Gear SUZUKI CELERIO 2022 Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2022, Model line: CELERIO, Model: SUZUKI CELERIO 2022Pages: 201, PDF Size: 5.82 MB

Page 147 of 201

6-1

VEHICLE LOADING AND TOWING

76MH1-74E

76MH1-74E

Vehicle Loading

Your vehicle was designed for specific weight capacities. The weight capacities ofyour vehicle are indicated by the Gross Vehicle Weight Rating (GVWR) and the Permissible maximum Axle Weight (PAW,front and rear). The GVWR and PAW (front and rear) are listed in the “SPECIFICA- TIONS” section.

GVWR – Maximum permissible overall weight of the fully loaded vehicle (includingall the occupants, accessories and cargo plus the trailer nose weight if towing a trailer).PAW – (Front and Rear) Maximum permis- sible weight on an individual axle.

Actual weight of the loaded vehicle and actual loads at the front and rear axles can only be determined by weighing the vehi-cle. Compare these weights to the GVWR and PAW (front and rear). If the gross vehi- cle weight or the load on either axleexceeds these ratings, you must remove enough weight to bring the load down to the rated capacity.

Trailer Towing

Your MARUTI SUZUKI was originallydesigned to carry people and a normal amount of cargo, not to tow a trailer.MAR- UTI SUZUKI does not recommend you useyour vehicle to tow a trailer. Towing a trailer can adversely affect handling, durability, and fuel economy.

Towing Your Vehicle

Your vehicle may be towed behind anothervehicle (such as a motorhome), providedyour vehicle is 2 wheel drive (2WD) and you use the proper towing method speci- fied for your vehicle. The towing methodyou must use depends on the specifica- tions of your vehicle: whether it is a manual transaxle vehicle or an Auto Gear Shiftvehicle.

Use the towing instruction table to select the proper towing method for your vehicle, and carefully follow the corresponding instructions. Be sure to use proper towingequipment designed for recreational tow- ing and make sure that towing speed does not exceed 90 km/h (55 mph).

WA R N I N G

Never overload your vehicle. Thegross vehicle weight (sum of theweights of the vehicle, all the occu- pants, accessories, cargo plus trailer nose weight if towing a trailer) mustnever exceed the Gross Vehicle Weight Rating (GVWR). In addition, never distribute a load so that theweight on either th e front or rear axle exceeds the Permissible maximum Axle Weight (PAW).

WA R N I N G

Always distribute cargo evenly. Toavoid personal injury or damage to your vehicle, always secure cargo to prevent it from shifting if the vehiclemoves suddenly. Place heavier objects on the floor and as far for- ward in the cargo area as possible.Never pile cargo higher than the top of the seat backs.

WA R N I N G

When you tow your vehicle, follow the instructions below to avoid acci-dents and damage to your vehicle. In addition, be sure to observe govern- ment and local requirements regard-ing vehicle lighting and trailer hitches or tow bars.

WA R N I N G

A safety chain should always be used when you tow your vehicle.

136

Page 148 of 201

6-2

VEHICLE LOADING AND TOWING

76MH1-74E

76MH1-74E

TOWING INSTRUCTION TABLE

76MH022

A: 2WD VEHICLES WITH MANUAL TRANSAXLE OR AUTO GEAR SHIFT 1) Secure the front wheels on a towingdolly according to the instructions pro- vided by the dolly manufacturer. 2) Release the parking brake.

76MH023

B: 2WD VEHICLES WITH MANUAL TRANSAXLE OR AUTO GEAR SHIFT 1) Shift the gearshift lever into neutral. 2) Turn the ignition key to the

Page 149 of 201

INSPECTION AND MAINTENANCE

76MH1-74E

76MH1-74E

138

INSPECTION AND MAINTENANCEMaintenance Schedule ....................................................... 7-2

Periodic Maintenance Schedule . ....................................... 7-2

Drive Belt ............................................................................. 7-6

Engine Oil and Filter ........................................................... 7-6

Engine Coolant .................................................................... 7-10

Air Cleaner ........................................................................... 7-12

Spark Plugs ......................................................................... 7-12

Gear Oil ................................................................................ 7-14

Clutch Pedal ........................................................................ 7-14

Fuel Filter (Diesel engine) .................................................. 7-15

Brakes .......... ........................................................................ 7-15

Steering ................................................................................ 7-17

Tires ...................................................................................... 7-18

Battery .................................................................................. 7-19

Fuses .................................................................................... 7-20

Bulb Replacement ............................................................... 7-23

Wiper Blades ....................................................................... 7-28

Windshield Washer Fluid ................................................... 7-31

Air Conditioning System .................................................... 7-31

Page 154 of 201

7-5

INSPECTION AND MAINTENANCE

76MH1-74E

76MH1-74E

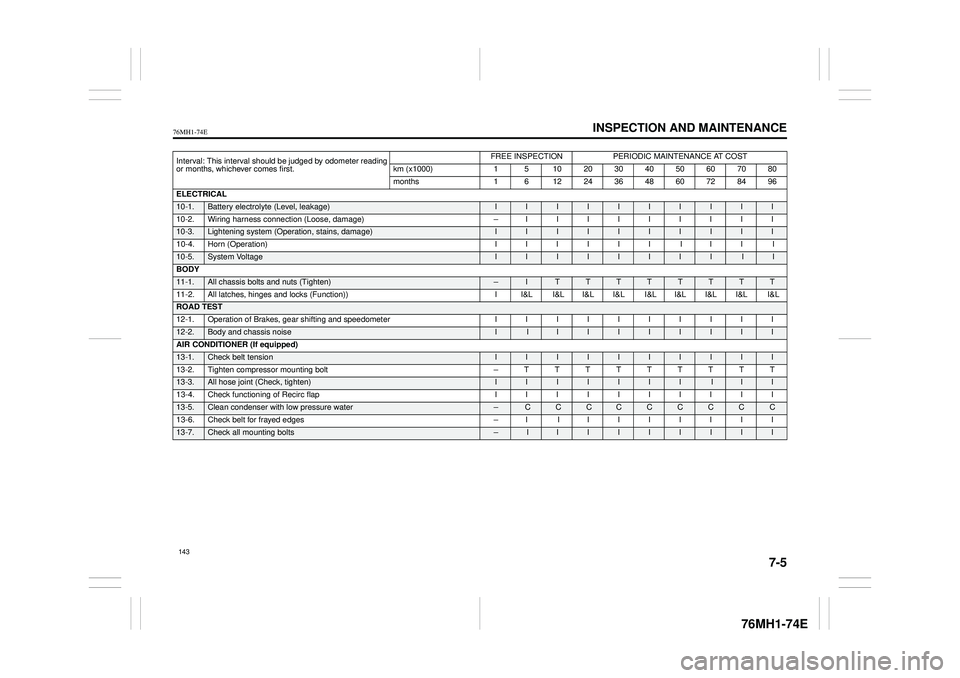

Interval: This interval should be judged by odometer reading or months, whichever comes first.

FREE INSPECTIONPERIODIC MAINTENANCE AT COST

km (x1000) 1 5 10 20 30 40 50 60 70 80

months 1 6 12 24 36 48 60 72 84 96

ELECTRICAL

10-1. Battery electrolyte (Level, leakage) I I I I I I I I I I

10-2. Wiring harness connection (Loose, damage) – I I I I I I I I I

10-3. Lightening system (Operat ion, stains, damage) I I I I I I I I I I

10-4. Horn (Operation) I I I I I I I I I I

10-5.System Voltage II I I I I I I I I

BODY

11-1. All chassis bolts and nuts (Tighten) – I T T T T T T T T

11-2. All latches, hinges and locks (Function)) I I&L I&L I&L I&L I&L I&L I&L I&L I&L

ROAD TEST

12-1. Operation of Brakes, gear shifting and speedometer I I I I I I I I I I

12-2.Body and chassis noise I I I I I I I I I I

AIR CONDITIONER (If equipped)

13-1. Check belt tension I I I I I I I I I I

13-2. Tighten compressor mounting bolt – T T T T T T T T T

13-3. All hose joint (Check, tighten) I I I I II I I I I

13-4. Check functioning of Recirc flap I I I I I I I I I I

13-5. Clean condenser with low pressure water – C C CCC C C C C

13-6. Check belt for frayed edges – I I I I I I I I I

13-7.Check all mounting bolts – I I I I I I I I I

143

Page 163 of 201

7-14

INSPECTION AND MAINTENANCE

76MH1-74E

76MH1-74E

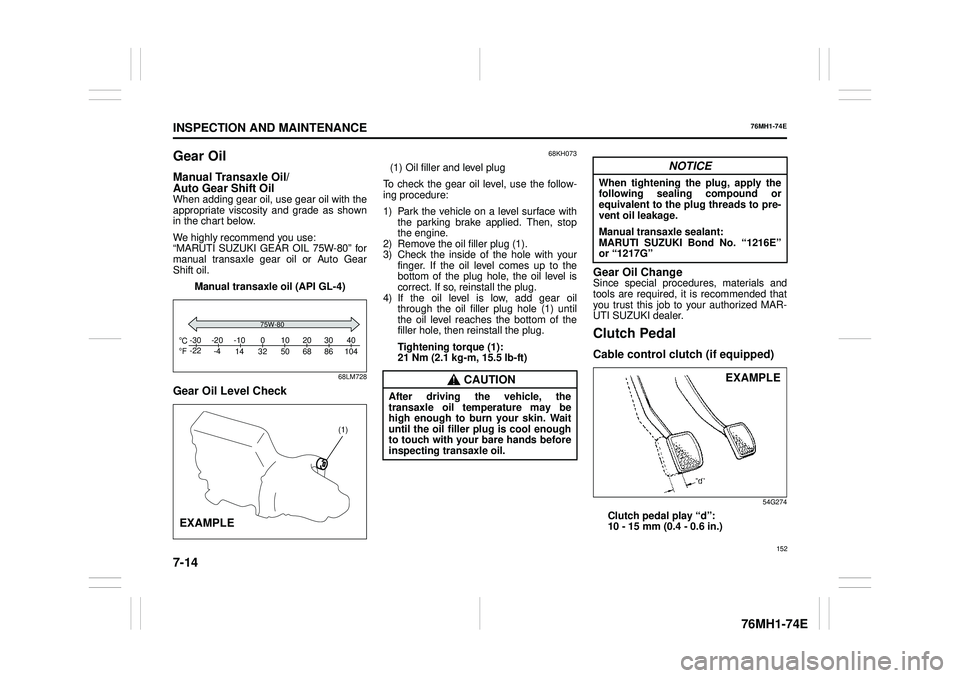

Gear Oil

Manual Transaxle Oil/

Auto Gear Shift OilWhen adding gear oil, use gear oil with the appropriate viscosity and grade as shown in the chart below.

We highly recommend you use: “MARUTI SUZUKI GEAR OIL 75W-80” formanual transaxle gear oil or Auto Gear Shift oil.

Manual transaxle oil (API GL-4)

68LM728

Gear Oil Level Check

68KH073

(1) Oil filler and level plug

To check the gear oil level, use the follow- ing procedure:

1) Park the vehicle on a level surface with the parking brake applied. Then, stop the engine.2) Remove the oil filler plug (1). 3) Check the inside of the hole with your finger. If the oil level comes up to thebottom of the plug hole, the oil level is correct. If so, reinstall the plug. 4) If the oil level is low, add gear oilthrough the oil filler plug hole (1) until the oil level reaches the bottom of the filler hole, then reinstall the plug.

Tightening torque (1): 21 Nm (2.1 kg -m, 15.5 lb-ft)

Gear Oil ChangeSince special procedures, materials and tools are required, it is recommended that you trust this job to your authorized MAR-UTI SUZUKI dealer.

Clutch Pedal

Cable control clutch (if equipped)

54G274

Clutch pedal play “d”: 10 - 15 mm (0.4 - 0.6 in.)

C Fo o-30 -22 -20 -4 -10 14 32 50 68 86 104 010203040

75W-80

(1)

EXAMPLE

CAUTION

After driving the vehicle, the transaxle oil temperature may behigh enough to burn your skin. Wait until the oil filler plug is cool enough to touch with your bare hands beforeinspecting transaxle oil.

NOTICE

When tightening the plug, apply thefollowing sealing compound orequivalent to the plug threads to pre- vent oil leakage.

Manual transaxle sealant: MARUTI SUZUKI Bond No. “1216E” or “1217G”

EXAMPLE

152

Page 186 of 201

8-5

EMERGENCY SERVICE

76MH1-74E

76MH1-74E

3) Make jump lead connections as follows:

1. Connect one end of the first jump lead to the positive (+) terminal of the flat battery (1). 2. Connect the other end to the positive(+) terminal of the booster battery (2). 3. Connect one end of the second jumplead to the negative (–) terminal of the booster battery (2). 4. Make the final connection to anunpainted, heavy metal part (i.e. engine mount bracket (3)) of the engine of the vehicle with the flatbattery (1).

4) If the booster battery you are using is fitted to another vehicle, start the

engine of the vehicle with the booster battery. Run the engine at moderate speed.5) Start the engine of the vehicle with the flat battery. 6) Remove the jump leads in the exactreverse order in which you connected them.

Towing

If you need to have your vehicle towed, contact a professional service. Your dealercan provide you with detailed towing instructions.

2-Wheel Drive (2WD) Manual Tran- saxle or Auto Gear ShiftManual transaxle vehicles or Auto Gear Shift vehicles may be towed using either of the following methods.

1) From the front, with the front wheels lifted and the rear wheels on the ground. Before towing, make sure thatthe parking brake is released. 2) From the rear, with the rear wheels lifted and the front wheels on theground, provided the steering and drivetrain are in operational condition. Before towing, make sure that transaxleis in neutral, the steering wheel is

unlocked (the ignition key should be in the “ACC” position), and the steering wheel is secured with a clampingdevice designed for towing service.

WA R N I N G

Never connect the jump lead directlyto the negative (–) terminal of the dis- charged battery, or an explosion may occur.

CAUTION

Connect the jump le ad to the engine mount bracket securely. If the jump lead disconnects from the engine mount bracket because of vibrationat the start of the engine, the jump lead could be caught in the drive belts.

NOTICE

To help avoid damage to your vehicle during towing, proper equipment and towing procedures must be used.

NOTICE

After shifting the Auto Gear Shiftlever to the “N” position, always check the gear position indicator in the instrument cluster shows the “N”position to make sure that the transaxle is disengaged. If the transaxle cannot be put in neu-tral, turn the key from the “LOCK” to the “ON” position, and move the Auto Gear Shift lever from “N” to “D”,“M” or “R”, then back to “N” again. Then turn the key from the “ON” to the “LOCK” position.These procedures may help put the transaxle in neutral. If the transaxle still cannot be put in neutral, you can-not tow the vehicle without using a towing dolly. The steering column is not strongenough to with stand shocks trans- mitted from the fr ont wheels during towing. Always unlock the steeringwheel before towing.

175

Page 196 of 201

11-1

SPECIFICATIONS

76MH1-74E

76MH1-74E

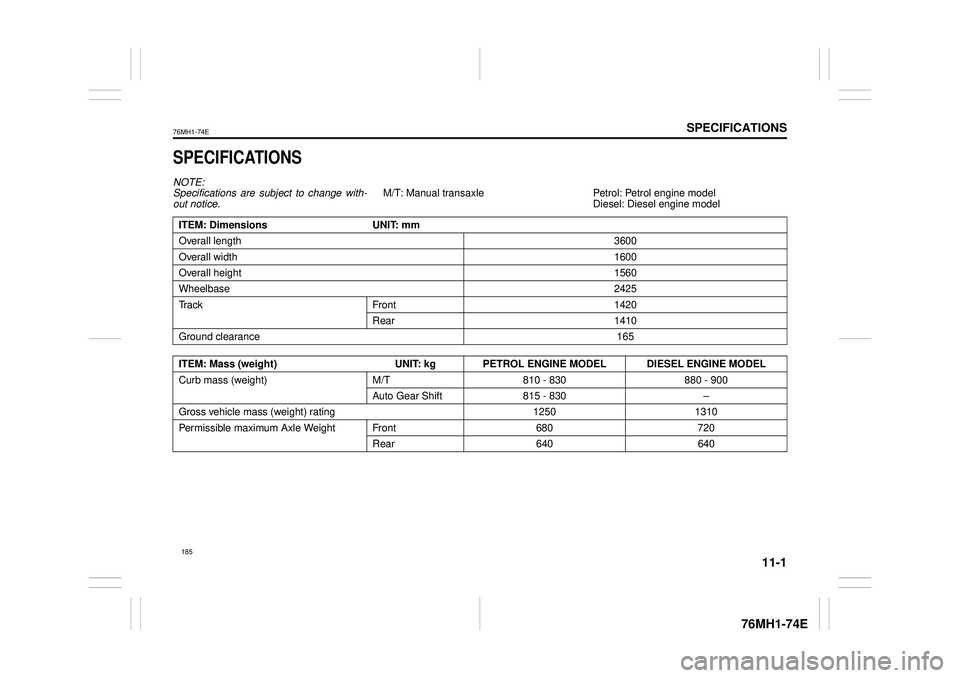

SPECIFICATIONS

NOTE: Specifications are s ubject to change with- out notice. M/T: Manual transaxle Petrol: Petrol engine model Diesel: Diesel engine model

ITEM: Dimensions UNIT: mm

Overall length 3600

Overall width 1600

Overall height 1560

Wheelbase 2425

Track Front 1420

Rear 1410

Ground clearance 165

ITEM: Mass (weigh t) UNIT: kg PETROL ENGINE MODEL DIESEL ENGINE MODEL

Curb mass (weight) M/T 810 - 830 880 - 900

Auto Gear Shift 815 - 830 –

Gross vehicle mass (weight) rating 1250 1310

Permissible maximum Axle Weight Front 680 720

Rear 640 640

185