four wheel drive SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 167 of 2453

CC-5

Cruise Control Command Switch

CRUISE CONTROL SYSTEM

3. Cruise Control Command

Switch

A: REMOVAL

CAUTION:

Before servicing, be sure to read the notes in

the “AB” section for proper handling of the

driver’s airbag module.

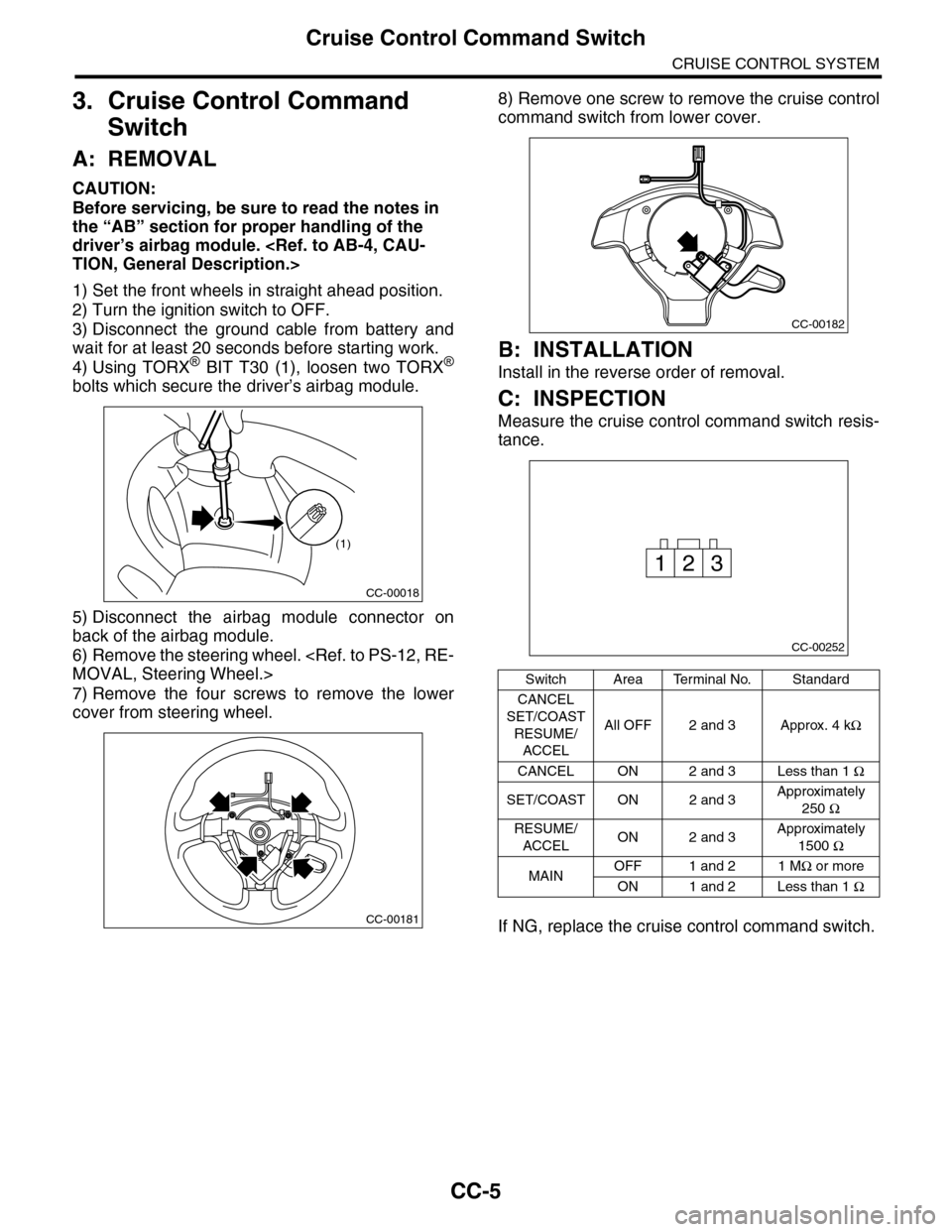

1) Set the front wheels in straight ahead position.

2) Turn the ignition switch to OFF.

3) Disconnect the ground cable from battery and

wait for at least 20 seconds before starting work.

4) Using TORX® BIT T30 (1), loosen two TORX®

bolts which secure the driver’s airbag module.

5) Disconnect the airbag module connector on

back of the airbag module.

6) Remove the steering wheel.

7) Remove the four screws to remove the lower

cover from steering wheel.

8) Remove one screw to remove the cruise control

command switch from lower cover.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

Measure the cruise control command switch resis-

tance.

If NG, replace the cruise control command switch.

CC-00018

(1)

CC-00181

Switch Area Terminal No. Standard

CANCEL

SET/COAST

RESUME/

ACCEL

All OFF 2 and 3 Approx. 4 kΩ

CANCEL ON 2 and 3 Less than 1 Ω

SET/COAST ON 2 and 3Approximately

250 Ω

RESUME/

ACCELON 2 and 3Approximately

1500 Ω

MAINOFF 1 and 2 1 MΩ or more

ON 1 and 2 Less than 1 Ω

CC-00182

CC-00252

231

Page 543 of 2453

LI-10

Combination Base Switch Assembly

LIGHTING SYSTEM

9. Combination Base Switch

Assembly

A: REMOVAL

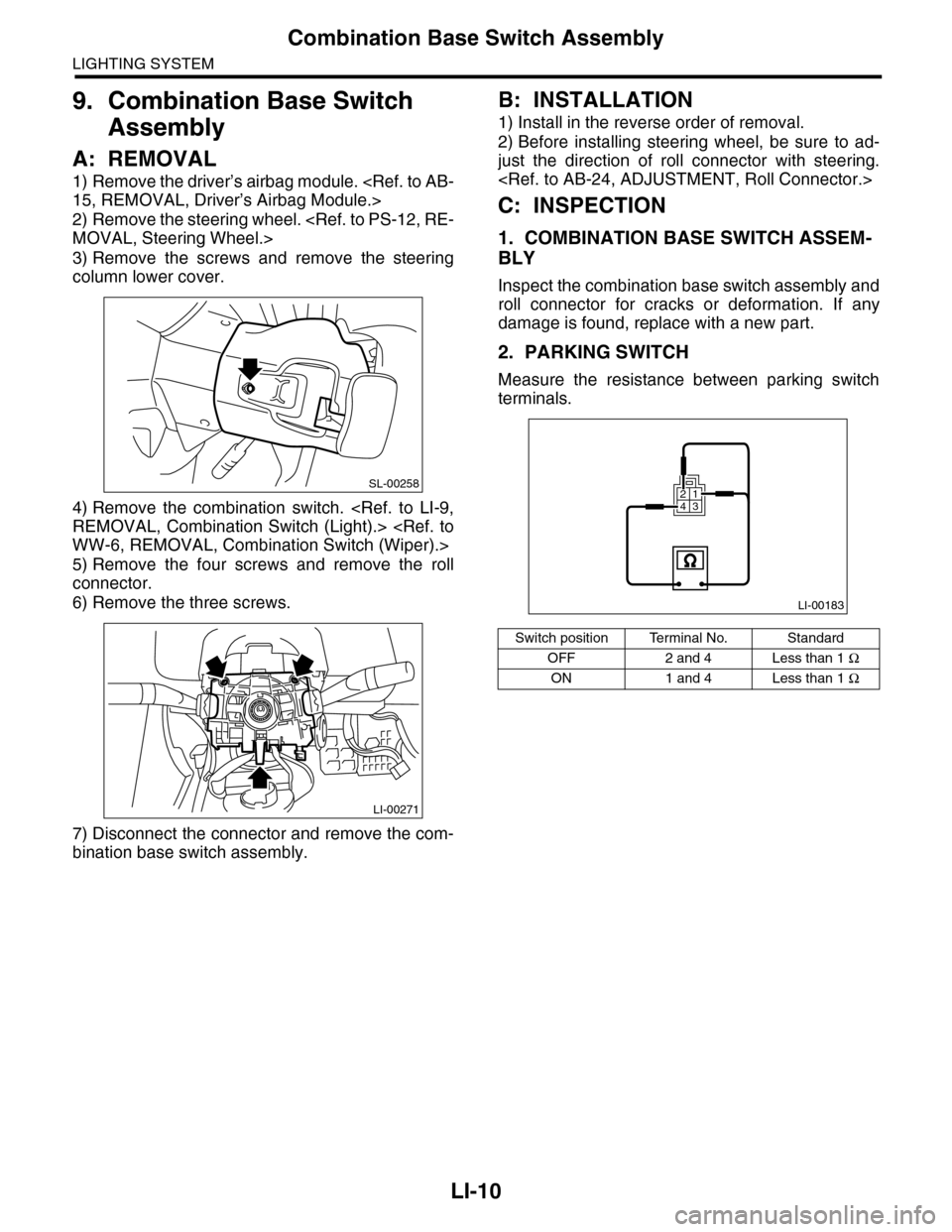

1) Remove the driver’s airbag module.

2) Remove the steering wheel.

3) Remove the screws and remove the steering

column lower cover.

4) Remove the combination switch.

5) Remove the four screws and remove the roll

connector.

6) Remove the three screws.

7) Disconnect the connector and remove the com-

bination base switch assembly.

B: INSTALLATION

1) Install in the reverse order of removal.

2) Before installing steering wheel, be sure to ad-

just the direction of roll connector with steering.

C: INSPECTION

1. COMBINATION BASE SWITCH ASSEM-

BLY

Inspect the combination base switch assembly and

roll connector for cracks or deformation. If any

damage is found, replace with a new part.

2. PARKING SWITCH

Measure the resistance between parking switch

terminals.

SL-00258

LI-00271

Switch position Terminal No. Standard

OFF 2 and 4 Less than 1 Ω

ON 1 and 4 Less than 1 Ω

LI-00183

1234

Page 818 of 2453

DI-34

General Diagnostic Table

DIFFERENTIALS

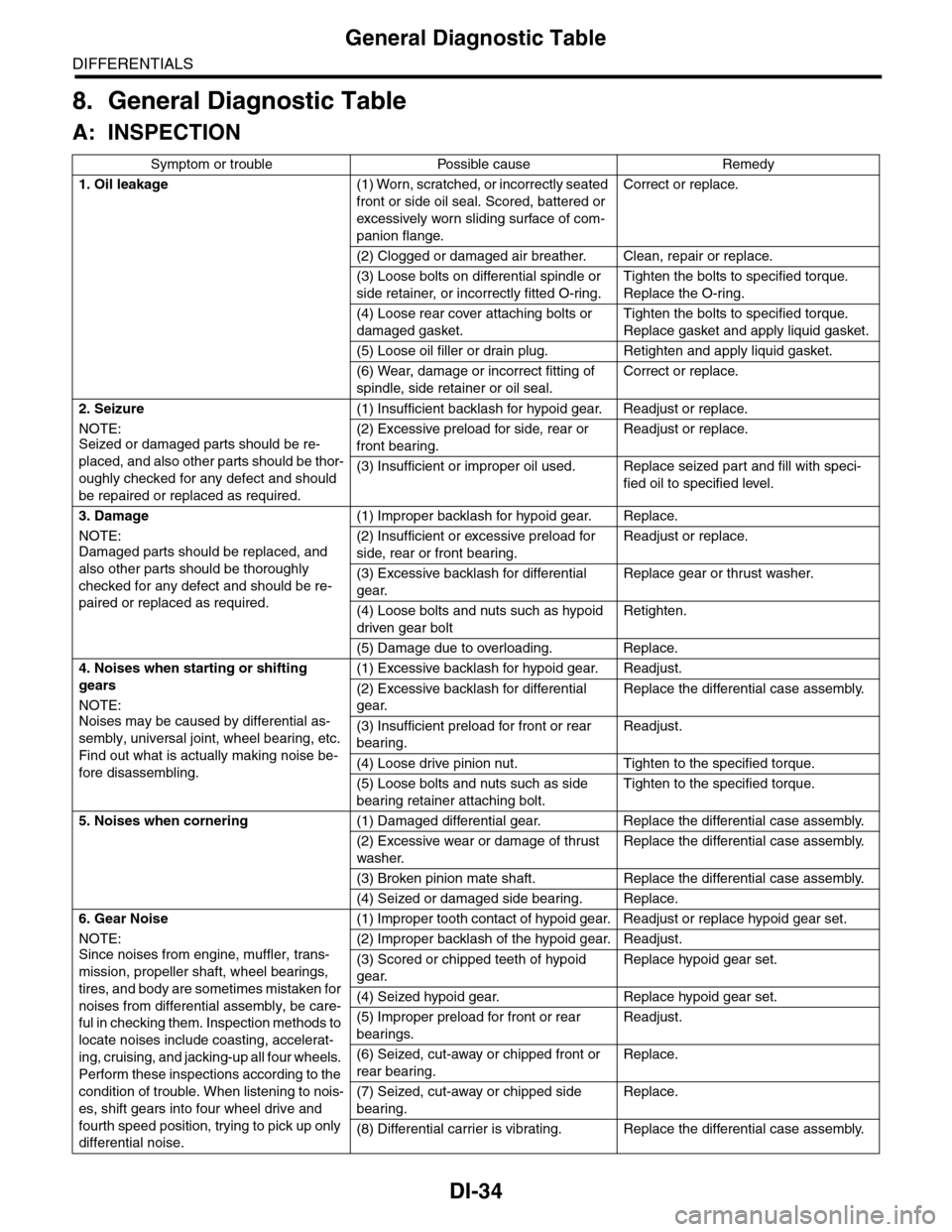

8. General Diagnostic Table

A: INSPECTION

Symptom or trouble Possible cause Remedy

1. Oil leakage(1) Worn, scratched, or incorrectly seated

front or side oil seal. Scored, battered or

excessively wor n sliding surface of com-

panion flange.

Correct or replace.

(2) Clogged or damaged air breather. Clean, repair or replace.

(3) Loose bolts on differential spindle or

side retainer, or incorrectly fitted O-ring.

Tighten the bolts to specified torque.

Replace the O-ring.

(4) Loose rear cover attaching bolts or

damaged gasket.

Tighten the bolts to specified torque.

Replace gasket and apply liquid gasket.

(5) Loose oil filler or drain plug. Retighten and apply liquid gasket.

(6) Wear, damage or incorrect fitting of

spindle, side retainer or oil seal.

Correct or replace.

2. Seizure

NOTE:Seized or damaged parts should be re-

placed, and also other parts should be thor-

oughly checked for any defect and should

be repaired or replaced as required.

(1) Insufficient backlash for hypoid gear. Readjust or replace.

(2) Excessive preload for side, rear or

front bearing.

Readjust or replace.

(3) Insufficient or improper oil used. Replace seized part and fill with speci-

fied oil to specified level.

3. Damage

NOTE:Damaged parts should be replaced, and

also other parts should be thoroughly

checked for any defect and should be re-

paired or replaced as required.

(1) Improper backlash for hypoid gear. Replace.

(2) Insufficient or excessive preload for

side, rear or front bearing.

Readjust or replace.

(3) Excessive backlash for differential

gear.

Replace gear or thrust washer.

(4) Loose bolts and nuts such as hypoid

driven gear bolt

Retighten.

(5) Damage due to overloading. Replace.

4. Noises when starting or shifting

gears

NOTE:

Noises may be caused by differential as-

sembly, universal joint, wheel bearing, etc.

Find out what is actually making noise be-

fore disassembling.

(1) Excessive backlash for hypoid gear. Readjust.

(2) Excessive backlash for differential

gear.

Replace the differential case assembly.

(3) Insufficient preload for front or rear

bearing.

Readjust.

(4) Loose drive pinion nut. Tighten to the specified torque.

(5) Loose bolts and nuts such as side

bearing retainer attaching bolt.

Tighten to the specified torque.

5. Noises when cornering(1) Damaged differential gear. Replace the differential case assembly.

(2) Excessive wear or damage of thrust

washer.

Replace the differential case assembly.

(3) Broken pinion mate shaft. Replace the differential case assembly.

(4) Seized or damaged side bearing. Replace.

6. Gear Noise

NOTE:

Since noises from engine, muffler, trans-

mission, propeller shaft, wheel bearings,

tires, and body are sometimes mistaken for

noises from differential assembly, be care-

ful in checking them. Inspection methods to

locate noises include coasting, accelerat-

ing, cruising, and jacking-up all four wheels.

Perform these inspections according to the

condition of trouble. When listening to nois-

es, shift gears into four wheel drive and

fourth speed position, trying to pick up only

differential noise.

(1) Improper tooth contact of hypoid gear. Readjust or replace hypoid gear set.

(2) Improper backlash of the hypoid gear. Readjust.

(3) Scored or chipped teeth of hypoid

gear.

Replace hypoid gear set.

(4) Seized hypoid gear. Replace hypoid gear set.

(5) Improper preload for front or rear

bearings.

Readjust.

(6) Seized, cut-away or chipped front or

rear bearing.

Replace.

(7) Seized, cut-away or chipped side

bearing.

Replace.

(8) Differential carrier is vibrating. Replace the differential case assembly.

Page 832 of 2453

DS-15

Front Axle

DRIVE SHAFT SYSTEM

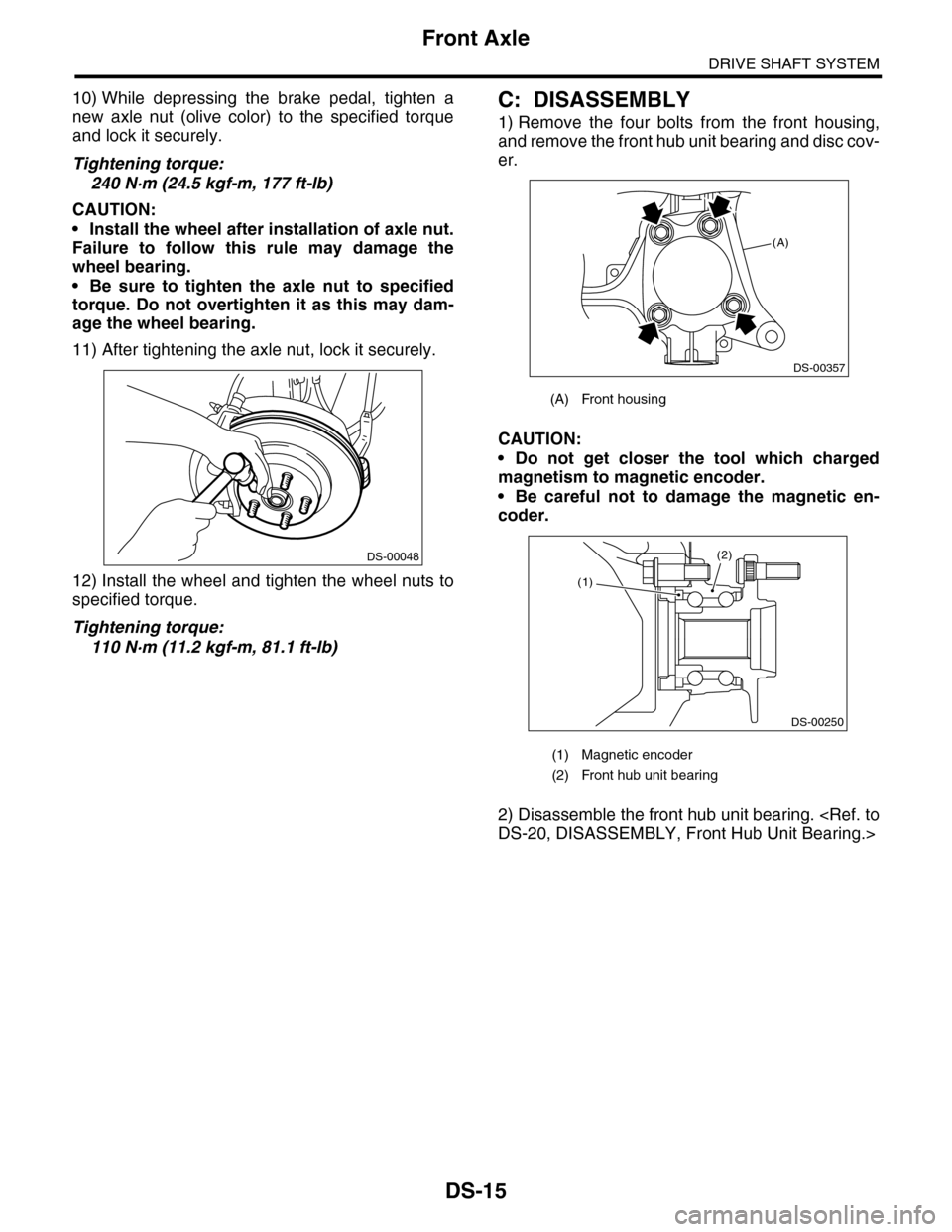

10) While depressing the brake pedal, tighten a

new axle nut (olive color) to the specified torque

and lock it securely.

Tightening torque:

240 N·m (24.5 kgf-m, 177 ft-lb)

CAUTION:

•Install the wheel after installation of axle nut.

Failure to follow this rule may damage the

wheel bearing.

•Be sure to tighten the axle nut to specified

torque. Do not overtighten it as this may dam-

age the wheel bearing.

11) After tightening the axle nut, lock it securely.

12) Install the wheel and tighten the wheel nuts to

specified torque.

Tightening torque:

110 N·m (11.2 kgf-m, 81.1 ft-lb)

C: DISASSEMBLY

1) Remove the four bolts from the front housing,

and remove the front hub unit bearing and disc cov-

er.

CAUTION:

•Do not get closer the tool which charged

magnetism to magnetic encoder.

•Be careful not to damage the magnetic en-

coder.

2) Disassemble the front hub unit bearing.

DS-00048

(A) Front housing

(1) Magnetic encoder

(2) Front hub unit bearing

(A)

DS-00357

(2)

DS-00250

(1)

Page 833 of 2453

DS-16

Front Axle

DRIVE SHAFT SYSTEM

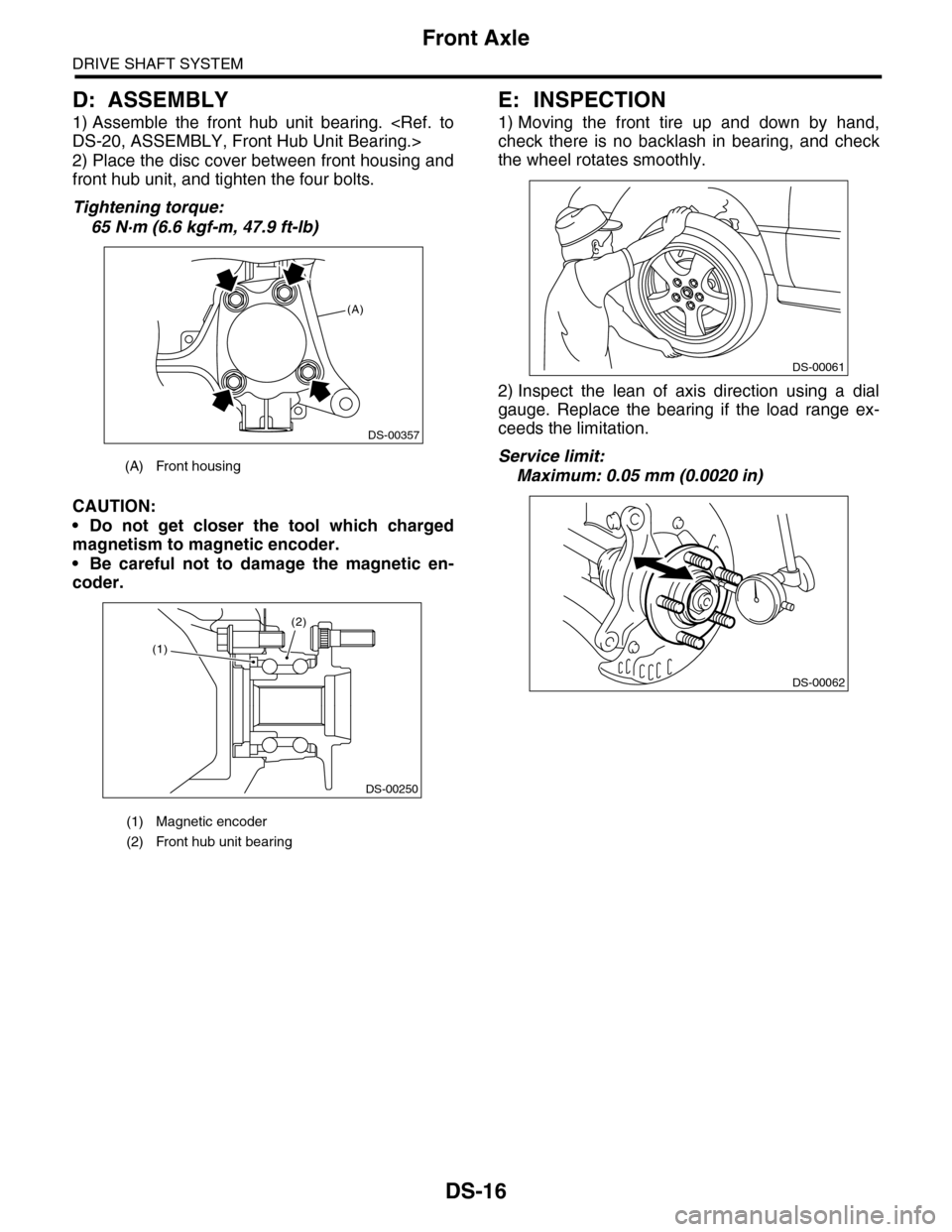

D: ASSEMBLY

1) Assemble the front hub unit bearing.

2) Place the disc cover between front housing and

front hub unit, and tighten the four bolts.

Tightening torque:

65 N·m (6.6 kgf-m, 47.9 ft-lb)

CAUTION:

•Do not get closer the tool which charged

magnetism to magnetic encoder.

•Be careful not to damage the magnetic en-

coder.

E: INSPECTION

1) Moving the front tire up and down by hand,

check there is no backlash in bearing, and check

the wheel rotates smoothly.

2) Inspect the lean of axis direction using a dial

gauge. Replace the bearing if the load range ex-

ceeds the limitation.

Service limit:

Maximum: 0.05 mm (0.0020 in)(A) Front housing

(1) Magnetic encoder

(2) Front hub unit bearing

(A)

DS-00357

(2)

DS-00250

(1)

DS-00061

DS-00062

Page 835 of 2453

DS-18

Rear Axle

DRIVE SHAFT SYSTEM

B: INSTALLATION

NOTE:

•Be sure to use a new self-locking nut.

•Always tighten the stabilizer bushing in the state

where the vehicle is at curb weight and the wheels

are in full contact with the ground.

Install in the reverse order of removal.

Tightening torque:

Refer to COMPONENT of General Description

for tightening torque.

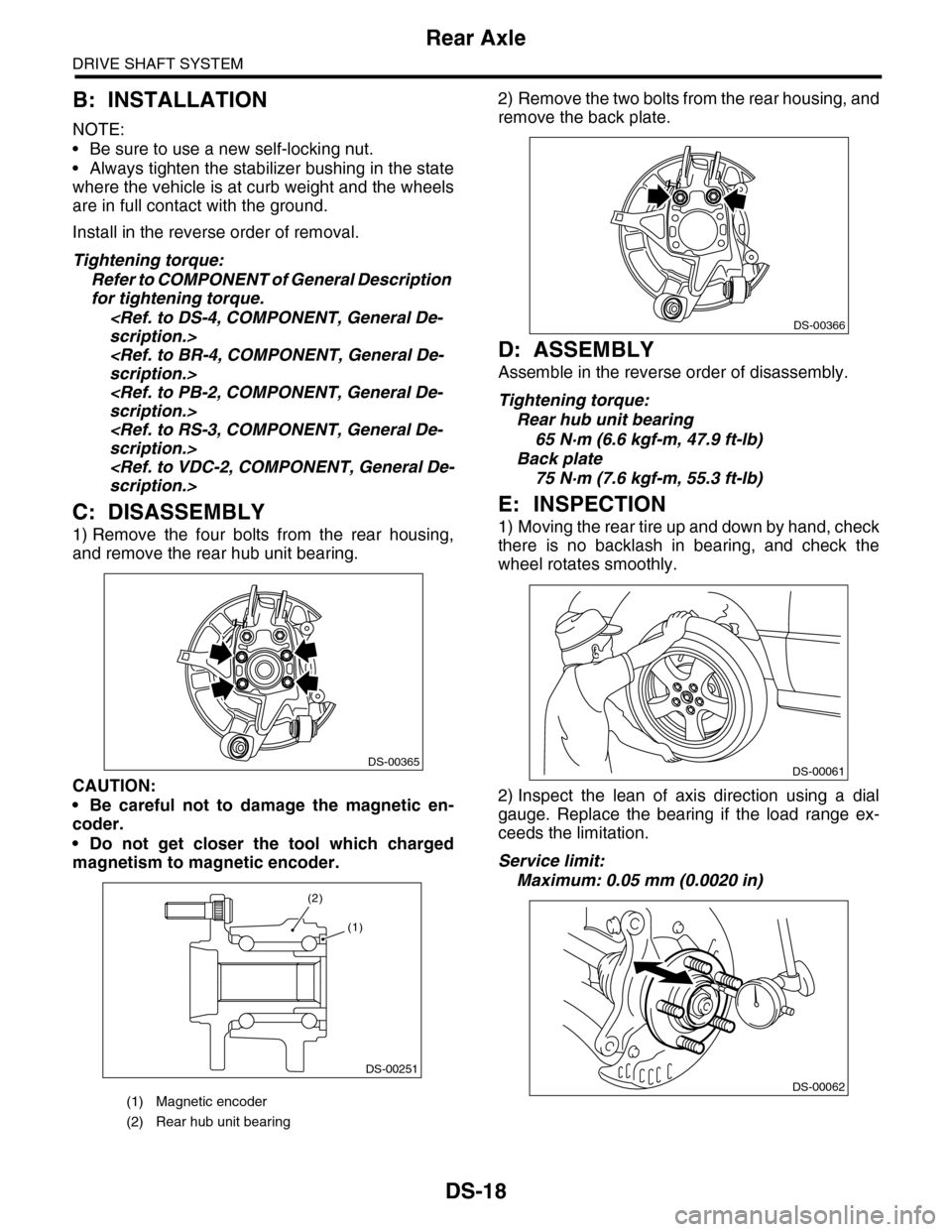

C: DISASSEMBLY

1) Remove the four bolts from the rear housing,

and remove the rear hub unit bearing.

CAUTION:

•Be careful not to damage the magnetic en-

coder.

•Do not get closer the tool which charged

magnetism to magnetic encoder.

2) Remove the two bolts from the rear housing, and

remove the back plate.

D: ASSEMBLY

Assemble in the reverse order of disassembly.

Tightening torque:

Rear hub unit bearing

65 N·m (6.6 kgf-m, 47.9 ft-lb)

Back plate

75 N·m (7.6 kgf-m, 55.3 ft-lb)

E: INSPECTION

1) Moving the rear tire up and down by hand, check

there is no backlash in bearing, and check the

wheel rotates smoothly.

2) Inspect the lean of axis direction using a dial

gauge. Replace the bearing if the load range ex-

ceeds the limitation.

Service limit:

Maximum: 0.05 mm (0.0020 in)

(1) Magnetic encoder

(2) Rear hub unit bearing

DS-00365

DS-00251

(2)

(1)

DS-00366

DS-00061

DS-00062

Page 836 of 2453

DS-19

Front Hub Unit Bearing

DRIVE SHAFT SYSTEM

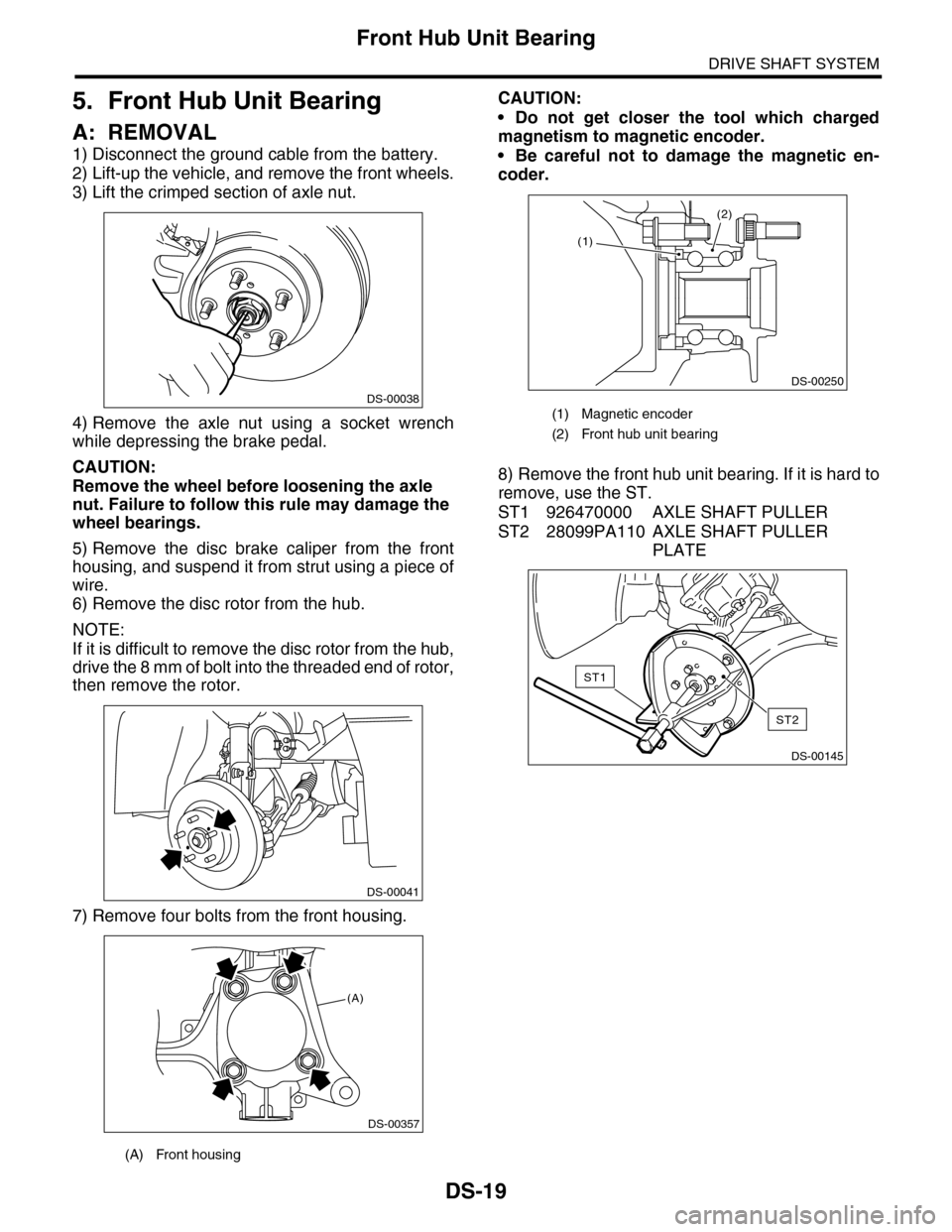

5. Front Hub Unit Bearing

A: REMOVAL

1) Disconnect the ground cable from the battery.

2) Lift-up the vehicle, and remove the front wheels.

3) Lift the crimped section of axle nut.

4) Remove the axle nut using a socket wrench

while depressing the brake pedal.

CAUTION:

Remove the wheel before loosening the axle

nut. Failure to follow this rule may damage the

wheel bearings.

5) Remove the disc brake caliper from the front

housing, and suspend it from strut using a piece of

wire.

6) Remove the disc rotor from the hub.

NOTE:

If it is difficult to remove the disc rotor from the hub,

drive the 8 mm of bolt into the threaded end of rotor,

then remove the rotor.

7) Remove four bolts from the front housing.

CAUTION:

•Do not get closer the tool which charged

magnetism to magnetic encoder.

•Be careful not to damage the magnetic en-

coder.

8) Remove the front hub unit bearing. If it is hard to

remove, use the ST.

ST1 926470000 AXLE SHAFT PULLER

ST2 28099PA110 AXLE SHAFT PULLER

PLATE

(A) Front housing

DS-00038

DS-00041

(A)

DS-00357

(1) Magnetic encoder

(2) Front hub unit bearing

(2)

DS-00250

(1)

DS-00145

ST2

ST1

Page 837 of 2453

DS-20

Front Hub Unit Bearing

DRIVE SHAFT SYSTEM

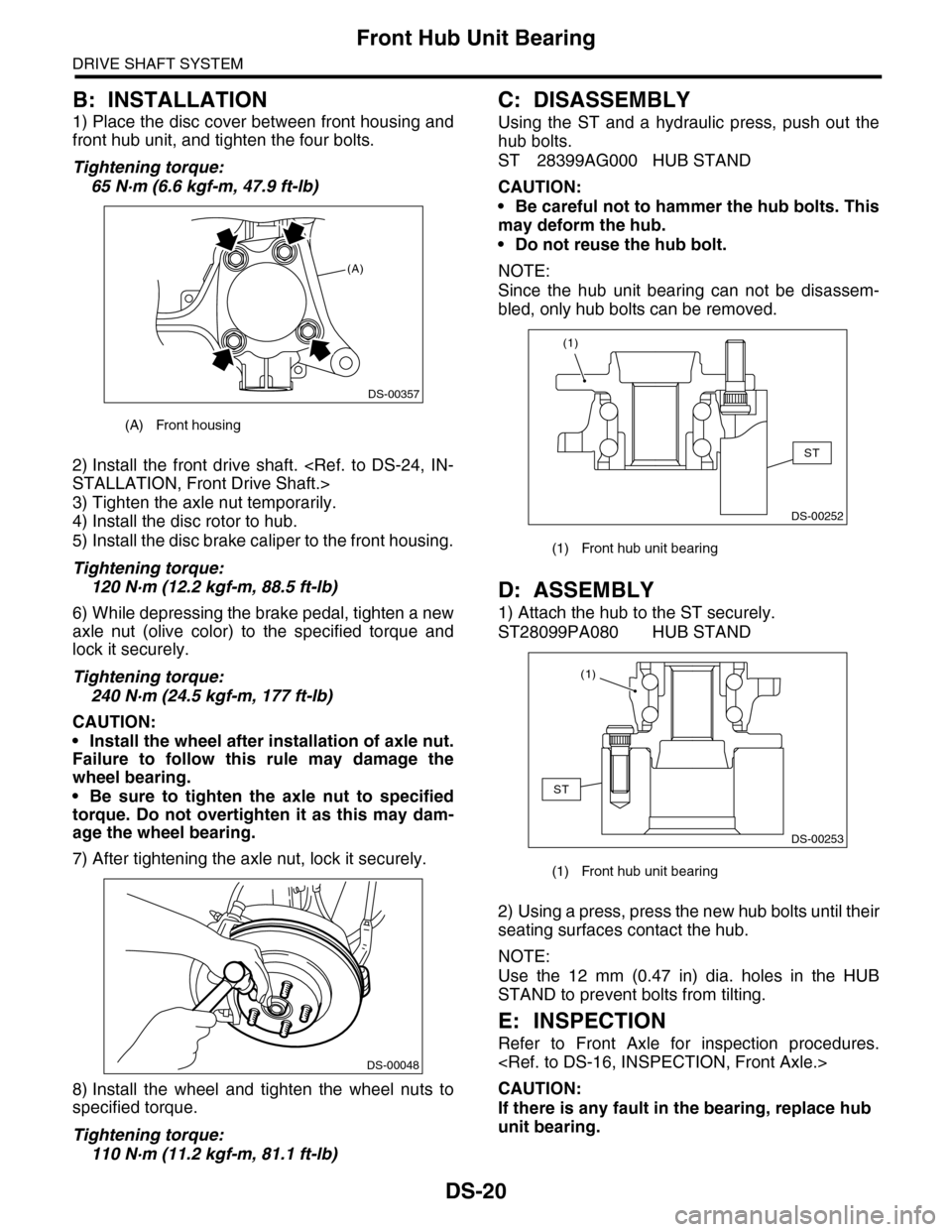

B: INSTALLATION

1) Place the disc cover between front housing and

front hub unit, and tighten the four bolts.

Tightening torque:

65 N·m (6.6 kgf-m, 47.9 ft-lb)

2) Install the front drive shaft.

3) Tighten the axle nut temporarily.

4) Install the disc rotor to hub.

5) Install the disc brake caliper to the front housing.

Tightening torque:

120 N·m (12.2 kgf-m, 88.5 ft-lb)

6) While depressing the brake pedal, tighten a new

axle nut (olive color) to the specified torque and

lock it securely.

Tightening torque:

240 N·m (24.5 kgf-m, 177 ft-lb)

CAUTION:

•Install the wheel after installation of axle nut.

Failure to follow this rule may damage the

wheel bearing.

•Be sure to tighten the axle nut to specified

torque. Do not overtighten it as this may dam-

age the wheel bearing.

7) After tightening the axle nut, lock it securely.

8) Install the wheel and tighten the wheel nuts to

specified torque.

Tightening torque:

110 N·m (11.2 kgf-m, 81.1 ft-lb)

C: DISASSEMBLY

Using the ST and a hydraulic press, push out the

hub bolts.

ST 28399AG000 HUB STAND

CAUTION:

•Be careful not to hammer the hub bolts. This

may deform the hub.

•Do not reuse the hub bolt.

NOTE:

Since the hub unit bearing can not be disassem-

bled, only hub bolts can be removed.

D: ASSEMBLY

1) Attach the hub to the ST securely.

ST28099PA080 HUB STAND

2) Using a press, press the new hub bolts until their

seating surfaces contact the hub.

NOTE:

Use the 12 mm (0.47 in) dia. holes in the HUB

STAND to prevent bolts from tilting.

E: INSPECTION

Refer to Front Axle for inspection procedures.

CAUTION:

If there is any fault in the bearing, replace hub

unit bearing.

(A) Front housing

(A)

DS-00357

DS-00048

(1) Front hub unit bearing

(1) Front hub unit bearing

ST

DS-00252

(1)

DS-00253

ST

(1)

Page 838 of 2453

DS-21

Rear Hub Unit Bearing

DRIVE SHAFT SYSTEM

6. Rear Hub Unit Bearing

A: REMOVAL

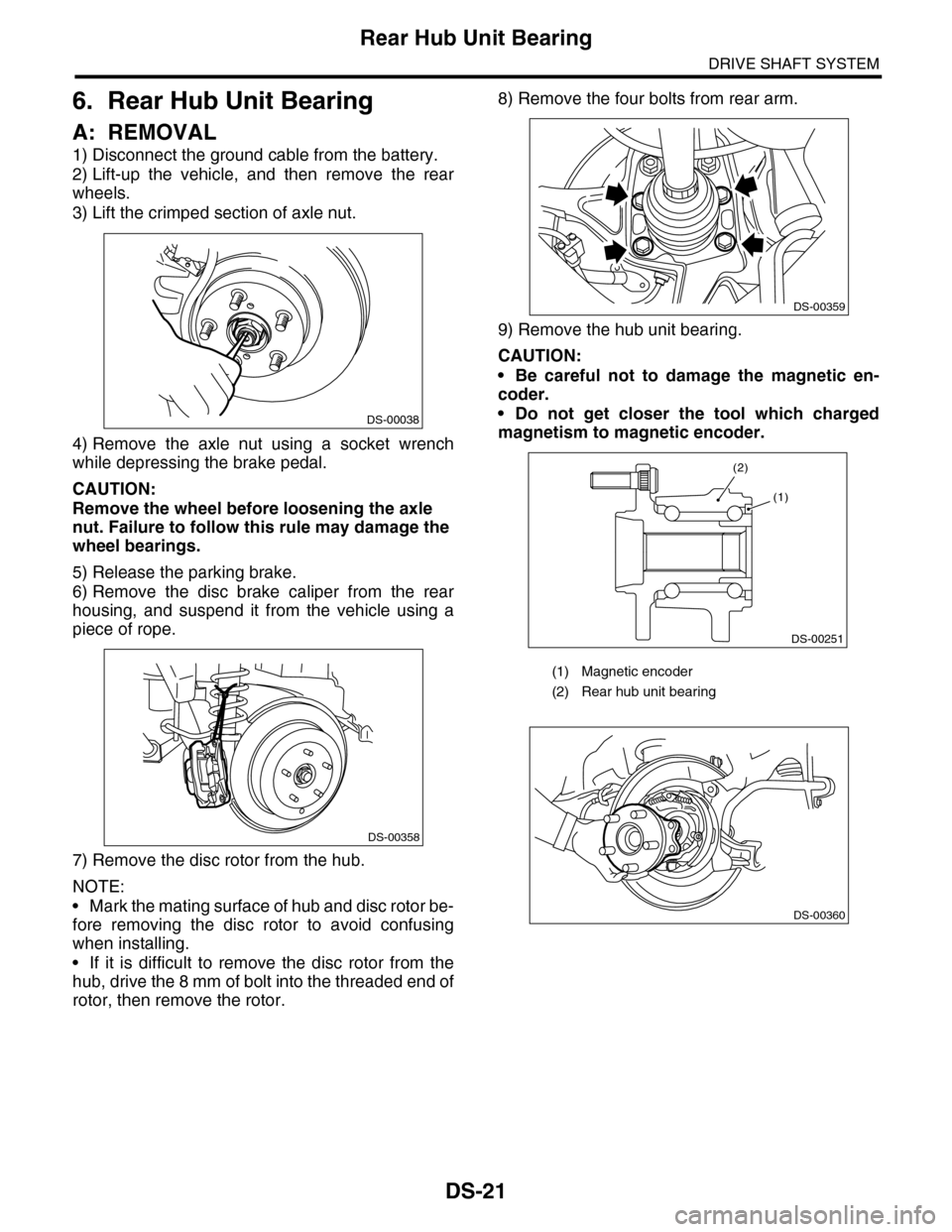

1) Disconnect the ground cable from the battery.

2) Lift-up the vehicle, and then remove the rear

wheels.

3) Lift the crimped section of axle nut.

4) Remove the axle nut using a socket wrench

while depressing the brake pedal.

CAUTION:

Remove the wheel before loosening the axle

nut. Failure to follow this rule may damage the

wheel bearings.

5) Release the parking brake.

6) Remove the disc brake caliper from the rear

housing, and suspend it from the vehicle using a

piece of rope.

7) Remove the disc rotor from the hub.

NOTE:

•Mark the mating surface of hub and disc rotor be-

fore removing the disc rotor to avoid confusing

when installing.

•If it is difficult to remove the disc rotor from the

hub, drive the 8 mm of bolt into the threaded end of

rotor, then remove the rotor.

8) Remove the four bolts from rear arm.

9) Remove the hub unit bearing.

CAUTION:

•Be careful not to damage the magnetic en-

coder.

•Do not get closer the tool which charged

magnetism to magnetic encoder.DS-00038

DS-00358

(1) Magnetic encoder

(2) Rear hub unit bearing

DS-00359

DS-00251

(2)

(1)

DS-00360

Page 839 of 2453

DS-22

Rear Hub Unit Bearing

DRIVE SHAFT SYSTEM

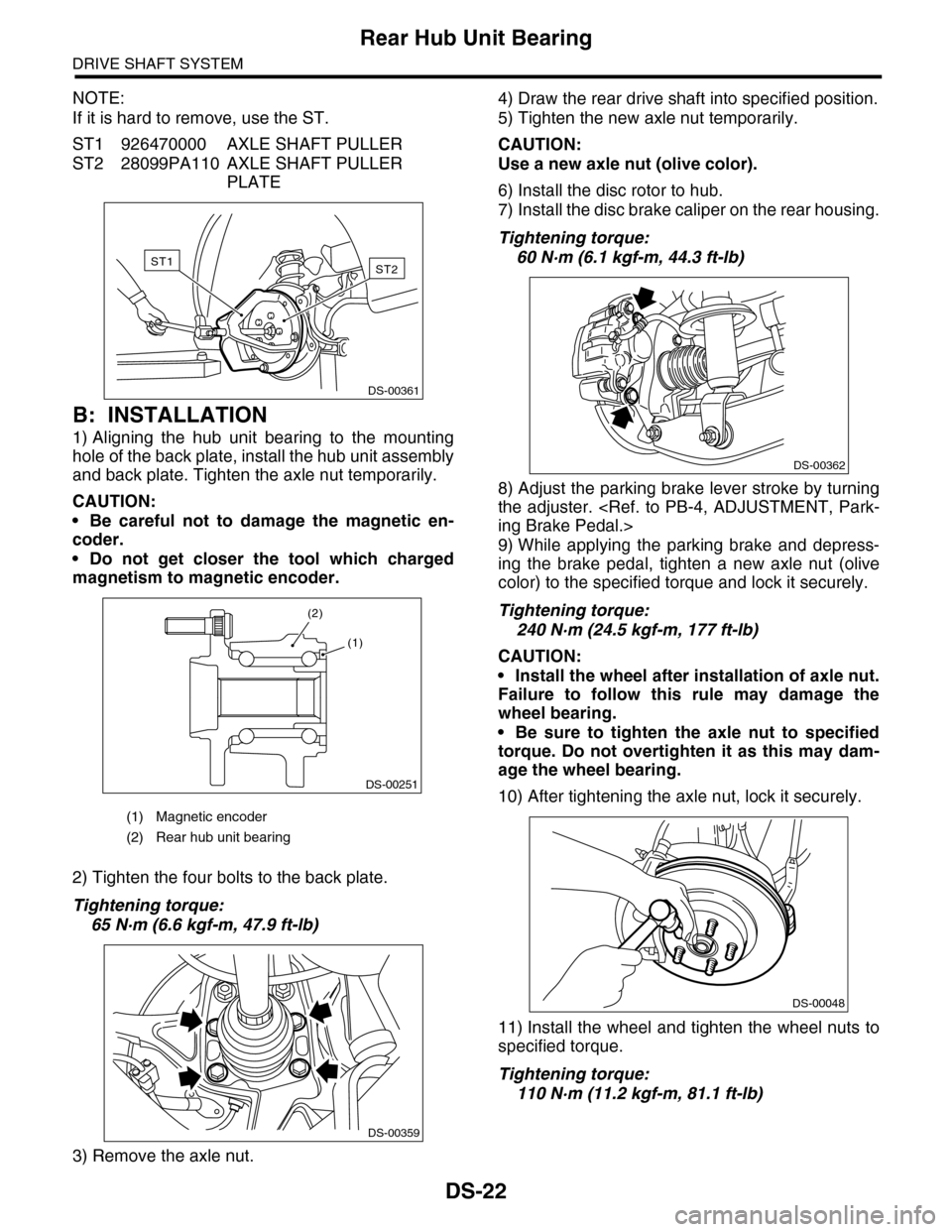

NOTE:

If it is hard to remove, use the ST.

ST1 926470000 AXLE SHAFT PULLER

ST2 28099PA110 AXLE SHAFT PULLER

PLATE

B: INSTALLATION

1) Aligning the hub unit bearing to the mounting

hole of the back plate, install the hub unit assembly

and back plate. Tighten the axle nut temporarily.

CAUTION:

•Be careful not to damage the magnetic en-

coder.

•Do not get closer the tool which charged

magnetism to magnetic encoder.

2) Tighten the four bolts to the back plate.

Tightening torque:

65 N·m (6.6 kgf-m, 47.9 ft-lb)

3) Remove the axle nut.

4) Draw the rear drive shaft into specified position.

5) Tighten the new axle nut temporarily.

CAUTION:

Use a new axle nut (olive color).

6) Install the disc rotor to hub.

7) Install the disc brake caliper on the rear housing.

Tightening torque:

60 N·m (6.1 kgf-m, 44.3 ft-lb)

8) Adjust the parking brake lever stroke by turning

the adjuster.

9) While applying the parking brake and depress-

ing the brake pedal, tighten a new axle nut (olive

color) to the specified torque and lock it securely.

Tightening torque:

240 N·m (24.5 kgf-m, 177 ft-lb)

CAUTION:

•Install the wheel after installation of axle nut.

Failure to follow this rule may damage the

wheel bearing.

•Be sure to tighten the axle nut to specified

torque. Do not overtighten it as this may dam-

age the wheel bearing.

10) After tightening the axle nut, lock it securely.

11) Install the wheel and tighten the wheel nuts to

specified torque.

Tightening torque:

110 N·m (11.2 kgf-m, 81.1 ft-lb)

(1) Magnetic encoder

(2) Rear hub unit bearing

ST2ST1

DS-00361

DS-00251

(2)

(1)

DS-00359

DS-00362

DS-00048