drain bolt SUZUKI GRAND VITARA 1987 Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 265 of 962

13-3. DISMOUNTINGIn Passenger Compartment

1) Loosen 4 bolts fastening gear shift lever boot

No. 2 and move boot upward.

Fig.

13-2- 1 Under Engine

7) Remove drain plug to drain oil in transmis-

sion.

8) Disconnect clutch wire from clutch release

lever.

9) Remove propeller shaft No. 1 (from trans-

mission to transfer).

10) Remove propeller shaft No. 2 (from transfer

to front differential).

11) Remove clutch housing lower plate from

transmission case.

2) Move gear shift boot No. 1 upward. Loosen

gear shift lever case cover bolts (3

PCS) and

draw gear shift lever out of lever case.

Fig. 13-2-3

Fig. 13-2-2 In Engine Room

3) Disconnect negative (-) and positive (+)

cords from battery terminals.

4) Disconnect back light and fifth switch lead

wires at coupler respectively.

5) Disconnect Black/Yellow lead wire and posi- tive

(+) cord from starter motor.

6) Remove starter motor from transmission

case and fuel hoses clamp from transmission

case.

12) Remove bolts and nuts fastening engine

cylinder block and transmission case.

13) Remove pipe (iJ as shown in Fig. 13-24.

Fig. 13-2-4

14) Remove exhaust center pipe.

15) Remove transmission rear mounting bracket

from chassis and transmission case.

NOTE:

Before starting to remove transmission, check

around once again to be sure that there is no

connection left undone.

16) Take down transmission.

13-4

Page 293 of 962

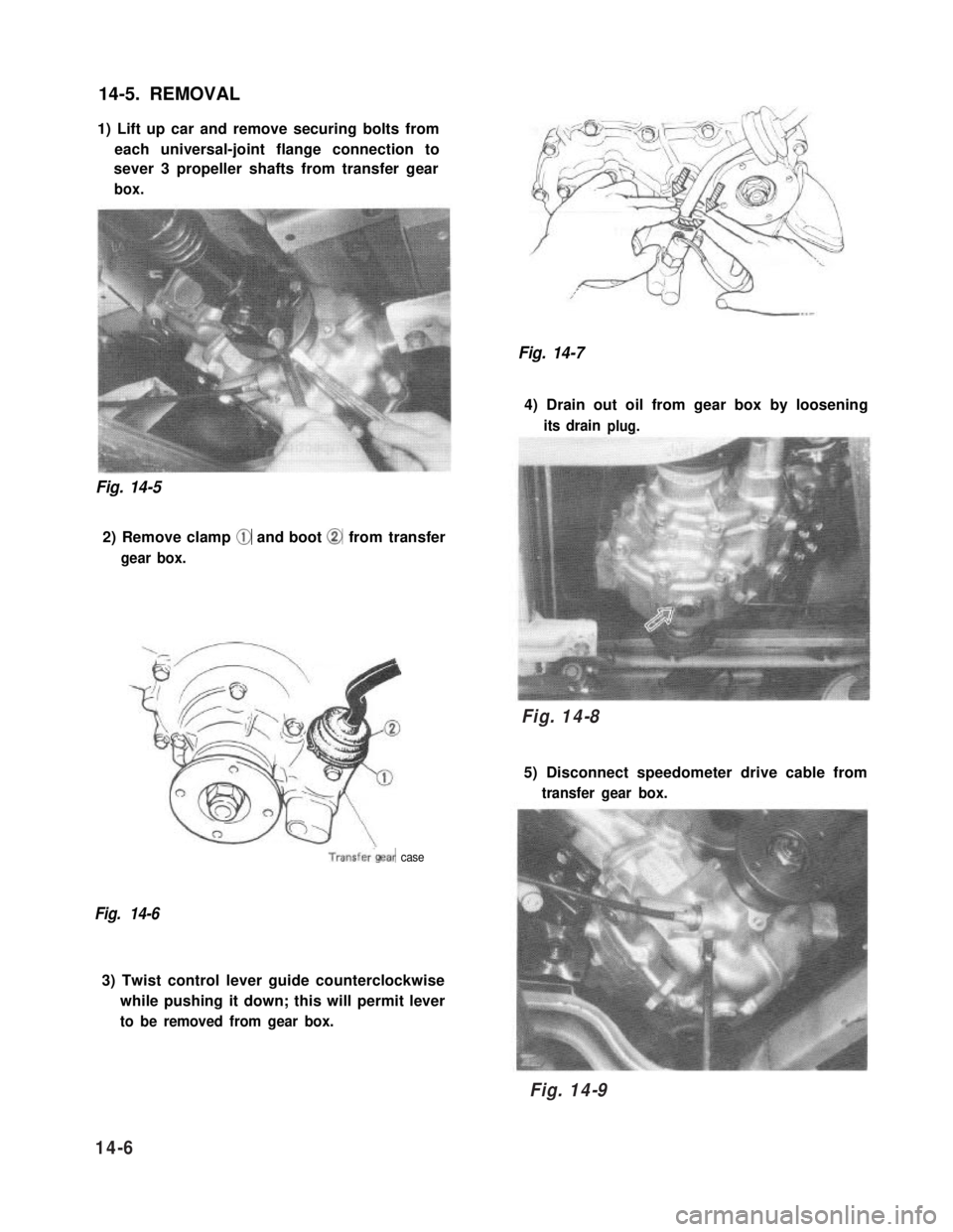

14-5. REMOVAL

1) Lift up car and remove securing bolts from

each universal-joint flange connection to

sever 3 propeller shafts from transfer gear

box.

Fig. 14-5

2) Remove clamp @ and boot @ from transfer

gear box.

Fig. 14-7

4) Drain out oil from gear box by loosening

its drainplug.

Fig. 14-8

5) Disconnect speedometer drive cable from

transfer gear box.

Transfer‘gear case

Fig. 14-6

3) Twist control lever guide counterclockwise

while pushing it down; this will permit lever

to be removed from gear box.

14-6

Fig. 14-8

Fig. 14-9

Page 310 of 962

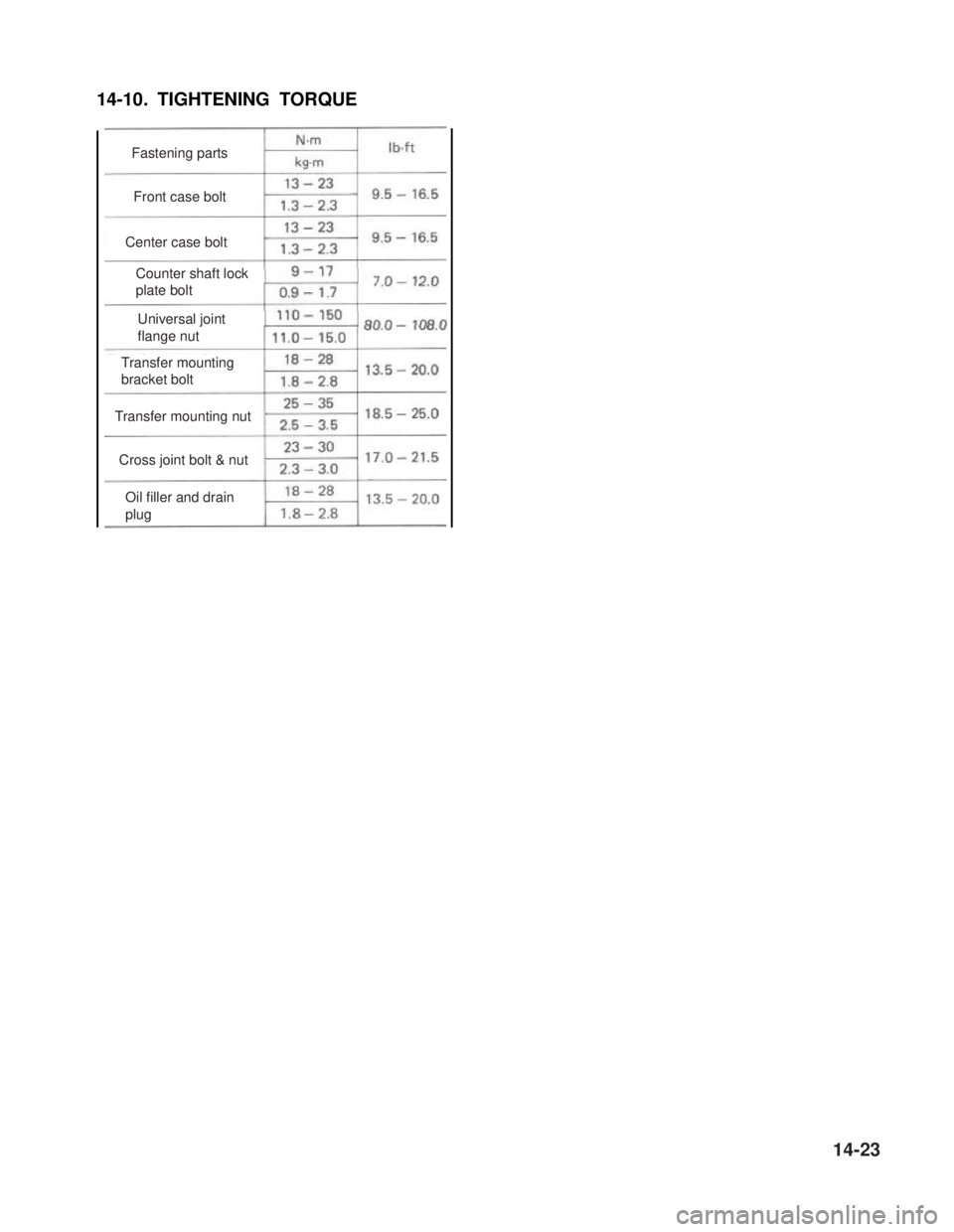

14-10. TIGHTENING TORQUE

Counter shaft lock

Universaljoint flange

Oil filler and drain

plug

Cross joint bolt & nut

Transfer mounting nut

Transfer mounting

bracket bolt

Universal joint

flange nut

Counter shaft lock

plate bolt

Center case bolt

Front case bolt

Fastening parts

14-23

Page 313 of 962

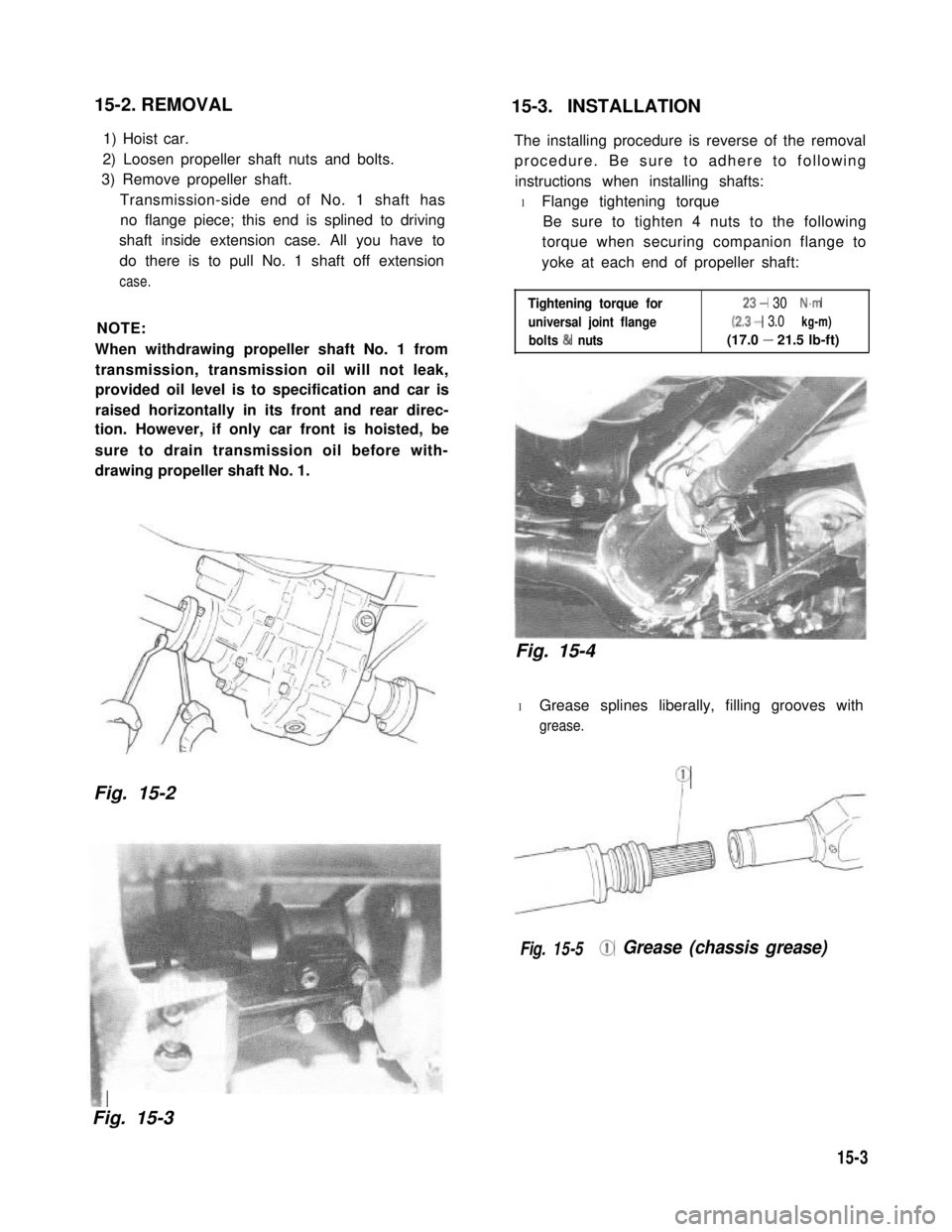

15-2. REMOVAL15-3. INSTALLATION

1) Hoist car.

2) Loosen propeller shaft nuts and bolts.

3) Remove propeller shaft.

Transmission-side end of No. 1 shaft has

no flange piece; this end is splined to driving

shaft inside extension case. All you have to

do there is to pull No. 1 shaft off extension

case.

NOTE:

When withdrawing propeller shaft No. 1 from

transmission, transmission oil will not leak,

provided oil level is to specification and car is

raised horizontally in its front and rear direc-

tion. However, if only car front is hoisted, be

sure to drain transmission oil before with-

drawing propeller shaft No. 1.

Fig. 15-2

The installing procedure is reverse of the removal

procedure. Be sure to adhere to following

instructions when installing shafts:

l Flange tightening torque

Be sure to tighten 4 nuts to the following

torque when securing companion flange to

yoke at each end of propeller shaft:

Tightening torque for

universal joint flange

bolts & nuts

23- 30 N.m

(2.3- 3.0 kg-m)

(17.0 - 21.5 lb-ft)

Fig. 15-4

l Grease splines liberally, filling grooves with

grease.

Q

Fig. 15-5@ Grease (chassis grease)

f&,a.

Fig. 15-3

15-3

Page 320 of 962

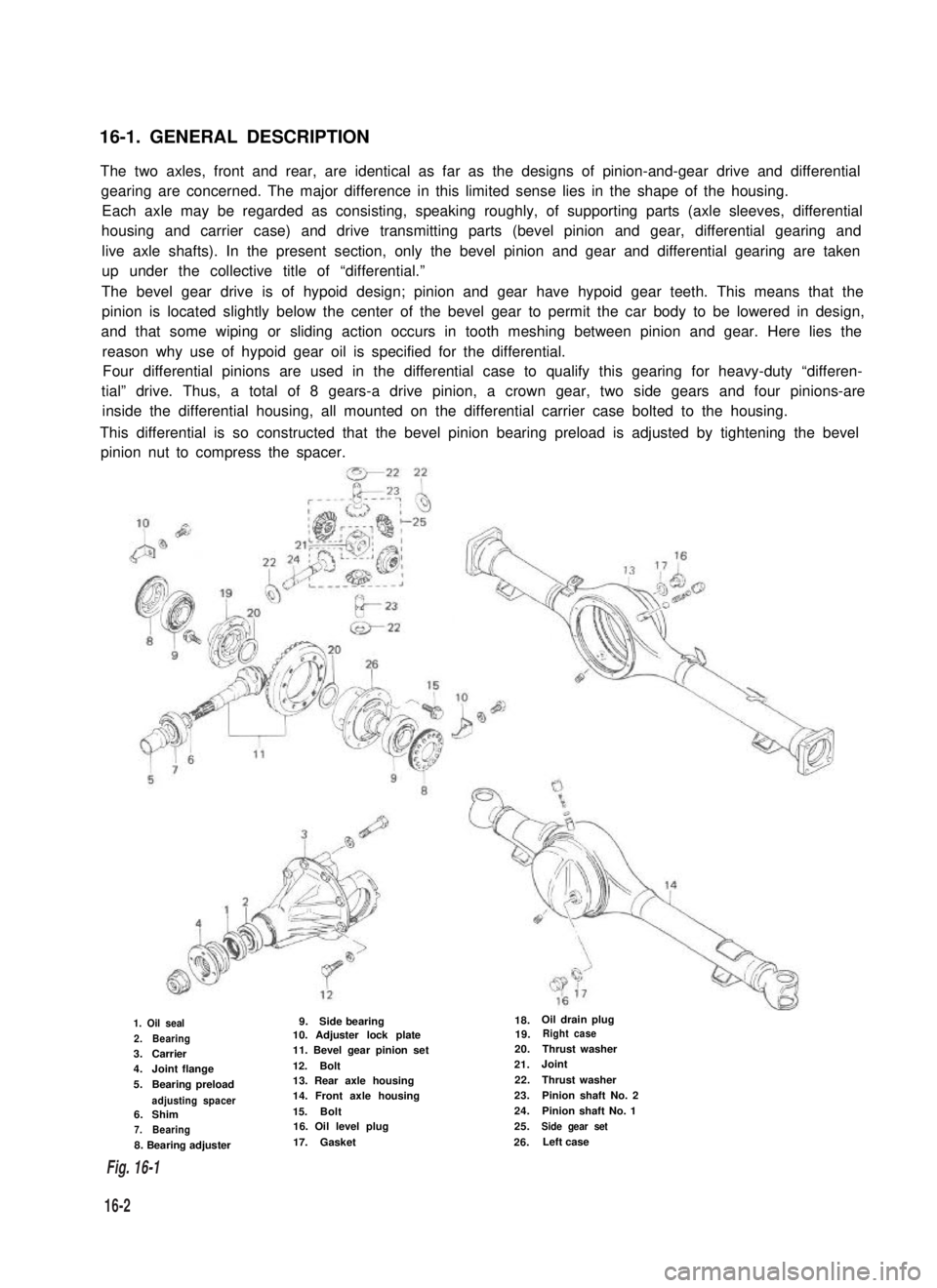

16-1. GENERAL DESCRIPTION

The two axles, front and rear, are identical as far as the designs of pinion-and-gear drive and differential

gearing are concerned. The major difference in this limited sense lies in the shape of the housing.

Each axle may be regarded as consisting, speaking roughly, of supporting parts (axle sleeves, differential

housing and carrier case) and drive transmitting parts (bevel pinion and gear, differential gearing and

live axle shafts). In the present section, only the bevel pinion and gear and differential gearing are taken

up under the collective title of “differential.”

The bevel gear drive is of hypoid design; pinion and gear have hypoid gear teeth. This means that the

pinion is located slightly below the center of the bevel gear to permit the car body to be lowered in design,

and that some wiping or sliding action occurs in tooth meshing between pinion and gear. Here lies the

reason why use of hypoid gear oil is specified for the differential.

Four differential pinions are used in the differential case to qualify this gearing for heavy-duty “differen-

tial” drive. Thus, a total of 8 gears-a drive pinion, a crown gear, two side gears and four pinions-are

inside the differential housing, all mounted on the differential carrier case bolted to the housing.

This differential is so constructed that the bevel pinion bearing preload is adjusted by tightening the bevel

pinion nut to compress the spacer.

1. Oil seal

2.Bearing3.Carrier4.Joint flange

5.Bearing preload

adjusting spacer6.Shim7.Bearing

8. Bearing adjuster

9.Side bearing10. Adjuster lock plate11. Bevel gear pinion set

12.Bolt13. Rear axle housing14. Front axle housing

15.Bolt16. Oil level plug

17.Gasket

18.Oil drain plug19.Right case

20.Thrust washer

21.Joint

22.Thrust washer

23.Pinion shaft No. 2

24.Pinion shaft No. 1

25.Side gear set

26.Left case

16-2

Fig. 16-1

Page 321 of 962

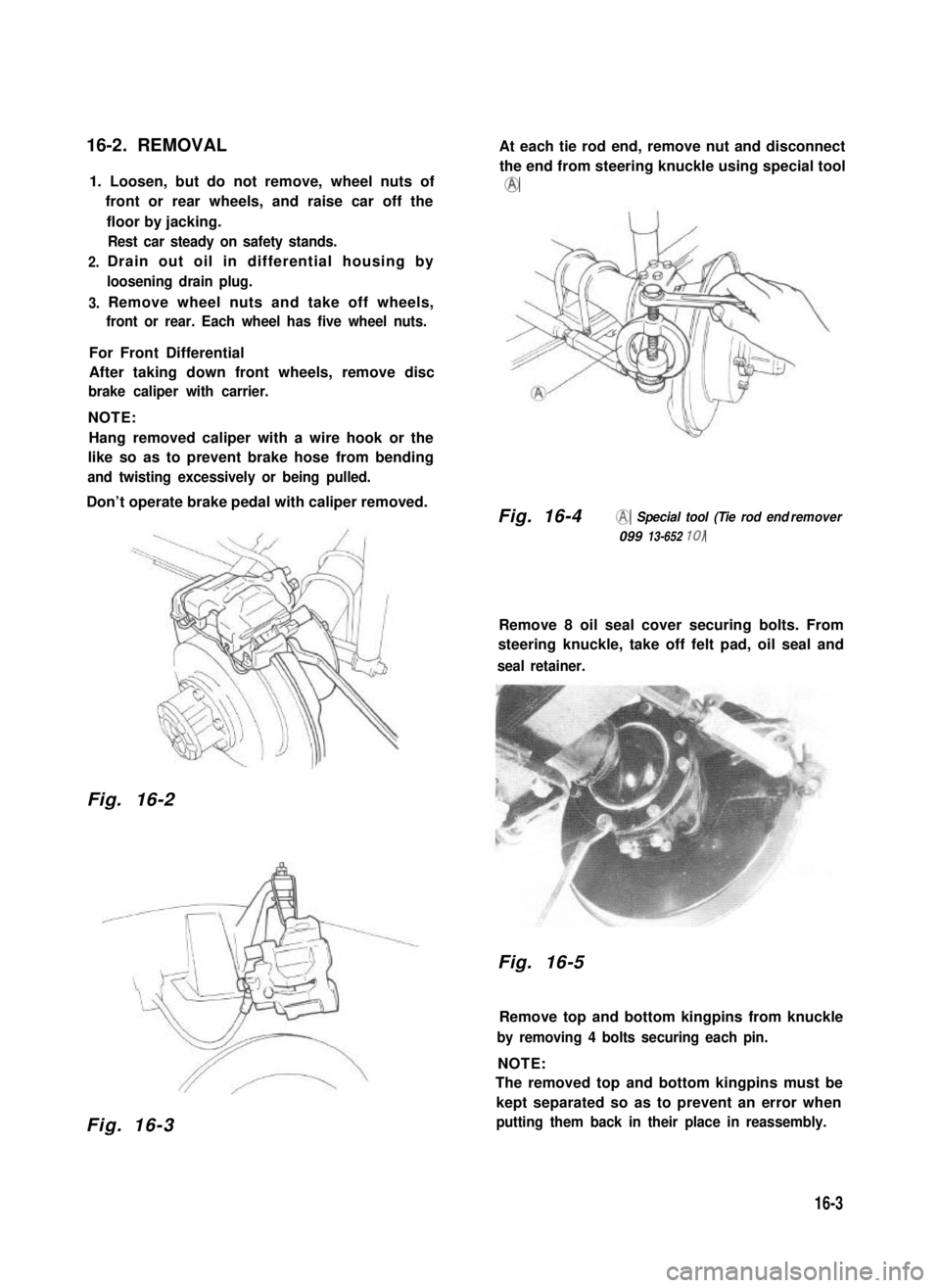

16-2. REMOVAL

1. Loosen, but do not remove, wheel nuts of

front or rear wheels, and raise car off the

2.

3.

floor by jacking.

Rest car steady on safety stands.

Drain out oil in differential housing by

loosening drain plug.

Remove wheel nuts and take off wheels,

front or rear. Each wheel has five wheel nuts.

For Front Differential

After taking down front wheels, remove disc

brake caliper with carrier.

NOTE:

Hang removed caliper with a wire hook or the

like so as to prevent brake hose from bending

and twisting excessively or being pulled.

Don’t operate brake pedal with caliper removed.

Fig. 16-2

Fig. 16-3

At each tie rod end, remove nut and disconnect

the end from steering knuckle using special tool

@

Fig. 16-4@ Special tool (Tie rod end remover

099 13-652 10)

Remove 8 oil seal cover securing bolts. From

steering knuckle, take off felt pad, oil seal and

seal retainer.

Fig. 16-5

Remove top and bottom kingpins from knuckle

by removing 4 bolts securing each pin.

NOTE:

The removed top and bottom kingpins must be

kept separated so as to prevent an error when

putting them back in their place in reassembly.

16-3

Page 334 of 962

16-7. MAINTENANCE SERVICES

Inspection

Inspect differential and differential housing for

evidence of oil leakage.

Oil level ‘is checked by means of its oil level

plug. Refer to p 1-20 for level inspection,

Fig. 16-33 @ Drain plug

CD Oil level & filler plug

Oil Change

1 ) Remove oil drain plug and drain oil.

2) Reinstall drain plug and tighten it to specified

tightening torque.

3) Remove oil level & filler plug and fill diffe-

rential housing with new specified oil.

Differential oilHypoid gear oil

specificationSAE 8OW-90,75W-80 or 75W-90

OilFront2.0 litres (4.2/3.5 US/Imp pt.)

capacityRear1.5 litres (3.2/2.6 US/Imp pt.)

It is highly recommended to use SAE 75W-90

gear oil.

For viscosity chart, refer to P. 1-20.

16-8. RECOMMENDED TORQUE

SPECIFICATIONS

ITightening torqueI

IFastening partsN.m1 kg-m 11

Side bearing capbolt70- 1007.0-10.051 .O-72.0

Drive bevel gearbolt80- 908.0-9.058.0-66.0

Differential casebolt37-453.7-4.527.0-32.5I

4) Reinstall oil level & filler plug and tighten it

to specified tightening torque.

16-16

Side bearing adjusterlock bolt

Differential carrier bolt

Oil level & filler plug

Oil drain plug

Page 350 of 962

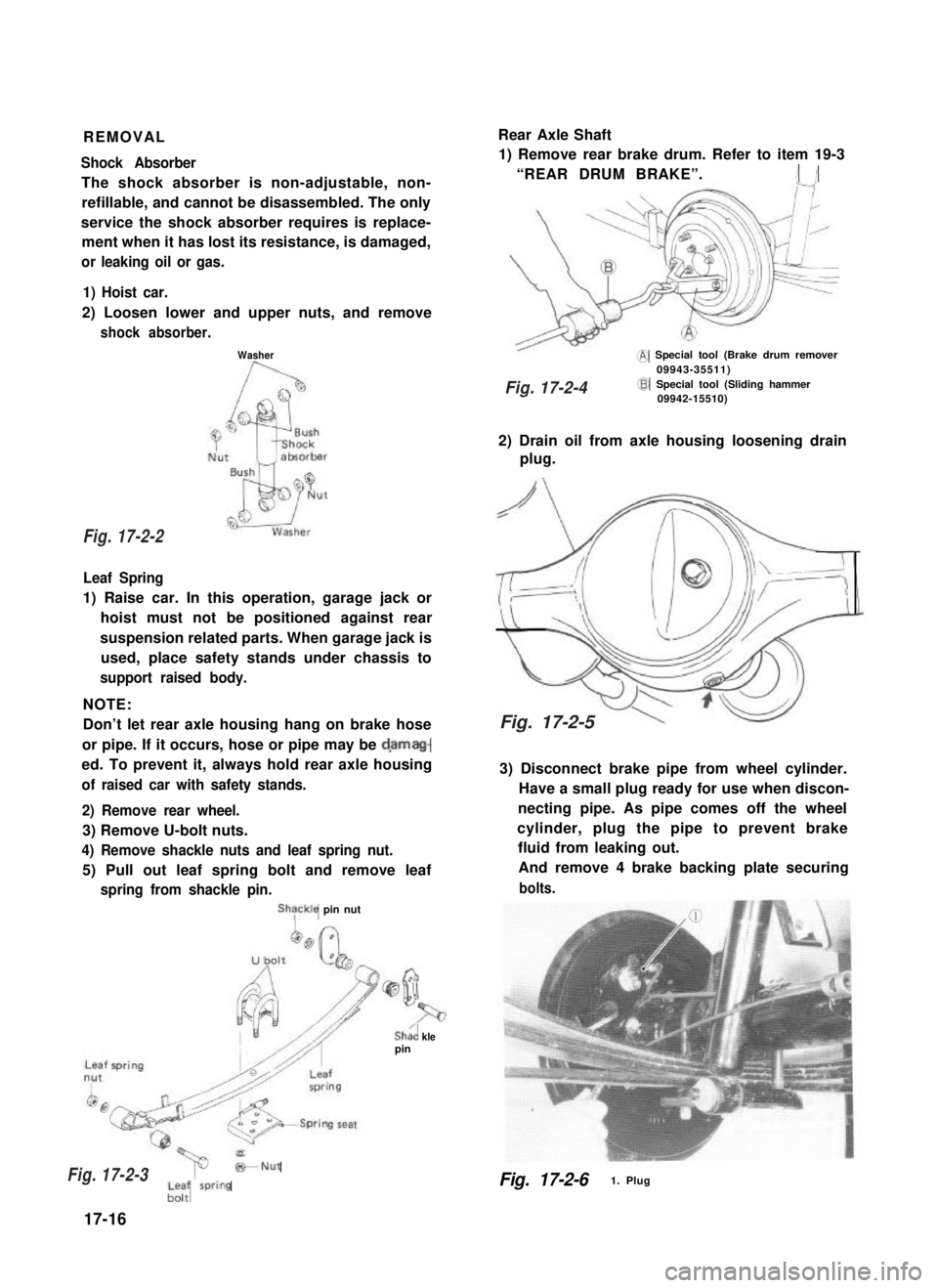

REMOVALRear Axle Shaft

Shock Absorber

The shock absorber is non-adjustable, non-

refillable, and cannot be disassembled. The only

service the shock absorber requires is replace-

ment when it has lost its resistance, is damaged,

or leaking oil or gas.

1) Remove rear brake drum. Refer to item 19-3

“REAR DRUM BRAKE”.I /

1) Hoist car.

2) Loosen lower and upper nuts, and remove

shock absorber.

Washer@ Special tool (Brake drum remover09943-35511)

Leaf Spring

1) Raise car. In this operation, garage jack or

hoist must not be positioned against rear

suspension related parts. When garage jack is

used, place safety stands under chassis to

support raised body.

NOTE:

Don’t let rear axle housing hang on brake hose

or pipe. If it occurs, hose or pipe may be d,amag-

ed. To prevent it, always hold rear axle housing

of raised car with safety stands.

2) Remove rear wheel.

3) Remove U-bolt nuts.

4) Remove shackle nuts and leaf spring nut.

5) Pull out leaf spring bolt and remove leaf

spring from shackle pin.

ShTckle pin nut

Sha’, klepin

@Special tool (Sliding hammer09942-15510)

2) Drain oil from axle housing loosening drain

plug.

3) Disconnect brake pipe from wheel cylinder.

Have a small plug ready for use when discon-

necting pipe. As pipe comes off the wheel

cylinder, plug the pipe to prevent brake

fluid from leaking out.

And remove 4 brake backing plate securing

bolts.

*Nut

;-; wring

17-16

Fig. 17-2-61. Plug

Fig. 17-2-2

Fig. 17-2-3

Fig. 17-2-4

Fig. 17-2-5