cam sensor SUBARU TRIBECA 2009 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1567 of 2453

FU(H6DO)-6

General Description

FUEL INJECTION (FUEL SYSTEMS)

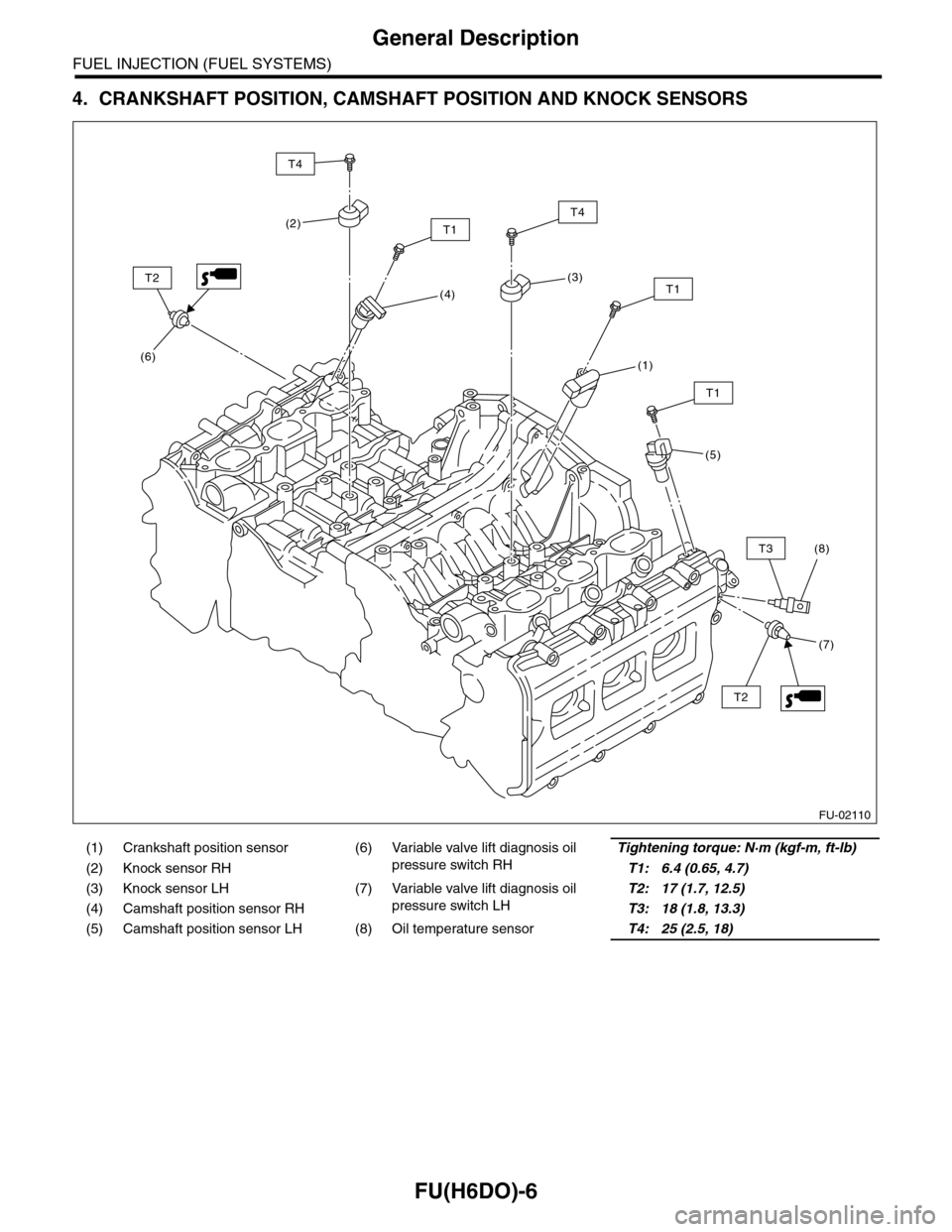

4. CRANKSHAFT POSITION, CAMSHAFT POSITION AND KNOCK SENSORS

(1) Crankshaft position sensor (6) Variable valve lift diagnosis oil

pressure switch RH

Tightening torque: N·m (kgf-m, ft-lb)

(2) Knock sensor RHT1: 6.4 (0.65, 4.7)

(3) Knock sensor LH (7) Variable valve lift diagnosis oil

pressure switch LH

T2: 17 (1.7, 12.5)

(4) Camshaft position sensor RHT3: 18 (1.8, 13.3)

(5) Camshaft position sensor LH (8) Oil temperature sensorT4: 25 (2.5, 18)

FU-02110

(6)

(4)

T2

T1

(3)

T4

(1)

(8)

T1

T3

(5)

T1

(2)

T4

(7)

T2

Page 1580 of 2453

FU(H6DO)-19

Camshaft Position Sensor

FUEL INJECTION (FUEL SYSTEMS)

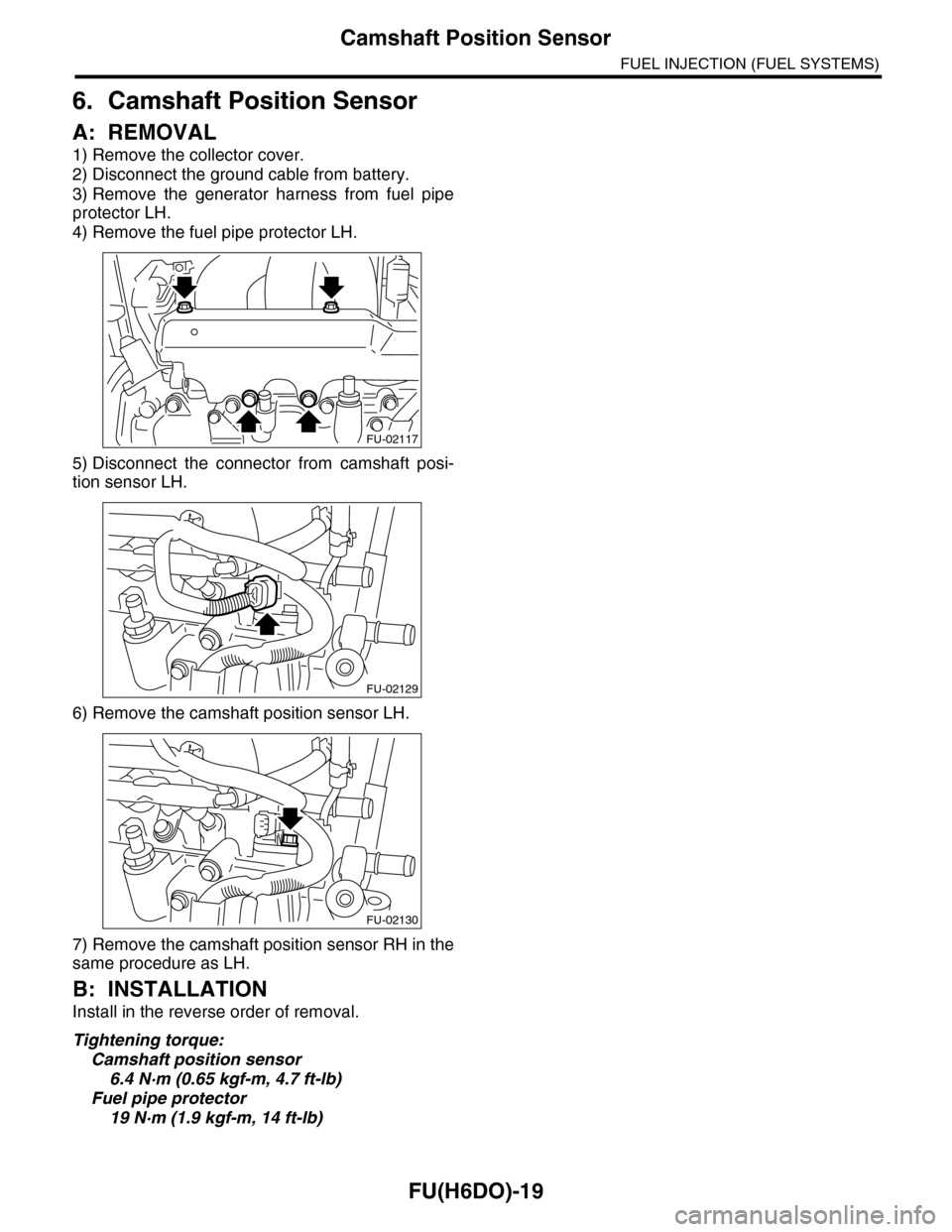

6. Camshaft Position Sensor

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Remove the generator harness from fuel pipe

protector LH.

4) Remove the fuel pipe protector LH.

5) Disconnect the connector from camshaft posi-

tion sensor LH.

6) Remove the camshaft position sensor LH.

7) Remove the camshaft position sensor RH in the

same procedure as LH.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

Camshaft position sensor

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

Fuel pipe protector

19 N·m (1.9 kgf-m, 14 ft-lb)

FU-02117

FU-02129

FU-02130

Page 1614 of 2453

GD(H6DO)-2

List of Diagnostic Trouble Code (DTC)

GENERAL DESCRIPTION

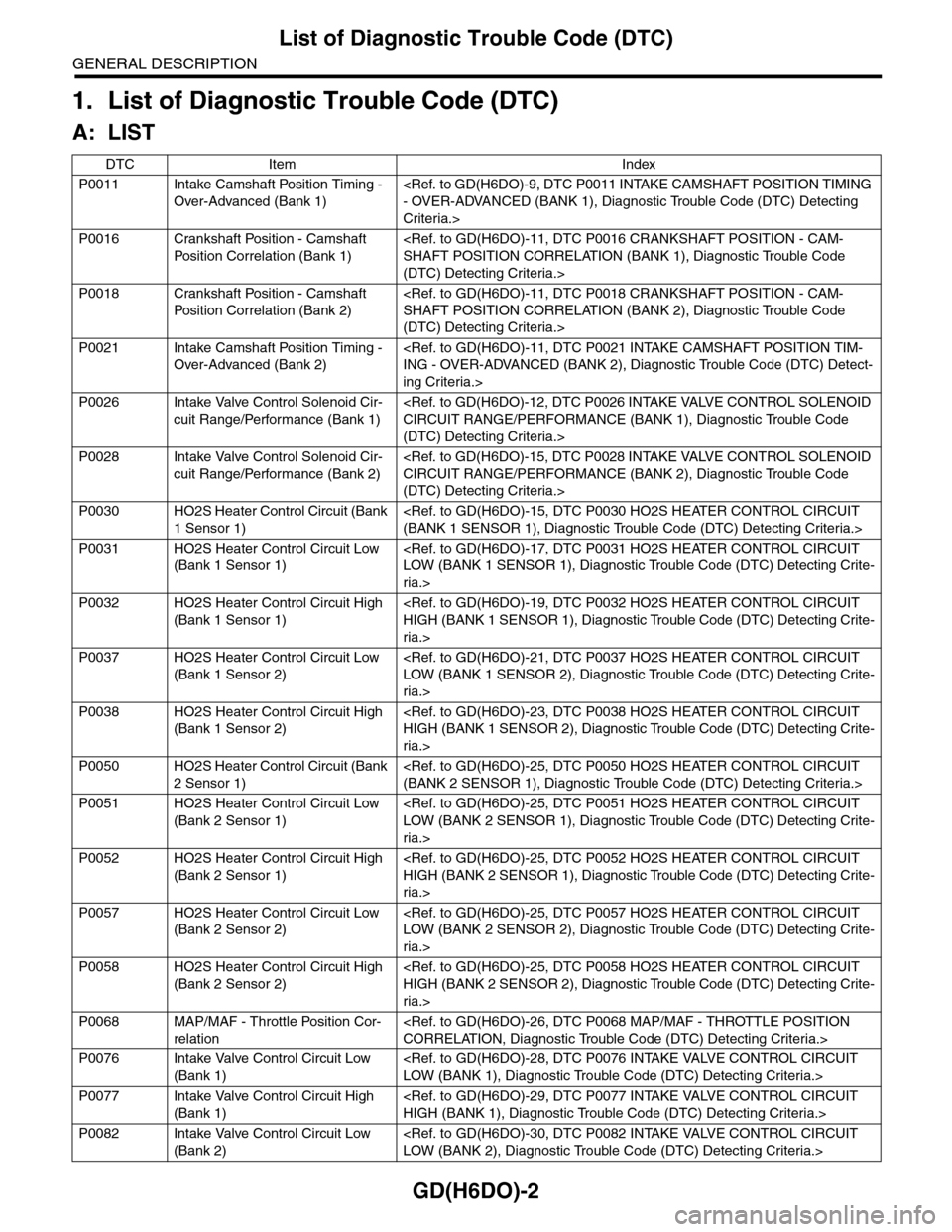

1. List of Diagnostic Trouble Code (DTC)

A: LIST

DTC Item Index

P0011 Intake Camshaft Position Timing -

Over-Advanced (Bank 1)

Criteria.>

P0016 Crankshaft Position - Camshaft

Pos it i o n C o r r el a ti o n ( B a nk 1)

(DTC) Detecting Criteria.>

P0018 Crankshaft Position - Camshaft

Pos it i o n C o r r el a ti o n ( B a nk 2)

(DTC) Detecting Criteria.>

P0021 Intake Camshaft Position Timing -

Over-Advanced (Bank 2)

ing Criteria.>

P0026 Intake Valve Control Solenoid Cir-

cuit Range/Performance (Bank 1)

(DTC) Detecting Criteria.>

P0028 Intake Valve Control Solenoid Cir-

cuit Range/Performance (Bank 2)

(DTC) Detecting Criteria.>

P0030 HO2S Heater Control Circuit (Bank

1 Sensor 1)

P0031 HO2S Heater Control Circuit Low

(Bank 1 Sensor 1)

ria.>

P0032 HO2S Heater Control Circuit High

(Bank 1 Sensor 1)

ria.>

P0037 HO2S Heater Control Circuit Low

(Bank 1 Sensor 2)

ria.>

P0038 HO2S Heater Control Circuit High

(Bank 1 Sensor 2)

ria.>

P0050 HO2S Heater Control Circuit (Bank

2 Sensor 1)

P0051 HO2S Heater Control Circuit Low

(Bank 2 Sensor 1)

ria.>

P0052 HO2S Heater Control Circuit High

(Bank 2 Sensor 1)

ria.>

P0057 HO2S Heater Control Circuit Low

(Bank 2 Sensor 2)

ria.>

P0058 HO2S Heater Control Circuit High

(Bank 2 Sensor 2)

ria.>

P0068 MAP/MAF - Throttle Position Cor-

relation

P0076 Intake Valve Control Circuit Low

(Bank 1)

P0077 Intake Valve Control Circuit High

(Bank 1)

P0082 Intake Valve Control Circuit Low

(Bank 2)

Page 1617 of 2453

GD(H6DO)-5

List of Diagnostic Trouble Code (DTC)

GENERAL DESCRIPTION

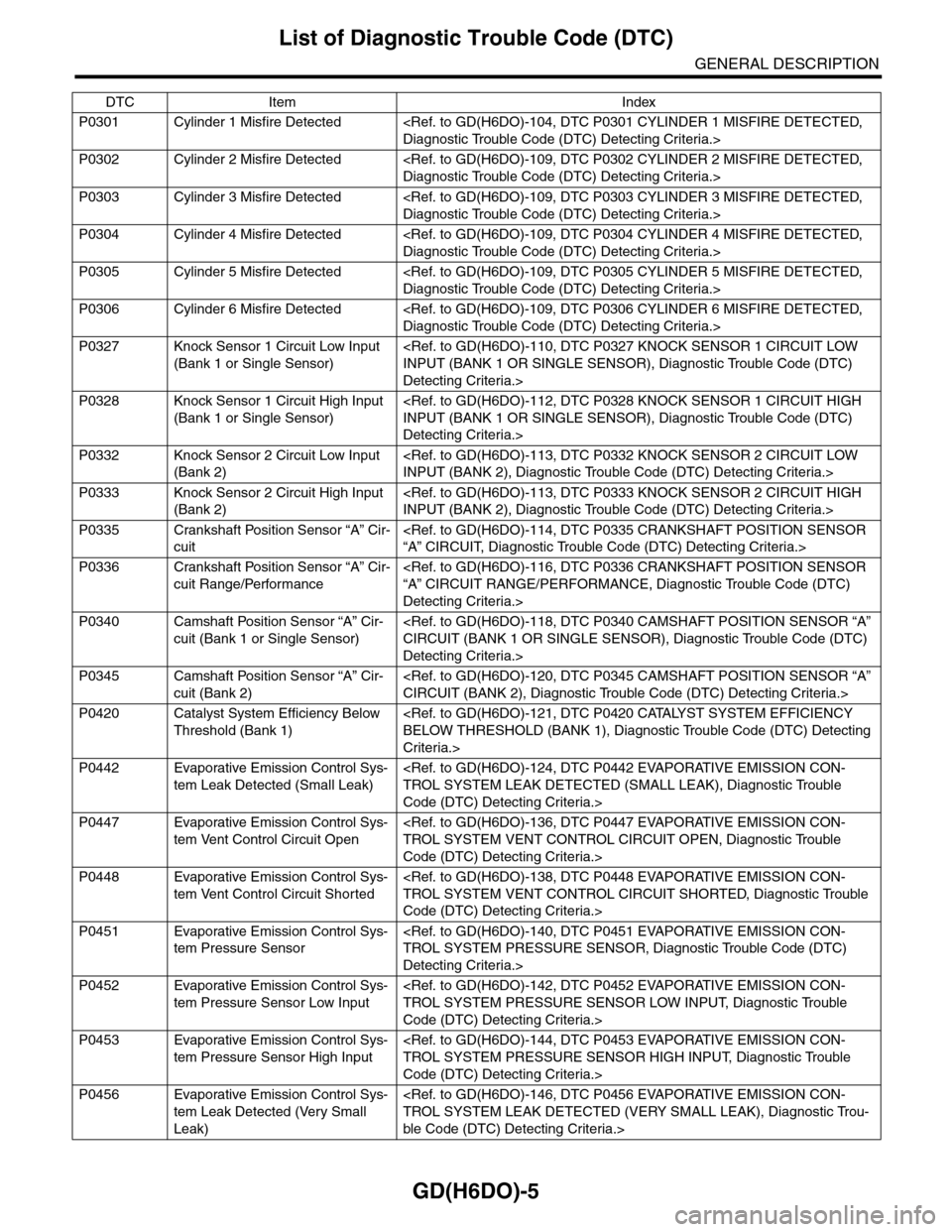

P0301 Cylinder 1 Misfire Detected

P0302 Cylinder 2 Misfire Detected

P0303 Cylinder 3 Misfire Detected

P0304 Cylinder 4 Misfire Detected

P0305 Cylinder 5 Misfire Detected

P0306 Cylinder 6 Misfire Detected

P0327 Knock Sensor 1 Circuit Low Input

(Bank 1 or Single Sensor)

Detecting Criteria.>

P0328 Knock Sensor 1 Circuit High Input

(Bank 1 or Single Sensor)

Detecting Criteria.>

P0332 Knock Sensor 2 Circuit Low Input

(Bank 2)

P0333 Knock Sensor 2 Circuit High Input

(Bank 2)

P0335 Crankshaft Position Sensor “A” Cir-

cuit

P0336 Crankshaft Position Sensor “A” Cir-

cuit Range/Performance

Detecting Criteria.>

P0340 Camshaft Position Sensor “A” Cir-

cuit (Bank 1 or Single Sensor)

Detecting Criteria.>

P0345 Camshaft Position Sensor “A” Cir-

cuit (Bank 2)

P0420 Catalyst System Efficiency Below

Threshold (Bank 1)

Criteria.>

P0442 Evaporative Emission Control Sys-

tem Leak Detected (Small Leak)

Code (DTC) Detecting Criteria.>

P0447 Evaporative Emission Control Sys-

tem Vent Control Circuit Open

Code (DTC) Detecting Criteria.>

P0448 Evaporative Emission Control Sys-

tem Vent Control Circuit Shorted

Code (DTC) Detecting Criteria.>

P0451 Evaporative Emission Control Sys-

tem Pressure Sensor

Detecting Criteria.>

P0452 Evaporative Emission Control Sys-

tem Pressure Sensor Low Input

Code (DTC) Detecting Criteria.>

P0453 Evaporative Emission Control Sys-

tem Pressure Sensor High Input

Code (DTC) Detecting Criteria.>

P0456 Evaporative Emission Control Sys-

tem Leak Detected (Very Small

Leak)

ble Code (DTC) Detecting Criteria.>

DTC Item Index

Page 1726 of 2453

GD(H6DO)-114

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

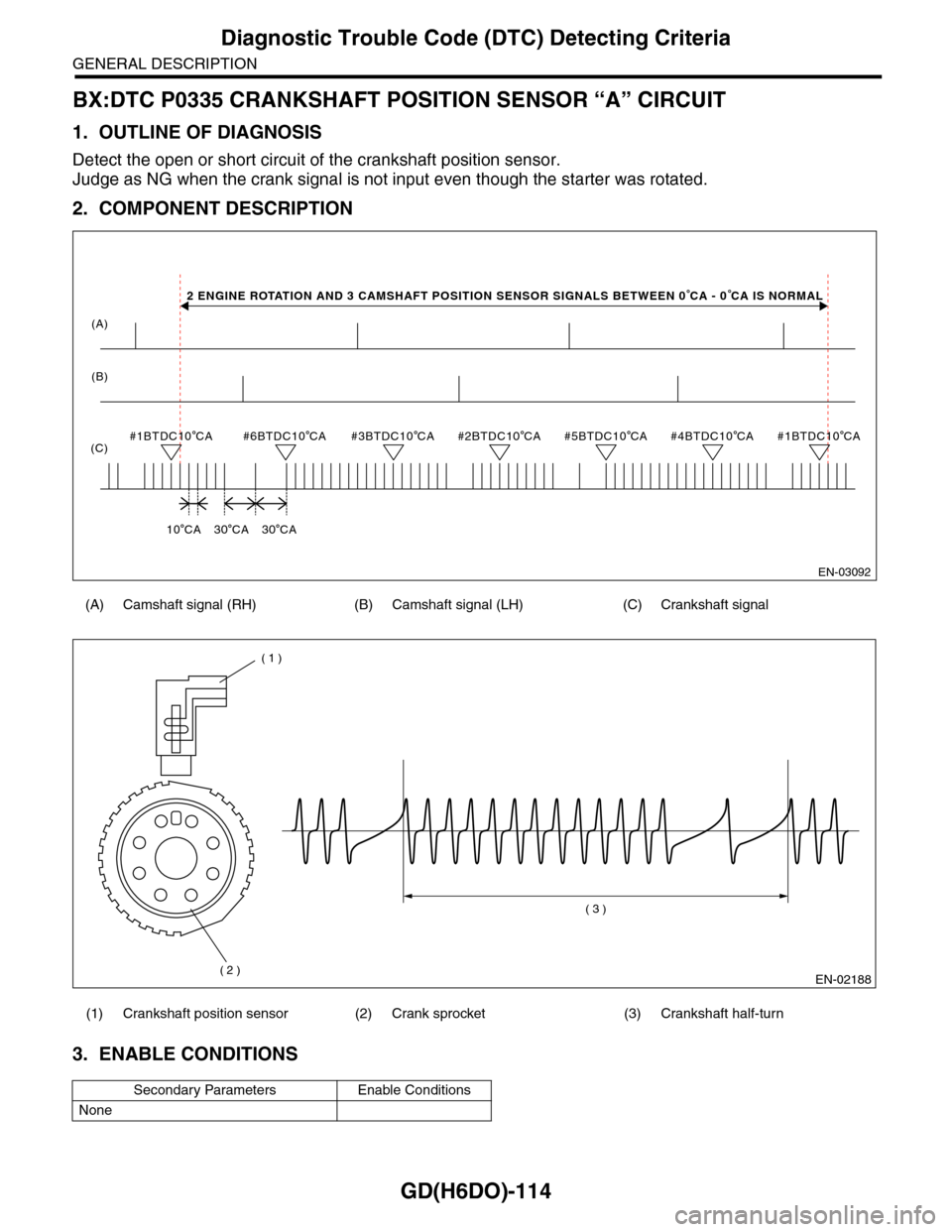

BX:DTC P0335 CRANKSHAFT POSITION SENSOR “A” CIRCUIT

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of the crankshaft position sensor.

Judge as NG when the crank signal is not input even though the starter was rotated.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

(A) Camshaft signal (RH) (B) Camshaft signal (LH) (C) Crankshaft signal

(1) Crankshaft position sensor (2) Crank sprocket (3) Crankshaft half-turn

Secondary Parameters Enable Conditions

None

(A)

(C)#6BTDC10 CA#3BTDC10 CA#2BTDC10 CA#5BTDC10 CA#4BTDC10 CA

10 CA30 CA30 CA

#1BTDC10 CA#1BTDC10 CA

EN-03092

(B)

2 ENGINE ROTATION AND 3 CAMSHAFT POSITION SENSOR SIGNALS BETWEEN 0 CA - 0 CA IS NORMAL

EN-02188

( 1 )

( 2 )

( 3 )

Page 1728 of 2453

GD(H6DO)-116

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

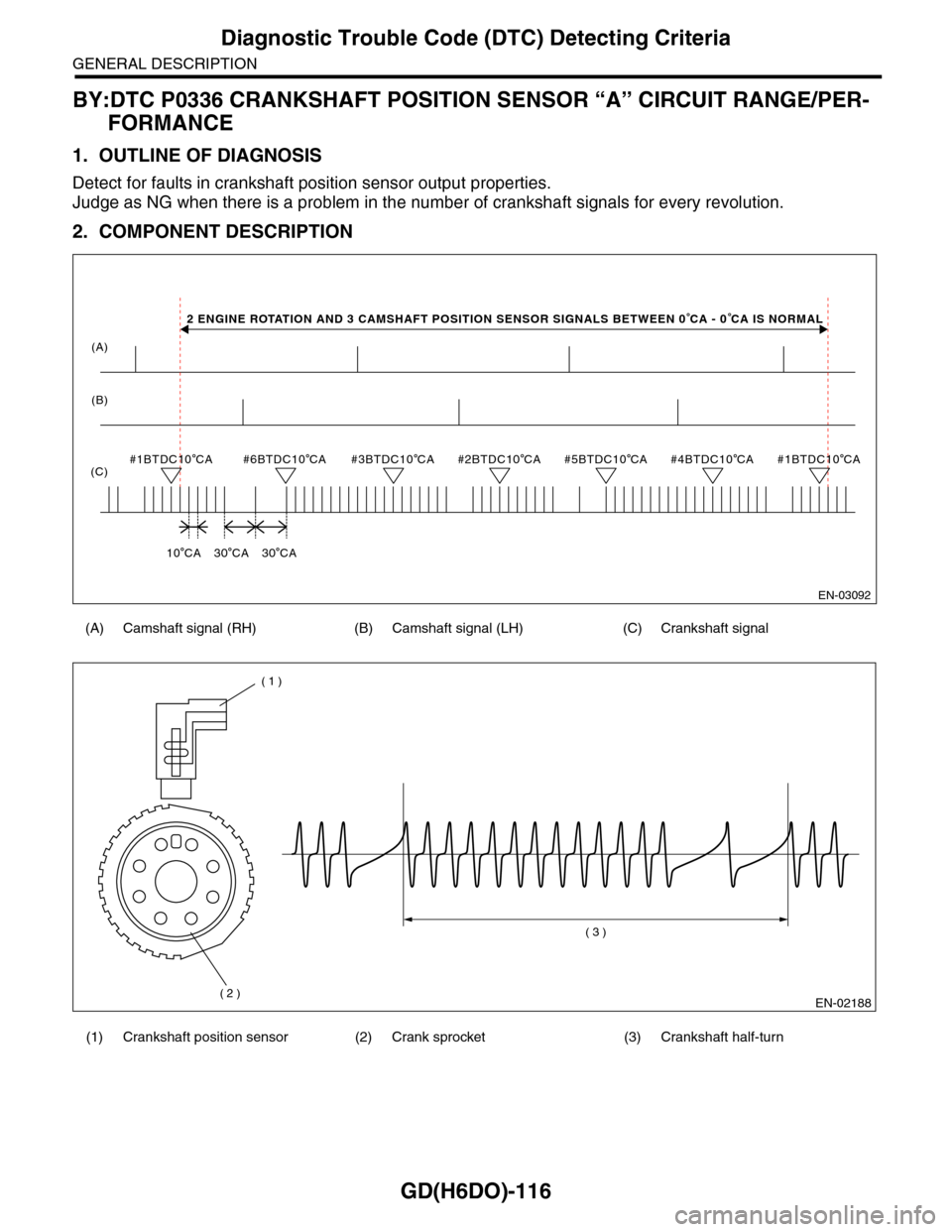

BY:DTC P0336 CRANKSHAFT POSITION SENSOR “A” CIRCUIT RANGE/PER-

FORMANCE

1. OUTLINE OF DIAGNOSIS

Detect for faults in crankshaft position sensor output properties.

Judge as NG when there is a problem in the number of crankshaft signals for every revolution.

2. COMPONENT DESCRIPTION

(A) Camshaft signal (RH) (B) Camshaft signal (LH) (C) Crankshaft signal

(1) Crankshaft position sensor (2) Crank sprocket (3) Crankshaft half-turn

(A)

(C)#6BTDC10 CA#3BTDC10 CA#2BTDC10 CA#5BTDC10 CA#4BTDC10 CA

10 CA30 CA30 CA

#1BTDC10 CA#1BTDC10 CA

EN-03092

(B)

2 ENGINE ROTATION AND 3 CAMSHAFT POSITION SENSOR SIGNALS BETWEEN 0 CA - 0 CA IS NORMAL

EN-02188

( 1 )

( 2 )

( 3 )

Page 1730 of 2453

GD(H6DO)-118

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

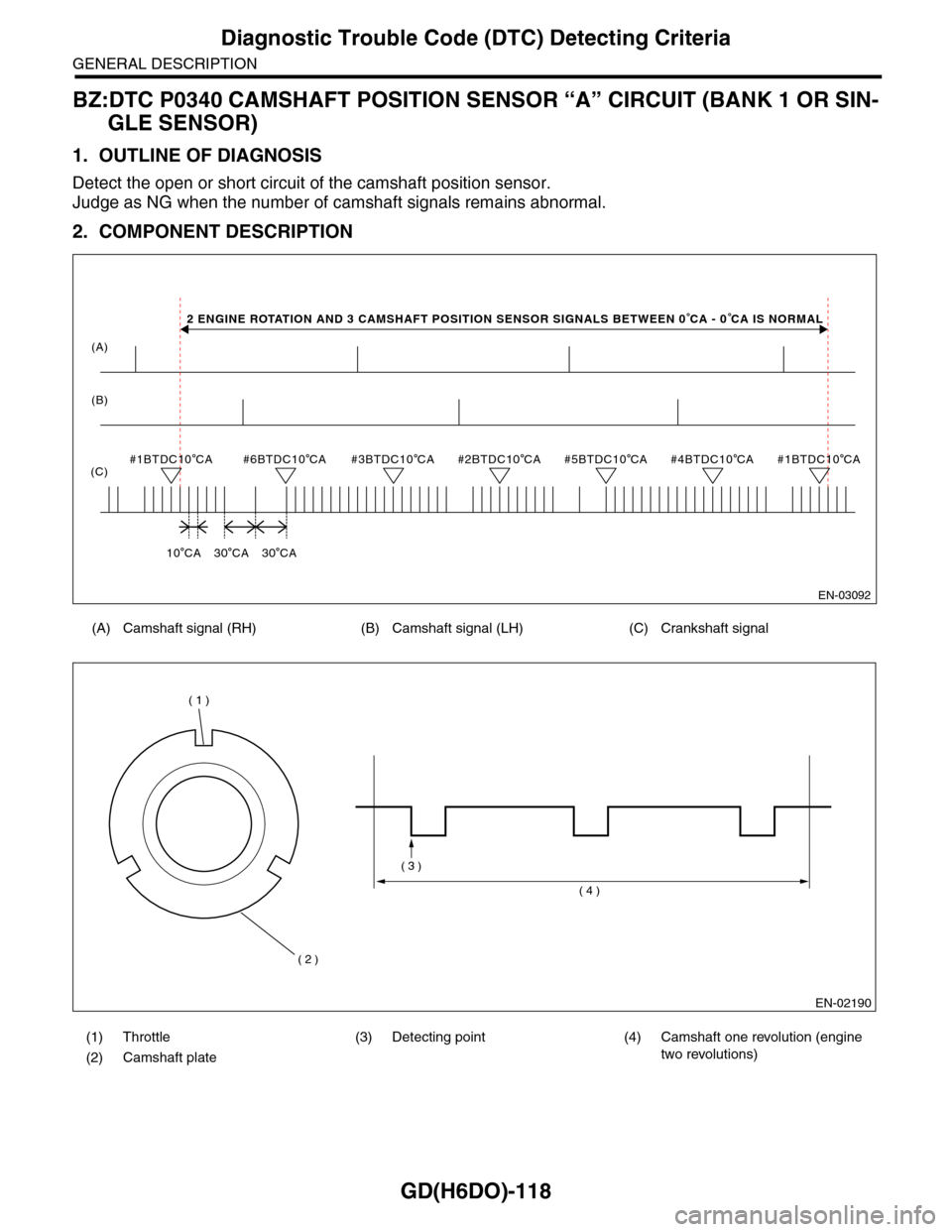

BZ:DTC P0340 CAMSHAFT POSITION SENSOR “A” CIRCUIT (BANK 1 OR SIN-

GLE SENSOR)

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of the camshaft position sensor.

Judge as NG when the number of camshaft signals remains abnormal.

2. COMPONENT DESCRIPTION

(A) Camshaft signal (RH) (B) Camshaft signal (LH) (C) Crankshaft signal

(1) Throttle (3) Detecting point (4) Camshaft one revolution (engine

two revolutions)(2) Camshaft plate

(A)

(C)#6BTDC10 CA#3BTDC10 CA#2BTDC10 CA#5BTDC10 CA#4BTDC10 CA

10 CA30 CA30 CA

#1BTDC10 CA#1BTDC10 CA

EN-03092

(B)

2 ENGINE ROTATION AND 3 CAMSHAFT POSITION SENSOR SIGNALS BETWEEN 0 CA - 0 CA IS NORMAL

EN-02190

( 1 )

( 2 )

( 3 )

( 4 )

Page 1731 of 2453

GD(H6DO)-119

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

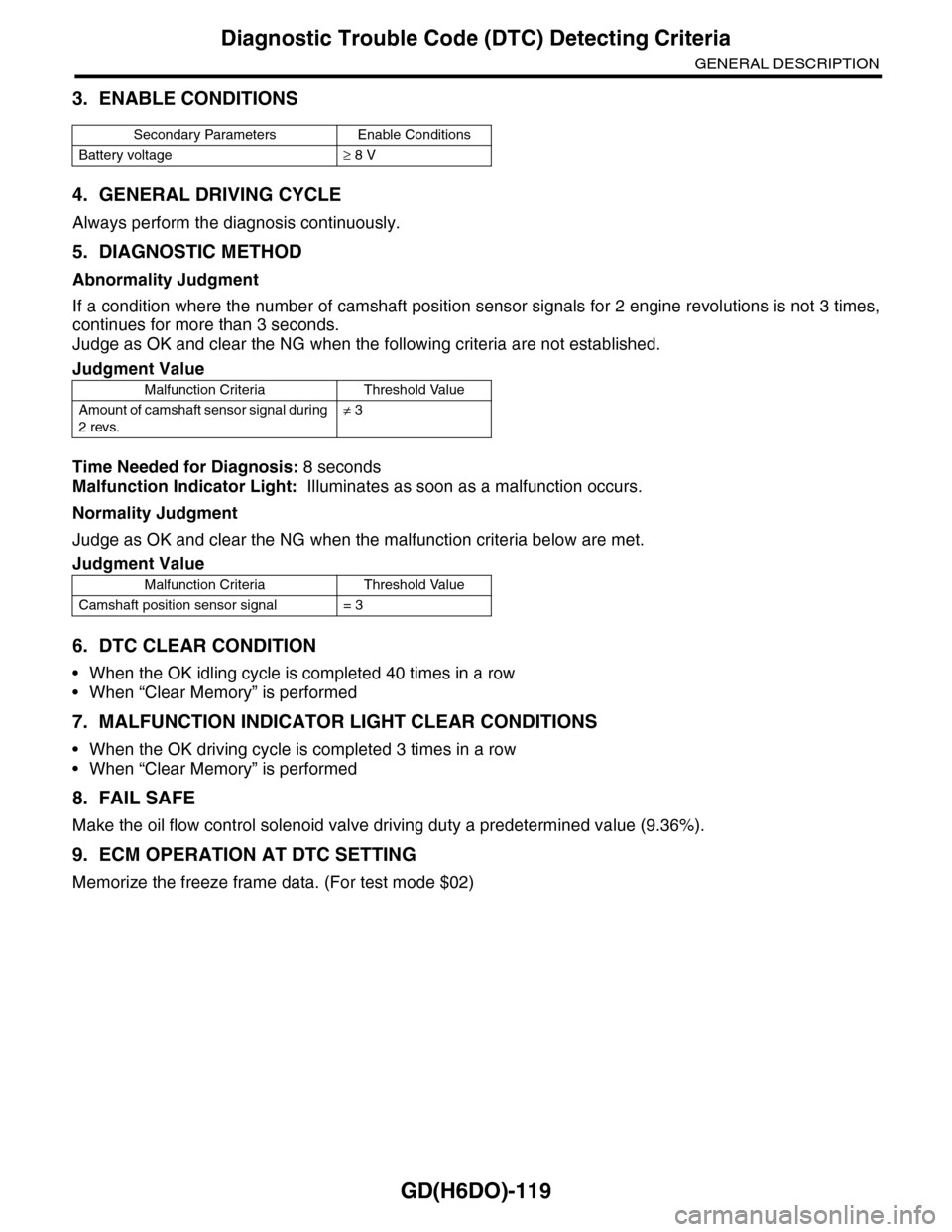

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Abnormality Judgment

If a condition where the number of camshaft position sensor signals for 2 engine revolutions is not 3 times,

continues for more than 3 seconds.

Judge as OK and clear the NG when the following criteria are not established.

Time Needed for Diagnosis: 8 seconds

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

Normality Judgment

Judge as OK and clear the NG when the malfunction criteria below are met.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

Make the oil flow control solenoid valve driving duty a predetermined value (9.36%).

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Secondary Parameters Enable Conditions

Battery voltage≥ 8 V

Judgment Value

Malfunction Criteria Threshold Value

Amount of camshaft sensor signal during

2 revs.

≠ 3

Judgment Value

Malfunction Criteria Threshold Value

Camshaft position sensor signal = 3

Page 1732 of 2453

GD(H6DO)-120

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

CA:DTC P0345 CAMSHAFT POSITION SENSOR “A” CIRCUIT (BANK 2)

1. OUTLINE OF DIAGNOSIS

NOTE:

For the diagnostic procedure, refer to DTC P0340.

Criteria.>

Page 1906 of 2453

ME(H6DO)-40

Preparation for Overhaul

MECHANICAL

12.Preparation for Overhaul

A: REMOVAL

1) Remove the engine assembly from the body.

2) Set the engine on ST.

ST 18232AA000 ENGINE STAND

3) Before servicing overhaul, remove the sensor,

pipe and hose that installed to engine.

(1) Remove the intake manifold.

(2) Remove the generator.

(3) Remove the A/C compressor.

(4) Disconnect the water pipe and hose.

(5) Disconnect the engine harness.

(6) Remove the spark plug.

(7) Remove the camshaft position sensor.

(8) Remove the crankshaft position sensor.

(9) Remove the knock sensor.

(10) Remove the engine coolant temperature

sensor.

(11) Remove the oil pressure switch.

Switch.>

(12) Remove the oil filter.

(13) Remove the oil cooler.

STME-02448