timing chain assembly SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1132 of 2453

CO(H6DO)-13

Water Pump

COOLING

4. Water Pump

A: REMOVAL

1) Remove the radiator.

2) Remove the V-belts.

3) Remove the front chain cover.

4) Remove the timing chain assembly.

5) Remove the water pump.

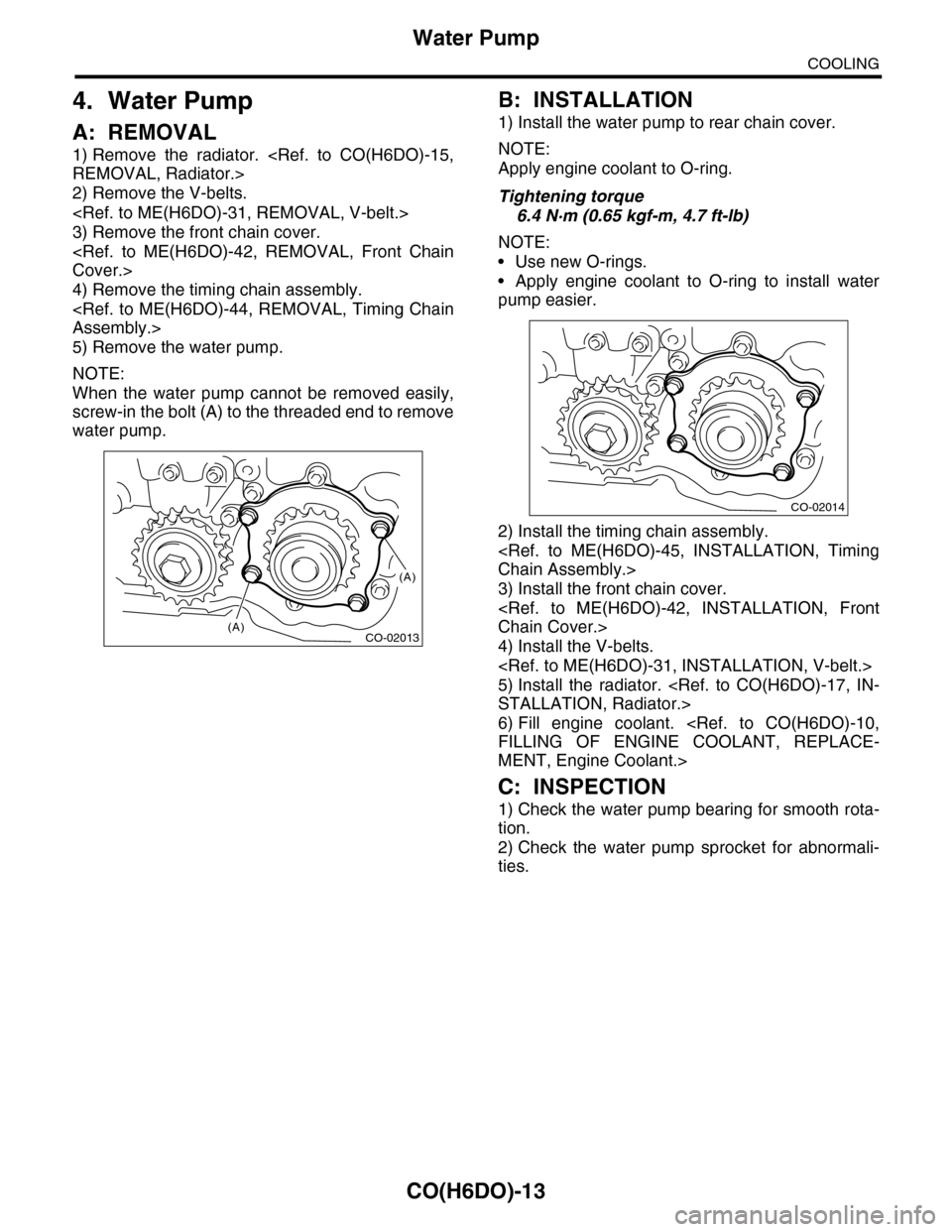

NOTE:

When the water pump cannot be removed easily,

screw-in the bolt (A) to the threaded end to remove

water pump.

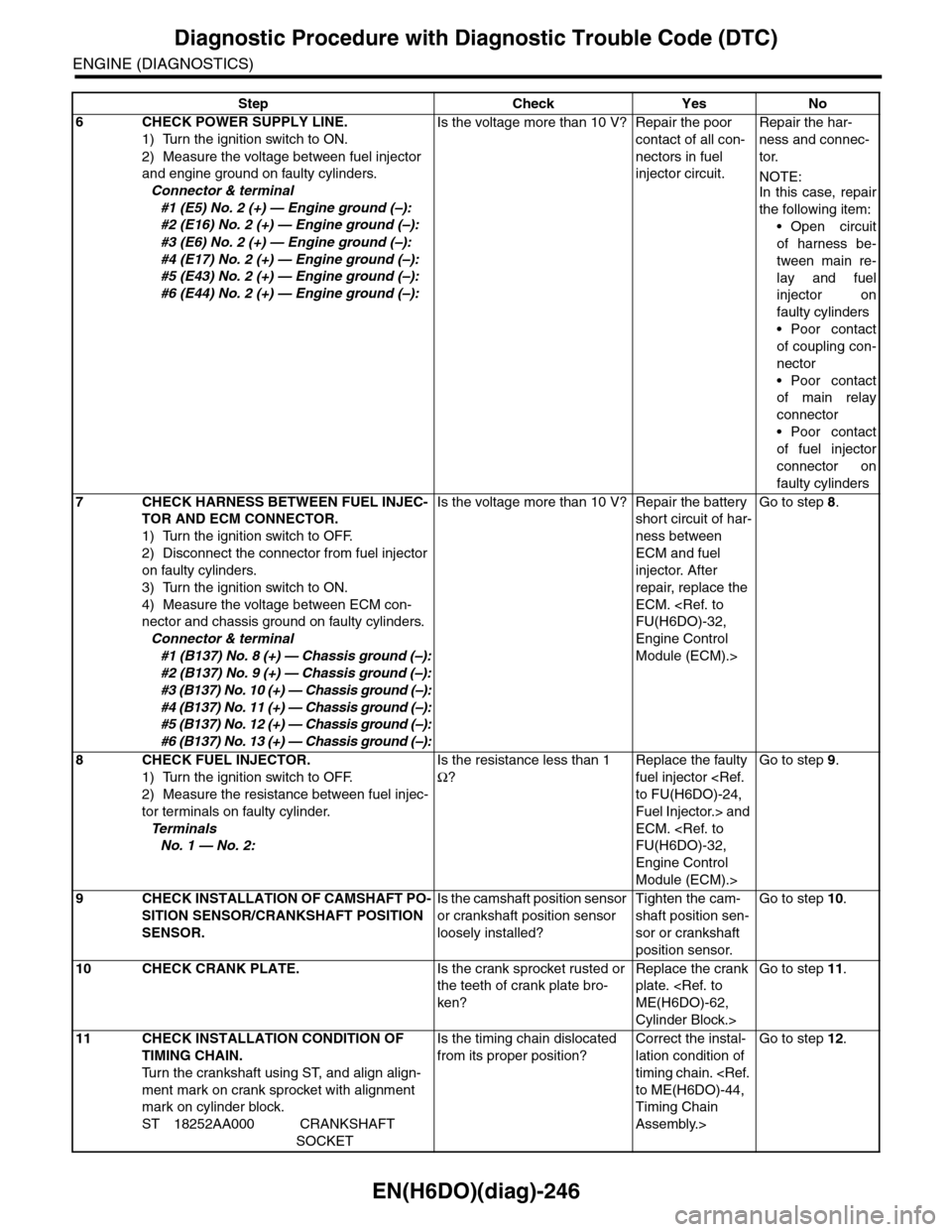

B: INSTALLATION

1) Install the water pump to rear chain cover.

NOTE:

Apply engine coolant to O-ring.

Tightening torque

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

NOTE:

•Use new O-rings.

•Apply engine coolant to O-ring to install water

pump easier.

2) Install the timing chain assembly.

3) Install the front chain cover.

4) Install the V-belts.

5) Install the radiator.

6) Fill engine coolant.

MENT, Engine Coolant.>

C: INSPECTION

1) Check the water pump bearing for smooth rota-

tion.

2) Check the water pump sprocket for abnormali-

ties.

CO-02013

(A)

(A)

CO-02014

Page 1407 of 2453

EN(H6DO)(diag)-246

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

6CHECK POWER SUPPLY LINE.

1) Turn the ignition switch to ON.

2) Measure the voltage between fuel injector

and engine ground on faulty cylinders.

Connector & terminal

#1 (E5) No. 2 (+) — Engine ground (–):

#2 (E16) No. 2 (+) — Engine ground (–):

#3 (E6) No. 2 (+) — Engine ground (–):

#4 (E17) No. 2 (+) — Engine ground (–):

#5 (E43) No. 2 (+) — Engine ground (–):

#6 (E44) No. 2 (+) — Engine ground (–):

Is the voltage more than 10 V? Repair the poor

contact of all con-

nectors in fuel

injector circuit.

Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween main re-

lay and fuel

injector on

faulty cylinders

•Poor contact

of coupling con-

nector

•Poor contact

of main relay

connector

•Poor contact

of fuel injector

connector on

faulty cylinders

7CHECK HARNESS BETWEEN FUEL INJEC-

TOR AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from fuel injector

on faulty cylinders.

3) Turn the ignition switch to ON.

4) Measure the voltage between ECM con-

nector and chassis ground on faulty cylinders.

Connector & terminal

#1 (B137) No. 8 (+) — Chassis ground (–):

#2 (B137) No. 9 (+) — Chassis ground (–):

#3 (B137) No. 10 (+) — Chassis ground (–):

#4 (B137) No. 11 (+) — Chassis ground (–):

#5 (B137) No. 12 (+) — Chassis ground (–):

#6 (B137) No. 13 (+) — Chassis ground (–):

Is the voltage more than 10 V? Repair the battery

short circuit of har-

ness between

ECM and fuel

injector. After

repair, replace the

ECM.

Engine Control

Module (ECM).>

Go to step 8.

8CHECK FUEL INJECTOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance between fuel injec-

tor terminals on faulty cylinder.

Te r m i n a l s

No. 1 — No. 2:

Is the resistance less than 1

Ω?

Replace the faulty

fuel injector

Fuel Injector.> and

ECM.

Engine Control

Module (ECM).>

Go to step 9.

9CHECK INSTALLATION OF CAMSHAFT PO-

SITION SENSOR/CRANKSHAFT POSITION

SENSOR.

Is the camshaft position sensor

or crankshaft position sensor

loosely installed?

Tighten the cam-

shaft position sen-

sor or crankshaft

position sensor.

Go to step 10.

10 CHECK CRANK PLATE.Is the crank sprocket rusted or

the teeth of crank plate bro-

ken?

Replace the crank

plate.

Cylinder Block.>

Go to step 11.

11 CHECK INSTALLATION CONDITION OF

TIMING CHAIN.

Tu r n t h e c r a n k s h a f t u s i n g S T, a n d a l i g n a l i g n -

ment mark on crank sprocket with alignment

mark on cylinder block.

ST 18252AA000 CRANKSHAFT

SOCKET

Is the timing chain dislocated

from its proper position?

Correct the instal-

lation condition of

timing chain.

Timing Chain

Assembly.>

Go to step 12.

Step Check Yes No

Page 1423 of 2453

EN(H6DO)(diag)-262

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check the appro-

priate DTC using

the “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

Go to step 2.

2CHECK CONDITION OF CRANKSHAFT PO-

SITION SENSOR.

Tu r n t h e i g n i t i o n s w i t c h t o O F F.

Is the crankshaft position sen-

sor installation bolt tightened

securely?

Go to step 3.Tighten the crank-

shaft position sen-

sor installation bolt

securely.

3CHECK CRANKSHAFT PLATE.Are the crankshaft plate teeth

cracked or damaged?

Replace the crank-

shaft plate.

Go to step 4.

4CHECK INSTALLATION CONDITION OF

TIMING CHAIN.

Tu r n t h e c r a n k s h a f t , a n d a l i g n a l i g n m e n t m a r k

on crank sprocket with alignment mark on cyl-

inder block.

Is the timing chain dislocated

from its proper position?

Correct the instal-

lation condition of

timing chain.

Timing Chain

Assembly.>

Replace the crank-

shaft position sen-

sor.

Crankshaft Posi-

tion Sensor.>

Page 1857 of 2453

LU(H6DO)-8

Oil Pump

LUBRICATION

4. Oil Pump

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Lift-up the vehicle.

4) Remove the under cover.

5) Drain engine coolant.

MENT, Engine Coolant.>

6) Lower the vehicle.

7) Remove the radiator.

8) Remove the V-belts.

9) Remove the front chain cover.

10) Remove the timing chain.

11) Remove the crank sprocket.

12) Remove the oil pump cover.

13) Remove the inner rotor and outer rotor.

B: INSTALLATION

1) Apply a coat of engine oil to the whole area of in-

ner rotor and outer rotor.

2) Set the inner rotor onto opening edge of crank

shaft, and install the inner rotor, and then assemble

the outer rotor.

3) Install the oil pump cover.

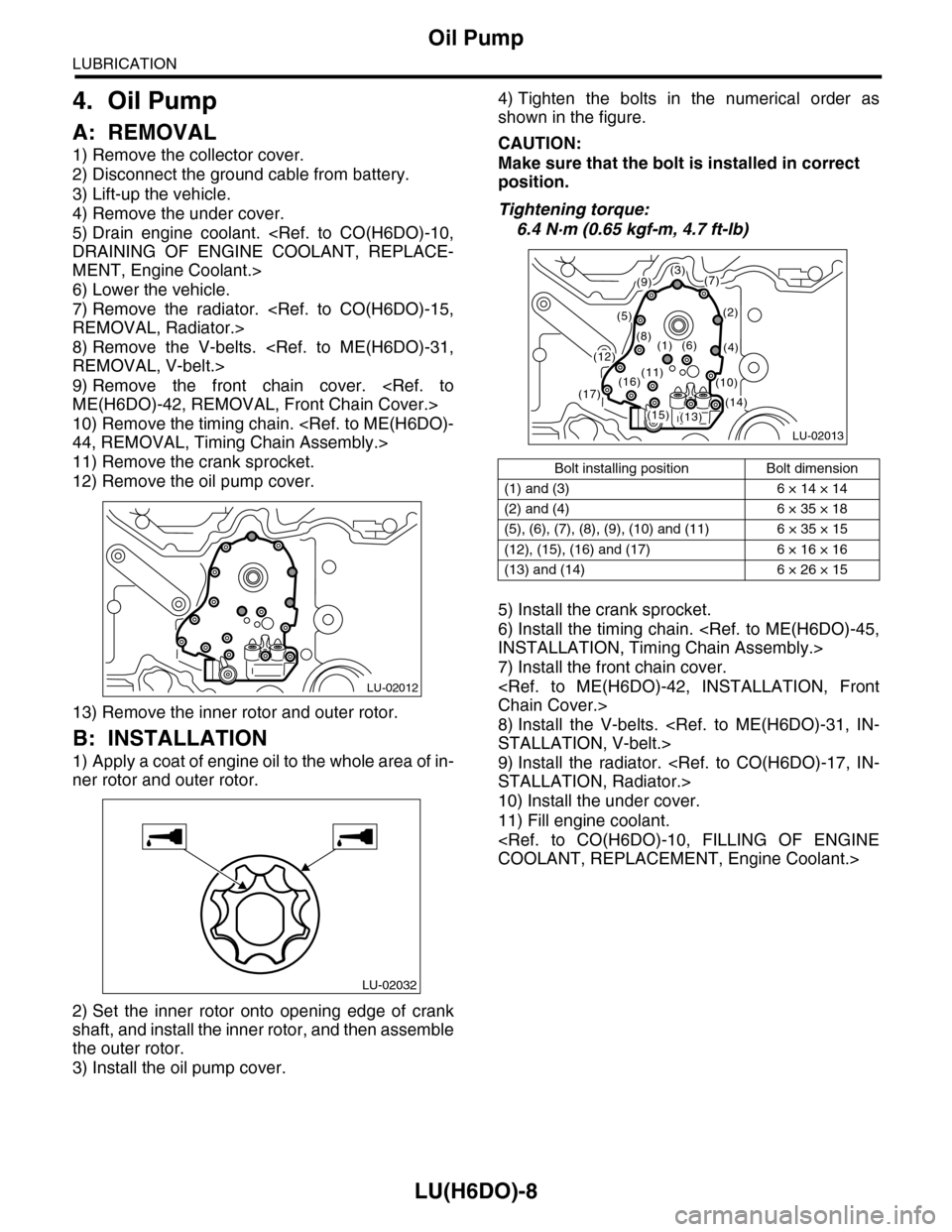

4) Tighten the bolts in the numerical order as

shown in the figure.

CAUTION:

Make sure that the bolt is installed in correct

position.

Tightening torque:

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

5) Install the crank sprocket.

6) Install the timing chain.

7) Install the front chain cover.

8) Install the V-belts.

9) Install the radiator.

10) Install the under cover.

11) Fill engine coolant.

LU-02012

LU-02032

Bolt installing position Bolt dimension

(1) and (3) 6 × 14 × 14

(2) and (4) 6 × 35 × 18

(5), (6), (7), (8), (9), (10) and (11) 6 × 35 × 15

(12), (15), (16) and (17) 6 × 16 × 16

(13) and (14) 6 × 26 × 15

LU-02013

(3)(7)

(2)

(4)

(9)

(5)

(8)(1)(6)(12)

(13)(14)(15)

(16)(17)

(11)(10)

Page 1880 of 2453

ME(H6DO)-14

General Description

MECHANICAL

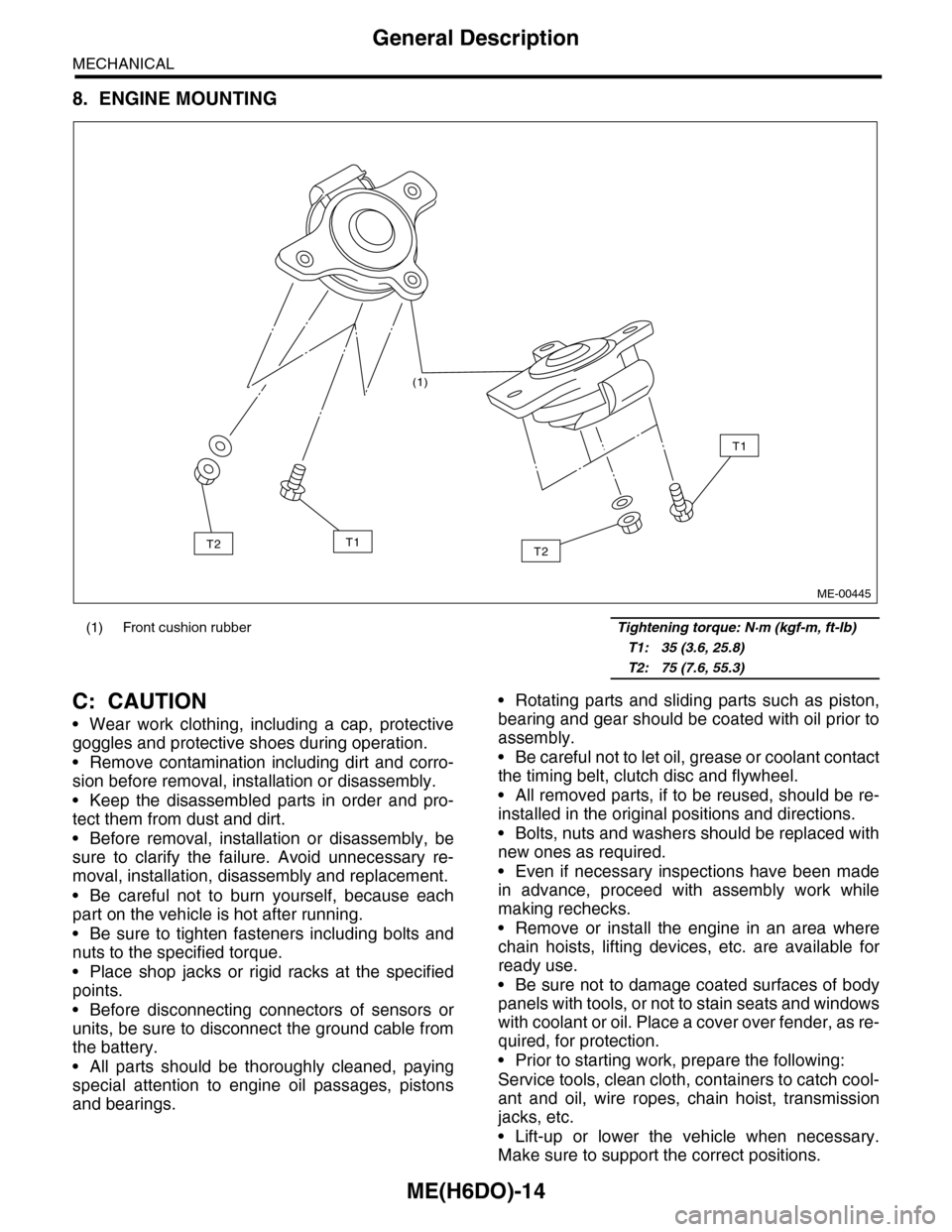

8. ENGINE MOUNTING

C: CAUTION

•Wear work clothing, including a cap, protective

goggles and protective shoes during operation.

•Remove contamination including dirt and corro-

sion before removal, installation or disassembly.

•Keep the disassembled parts in order and pro-

tect them from dust and dirt.

•Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly and replacement.

•Be careful not to burn yourself, because each

part on the vehicle is hot after running.

•Be sure to tighten fasteners including bolts and

nuts to the specified torque.

•Place shop jacks or rigid racks at the specified

points.

•Before disconnecting connectors of sensors or

units, be sure to disconnect the ground cable from

the battery.

•All parts should be thoroughly cleaned, paying

special attention to engine oil passages, pistons

and bearings.

•Rotating parts and sliding parts such as piston,

bearing and gear should be coated with oil prior to

assembly.

•Be careful not to let oil, grease or coolant contact

the timing belt, clutch disc and flywheel.

•All removed parts, if to be reused, should be re-

installed in the original positions and directions.

•Bolts, nuts and washers should be replaced with

new ones as required.

•Even if necessary inspections have been made

in advance, proceed with assembly work while

making rechecks.

•Remove or install the engine in an area where

chain hoists, lifting devices, etc. are available for

ready use.

•Be sure not to damage coated surfaces of body

panels with tools, or not to stain seats and windows

with coolant or oil. Place a cover over fender, as re-

quired, for protection.

•Prior to starting work, prepare the following:

Service tools, clean cloth, containers to catch cool-

ant and oil, wire ropes, chain hoist, transmission

jacks, etc.

•Lift-up or lower the vehicle when necessary.

Make sure to support the correct positions.

(1) Front cushion rubber Tightening torque: N·m (kgf-m, ft-lb)

T1: 35 (3.6, 25.8)

T2: 75 (7.6, 55.3)

(1)

T2

T1

T1T2

ME-00445

Page 1910 of 2453

ME(H6DO)-44

Timing Chain Assembly

MECHANICAL

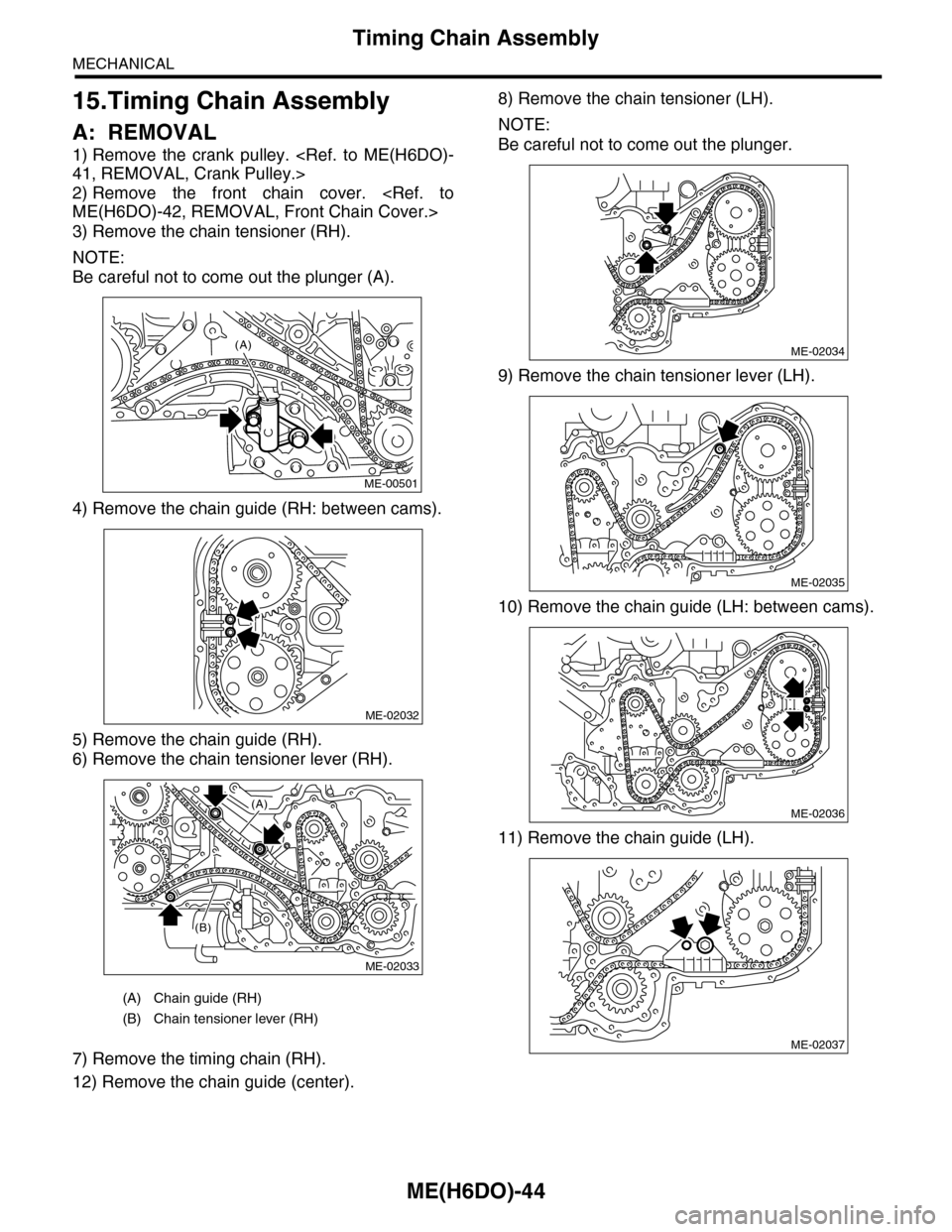

15.Timing Chain Assembly

A: REMOVAL

1) Remove the crank pulley.

2) Remove the front chain cover.

3) Remove the chain tensioner (RH).

NOTE:

Be careful not to come out the plunger (A).

4) Remove the chain guide (RH: between cams).

5) Remove the chain guide (RH).

6) Remove the chain tensioner lever (RH).

7) Remove the timing chain (RH).

8) Remove the chain tensioner (LH).

NOTE:

Be careful not to come out the plunger.

9) Remove the chain tensioner lever (LH).

10) Remove the chain guide (LH: between cams).

11) Remove the chain guide (LH).

12) Remove the chain guide (center).

(A) Chain guide (RH)

(B) Chain tensioner lever (RH)

(A)

ME-00501

ME-02032

ME-02033

(A)

(B)

ME-02034

ME-02035

ME-02036

ME-02037

Page 1911 of 2453

ME(H6DO)-45

Timing Chain Assembly

MECHANICAL

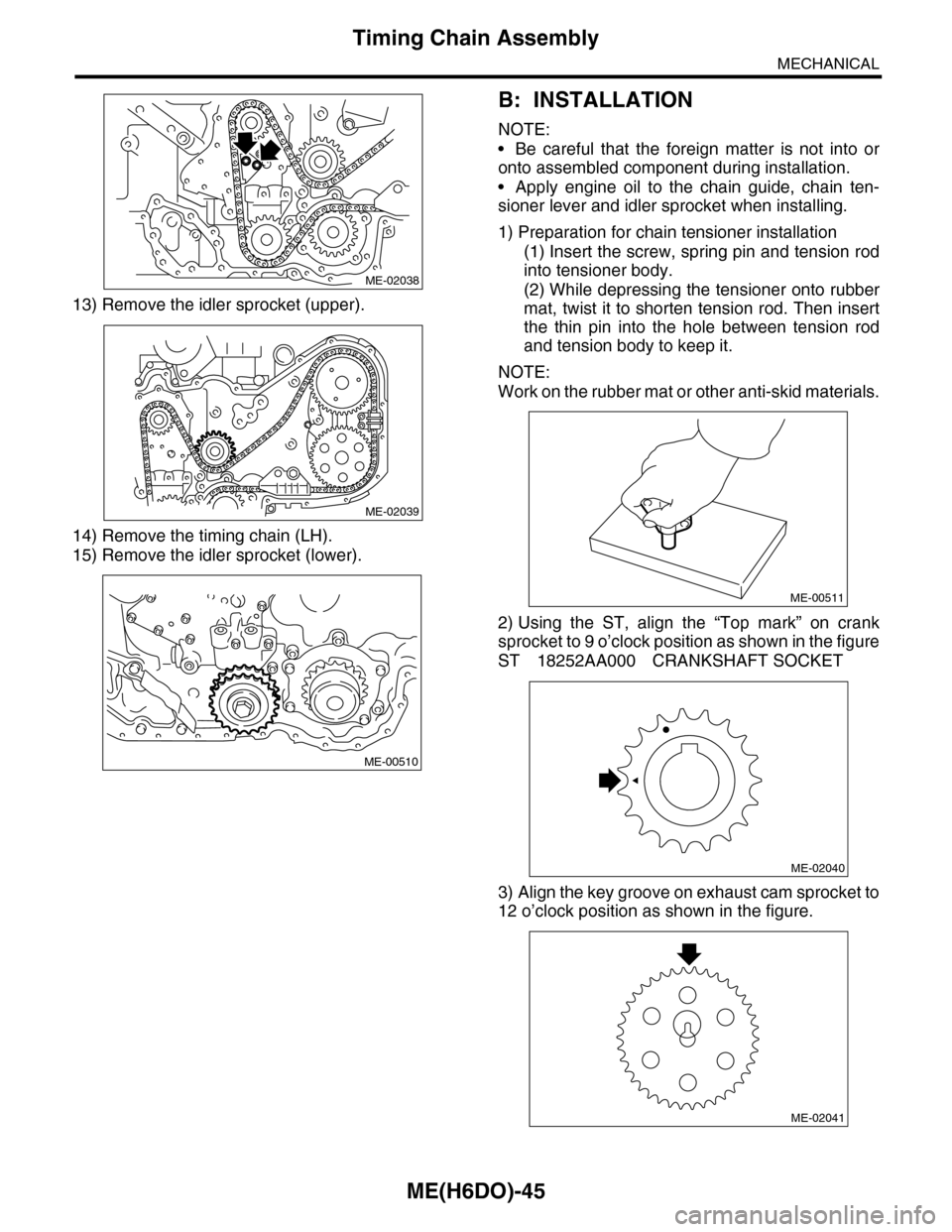

13) Remove the idler sprocket (upper).

14) Remove the timing chain (LH).

15) Remove the idler sprocket (lower).

B: INSTALLATION

NOTE:

•Be careful that the foreign matter is not into or

onto assembled component during installation.

•Apply engine oil to the chain guide, chain ten-

sioner lever and idler sprocket when installing.

1) Preparation for chain tensioner installation

(1) Insert the screw, spring pin and tension rod

into tensioner body.

(2) While depressing the tensioner onto rubber

mat, twist it to shorten tension rod. Then insert

the thin pin into the hole between tension rod

and tension body to keep it.

NOTE:

Work on the rubber mat or other anti-skid materials.

2) Using the ST, align the “Top mark” on crank

sprocket to 9 o’clock position as shown in the figure

ST 18252AA000 CRANKSHAFT SOCKET

3) Align the key groove on exhaust cam sprocket to

12 o’clock position as shown in the figure.

ME-02038

ME-02039

ME-00510

ME-00511

ME-02040

ME-02041

Page 1912 of 2453

ME(H6DO)-46

Timing Chain Assembly

MECHANICAL

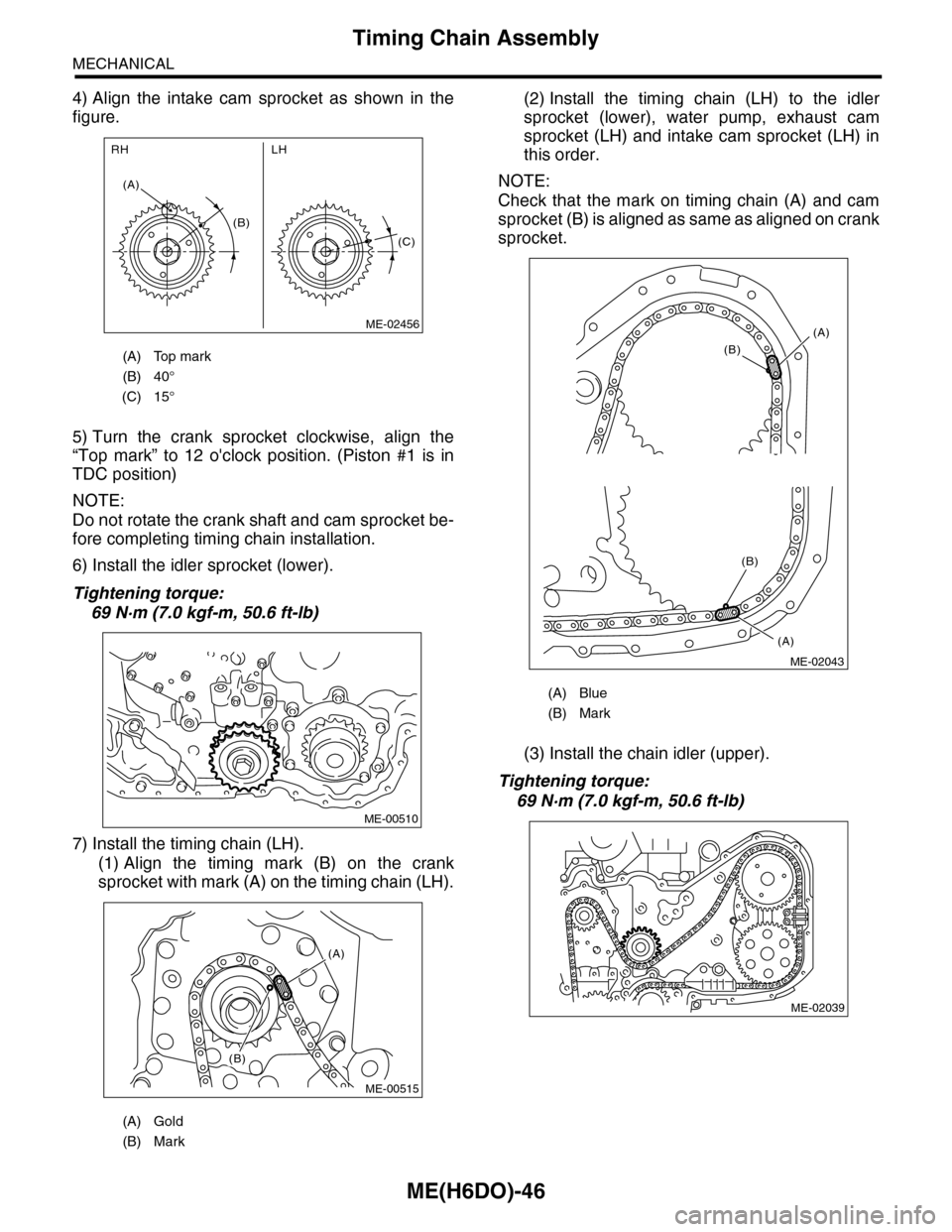

4) Align the intake cam sprocket as shown in the

figure.

5) Turn the crank sprocket clockwise, align the

“Top mark” to 12 o'clock position. (Piston #1 is in

TDC position)

NOTE:

Do not rotate the crank shaft and cam sprocket be-

fore completing timing chain installation.

6) Install the idler sprocket (lower).

Tightening torque:

69 N·m (7.0 kgf-m, 50.6 ft-lb)

7) Install the timing chain (LH).

(1) Align the timing mark (B) on the crank

sprocket with mark (A) on the timing chain (LH).

(2) Install the timing chain (LH) to the idler

sprocket (lower), water pump, exhaust cam

sprocket (LH) and intake cam sprocket (LH) in

this order.

NOTE:

Check that the mark on timing chain (A) and cam

sprocket (B) is aligned as same as aligned on crank

sprocket.

(3) Install the chain idler (upper).

Tightening torque:

69 N·m (7.0 kgf-m, 50.6 ft-lb)

(A) Top mark

(B) 40°

(C) 15°

(A) Gold

(B) Mark

(B)

(A)

LHRH

(C)

ME-02456

ME-00510

(A)

(B)

ME-00515

(A) Blue

(B) Mark

(A)

(B)

(A)

(B)

ME-02043

ME-02039

Page 1913 of 2453

ME(H6DO)-47

Timing Chain Assembly

MECHANICAL

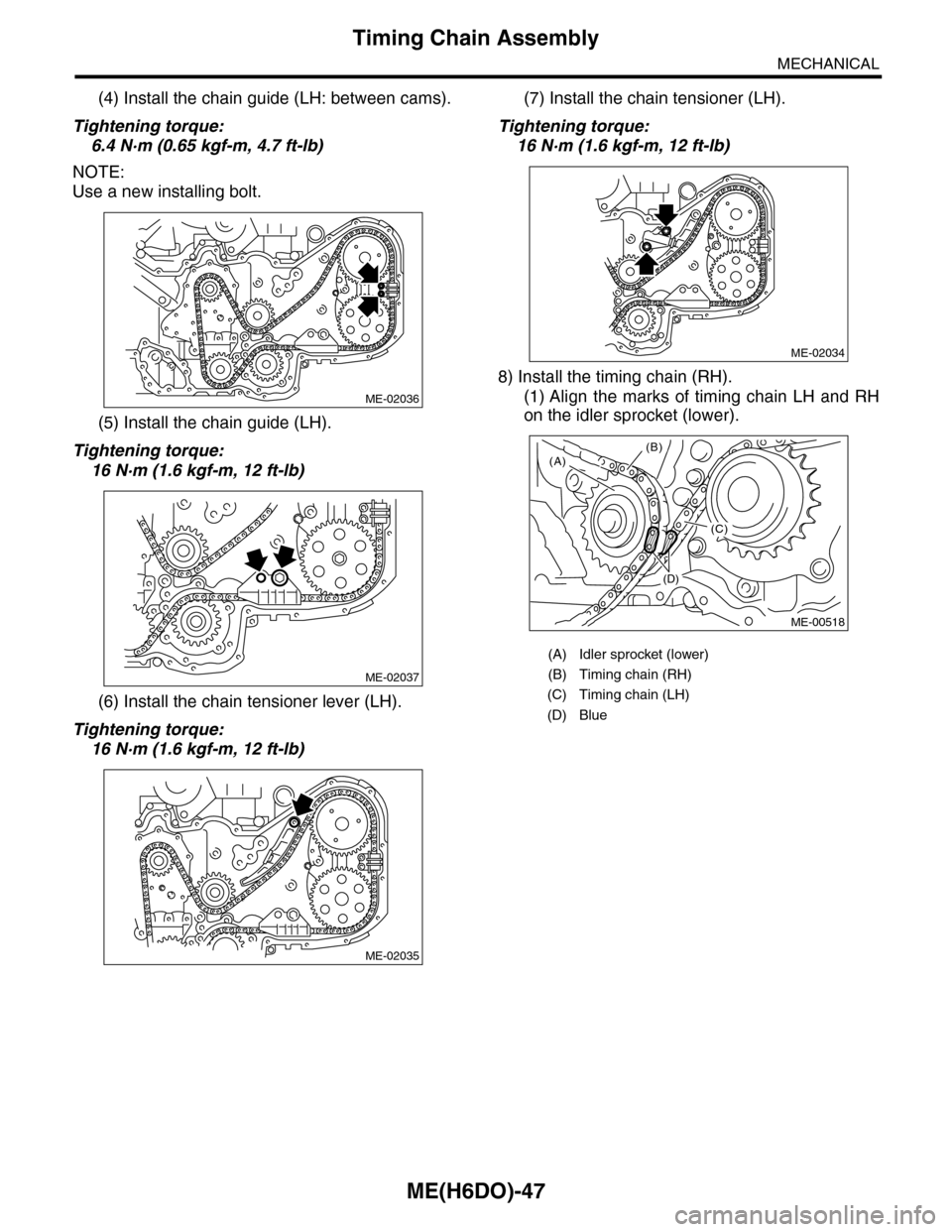

(4) Install the chain guide (LH: between cams).

Tightening torque:

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

NOTE:

Use a new installing bolt.

(5) Install the chain guide (LH).

Tightening torque:

16 N·m (1.6 kgf-m, 12 ft-lb)

(6) Install the chain tensioner lever (LH).

Tightening torque:

16 N·m (1.6 kgf-m, 12 ft-lb)

(7) Install the chain tensioner (LH).

Tightening torque:

16 N·m (1.6 kgf-m, 12 ft-lb)

8) Install the timing chain (RH).

(1) Align the marks of timing chain LH and RH

on the idler sprocket (lower).

ME-02036

ME-02037

ME-02035

(A) Idler sprocket (lower)

(B) Timing chain (RH)

(C) Timing chain (LH)

(D) Blue

ME-02034

(A)(B)

(C)

(D)

ME-00518

Page 1914 of 2453

ME(H6DO)-48

Timing Chain Assembly

MECHANICAL

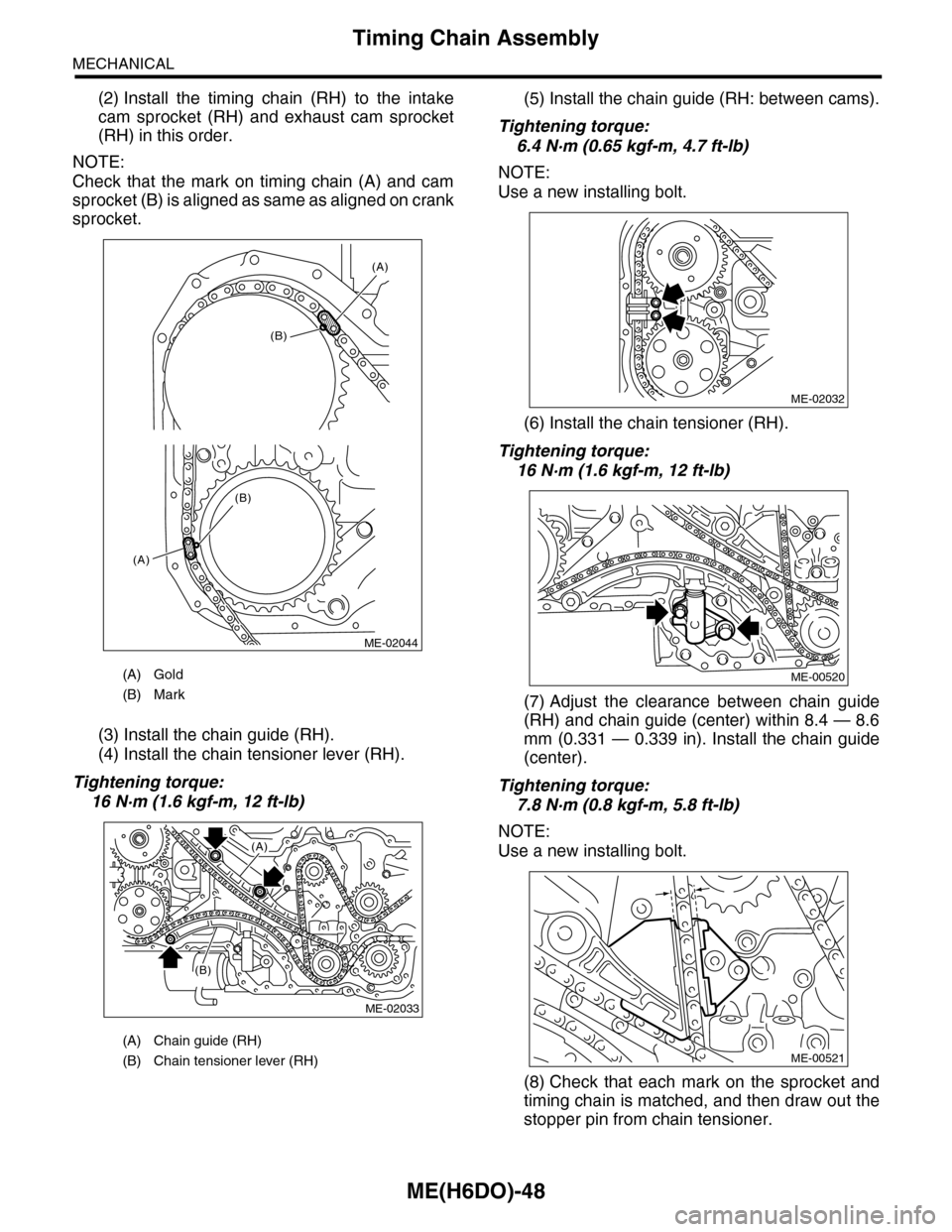

(2) Install the timing chain (RH) to the intake

cam sprocket (RH) and exhaust cam sprocket

(RH) in this order.

NOTE:

Check that the mark on timing chain (A) and cam

sprocket (B) is aligned as same as aligned on crank

sprocket.

(3) Install the chain guide (RH).

(4) Install the chain tensioner lever (RH).

Tightening torque:

16 N·m (1.6 kgf-m, 12 ft-lb)

(5) Install the chain guide (RH: between cams).

Tightening torque:

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

NOTE:

Use a new installing bolt.

(6) Install the chain tensioner (RH).

Tightening torque:

16 N·m (1.6 kgf-m, 12 ft-lb)

(7) Adjust the clearance between chain guide

(RH) and chain guide (center) within 8.4 — 8.6

mm (0.331 — 0.339 in). Install the chain guide

(center).

Tightening torque:

7.8 N·m (0.8 kgf-m, 5.8 ft-lb)

NOTE:

Use a new installing bolt.

(8) Check that each mark on the sprocket and

timing chain is matched, and then draw out the

stopper pin from chain tensioner.

(A) Gold

(B) Mark

(A) Chain guide (RH)

(B) Chain tensioner lever (RH)

(A)

(A)

(B)

(B)

ME-02044

ME-02033

(A)

(B)

ME-02032

ME-00520

ME-00521