lock SUZUKI ERTIGA 2013 1.G Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2013, Model line: ERTIGA, Model: SUZUKI ERTIGA 2013 1.GPages: 207, PDF Size: 5.14 MB

Page 155 of 207

Downloaded from www.Manualslib.com manuals search engine 7-10

INSPECTION AND MAINTENANCE

60MK0-14E

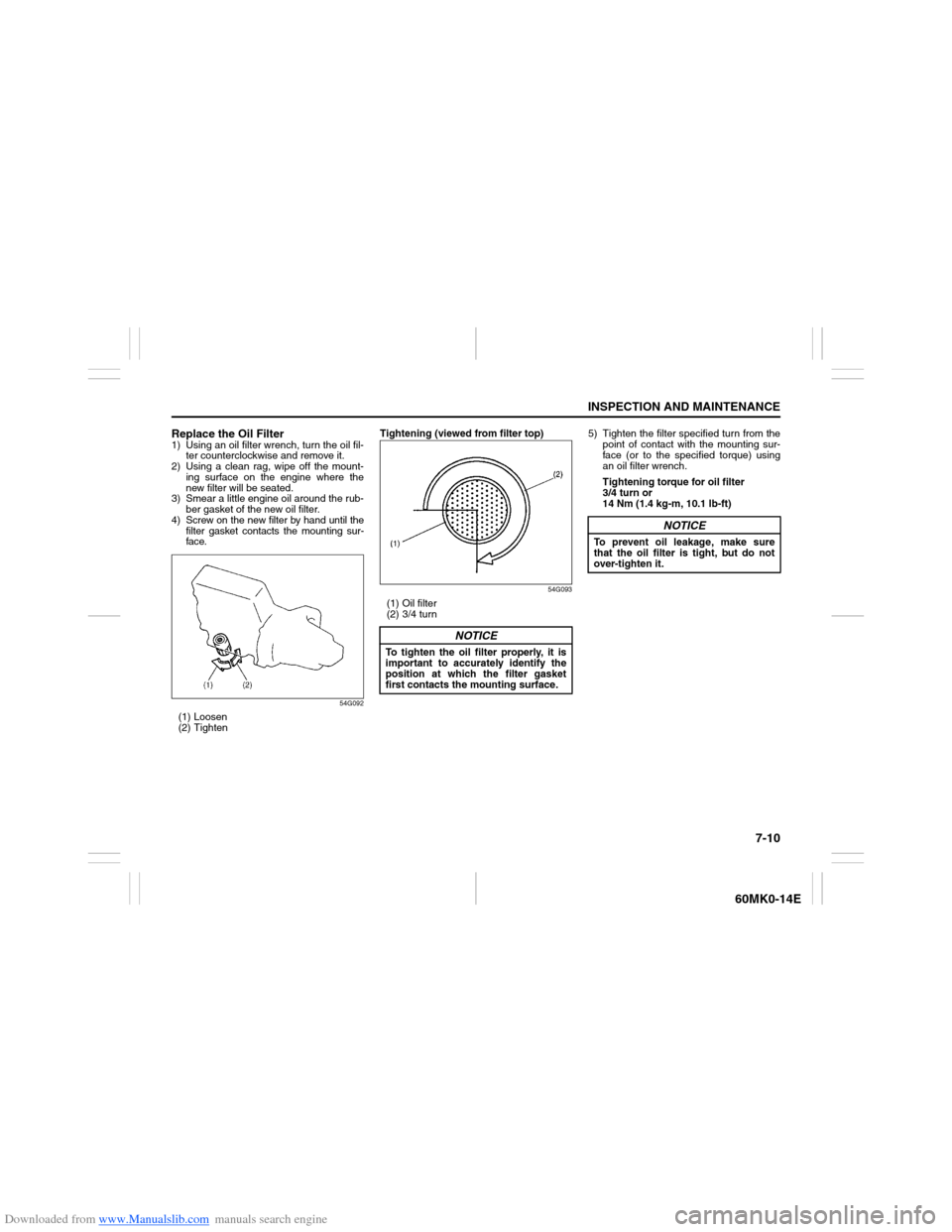

Replace the Oil Filter1) Using an oil filter wrench, turn the oil fil-

ter counterclockwise and remove it.

2) Using a clean rag, wipe off the mount-

ing surface on the engine where the

new filter will be seated.

3) Smear a little engine oil around the rub-

ber gasket of the new oil filter.

4) Screw on the new filter by hand until the

filter gasket contacts the mounting sur-

face.

54G092

(1) Loosen

(2) TightenTightening (viewed from filter top)

54G093

(1) Oil filter

(2) 3/4 turn5) Tighten the filter specified turn from the

point of contact with the mounting sur-

face (or to the specified torque) using

an oil filter wrench.

Tightening torque for oil filter

3/4 turn or

14 Nm (1.4 kg-m, 10.1 lb-ft)

NOTICE

To tighten the oil filter properly, it is

important to accurately identify the

position at which the filter gasket

first contacts the mounting surface.

NOTICE

To prevent oil leakage, make sure

that the oil filter is tight, but do not

over-tighten it.

Page 164 of 207

Downloaded from www.Manualslib.com manuals search engine 7-19INSPECTION AND MAINTENANCE

60MK0-14E

60G104S

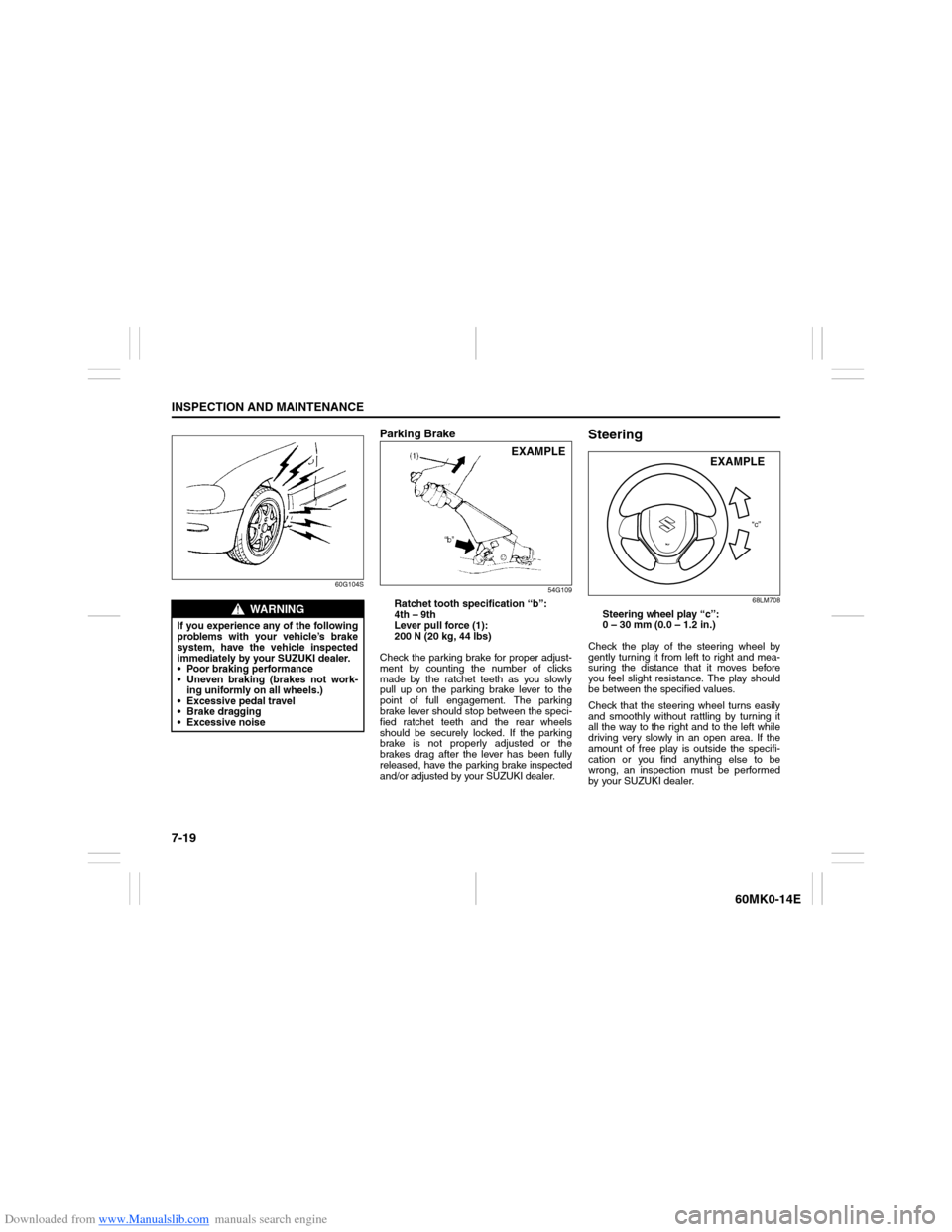

Parking Brake

54G109

Ratchet tooth specification “b”:

4th – 9th

Lever pull force (1):

200 N (20 kg, 44 lbs)

Check the parking brake for proper adjust-

ment by counting the number of clicks

made by the ratchet teeth as you slowly

pull up on the parking brake lever to the

point of full engagement. The parking

brake lever should stop between the speci-

fied ratchet teeth and the rear wheels

should be securely locked. If the parking

brake is not properly adjusted or the

brakes drag after the lever has been fully

released, have the parking brake inspected

and/or adjusted by your SUZUKI dealer.

Steering

68LM708

Steering wheel play “c”:

0 – 30 mm (0.0 – 1.2 in.)

Check the play of the steering wheel by

gently turning it from left to right and mea-

suring the distance that it moves before

you feel slight resistance. The play should

be between the specified values.

Check that the steering wheel turns easily

and smoothly without rattling by turning it

all the way to the right and to the left while

driving very slowly in an open area. If the

amount of free play is outside the specifi-

cation or you find anything else to be

wrong, an inspection must be performed

by your SUZUKI dealer.

WARNING

If you experience any of the following

problems with your vehicle’s brake

system, have the vehicle inspected

immediately by your SUZUKI dealer.

Poor braking performance

Uneven braking (brakes not work-

ing uniformly on all wheels.)

Excessive pedal travel

Brake dragging

Excessive noise

EXAMPLE

“c”

EXAMPLE

Page 173 of 207

Downloaded from www.Manualslib.com manuals search engine 7-28

INSPECTION AND MAINTENANCE

60MK0-14E

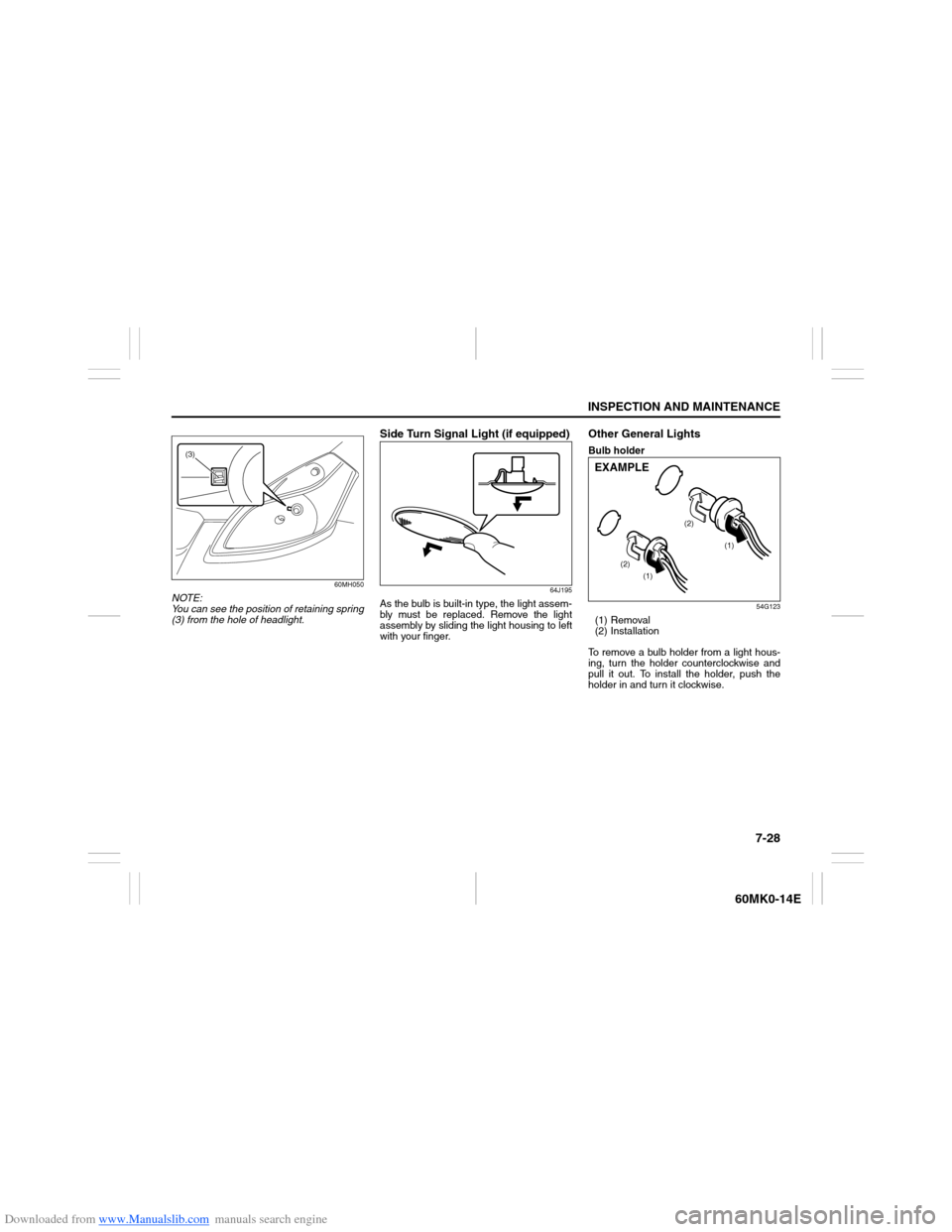

60MH050

NOTE:

You can see the position of retaining spring

(3) from the hole of headlight.

Side Turn Signal Light (if equipped)

64J195

As the bulb is built-in type, the light assem-

bly must be replaced. Remove the light

assembly by sliding the light housing to left

with your finger.

Other General LightsBulb holder

54G123

(1) Removal

(2) Installation

To remove a bulb holder from a light hous-

ing, turn the holder counterclockwise and

pull it out. To install the holder, push the

holder in and turn it clockwise.

(3)

(1)

(1) (2)(2)

EXAMPLE

Page 174 of 207

Downloaded from www.Manualslib.com manuals search engine 7-29INSPECTION AND MAINTENANCE

60MK0-14E

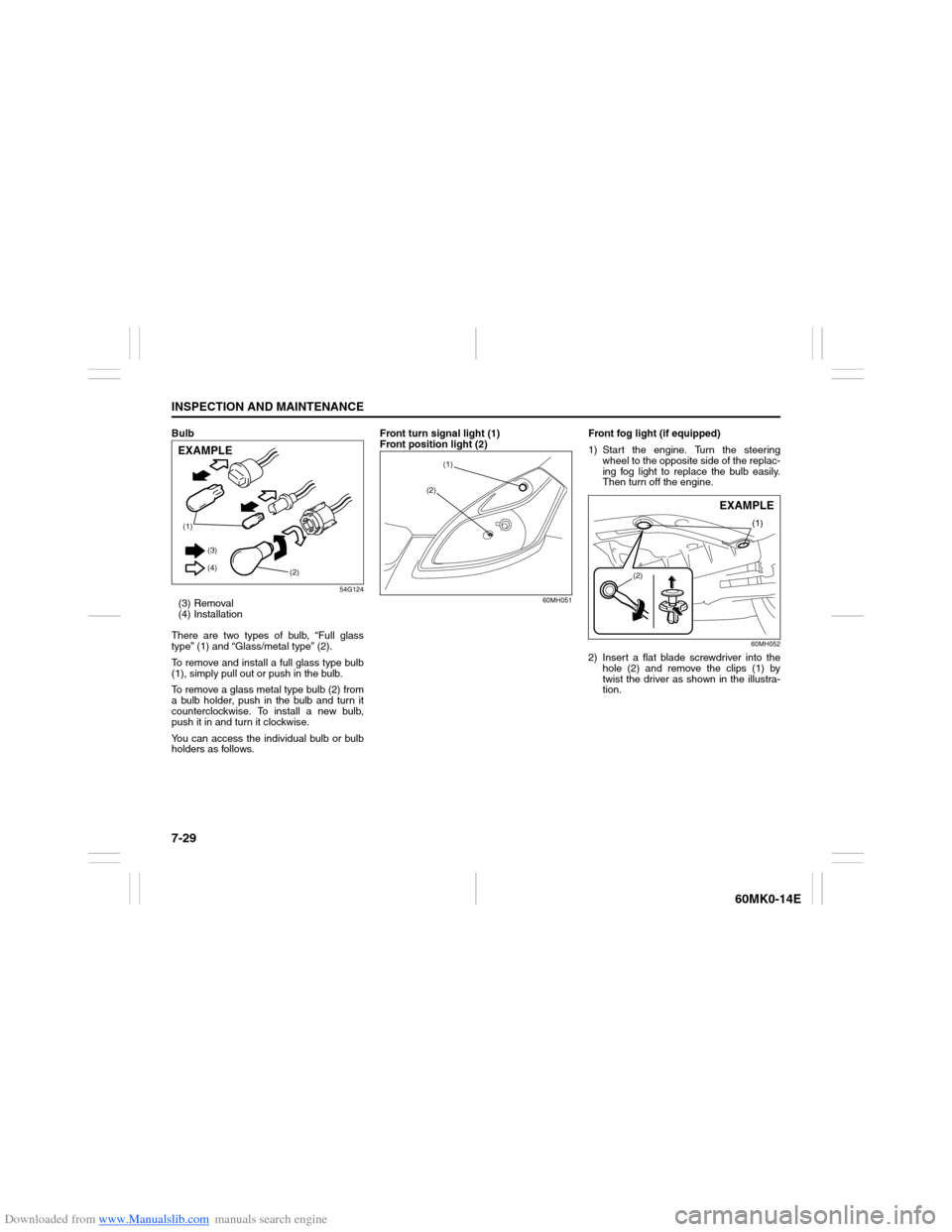

Bulb

54G124

(3) Removal

(4) Installation

There are two types of bulb, “Full glass

type” (1) and “Glass/metal type” (2).

To remove and install a full glass type bulb

(1), simply pull out or push in the bulb.

To remove a glass metal type bulb (2) from

a bulb holder, push in the bulb and turn it

counterclockwise. To install a new bulb,

push it in and turn it clockwise.

You can access the individual bulb or bulb

holders as follows.Front turn signal light (1)

Front position light (2)

60MH051

Front fog light (if equipped)

1) Start the engine. Turn the steering

wheel to the opposite side of the replac-

ing fog light to replace the bulb easily.

Then turn off the engine.

60MH052

2) Insert a flat blade screwdriver into the

hole (2) and remove the clips (1) by

twist the driver as shown in the illustra-

tion.

(1)

(2) (3)

(4)EXAMPLE

(1)

(2)

(1)

(2)

EXAMPLE

Page 175 of 207

Downloaded from www.Manualslib.com manuals search engine 7-30

INSPECTION AND MAINTENANCE

60MK0-14E

80JM071

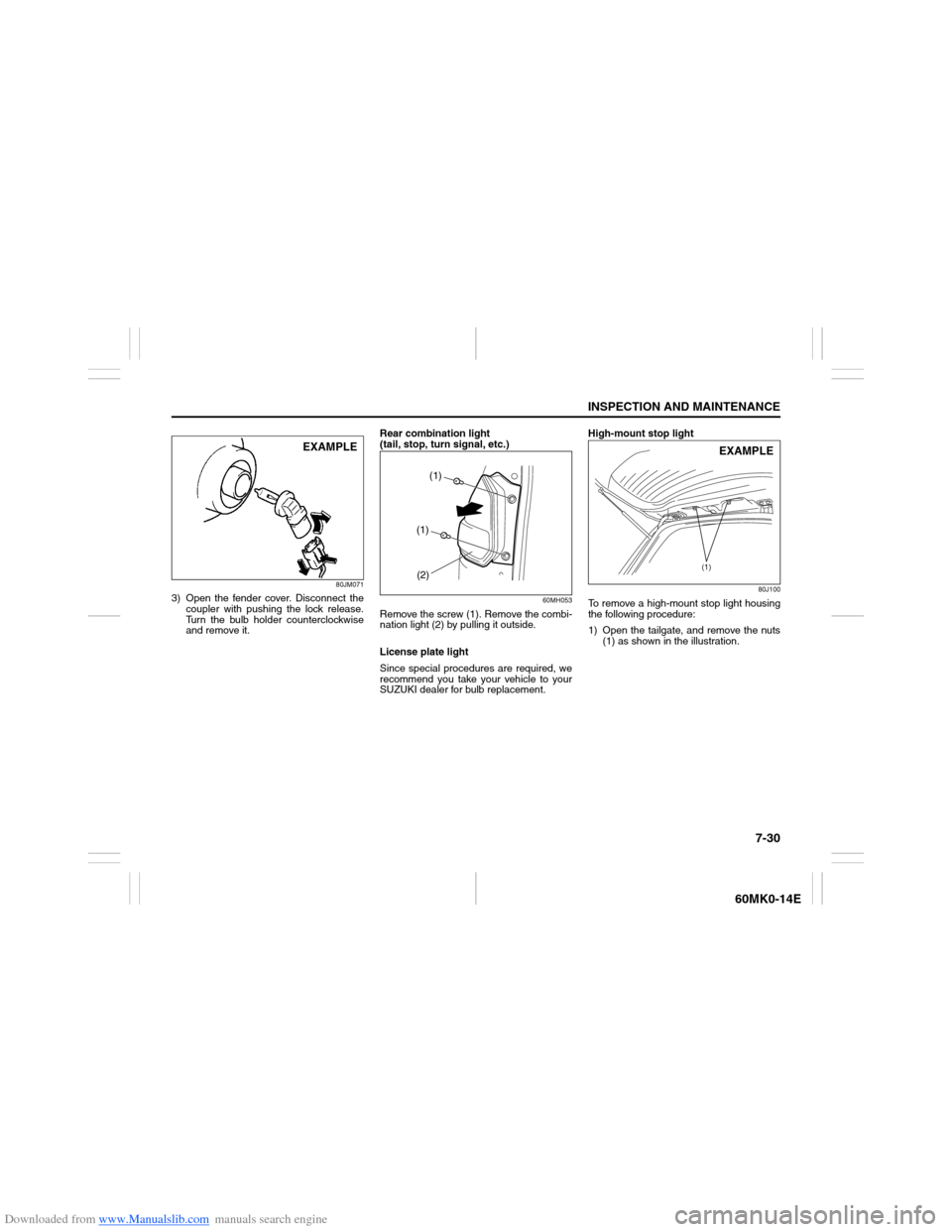

3) Open the fender cover. Disconnect the

coupler with pushing the lock release.

Turn the bulb holder counterclockwise

and remove it.Rear combination light

(tail, stop, turn signal, etc.)

60MH053

Remove the screw (1). Remove the combi-

nation light (2) by pulling it outside.

License plate light

Since special procedures are required, we

recommend you take your vehicle to your

SUZUKI dealer for bulb replacement.High-mount stop light

80J100

To remove a high-mount stop light housing

the following procedure:

1) Open the tailgate, and remove the nuts

(1) as shown in the illustration.

EXAMPLE

(1)

(1)(2)

(1)

EXAMPLE

Page 177 of 207

Downloaded from www.Manualslib.com manuals search engine 7-32

INSPECTION AND MAINTENANCE

60MK0-14E

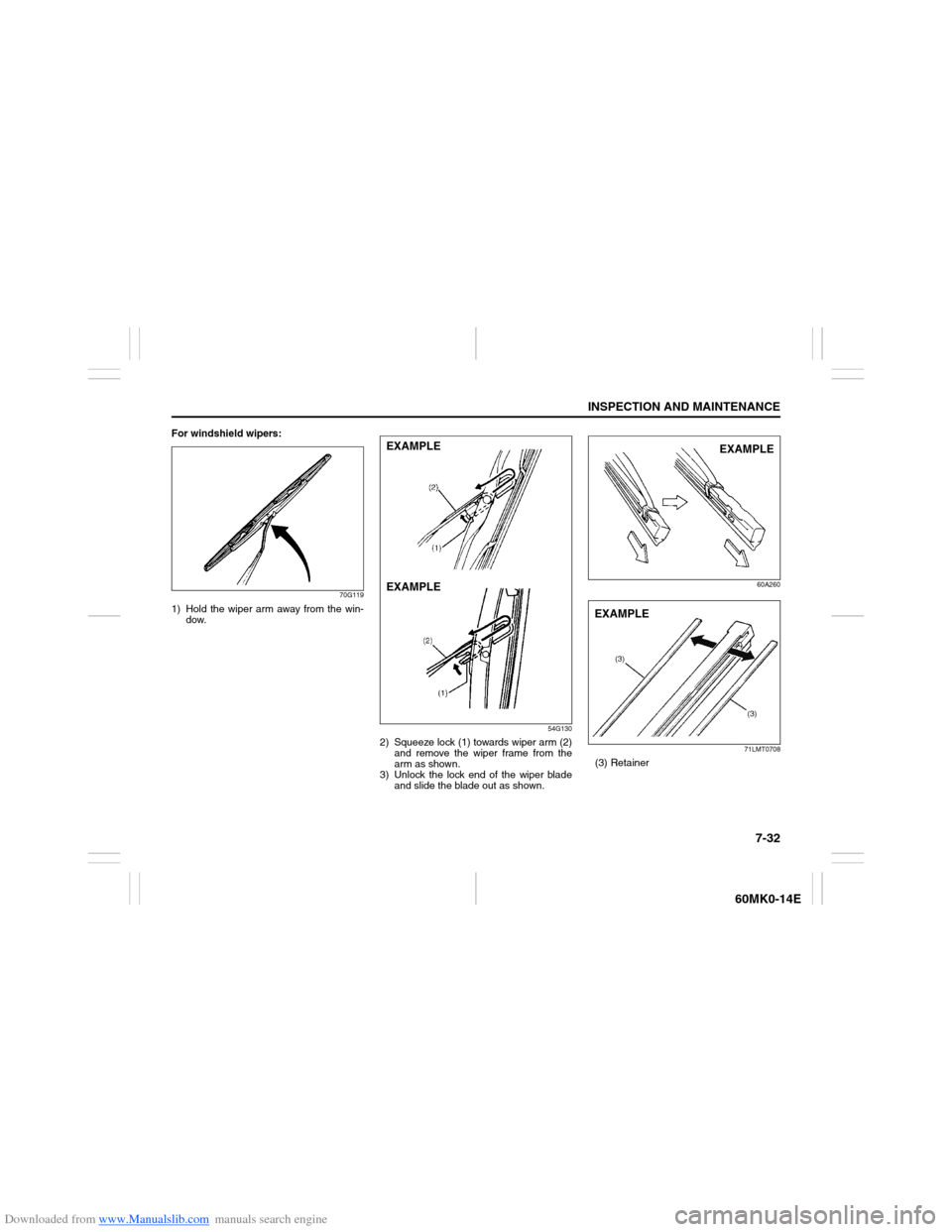

For windshield wipers:

70G119

1) Hold the wiper arm away from the win-

dow.

54G130

2) Squeeze lock (1) towards wiper arm (2)

and remove the wiper frame from the

arm as shown.

3) Unlock the lock end of the wiper blade

and slide the blade out as shown.

60A260

71LMT0708

(3) Retainer

EXAMPLE

EXAMPLE

EXAMPLE

(3)

(3)

EXAMPLE

Page 178 of 207

Downloaded from www.Manualslib.com manuals search engine 7-33INSPECTION AND MAINTENANCE

60MK0-14E

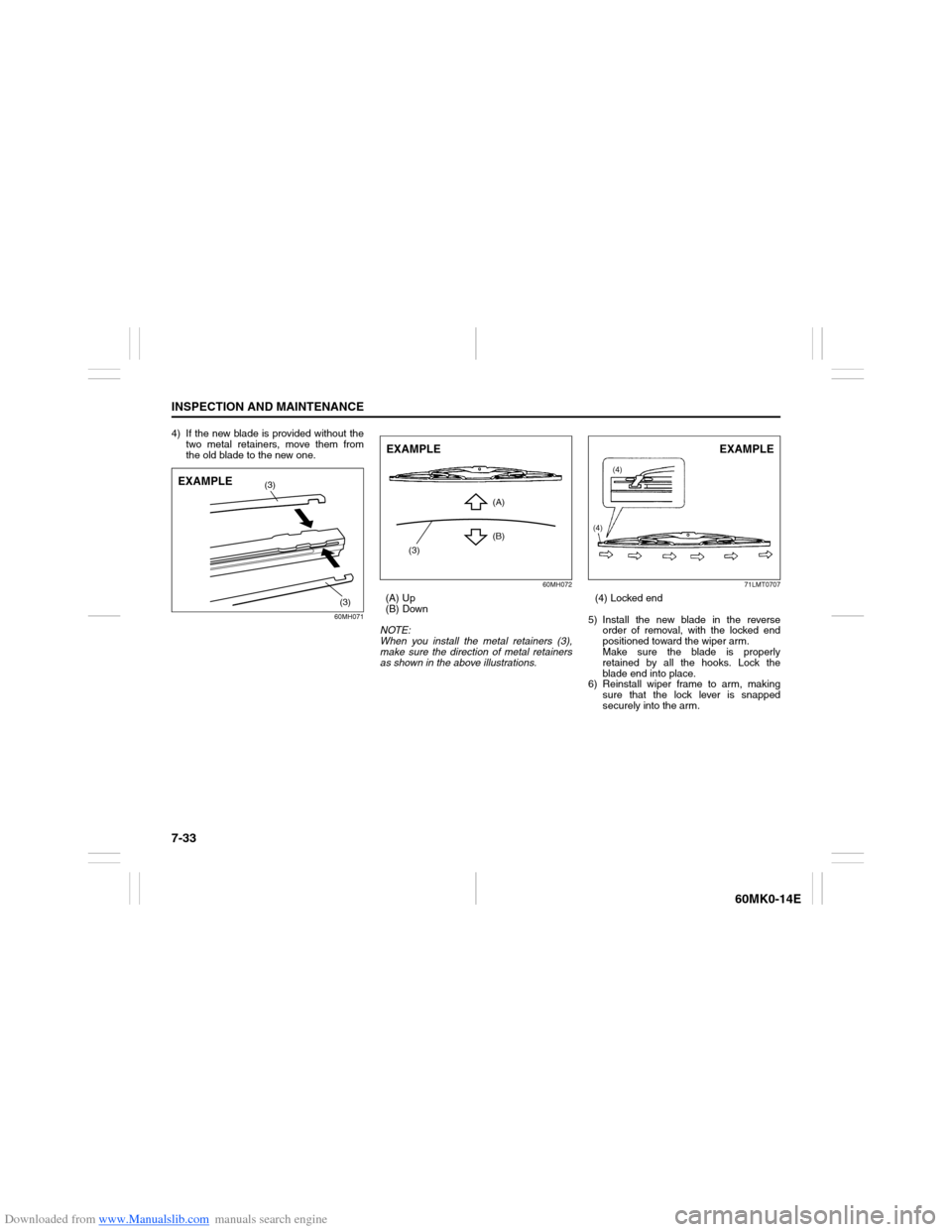

4) If the new blade is provided without the

two metal retainers, move them from

the old blade to the new one.

60MH07160MH072

(A) Up

(B) Down

NOTE:

When you install the metal retainers (3),

make sure the direction of metal retainers

as shown in the above illustrations.

71LMT0707

(4) Locked end

5) Install the new blade in the reverse

order of removal, with the locked end

positioned toward the wiper arm.

Make sure the blade is properly

retained by all the hooks. Lock the

blade end into place.

6) Reinstall wiper frame to arm, making

sure that the lock lever is snapped

securely into the arm.

(3)

(3)

EXAMPLE

(3)(A)

(B)

EXAMPLE

(4)(4)

EXAMPLE

Page 182 of 207

Downloaded from www.Manualslib.com manuals search engine 8-1EMERGENCY SERVICE

60MK0-14E

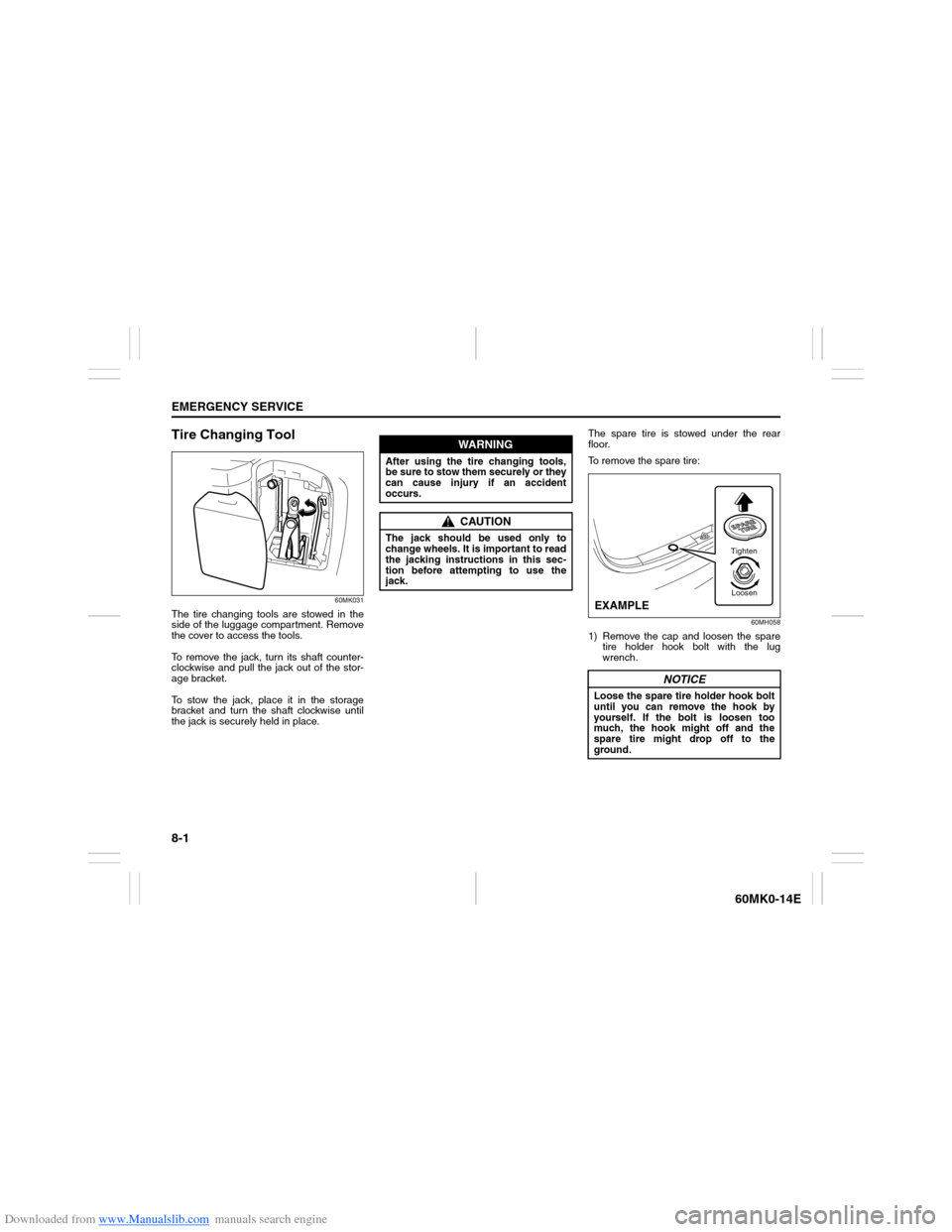

Tire Changing Tool

60MK031

The tire changing tools are stowed in the

side of the luggage compartment. Remove

the cover to access the tools.

To remove the jack, turn its shaft counter-

clockwise and pull the jack out of the stor-

age bracket.

To stow the jack, place it in the storage

bracket and turn the shaft clockwise until

the jack is securely held in place.The spare tire is stowed under the rear

floor.

To remove the spare tire:

60MH058

1) Remove the cap and loosen the spare

tire holder hook bolt with the lug

wrench.

WARNING

After using the tire changing tools,

be sure to stow them securely or they

can cause injury if an accident

occurs.

CAUTION

The jack should be used only to

change wheels. It is important to read

the jacking instructions in this sec-

tion before attempting to use the

jack.

NOTICE

Loose the spare tire holder hook bolt

until you can remove the hook by

yourself. If the bolt is loosen too

much, the hook might off and the

spare tire might drop off to the

ground.

Tighten

Loosen

EXAMPLE

Page 184 of 207

Downloaded from www.Manualslib.com manuals search engine 8-3EMERGENCY SERVICE

60MK0-14E

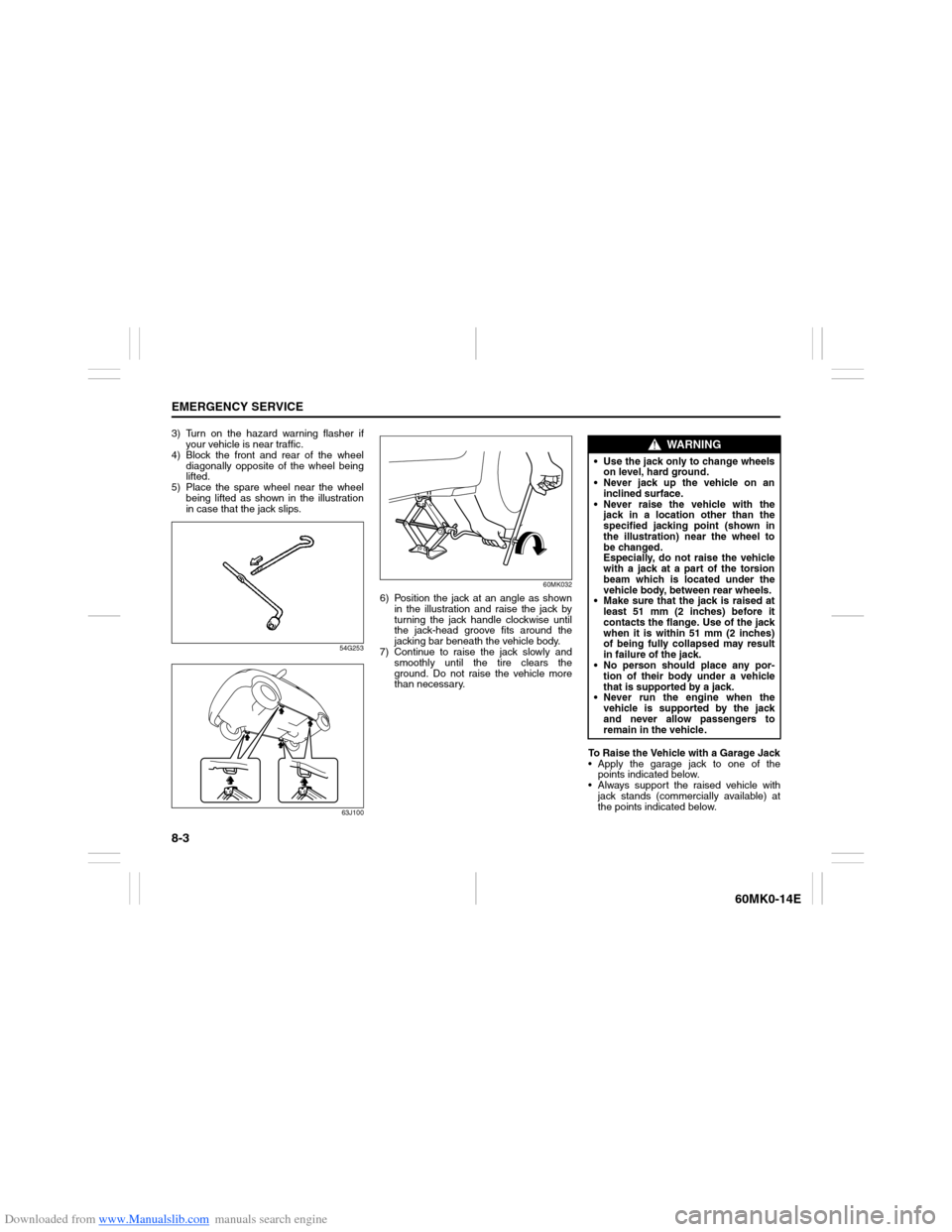

3) Turn on the hazard warning flasher if

your vehicle is near traffic.

4) Block the front and rear of the wheel

diagonally opposite of the wheel being

lifted.

5) Place the spare wheel near the wheel

being lifted as shown in the illustration

in case that the jack slips.

54G253

63J10060MK032

6) Position the jack at an angle as shown

in the illustration and raise the jack by

turning the jack handle clockwise until

the jack-head groove fits around the

jacking bar beneath the vehicle body.

7) Continue to raise the jack slowly and

smoothly until the tire clears the

ground. Do not raise the vehicle more

than necessary.

To Raise the Vehicle with a Garage Jack

Apply the garage jack to one of the

points indicated below.

Always support the raised vehicle with

jack stands (commercially available) at

the points indicated below.

WARNING

Use the jack only to change wheels

on level, hard ground.

Never jack up the vehicle on an

inclined surface.

Never raise the vehicle with the

jack in a location other than the

specified jacking point (shown in

the illustration) near the wheel to

be changed.

Especially, do not raise the vehicle

with a jack at a part of the torsion

beam which is located under the

vehicle body, between rear wheels.

Make sure that the jack is raised at

least 51 mm (2 inches) before it

contacts the flange. Use of the jack

when it is within 51 mm (2 inches)

of being fully collapsed may result

in failure of the jack.

No person should place any por-

tion of their body under a vehicle

that is supported by a jack.

Never run the engine when the

vehicle is supported by the jack

and never allow passengers to

remain in the vehicle.

Page 189 of 207

Downloaded from www.Manualslib.com manuals search engine 8-8

EMERGENCY SERVICE

60MK0-14E

2-Wheel Drive (2WD) Manual Tran-

saxleManual transaxle vehicles may be towed

using either of the following methods.

1) From the front, with the front wheels

lifted and the rear wheels on the

ground. Before towing, make sure that

the parking brake is released.

2) From the rear, with the rear wheels

lifted and the front wheels on the

ground, provided the steering and driv-

etrain are in operational condition.

Before towing, make sure that transaxle

is in neutral, the steering wheel is

unlocked (the ignition key should be in

the “ACC” position), and the steering

wheel is secured with a clamping

device designed for towing service.

If the Starter Does Not

Operate1) Try turning the ignition switch to the

“START” position with the headlights

turned on to determine the battery con-

dition. If the headlights go excessively

dim or go off, it usually means that

either the battery is flat or the battery

terminal contact is poor. Recharge the

battery or correct battery terminal con-

tact as necessary.

2) If the headlights remain bright, check

the fuses. If the reason for failure of the

starter is not obvious, there may be a

major electrical problem. Have the vehi-

cle inspected by your authorized

SUZUKI dealer.

If the Engine is FloodedIf the engine is flooded with gasoline, it

may be hard to start. If this happens, press

the accelerator pedal all the way to the

floor and hold it there while cranking the

engine. (Do not operate the starter motor

for more than 15 seconds).

NOTICE

The steering column is not strong

enough to withstand shocks trans-

mitted from the front wheels during

towing. Always unlock the steering

wheel before towing.