engine SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1040 of 2453

VDC(diag)-48

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

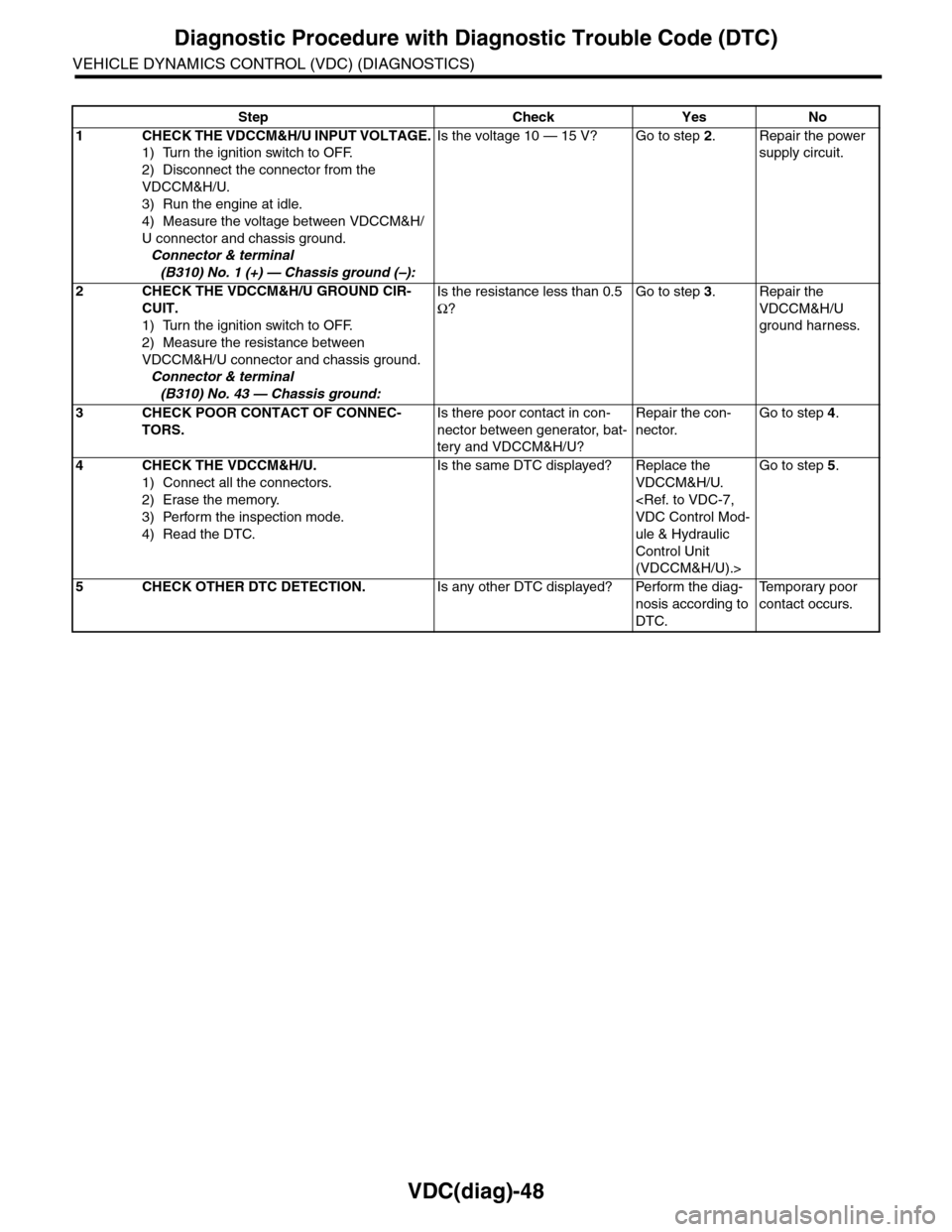

Step Check Yes No

1CHECK THE VDCCM&H/U INPUT VOLTAGE.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from the

VDCCM&H/U.

3) Run the engine at idle.

4) Measure the voltage between VDCCM&H/

U connector and chassis ground.

Connector & terminal

(B310) No. 1 (+) — Chassis ground (–):

Is the voltage 10 — 15 V? Go to step 2.Repair the power

supply circuit.

2CHECK THE VDCCM&H/U GROUND CIR-

CUIT.

1) Turn the ignition switch to OFF.

2) Measure the resistance between

VDCCM&H/U connector and chassis ground.

Connector & terminal

(B310) No. 43 — Chassis ground:

Is the resistance less than 0.5

Ω?

Go to step 3.Repair the

VDCCM&H/U

ground harness.

3CHECK POOR CONTACT OF CONNEC-

TORS.

Is there poor contact in con-

nector between generator, bat-

tery and VDCCM&H/U?

Repair the con-

nector.

Go to step 4.

4CHECK THE VDCCM&H/U.

1) Connect all the connectors.

2) Erase the memory.

3) Perform the inspection mode.

4) Read the DTC.

Is the same DTC displayed? Replace the

VDCCM&H/U.

ule & Hydraulic

Control Unit

(VDCCM&H/U).>

Go to step 5.

5CHECK OTHER DTC DETECTION.Is any other DTC displayed? Perform the diag-

nosis according to

DTC.

Te m p o r a r y p o o r

contact occurs.

Page 1043 of 2453

VDC(diag)-51

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

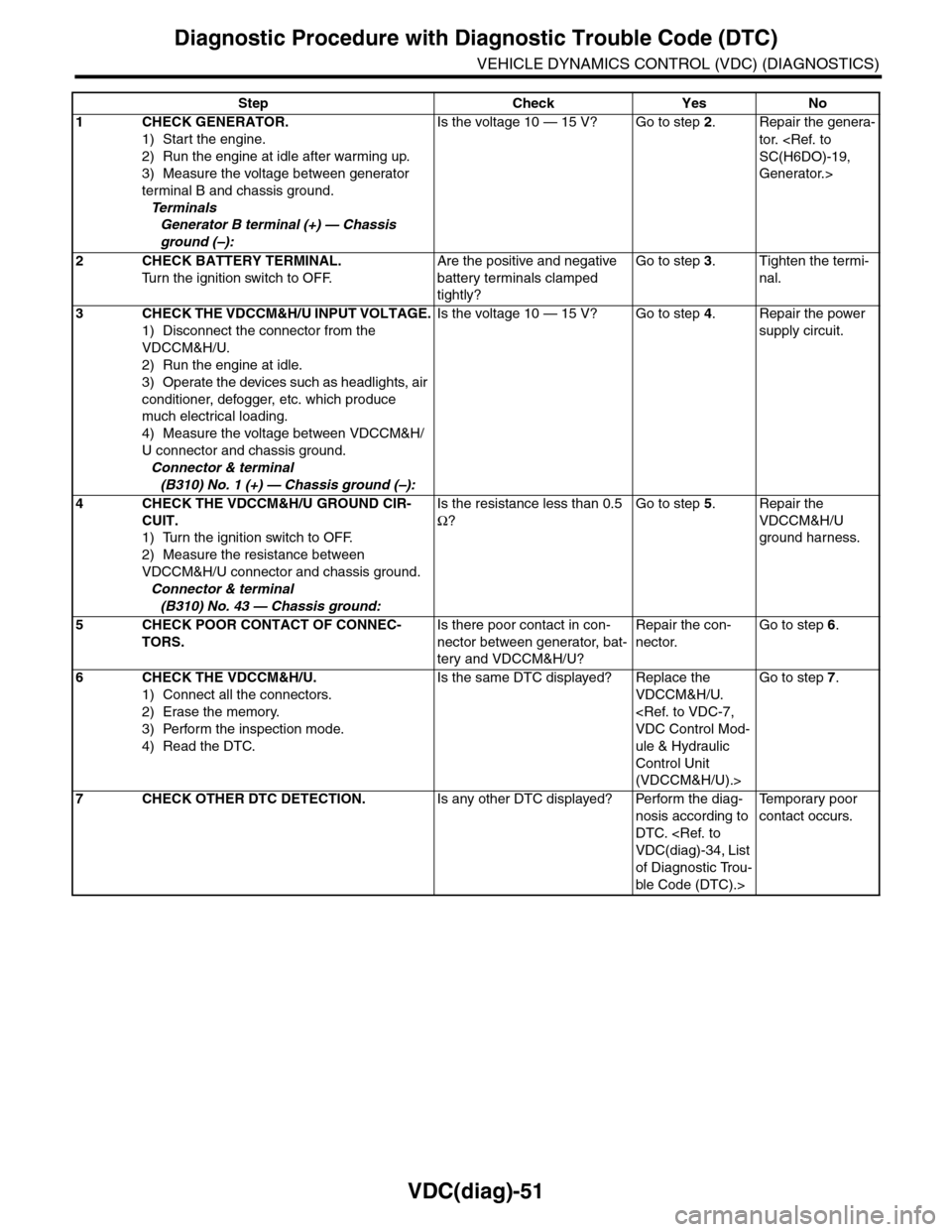

Step Check Yes No

1CHECK GENERATOR.

1) Start the engine.

2) Run the engine at idle after warming up.

3) Measure the voltage between generator

terminal B and chassis ground.

Te r m i n a l s

Generator B terminal (+) — Chassis

ground (–):

Is the voltage 10 — 15 V? Go to step 2.Repair the genera-

tor.

Generator.>

2CHECK BATTERY TERMINAL.

Tu r n t h e i g n i t i o n s w i t c h t o O F F.

Are the positive and negative

battery terminals clamped

tightly?

Go to step 3.Tighten the termi-

nal.

3CHECK THE VDCCM&H/U INPUT VOLTAGE.

1) Disconnect the connector from the

VDCCM&H/U.

2) Run the engine at idle.

3) Operate the devices such as headlights, air

conditioner, defogger, etc. which produce

much electrical loading.

4) Measure the voltage between VDCCM&H/

U connector and chassis ground.

Connector & terminal

(B310) No. 1 (+) — Chassis ground (–):

Is the voltage 10 — 15 V? Go to step 4.Repair the power

supply circuit.

4CHECK THE VDCCM&H/U GROUND CIR-

CUIT.

1) Turn the ignition switch to OFF.

2) Measure the resistance between

VDCCM&H/U connector and chassis ground.

Connector & terminal

(B310) No. 43 — Chassis ground:

Is the resistance less than 0.5

Ω?

Go to step 5.Repair the

VDCCM&H/U

ground harness.

5CHECK POOR CONTACT OF CONNEC-

TORS.

Is there poor contact in con-

nector between generator, bat-

tery and VDCCM&H/U?

Repair the con-

nector.

Go to step 6.

6CHECK THE VDCCM&H/U.

1) Connect all the connectors.

2) Erase the memory.

3) Perform the inspection mode.

4) Read the DTC.

Is the same DTC displayed? Replace the

VDCCM&H/U.

ule & Hydraulic

Control Unit

(VDCCM&H/U).>

Go to step 7.

7CHECK OTHER DTC DETECTION.Is any other DTC displayed? Perform the diag-

nosis according to

DTC.

of Diagnostic Trou-

ble Code (DTC).>

Te m p o r a r y p o o r

contact occurs.

Page 1046 of 2453

VDC(diag)-54

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

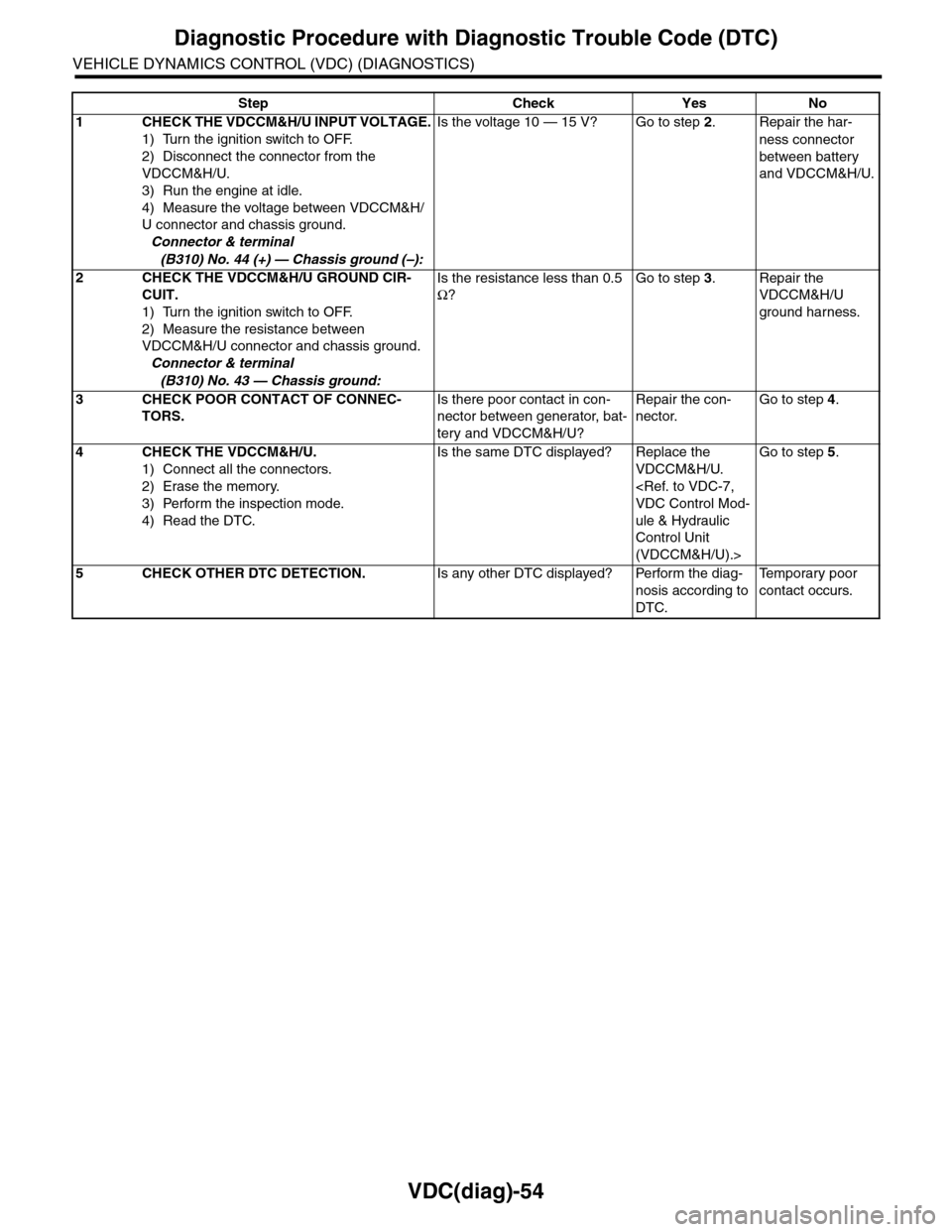

Step Check Yes No

1CHECK THE VDCCM&H/U INPUT VOLTAGE.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from the

VDCCM&H/U.

3) Run the engine at idle.

4) Measure the voltage between VDCCM&H/

U connector and chassis ground.

Connector & terminal

(B310) No. 44 (+) — Chassis ground (–):

Is the voltage 10 — 15 V? Go to step 2.Repair the har-

ness connector

between battery

and VDCCM&H/U.

2CHECK THE VDCCM&H/U GROUND CIR-

CUIT.

1) Turn the ignition switch to OFF.

2) Measure the resistance between

VDCCM&H/U connector and chassis ground.

Connector & terminal

(B310) No. 43 — Chassis ground:

Is the resistance less than 0.5

Ω?

Go to step 3.Repair the

VDCCM&H/U

ground harness.

3CHECK POOR CONTACT OF CONNEC-

TORS.

Is there poor contact in con-

nector between generator, bat-

tery and VDCCM&H/U?

Repair the con-

nector.

Go to step 4.

4CHECK THE VDCCM&H/U.

1) Connect all the connectors.

2) Erase the memory.

3) Perform the inspection mode.

4) Read the DTC.

Is the same DTC displayed? Replace the

VDCCM&H/U.

ule & Hydraulic

Control Unit

(VDCCM&H/U).>

Go to step 5.

5CHECK OTHER DTC DETECTION.Is any other DTC displayed? Perform the diag-

nosis according to

DTC.

Te m p o r a r y p o o r

contact occurs.

Page 1064 of 2453

VDC(diag)-72

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

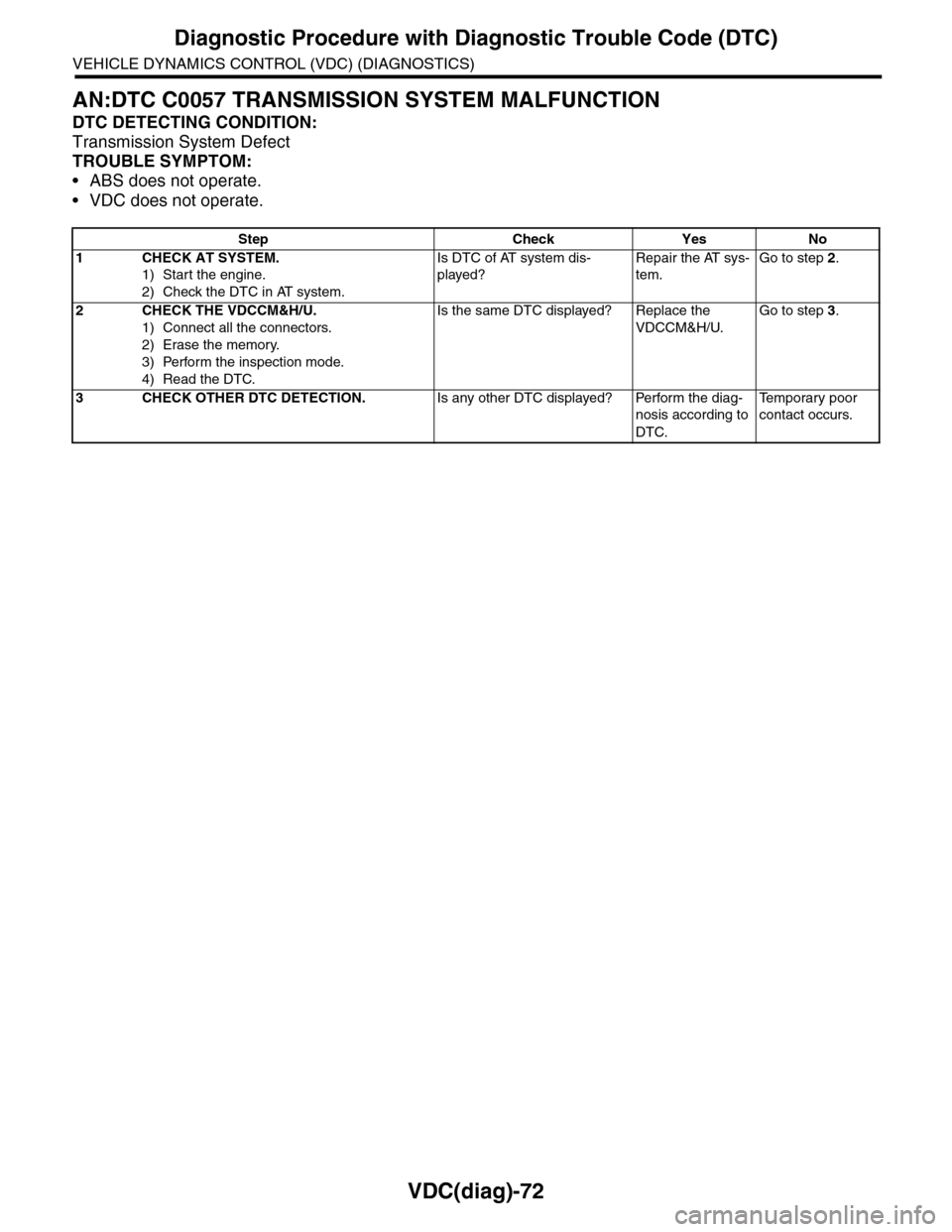

AN:DTC C0057 TRANSMISSION SYSTEM MALFUNCTION

DTC DETECTING CONDITION:

Transmission System Defect

TROUBLE SYMPTOM:

•ABS does not operate.

•VDC does not operate.

Step Check Yes No

1CHECK AT SYSTEM.

1) Start the engine.

2) Check the DTC in AT system.

Is DTC of AT system dis-

played?

Repair the AT sys-

tem.

Go to step 2.

2CHECK THE VDCCM&H/U.

1) Connect all the connectors.

2) Erase the memory.

3) Perform the inspection mode.

4) Read the DTC.

Is the same DTC displayed? Replace the

VDCCM&H/U.

Go to step 3.

3CHECK OTHER DTC DETECTION.Is any other DTC displayed? Perform the diag-

nosis according to

DTC.

Te m p o r a r y p o o r

contact occurs.

Page 1080 of 2453

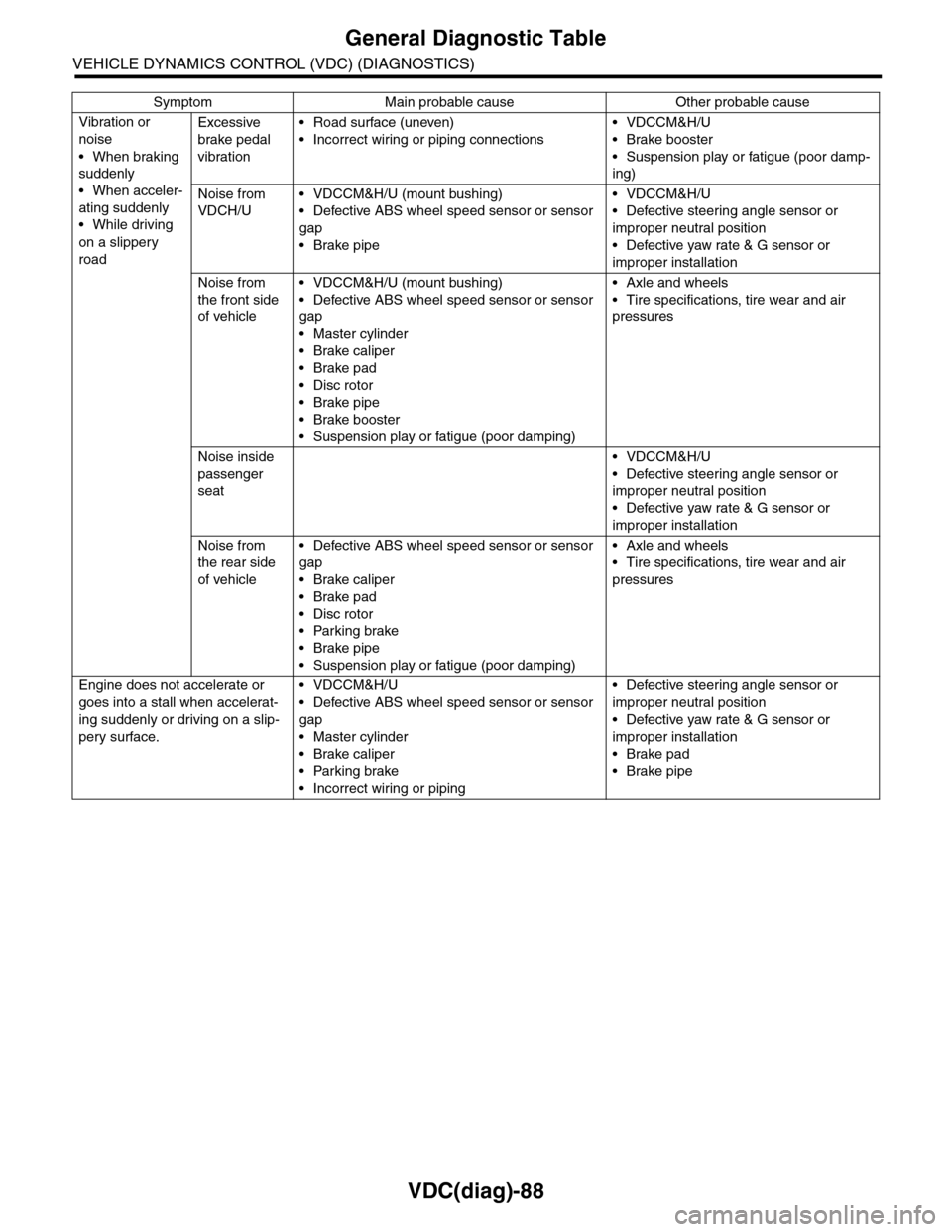

VDC(diag)-88

General Diagnostic Table

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

Vibration or

noise

•When braking

suddenly

•When acceler-

ating suddenly

•While driving

on a slippery

road

Excessive

brake pedal

vibration

•Road surface (uneven)

•Incorrect wiring or piping connections

•VDCCM&H/U

•Brake booster

•Suspension play or fatigue (poor damp-

ing)

Noise from

VDCH/U

•VDCCM&H/U (mount bushing)

•Defective ABS wheel speed sensor or sensor

gap

•Brake pipe

•VDCCM&H/U

•Defective steering angle sensor or

improper neutral position

•Defective yaw rate & G sensor or

improper installation

Noise from

the front side

of vehicle

•VDCCM&H/U (mount bushing)

•Defective ABS wheel speed sensor or sensor

gap

•Master cylinder

•Brake caliper

•Brake pad

•Disc rotor

•Brake pipe

•Brake booster

•Suspension play or fatigue (poor damping)

•Axle and wheels

•Tire specifications, tire wear and air

pressures

Noise inside

passenger

seat

•VDCCM&H/U

•Defective steering angle sensor or

improper neutral position

•Defective yaw rate & G sensor or

improper installation

Noise from

the rear side

of vehicle

•Defective ABS wheel speed sensor or sensor

gap

•Brake caliper

•Brake pad

•Disc rotor

•Parking brake

•Brake pipe

•Suspension play or fatigue (poor damping)

•Axle and wheels

•Tire specifications, tire wear and air

pressures

Engine does not accelerate or

goes into a stall when accelerat-

ing suddenly or driving on a slip-

pery surface.

•VDCCM&H/U

•Defective ABS wheel speed sensor or sensor

gap

•Master cylinder

•Brake caliper

•Parking brake

•Incorrect wiring or piping

•Defective steering angle sensor or

improper neutral position

•Defective yaw rate & G sensor or

improper installation

•Brake pad

•Brake pipe

Symptom Main probable cause Other probable cause

Page 1102 of 2453

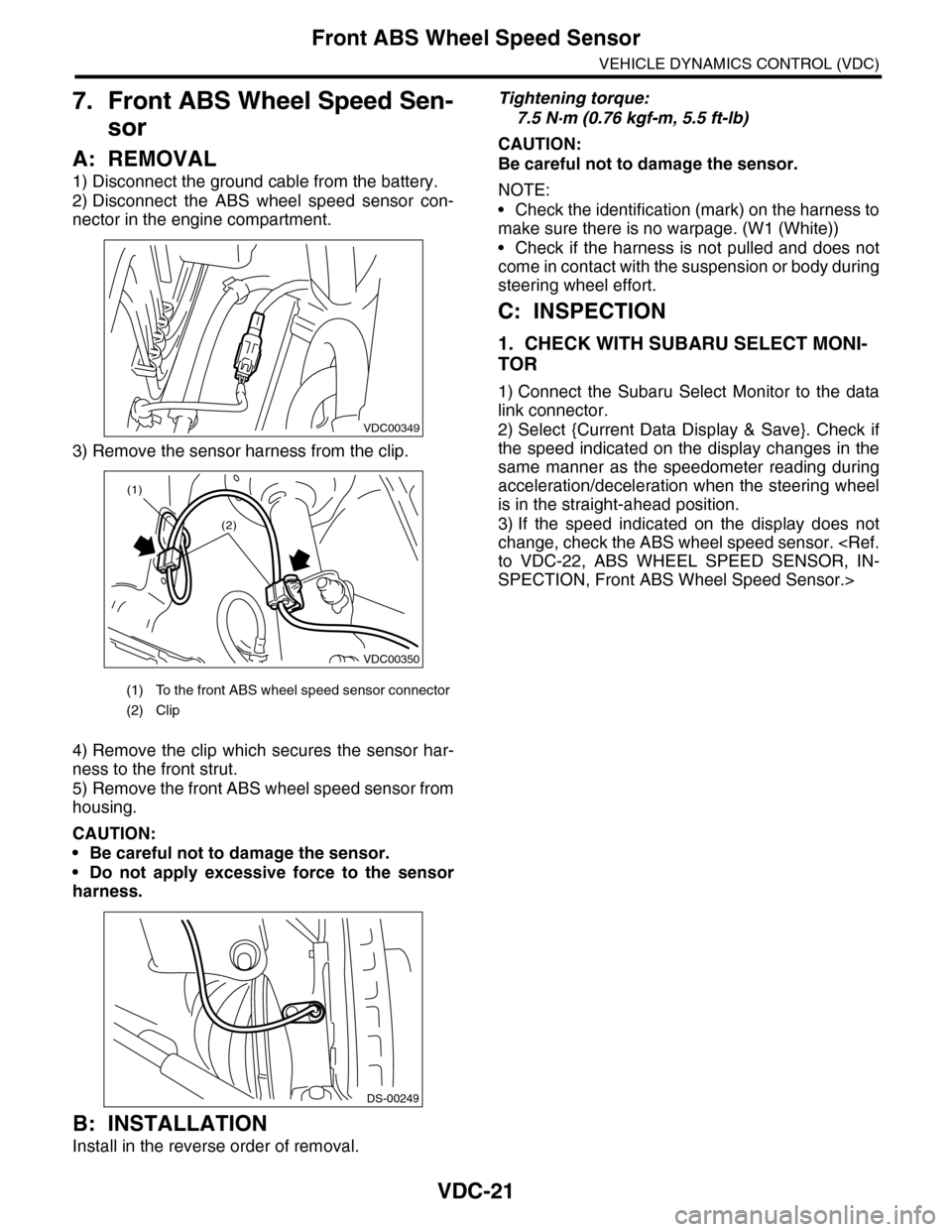

VDC-21

Front ABS Wheel Speed Sensor

VEHICLE DYNAMICS CONTROL (VDC)

7. Front ABS Wheel Speed Sen-

sor

A: REMOVAL

1) Disconnect the ground cable from the battery.

2) Disconnect the ABS wheel speed sensor con-

nector in the engine compartment.

3) Remove the sensor harness from the clip.

4) Remove the clip which secures the sensor har-

ness to the front strut.

5) Remove the front ABS wheel speed sensor from

housing.

CAUTION:

•Be careful not to damage the sensor.

•Do not apply excessive force to the sensor

harness.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

7.5 N·m (0.76 kgf-m, 5.5 ft-lb)

CAUTION:

Be careful not to damage the sensor.

NOTE:

•Check the identification (mark) on the harness to

make sure there is no warpage. (W1 (White))

•Check if the harness is not pulled and does not

come in contact with the suspension or body during

steering wheel effort.

C: INSPECTION

1. CHECK WITH SUBARU SELECT MONI-

TOR

1) Connect the Subaru Select Monitor to the data

link connector.

2) Select {Current Data Display & Save}. Check if

the speed indicated on the display changes in the

same manner as the speedometer reading during

acceleration/deceleration when the steering wheel

is in the straight-ahead position.

3) If the speed indicated on the display does not

change, check the ABS wheel speed sensor.

SPECTION, Front ABS Wheel Speed Sensor.>

(1) To the front ABS wheel speed sensor connector

(2) Clip

VDC00349

VDC00350

(1)

(2)

DS-00249

Page 1121 of 2453

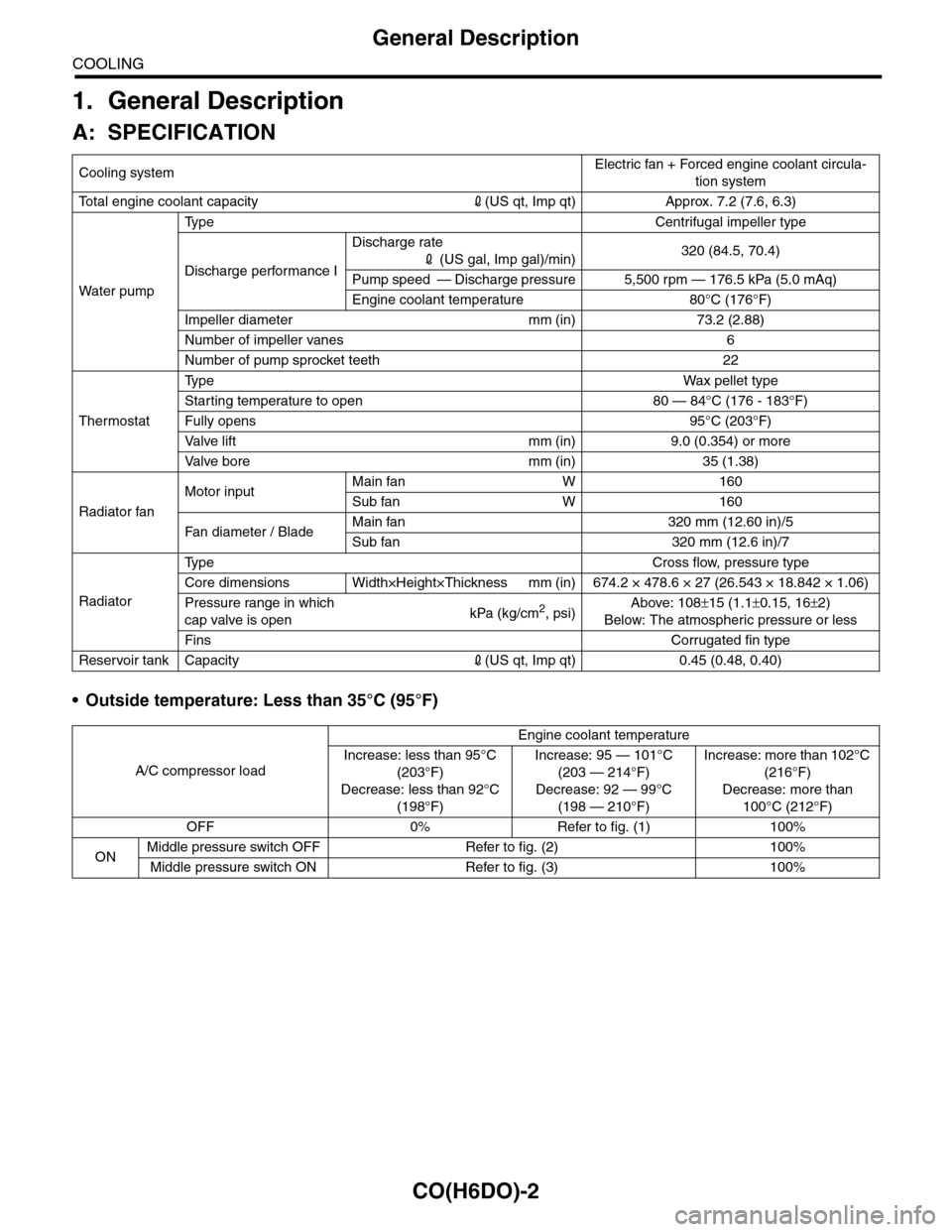

CO(H6DO)-2

General Description

COOLING

1. General Description

A: SPECIFICATION

•Outside temperature: Less than 35°C (95°F)

Cooling systemElectric fan + Forced engine coolant circula-

tion system

To t a l e n g i n e c o o l a n t c a p a c i t y2(US qt, Imp qt) Approx. 7.2 (7.6, 6.3)

Wa t er p u mp

Ty p e C e n t r i f u g a l i m p e l l e r t y p e

Discharge performance I

Discharge rate

2 (US gal, Imp gal)/min)320 (84.5, 70.4)

Pump speed — Discharge pressure 5,500 rpm — 176.5 kPa (5.0 mAq)

Engine coolant temperature 80°C (176°F)

Impeller diameter mm (in) 73.2 (2.88)

Number of impeller vanes 6

Number of pump sprocket teeth 22

Thermostat

Ty p eWa x p el l et t yp e

Starting temperature to open 80 — 84°C (176 - 183°F)

Fully opens 95°C (203°F)

Va l ve l i f t m m ( i n ) 9 . 0 ( 0 . 3 5 4 ) o r m o r e

Va l ve b o r e m m ( i n ) 3 5 ( 1 . 3 8 )

Radiator fan

Motor inputMain fan W 160

Sub fan W 160

Fan di a me t er / B la deMain fan 320 mm (12.60 in)/5

Sub fan 320 mm (12.6 in)/7

Radiator

Ty p e C r o s s f l o w , p r e s s u r e t y p e

Core dimensions Width×Height×Thickness mm (in) 674.2 × 478.6 × 27 (26.543 × 18.842 × 1.06)

Pressure range in which

cap valve is openkPa (kg/cm2, psi)Above: 108±15 (1.1±0.15, 16±2)

Below: The atmospheric pressure or less

FinsCorrugated fin type

Reservoir tank Capacity2(US qt, Imp qt) 0.45 (0.48, 0.40)

A/C compressor load

Engine coolant temperature

Increase: less than 95°C

(203°F)

Decrease: less than 92°C

(198°F)

Increase: 95 — 101°C

(203 — 214°F)

Decrease: 92 — 99°C

(198 — 210°F)

Increase: more than 102°C

(216°F)

Decrease: more than

100°C (212°F)

OFF 0% Refer to fig. (1) 100%

ONMiddle pressure switch OFF Refer to fig. (2) 100%

Middle pressure switch ON Refer to fig. (3) 100%

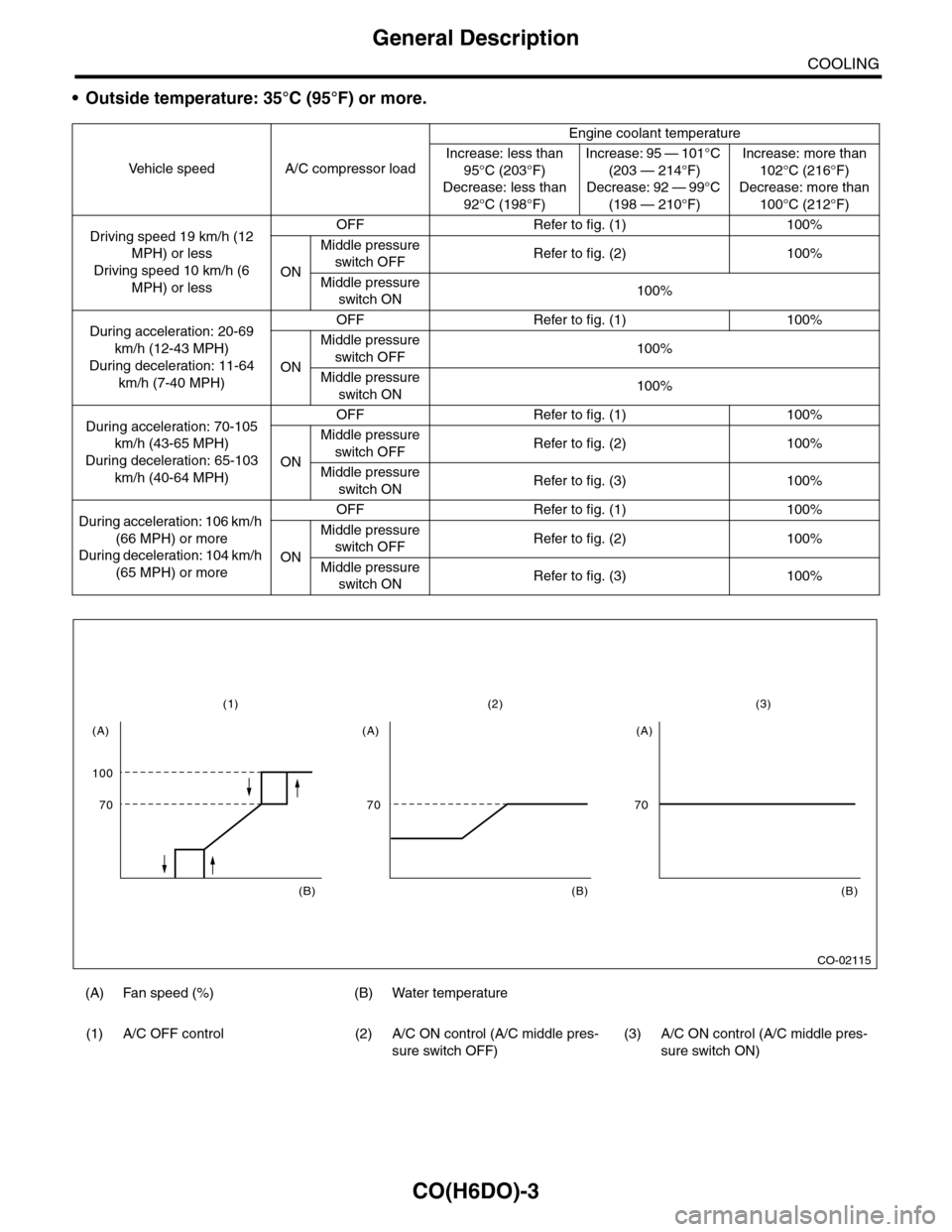

Page 1122 of 2453

CO(H6DO)-3

General Description

COOLING

•Outside temperature: 35°C (95°F) or more.

Ve h i c l e s p e e d A / C c o m p r e s s o r l o a d

Engine coolant temperature

Increase: less than

95°C (203°F)

Decrease: less than

92°C (198°F)

Increase: 95 — 101°C

(203 — 214°F)

Decrease: 92 — 99°C

(198 — 210°F)

Increase: more than

102°C (216°F)

Decrease: more than

100°C (212°F)

Driving speed 19 km/h (12

MPH) or less

Driving speed 10 km/h (6

MPH) or less

OFF Refer to fig. (1) 100%

ON

Middle pressure

switch OFFRefer to fig. (2) 100%

Middle pressure

switch ON100%

During acceleration: 20-69

km/h (12-43 MPH)

During deceleration: 11-64

km/h (7-40 MPH)

OFF Refer to fig. (1) 100%

ON

Middle pressure

switch OFF100%

Middle pressure

switch ON100%

During acceleration: 70-105

km/h (43-65 MPH)

During deceleration: 65-103

km/h (40-64 MPH)

OFF Refer to fig. (1) 100%

ON

Middle pressure

switch OFFRefer to fig. (2) 100%

Middle pressure

switch ONRefer to fig. (3) 100%

During acceleration: 106 km/h

(66 MPH) or more

During deceleration: 104 km/h

(65 MPH) or more

OFF Refer to fig. (1) 100%

ON

Middle pressure

switch OFFRefer to fig. (2) 100%

Middle pressure

switch ONRefer to fig. (3) 100%

(A) Fan speed (%) (B) Water temperature

(1) A/C OFF control (2) A/C ON control (A/C middle pres-

sure switch OFF)

(3) A/C ON control (A/C middle pres-

sure switch ON)

CO-02115

100

(1)

70

(A)

(B)

(2)

70

(A)

(B)

(3)

70

(A)

(B)

Page 1124 of 2453

CO(H6DO)-5

General Description

COOLING

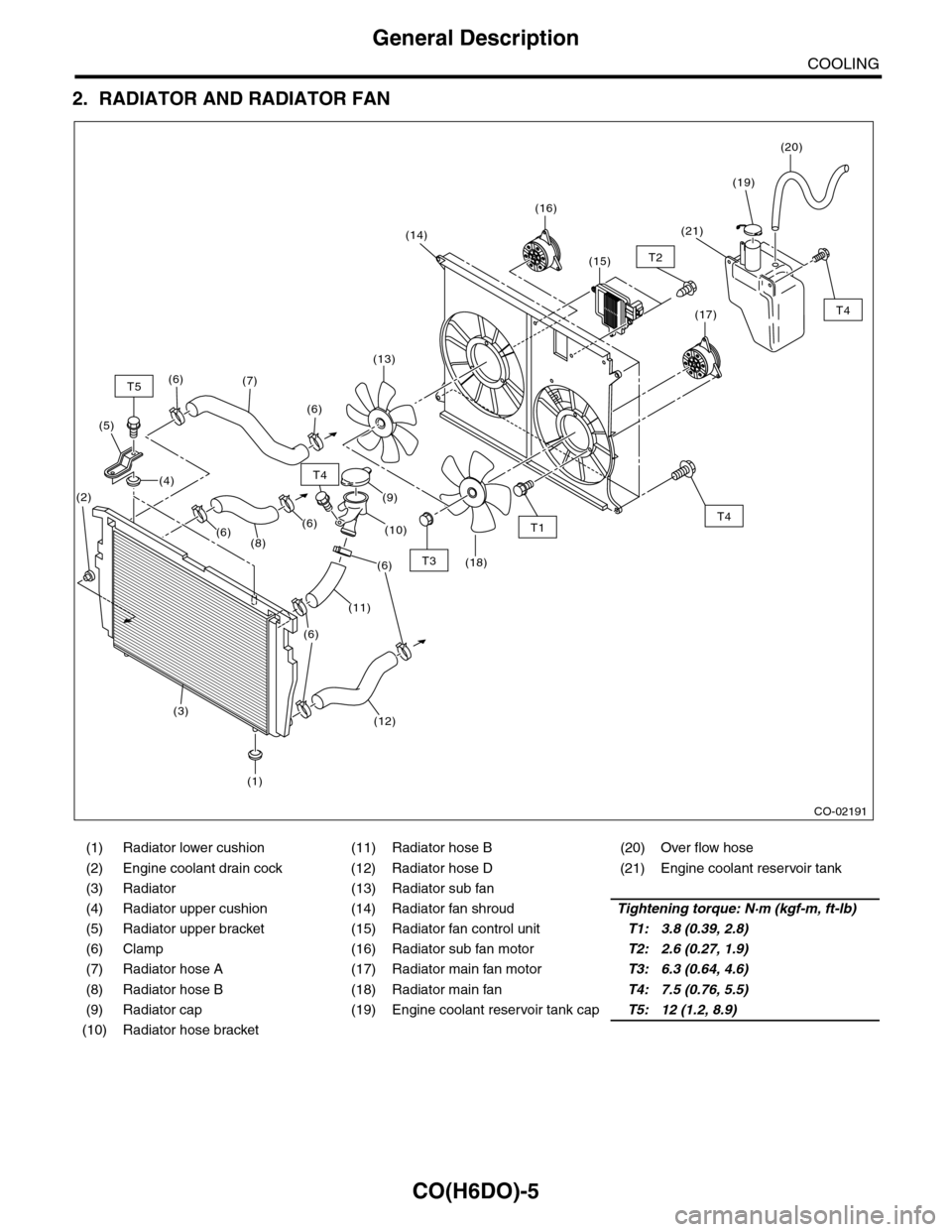

2. RADIATOR AND RADIATOR FAN

(1) Radiator lower cushion (11) Radiator hose B (20) Over flow hose

(2) Engine coolant drain cock (12) Radiator hose D (21) Engine coolant reservoir tank

(3) Radiator (13) Radiator sub fan

(4) Radiator upper cushion (14) Radiator fan shroudTightening torque: N·m (kgf-m, ft-lb)

(5) Radiator upper bracket (15) Radiator fan control unitT1: 3.8 (0.39, 2.8)

(6) Clamp (16) Radiator sub fan motorT2: 2.6 (0.27, 1.9)

(7) Radiator hose A (17) Radiator main fan motorT3: 6.3 (0.64, 4.6)

(8) Radiator hose B (18) Radiator main fanT4: 7.5 (0.76, 5.5)

(9) Radiator cap (19) Engine coolant reservoir tank capT5: 12 (1.2, 8.9)

(10) Radiator hose bracket

CO-02191

T4

T4

T4

T2

T1

T3

T5(7)

(6)

(13)

(18)

(14)

(16)

(17)

(15)

(21)

(19)

(20)

(9)

(10)

(6)

(11)

(6)

(1)

(3)

(2)

(12)

(6)

(8)

(4)

(5)

(6)(6)

Page 1127 of 2453

CO(H6DO)-8

Radiator Fan System

COOLING

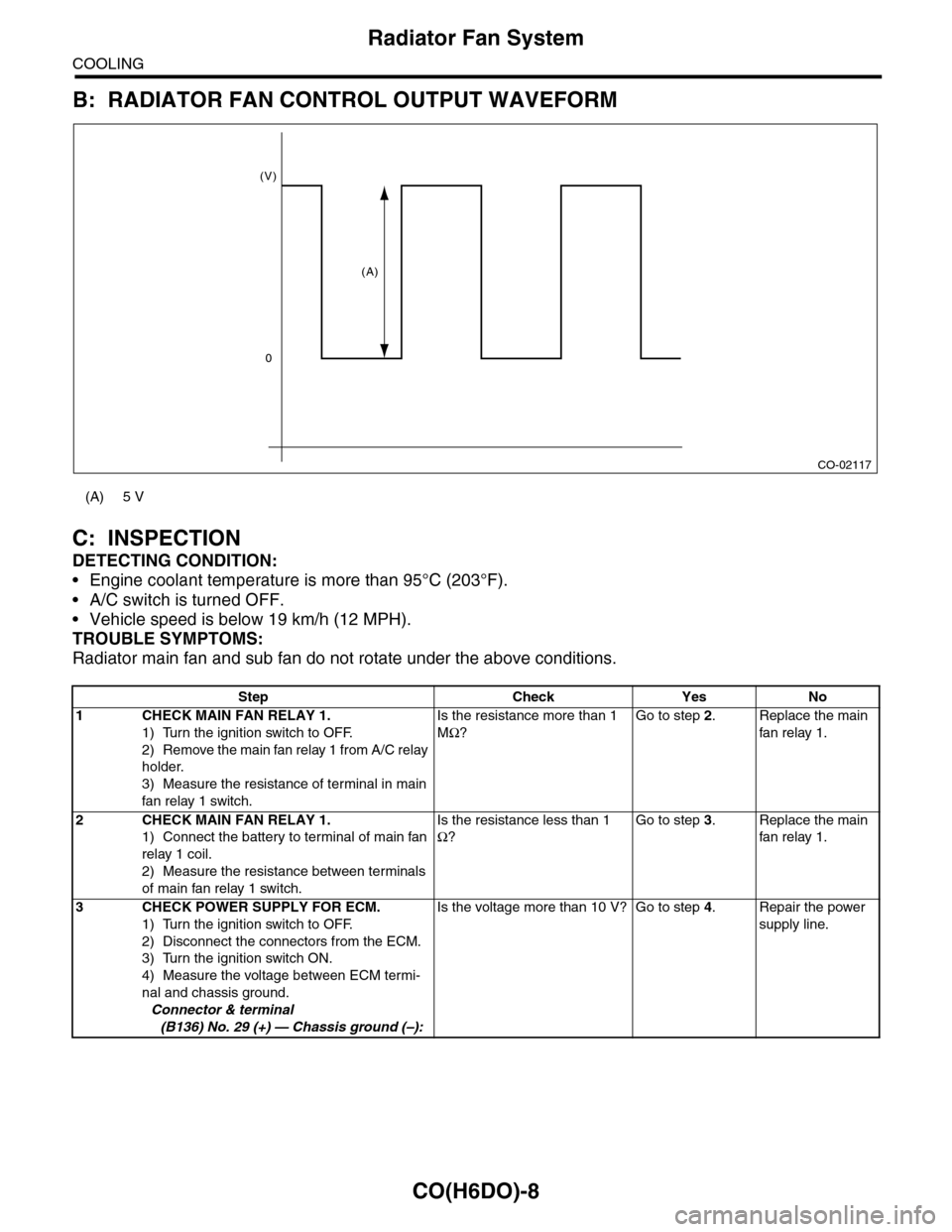

B: RADIATOR FAN CONTROL OUTPUT WAVEFORM

C: INSPECTION

DETECTING CONDITION:

•Engine coolant temperature is more than 95°C (203°F).

•A/C switch is turned OFF.

•Vehicle speed is below 19 km/h (12 MPH).

TROUBLE SYMPTOMS:

Radiator main fan and sub fan do not rotate under the above conditions.

(A) 5 V

Step Check Yes No

1CHECK MAIN FAN RELAY 1.

1) Turn the ignition switch to OFF.

2) Remove the main fan relay 1 from A/C relay

holder.

3) Measure the resistance of terminal in main

fan relay 1 switch.

Is the resistance more than 1

MΩ?

Go to step 2.Replace the main

fan relay 1.

2CHECK MAIN FAN RELAY 1.

1) Connect the battery to terminal of main fan

relay 1 coil.

2) Measure the resistance between terminals

of main fan relay 1 switch.

Is the resistance less than 1

Ω?

Go to step 3.Replace the main

fan relay 1.

3CHECK POWER SUPPLY FOR ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from the ECM.

3) Turn the ignition switch ON.

4) Measure the voltage between ECM termi-

nal and chassis ground.

Connector & terminal

(B136) No. 29 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 4.Repair the power

supply line.

CO-02117

(V)

0

(A)