breezes, or

driven on roads treated with salt or other

agents.Corrosion protection

Your SUBARU has been designed and

built to resist corrosion. Special materials

and protective finishes have been used on

most parts of the vehicle to help maintain

fine appearance, strength, and reliable

operation.

& Most common causes of

corrosion

The most common causes of corrosion

are:

. The accumulation of moisture retaining

dirt and debris in body panel sections,

cavities, and other areas.

. Damage to paint and other protective

coatings caused by gravel and stone

chips or minor accidents.

Corrosion is accelerated on the vehicle

when:

. It is exposed to road salt or dust control

chemicals, or used in coastal areas where

there is more salt in the air, or in areas

where there is considerable industrial

pollution.

. It is driven in areas of high humidity,

especially when temperatures range just

above freezing.

. Dampness in certain parts of the vehicle remains for a long time, even

though other parts of the vehicle may be

dry.

.

High temperatures will cause corrosion

to parts of the vehicle which cannot dry

quickly due to lack of proper ventilation.

& To help prevent corrosion

Wash the vehicle regularly to prevent

corrosion of the body and suspension

components. Also, wash the vehicle

promptly after driving on any of the

following surfaces.

. roads that have been salted to prevent

them from freezing in winter

. mud, sand, or gravel

. coastal roads

After the winter has ended, it is recom-

mended that the underbody be given a

very thorough washing.

Before the beginning of winter, check the

condition of underbody components, such

as the exhaust system, fuel and brake

lines, brake cables, suspension, steering

system, floor pan, and fenders. If any of

them are found to be rusted, they should

be given an appropriate rust prevention

treatment or should be replaced. Contact

your SUBARU dealer to perform this kind

of maintenance and treatment if you need

10-4

Page 527 of 610

Maintenance and service/Replacement of brake pad

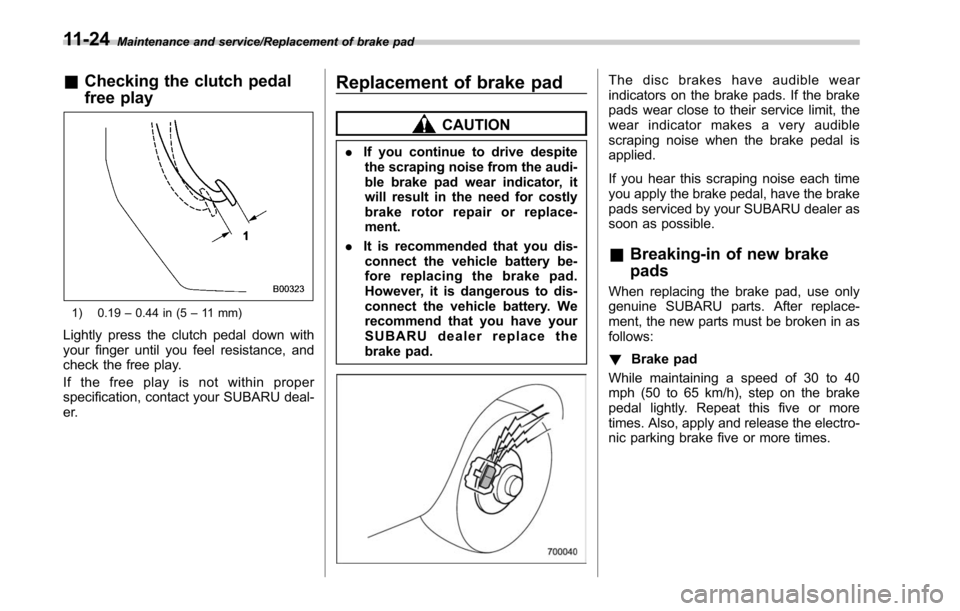

&Checking the clutch pedal

free play

1) 0.19 –0.44 in (5 –11 mm)

Lightly press the clutch pedal down with

your finger until you feel resistance, and

check the free play.

If the free play is not within proper

specification, contact your SUBARU deal-

er.

Replacement of brake pad

CAUTION

. If you continue to drive despite

the scraping noise from the audi-

ble brake pad wear indicator, it

will result in the need for costly

brake rotor repair or replace-

ment.

. It is recommended that you dis-

connect the vehicle battery be-

fore replacing the brake pad.

However, it is dangerous to dis-

connect the vehicle battery. We

recommend that you have your

SUBARU dealer replace the

brake pad.

The disc brakes have audible wear

indicators on the brake pads. If the brake

pads wear close to their service limit, the

wear indicator makes a very audible

scraping noise when the brake pedal is

applied.

If you hear this scraping noise each time

you apply the brake pedal, have the brake

pads serviced by your SUBARU dealer as

soon as possible.

& Breaking-in of new brake

pads

When replacing the brake pad, use only

genuine SUBARU parts. After replace-

ment, the new parts must be broken in as

follows:

! Brake pad

While maintaining a speed of 30 to 40

mph (50 to 65 km/h), step on the brake

pedal lightly. Repeat this five or more

times. Also, apply and release the electro-

nic parking brake five or more times.

11-24

Page 528 of 610

Tires and wheels

&Types of tires

You should be familiar with type of tires

present on your vehicle.

! All season tires

The factory-installed tires on your new

vehicle are all season tires.

All season tires are designed to provide

an adequate measure of traction, handling

and braking performance in year-round

driving including snowy and icy road

conditions. However all season tires do

not offer as much traction performance as

winter (snow) tires in heavy or loose snow

or on icy roads.

All season tires are identified by “ALL

SEASON ”and/or “M+S”(Mud & Snow) on

the tire sidewall.

! Summer tires

Summer tires are high-speed capability

tires best suited for highway driving under

dry conditions.

Summer tires are inadequate for driving

on slippery roads such as on snow-

covered or icy roads.

If you drive your vehicle on snow-covered

or icy roads, we strongly recommend the

use of winter (snow) tires.

When installing winter tires, be sure to replace all four tires.

!

Winter (snow) tires

Winter tires are best suited for driving on

snow-covered and icy roads. However

winter tires do not perform as well as

summer tires and all season tires on roads

other than snow-covered and icy roads.

& Tire pressure monitoring

system (TPMS) (if equipped)

The tire pressure monitoring system pro-

vides the driver with a warning message

by sending a signal from a sensor that is

installed in each wheel when tire pressure

is severely low. The tire pressure monitor-

ing system will activate only when the

vehicle is driven. Also, this system may

not react immediately to a sudden drop in

tire pressure (for example, a blow-out

caused by running over a sharp object).

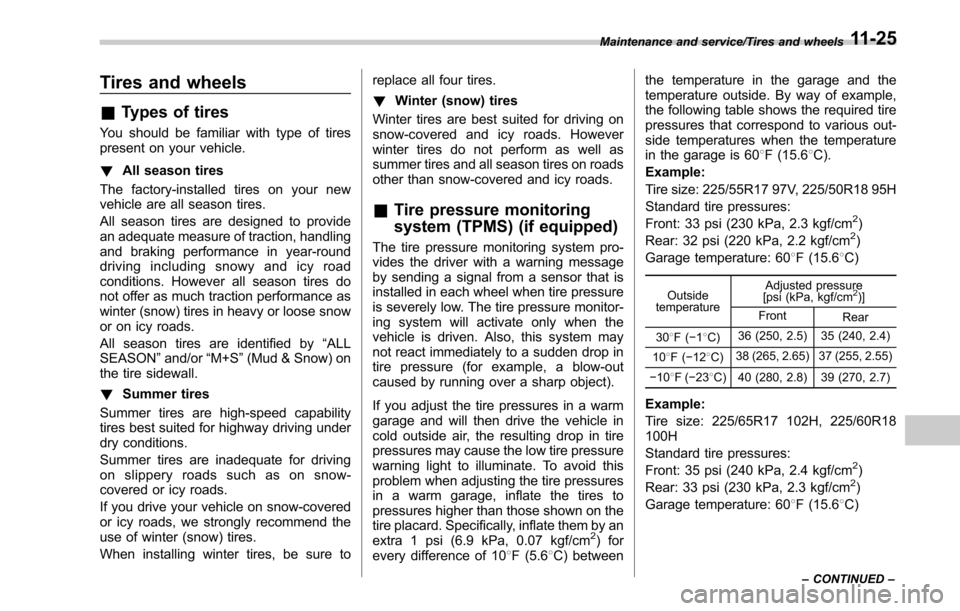

If you adjust the tire pressures in a warm

garage and will then drive the vehicle in

cold outside air, the resulting drop in tire

pressures may cause the low tire pressure

warning light to illuminate. To avoid this

problem when adjusting the tire pressures

in a warm garage, inflate the tires to

pressures higher than those shown on the

tire placard. Specifically, inflate them by an

extra 1 psi (6.9 kPa, 0.07 kgf/cm

2) for

every difference of 10 8F (5.6 8C) between the temperature in the garage and the

temperature outside. By way of example,

the following table shows the required tire

pressures that correspond to various out-

side temperatures when the temperature

in the garage is 60

8F (15.6 8C).

Example:

Tire size: 225/55R17 97V, 225/50R18 95H

Standard tire pressures:

Front: 33 psi (230 kPa, 2.3 kgf/cm

2)

Rear: 32 psi (220 kPa, 2.2 kgf/cm2)

Garage temperature: 60 8F (15.6 8C)

Outside

temperature Adjusted pressure

[psi (kPa, kgf/cm2)]

Front Rear

30 8F( −18C) 36 (250, 2.5) 35 (240, 2.4)

10 8F( −12 8C) 38 (265, 2.65) 37 (255, 2.55)

−10 8F( −23 8C) 40 (280, 2.8) 39 (270, 2.7)

Example:

Tire size: 225/65R17 102H, 225/60R18

100H

Standard tire pressures:

Front: 35 psi (240 kPa, 2.4 kgf/cm

2)

Rear: 33 psi (230 kPa, 2.3 kgf/cm2)

Garage temperature: 60 8F (15.6 8C)

Maintenance and service/Tires and wheels

–CONTINUED –11-25

Page 531 of 610

Maintenance and service/Tires and wheels

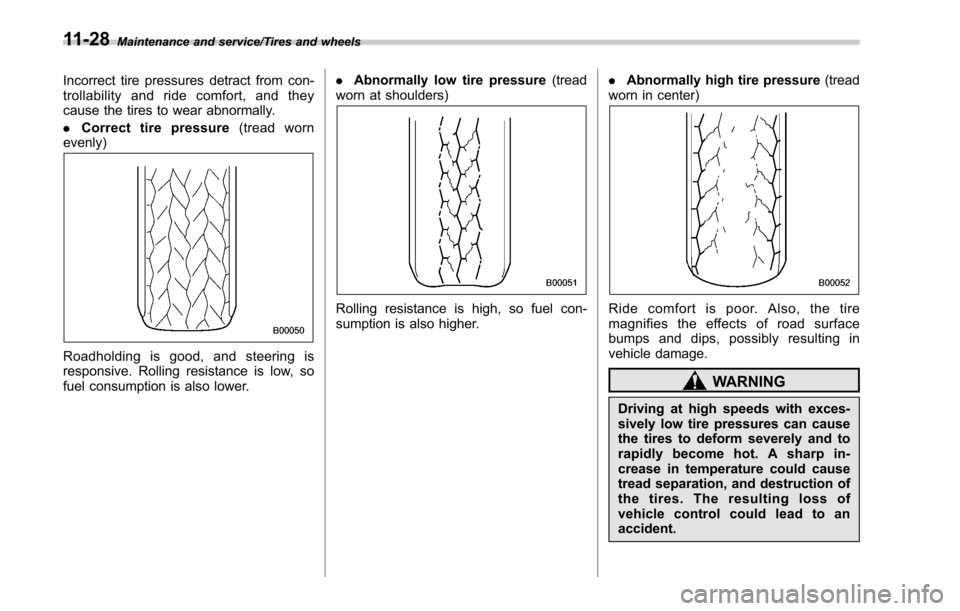

Incorrect tire pressures detract from con-

trollability and ride comfort, and they

cause the tires to wear abnormally.

.Correct tire pressure (tread worn

evenly)

Roadholding is good, and steering is

responsive. Rolling resistance is low, so

fuel consumption is also lower. .

Abnormally low tire pressure (tread

worn at shoulders)

Rolling resistance is high, so fuel con-

sumption is also higher. .

Abnormally high tire pressure (tread

worn in center)Ride comfort is poor. Also, the tire

magnifies the effects of road surface

bumps and dips, possibly resulting in

vehicle damage.

WARNING

Driving at high speeds with exces-

sively low tire pressures can cause

the tires to deform severely and to

rapidly become hot. A sharp in-

crease in temperature could cause

tread separation, and destruction of

the tires. The resulting loss of

vehicle control could lead to an

accident.

11-28

Page 542 of 610

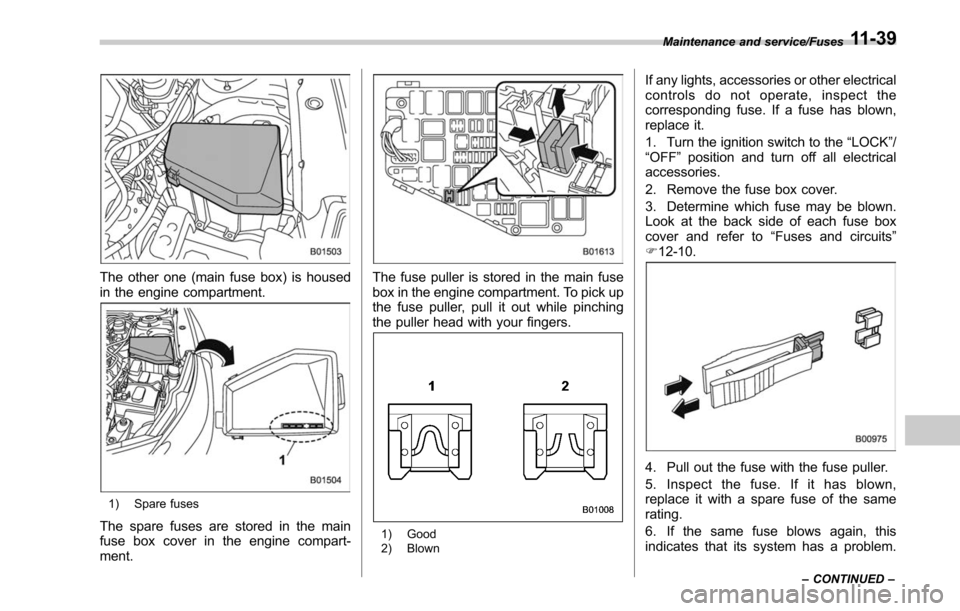

The other one (main fuse box) is housed

in the engine compartment.

1) Spare fuses

The spare fuses are stored in the main

fuse box cover in the engine compart-

ment.

The fuse puller is stored in the main fuse

box in the engine compartment. To pick up

the fuse puller, pull it out while pinching

the puller head with your fingers.

1) Good

2) Blown

If any lights, accessories or other electrical

controls do not operate, inspect the

corresponding fuse. If a fuse has blown,

replace it.

1. Turn the ignition switch to the“LOCK”/

“OFF ”position and turn off all electrical

accessories.

2. Remove the fuse box cover.

3. Determine which fuse may be blown.

Look at the back side of each fuse box

cover and refer to “Fuses and circuits”

F 12-10.

4. Pull out the fuse with the fuse puller.

5. Inspect the fuse. If it has blown,

replace it with a spare fuse of the same

rating.

6. If the same fuse blows again, this

indicates that its system has a problem.

Maintenance and service/Fuses

–CONTINUED –11-39

Page 571 of 610

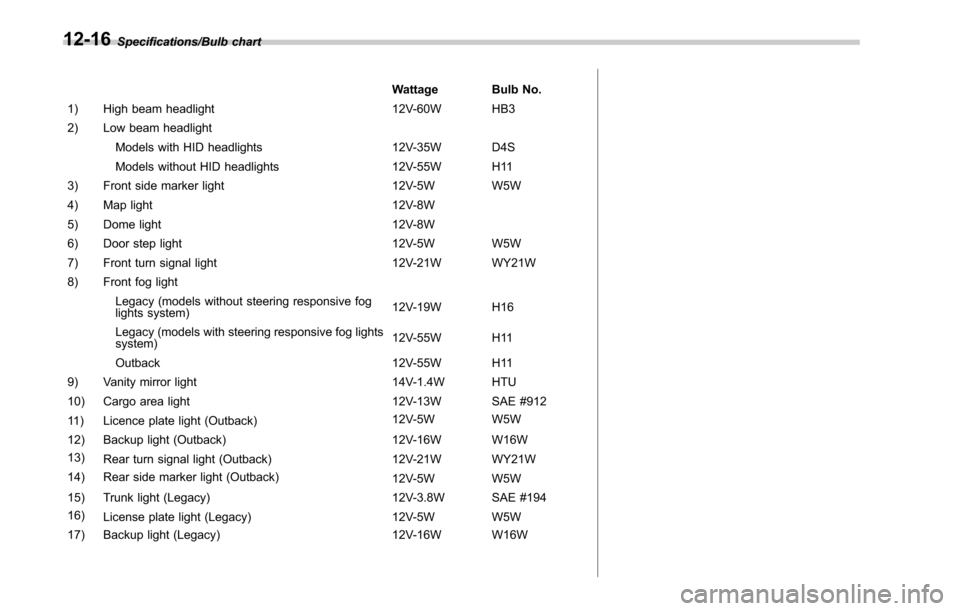

Specifications/Bulb chartWattage Bulb No.

1) High beam headlight 12V-60W HB3

2) Low beam headlight Models with HID headlights 12V-35W D4S

Models without HID headlights 12V-55W H11

3) Front side marker light 12V-5W W5W

4) Map light 12V-8W

5) Dome light 12V-8W

6) Door step light 12V-5W W5W

7) Front turn signal light 12V-21W WY21W

8) Front fog light

Legacy (models without steering responsive fog

lights system) 12V-19W H16

Legacy (models with steering responsive fog lights

system) 12V-55W H11

Outback 12V-55W H11

9) Vanity mirror light 14V-1.4W HTU

10) Cargo area light 12V-13W SAE #912

11) Licence plate light (Outback) 12V-5W W5W

12) Backup light (Outback) 12V-16W W16W

13) Rear turn signal light (Outback) 12V-21W WY21W

14) Rear side marker light (Outback) 12V-5W W5W

15) Trunk light (Legacy) 12V-3.8W SAE #194

16) License plate light (Legacy) 12V-5W W5W

17) Backup light (Legacy) 12V-16W W16W12-16

Page 579 of 610

Consumer information and Reporting safety defects/Tire information

rubber compounds.

.Cracking

Any parting within the tread, side-

wall, or inner liner of the tire

extending to cord material.

.Curb weight

The weight of a motor vehicle with

standard equipment including the

maximum capacity of fuel, oil and

coolant, and if so equipped, air

conditioning and additional weight

optional engine.

.Extra load tire

A tire designed to operate at higher

loads and higher inflation pressure

than the corresponding standard

tire.

.Groove

The space between two adjacent

tread ribs.

.Innerliner

The layer(s) forming the inside sur-

face of a tubeless tire that contains

the inflating medium within the tire.

.Innerliner separation

The parting of the innerliner from

cord material in the carcass.

.Intended outboard sidewall

(1)The sidewall that contains a

whitewall, bears white lettering

or bears manufacturer, brand,

and/or model name molding that

is higher or deeper than the

same molding on the other side-

wall of the tire, or

(2)The outward facing sidewall

of an asymmetrical tire that has

a particular side that must al-

ways face outward when mount-

ing on a vehicle.

.Light truck (LT) tire

A tire designated by its manufac-

turer as primarily intended for use

on lightweight trucks or multipur-

pose passenger vehicles.

.Load rating

The maximum load that a tire is

rated to carry for a given inflation

pressure.

.Maximum inflation pressure

The maximum cold inflation pres-

sure to which a tire may be inflated.

.Maximum load rating

The load rating for a tire at the maximum permissible inflation

pressure for that tire.

.Maximum loaded vehicle weight

The sum of:

(a)Curb weight

(b)Accessory weight

(c)Vehicle capacity weight

(d)Production options weight.Maximum permissible inflation

pressure

The maximum cold inflation pres-

sure to which a tire may be inflated.

.Measuring rim

The rim on which a tire is fitted for

physical dimension requirements.

.Normal occupant weight

150 lbs (68 kg) times the number of

occupants specified in the second

column of Table 1 that is appended

to the end of this section.

.Occupant distribution

Distribution of occupants in a vehi-

cle as specified in the third column

of Table 1 that is appended to the

end of this section.

.Open splice

Any parting at any junction of tread,

13-6

Page 580 of 610

sidewall, or innerliner that extends

to cord material.

.Outer diameter

The overall diameter of an inflated

new tire.

.Overall width

The linear distance between the

exteriors of the sidewalls of an

inflated tire, including elevations

due to labeling, decorations, or

protective bands or ribs.

.Passenger car tire

A tire intended for use on passen-

ger cars, multipurpose passenger

vehicles, and trucks, that have a

gross vehicle weight rating (GVWR)

of 10,000 lbs (4,535 kg) or less.

.Ply

A layer of rubber-coated parallel

cords.

.Ply separation

A parting of rubber compound

between adjacent plies.

.Pneumatic tire

A mechanical device made of rub-

ber, chemicals, fabric and steel or

other materials, that, whenmounted on an automotive wheel,

provides the traction and contains

the gas or fluid that sustains the

load.

.Production options weight

The combined weight of those

installed regular production options

weighing over 5.1 lbs (2.3 kg) in

excess of those standard items

which they replace, not previously

considered in curb weight or acces-

sory weight, including heavy duty

brakes, ride levelers, roof rack,

heavy duty battery, and special

trim.

.Radial ply tire

A pneumatic tire in which the ply

cords that extend to the beads are

laid at substantially 90 degrees to

the centerline of the tread.

.Recommended inflation pres-

sure

The cold inflation pressure recom-

mended by a vehicle manufacturer.

.Reinforced tire

A tire designed to operate at higher

loads and at higher inflation pres- sures than the corresponding stan-

dard tire.

.Rim

A metal support for a tire or a tire

and tube assembly upon which the

tire beads are seated.

.Rim diameter

Nominal diameter of the bead seat.

.Rim size designation

Rim diameter and width.

.Rim type designation

The industry of manufacturer

’s des-

ignation for a rim by style or code.

.Rim width

Nominal distance between rim

flanges.

.Section width

The linear distance between the

exteriors of the sidewalls of an

inflated tire, excluding elevations

due to labeling, decoration, or

protective bands.

.Sidewall

That portion of a tire between the

tread and bead.

.Sidewall separation

The parting of the rubber com-

Consumer information and Reporting safety defects/Tire information

–CONTINUED –13-7