Oil SUZUKI BALENO 1999 1.G User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1999, Model line: BALENO, Model: SUZUKI BALENO 1999 1.GPages: 65, PDF Size: 3.28 MB

Page 31 of 65

OTHER CONTROLS AND EQUIPMENTS

60G-74E

FRONT SEAT BACK POCKET

(if equipped)

REAR SPOILER WITH STOP LAMP

Other Controls (if equipped)

63B-06-022

This pocket is provided for holding light and

soft things such as gloves, newspapers or

magazines.

Do not put hard or breakable objects

In the pocket. If an accident occurs,

objects such as bottles, cans etc. can

injure the occupants in the rear seat.

60G-50-002E

Rear Spoiler is provided to improve

aerodynamic stability at higher speeds and

better asthetics. Stop Lamp (if equipped) is

fitted inside the Rear Spoiler. The stop lamp

will glow as and when the Brake Pedal is

depressed.

CAUTION

Never close the dicky door too hard or

with jerk or lift the dicky by holding

spoiler, rear spoiler may get damaged.

Close the dicky door gently and make

sure it is closed properly.

ALLOY WHEELS

Maintenance with tyre wears (if equipped)

60G-50-003E

Wider alloy wheels are provided in the vehicle

for better grip on the road and more fuel

economy. For balancing of wheels please

consult MARUTI authorised workshop.

CAUTION

Never try to remove the tyre from alloy

wheel rim in convention manner (by

hammering), it will damage the wheel

rim. Always insist on tyre changing

machine.

6-9

62

60G-74E

OTHER CONTROLS AND EQUIPMENT

POWER ANTENNA Other Controls

(if equipped)

LEATHER COVER

Steering Column Controls (if equipped)

60G-50-004E

60G-50-006E

Power antenna on the rear side will

automatically come up on switching on the

AM/FM receiver fitted in the vehicle.

For better control on steering wheel leather

cover is provided.

HIGH MOUNT STOP LAMP

(if equipped)

High mount stop lamp is provided with your

vehicle and is fitted on rear parcel tray. The

stop lamp will glow as when the brake pedal

will be depressed.

To change the bulb of the stop lamp, remove

the clips at both sides of the cover, by

pressing the inner pin inside so that the clip

gets loose and remove the bulb on turning

it anticlock-wise

The rating of bulb is 21W/12V.There are one

bulb in high mount stop lamp.

63

6-10

Page 32 of 65

S0G-74E

OPERATING YOUR VEHICLE

OPERATING YOUR VEHICLE

Exhaust Gas Warning 7-1

Daily Inspection Checklist 7-1

Starting the Engine 7-2

Using the Transmission 7-3

Braking 7-4

Running-in 7-5

Catalytic Converter (if equipped) 7-6

Improving Fuel Economy 7-7

Trailer Towing 7-7

OPERATING YOUR VECHILE

60G-74E

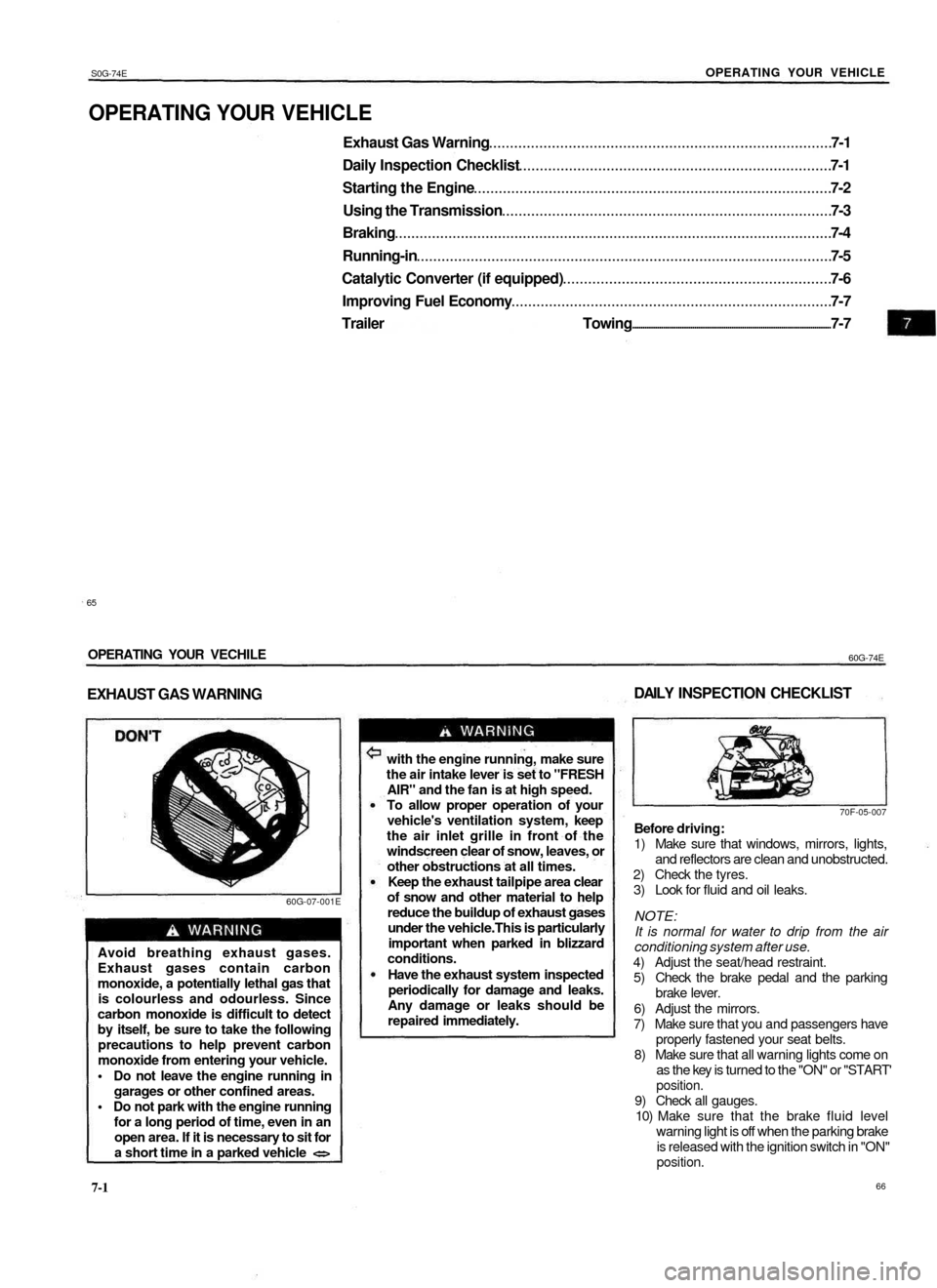

EXHAUST GAS WARNING

DAILY INSPECTION CHECKLIST

60G-07-001E

Avoid breathing exhaust gases.

Exhaust gases contain carbon

monoxide, a potentially lethal gas that

is colourless and odourless. Since

carbon monoxide is difficult to detect

by itself, be sure to take the following

precautions to help prevent carbon

monoxide from entering your vehicle.

• Do not leave the engine running in

garages or other confined areas.

• Do not park with the engine running

for a long period of time, even in an

open area. If it is necessary to sit for

a short time in a parked vehicle <=>

with the engine running, make sure

the air intake lever is set to "FRESH

AIR" and the fan is at high speed.

To allow proper operation of your

vehicle's ventilation system, keep

the air inlet grille in front of the

windscreen clear of snow, leaves, or

other obstructions at all times.

Keep the exhaust tailpipe area clear

of snow and other material to help

reduce the buildup of exhaust gases

under the vehicle.This is particularly

important when parked in blizzard

conditions.

Have the exhaust system inspected

periodically for damage and leaks.

Any damage or leaks should be

repaired immediately.

7-1

70F-05-007

Before driving:

1) Make sure that windows, mirrors, lights,

and reflectors are clean and unobstructed.

2) Check the tyres.

3) Look for fluid and oil leaks.

NOTE:

It is normal for water to drip from the air

conditioning system after use.

4) Adjust the seat/head restraint.

5) Check the brake pedal and the parking

brake lever.

6) Adjust the mirrors.

7) Make sure that you and passengers have

properly fastened your seat belts.

8) Make sure that all warning lights come on

as the key is turned to the "ON" or "START'

position.

9) Check all gauges.

10) Make sure that the brake fluid level

warning light is off when the parking brake

is released with the ignition switch in "ON"

position.

66

65

Page 33 of 65

60G-74E

OPERATING YOUR VEHICLE

Once a week, or each time you fill your fuel

tank, perform the following under-bonnet

checks:

1) Engine oil level.

2) Coolant level.

3) Brake fluid level.

4) Power steering (if equipped) fluid level.

5) Windscreen washer fluid level.

6) Battery solution level.

7) Bonnet latch operation.

Pull the bonnet release handle inside the

vehicle. Make sure that you can not open

the hood all the way without releasing the

secondary latch. Be sure to close the hood

securely after checking for proper

operation. See "All Latches, Hinges &

Locks" of "PERIODIC MAINTENANCE

SCHEDULE" in the "INSPECTION AND

MAINTENANCE" section for lubrication

schedule.

Make sure the bonnet is fully closed

and latched before driving. If it is not,

it can fly up unexpectedly during

driving, obstructing your view and

resulting in an accident.

STARTING THE ENGINE

Before starting the engine:

1) Make sure the parking brake is applied

fully.

2) Manual Transmission - Shift into "N"

(neutral) and depress the clutch pedal all

the way to the floor. Hold it while starting

the engine.

Make sure that the parking brake is

applied fully and the transmission is in

Neutral before attempting to start the

engine.

CAUTION

Stop turning the starter immediately

after the engine has started or the

starter system can be damaged.

Do not crank the engine for more

than 15 seconds at a time. If the

engine doesn't start on the first try,

wait about 15 seconds before trying

again.

Starting a Cold Engine

Engine which is started after 6 hours should

be treated as cold engine.

For Electronic fuel injection models

• With your foot off the accelerator pedal,

crank the engine by turning the ignition

key to "START1. Release the key when the

engine starts.

• If the engine does not start after 15

seconds of cranking, wait about 15

seconds, then press down the accelerator

pedal to 1/3 of its travel and try cranking

the engine again. Release the key and

accelerator pedal when the engine starts.

• If the engine still does not start, try holding

the accelerator pedal all the way to the

floor while cranking. This should clear the

engine if it is flooded.

Starting a Warm Engine

For Electronic fuel injection models:

Use the same procedure as for "Starting a cold

Engine".

67

7-2

OPERATING YOUR VECHILE

60G-74E

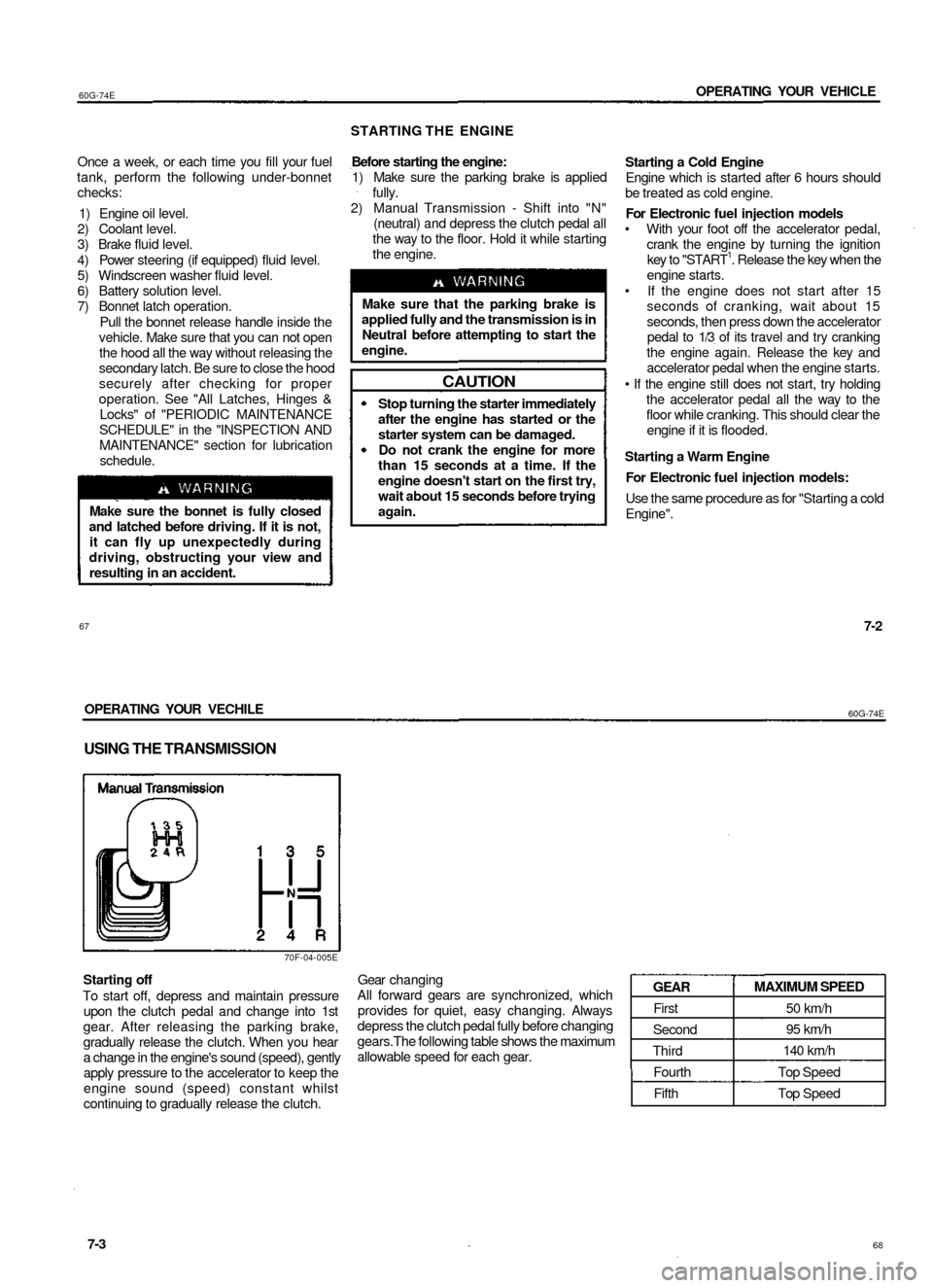

USING THE TRANSMISSION

70F-04-005E

Starting off

To start off, depress and maintain pressure

upon the clutch pedal and change into 1st

gear. After releasing the parking brake,

gradually release the clutch. When you hear

a change in the engine's sound (speed), gently

apply pressure to the accelerator to keep the

engine sound (speed) constant whilst

continuing to gradually release the clutch.

Gear changing

All forward gears are synchronized, which

provides for quiet, easy changing. Always

depress the clutch pedal fully before changing

gears.The following table shows the maximum

allowable speed for each gear.

GEAR

First

Second

Third

Fourth

Fifth

MAXIMUM SPEED

50 km/h

95 km/h

140 km/h

Top Speed

Top Speed

7-3

68

Page 41 of 65

60G-74E

INSPECTION AND MAINTENANCE

INSPECTION AND MAINTENANCE

Periodic Maintenance Schedule.. 9-2

Engine Oil and Filter 9-7

Gear OH 9-10

Engine Coolant 9-11

Windscreen Washer Fluid 9-13

Air Cleaner 9-13

Spark Plugs 9-14

Brakes 9-15

Steering 9-17

Power Steering (if equipped) 9-18

Clutch Pedal 9-18

Tyres... 9-19

Battery 9-22

Fuses 9-23

Bulb Replacement , 9-25

Wiper Blades 9-29

83

INSPECTION AND MAINTENANCE

60G-74E

70F-05-002

You should take extreme care when

working on your vehicle to prevent

accidental injury. Here are a few

precautions that you should be

especially careful to observe:

• Do not leave the engine running in

garages or other confined areas.

• When the engine Is running, keep

hands, clothing, tools, and other

objects away from the fan and water

pump belt. Even though the fan may

not be moving, it can automatically

turn on without warning. ^

When it is necessary to do service

work with the engine running, make

sure that the parking brake is applied

fully and the transmission is in

Neutral.

Do not touch ignition wires or other

ignition system parts when starting

the engine or when the engine is

running, or you could receive an

electric shock.

Be careful not to touch a hot engine,

exhaust manifold and pipes, muffler,

radiator and water hoses.

Do not allow smoking, sparks, or

flames around gasoline or the

battery. Flammable fumes are

present.

Do not get under your vehicle if it is

supported only with the portable

jack provided in your vehicle.

Be careful not to cause accidental

short circuits between the positive

and negative battery terminals.

Keep used oil, coolant, and other

fluids away from children and pets.

Dispose of used fluids properly;

never pour them on the ground, into

sewers, etc.

9-1

84

Page 42 of 65

60G-74E

INSPECTION AND MAINTENANCE

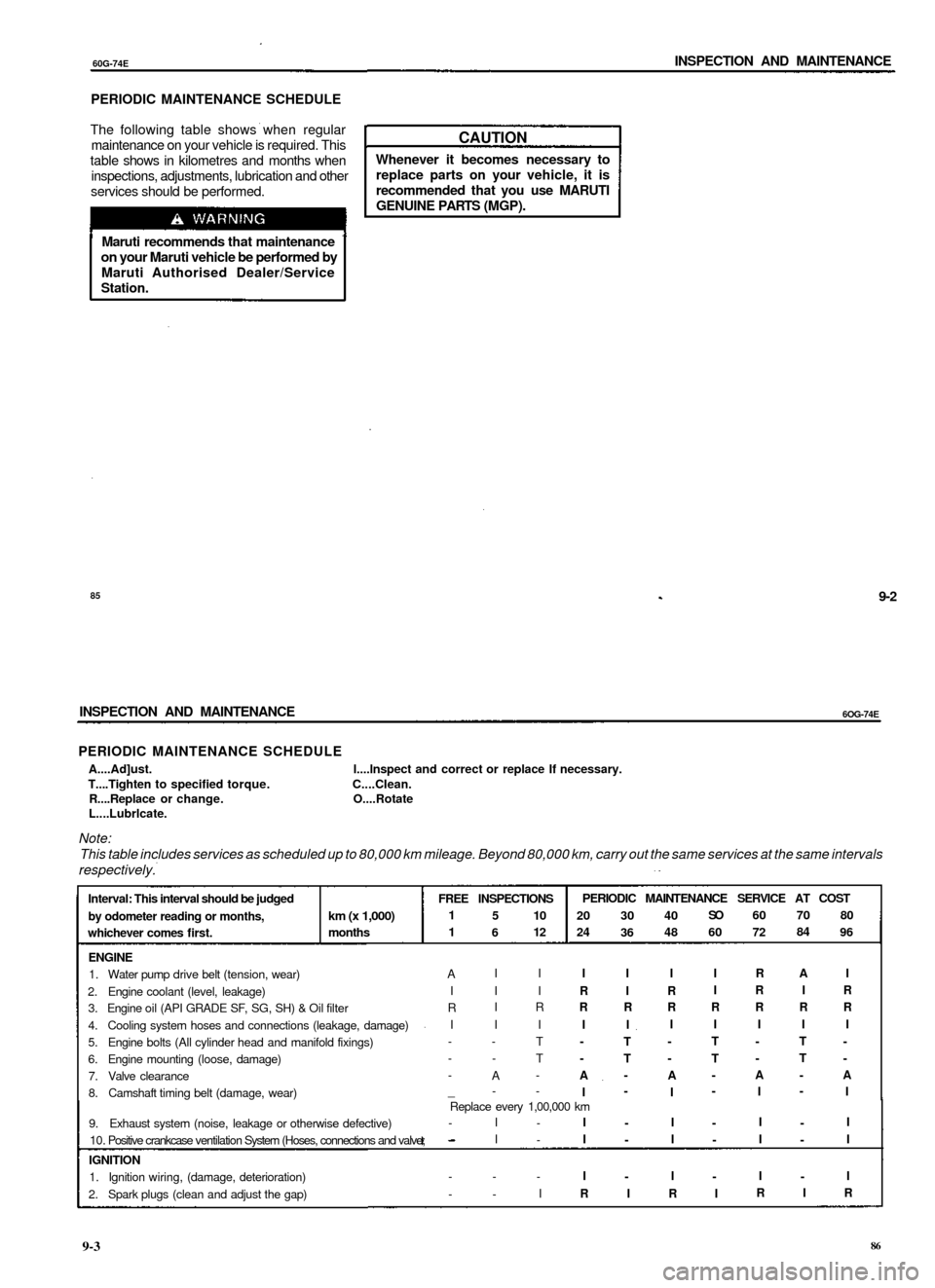

PERIODIC MAINTENANCE SCHEDULE

The following table shows when regular

maintenance on your vehicle is required. This

table shows in kilometres and months when

inspections, adjustments, lubrication and other

services should be performed.

Maruti recommends that maintenance

on your Maruti vehicle be performed by

Maruti Authorised Dealer/Service

Station.

CAUTION

Whenever it becomes necessary to

replace parts on your vehicle, it is

recommended that you use MARUTI

GENUINE PARTS (MGP).

85

9-2

INSPECTION AND MAINTENANCE

6OG-74E

PERIODIC MAINTENANCE SCHEDULE

A....Ad]ust. l....lnspect and correct or replace If necessary.

T....Tighten to specified torque. C....CIean.

R....Replace or change. O....Rotate

L....Lubrlcate.

Note:

This table includes services as scheduled up to 80,000 km mileage. Beyond 80,000 km, carry out the same services at the same intervals

respectively.

Interval: This interval should be judged

by odometer reading or months,

whichever comes first.

km (x 1,000)

months

ENGINE

1. Water pump drive belt (tension, wear)

2. Engine coolant (level, leakage)

3. Engine oil (API GRADE SF, SG, SH) & Oil filter

4. Cooling system hoses and connections (leakage, damage)

5. Engine bolts (All cylinder head and manifold fixings)

6. Engine mounting (loose, damage)

7. Valve clearance

8. Camshaft timing belt (damage, wear)

9. Exhaust system (noise, leakage or otherwise defective)

10. Positive crankcase ventilation System (Hoses, connections and valve;

IGNITION

1. Ignition wiring, (damage, deterioration)

2. Spark plugs (clean and adjust the gap)

FREE INSPECTIONS

1

1

A

I

R

I

-

-

-

_

5

6

I

I

I

I

-

-

A

-

10

12

I

I

R

I

T

T

-

-

PERIODIC MAINTENANCE SERVICE AT COST

20

24

I

R

R

I

-

-

A

I

Replace every 1,00,000 km

-

-

-

I

I

-

-

-

-

-

I

I

I

I

R

30

36

I

I

R

I

T

T

-

-

-

-

-

I

40

48

I

R

R

I

-

-

A

I

I

I

I

R

SO

60

I

I

R

I

T

T

-

-

-

-

-

I

60

72

R

R

R

I

-

-

A

I

I

I

I

R

70

84

A

I

R

I

T

T

-

-

-

-

-

I

80

96

I

R

R

I

-

-

A

I

I

I

I

R

9-3

86

Page 43 of 65

60G-74E

INSPECTION AND MAINTENANCE

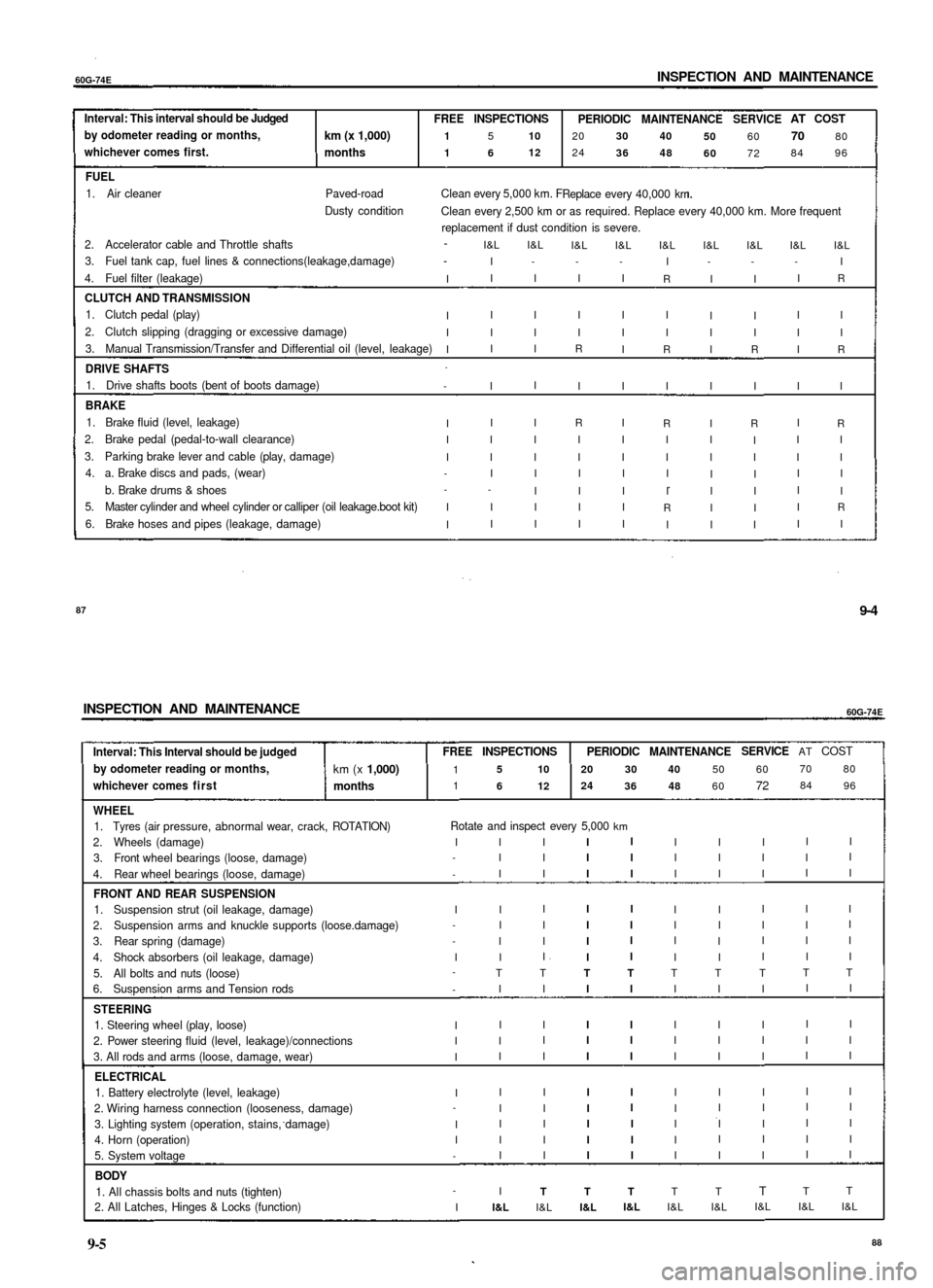

Interval: This interval should be Judged

by odometer reading or months,

whichever comes first.

km (x 1,000)

months

FUEL

1. Air cleaner Paved-road

Dusty condition

2. Accelerator cable and Throttle shafts

3. Fuel tank cap, fuel lines & connections(leakage,damage)

4. Fuel filter (leakage)

CLUTCH AND TRANSMISSION

1. Clutch pedal (play)

2. Clutch slipping (dragging or excessive damage)

3. Manual Transmission/Transfer and Differential oil (level, leakage)

DRIVE SHAFTS

1. Drive shafts boots (bent of boots damage)

BRAKE

1. Brake fluid (level, leakage)

2. Brake pedal (pedal-to-wall clearance)

3. Parking brake lever and cable (play, damage)

4. a. Brake discs and pads, (wear)

b. Brake drums & shoes

5. Master cylinder and wheel cylinder or calliper (oil leakage.boot kit)

6. Brake hoses and pipes (leakage, damage)

FREE

1

1

INSPECTIONS

5

6

10

12

Clean every 5,000 km. F

PERIODIC MAINTENANCE

20

24

30

36

40

48

Replace every 40,000 krr

50

60

SERVICE

60

72

AT

70

84

COST

80

96

Clean every 2,500 km or as required. Replace every 40,000 km. More frequent

replacement if dust condition is severe.

-

-

I

I

I

I

-

I

I

I

-

-

I

I

I&L

I

I

I

I

I

I

I

I

I

I

-

I

I

I&L

-

I

I

I

I

I

I

I

I

I

I

I

I

I&L

-

I

I

I

R

I

R

I

I

I

I

I

I

I&L

-

I

I

I

I

I

I

I

I

I

I

I

I

I&L

I

R

I

I

R

I

R

I

I

I

I

R

I

I&L

-

I

I

I

I

I

I

I

I

I

I

I

I

I&L

-

I

I

I

R

I

R

I

I

I

I

I

I

I&L

-

I

I

I

I

I

I

I

I

I

I

I

I

I&L

I

R

I

I

R

I

R

I

I

I

I

R

I

87

9-4

INSPECTION AND MAINTENANCE

60G-74E

Interval: This Interval should be judged

by odometer reading or months,

whichever comes first

km (x 1,000)

months

WHEEL

1. Tyres (air pressure, abnormal wear, crack, ROTATION)

2. Wheels (damage)

3. Front wheel bearings (loose, damage)

4. Rear wheel bearings (loose, damage)

FRONT AND REAR SUSPENSION

1. Suspension strut (oil leakage, damage)

2. Suspension arms and knuckle supports (loose.damage)

3. Rear spring (damage)

4. Shock absorbers (oil leakage, damage)

5. All bolts and nuts (loose)

6. Suspension arms and Tension rods

STEERING

1. Steering wheel (play, loose)

2. Power steering fluid (level, leakage)/connections

3. All rods and arms (loose, damage, wear)

ELECTRICAL

1. Battery electrolyte (level, leakage)

2. Wiring harness connection (looseness, damage)

3. Lighting system (operation, stains, damage)

4. Horn (operation)

5. System voltage

BODY

1. All chassis bolts and nuts (tighten)

2. All Latches, Hinges & Locks (function)

FREE

1

1

INSPECTIONS

5

6

Rotate and

I

-

-

I

-

-

I

-

-

I

I

I

I

-

I

I

-

-

I

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

I

I&L

10

12

PERIODIC

20

24

inspect every 5,000

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

T

I&L

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

T

I&L

30

36

km

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

T

I&L

MAINTENANCE

40

48

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

T

I&L

50

60

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

T

I&L

SERVICE

60

72

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

T

I&L

AT

70

84

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

T

I&L

COST

80

96

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

T

I&L

9-5

88

Page 44 of 65

60G-74E

INSPECTION AND MAINTENANCE

Interval: This Interval should be judged

by odometer reading or months,

whichever comes first.

km (x 1,000)

months

ROAD TEST

1. Operation of Brakes, Gear shifting & speedometer

2. Body and Chassis noise

AIR CONDITIONER (if equipped)

1. Check belt tension

2. Check Receiver Drier bubbles.

3. Tighten compressor mounting bolts

4. Check all hose joints, tighten if necessary

5. Check functioning of Recirc flap .*

6. Clean condenser with low pressure water

7. Check belt for frayed edges, change if necessary

8. Check all mounting bolts

FREE

1

1

I

I

I

I

—

I

I

_

-

-

INSPECTIONS

5

6

I

I

I

I

T

I

I

C

I

I

10

12

I

I

I

I

T

I

I

C

I

I

PERIODIC

20

24

I

I

I

I

T

I

I

C

I

I

30

36

I

I

I

I

T

I

I

C

I

I

MAINTENANCE

40

48

I

I

I

I

T

I

I

C

I

I

50

60

I

I

I

I

T

I

I

C

I

I

SERVICE

60

72

I

I

I

I

T

I

I

C

I

I

AT,

70

84

I

I

I

I

T

I

I

C

I

I

COST

80

96

I

I

I

I

T

I

I

C

I

I

The rear shock absorbers are filled with

high pressure gas. Never attempt to

disassemble it or throw it into a fire.

Avoid storing it near a heater or heating

device. When scrapping the absorber,

the gas must be released from the

absorber safely. Ask your dealer for

assistance.

89

9-6

INSPECTION AND MAINTENANCE

60G-74E

All maintenance should be carried

out with the Ignition switch in the

"OFF" position and the car parked

securely on the level ground unless

otherwise specified.

If you are In any way unsure of your

ability to undertake a task, then do

not start it but contact your Maruti

dealer to perform the work for you.

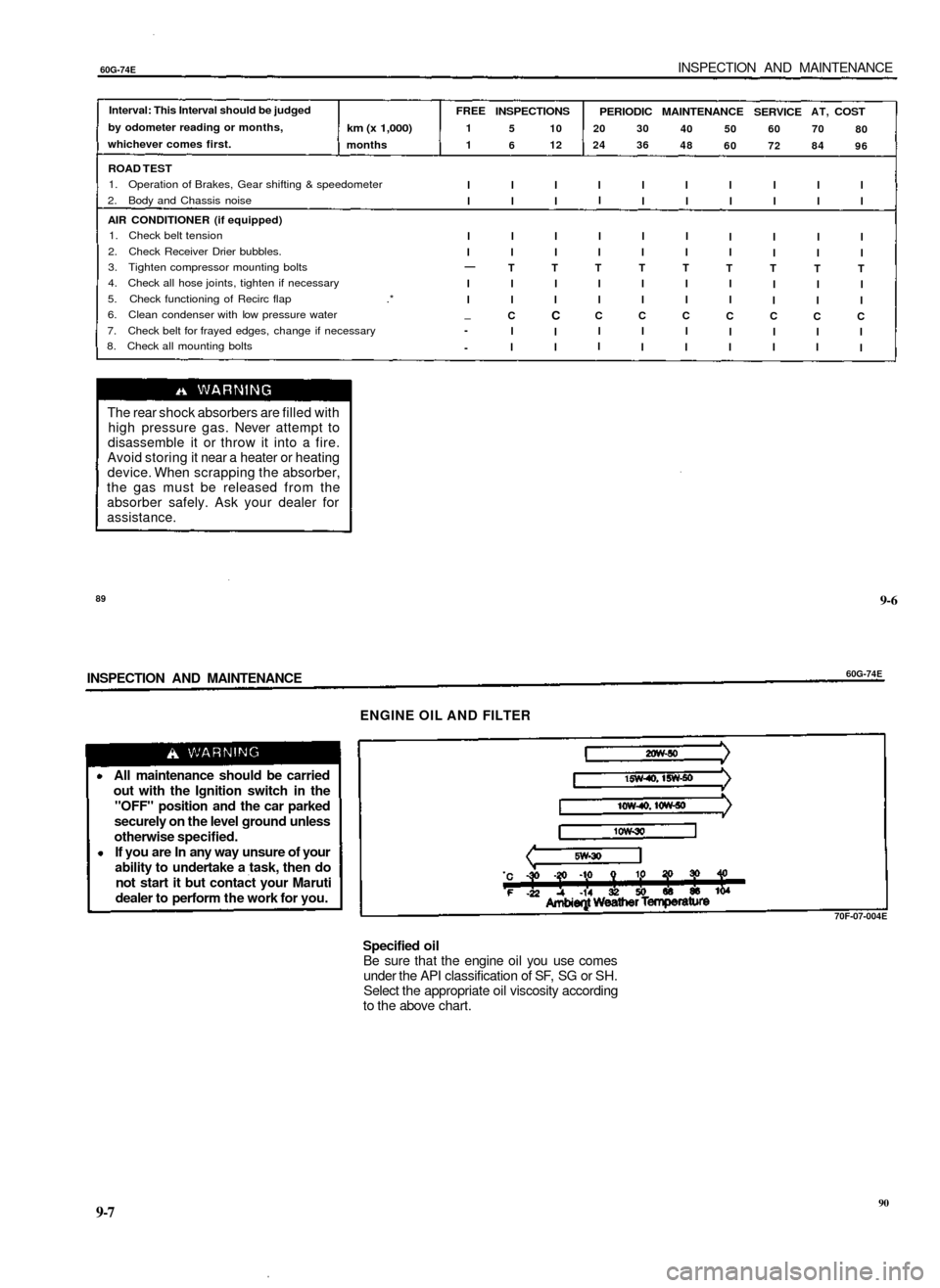

ENGINE OIL AND FILTER

Specified oil

Be sure that the engine oil you use comes

under the API classification of SF, SG or SH.

Select the appropriate oil viscosity according

to the above chart.

9-7

90

70F-07-004E

Page 45 of 65

60G-74E

INSPECTION AND MAINTENANCE

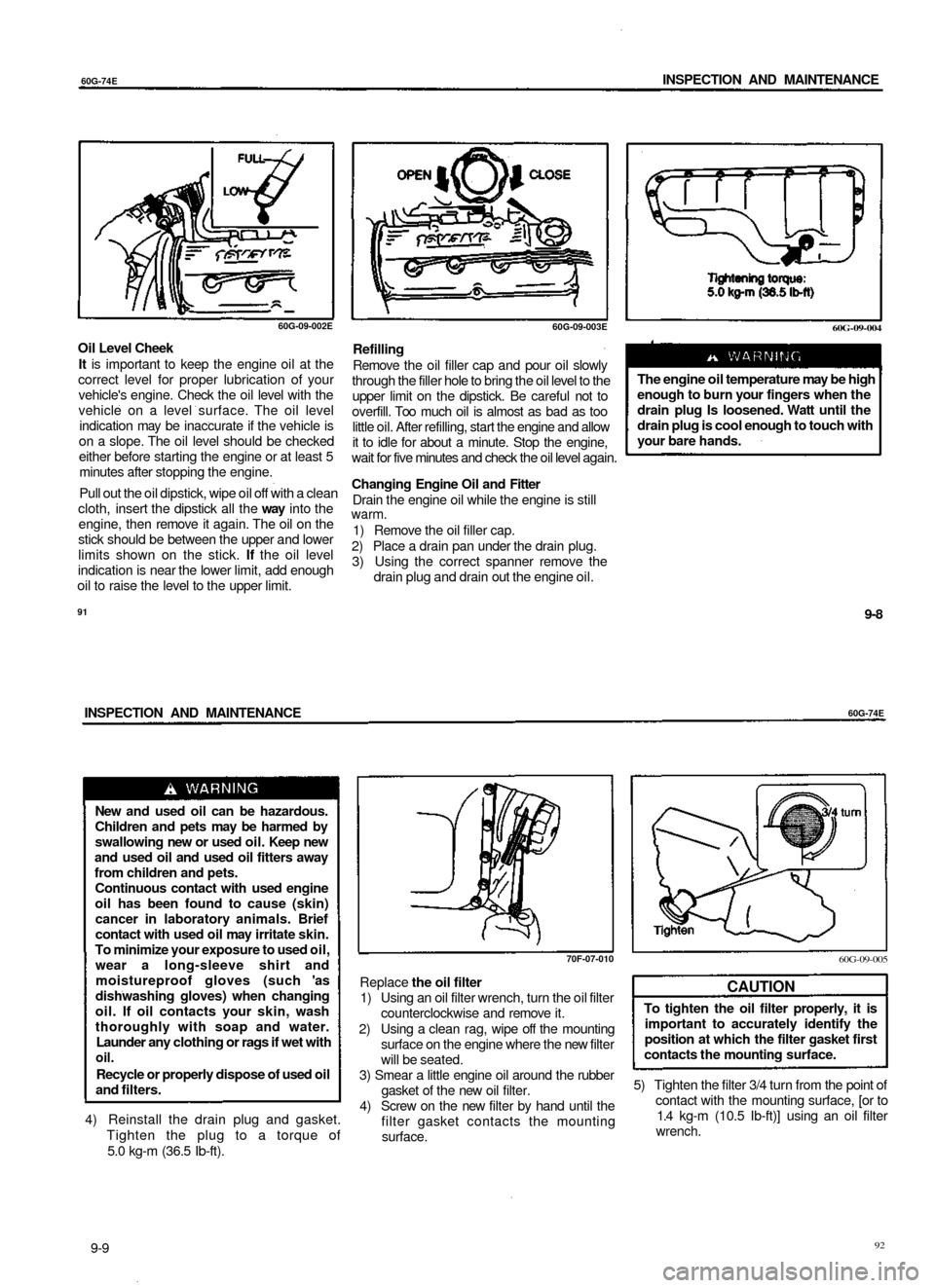

60G-09-002E

Oil Level Cheek

It is important to keep the engine oil at the

correct level for proper lubrication of your

vehicle's engine. Check the oil level with the

vehicle on a level surface. The oil level

indication may be inaccurate if the vehicle is

on a slope. The oil level should be checked

either before starting the engine or at least 5

minutes after stopping the engine.

Pull out the oil dipstick, wipe oil off with a clean

cloth, insert the dipstick all the way into the

engine, then remove it again. The oil on the

stick should be between the upper and lower

limits shown on the stick. If the oil level

indication is near the lower limit, add enough

oil to raise the level to the upper limit.

91

60G-09-003E

Refilling

Remove the oil filler cap and pour oil slowly

through the filler hole to bring the oil level to the

upper limit on the dipstick. Be careful not to

overfill. Too much oil is almost as bad as too

little oil. After refilling, start the engine and allow

it to idle for about a minute. Stop the engine,

wait for five minutes and check the oil level again.

Changing Engine Oil and Fitter

Drain the engine oil while the engine is still

warm.

1) Remove the oil filler cap.

2) Place a drain pan under the drain plug.

3) Using the correct spanner remove the

drain plug and drain out the engine oil.

60G-09-004

The engine oil temperature may be high

enough to burn your fingers when the

drain plug Is loosened. Watt until the

drain plug is cool enough to touch with

your bare hands.

9-8

INSPECTION AND MAINTENANCE

60G-74E

New and used oil can be hazardous.

Children and pets may be harmed by

swallowing new or used oil. Keep new

and used oil and used oil fitters away

from children and pets.

Continuous contact with used engine

oil has been found to cause (skin)

cancer in laboratory animals. Brief

contact with used oil may irritate skin.

To minimize your exposure to used oil,

wear a long-sleeve shirt and

moistureproof gloves (such 'as

dishwashing gloves) when changing

oil. If oil contacts your skin, wash

thoroughly with soap and water.

Launder any clothing or rags if wet with

oil.

Recycle or properly dispose of used oil

and filters.

4) Reinstall the drain plug and gasket.

Tighten the plug to a torque of

5.0 kg-m (36.5 Ib-ft).

70F-07-010

Replace the oil filter

1) Using an oil filter wrench, turn the oil filter

counterclockwise and remove it.

2) Using a clean rag, wipe off the mounting

surface on the engine where the new filter

will be seated.

3) Smear a little engine oil around the rubber

gasket of the new oil filter.

4) Screw on the new filter by hand until the

filter gasket contacts the mounting

surface.

60G-09-005

CAUTION

To tighten the oil filter properly, it is

important to accurately identify the

position at which the filter gasket first

contacts the mounting surface.

5) Tighten the filter 3/4 turn from the point of

contact with the mounting surface, [or to

1.4 kg-m (10.5 Ib-ft)] using an oil filter

wrench.

9-9

92

Page 46 of 65

60G-74E

INSPECTION AND MAINTENANCE

GEAR OIL

CAUTION

To prevent oil leakage, make sure that

the oil filter is tight, but do not

overtighten it.

Refill with oil and check for leaks.

1) Pour 3.1 litres of oil through the filler hole

and install the filler cap.

2) Start the engine and look carefully for

leaks at the oil filter and drain plug. Run

the engine at various speeds for at least 5

minutes.

3) Stop the engine and wait for 5 minutes.

Check the oil level again and add oil if

necessary. Check for leaks again.

CAUTION

When replacing the oil filter, it is

recommended that you use a genuine

MARUTI replacement filter.

60G-09-006

CAUTION

Oil leaks from around the oil filter or

drain plug indicate incorrect

installation or gasket damage. If you

find any leaks or are not sure that the

fitter has been properly tightened, have

the vehicle inspected by your MARUTI

dealer.

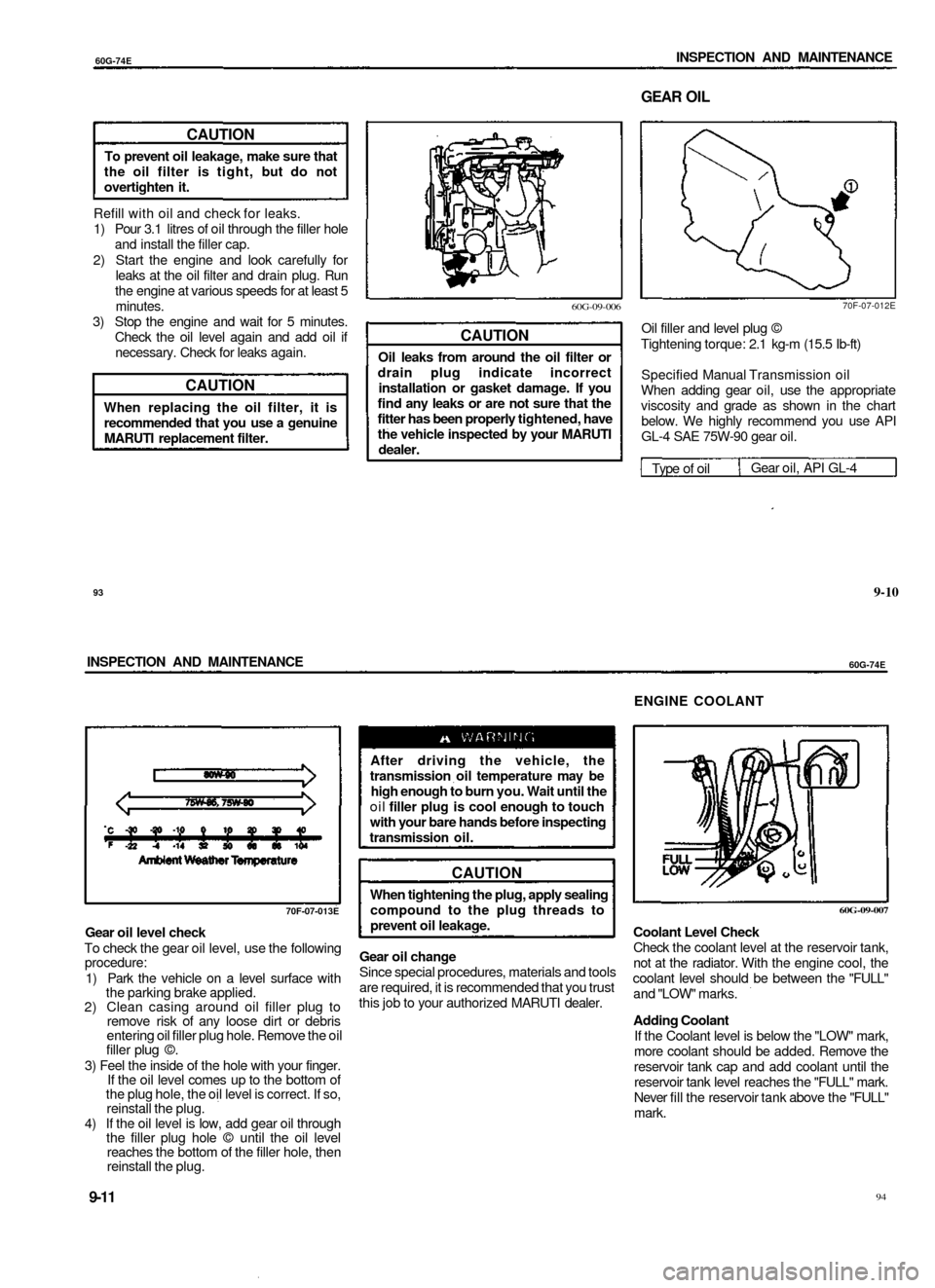

70F-07-012E

Oil filler and level plug ©

Tightening torque: 2.1 kg-m (15.5 Ib-ft)

Specified Manual Transmission oil

When adding gear oil, use the appropriate

viscosity and grade as shown in the chart

below. We highly recommend you use API

GL-4 SAE 75W-90 gear oil.

Type of oil

Gear oil, API GL-4

93

9-10

INSPECTION AND MAINTENANCE

60G-74E

ENGINE COOLANT

70F-07-013E

Gear oil level check

To check the gear oil level, use the following

procedure:

1) Park the vehicle on a level surface with

the parking brake applied.

2) Clean casing around oil filler plug to

remove risk of any loose dirt or debris

entering oil filler plug hole. Remove the oil

filler plug ©.

3) Feel the inside of the hole with your finger.

If the oil level comes up to the bottom of

the plug hole, the oil level is correct. If so,

reinstall the plug.

4) If the oil level is low, add gear oil through

the filler plug hole © until the oil level

reaches the bottom of the filler hole, then

reinstall the plug.

After driving the vehicle, the

transmission oil temperature may be

high enough to burn you. Wait until the

oil filler plug is cool enough to touch

with your bare hands before inspecting

transmission oil.

CAUTION

When tightening the plug, apply sealing

compound to the plug threads to

prevent oil leakage.

Gear oil change

Since special procedures, materials and tools

are required, it is recommended that you trust

this job to your authorized MARUTI dealer.

60G-09-007

Coolant Level Check

Check the coolant level at the reservoir tank,

not at the radiator. With the engine cool, the

coolant level should be between the "FULL"

and "LOW" marks.

Adding Coolant

If the Coolant level is below the "LOW" mark,

more coolant should be added. Remove the

reservoir tank cap and add coolant until the

reservoir tank level reaches the "FULL" mark.

Never fill the reservoir tank above the "FULL"

mark.

9-11

94

Page 52 of 65

60G-74E

INSPECTION AND MAINTENANCE

BATTERY

60G-09-022E

When installing the cover, make sure that it is

positioned so that it does not cover or foul the

air valve.

60G-09-038

Batteries produce flammable hydrogen

gas. Keep flames and sparks away from

the battery or an explosion may occur.

Never smoke when working in the

vicinity of the battery .

When checking or servicing the battery,

disconnect the negative cable. Be

careful not to cause a short circuit by

allowing metal objects to contact the

battery posts and the vehicle at the

same time.

To avoid harm to yourself or damage

to your vehicle or battery, follow the

jump starting instructions in the

EMERGENCY SERVICE section of this

manual if it is necessary to jump start

your vehicle.

The level of the battery solution must be kept

between the "UPPER" and the "LOWER" level

lines at all times. If the level is found to be

below the "LOWER" level line, add distilled

water to the "UPPER" level line. You should

periodically check the battery, battery

terminals, and battery holddown bracket for

corrosion. Remove corrosion using a stiff

brush and ammonia mixed with water, or

baking soda mixed with water. After removing

corrosion, rinse with clean water.

If your vehicle is not going to be driven for a

month or longer, disconnect the cable from

the negative terminal of the battery to help

prevent discharge.

105

9-22

INSPECTION AND MAINTENANCE

60G-74E

FUSES

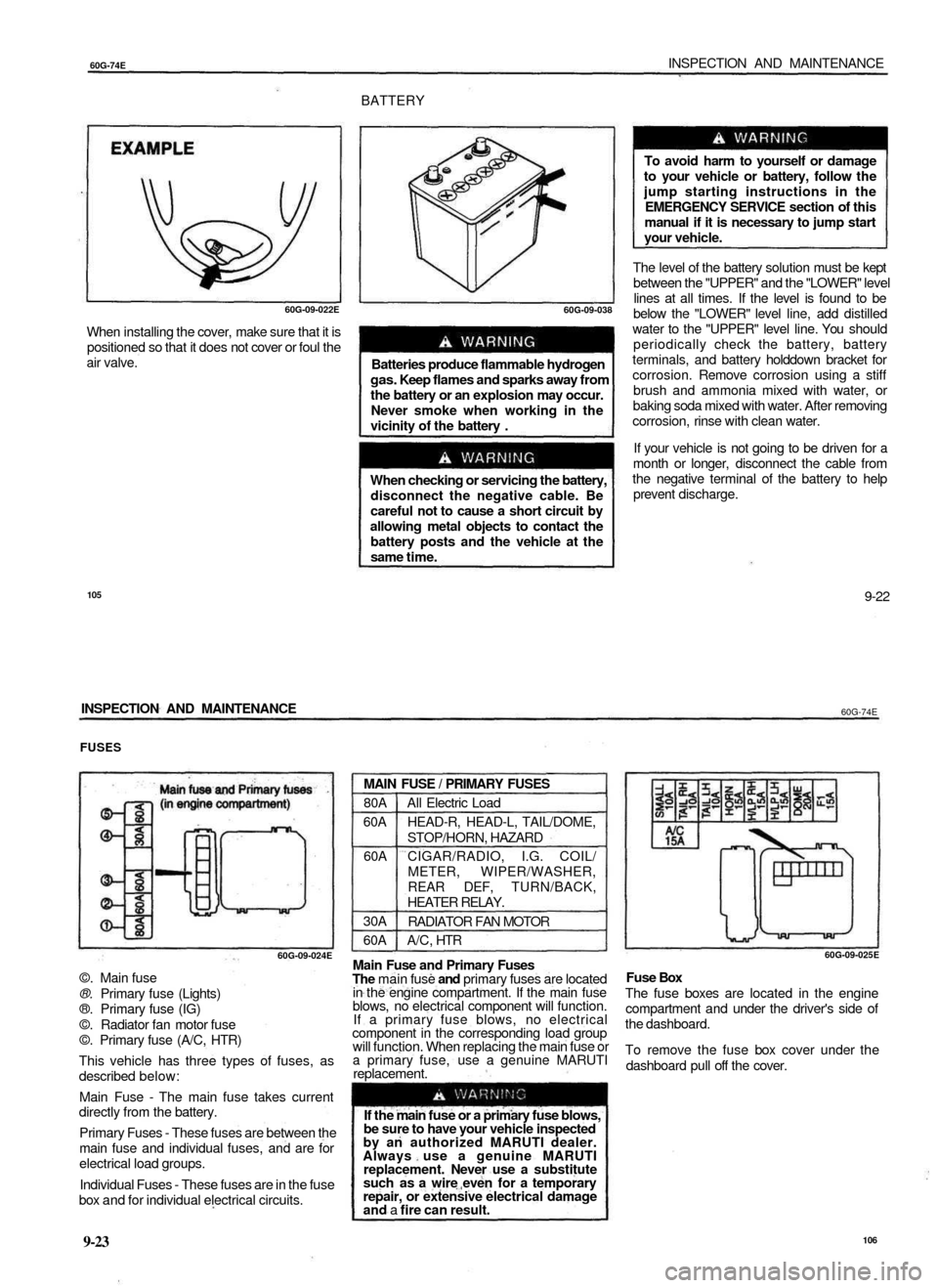

60G-09-024E

©. Main fuse

®. Primary fuse (Lights)

®. Primary fuse (IG)

©. Radiator fan motor fuse

©. Primary fuse (A/C, HTR)

This vehicle has three types of fuses, as

described below:

Main Fuse - The main fuse takes current

directly from the battery.

Primary Fuses - These fuses are between the

main fuse and individual fuses, and are for

electrical load groups.

Individual Fuses - These fuses are in the fuse

box and for individual electrical circuits.

MAIN FUSE / PRIMARY FUSES

80A

60A

60A

30A

60A

All Electric Load

HEAD-R, HEAD-L, TAIL/DOME,

STOP/HORN, HAZARD

CIGAR/RADIO, I.G. COIL/

METER, WIPER/WASHER,

REAR DEF, TURN/BACK,

HEATER RELAY.

RADIATOR FAN MOTOR

A/C, HTR

Main Fuse and Primary Fuses

The main fuse and primary fuses are located

in the engine compartment. If the main fuse

blows, no electrical component will function.

If a primary fuse blows, no electrical

component in the corresponding load group

will function. When replacing the main fuse or

a primary fuse, use a genuine MARUTI

replacement.

If the main fuse or a primary fuse blows,

be sure to have your vehicle inspected

by an authorized MARUTI dealer.

Always use a genuine MARUTI

replacement. Never use a substitute

such as a wire even for a temporary

repair, or extensive electrical damage

and a fire can result.

60G-09-025E

Fuse Box

The fuse boxes are located in the engine

compartment and under the driver's side of

the dashboard.

To remove the fuse box cover under the

dashboard pull off the cover.

9-23

106