Service SUZUKI BALENO 1999 1.G User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1999, Model line: BALENO, Model: SUZUKI BALENO 1999 1.GPages: 65, PDF Size: 3.28 MB

Page 43 of 65

60G-74E

INSPECTION AND MAINTENANCE

Interval: This interval should be Judged

by odometer reading or months,

whichever comes first.

km (x 1,000)

months

FUEL

1. Air cleaner Paved-road

Dusty condition

2. Accelerator cable and Throttle shafts

3. Fuel tank cap, fuel lines & connections(leakage,damage)

4. Fuel filter (leakage)

CLUTCH AND TRANSMISSION

1. Clutch pedal (play)

2. Clutch slipping (dragging or excessive damage)

3. Manual Transmission/Transfer and Differential oil (level, leakage)

DRIVE SHAFTS

1. Drive shafts boots (bent of boots damage)

BRAKE

1. Brake fluid (level, leakage)

2. Brake pedal (pedal-to-wall clearance)

3. Parking brake lever and cable (play, damage)

4. a. Brake discs and pads, (wear)

b. Brake drums & shoes

5. Master cylinder and wheel cylinder or calliper (oil leakage.boot kit)

6. Brake hoses and pipes (leakage, damage)

FREE

1

1

INSPECTIONS

5

6

10

12

Clean every 5,000 km. F

PERIODIC MAINTENANCE

20

24

30

36

40

48

Replace every 40,000 krr

50

60

SERVICE

60

72

AT

70

84

COST

80

96

Clean every 2,500 km or as required. Replace every 40,000 km. More frequent

replacement if dust condition is severe.

-

-

I

I

I

I

-

I

I

I

-

-

I

I

I&L

I

I

I

I

I

I

I

I

I

I

-

I

I

I&L

-

I

I

I

I

I

I

I

I

I

I

I

I

I&L

-

I

I

I

R

I

R

I

I

I

I

I

I

I&L

-

I

I

I

I

I

I

I

I

I

I

I

I

I&L

I

R

I

I

R

I

R

I

I

I

I

R

I

I&L

-

I

I

I

I

I

I

I

I

I

I

I

I

I&L

-

I

I

I

R

I

R

I

I

I

I

I

I

I&L

-

I

I

I

I

I

I

I

I

I

I

I

I

I&L

I

R

I

I

R

I

R

I

I

I

I

R

I

87

9-4

INSPECTION AND MAINTENANCE

60G-74E

Interval: This Interval should be judged

by odometer reading or months,

whichever comes first

km (x 1,000)

months

WHEEL

1. Tyres (air pressure, abnormal wear, crack, ROTATION)

2. Wheels (damage)

3. Front wheel bearings (loose, damage)

4. Rear wheel bearings (loose, damage)

FRONT AND REAR SUSPENSION

1. Suspension strut (oil leakage, damage)

2. Suspension arms and knuckle supports (loose.damage)

3. Rear spring (damage)

4. Shock absorbers (oil leakage, damage)

5. All bolts and nuts (loose)

6. Suspension arms and Tension rods

STEERING

1. Steering wheel (play, loose)

2. Power steering fluid (level, leakage)/connections

3. All rods and arms (loose, damage, wear)

ELECTRICAL

1. Battery electrolyte (level, leakage)

2. Wiring harness connection (looseness, damage)

3. Lighting system (operation, stains, damage)

4. Horn (operation)

5. System voltage

BODY

1. All chassis bolts and nuts (tighten)

2. All Latches, Hinges & Locks (function)

FREE

1

1

INSPECTIONS

5

6

Rotate and

I

-

-

I

-

-

I

-

-

I

I

I

I

-

I

I

-

-

I

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

I

I&L

10

12

PERIODIC

20

24

inspect every 5,000

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

T

I&L

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

T

I&L

30

36

km

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

T

I&L

MAINTENANCE

40

48

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

T

I&L

50

60

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

T

I&L

SERVICE

60

72

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

T

I&L

AT

70

84

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

T

I&L

COST

80

96

I

I

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

T

I&L

9-5

88

Page 44 of 65

60G-74E

INSPECTION AND MAINTENANCE

Interval: This Interval should be judged

by odometer reading or months,

whichever comes first.

km (x 1,000)

months

ROAD TEST

1. Operation of Brakes, Gear shifting & speedometer

2. Body and Chassis noise

AIR CONDITIONER (if equipped)

1. Check belt tension

2. Check Receiver Drier bubbles.

3. Tighten compressor mounting bolts

4. Check all hose joints, tighten if necessary

5. Check functioning of Recirc flap .*

6. Clean condenser with low pressure water

7. Check belt for frayed edges, change if necessary

8. Check all mounting bolts

FREE

1

1

I

I

I

I

—

I

I

_

-

-

INSPECTIONS

5

6

I

I

I

I

T

I

I

C

I

I

10

12

I

I

I

I

T

I

I

C

I

I

PERIODIC

20

24

I

I

I

I

T

I

I

C

I

I

30

36

I

I

I

I

T

I

I

C

I

I

MAINTENANCE

40

48

I

I

I

I

T

I

I

C

I

I

50

60

I

I

I

I

T

I

I

C

I

I

SERVICE

60

72

I

I

I

I

T

I

I

C

I

I

AT,

70

84

I

I

I

I

T

I

I

C

I

I

COST

80

96

I

I

I

I

T

I

I

C

I

I

The rear shock absorbers are filled with

high pressure gas. Never attempt to

disassemble it or throw it into a fire.

Avoid storing it near a heater or heating

device. When scrapping the absorber,

the gas must be released from the

absorber safely. Ask your dealer for

assistance.

89

9-6

INSPECTION AND MAINTENANCE

60G-74E

All maintenance should be carried

out with the Ignition switch in the

"OFF" position and the car parked

securely on the level ground unless

otherwise specified.

If you are In any way unsure of your

ability to undertake a task, then do

not start it but contact your Maruti

dealer to perform the work for you.

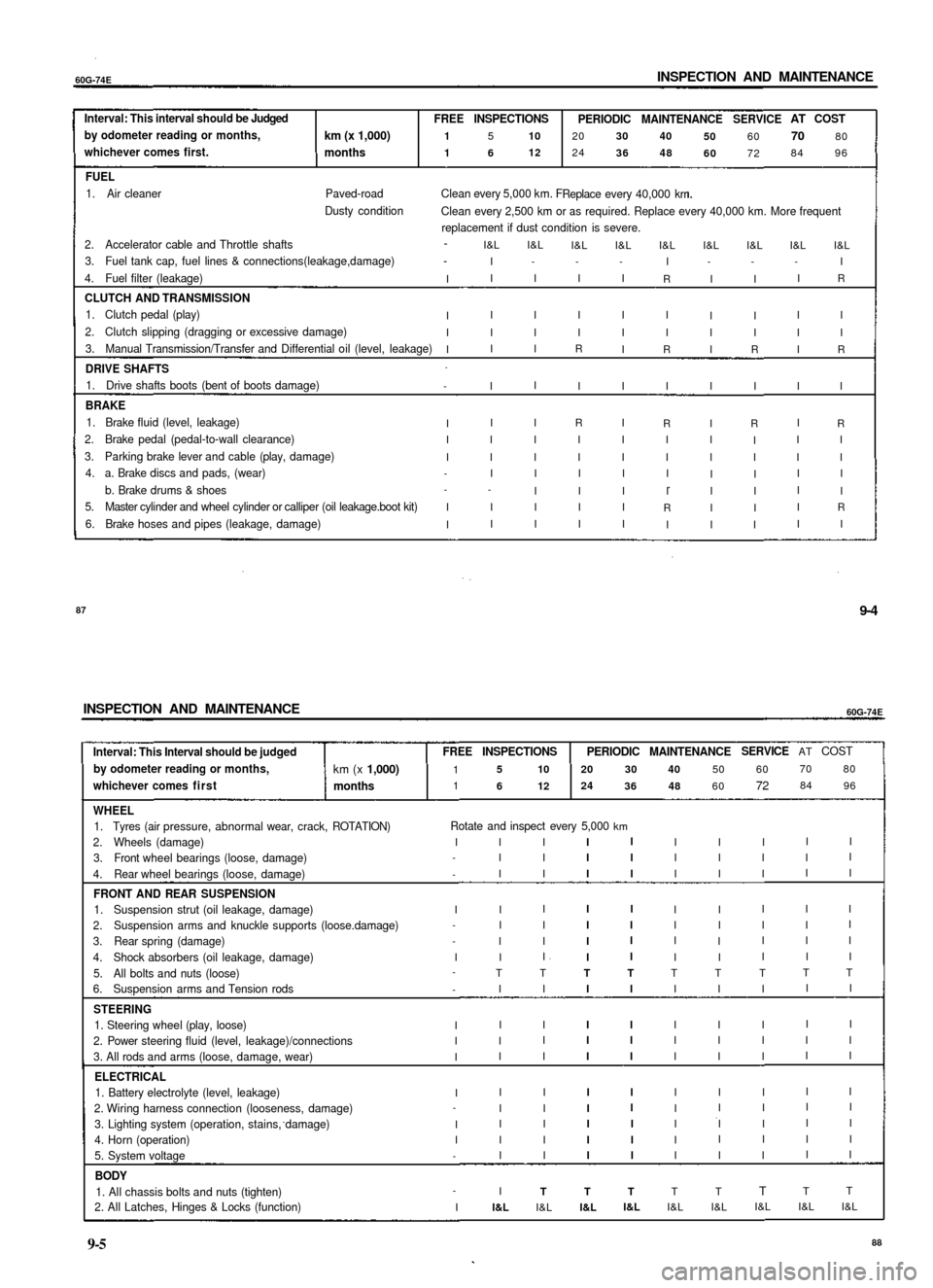

ENGINE OIL AND FILTER

Specified oil

Be sure that the engine oil you use comes

under the API classification of SF, SG or SH.

Select the appropriate oil viscosity according

to the above chart.

9-7

90

70F-07-004E

Page 51 of 65

60G-74E

INSPECTION AND MAINTENANCE

Hitting curbs and running over rocks

can damage tyres and affect wheel

alignment. Be sure to have tyres and

wheel alignment checked periodically

by your MARUTI dealer.

4) Check for loose wheel nuts.

5) Check that there are no nails, stones, or

other objects sticking into the tyres.

Your MARUTI is equipped with tyres

which are all the same type and size.

This is important to ensure proper

steering and handling of the vehicle.

Never mix tyres of different size or type

on the four wheels of your vehicle. The

size and type of tyres used should be

only those approved by MARUTI as

standard or optional equipment for

your vehicle.

Replacing the wheels and tyres

equipped on your vehicle with certain

combinations of aftermarket wheels

and tyres can significantly change the

steering and handling characteristics

of your vehicle. Therefore, use only

those wheel and tyre combinations

approved by MARUTI as standard or

optional equipment for your vehicle.

CAUTION

Replacing the original tyres with tyres

of a different size may result in false

speedometer or odometer readings.

60G-09-019E

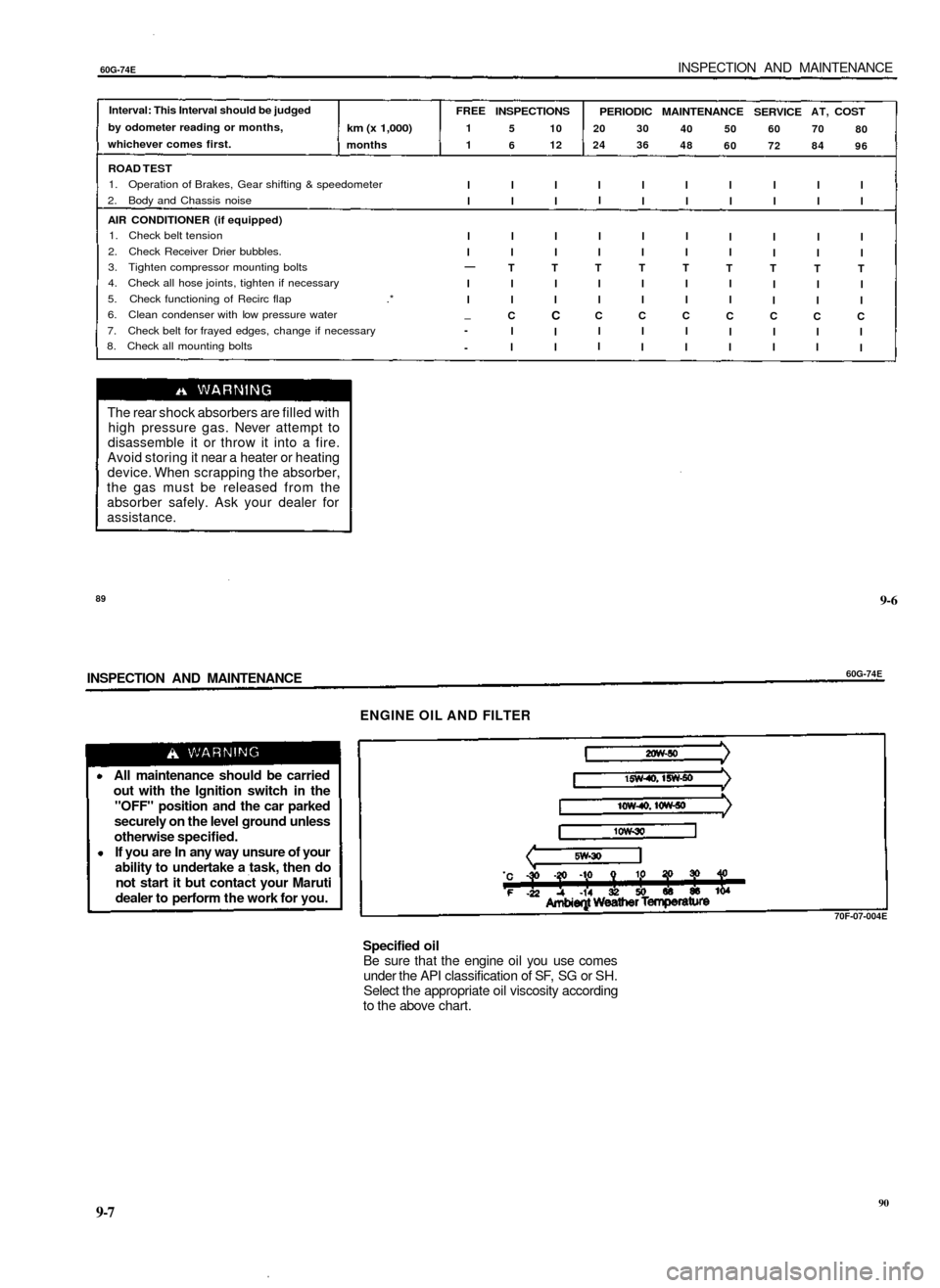

Tyre Rotation

To avoid uneven wear of your tyres and to

prolong their life, rotate the tyres as illustrated.

Tyres should be rotated every 5,000 km as

recommended in the periodic maintenance

schedule. After rotation, adjust front and rear

tyre pressures to the specification listed on

your vehicle's Tyre Inflation Pressure Label.

103

9-20

INSPECTION AND MAINTENANCE

60G-74E

60G-06-009

5)

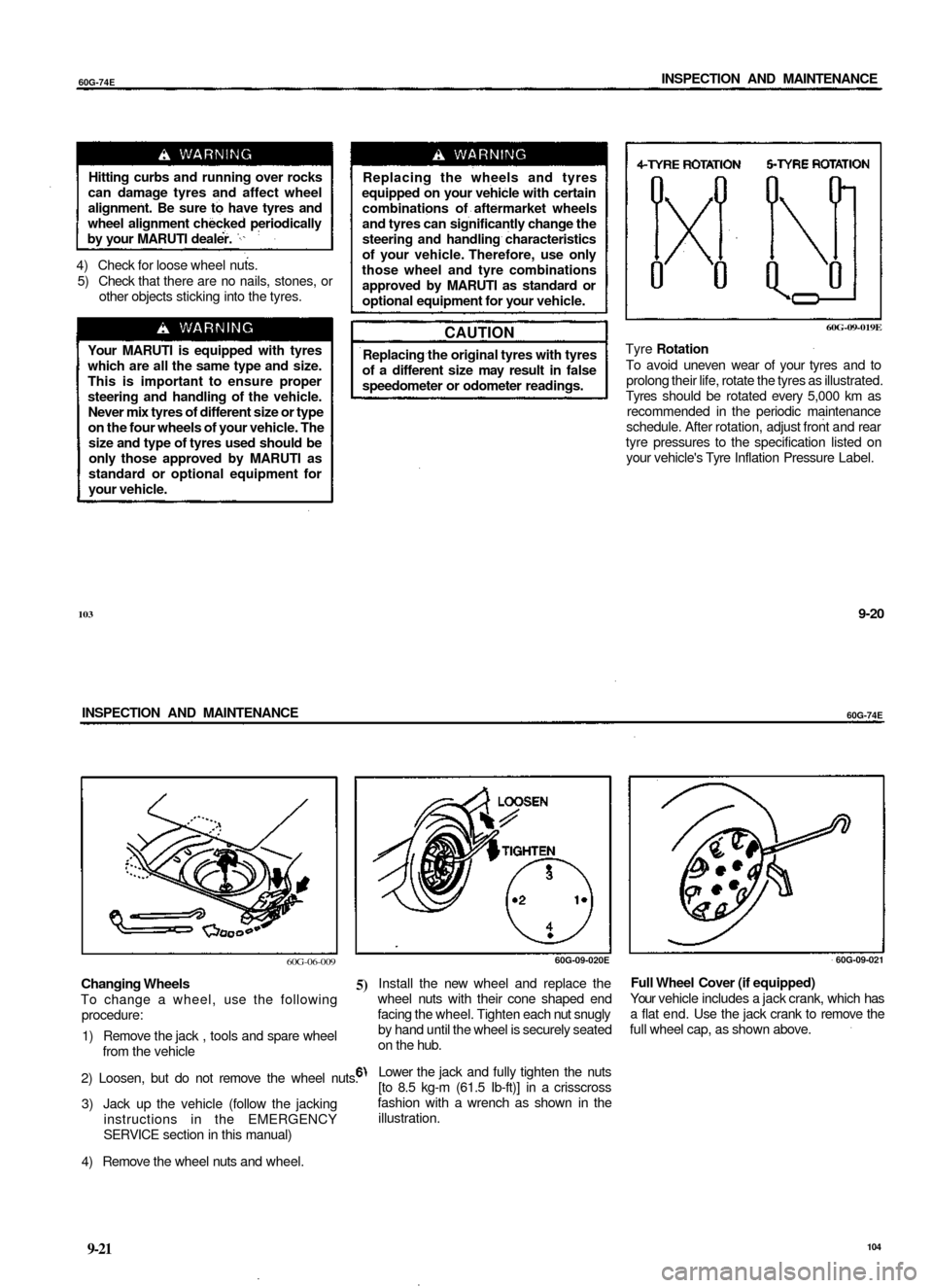

Changing Wheels

To change a wheel, use the following

procedure:

1) Remove the jack , tools and spare wheel

from the vehicle

2) Loosen, but do not remove the wheel nuts. '

3) Jack up the vehicle (follow the jacking

instructions in the EMERGENCY

SERVICE section in this manual)

4) Remove the wheel nuts and wheel.

60G-09-020E

Install the new wheel and replace the

wheel nuts with their cone shaped end

facing the wheel. Tighten each nut snugly

by hand until the wheel is securely seated

on the hub.

Lower the jack and fully tighten the nuts

[to 8.5 kg-m (61.5 Ib-ft)] in a crisscross

fashion with a wrench as shown in the

illustration.

60G-09-021

Full Wheel Cover (if equipped)

Your vehicle includes a jack crank, which has

a flat end. Use the jack crank to remove the

full wheel cap, as shown above.

9-21

104

Page 52 of 65

60G-74E

INSPECTION AND MAINTENANCE

BATTERY

60G-09-022E

When installing the cover, make sure that it is

positioned so that it does not cover or foul the

air valve.

60G-09-038

Batteries produce flammable hydrogen

gas. Keep flames and sparks away from

the battery or an explosion may occur.

Never smoke when working in the

vicinity of the battery .

When checking or servicing the battery,

disconnect the negative cable. Be

careful not to cause a short circuit by

allowing metal objects to contact the

battery posts and the vehicle at the

same time.

To avoid harm to yourself or damage

to your vehicle or battery, follow the

jump starting instructions in the

EMERGENCY SERVICE section of this

manual if it is necessary to jump start

your vehicle.

The level of the battery solution must be kept

between the "UPPER" and the "LOWER" level

lines at all times. If the level is found to be

below the "LOWER" level line, add distilled

water to the "UPPER" level line. You should

periodically check the battery, battery

terminals, and battery holddown bracket for

corrosion. Remove corrosion using a stiff

brush and ammonia mixed with water, or

baking soda mixed with water. After removing

corrosion, rinse with clean water.

If your vehicle is not going to be driven for a

month or longer, disconnect the cable from

the negative terminal of the battery to help

prevent discharge.

105

9-22

INSPECTION AND MAINTENANCE

60G-74E

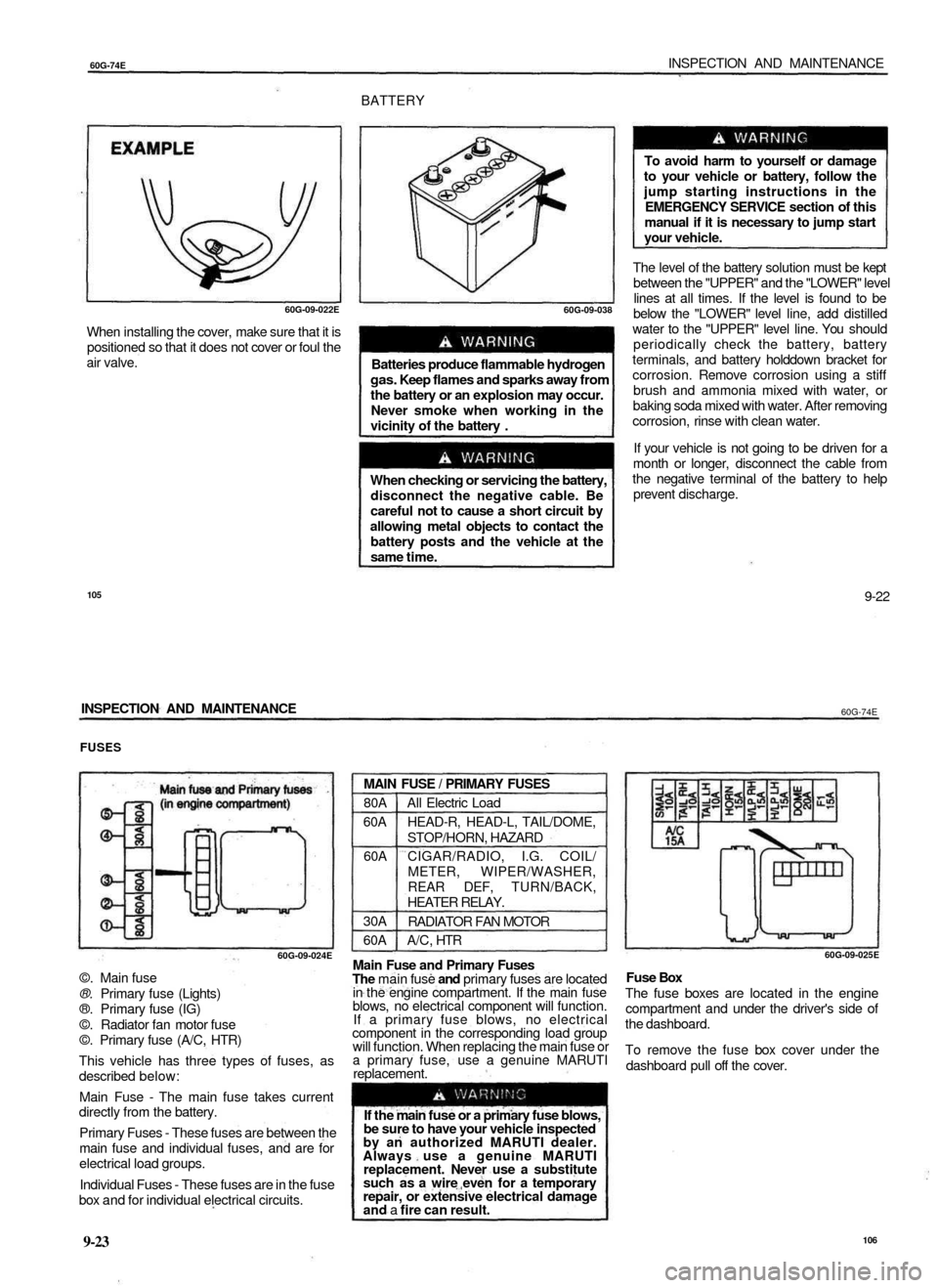

FUSES

60G-09-024E

©. Main fuse

®. Primary fuse (Lights)

®. Primary fuse (IG)

©. Radiator fan motor fuse

©. Primary fuse (A/C, HTR)

This vehicle has three types of fuses, as

described below:

Main Fuse - The main fuse takes current

directly from the battery.

Primary Fuses - These fuses are between the

main fuse and individual fuses, and are for

electrical load groups.

Individual Fuses - These fuses are in the fuse

box and for individual electrical circuits.

MAIN FUSE / PRIMARY FUSES

80A

60A

60A

30A

60A

All Electric Load

HEAD-R, HEAD-L, TAIL/DOME,

STOP/HORN, HAZARD

CIGAR/RADIO, I.G. COIL/

METER, WIPER/WASHER,

REAR DEF, TURN/BACK,

HEATER RELAY.

RADIATOR FAN MOTOR

A/C, HTR

Main Fuse and Primary Fuses

The main fuse and primary fuses are located

in the engine compartment. If the main fuse

blows, no electrical component will function.

If a primary fuse blows, no electrical

component in the corresponding load group

will function. When replacing the main fuse or

a primary fuse, use a genuine MARUTI

replacement.

If the main fuse or a primary fuse blows,

be sure to have your vehicle inspected

by an authorized MARUTI dealer.

Always use a genuine MARUTI

replacement. Never use a substitute

such as a wire even for a temporary

repair, or extensive electrical damage

and a fire can result.

60G-09-025E

Fuse Box

The fuse boxes are located in the engine

compartment and under the driver's side of

the dashboard.

To remove the fuse box cover under the

dashboard pull off the cover.

9-23

106

Page 56 of 65

60G-74E

INSPECTION AND MAINTENANCE

70F-07-060

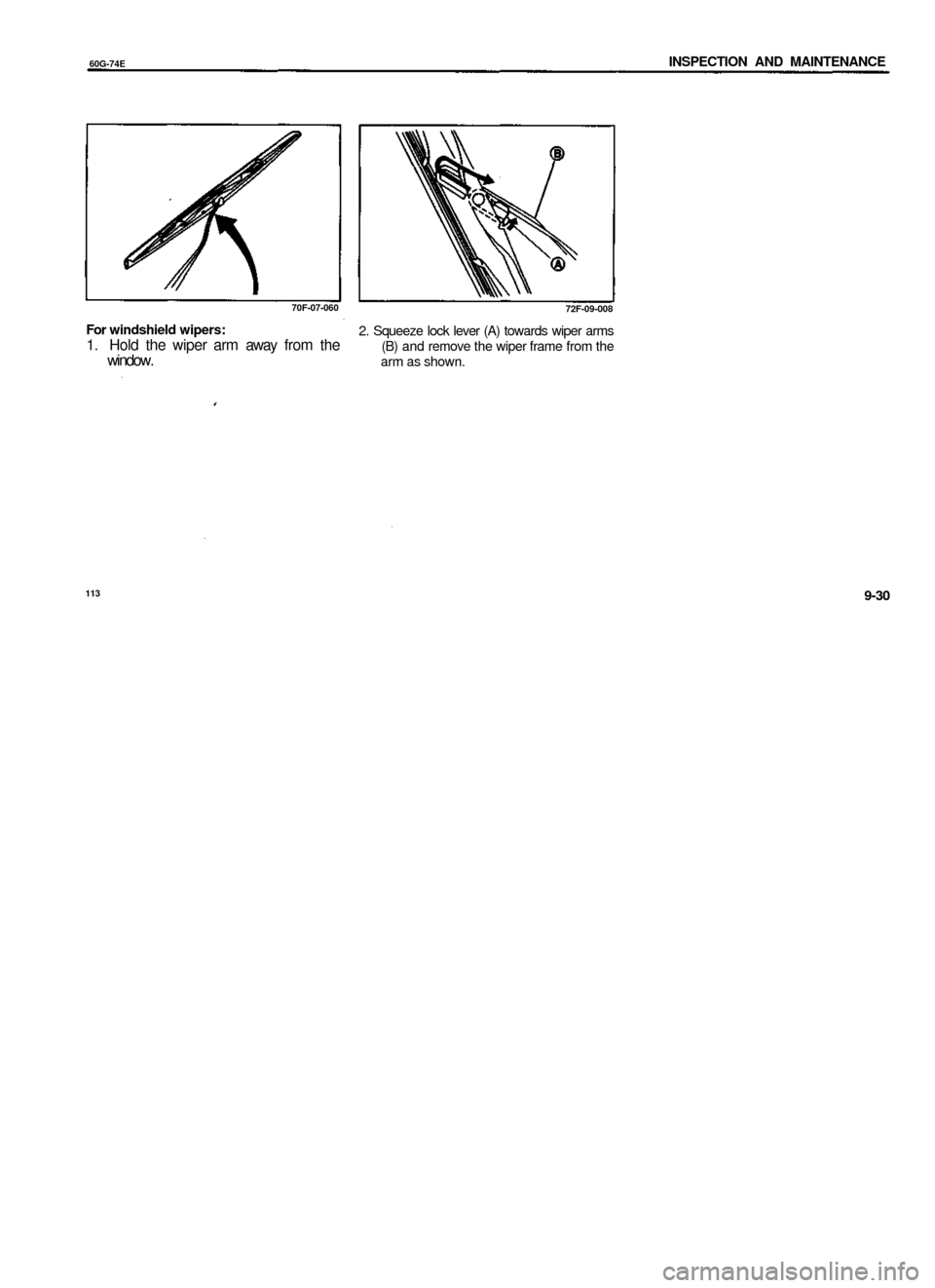

For windshield wipers:

1. Hold the wiper arm away from the

window.

72F-09-008

2. Squeeze lock lever (A) towards wiper arms

(B) and remove the wiper frame from the

arm as shown.

113

9-30

60G-74E

EMERGENCY SERVICE

EMERGENCY SERVICE

Jacking Instructions 10-1

Jump Starting Instructions 10-2

Towing 10-4

Emergency Remedies 10-4

Warning Triangle 10-5

115

Page 57 of 65

60G-74E

INSPECTION AND MAINTENANCE

70F-07-060

For windshield wipers:

1. Hold the wiper arm away from the

window.

72F-09-008

2. Squeeze lock lever (A) towards wiper arms

(B) and remove the wiper frame from the

arm as shown.

113

9-30

60G-74E

EMERGENCY SERVICE

EMERGENCY SERVICE

Jacking Instructions 10-1

Jump Starting Instructions 10-2

Towing 10-4

Emergency Remedies 10-4

Warning Triangle 10-5

115

Page 58 of 65

EMERGENCY SERVICE

60G-74E

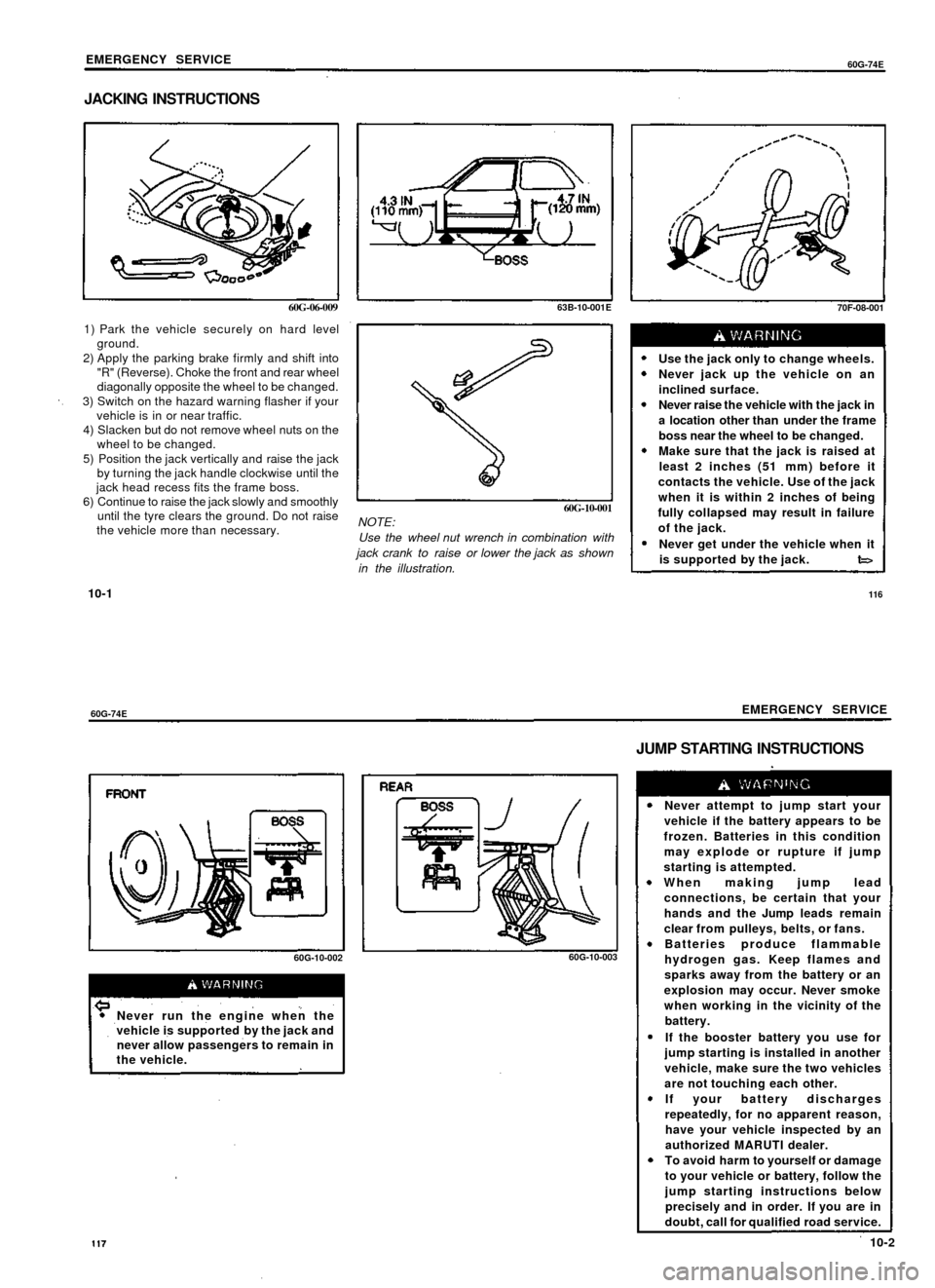

JACKING INSTRUCTIONS

60G-06-009

1) Park the vehicle securely on hard level

ground.

2) Apply the parking brake firmly and shift into

"R" (Reverse). Choke the front and rear wheel

diagonally opposite the wheel to be changed.

3) Switch on the hazard warning flasher if your

vehicle is in or near traffic.

4) Slacken but do not remove wheel nuts on the

wheel to be changed.

5) Position the jack vertically and raise the jack

by turning the jack handle clockwise until the

jack head recess fits the frame boss.

6) Continue to raise the jack slowly and smoothly

until the tyre clears the ground. Do not raise

the vehicle more than necessary.

10-1

63B-10-001E

70F-08-001

60G-10-001

NOTE:

Use the wheel nut wrench in combination with

jack crank to raise or lower the jack as shown

in the illustration.

Use the jack only to change wheels.

Never jack up the vehicle on an

inclined surface.

Never raise the vehicle with the jack in

a location other than under the frame

boss near the wheel to be changed.

Make sure that the jack is raised at

least 2 inches (51 mm) before it

contacts the vehicle. Use of the jack

when it is within 2 inches of being

fully collapsed may result in failure

of the jack.

Never get under the vehicle when it

is supported by the jack. t=>

116

60G-74E

EMERGENCY SERVICE

JUMP STARTING INSTRUCTIONS

60G-10-002

60G-10-003

Never run the engine when the

vehicle is supported by the jack and

never allow passengers to remain in

the vehicle.

Never attempt to jump start your

vehicle if the battery appears to be

frozen. Batteries in this condition

may explode or rupture if jump

starting is attempted.

When making jump lead

connections, be certain that your

hands and the Jump leads remain

clear from pulleys, belts, or fans.

Batteries produce flammable

hydrogen gas. Keep flames and

sparks away from the battery or an

explosion may occur. Never smoke

when working in the vicinity of the

battery.

If the booster battery you use for

jump starting is installed in another

vehicle, make sure the two vehicles

are not touching each other.

If your battery discharges

repeatedly, for no apparent reason,

have your vehicle inspected by an

authorized MARUTI dealer.

To avoid harm to yourself or damage

to your vehicle or battery, follow the

jump starting instructions below

precisely and in order. If you are in

doubt, call for qualified road service.

10-2

Page 59 of 65

EMERGENCY SERVICE

60G-74E

CAUTION

Vehicle equipped with electronic fuel

injection system will not start by

pushing or towing as the fuel pump

will not work in this condition. This

starting method could also result in

permanent damage to the catalytic

converter. Use jump leads to start a

vehicle with a weak or flat battery.

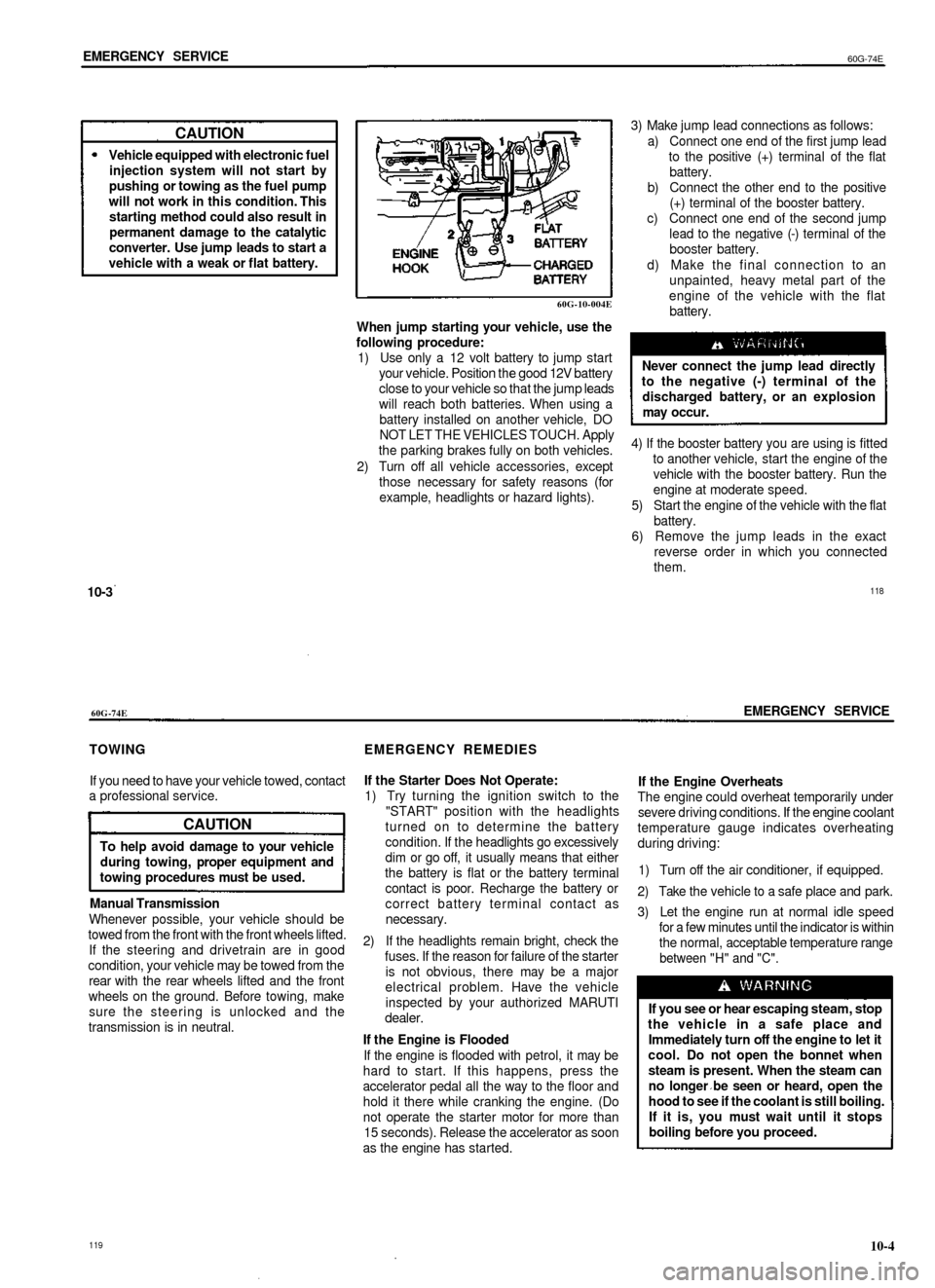

60G-10-004E

When jump starting your vehicle, use the

following procedure:

1) Use only a 12 volt battery to jump start

your vehicle. Position the good 12V battery

close to your vehicle so that the jump leads

will reach both batteries. When using a

battery installed on another vehicle, DO

NOT LET THE VEHICLES TOUCH. Apply

the parking brakes fully on both vehicles.

2) Turn off all vehicle accessories, except

those necessary for safety reasons (for

example, headlights or hazard lights).

3) Make jump lead connections as follows:

a) Connect one end of the first jump lead

to the positive (+) terminal of the flat

battery.

b) Connect the other end to the positive

(+) terminal of the booster battery.

c) Connect one end of the second jump

lead to the negative (-) terminal of the

booster battery.

d) Make the final connection to an

unpainted, heavy metal part of the

engine of the vehicle with the flat

battery.

Never connect the jump lead directly

to the negative (-) terminal of the

discharged battery, or an explosion

may occur.

10-3

4) If the booster battery you are using is fitted

to another vehicle, start the engine of the

vehicle with the booster battery. Run the

engine at moderate speed.

5) Start the engine of the vehicle with the flat

battery.

6) Remove the jump leads in the exact

reverse order in which you connected

them.

118

60G-74E

EMERGENCY SERVICE

TOWING

If you need to have your vehicle towed, contact

a professional service.

CAUTION

To help avoid damage to your vehicle

during towing, proper equipment and

towing procedures must be used.

Manual Transmission

Whenever possible, your vehicle should be

towed from the front with the front wheels lifted.

If the steering and drivetrain are in good

condition, your vehicle may be towed from the

rear with the rear wheels lifted and the front

wheels on the ground. Before towing, make

sure the steering is unlocked and the

transmission is in neutral.

EMERGENCY REMEDIES

If the Starter Does Not Operate:

1) Try turning the ignition switch to the

"START" position with the headlights

turned on to determine the battery

condition. If the headlights go excessively

dim or go off, it usually means that either

the battery is flat or the battery terminal

contact is poor. Recharge the battery or

correct battery terminal contact as

necessary.

2) If the headlights remain bright, check the

fuses. If the reason for failure of the starter

is not obvious, there may be a major

electrical problem. Have the vehicle

inspected by your authorized MARUTI

dealer.

If the Engine is Flooded

If the engine is flooded with petrol, it may be

hard to start. If this happens, press the

accelerator pedal all the way to the floor and

hold it there while cranking the engine. (Do

not operate the starter motor for more than

15 seconds). Release the accelerator as soon

as the engine has started.

If the Engine Overheats

The engine could overheat temporarily under

severe driving conditions. If the engine coolant

temperature gauge indicates overheating

during driving:

1) Turn off the air conditioner, if equipped.

2) Take the vehicle to a safe place and park.

3) Let the engine run at normal idle speed

for a few minutes until the indicator is within

the normal, acceptable temperature range

between "H" and "C".

If you see or hear escaping steam, stop

the vehicle in a safe place and

Immediately turn off the engine to let it

cool. Do not open the bonnet when

steam is present. When the steam can

no longer be seen or heard, open the

hood to see if the coolant is still boiling.

If it is, you must wait until it stops

boiling before you proceed.

119

10-4

Page 60 of 65

EMERGENCY SERVICE

60G-74E

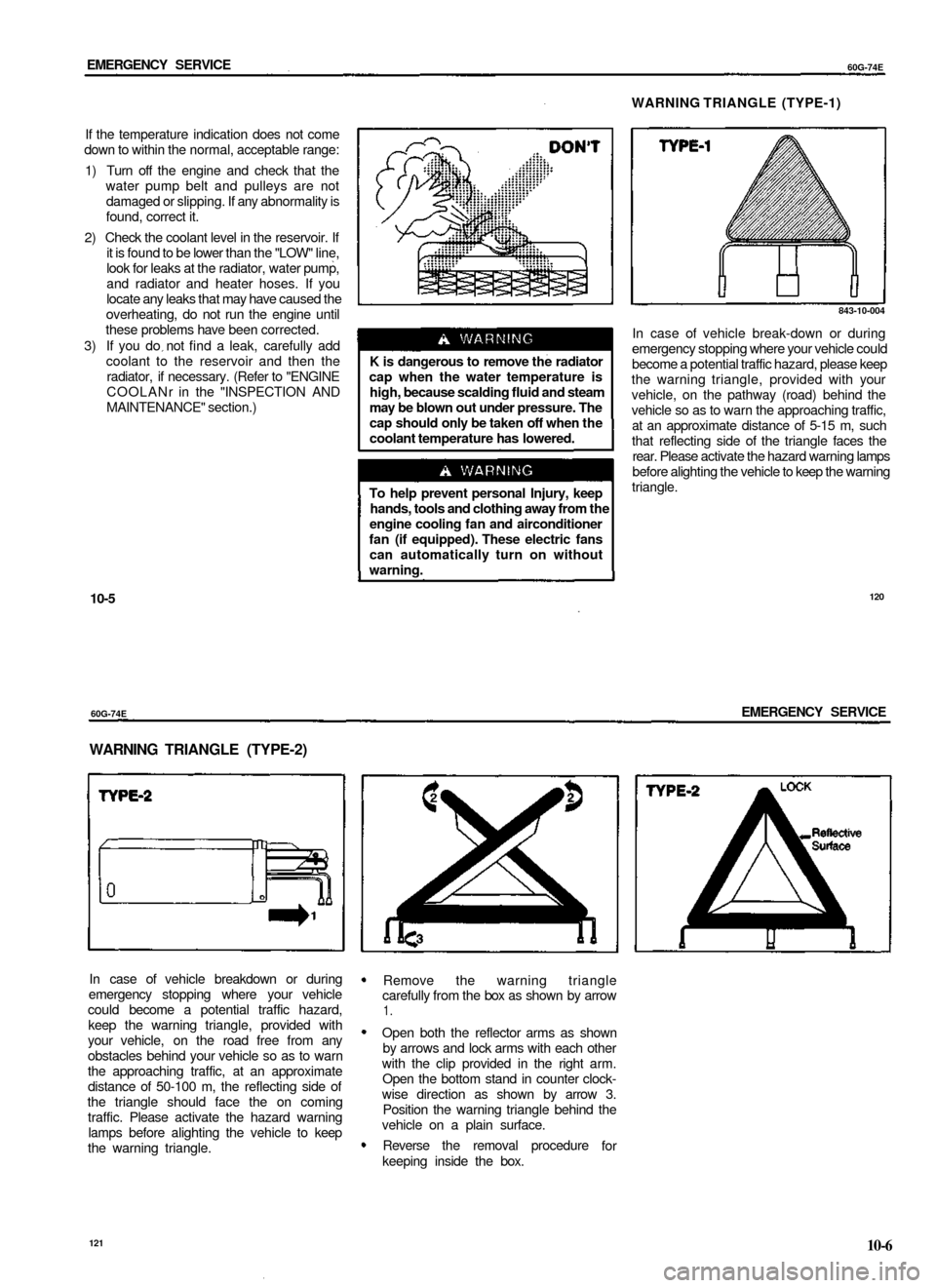

WARNING TRIANGLE (TYPE-1)

If the temperature indication does not come

down to within the normal, acceptable range:

1) Turn off the engine and check that the

water pump belt and pulleys are not

damaged or slipping. If any abnormality is

found, correct it.

2) Check the coolant level in the reservoir. If

it is found to be lower than the "LOW" line,

look for leaks at the radiator, water pump,

and radiator and heater hoses. If you

locate any leaks that may have caused the

overheating, do not run the engine until

these problems have been corrected.

3) If you do not find a leak, carefully add

coolant to the reservoir and then the

radiator, if necessary. (Refer to "ENGINE

COOLANr in the "INSPECTION AND

MAINTENANCE" section.)

K is dangerous to remove the radiator

cap when the water temperature is

high, because scalding fluid and steam

may be blown out under pressure. The

cap should only be taken off when the

coolant temperature has lowered.

To help prevent personal Injury, keep

hands, tools and clothing away from the

engine cooling fan and airconditioner

fan (if equipped). These electric fans

can automatically turn on without

warning.

843-10-004

In case of vehicle break-down or during

emergency stopping where your vehicle could

become a potential traffic hazard, please keep

the warning triangle, provided with your

vehicle, on the pathway (road) behind the

vehicle so as to warn the approaching traffic,

at an approximate distance of 5-15 m, such

that reflecting side of the triangle faces the

rear. Please activate the hazard warning lamps

before alighting the vehicle to keep the warning

triangle.

10-5

120

60G-74E

EMERGENCY SERVICE

WARNING TRIANGLE (TYPE-2)

In case of vehicle breakdown or during

emergency stopping where your vehicle

could become a potential traffic hazard,

keep the warning triangle, provided with

your vehicle, on the road free from any

obstacles behind your vehicle so as to warn

the approaching traffic, at an approximate

distance of 50-100 m, the reflecting side of

the triangle should face the on coming

traffic. Please activate the hazard warning

lamps before alighting the vehicle to keep

the warning triangle.

Remove the warning triangle

carefully from the box as shown by arrow

1.

Open both the reflector arms as shown

by arrows and lock arms with each other

with the clip provided in the right arm.

Open the bottom stand in counter clock-

wise direction as shown by arrow 3.

Position the warning triangle behind the

vehicle on a plain surface.

Reverse the removal procedure

keeping inside the box.

for

121

10-6

Page 63 of 65

60G-74E

GENERAL INFORMATION

GENERAL INFORMATION

Vehicle Identification 12-1

127

GENERAL INFORMATION

60G-74E

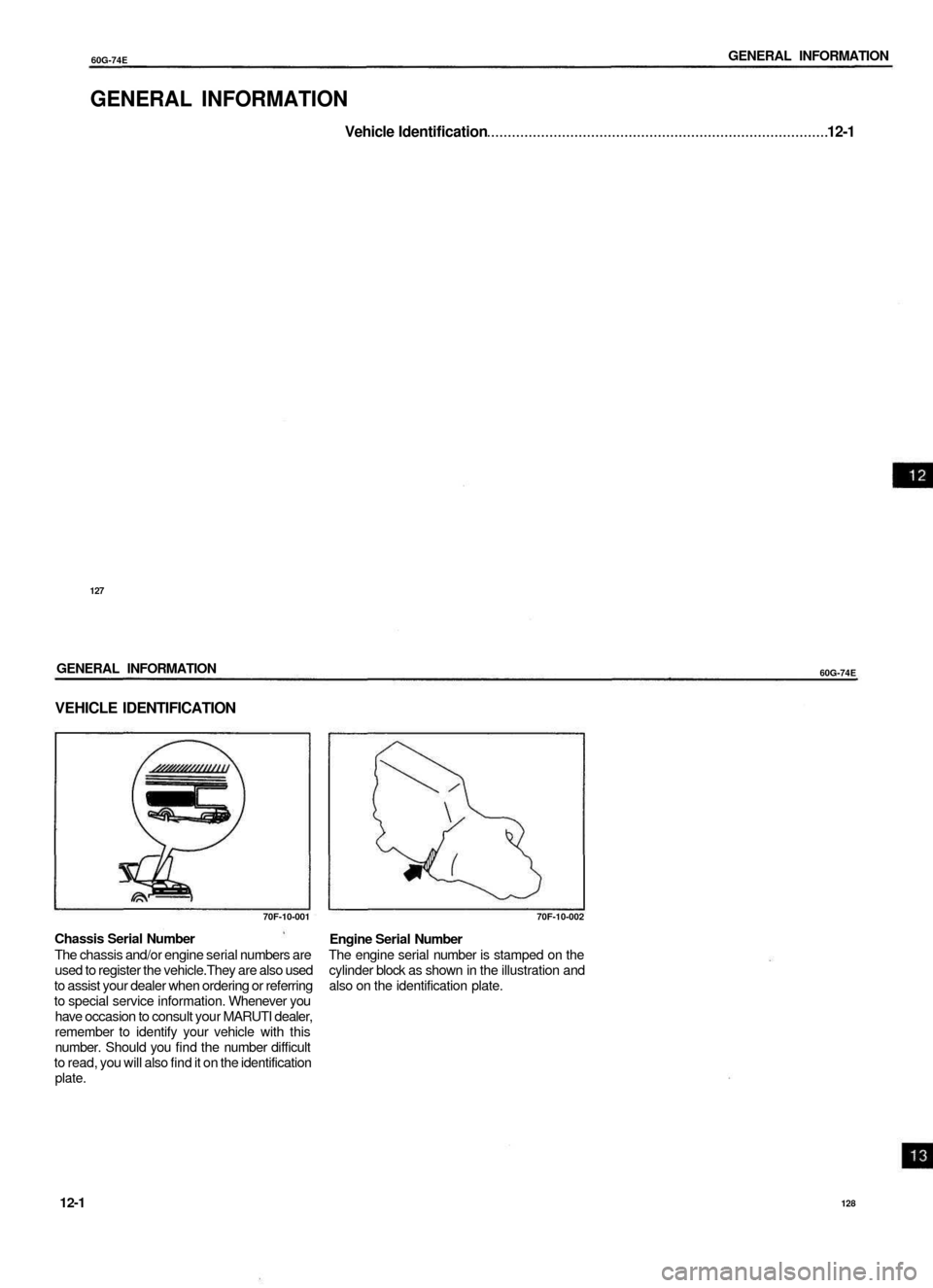

VEHICLE IDENTIFICATION

70F-10-001

Chassis Serial Number

The chassis and/or engine serial numbers are

used to register the vehicle.They are also used

to assist your dealer when ordering or referring

to special service information. Whenever you

have occasion to consult your MARUTI dealer,

remember to identify your vehicle with this

number. Should you find the number difficult

to read, you will also find it on the identification

plate.

70F-10-002

Engine Serial Number

The engine serial number is stamped on the

cylinder block as shown in the illustration and

also on the identification plate.

12-1

128