engine SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1213 of 2453

EN(H6DO)(diag)-52

Malfunction Indicator Light

ENGINE (DIAGNOSTICS)

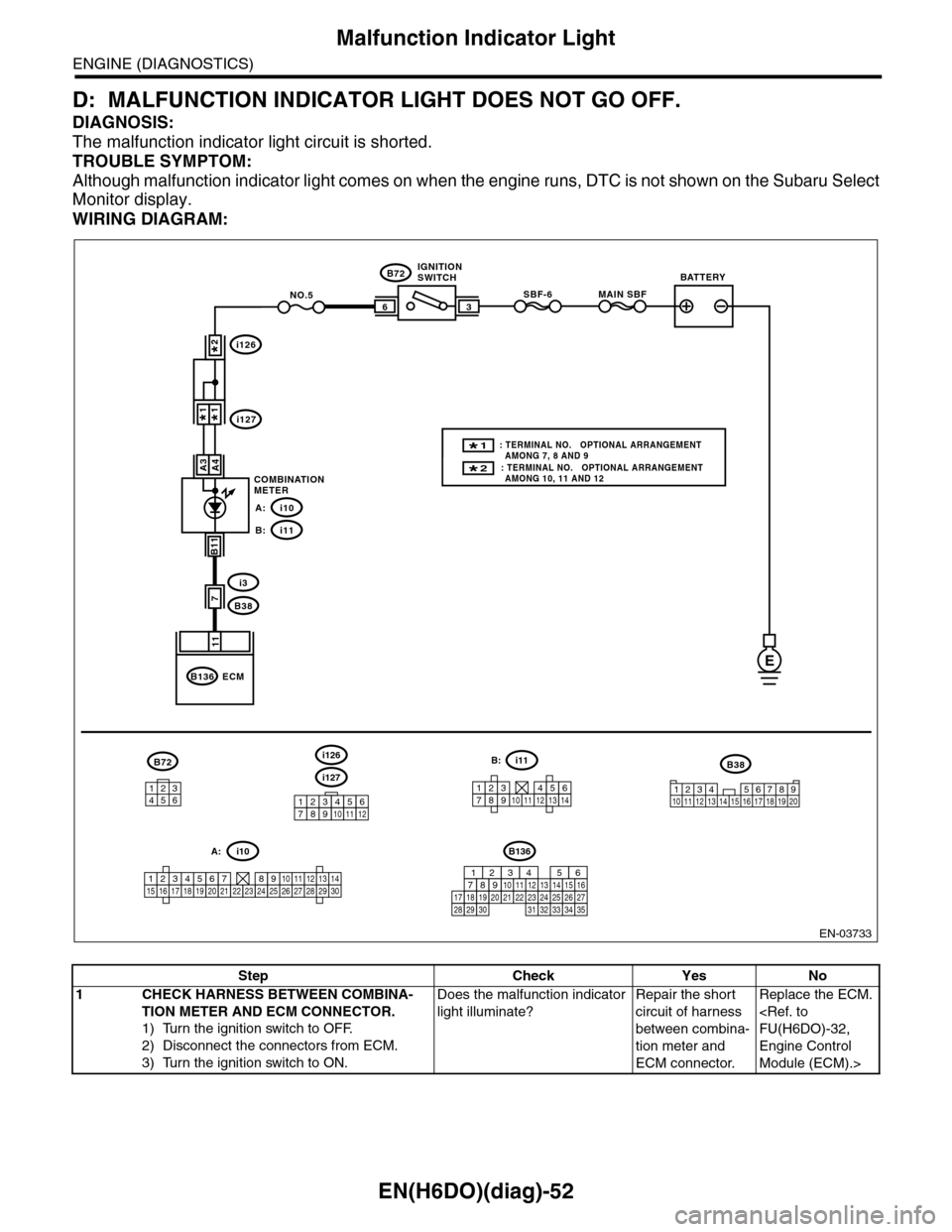

D: MALFUNCTION INDICATOR LIGHT DOES NOT GO OFF.

DIAGNOSIS:

The malfunction indicator light circuit is shorted.

TROUBLE SYMPTOM:

Although malfunction indicator light comes on when the engine runs, DTC is not shown on the Subaru Select

Monitor display.

WIRING DIAGRAM:

EN-03733

3

B72

i3

B38

B136

SBF-66

11

A4

7

MAIN SBFNO.5

B11

E

A3

B72

134562

B38

1234 5678910 11 12 13 14 15 16 17 18 19 20

ECM

COMBINATIONMETER

IGNITIONSWITCHBATTERY

i126

i1271*1*

2*

i10A:

i11B:

i127

i126

123456789101112

1234567891011121314

i11B:

123456789101112131415161718192021222324252627282930

i10A:

2* : TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 10, 11 AND 12

1* : TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 7, 8 AND 9

B136

16101112131415252430

9871718192028212223293231

123456

2726333435

Step Check Yes No

1CHECK HARNESS BETWEEN COMBINA-

TION METER AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Turn the ignition switch to ON.

Does the malfunction indicator

light illuminate?

Repair the short

circuit of harness

between combina-

tion meter and

ECM connector.

Replace the ECM.

Engine Control

Module (ECM).>

Page 1214 of 2453

EN(H6DO)(diag)-53

Malfunction Indicator Light

ENGINE (DIAGNOSTICS)

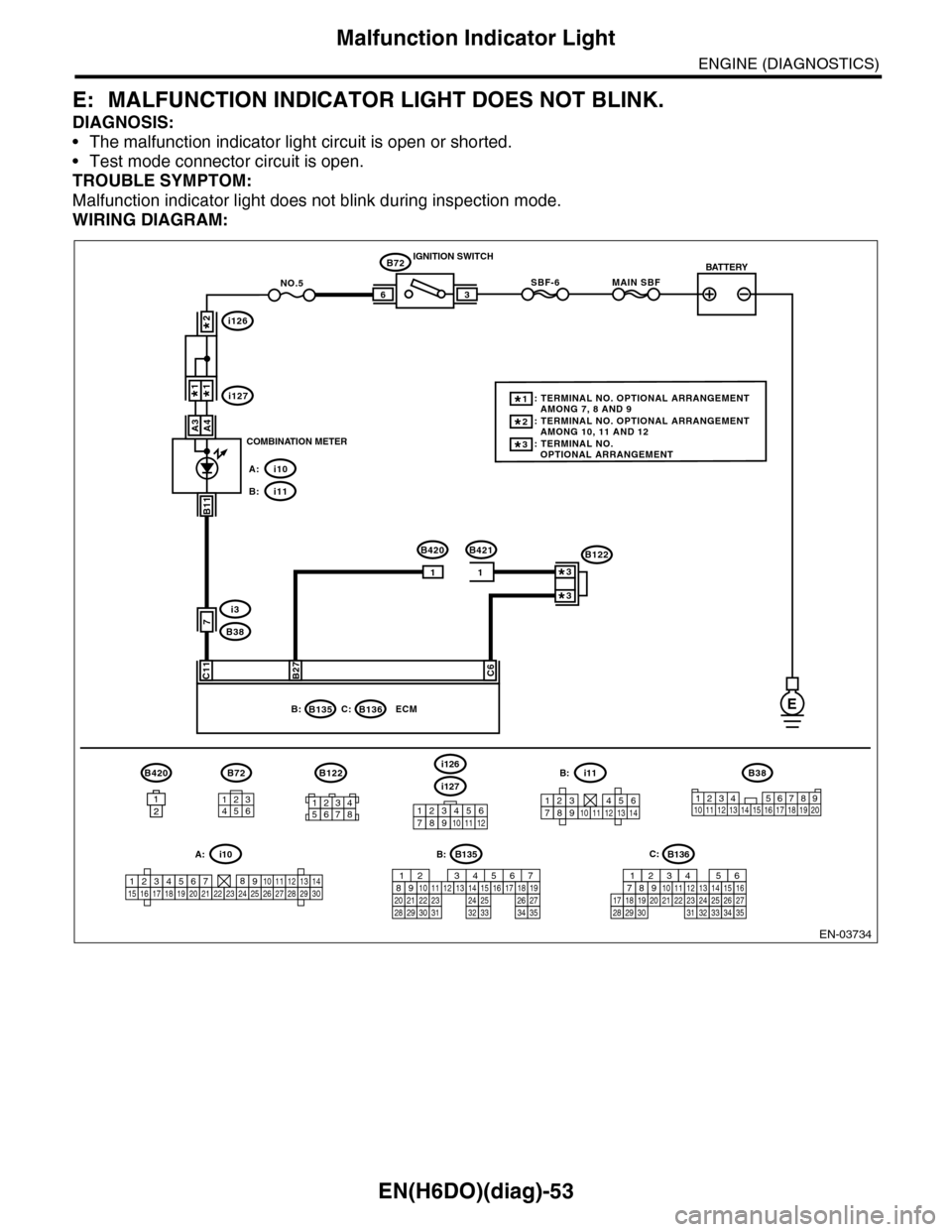

E: MALFUNCTION INDICATOR LIGHT DOES NOT BLINK.

DIAGNOSIS:

•The malfunction indicator light circuit is open or shorted.

•Test mode connector circuit is open.

TROUBLE SYMPTOM:

Malfunction indicator light does not blink during inspection mode.

WIRING DIAGRAM:

EN-03734

i126

i1271*1*

2*

i10A:

i11B:

BATTERY

3

B72

B420B421

IGNITION SWITCH

COMBINATION METER

B135B:

SBF-66

C11B27C6

ECM

B72

7

MAIN SBFNO.5

11

B420

1212

B11

i3

B38

E

A4A3

B136C:

134562

B38

1234 5678910 11 12 13 14 15 16 17 18 19 2012345678

B122

3*: TERMINAL NO. OPTIONAL ARRANGEMENT

2*: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 10, 11 AND 12

1*: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 7, 8 AND 9

B122

3*

3*

i127

i126

123456789101112

1234567891011121314

i11B:

123456789101112131415161718192021222324252627282930

i10A:B135

5672134

29

101112131415252416

30

98171819202821222332312627333435

B:B136

16101112131415252430

9871718192028212223293231

123456

2726333435

C:

Page 1215 of 2453

EN(H6DO)(diag)-54

Malfunction Indicator Light

ENGINE (DIAGNOSTICS)

Step Check Yes No

1CHECK STATUS OF MALFUNCTION INDI-

CATOR LIGHT.

1) Turn the ignition switch to OFF.

2) Disconnect the test mode connectors.

3) Turn the ignition switch to ON.(Engine OFF)

Does the malfunction indicator

light illuminate?

Go to step 2.Repair the mal-

function indicator

light circuit.

EN(H6DO)(diag)-

50, MALFUNC-

TION INDICATOR

LIGHT DOES NOT

COME ON, Mal-

function Indicator

Light.>

2CHECK HARNESS BETWEEN COMBINA-

TION METER AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Turn the ignition switch to ON.

Does the malfunction indicator

light illuminate?

Repair the short

circuit of harness

between combina-

tion meter and

ECM connector.

Go to step 3.

3CHECK HARNESS BETWEEN TEST MODE

CONNECTOR AND CHASSIS GROUND.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance of harness

between test mode connector and chassis

ground.

Connector & terminal

(B421) No. 1 — Chassis ground:

Is the resistance less than 1

Ω?

Go to step 4.Repair the har-

ness and connec-

tor.

NOTE:

In this case, repair

the following item:

•Open circuit

of harness be-

tween test

mode connector

and chassis

ground

4CHECK POOR CONTACT.

Check poor contact of ECM connector.

Is there poor contact in ECM

connector?

Repair poor con-

tact in ECM con-

nector.

Go to step 5.

5CHECK HARNESS BETWEEN ECM AND

TEST MODE CONNECTOR.

1) Connect the test mode connector.

2) Measure the resistance of harness

between ECM and chassis ground.

Connector & terminal

(B135) No. 27 — Chassis ground:

Is the resistance less than 1

Ω?

Go to step 6.Repair the open

circuit of harness

between ECM and

test mode connec-

tor.

6CHECK POOR CONTACT.

Check poor contact of ECM connector.

Is there poor contact in ECM

connector?

Repair poor con-

tact in ECM con-

nector.

Replace the ECM.

Engine Control

Module (ECM).>

Page 1216 of 2453

EN(H6DO)(diag)-55

Malfunction Indicator Light

ENGINE (DIAGNOSTICS)

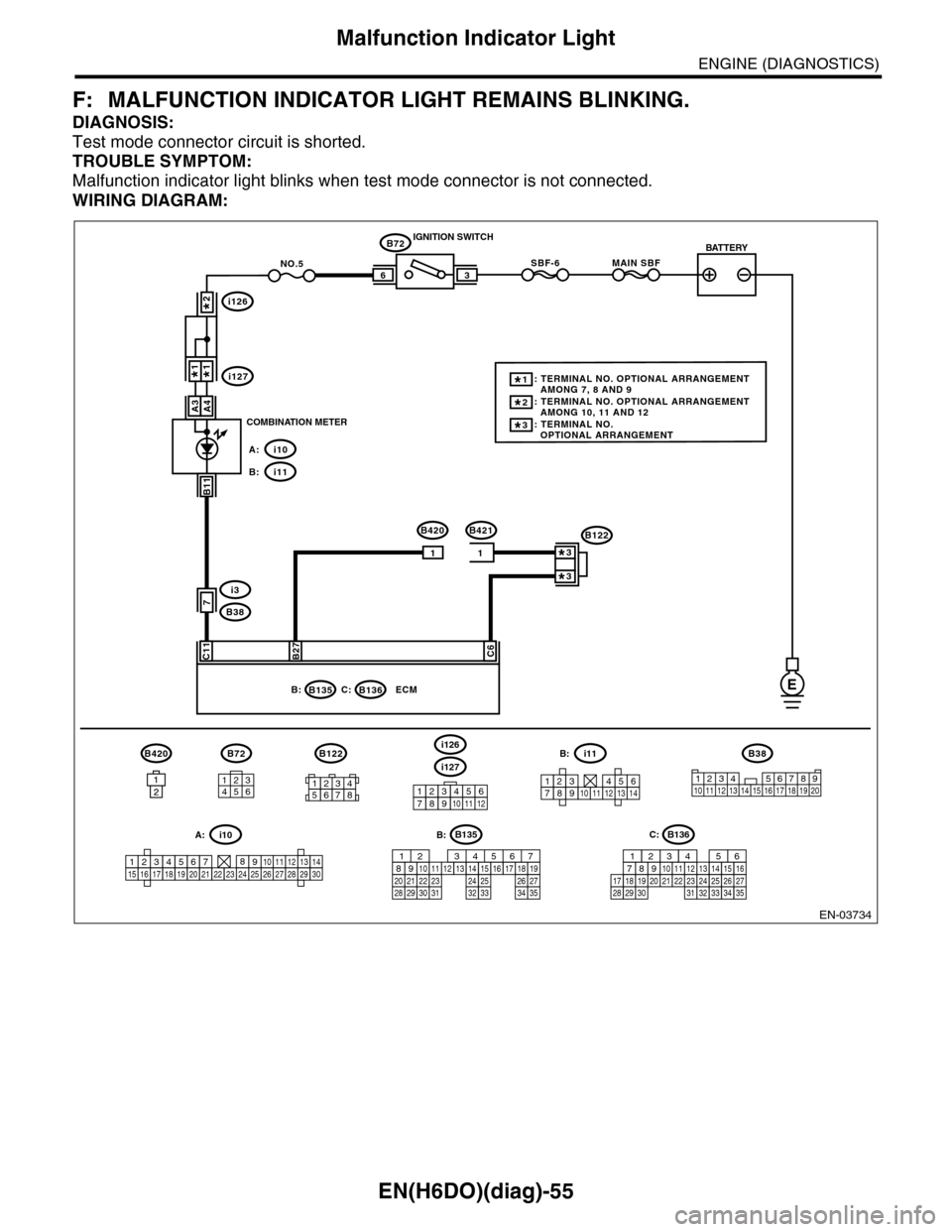

F: MALFUNCTION INDICATOR LIGHT REMAINS BLINKING.

DIAGNOSIS:

Test mode connector circuit is shorted.

TROUBLE SYMPTOM:

Malfunction indicator light blinks when test mode connector is not connected.

WIRING DIAGRAM:

EN-03734

i126

i1271*1*

2*

i10A:

i11B:

BATTERY

3

B72

B420B421

IGNITION SWITCH

COMBINATION METER

B135B:

SBF-66

C11B27C6

ECM

B72

7

MAIN SBFNO.5

11

B420

1212

B11

i3

B38

E

A4A3

B136C:

134562

B38

1234 5678910 11 12 13 14 15 16 17 18 19 2012345678

B122

3*: TERMINAL NO. OPTIONAL ARRANGEMENT

2*: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 10, 11 AND 12

1*: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 7, 8 AND 9

B122

3*

3*

i127

i126

123456789101112

1234567891011121314

i11B:

123456789101112131415161718192021222324252627282930

i10A:B135

5672134

29

101112131415252416

30

98171819202821222332312627333435

B:B136

16101112131415252430

9871718192028212223293231

123456

2726333435

C:

Page 1217 of 2453

EN(H6DO)(diag)-56

Malfunction Indicator Light

ENGINE (DIAGNOSTICS)

Step Check Yes No

1CHECK TEST MODE CONNECTOR.

1) Disconnect the test mode connectors.

2) Turn the ignition switch to ON.

Does the malfunction indicator

light blink?

Go to step 2.System is normal.

NOTE:Malfunction indica-

tor light blinks

when test mode

connector is con-

nected.

2CHECK HARNESS BETWEEN ECM CON-

NECTOR AND CHASSIS GROUND TERMI-

NAL.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance of harness

between ECM connector and chassis ground.

Connector & terminal

(B135) No. 27 — Chassis ground:

Is the resistance less than 5

Ω?

Repair the short

circuit of harness

between ECM and

test mode connec-

tor.

Replace the ECM.

Engine Control

Module (ECM).>

Page 1218 of 2453

EN(H6DO)(diag)-57

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

16.Diagnostics for Engine Starting Failure

A: PROCEDURE

1. Check for fuel amount.

↓

2. Inspection of starter motor circuit.

↓

3. Inspection of ECM power supply and ground line.

↓

4. Inspection of ignition control system.

↓

5. Inspection of fuel pump circuit

↓

6. Inspection of fuel injector circuit

Page 1219 of 2453

EN(H6DO)(diag)-58

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

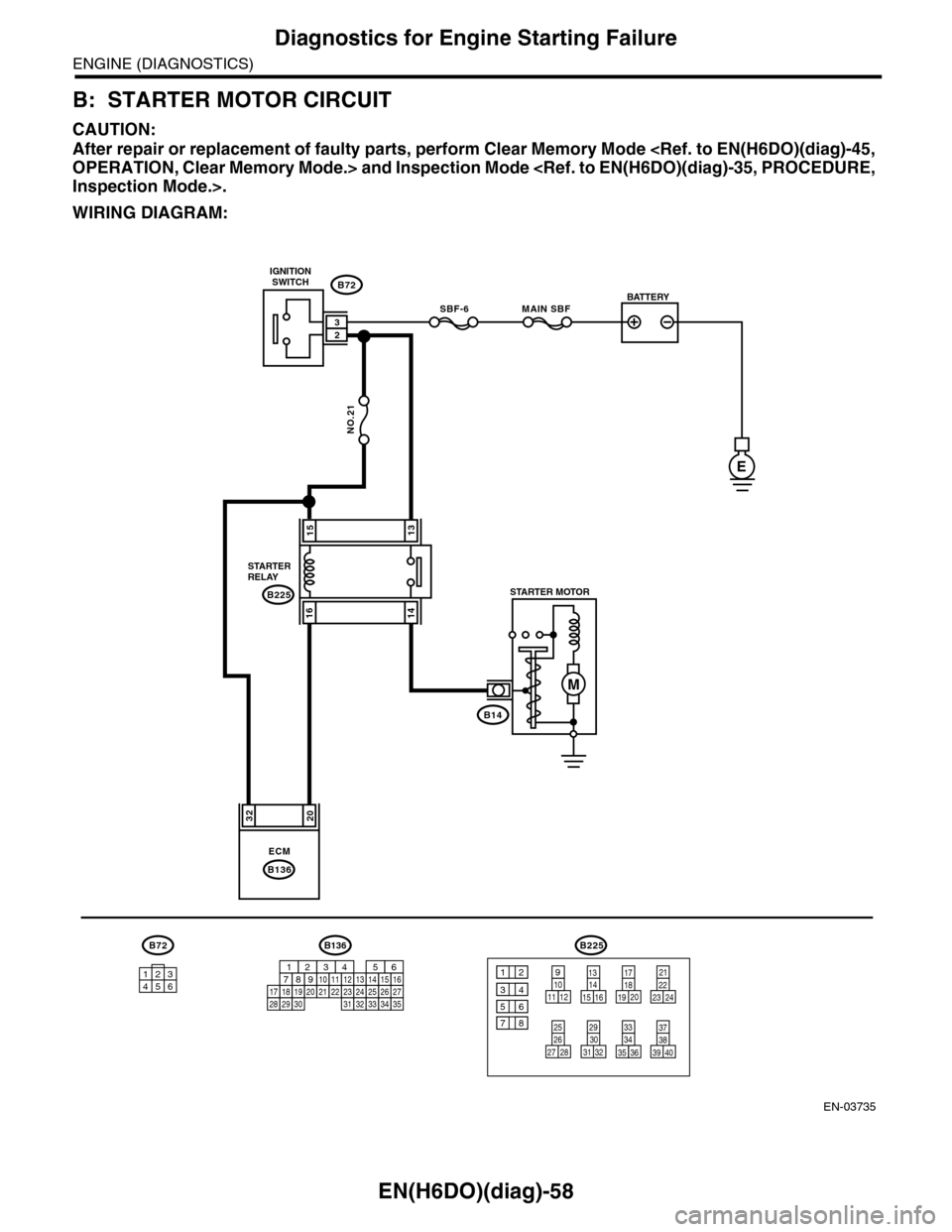

B: STARTER MOTOR CIRCUIT

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03735

3220

NO.21

B225

MAIN SBFSBF-6

E

1513

1614

ECM

B136

B72

B14

M

23

B72B225

101112

131415 16

17181920

21222324

25262728

293031 32

333435 36 39 40

3738

129

34

56

78

134562

BATTERY

IGNITIONSWITCH

STARTERRELAYSTARTER MOTOR

B136

16101112131415252430

9871718192028212223293231

123456

2726333435

Page 1220 of 2453

EN(H6DO)(diag)-59

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

Step Check Yes No

1CHECK BATTERY.

Check the battery voltage.

Is the voltage more than 12 V? Go to step 2.Charge or replace

the battery.

2CHECK OPERATION OF STARTER MOTOR.Does the starter motor oper-

ate?

Go to step 3.Go to step 4.

3CHECK DTC.Is DTC displayed?

TION, Read Diagnostic Trouble

Code (DTC).>

Check the appro-

priate DTC using

the List of Diag-

nostic Trouble

Code (DTC).

EN(H6DO)(diag)-

69, List of Diag-

nostic Trouble

Code (DTC).>

Repair poor con-

tact in ECM con-

nector.

4CHECK INPUT SIGNAL FOR STARTER MO-

TOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from starter

motor.

3) Turn the ignition switch to START.

4) Measure the power supply voltage between

starter motor connector terminal and engine

ground.

Connector & terminal

(B14) No. 1 (+) — Engine ground (–):

NOTE:Place the select lever in “P” or “N” range.

Is the voltage more than 10 V? Check the starter

motor.

Starter.>

Go to step 5.

5CHECK HARNESS BETWEEN BATTERY

AND IGNITION SWITCH CONNECTOR.

1) Disconnect the connector from ignition

switch.

2) Measure the power supply voltage between

ignition switch connector and chassis ground.

Connector & terminal

(B72) No. 3 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 6.Repair the open

circuit of harness

between ignition

switch and bat-

tery, and check

fuse SBF No. 7

and SBF No. 1.

6CHECK IGNITION SWITCH.

1) Disconnect the connector from ignition

switch.

2) Measure the resistance between ignition

switch terminals after turning the ignition

switch to START position.

Te r m i n a l s

No. 2 — No. 3:

Is the resistance less than 5

Ω?

Go to step 7.Replace the igni-

tion switch.

7CHECK INPUT VOLTAGE OF STARTER RE-

LAY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from starter relay.

3) Connect the connector to ignition switch.

4) Measure the input voltage between starter

relay connector and chassis ground after turn-

ing the ignition switch to START position.

Connector & terminal

(B225) No. 13 (+) — Chassis ground (–):

(B225) No. 15 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 8.Repair the open

circuit of harness

between starter

relay and ignition

switch.

Page 1221 of 2453

EN(H6DO)(diag)-60

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

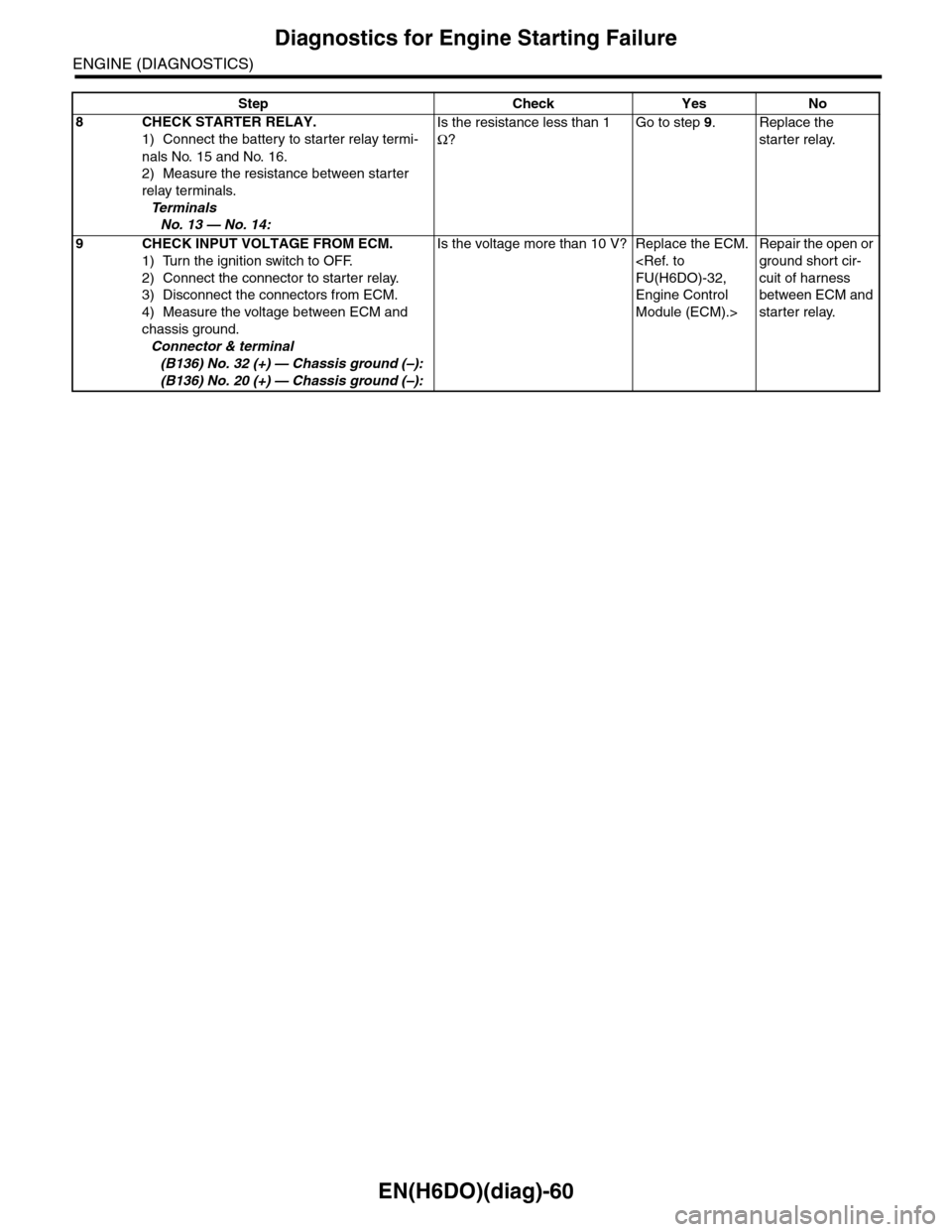

8CHECK STARTER RELAY.

1) Connect the battery to starter relay termi-

nals No. 15 and No. 16.

2) Measure the resistance between starter

relay terminals.

Te r m i n a l s

No. 13 — No. 14:

Is the resistance less than 1

Ω?

Go to step 9.Replace the

starter relay.

9CHECK INPUT VOLTAGE FROM ECM.

1) Turn the ignition switch to OFF.

2) Connect the connector to starter relay.

3) Disconnect the connectors from ECM.

4) Measure the voltage between ECM and

chassis ground.

Connector & terminal

(B136) No. 32 (+) — Chassis ground (–):

(B136) No. 20 (+) — Chassis ground (–):

Is the voltage more than 10 V? Replace the ECM.

Engine Control

Module (ECM).>

Repair the open or

ground short cir-

cuit of harness

between ECM and

starter relay.

Step Check Yes No

Page 1222 of 2453

EN(H6DO)(diag)-61

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

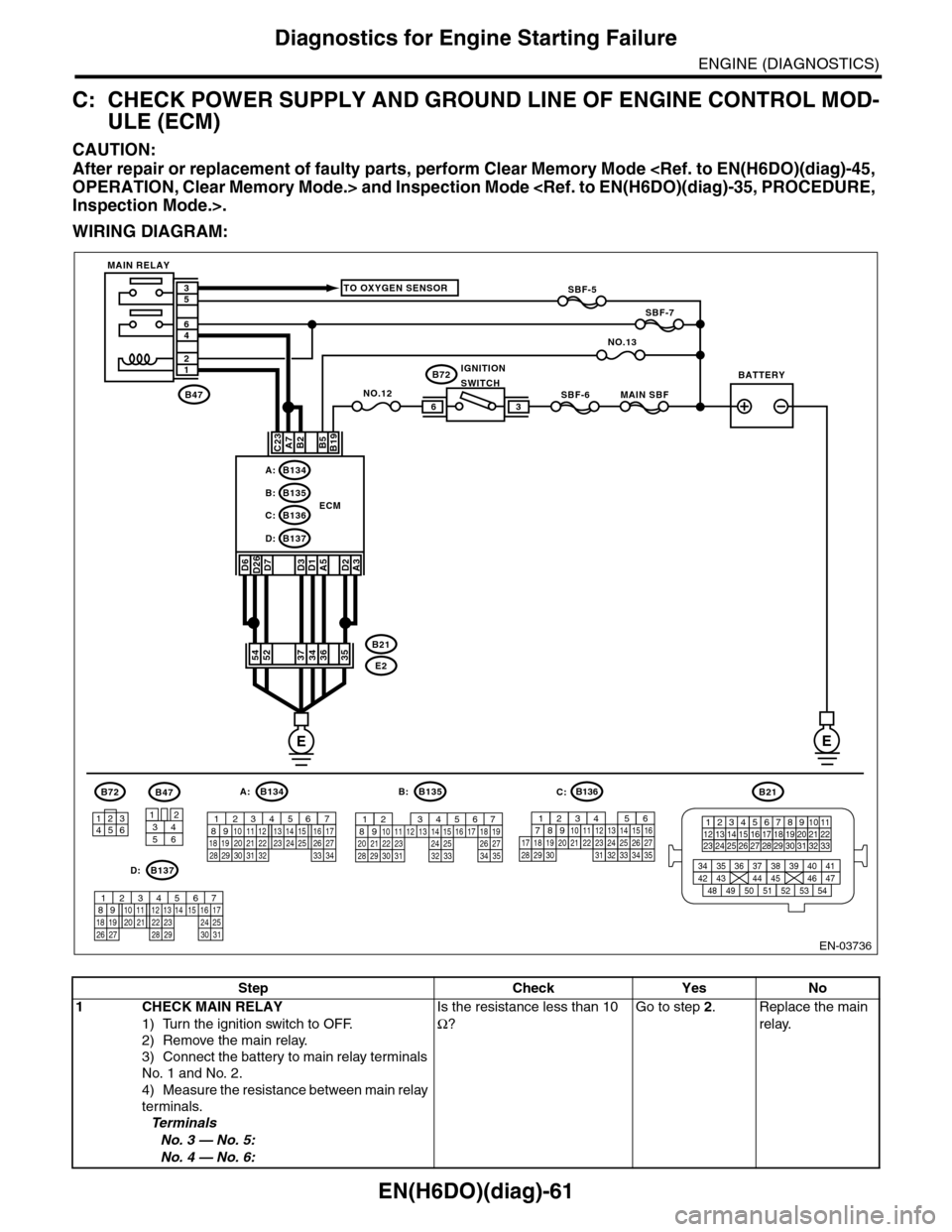

C: CHECK POWER SUPPLY AND GROUND LINE OF ENGINE CONTROL MOD-

ULE (ECM)

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03736

SBF-6MAIN SBF

SBF-7

B72

B2A7C23

D7D3D1A5

B5B19

NO.12B47

E2

B21

12

46

53

ECM

EE

36

B134A:

D:B137

B135B:

B136C:

A3

52373634

3412

56

B47

TO OXYGEN SENSOR

NO.13

D2

35

B21

123412131415567816171819910 1120212223 24 25 2627 28 29 3031 32 33

3534 37363938 41404342 4445 47464948 51505352 54

B72

134562

B134

56 7821943102422 23 2511 12 13 14 1526 2728

16 1718 19 20 2133 34293230 31

A:B135

567821943102422 23 2511 12 13 14 1526 2728

16 17 18 1920 2129 30 31 32 33 34 35

B:

B137

5678219431022 2311 12 13 14 1524 2526

16 1718 19 20 2127 28 29 30 31

D:

SBF-5

D6D26

54

MAIN RELAY

BATTERYIGNITIONSWITCH

B136

16101112131415252430

9871718192028212223293231

123456

2726333435

C:

Step Check Yes No

1CHECK MAIN RELAY

1) Turn the ignition switch to OFF.

2) Remove the main relay.

3) Connect the battery to main relay terminals

No. 1 and No. 2.

4) Measure the resistance between main relay

terminals.

Te r m i n a l s

No. 3 — No. 5:

No. 4 — No. 6:

Is the resistance less than 10

Ω?

Go to step 2.Replace the main

relay.