key SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2259 of 2453

CS-7

AT Shift Lock Control System

CONTROL SYSTEMS

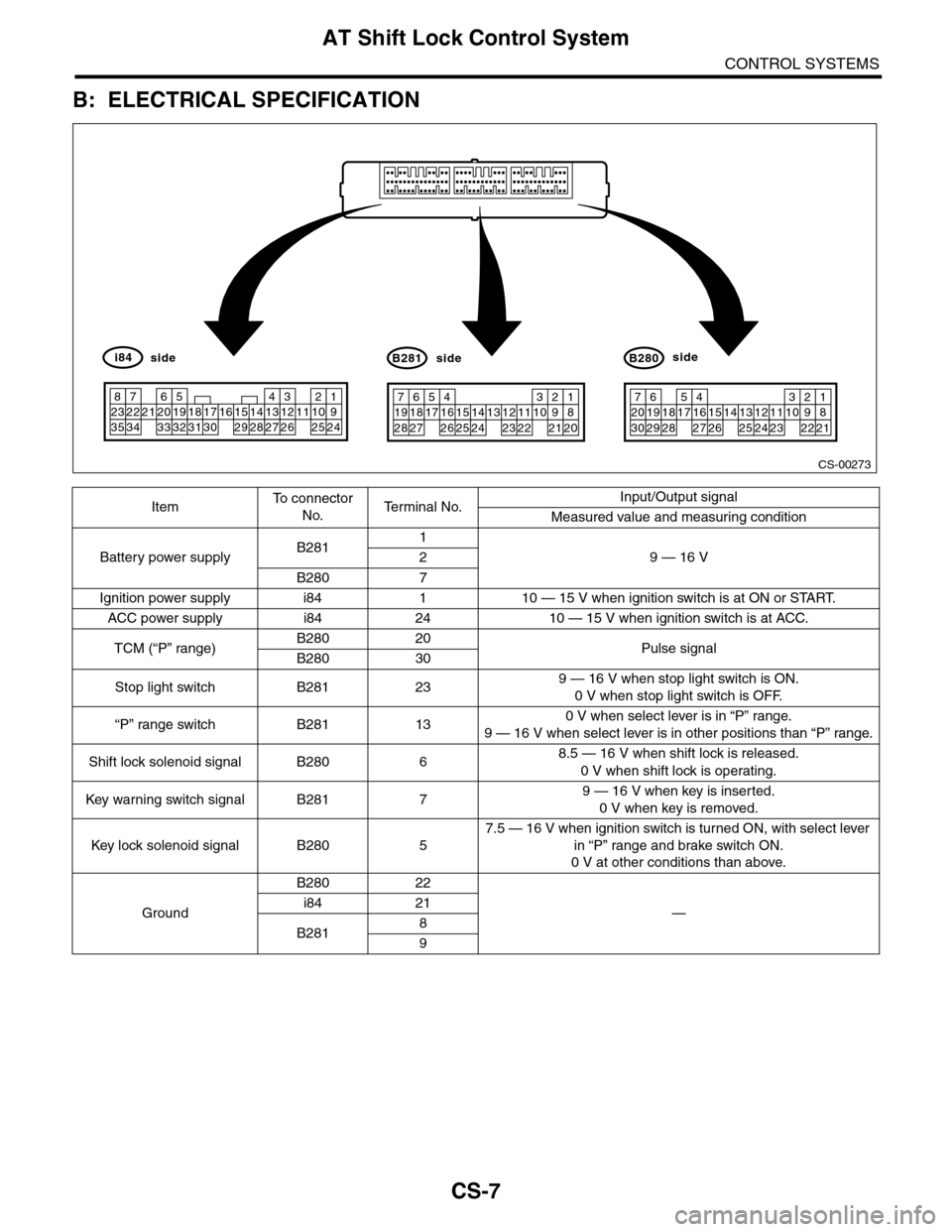

B: ELECTRICAL SPECIFICATION

ItemTo c o n n e c t o r

No.Te r m i n a l N o .Input/Output signal

Measured value and measuring condition

Battery power supplyB2811

9 — 16 V2

B280 7

Ignition power supply i84 1 10 — 15 V when ignition switch is at ON or START.

ACC power supply i84 24 10 — 15 V when ignition switch is at ACC.

TCM (“P” range)B280 20Pulse signalB280 30

Stop light switch B281 239 — 16 V when stop light switch is ON.

0 V when stop light switch is OFF.

“P” range switch B281 130 V when select lever is in “P” range.

9 — 16 V when select lever is in other positions than “P” range.

Shift lock solenoid signal B280 68.5 — 16 V when shift lock is released.

0 V when shift lock is operating.

Key war ning switch signal B281 79 — 16 V when key is inserted.

0 V when key is removed.

Key lock solenoid signal B280 5

7.5 — 16 V when ignition switch is turned ON, with select lever

in “P” range and brake switch ON.

0 V at other conditions than above.

Ground

B280 22

—i84 21

B2818

9

CS-00273

71928

61827

51741626152514241312231122

3102921

1820

B281side

72030

619291828

51741627152614132512241123

3102922

1821

B280side

82335

722342162033

51932183117301615291428

41327

312261121025

1924

i84side

Page 2260 of 2453

CS-8

AT Shift Lock Control System

CONTROL SYSTEMS

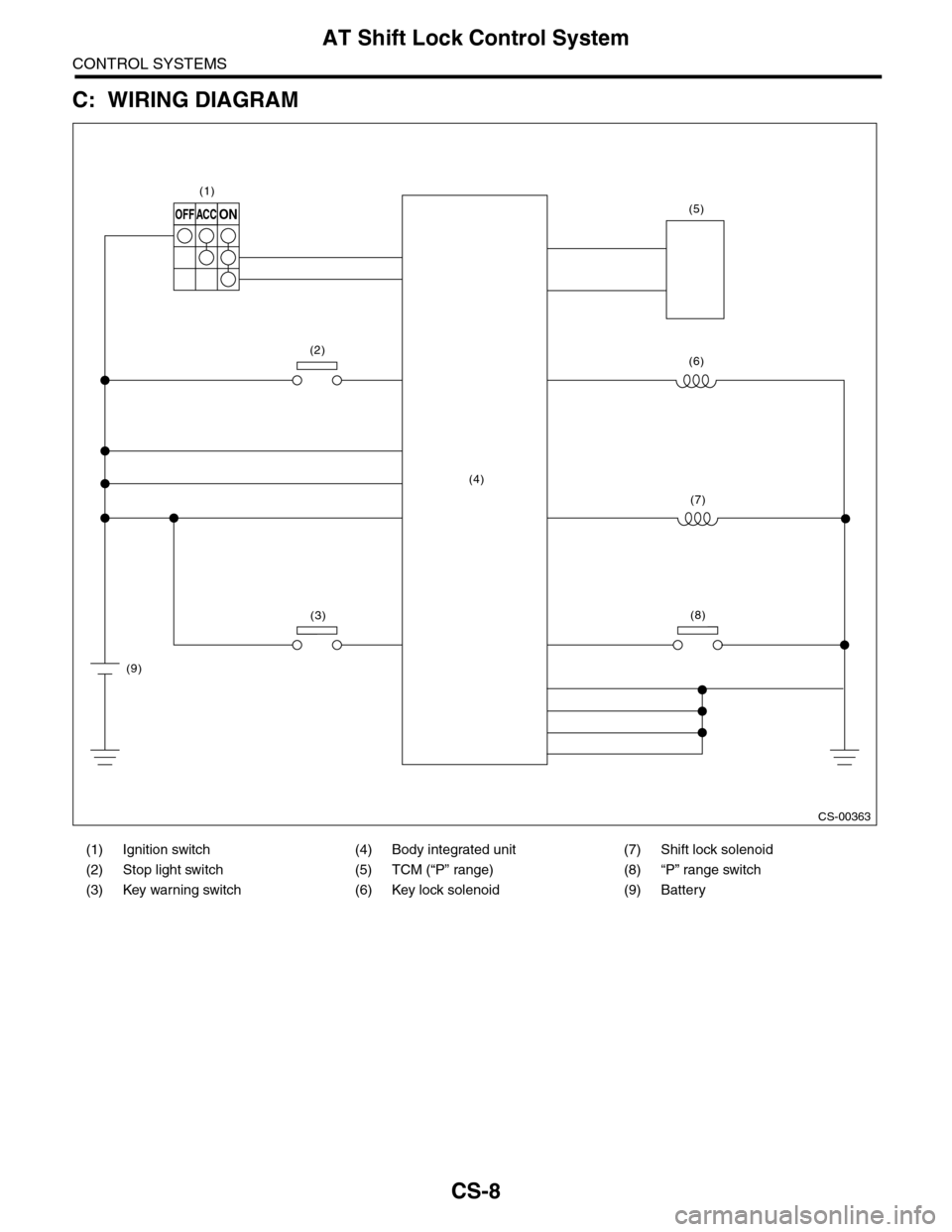

C: WIRING DIAGRAM

(1) Ignition switch (4) Body integrated unit (7) Shift lock solenoid

(2) Stop light switch (5) TCM (“P” range) (8) “P” range switch

(3) Key warning switch (6) Key lock solenoid (9) Battery

CS-00363

OFFACCON

(1)

(2)

(3)

(4)

(9)

(6)

(7)

(8)

(5)

Page 2261 of 2453

CS-9

AT Shift Lock Control System

CONTROL SYSTEMS

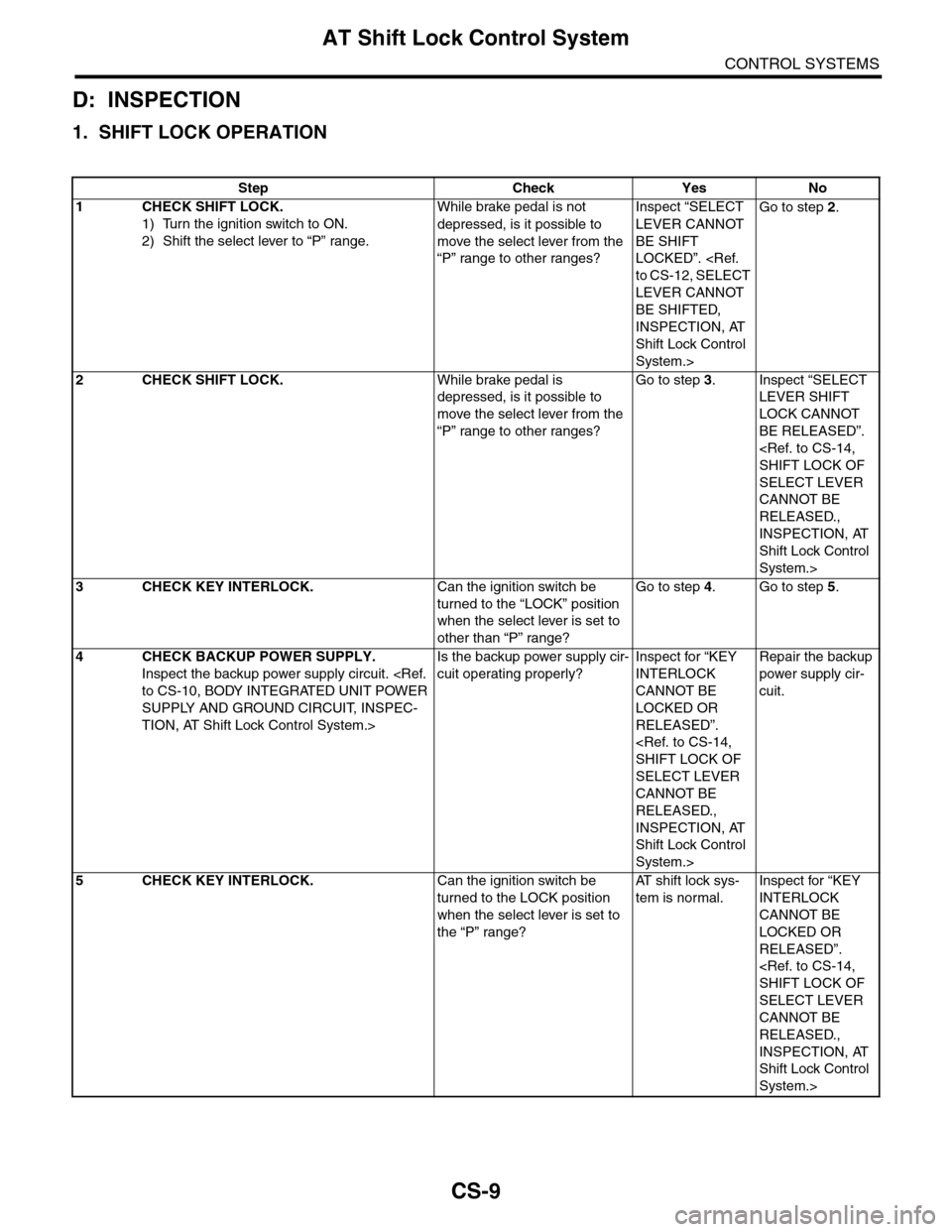

D: INSPECTION

1. SHIFT LOCK OPERATION

Step Check Yes No

1CHECK SHIFT LOCK.

1) Turn the ignition switch to ON.

2) Shift the select lever to “P” range.

While brake pedal is not

depressed, is it possible to

move the select lever from the

“P” range to other ranges?

Inspect “SELECT

LEVER CANNOT

BE SHIFT

LOCKED”.

LEVER CANNOT

BE SHIFTED,

INSPECTION, AT

Shift Lock Control

System.>

Go to step 2.

2CHECK SHIFT LOCK.While brake pedal is

depressed, is it possible to

move the select lever from the

“P” range to other ranges?

Go to step 3.Inspect “SELECT

LEVER SHIFT

LOCK CANNOT

BE RELEASED”.

SELECT LEVER

CANNOT BE

RELEASED.,

INSPECTION, AT

Shift Lock Control

System.>

3CHECK KEY INTERLOCK.Can the ignition switch be

turned to the “LOCK” position

when the select lever is set to

other than “P” range?

Go to step 4.Go to step 5.

4CHECK BACKUP POWER SUPPLY.

Inspect the backup power supply circuit.

SUPPLY AND GROUND CIRCUIT, INSPEC-

TION, AT Shift Lock Control System.>

Is the backup power supply cir-

cuit operating properly?

Inspect for “KEY

INTERLOCK

CANNOT BE

LOCKED OR

RELEASED”.

SELECT LEVER

CANNOT BE

RELEASED.,

INSPECTION, AT

Shift Lock Control

System.>

Repair the backup

power supply cir-

cuit.

5CHECK KEY INTERLOCK.Can the ignition switch be

turned to the LOCK position

when the select lever is set to

the “P” range?

AT s h i f t l o c k s y s -

tem is normal.

Inspect for “KEY

INTERLOCK

CANNOT BE

LOCKED OR

RELEASED”.

SELECT LEVER

CANNOT BE

RELEASED.,

INSPECTION, AT

Shift Lock Control

System.>

Page 2268 of 2453

CS-16

AT Shift Lock Control System

CONTROL SYSTEMS

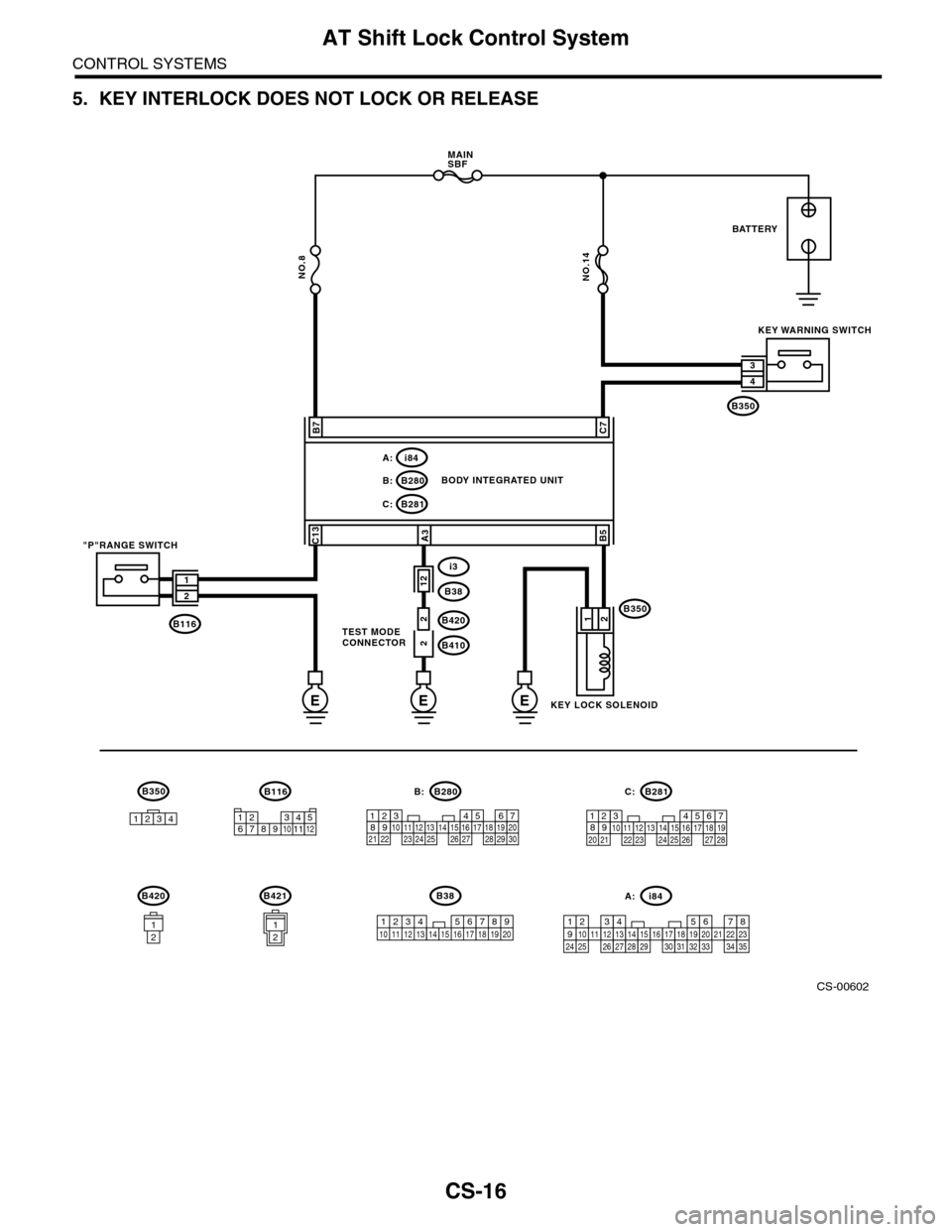

5. KEY INTERLOCK DOES NOT LOCK OR RELEASE

CS-00602

E

B116

5467821931022 231112131415242526 2716171828 29192021 30

B280B:

NO.14

EE

B281C:

B280B:

i84A:

C7B7

B5

12

C13A3

B1162

212

1

2

B350

B350

i3

B38

B420

B410

3

4

BATTERY

KEY WARNING SWITCH

BODY INTEGRATED UNIT

"P"RANGE SWITCH

KEY LOCK SOLENOID

TEST MODECONNECTOR

1234

B350

567821943102422 23 25111213141526 27281617181920 21

B281C:

i84A:

123456789101112

NO.8

MAINSBF

B420

12

B421

12

B38

1234 5678910 11 12 13 16 17 18 19 2014151234567891011121415161718192021222324252627282930313233343513

Page 2269 of 2453

CS-17

AT Shift Lock Control System

CONTROL SYSTEMS

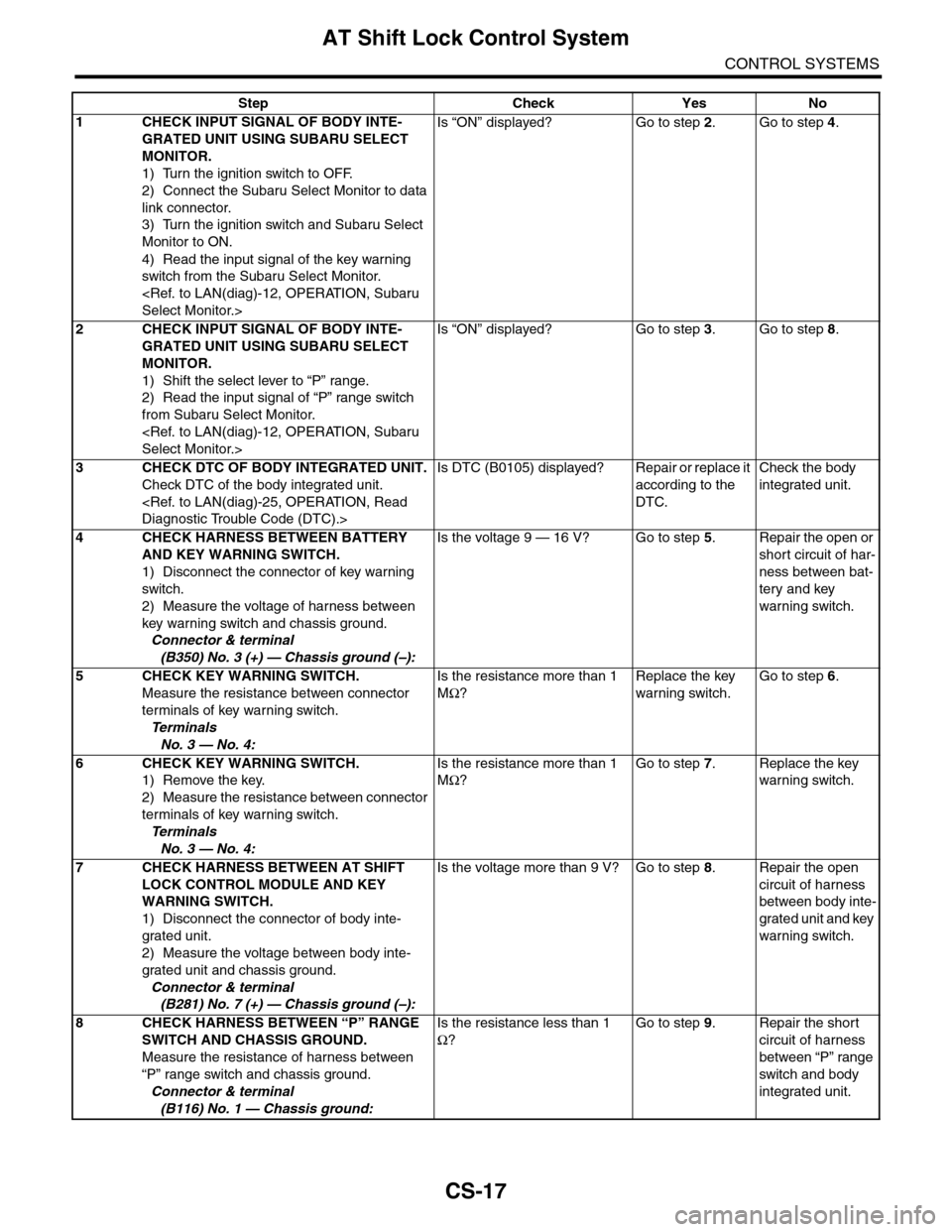

Step Check Yes No

1CHECK INPUT SIGNAL OF BODY INTE-

GRATED UNIT USING SUBARU SELECT

MONITOR.

1) Turn the ignition switch to OFF.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch and Subaru Select

Monitor to ON.

4) Read the input signal of the key warning

switch from the Subaru Select Monitor.

Is “ON” displayed? Go to step 2.Go to step 4.

2CHECK INPUT SIGNAL OF BODY INTE-

GRATED UNIT USING SUBARU SELECT

MONITOR.

1) Shift the select lever to “P” range.

2) Read the input signal of “P” range switch

from Subaru Select Monitor.

Is “ON” displayed? Go to step 3.Go to step 8.

3CHECK DTC OF BODY INTEGRATED UNIT.

Check DTC of the body integrated unit.

Is DTC (B0105) displayed? Repair or replace it

according to the

DTC.

Check the body

integrated unit.

4CHECK HARNESS BETWEEN BATTERY

AND KEY WARNING SWITCH.

1) Disconnect the connector of key warning

switch.

2) Measure the voltage of harness between

key warning switch and chassis ground.

Connector & terminal

(B350) No. 3 (+) — Chassis ground (–):

Is the voltage 9 — 16 V? Go to step 5.Repair the open or

short circuit of har-

ness between bat-

tery and key

warning switch.

5 CHECK KEY WARNING SWITCH.

Measure the resistance between connector

terminals of key warning switch.

Te r m i n a l s

No. 3 — No. 4:

Is the resistance more than 1

MΩ?

Replace the key

warning switch.

Go to step 6.

6 CHECK KEY WARNING SWITCH.

1) Remove the key.

2) Measure the resistance between connector

terminals of key warning switch.

Te r m i n a l s

No. 3 — No. 4:

Is the resistance more than 1

MΩ?

Go to step 7.Replace the key

warning switch.

7CHECK HARNESS BETWEEN AT SHIFT

LOCK CONTROL MODULE AND KEY

WARNING SWITCH.

1) Disconnect the connector of body inte-

grated unit.

2) Measure the voltage between body inte-

grated unit and chassis ground.

Connector & terminal

(B281) No. 7 (+) — Chassis ground (–):

Is the voltage more than 9 V? Go to step 8.Repair the open

circuit of harness

between body inte-

grated unit and key

warning switch.

8CHECK HARNESS BETWEEN “P” RANGE

SWITCH AND CHASSIS GROUND.

Measure the resistance of harness between

“P” range switch and chassis ground.

Connector & terminal

(B116) No. 1 — Chassis ground:

Is the resistance less than 1

Ω?

Go to step 9.Repair the short

circuit of harness

between “P” range

switch and body

integrated unit.

Page 2270 of 2453

CS-18

AT Shift Lock Control System

CONTROL SYSTEMS

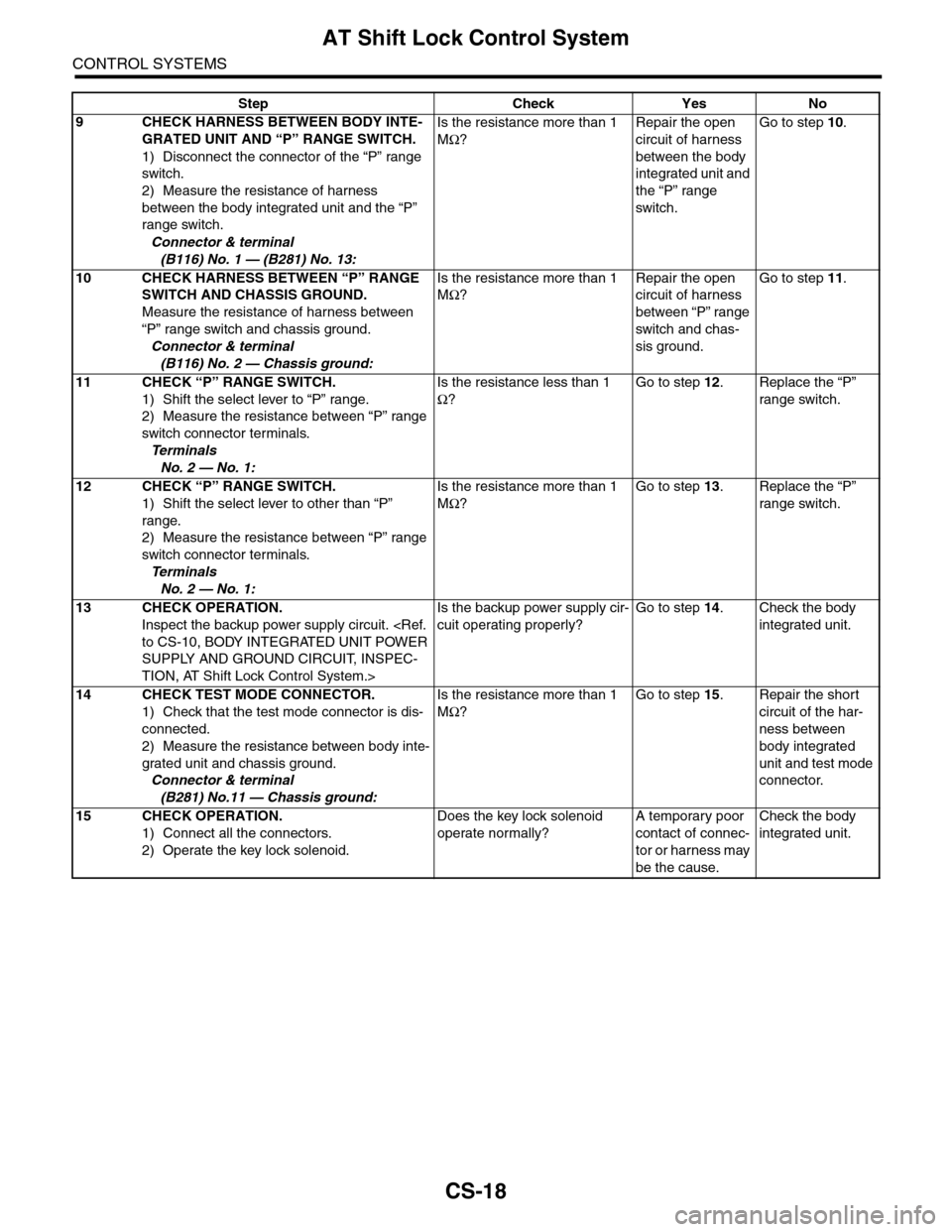

9CHECK HARNESS BETWEEN BODY INTE-

GRATED UNIT AND “P” RANGE SWITCH.

1) Disconnect the connector of the “P” range

switch.

2) Measure the resistance of harness

between the body integrated unit and the “P”

range switch.

Connector & terminal

(B116) No. 1 — (B281) No. 13:

Is the resistance more than 1

MΩ?

Repair the open

circuit of harness

between the body

integrated unit and

the “P” range

switch.

Go to step 10.

10 CHECK HARNESS BETWEEN “P” RANGE

SWITCH AND CHASSIS GROUND.

Measure the resistance of harness between

“P” range switch and chassis ground.

Connector & terminal

(B116) No. 2 — Chassis ground:

Is the resistance more than 1

MΩ?

Repair the open

circuit of harness

between “P” range

switch and chas-

sis ground.

Go to step 11.

11 CHECK “P” RANGE SWITCH.

1) Shift the select lever to “P” range.

2) Measure the resistance between “P” range

switch connector terminals.

Te r m i n a l s

No. 2 — No. 1:

Is the resistance less than 1

Ω?

Go to step 12.Replace the “P”

range switch.

12 CHECK “P” RANGE SWITCH.

1) Shift the select lever to other than “P”

range.

2) Measure the resistance between “P” range

switch connector terminals.

Te r m i n a l s

No. 2 — No. 1:

Is the resistance more than 1

MΩ?

Go to step 13.Replace the “P”

range switch.

13 CHECK OPERATION.

Inspect the backup power supply circuit.

SUPPLY AND GROUND CIRCUIT, INSPEC-

TION, AT Shift Lock Control System.>

Is the backup power supply cir-

cuit operating properly?

Go to step 14.Check the body

integrated unit.

14 CHECK TEST MODE CONNECTOR.

1) Check that the test mode connector is dis-

connected.

2) Measure the resistance between body inte-

grated unit and chassis ground.

Connector & terminal

(B281) No.11 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 15.Repair the short

circuit of the har-

ness between

body integrated

unit and test mode

connector.

15 CHECK OPERATION.

1) Connect all the connectors.

2) Operate the key lock solenoid.

Does the key lock solenoid

operate normally?

A temporary poor

contact of connec-

tor or harness may

be the cause.

Check the body

integrated unit.

Step Check Yes No

Page 2292 of 2453

WI-8

Basic Diagnostic Procedure

WIRING SYSTEM

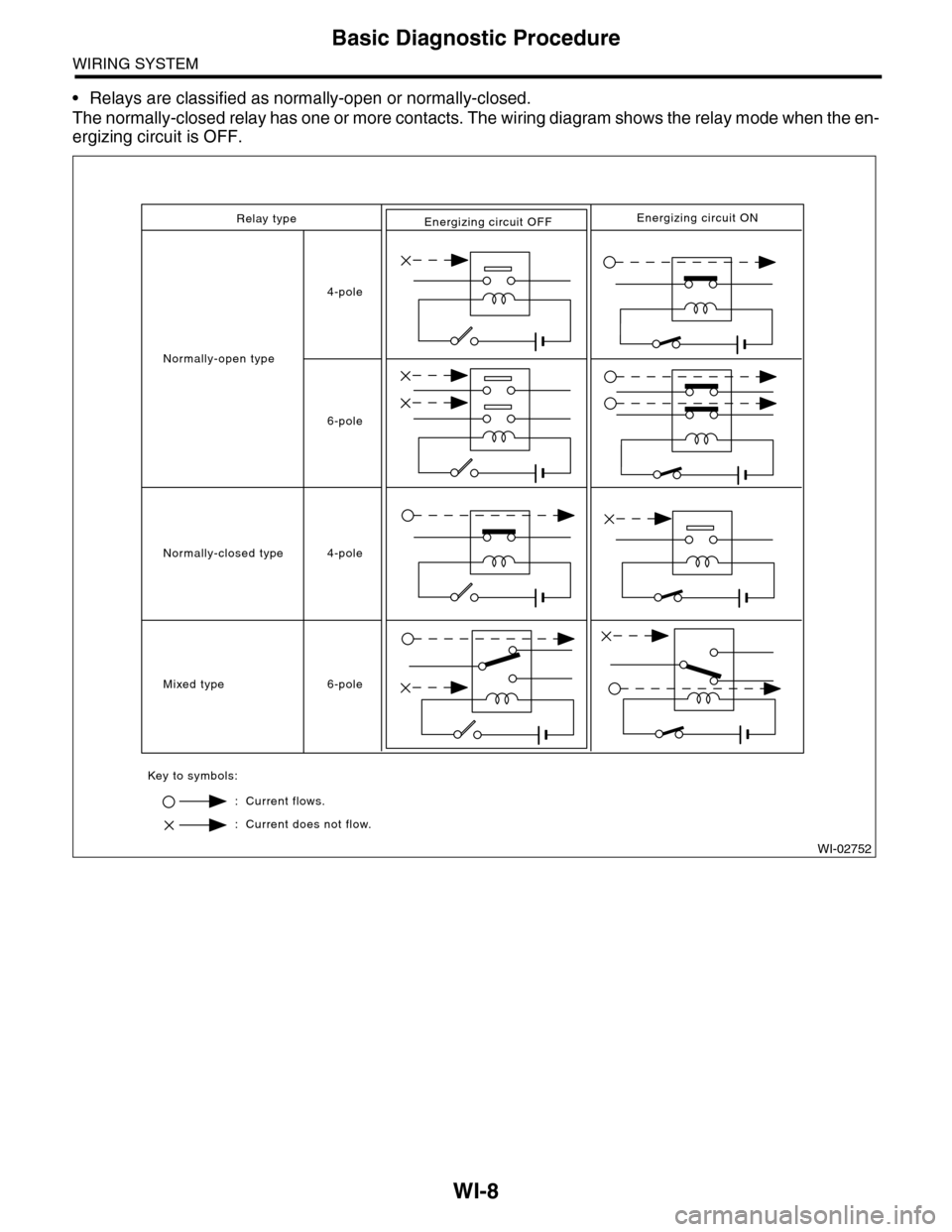

•Relays are classified as normally-open or normally-closed.

The normally-closed relay has one or more contacts. The wiring diagram shows the relay mode when the en-

ergizing circuit is OFF.

Relay type

4-pole

6-pole

4-pole

6-pole

Normally-open type

Normally-closed type

Mixed type

Key to symbols:

: Current flows.

: Current does not flow.

Energizing circuit OFFEnergizing circuit ON

WI-02752

Page 2304 of 2453

WI-20

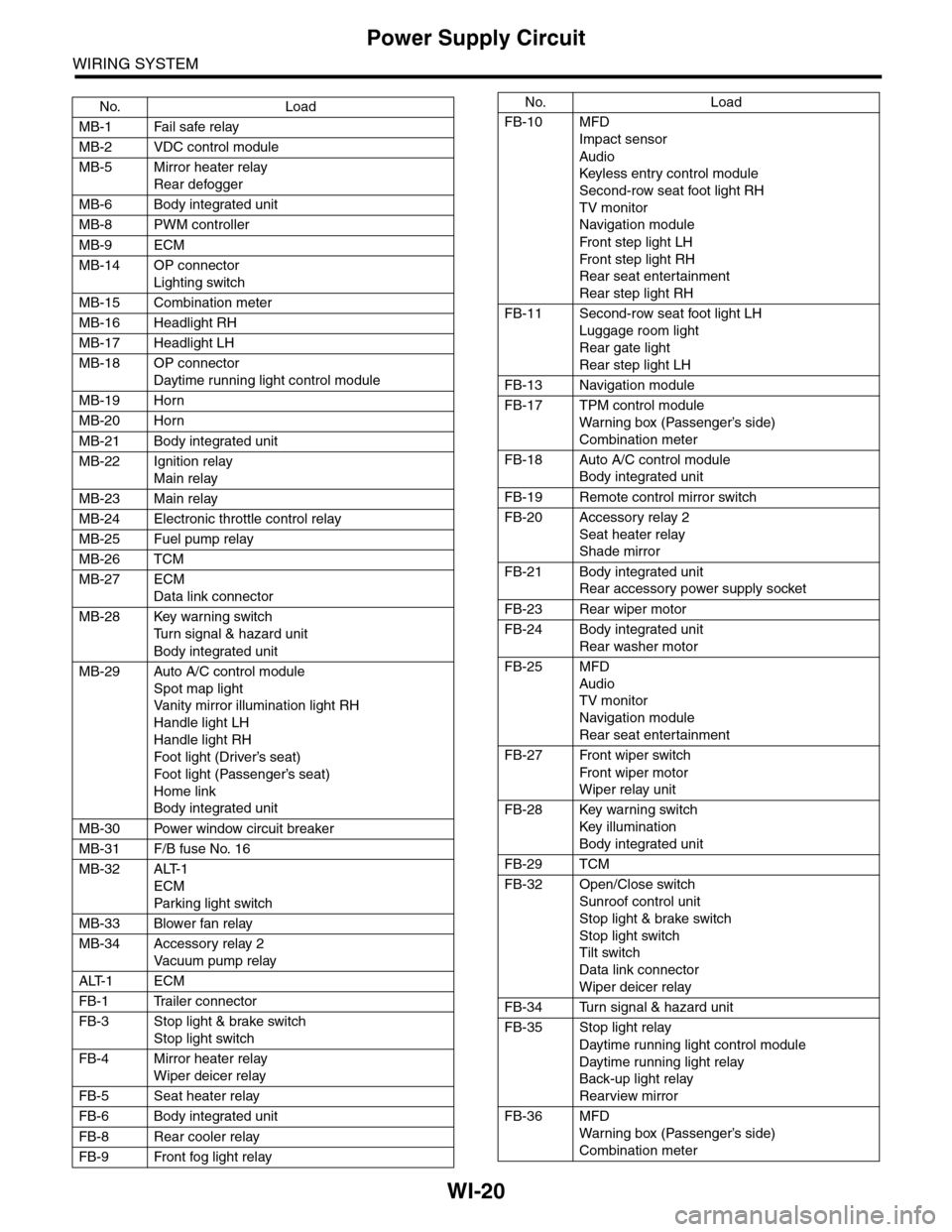

Power Supply Circuit

WIRING SYSTEM

No. Load

MB-1 Fail safe relay

MB-2 VDC control module

MB-5 Mirror heater relay

Rear defogger

MB-6 Body integrated unit

MB-8 PWM controller

MB-9 ECM

MB-14 OP connector

Lighting switch

MB-15 Combination meter

MB-16 Headlight RH

MB-17 Headlight LH

MB-18 OP connector

Daytime running light control module

MB-19 Horn

MB-20 Horn

MB-21 Body integrated unit

MB-22 Ignition relay

Main relay

MB-23 Main relay

MB-24 Electronic throttle control relay

MB-25 Fuel pump relay

MB-26 TCM

MB-27 ECM

Data link connector

MB-28 Key warning switch

Tu r n s i g n a l & h a z a r d u n i t

Body integrated unit

MB-29 Auto A/C control module

Spot map light

Va n i t y m i r r o r i l l u m i n a t i o n l i g h t R H

Handle light LH

Handle light RH

Foot light (Driver’s seat)

Foot light (Passenger’s seat)

Home link

Body integrated unit

MB-30 Power window circuit breaker

MB-31 F/B fuse No. 16

MB-32 ALT-1

ECM

Par king light switch

MB-33 Blower fan relay

MB-34 Accessory relay 2

Va c u u m p u m p r e l ay

ALT-1 ECM

FB-1 Trailer connector

FB-3 Stop light & brake switch

Stop light switch

FB-4 Mirror heater relay

Wiper deicer relay

FB-5 Seat heater relay

FB-6 Body integrated unit

FB-8 Rear cooler relay

FB-9 Front fog light relay

FB-10 MFD

Impact sensor

Audio

Keyless entr y control module

Second-row seat foot light RH

TV monitor

Navigation module

Fr o n t s te p li gh t LH

Fr o n t s te p li gh t RH

Rear seat entertainment

Rear step light RH

FB-11 Second-row seat foot light LH

Luggage room light

Rear gate light

Rear step light LH

FB-13 Navigation module

FB-17 TPM control module

War ning box (Passenger’s side)

Combination meter

FB-18 Auto A/C control module

Body integrated unit

FB-19 Remote control mirror switch

FB-20 Accessory relay 2

Seat heater relay

Shade mirror

FB-21 Body integrated unit

Rear accessory power supply socket

FB-23 Rear wiper motor

FB-24 Body integrated unit

Rear washer motor

FB-25 MFD

Audio

TV monitor

Navigation module

Rear seat entertainment

FB-27 Front wiper switch

Fr o n t wi p er mo t or

Wiper relay unit

FB-28 Key warning switch

Key illumination

Body integrated unit

FB-29 TCM

FB-32 Open/Close switch

Sunroof control unit

Stop light & brake switch

Stop light switch

Tilt switch

Data link connector

Wiper deicer relay

FB-34 Turn signal & hazard unit

FB-35 Stop light relay

Daytime running light control module

Daytime running light relay

Back-up light relay

Rearview mirror

FB-36 MFD

War ning box (Passenger’s side)

Combination meter

No. Load

Page 2306 of 2453

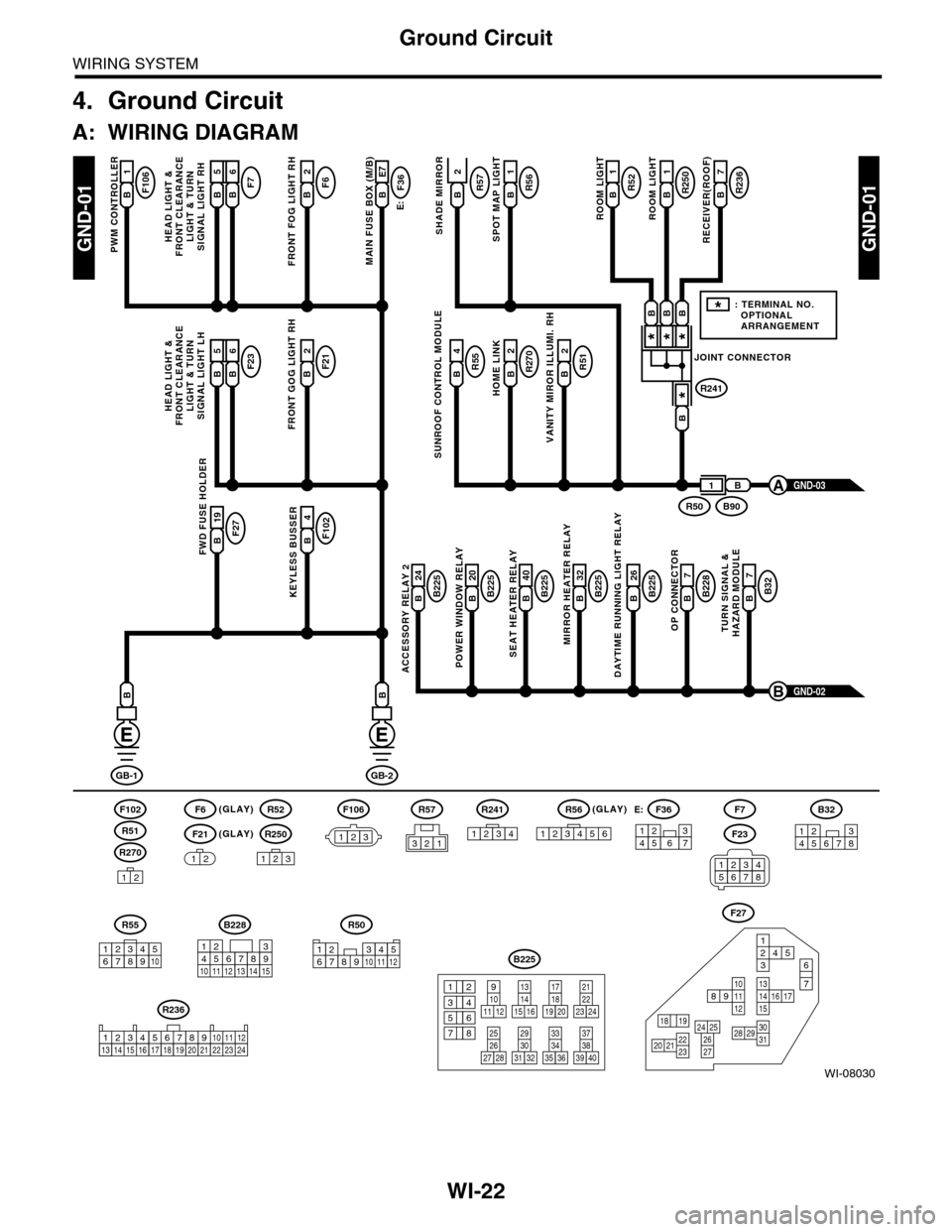

WI-22

Ground Circuit

WIRING SYSTEM

4. Ground Circuit

A: WIRING DIAGRAM

WI-08030

GND-01GND-01

F106B1

PWM CONTROLLER

F6(GLAY)(GLAY)

(GLAY)

F102

R270

F21

F7F6B2

FRONT FOG LIGHT RH

E:

F36B E7

MAIN FUSE BOX (M/B)

R55B4R51B2

VANITY MIROR ILLUMI. RH

R270B2

HOME LINK

R52B1

1

ROOM LIGHT

R250R57B1

ROOM LIGHT

R236B7

RECEIVER(ROOF)SHADE MIRROR

B225B 26

DAYTIME RUNNING LIGHT RELAY

F27B 19FWD FUSE HOLDER

F102B4

KEYLESS BUSSERB225B 24

ACCESSORY RELAY 2

B225B 40

SEAT HEATER RELAY

B225B 20

POWER WINDOW RELAY

B228B7

OP CONNECTOR

B32B7

TURN SIGNAL &HAZARD MODULE

B225B 32

MIRROR HEATER RELAY

GND-02B

GB-1

B

GB-2

B

B

12

12

R52

R250

123

F7

F23

R57

B228

131415

123456789101112

F27

13141516 17

27

24 252620 212223

29303128

89101112

12534

7

6

1918

B225

13141516

17

27

24

2526

20

212223

293031283235

33343738393640

8

9101112

12

534

761918

B32

12345678

SUNROOF CONTROL MODULE

HEAD LIGHT &FRONT CLEARANCELIGHT & TURNSIGNAL LIGHT RH

GND-03A

R51

234510 111678912

R50

F106

123

B A16B5B6

F23F21B2

FRONT GOG LIGHT RH

HEAD LIGHT &FRONT CLEARANCELIGHT & TURNSIGNAL LIGHT LH

B A16B5B6

R56B

SPOT MAP LIGHT

JOINT CONNECTOR

R241

***

*

B90R50

B

B

BBB

1

*: TERMINAL NO. OPTIONAL ARRANGEMENT

123

R56

1234561234567

F36E:

R55

12346789510

R241

1234

R236

123 8910413 14 15 1656711121718192021222324

2

34561278

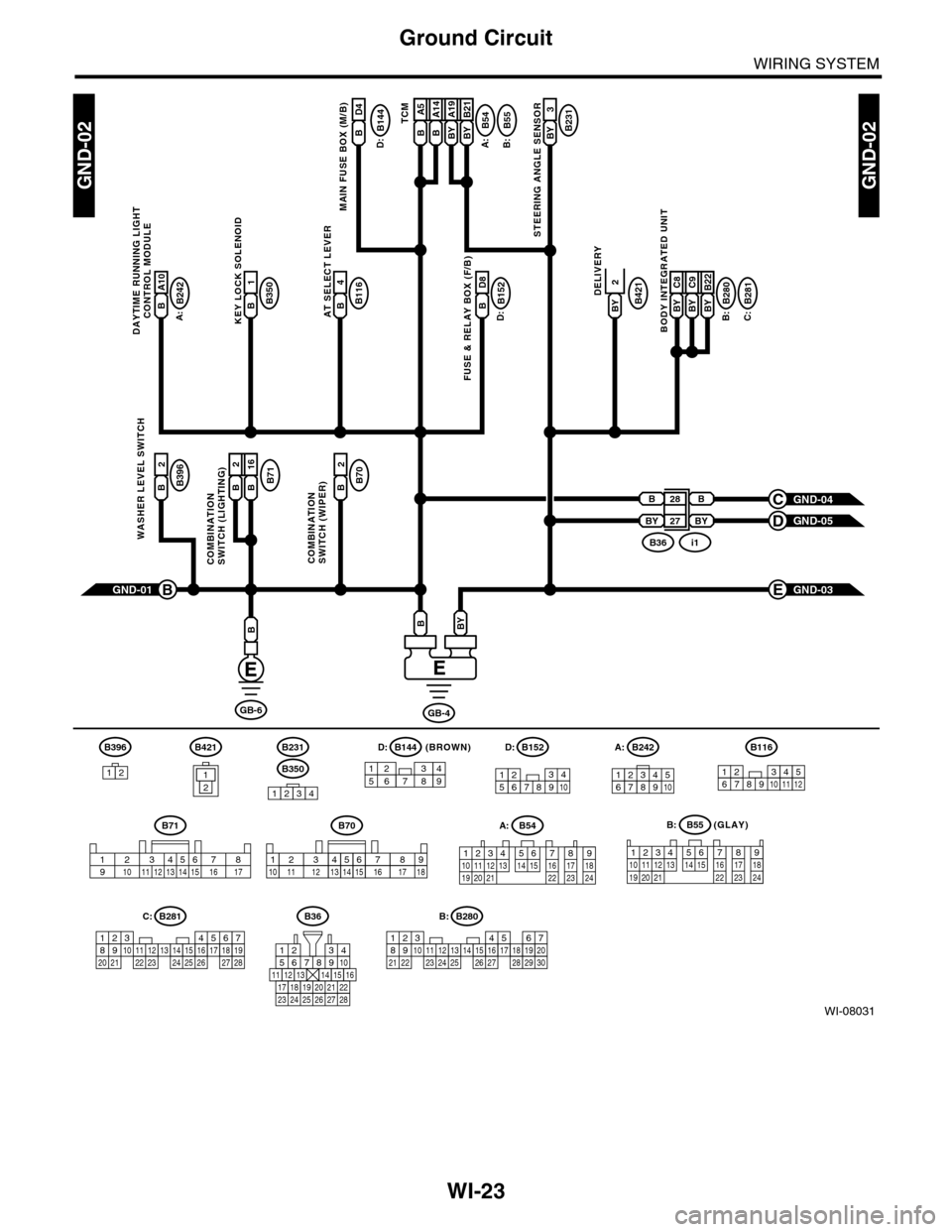

Page 2307 of 2453

WI-23

Ground Circuit

WIRING SYSTEM

WI-08031

GND-02GND-02

GB-6

B28

BY

B

BY 27

GND-01B

B

GB-4

BYB

B144B

MAIN FUSE BOX (M/B)

A:

B116B4AT SELECT LEVER

B54

A:

B242

B:

B:C:D:

B55B A5B A14BY A19BY B21TCMB231BY 3

STEERING ANGLE SENSOR

B350B1KEY LOCK SOLENOID

B152B D8

FUSE & RELAY BOX (F/B)

B421BY

DELIVERY

B71B2B 16

COMBINATIONSWITCH (LIGHTING)

B70B2

COMBINATIONSWITCH (WIPER)

B396B2

WASHER LEVEL SWITCH

GND-04C

GND-05D

B280B281BY C8BY C9BY B22

BODY INTEGRATED UNIT

GND-03E

B36i1

D4

D:

B231

B350

1234

B152

12345678910

B70

2364571891112151314 1610 1718

A:B54

A:B242

B:B55

123410 11 1219 20 21135614 1578916 17 1822 23 24

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

567821943102422 23 25111213141526 27 281617181920 21

B281C:

5467821931022 23111213141524 25 26 2716171828 29192021 30

B280B:B36

56782194310

242223 252726 28

11121314151617181920 21

(GLAY)

D:

B71

23456718910 11 12 13 14 15 16 17

B A10

DAYTIME RUNNING LIGHT

CONTROL MODULE

12346789510

B116

123456789101112

B396

1212

B421(BROWN)B144D:

157628349

2