brake fluid SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 33 of 962

1-3. CHASSIS AND BODY

30. CLUTCH PEDAL INSPECTION

1) Check clutch pedal height. It should be the

same as brake pedal height.

2) Check clutch pedal free travel.

Clutch pedal free travel20 - 30 mm

(0.8 - 1.1 in.)

For the details of the above steps 1) and 2),

refer to MAINTENANCE SERVICE (p. 11-8) of

SECTION 11.

31. BRAKE DISCS, PADS, BRAKE DRUMS

AND SHOES INSPECTION

Brake Discs and Pads

I) Remove wheel and caliper but don’t discon-

nect brake hose from caliper.

2) Check front disc brake pads and discs for

excessivewear,damageand deflection.

Replace parts as necessary. For the details,

refer to p. 19-I 6 and 19-I 7 of SECT ION 19.

Be sure to torque caliper guide pins to specifi-

cation for reinstallation.

Brake Drums and Shoes

I) Remove wheel and brake drum.

2) Check rear brake drums and brake linings for

excessive wear and damage, while wheels and

drums are removed. Also check wheel cylin-

ders for leaks, at the same time. Replace

these parts as necessary.

For the details, refer to p. 19-21 and p. 19-

22 of SECTION 19.

32. BRAKE HOSES AND PIPES INSPECTION

Check brake hoses and pipes for proper hook-

up, leaks, cracks, chafing and other damage.

Replace any of these parts as necessary.

CAUTION:

After replacing any brake pipe or hose, be

sure to carry out air purge operation.

33. BRAKE FLUID INSPECTION AND

CHANGE

[INSPECTION]

1) Check around master cylinder and reservoir

for fluid leakage.

If found leaky, correct.

2) Check fluid level

If fluid level is lower than the minimum level

of reservoir, refilling is necessary. Fill reservoir

with specified brake fluids.

Brake fluid Speifi;t3ons

For the details, refer to MAINTENANCE

SERVICE (p. 19-42) of SECTION 19.

CAUTION:

Since the brake system of this car is factory-

filled with glycol-base brake fluid, do not

use or mix different type of fluid when

refilling the system; otherwise serious

damage will occur. Do not use old or used

brake fluid, or one taken from unsealed

container.

[CHANGE]

1) Change brake fluid. As fluid change procedure,

drain existing fluid from brake system com-

pletely, fill the system with above recom-

mended fluid and carry out air purge opera-

tion.

For description of air purge, refer to p. 19-46

and 19-47 of SECTION 19.

34. BRAKE PEDAL INSPECTION

Check brake pedal travel.

For -checking procedure, refer to PEDAL TRA-

VEL CHECK (p. 19-43) of SECTION 19.

35. BRAKE LEVER AND CABLE

INSPECTION

Parking Brake Lever

I) Check tooth tip of each notch for damage or

wear. If any damage or wear is found, replace

parking lever.

2) Check parking brake lever for proper opera-

tion and stroke, and adjust it if necessary.

For checking and adjusting procedures,

refer to PARKING BRAKE INSPECTION

AND ADJUSTMENT (p. 19-44) of SECTION

19.

1-17

Page 51 of 962

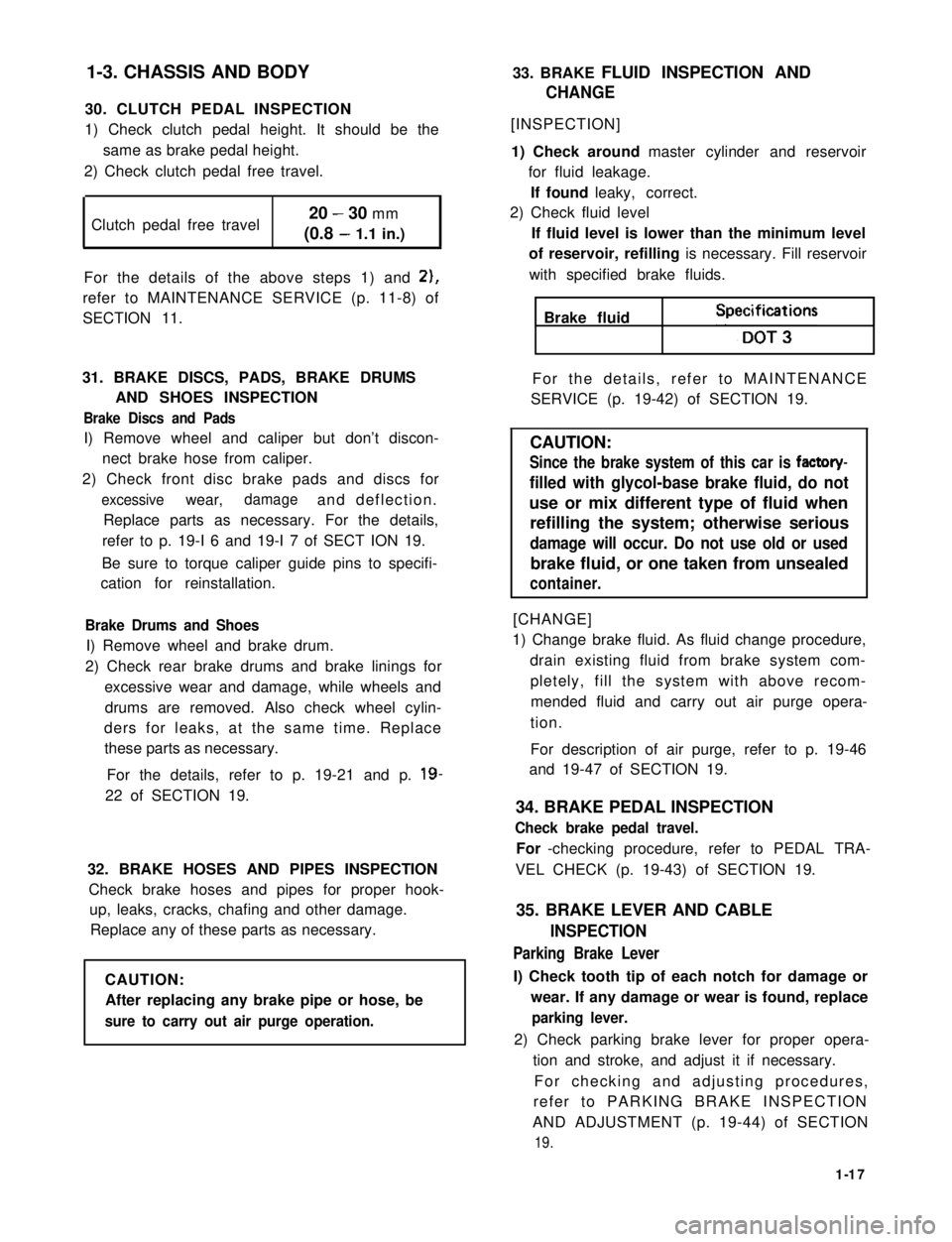

Condition

Excessive pedal travel

(Pedal stroke too

large)

Possible cause

1. Partial brake system failure

2. Insufficient fluid in master

cylinder reservoirs

Correction

Check diagonal brake systems and

repair as necessary

Fill reservoirs with approved brake

fluid. Check for leaks and air in

brake systems. Check warning light.

Bleed system if necessary.

3. Air in system (Pedal soft/spongy)Bleed system

4. Rear brake system not adjustedAdjust rear brakes (Repair auto

(malfunctioning auto adjustingadjusting mechanism)

mechanism)

5. Bent brake shoesReplace brake shoes

6. Worn rear brake shoesReplace brake shoes.

Dragging brakes (A

very light drag is pre-

sent in all disc brakes

immediately after

pedal is released)

1. Master cylinder pistons not

returning correctly

2. Clogged return port in master

cylinder

3. Restricted brake tubes or hoses

4. Incorrect parking brake

adjustment

5. Weakened or broken return

springs in the brake

Repair master cylinder

Clean

Check for soft hoses or damaged tubes

and replace with new hoses and/or

new double-walled steel brake tubing

Check and adjust to correct specifica-

tions

Replace

6. Sluggish parking-brake cables or

linkage

Repair or replace

7. Wheel cylinder or caliper piston

sticking

Repair as necessary

Pedal pulsation1. Damaged or loose wheel bearingsReplace wheel bearings

(Pedal pulsates when2. Excessive disc lateral runout Check per instructions. If not within

depressed for braking)specifications, replace or machine the

disc.

3. Parallelism not within specifica-Check per instructions. If not within

tionsspecifications, replace or machine the

disc.

4. Rear drums out of roundCheck runout.

Braking noise1. Glazed shoe linings, or foreignRepair or replace shoe lining

matters stuck to linings

2. Worn or distorted shoe liningsReplace shoe lining (or pad)

3. Loose front wheel bearingsReplace wheel bearings

4. Distorted backing plates or looseReplace or retighten securing bolts

mounting bolts

2-13

Page 244 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual [Carrier and hold-down]

The battery carrier and hold-down clamp should

be clean and free from corrosion before instal-

ling the battery. The carrier should be in good

condition so that it will support SUZUKI GRAND VITARA 1987 Service Repair Manual [Carrier and hold-down]

The battery carrier and hold-down clamp should

be clean and free from corrosion before instal-

ling the battery. The carrier should be in good

condition so that it will support](/img/20/57437/w960_57437-243.png)

[Carrier and hold-down]

The battery carrier and hold-down clamp should

be clean and free from corrosion before instal-

ling the battery. The carrier should be in good

condition so that it will support the battery

securely and keep it level.

Make certain there are no parts in carrier before

installing the battery.

To prevent the battery from shaking in its

carrier, the hold-down bolts should be tight but

not over tightened.

[Visual inspection]

Check for obvious damage, such as cracked or

broken case or cover, that could permit loss of

electrolyte. If obvious damage is noted, replace

the battery. Determine cause of damage and

correct as needed.

Check the battery terminal and cords for corro-

sion. If any, it should be cleaned.

[Built-in indicator]

This sealed battery has a built-in temperature

compensated indicator in the top of the battery.

This indicator is to be used with the following

diagnostic procedure. When observing the

indicator, make sure that the battery has a clean

top. A light may be needed in some poorly-lit

areas.

Under normal operation, two indications can

be seen

2

Clear

RedCHARGING

NECESSARY

Fig. lo-23

l Clear with Red Dot

This means the discharging battery. In this case,

charge the battery until the indicator will be

blue with red dot. The charging and electrical

systems should also be checked at this time. If

any defective is found, correct it. While charging

it, if the battery feels hot 52°C (125” F), or if

violent gassing or spewing of electrolyte through

the vent hole occurs, discontinue charging or

reduce charging rate.

[Jump starting in case of emergency with

auxiliary (booster) battery]

NOTE:

l Do not push or tow the vehicle to start.

Damage to the emission system and/or to

other parts of the vehicle may result.

8 Both booster and discharged battery should

be treated carefully when using jumper cables.

Follow the procedure outlined below, being

careful not to cause sparks:

CAUTION:

l Departure from these conditions or the

procedure below could result in: (1)

Serious personal injury (particularly to

eyes) or property damage from such

causes as battery explosion, battery acid,

or electrical burns; and/or (2) damage to

electronic components of either vehicle.

l Never expose battery to open flame or

electric spark-batteries generate a gas

which is flammable and explosive.

l Remove rings,watches,and other

jewelry. Wear approved eye protection.

l Do not allow battery fluid to contact

eyes, skin, fabrics, or painted surfaces -

fluid is a corrosive acid. Flush any con-

tacted area with water immediately and

thoroughly. Be careful that metal tools

or jumper cables do not contact the

positive battery terminal (or metal in

contact with it) and any other metal on

the car, because a short circuit could

occur. Batteries should always be kept

out of the reach of children.

1) Set parking brake and place transmission in

neutral. Turn off the ignition, turn off lights

and all other electrical loads.

2) Check electrolyte level. If level is below low

level line, replace battery.

NOTE:

When jump starting an engine with charging

equipment, be sure equipment used is 12volt

and negative ground. Do not use 24volt charging

equipment. Using each equipment can cause

serious damage to the electrical system or

electronic parts.

10-11

Page 323 of 962

Fig. 16-19-1 @ Special tool (Brake drum remover

09943-355 7 1)

Fig. 16-10 @ Special tool (Rear axle remover

09922-66010)

@ Special tool (Sliding hammer@ Special tool (Sliding hammer

09942- 15510)09942-15510)

Disconnect brake pipe from wheel cylinder.

Have a small plug ready for use when disconnect-

ing pipe. As pipe comes off the wheel cylinder,

plug the pipe to prevent brake fluid from

leaking out.

And remove 4 brake backing plate securing

bolts.

Fig. 16-9-2 @ Plug

Using special tools indicated below, draw out

each axle shaft with brake backing plate.

Disconnect propeller shaft as in the case of front

axle, and detach and take down differential

carrier case from housing by removing 8 bolts.

Fig. 16-11

16-5

Page 350 of 962

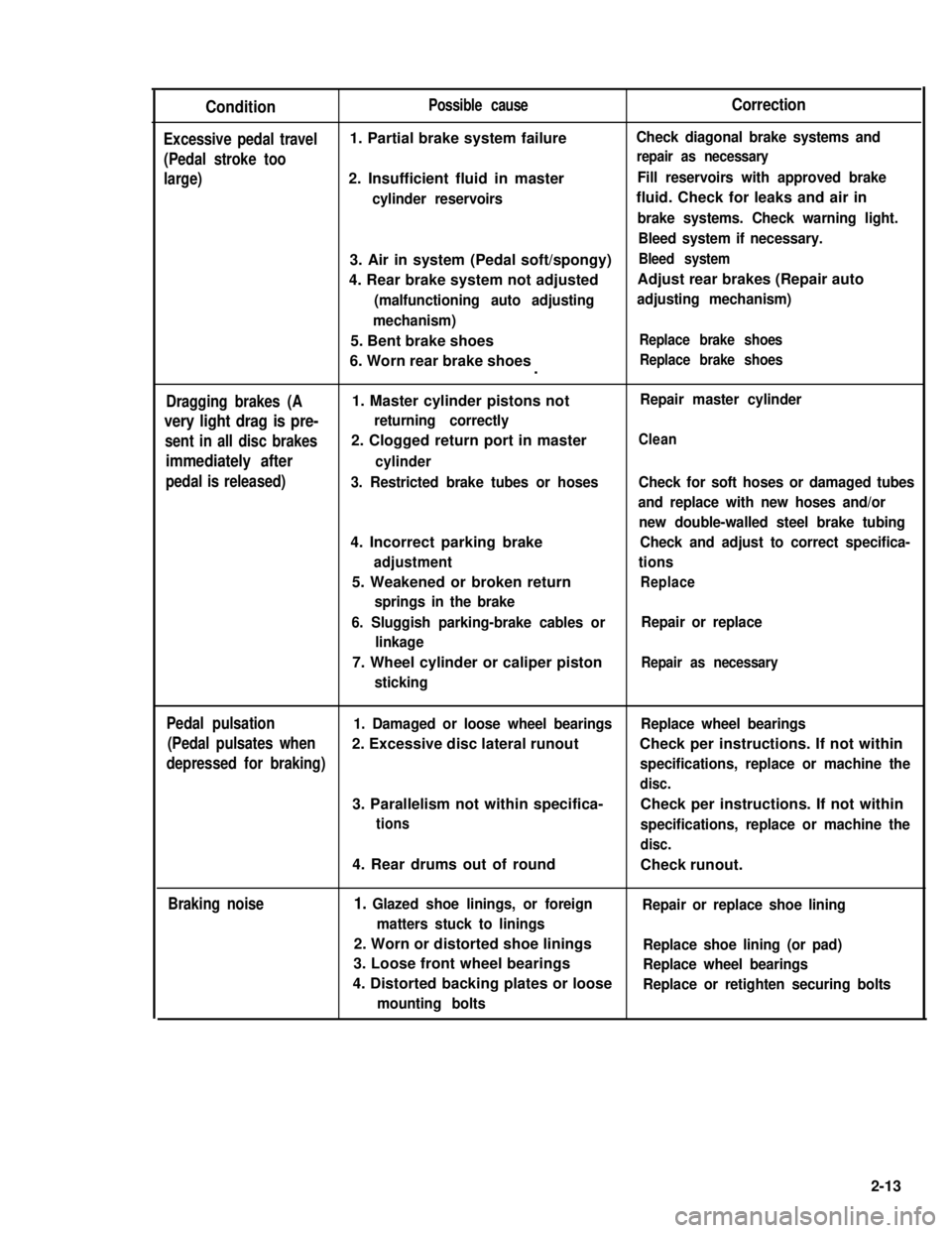

REMOVALRear Axle Shaft

Shock Absorber

The shock absorber is non-adjustable, non-

refillable, and cannot be disassembled. The only

service the shock absorber requires is replace-

ment when it has lost its resistance, is damaged,

or leaking oil or gas.

1) Remove rear brake drum. Refer to item 19-3

“REAR DRUM BRAKE”.I /

1) Hoist car.

2) Loosen lower and upper nuts, and remove

shock absorber.

Washer@ Special tool (Brake drum remover09943-35511)

Leaf Spring

1) Raise car. In this operation, garage jack or

hoist must not be positioned against rear

suspension related parts. When garage jack is

used, place safety stands under chassis to

support raised body.

NOTE:

Don’t let rear axle housing hang on brake hose

or pipe. If it occurs, hose or pipe may be d,amag-

ed. To prevent it, always hold rear axle housing

of raised car with safety stands.

2) Remove rear wheel.

3) Remove U-bolt nuts.

4) Remove shackle nuts and leaf spring nut.

5) Pull out leaf spring bolt and remove leaf

spring from shackle pin.

ShTckle pin nut

Sha’, klepin

@Special tool (Sliding hammer09942-15510)

2) Drain oil from axle housing loosening drain

plug.

3) Disconnect brake pipe from wheel cylinder.

Have a small plug ready for use when discon-

necting pipe. As pipe comes off the wheel

cylinder, plug the pipe to prevent brake

fluid from leaking out.

And remove 4 brake backing plate securing

bolts.

*Nut

;-; wring

17-16

Fig. 17-2-61. Plug

Fig. 17-2-2

Fig. 17-2-3

Fig. 17-2-4

Fig. 17-2-5

Page 389 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual MASTER CYLINDER ASSEMBLY

[GENERAL DESCRIPTION]

The master cylinder has two pistons and three piston cups. Its hydraulic pressure is produced in the

primary (“a” in the below figure) and secondary SUZUKI GRAND VITARA 1987 Service Repair Manual MASTER CYLINDER ASSEMBLY

[GENERAL DESCRIPTION]

The master cylinder has two pistons and three piston cups. Its hydraulic pressure is produced in the

primary (“a” in the below figure) and secondary](/img/20/57437/w960_57437-388.png)

MASTER CYLINDER ASSEMBLY

[GENERAL DESCRIPTION]

The master cylinder has two pistons and three piston cups. Its hydraulic pressure is produced in the

primary (“a” in the below figure) and secondary (“b”) chambers. The hydraulic pressure produced in the

primary chamber (“a”) acts on the front wheel brakes (right & left).

Also, the hydraulic pressure produced in the secondary chamber (“b”) acts on the rear wheel brakes

(right & left).

NOTE:

Replace all components included in repair kits to service this master cylinder. Lubricate rubber parts with

clean, fresh brake fluid to ease assembly. Do not use lubricated shop air on brake parts as damage to rubber

components may result. If any hydraulic component is removed or brake line disconnected, bleed the

brake system. The torque values specified are for dry, unlubricated fasteners.

1.Piston stopper circllp

2.Piston stopper

3.Piston stopper sealing

4.Primary piston

5.Piston cup

6.Secondary piston pressure cup

7.Piston cup

8Secondary piston

9.Return spring secondary seat

10.Secondary piston return spring

11.Secondary piston stopper bolt

12.Master cylinder body

A :Primary piston

BSecondary piston

Fig. 19-3

[Master cylinder OPERATION]

Normal operation

Depressing the brake pedal forces the primary piston“A” to move to the left in the below figure and

consequently the hydraulic pressure is produced in the chamber “a”.

By means of this pressure and the return spring force, the secondary piston “B” is also pushed to the left

and thus the hydraulic pressure is produced in the chamber “b”.

Fig. 19-3-1

19-4

Page 390 of 962

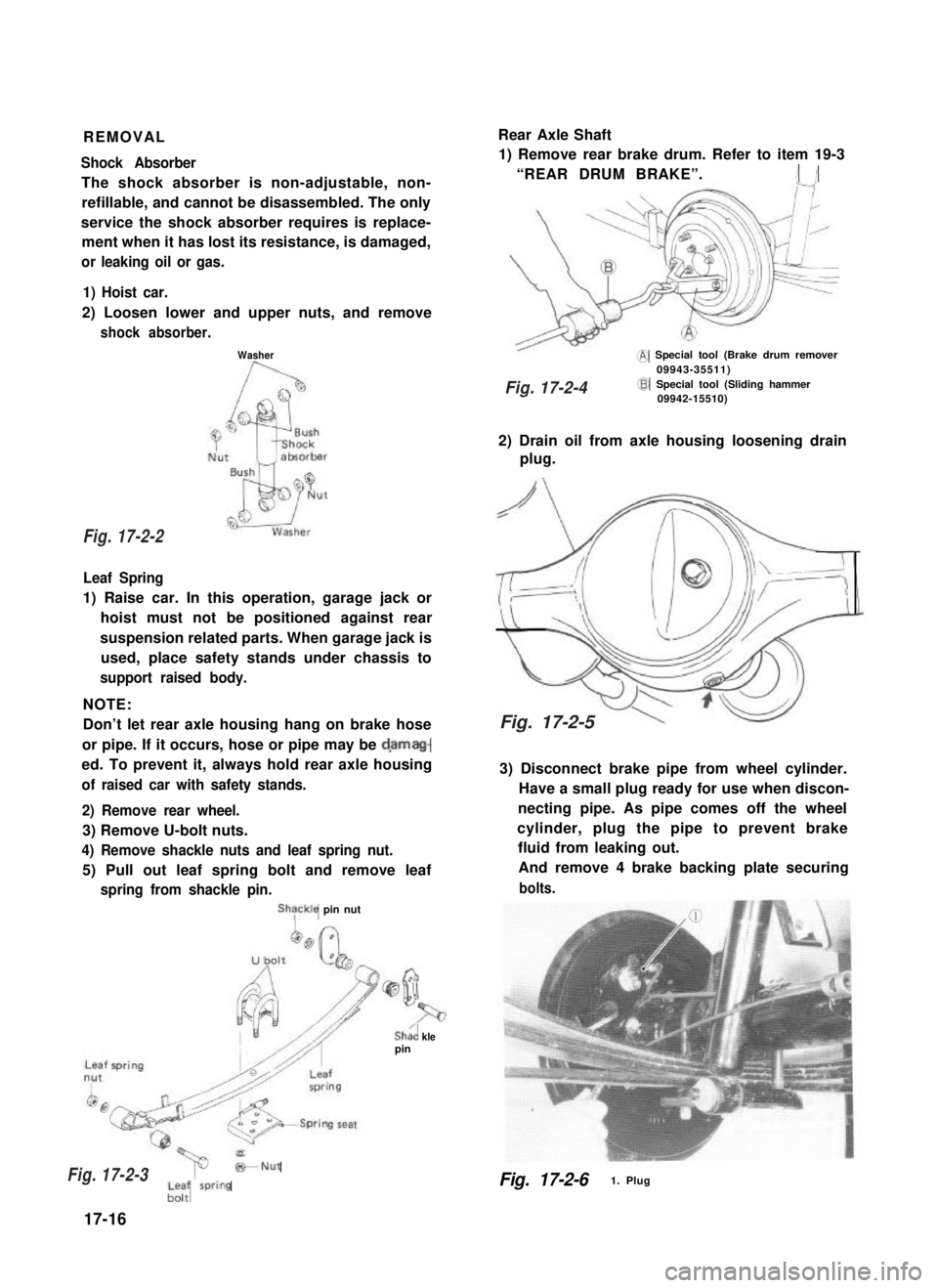

One-circuit operation (Primary chamber “a” circuit failure)

Depressing the brake pedal forces the primary piston “A” to move as described previously, but since the

brake circuit connected to the chamber “a” cannot hold the pressure, no pressure is produced in the fluid

immediately ahead of the piston“A”. The piston “A” keeps moving while compressing the spring and

when it reaches the retainer, the piston “B” is pushed and begins to move. This causes the pressure to rise

in the chamber “b” and the pressure acts on rear wheel brakes (right & left).

One-circuit operation (Secondary chamber “b” circuit failure)

In this case, the leftward movement of the piston “A” has but little effect in causing the fluid pressure to

rise in the chamber “a” in the beginning, because the initial rise of the fluid pressure causes the piston “B”

to promptly yield and move to the left. However, when the forward end of the piston “B” comes to the

head of the cylinder and stops there, the Ieftward movement of the piston “A” becomes effective. Thus

the’fluid pressure is produced in the chamber “a” and it acts on front wheel brakes (right & left).

The below figure shows secondary piston “B” at halt.

19-5

Fig. 19-4

Fig. 19-4

Page 392 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual [Caliper OPERATION]

Single piston floating caliper type

The single piston floating caliper type brake is

employed in this model. One cylinder and one

piston are used for this type. (The cylinder is

co SUZUKI GRAND VITARA 1987 Service Repair Manual [Caliper OPERATION]

Single piston floating caliper type

The single piston floating caliper type brake is

employed in this model. One cylinder and one

piston are used for this type. (The cylinder is

co](/img/20/57437/w960_57437-391.png)

[Caliper OPERATION]

Single piston floating caliper type

The single piston floating caliper type brake is

employed in this model. One cylinder and one

piston are used for this type. (The cylinder is

constructed as a monoblock with the caliper.)

Fluid pressure generated in the cylinder causes

the pad (1) on the piston side to press against

the disc. At the same time, the floating type

caliper body is moved to the right by the cylin-

der pressure, as shown in below figure, which

pulls pad (2) against the disc and so brakes the

wheel.

Caliper body

\Brake disc (rotor)

Fig. 19-6 - ’

The disc brake has no servo assistance as in drum

braking, and it is necessary to increase the work-

ing pressure of the piston and pad. For this pur-

pose, the wheel cylinder has a large bore. Even

only a little change in clearance between the disc

and pad has therefore a large influence on the

brake pedal stroke. It is necessary to have the

clearance adjusted to the minimum at all times,

by means of the piston (rubber) seal.

Piston seal (Rubber seal)Piston sealWinder (Rubber seal)

II

IPiston

Hydraulic pressure

“OFF“

Fig. 19-7

Clearance correction

Piston

Hydraulic pressure

“ON”

When oil pressure is applied to the piston, the

piston moves forward. The rubber seal, which

exerts considerable pressure against the piston,

moves with the cylinder. However, as a part of

the rubber seal has been fixed into a groove in

the cylinder, the shape of the rubber seal is dis-

torted toward internal end of the cylinder, as

shown in above figure. When pressure is taken

off from the foot brake pedal and fluid pressure

is released from the piston, a restoring force is

generated at the seal and pushes the piston back.

As the pads wear away and the clearance be-

tween the disc and pads becomes larger, the

piston moves a larger distance. The seal then

could change in shape further but, since the end

of the seal is fixed into the groove in the cylin-

der, the distortion is limited to the same amount

as previously described. The piston moves

further to cover the distance of clearance. The

piston returns by the same distance and the

rubber seal recovers its shape as described

above and thus the clearance between the disc

and pads are maintained in adjustment.

19-7

Cylinder

Page 394 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual [Rear brake OPERATION]

With the general drum brake type, when the

brake pedal is depressed, two pistons in the

wheel cylinder force the brake shoes outward,

restraining the turn of the drum.

The more SUZUKI GRAND VITARA 1987 Service Repair Manual [Rear brake OPERATION]

With the general drum brake type, when the

brake pedal is depressed, two pistons in the

wheel cylinder force the brake shoes outward,

restraining the turn of the drum.

The more](/img/20/57437/w960_57437-393.png)

[Rear brake OPERATION]

With the general drum brake type, when the

brake pedal is depressed, two pistons in the

wheel cylinder force the brake shoes outward,

restraining the turn of the drum.

The more the brake shoes get worn, the longer

distance the pistons must move. As a result, the

brake pedal travel (pedal-to-wall clearance)

increases. Then the shoe clearance must be

adjusted by the shoe adjusting screws. Thus

periodical adjustment is required for the drum

brake type in general.

This rear brake is provided with a self-adjusting

system which automatically adjusts the shoe-to-

drum clearance (pedal-to-wall clearance) caused

by such brake shoe wear.

Clearance correction

In each rear wheel cylinder, pistons, piston cups,

and a piston spring (1) are installed. When the

brake pedal is depressed, fluid pressure is applied

to the inside of the chamber on the piston (2),

(3).

Being actuated by this pressure, the piston (2)

moves to the left (piston (3) moves to the right)

in the following figure and presses the brake

shoe against the brake drum, thus producing

brake force.

(2)(3)

Fig. 19-9

At this time, the distance the brake shoe moves

is “B”,that is, the distance that “A” (the end of

the long hole made in the brake shoes web)

moves till it contacts the lever (1) which is fitted

in the long hole.

Fig. 19-10

When the brake pedal is depressed, the piston

and brake shoe move toward the brake drum

side by the aforementioned distance “B” and

“A” of the brake shoe web contacts the lever

(1). As the brake shoe gets worn and the brake

shoe clearance becomes larger, the force applied

to the lever (1) at the time of such a contact

becomes larger. When it exceeds 10 - 12 kg

(22 - 26 Ibs), the “A” of the brake shoe web

moves the lever (1) as much as the amount of

the brake shoe lining wear toward the direction

as shown with an arrow in the figure. Thus the

shoe is forced against the drum and the brake

force is produced.

19-9

Page 400 of 962

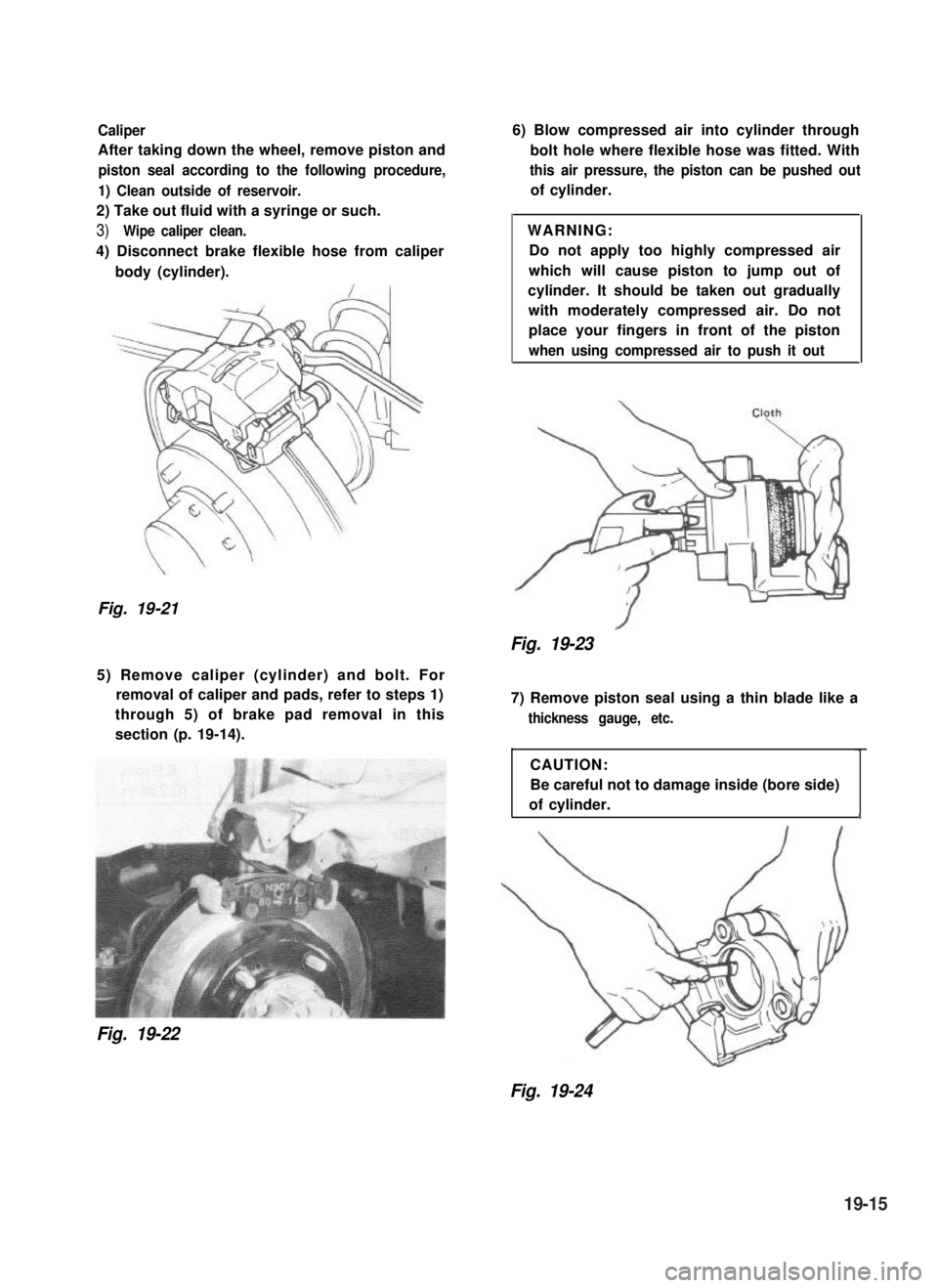

Caliper

After taking down the wheel, remove piston and

piston seal according to the following procedure,

1) Clean outside of reservoir.

2) Take out fluid with a syringe or such.

3)Wipe caliper clean.

4) Disconnect brake flexible hose from caliper

body (cylinder).

Fig. 19-21

6) Blow compressed air into cylinder through

bolt hole where flexible hose was fitted. With

this air pressure, the piston can be pushed out

of cylinder.

WARNING:

Do not apply too highly compressed air

which will cause piston to jump out of

cylinder. It should be taken out gradually

with moderately compressed air. Do not

place your fingers in front of the piston

when using compressed air to push it out

Fig. 19-23

5) Remove caliper (cylinder) and bolt. For

removal of caliper and pads, refer to steps 1)

through 5) of brake pad removal in this

section (p. 19-14).

Fig. 19-22

7) Remove piston seal using a thin blade like a

thickness gauge, etc.

CAUTION:

Be careful not to damage inside (bore side)

of cylinder.1

Fig. 19-24

19-15