lock SUZUKI CELERIO 2016 Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2016, Model line: CELERIO, Model: SUZUKI CELERIO 2016Pages: 201, PDF Size: 5.82 MB

Page 166 of 201

7-17

INSPECTION AND MAINTENANCE

76MH1-74E

76MH1-74E

NOTE: When measuring the distance between the brake pedal and floor wall, be sure not toinclude the floor mat or rubber on the floor wall in your measurement.

60G104S

Parking Brake

54G109

Ratchet tooth speci fication “b”: 4th – 9th Lever pull force (1): 200 N (20 kg, 45 lbs)

Check the parking brake for proper adjust- ment by counting the number of clicksmade by the ratchet teeth as you slowly pull up on the parking brake lever to the point of full engagement. The parkingbrake lever should stop between the speci- fied ratchet teeth and the rear wheels should be securely locked. If the parkingbrake is not properly adjusted or the brakes drag after the lever has been fully released, have the parking brake inspectedand/or adjusted by your MARUTI SUZUKI dealer.

Steering

68LM708

Steering wheel play “c”: 0 – 30 mm (0.0 – 1.2 in.)

Check the play of the steering wheel by gently turning it from left to right and mea-suring the distance that it moves before you feel slight resistance. The play should be between the specified values.

Check that the steering wheel turns easily and smoothly without rattling by turning itall the way to the right and to the left while driving very slowly in an open area. If the amount of free play is outside the specifi-cation or you find anything else to be wrong, an inspection must be performed by your MARUTI SUZUKI dealer.

WA R N I N G

If you experience any of the following problems with your vehicle’s brake system, have the vehicle inspectedimmediately by your MARUTI SUZUKI dealer. • Poor braking performance• Uneven braking (brakes not work- ing uniformly on all wheels.) • Excessive pedal travel• Brake dragging • Excessive noise • Pedal pulsation (pedal pulsateswhen depressed.)

EXAMPLE

EXAMPLE

“c”

EXAMPLE

155

Page 172 of 201

7-23

INSPECTION AND MAINTENANCE

76MH1-74E

76MH1-74E

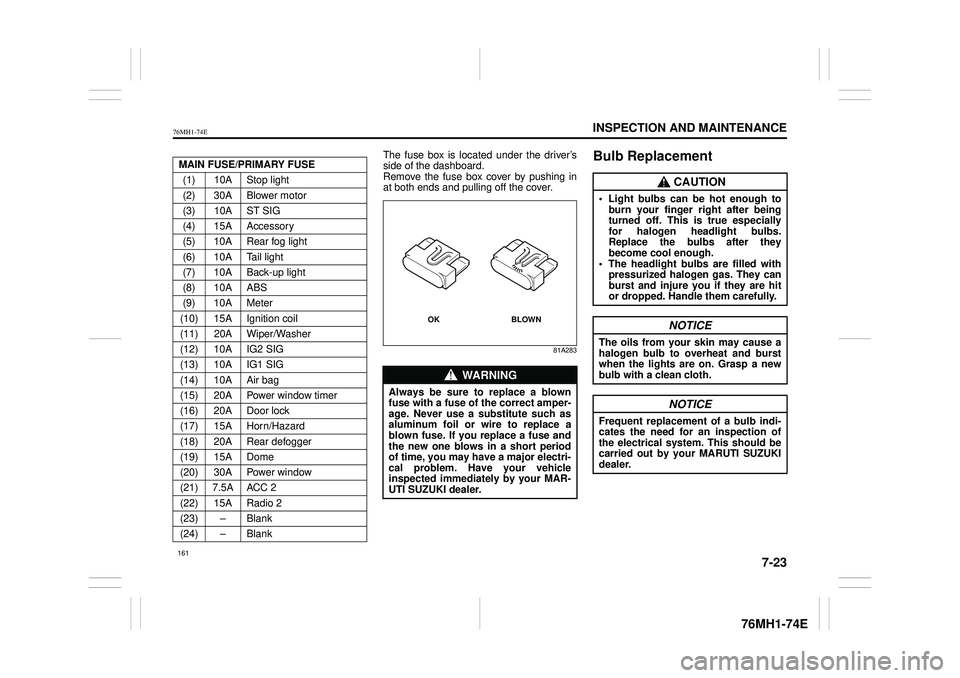

The fuse box is located under the driver’s side of the dashboard. Remove the fuse box cover by pushing inat both ends and pulling off the cover.

81A283

Bulb ReplacementMAIN FUSE/PRIMARY FUSE

(1) 10A Stop light

(2) 30A Blower motor

(3) 10A ST SIG

(4) 15A Accessory

(5) 10A Rear fog light

(6) 10A Tail light

(7) 10A Back-up light

(8) 10A ABS

(9) 10A Meter

(10) 15A Ignition coil

(11) 20A Wiper/Washer

(12) 10A IG2 SIG

(13) 10A IG1 SIG

(14) 10A Air bag

(15) 20A Power window timer

(16) 20A Door lock

(17) 15A Horn/Hazard

(18) 20A Rear defogger

(19) 15A Dome

(20) 30A Power window

(21) 7.5A ACC 2

(22) 15A Radio 2

(23) – Blank

(24) – Blank

WA R N I N G

Always be sure to replace a blown fuse with a fuse of the correct amper- age. Never use a substitute such as aluminum foil or wire to replace ablown fuse. If you replace a fuse and the new one blows in a short period of time, you may have a major electri-cal problem. Have your vehicle inspected immediately by your MAR- UTI SUZUKI dealer.

BLOWN OK

CAUTION

• Light bulbs can be hot enough toburn your finger right after being turned off. This is true especially for halogen headlight bulbs.Replace the bulbs after they become cool enough. • The headlight bulbs are filled withpressurized halogen gas. They can burst and injure you if they are hit or dropped. Handle them carefully.

NOTICE

The oils from your skin may cause ahalogen bulb to overheat and burst when the lights are on. Grasp a new bulb with a clean cloth.

NOTICE

Frequent replacement of a bulb indi-cates the need for an inspection of the electrical system. This should be carried out by your MARUTI SUZUKIdealer.

161

Page 173 of 201

7-24

INSPECTION AND MAINTENANCE

76MH1-74E

76MH1-74E

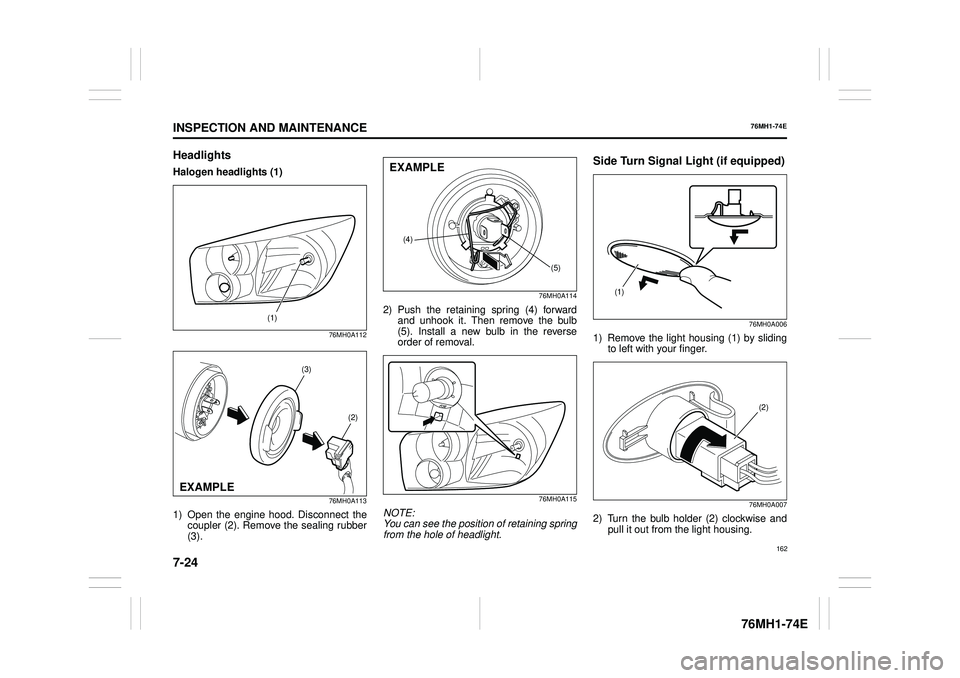

Headlights

Halogen headlights (1)

76MH0A112

76MH0A113

1) Open the engine hood. Disconnect the coupler (2). Remove the sealing rubber(3).

76MH0A114

2) Push the retaining spring (4) forward and unhook it. Then remove the bulb(5). Install a new bulb in the reverse order of removal.

76MH0A115

NOTE: You can see the position of retaining springfrom the hole of headlight.

Side Turn Signal Light (if equipped)

76MH0A006

1) Remove the light housing (1) by sliding to left with your finger.

76MH0A007

2) Turn the bulb holder (2) clockwise and pull it out from the light housing.

(1)

(3)

(2)

EXAMPLE

(4)

(5)

EXAMPLE

(1)

(2)

162

Page 174 of 201

7-25

INSPECTION AND MAINTENANCE

76MH1-74E

76MH1-74E

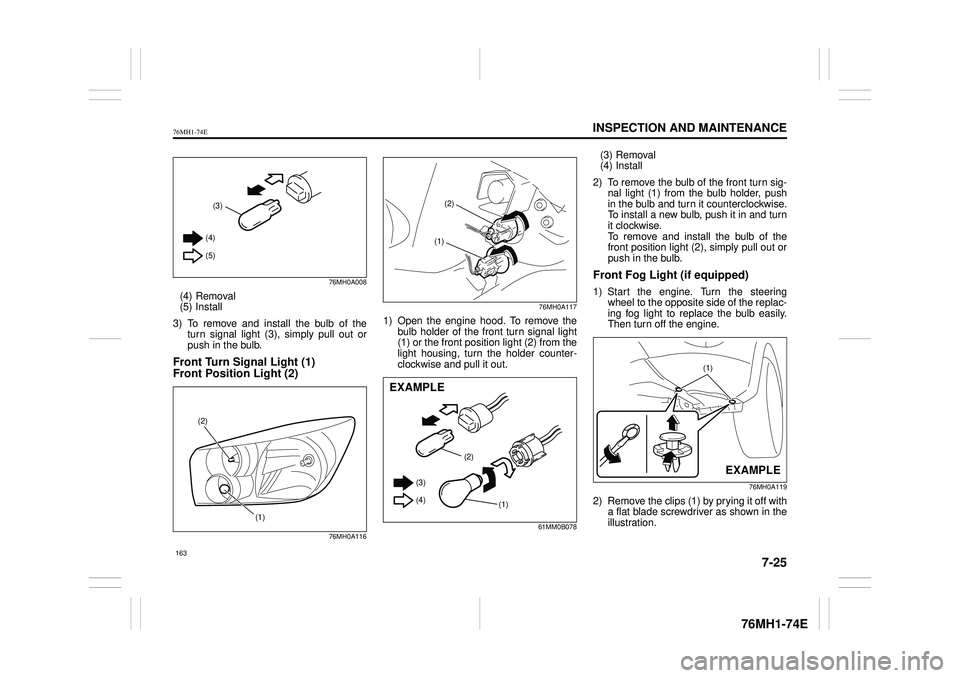

76MH0A008

(4) Removal (5) Install

3) To remove and install the bulb of the turn signal light (3), simply pull out orpush in the bulb.

Front Turn Signal Light (1)

Front Position Light (2)

76MH0A116

76MH0A117

1) Open the engine hood. To remove the bulb holder of the front turn signal light (1) or the front position light (2) from thelight housing, turn the holder counter- clockwise and pull it out.

61MM0B078

(3) Removal(4) Install

2) To remove the bulb of the front turn sig- nal light (1) from the bulb holder, push in the bulb and turn it counterclockwise.To install a new bulb, push it in and turn it clockwise. To remove and install the bulb of thefront position light (2), simply pull out or push in the bulb.

Front Fog Light (if equipped)

1) Start the engine. Turn the steeringwheel to the opposite side of the replac- ing fog light to replace the bulb easily.Then turn off the engine.

76MH0A119

2) Remove the clips (1) by prying it off witha flat blade screwdriver as shown in theillustration.

(3)

(4)

(5)

(1)

(2)

(2)

(1)

(2)

(1)

(3)

(4)

EXAMPLE

(1)

EXAMPLE

163

Page 175 of 201

7-26

INSPECTION AND MAINTENANCE

76MH1-74E

76MH1-74E

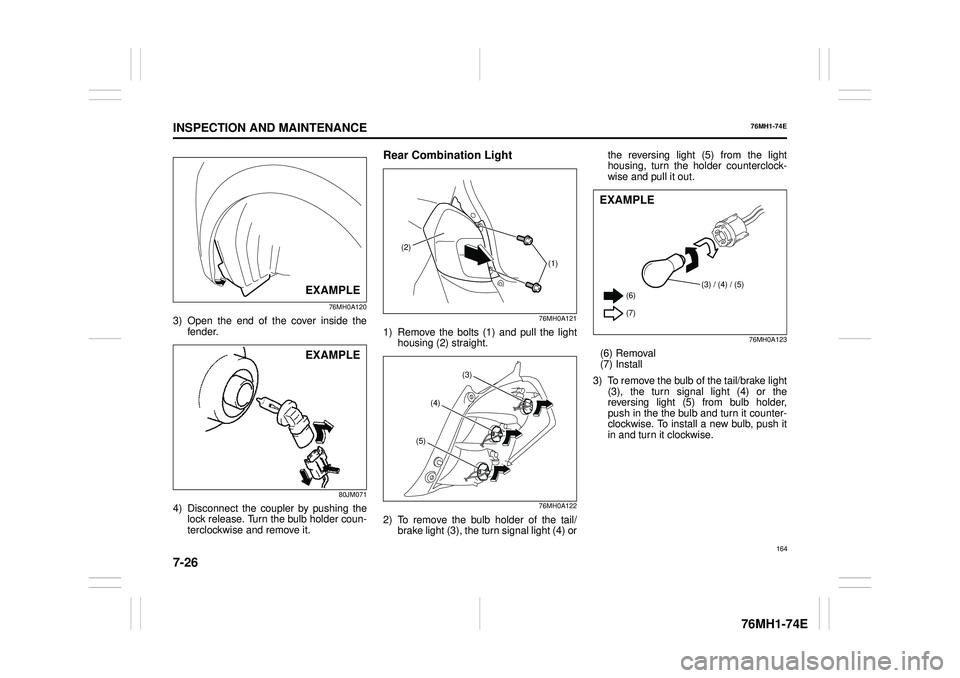

76MH0A120

3) Open the end of the cover inside the fender.

80JM071

4) Disconnect the coupler by pushing the lock release. Turn the bulb holder coun- terclockwise and remove it.

Rear Combination Light

76MH0A121

1) Remove the bolts (1) and pull the light housing (2) straight.

76MH0A122

2) To remove the bulb holder of the tail/brake light (3), the turn signal light (4) or

the reversing light (5) from the light housing, turn the holder counterclock- wise and pull it out.

76MH0A123

(6) Removal (7) Install

3) To remove the bulb of the tail/brake light (3), the turn signal light (4) or the reversing light (5) from bulb holder,push in the the bulb and turn it counter- clockwise. To install a new bulb, push it in and turn it clockwise.

EXAMPLE

EXAMPLE

(2)

(1)

(3)

(4)

(5)

(3) / (4) / (5) (6)

(7)

EXAMPLE

164

Page 176 of 201

7-27

INSPECTION AND MAINTENANCE

76MH1-74E

76MH1-74E

76MH0A124

NOTE: When reinstalling the light housing, makesure the clips are properly attached.

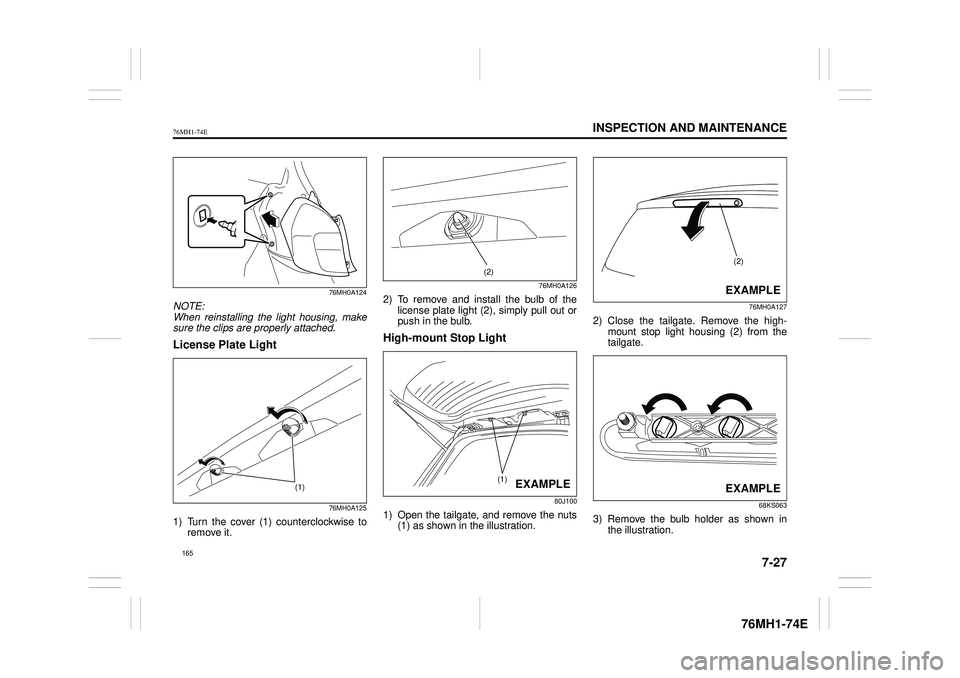

License Plate Light

76MH0A125

1) Turn the cover (1) counterclockwise toremove it.

76MH0A126

2) To remove and install the bulb of thelicense plate light (2), simply pull out orpush in the bulb.

High-mount Stop Light

80J100

1) Open the tailgate, and remove the nuts(1) as shown in the illustration.

76MH0A127

2) Close the tailgate. Remove the high- mount stop light housing (2) from the tailgate.

68KS063

3) Remove the bulb holder as shown in the illustration.

(1)

(2)

(1)EXAMPLE

(2)

EXAMPLE

EXAMPLE

165

Page 178 of 201

7-29

INSPECTION AND MAINTENANCE

76MH1-74E

76MH1-74E

NOTE: Some wiper blades may be different from the ones described here depending onvehicle specifications. If so, consult your MARUTI SUZUKI dealer for proper replacement method.

For windshield wipers:

70G119

1) Hold the wiper arm away from the win- dow.

54G130

2) Squeeze lock (1) towards wiper arm (2) and remove the wiper frame from the arm as shown.3) Unlock the lock end of the wiper blade and slide the blade out as shown.

Removal

60A260

Installation

54G132

(1) Locked end

EXAMPLE

EXAMPLE

167

Page 179 of 201

7-30

INSPECTION AND MAINTENANCE

76MH1-74E

76MH1-74E

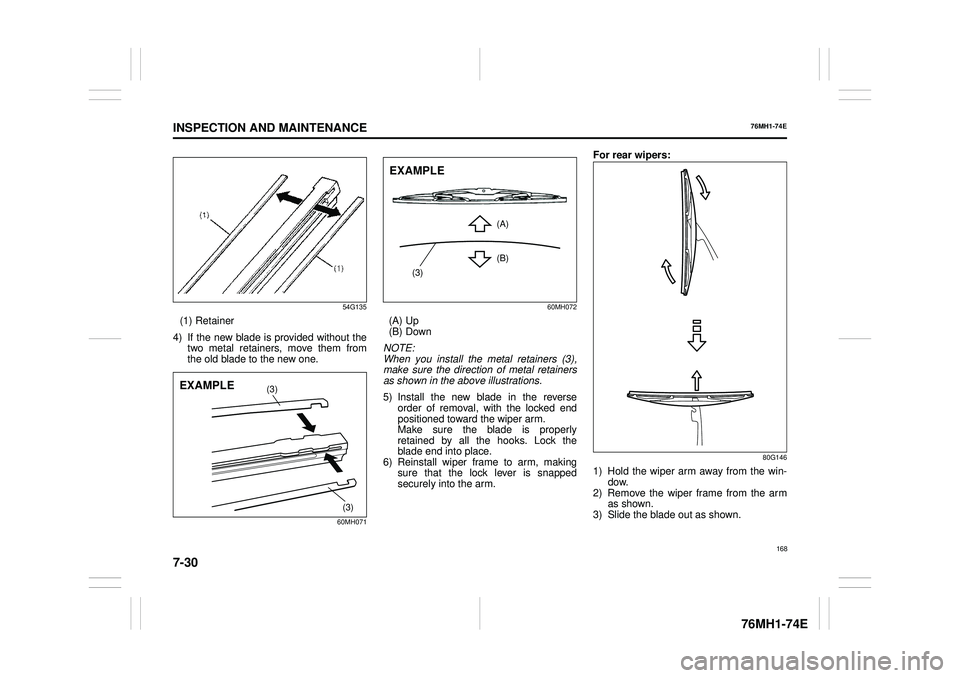

54G135

(1) Retainer

4) If the new blade is provided without the two metal retainers, move them from the old blade to the new one.

60MH071

60MH072

(A) Up (B) Down

NOTE: When you install the metal retainers (3), make sure the direction of metal retainersas shown in the above illustrations.

5) Install the new blade in the reverse order of removal, with the locked end positioned toward the wiper arm. Make sure the blade is properlyretained by all the hooks. Lock the blade end into place. 6) Reinstall wiper frame to arm, makingsure that the lock lever is snapped securely into the arm.

For rear wipers:

80G146

1) Hold the wiper arm away from the win- dow. 2) Remove the wiper frame from the armas shown. 3) Slide the blade out as shown.

(3)

(3)

EXAMPLE

(3)

(A)

(B)

EXAMPLE

168

Page 182 of 201

8-1

EMERGENCY SERVICE

76MH1-74E

76MH1-74E

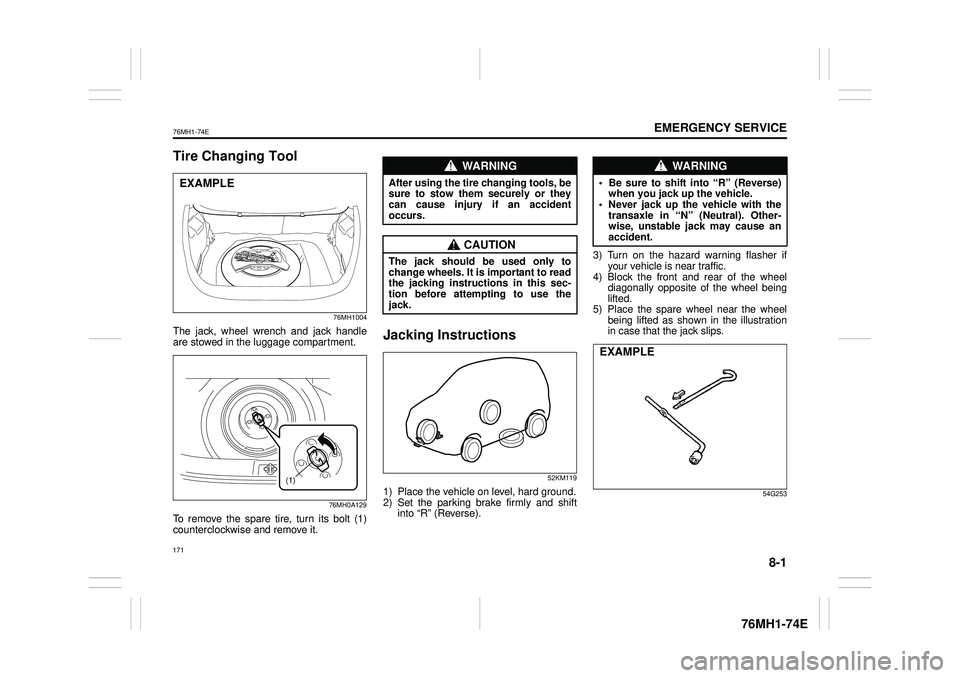

Tire Changing Tool

76MH1004

The jack, wheel wrench and jack handle are stowed in the luggage compartment.

76MH0A129

To remove the spare tire, turn its bolt (1) counterclockwise and remove it.

Jacking Instructions

52KM119

1) Place the vehicle on level, hard ground. 2) Set the parking brake firmly and shift into “R” (Reverse).

3) Turn on the hazard warning flasher if your vehicle is near traffic. 4) Block the front and rear of the wheel diagonally opposite of the wheel beinglifted. 5) Place the spare wheel near the wheel being lifted as shown in the illustrationin case that the jack slips.

54G253

EXAMPLE

(1)

WA R N I N G

After using the tire changing tools, besure to stow them securely or theycan cause injury if an accident occurs.

CAUTION

The jack should be used only to change wheels. It is important to readthe jacking instructions in this sec- tion before attemp ting to use the jack.

WA R N I N G

• Be sure to shift into “R” (Reverse) when you jack up the vehicle.• Never jack up the vehicle with the transaxle in “N” (Neutral). Other- wise, unstable jack may cause anaccident.

EXAMPLE

171

Page 183 of 201

8-2

EMERGENCY SERVICE

76MH1-74E

76MH1-74E

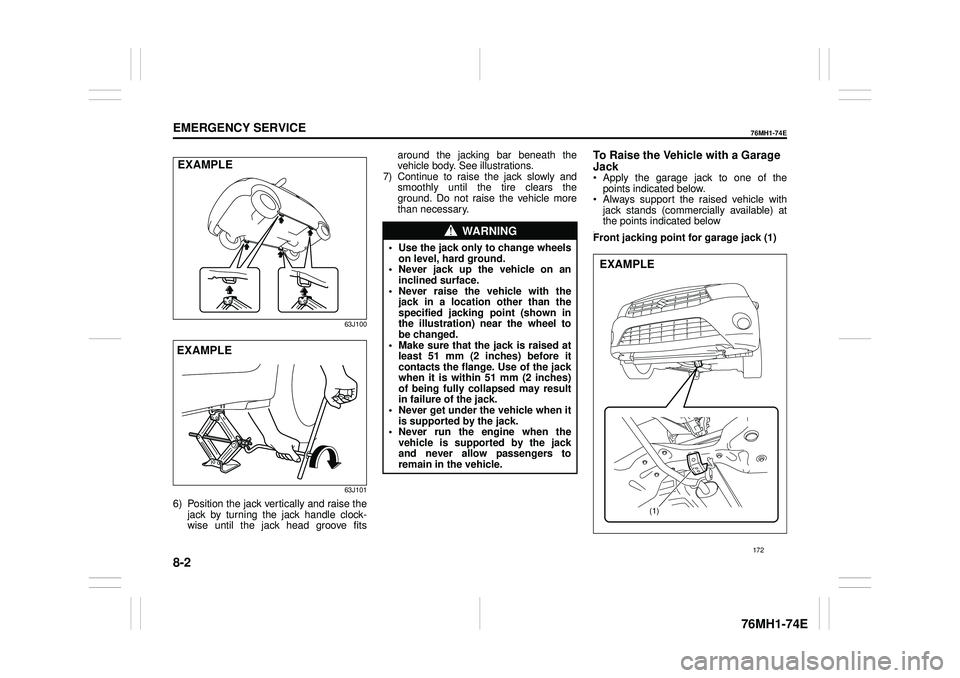

63J100

63J101

6) Position the jack vertically and raise the jack by turning the jack handle clock- wise until the jack head groove fits

around the jacking bar beneath the vehicle body. See illustrations. 7) Continue to raise the jack slowly andsmoothly until the tire clears the ground. Do not raise the vehicle more than necessary.

To Raise the Vehicle with a Garage

Jack Apply the garage jack to one of the points indicated below. Always support the raised vehicle with jack stands (commercially available) at the points indicated below.Front jacking point for garage jack (1)

EXAMPLE

EXAMPLE

WA R N I N G

• Use the jack only to change wheelson level, hard ground.• Never jack up the vehicle on an inclined surface. • Never raise the vehicle with thejack in a location other than the specified jacking point (shown in the illustration) near the wheel tobe changed. • Make sure that the jack is raised at least 51 mm (2 inches) before itcontacts the flange. Use of the jack when it is within 51 mm (2 inches) of being fully collapsed may resultin failure of the jack. • Never get under the vehicle when it is supported by the jack.• Never run the engine when the vehicle is supported by the jack and never allow passengers toremain in the vehicle.

(1)

EXAMPLE

172