fuel SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 2 of 962

TABLE OF CONTENTS

GENERAL, SPECIAL TOOLS AND SERVICE MATERIALS

PERIODIC MAINTENANCE SERVICE

TROUBLE SHOOTING

ENGINE

FUEL SYSTEM (CARBURETOR, AIR CLEANER FUEL PUMP AND FUEL FILTER)

EMISSION CONTROL SYSTEM

ENGINE COOLING SYSTEM

CAR HEATER

IGNITION SYSTEM

CRANKING SYSTEM

CHARGING SYSTEM

CLUTCH

GEAR SHIFTING CONTROL

TRANSMISSION

TRANSFER GEAR BOX

PROPELLER SHAFTS

DIFFERENTIAL

SUSPENSION

STEERING SYSTEM

BRAKES

BODY SERVICE

,i BODY ELECTRICAL EQUIPMENT

SERVICE DATA

0

1

2

5

6

7

8

9

10

1111

12

13

14

15

16

17

18

19

20

21

22

4

3

SECTION

Page 27 of 962

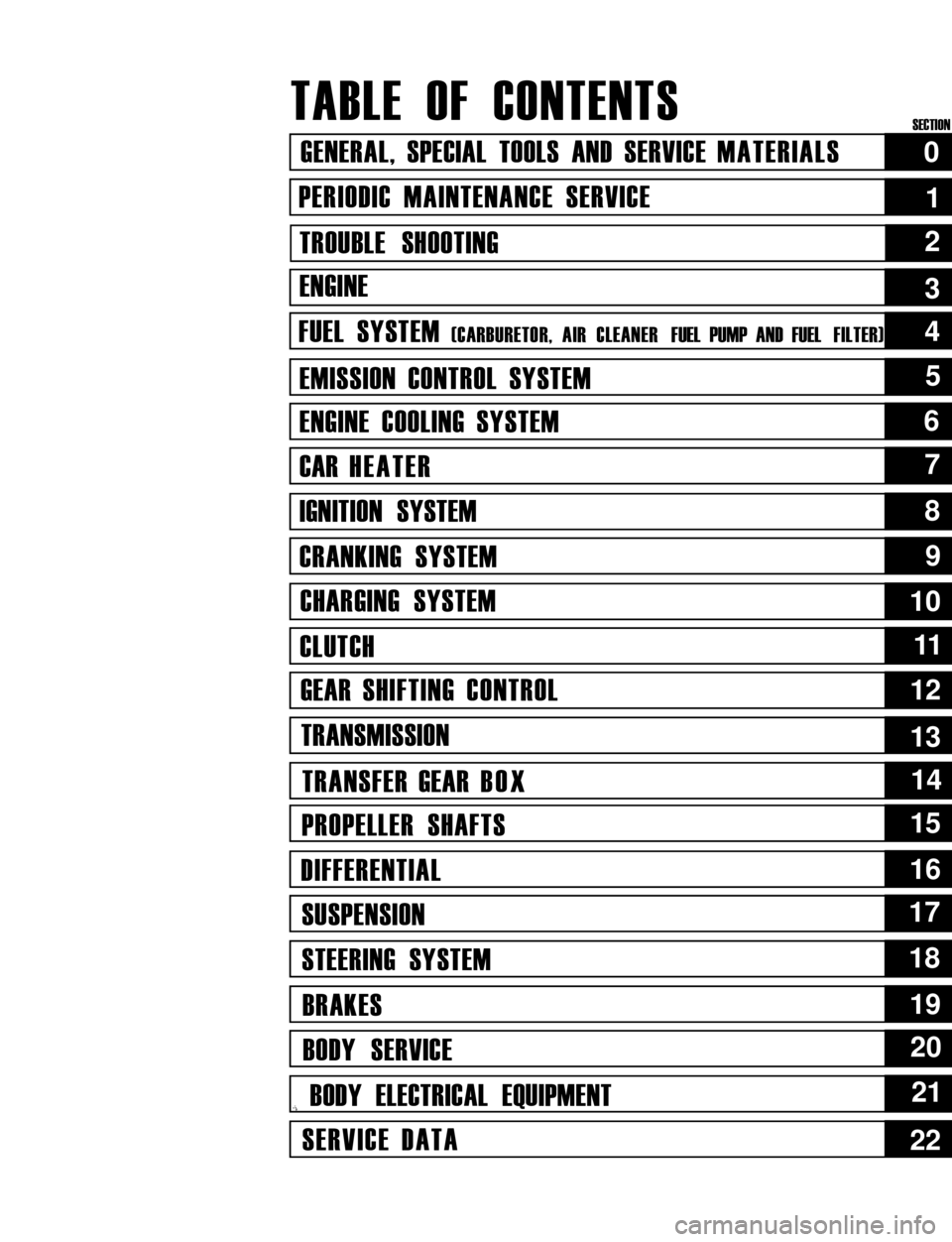

1. CHARCOAL CANISTER REPLACEMENT

WARNING:

The following cautions should be always

observed.

l Disconnect negative cable at battery.

l DO NOT smoke and place “NO SMOK-

ING” signs near work area.

l Be sure to have COZ fire extinguisher

handy.

l Wear safety glasses.

l To release the fuel vapor pressure in

fuel tank, remove the fuel tank cap and

then reinstall it.

1) Disconnect 3 hoses from canister.

2) Remove canister from car body.

3) Install new canister.

4) Connect 3 hoses to canister securely.

5) Clamp them securely.

//valve

To fuel tank

12. EMISSION-RELATED HOSES AND

TUBES INSPECTION

Check each vacuum hose and tube for secure

connection. Also, check that it is free from any

bend or damage.

Correct faulty condition, if any.

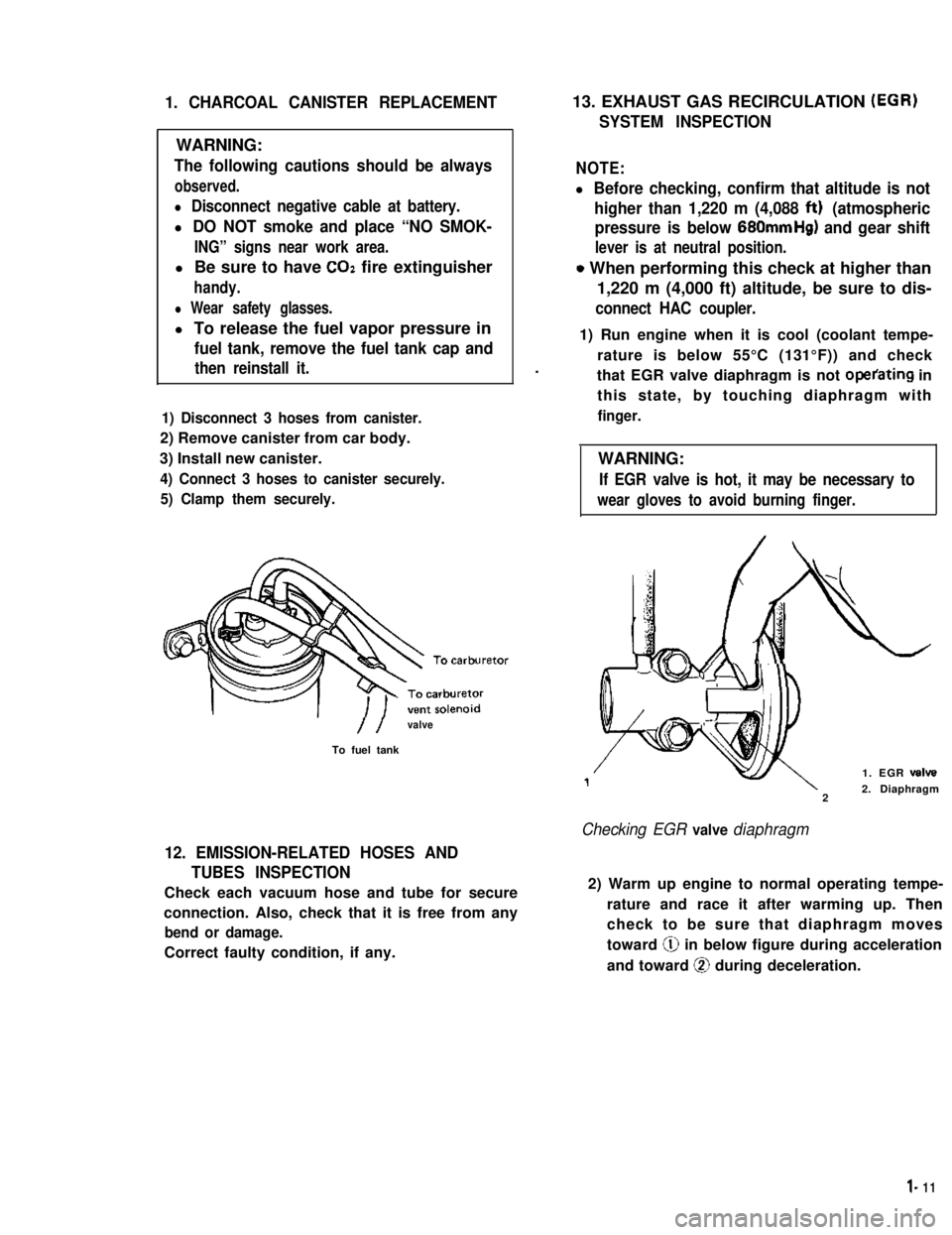

13. EXHAUST GAS RECIRCULATION (EGR)

SYSTEM INSPECTION

NOTE:

l Before checking, confirm that altitude is not

higher than 1,220 m (4,088 ftt) (atmospheric

pressure is below 680mmHg) and gear shift

lever is at neutral position.

o When performing this check at higher than

1,220 m (4,000 ft) altitude, be sure to dis-

connect HAC coupler.

.

1) Run engine when it is cool (coolant tempe-

rature is below 55°C (131°F)) and check

that EGR valve diaphragm is not operating in

this state, by touching diaphragm with

finger.

WARNING:

If EGR valve is hot, it may be necessary to

wear gloves to avoid burning finger.

1. EGR valve

22. Diaphragm

Checking EGR valve diaphragm

2) Warm up engine to normal operating tempe-

rature and race it after warming up. Then

check to be sure that diaphragm moves

toward @ in below figure during acceleration

and toward @ during deceleration.

l- 11

Page 30 of 962

21. FUEL TANK CAP GASKET INSPECTION

AND REPLACEMENT

Visually inspect gasket of fuel tank cap. If it is

damaged or deteriorated, replace it with new

one.

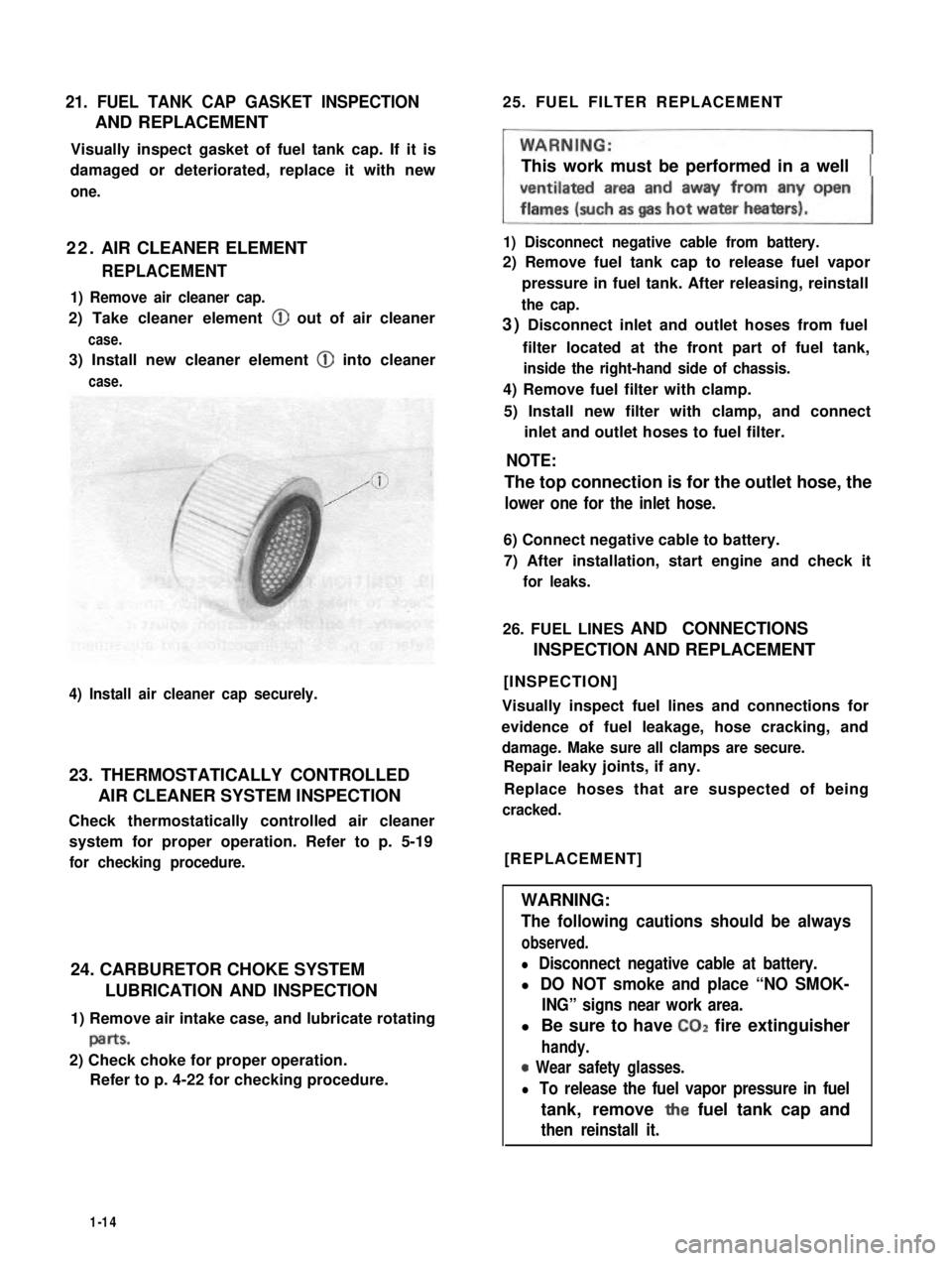

22. AIR CLEANER ELEMENT

REPLACEMENT

1) Remove air cleaner cap.

2) Take cleaner element @ out of air cleaner

case.

3) Install new cleaner element @ into cleaner

case.

4) Install air cleaner cap securely.

23. THERMOSTATICALLY CONTROLLED

AIR CLEANER SYSTEM INSPECTION

Check thermostatically controlled air cleaner

system for proper operation. Refer to p. 5-19

for checking procedure.

24. CARBURETOR CHOKE SYSTEM

LUBRICATION AND INSPECTION

1) Remove air intake case, and lubricate rotating

paItS.

2) Check choke for proper operation.

Refer to p. 4-22 for checking procedure.

25. FUEL FILTER REPLACEMENT

This work must be performed in a well

1) Disconnect negative cable from battery.

2) Remove fuel tank cap to release fuel vapor

pressure in fuel tank. After releasing, reinstall

the cap.

3) Disconnect inlet and outlet hoses from fuel

filter located at the front part of fuel tank,

inside the right-hand side of chassis.

4) Remove fuel filter with clamp.

5) Install new filter with clamp, and connect

inlet and outlet hoses to fuel filter.

NOTE:

The top connection is for the outlet hose, the

lower one for the inlet hose.

6) Connect negative cable to battery.

7) After installation, start engine and check it

for leaks.

26. FUEL LINES AND CONNECTIONS

INSPECTION AND REPLACEMENT

[INSPECTION]

Visually inspect fuel lines and connections for

evidence of fuel leakage, hose cracking, and

damage. Make sure all clamps are secure.

Repair leaky joints, if any.

Replace hoses that are suspected of being

cracked.

[REPLACEMENT]

WARNING:

The following cautions should be always

observed.

l Disconnect negative cable at battery.

l DO NOT smoke and place “NO SMOK-

ING” signs near work area.

l Be sure to have CO2 fire extinguisher

handy.

0 Wear safety glasses.

l To release the fuel vapor pressure in fuel

tank, remove the fuel tank cap and

then reinstall it.

1-14

Page 31 of 962

1) Replace fuel hoses (pipe to fuel pump, pipe to

fuel filter and breather hose) in fuel feed and

return lines with new ones.

2) Remove fuel tank.

3) Replace return hose (tank to return pipe)

with new one.

4) Clamp hoses securely.

5) Install fuel tank referring to p. 4-35.

6) After installation, start engine and check it

for leaks.

27. IDLE SPEED INSPECTION

NOTE:

Before starting engine, place transmission gear

shift lever in “Neutral”, and set parking brake

and block drive wheels.

1) Warm up engine to normal operating tempe-

rature.

2) Check to ensure that idle speed is within

750 - 850 r/min (rpm).

3) If idle speed is not within specified range,

adjust idle speed. Refer to MAINTENANCE

SERVICE (p. 4-26) for procedures to check

and adjust idle speed.

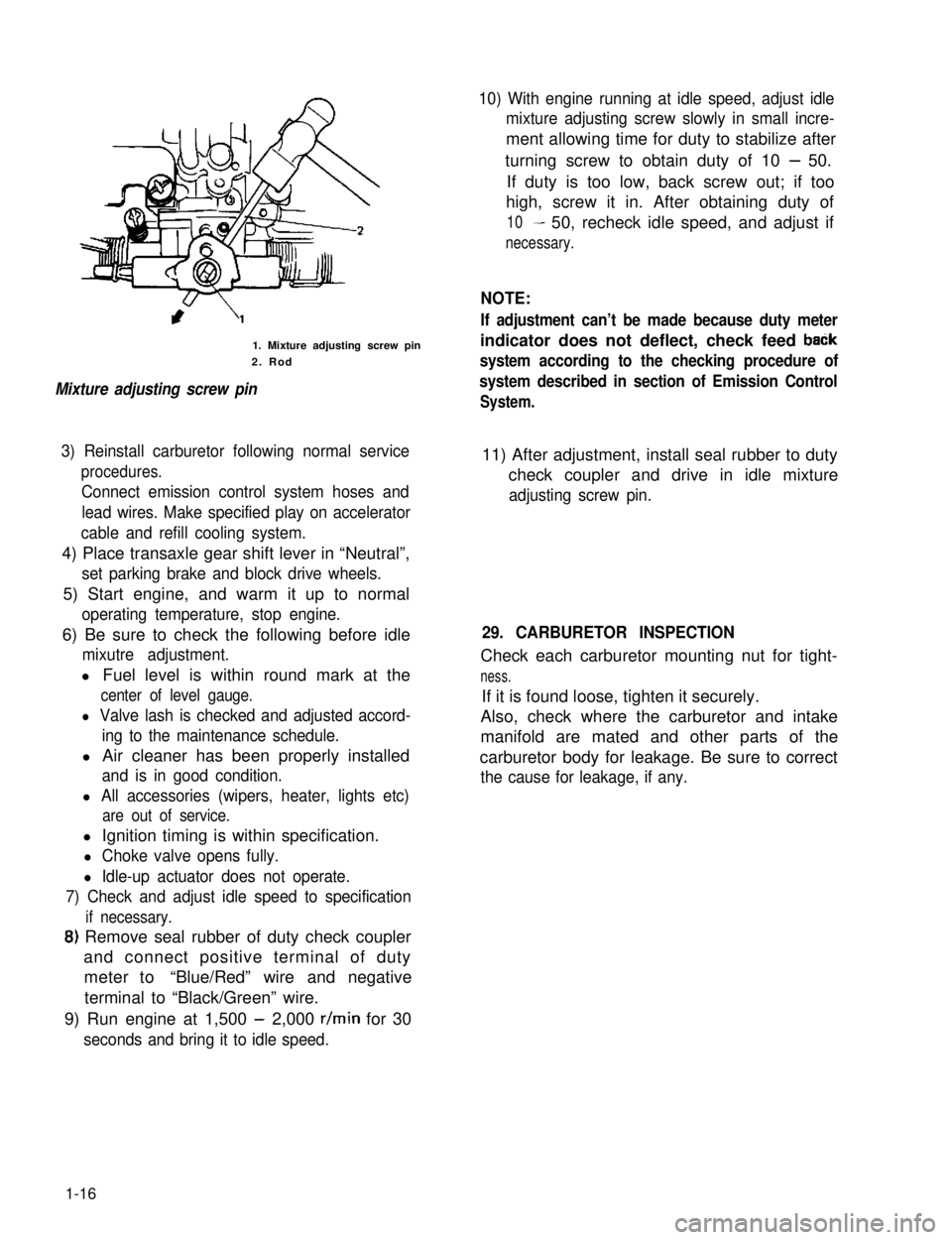

28. IDLE MIXTURE INSPECTION

1) Warm up engine to normal operating tem-

perature.

2) Remove seal rubber of duty check coupler

and connect positive terminal of duty meter

to “Blue/Red” wire and negative terminal to

“Black/Green” wire.

1

1. Duty check coupler

2. Air intake case

3) Set tachometer.

4) Run engine at 1,500 - 2,000 r/min for 30

seconds and bring it to idle speed.

5) Check duty at specified idle speed. If it is out

of specification,adjust it to specification

according to following adjustment procedure.

Specified Duty10-50

at 750 - 850 r/min.I

After inspection, install seal rubber to duty

check coupler.

Idle mixture adjustment procedure is as follows:

1) Remove carburetor from intake manifold

following normal service procedure to gain

access to mixture adjusting screw pin covering

mixture adjusting screw.

2) Drive out mixture adjusting screw pin using

about 4.5 mm (0.18 in) thick iron rod as

shown below.

1-15

Page 32 of 962

1. Mixture adjusting screw pin

2. Rod

Mixture adjusting screw pin

10) With engine running at idle speed, adjust idle

mixture adjusting screw slowly in small incre-

ment allowing time for duty to stabilize after

turning screw to obtain duty of 10 - 50.

If duty is too low, back screw out; if too

high, screw it in. After obtaining duty of

10- 50, recheck idle speed, and adjust if

necessary.

NOTE:

If adjustment can’t be made because duty meter

indicator does not deflect, check feed baCk

system according to the checking procedure of

system described in section of Emission Control

System.

3) Reinstall carburetor following normal service

procedures.

Connect emission control system hoses and

lead wires. Make specified play on accelerator

cable and refill cooling system.

11) After adjustment, install seal rubber to duty

check coupler and drive in idle mixture

adjusting screw pin.

4) Place transaxle gear shift lever in “Neutral”,

set parking brake and block drive wheels.

5) Start engine, and warm it up to normal

operating temperature, stop engine.

6) Be sure to check the following before idle

mixutre adjustment.

l Fuel level is within round mark at the

center of level gauge.

l Valve lash is checked and adjusted accord-

ing to the maintenance schedule.

l Air cleaner has been properly installed

and is in good condition.

l All accessories (wipers, heater, lights etc)

are out of service.

29. CARBURETOR INSPECTION

Check each carburetor mounting nut for tight-

ness.

If it is found loose, tighten it securely.

Also, check where the carburetor and intake

manifold are mated and other parts of the

carburetor body for leakage. Be sure to correct

the cause for leakage, if any.

l Ignition timing is within specification.

l Choke valve opens fully.

l Idle-up actuator does not operate.

7) Check and adjust idle speed to specification

if necessary.

8) Remove seal rubber of duty check coupler

and connect positive terminal of duty

meter to“Blue/Red” wire and negative

terminal to “Black/Green” wire.

9) Run engine at 1,500 - 2,000 r/min for 30

seconds and bring it to idle speed.

1-16

Page 39 of 962

2-1.

2-2.

2-3.

2-4.

2-5.

2-6.

2-7.

2-6.

2-9.

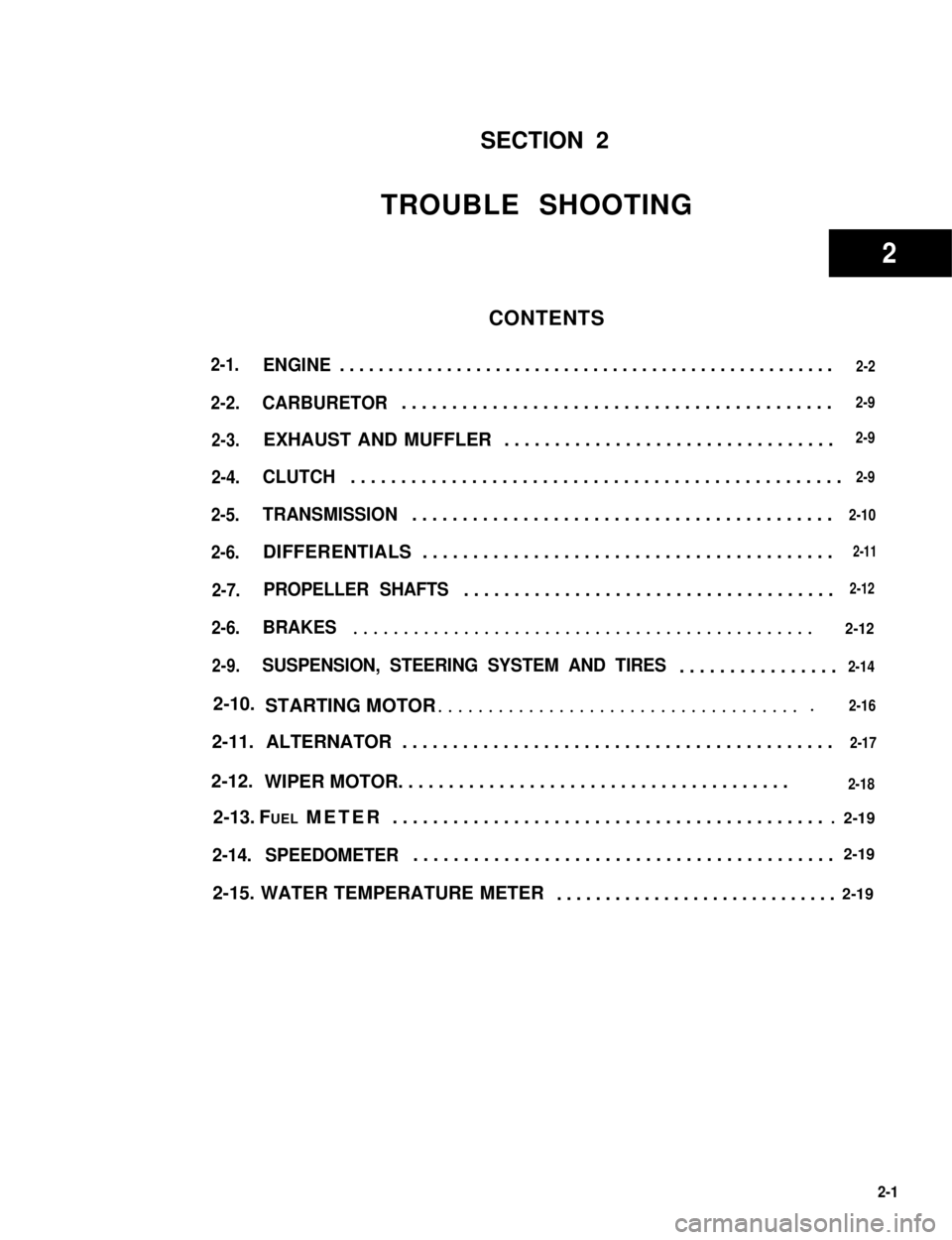

SECTION 2

TROUBLE SHOOTING

CONTENTS

ENGINE...................................................2-2

CARBURETOR...........................................

EXHAUST AND MUFFLER.................................

CLUTCH.................................................2-9

TRANSMISSION..........................................

DIFFERENTIALS.........................................2-11

PROPELLER SHAFTS.....................................2-12

BRAKES.............................................. 2-12

SUSPENSION, STEERING SYSTEM AND TIRES................

STARTING MOTOR.....................................

2-11. ALTERNATOR...........................................

FUEL METER............................................ 2-19

2-14. SPEEDOMETER..........................................2-19

2-15. WATER TEMPERATURE METER.............................2-19

2-9

2-9

2-10

2-14

2-16

2-17

2-18WIPER MOTOR.......................................

2-10.

2-12.

2-13.

2-1

2

Page 40 of 962

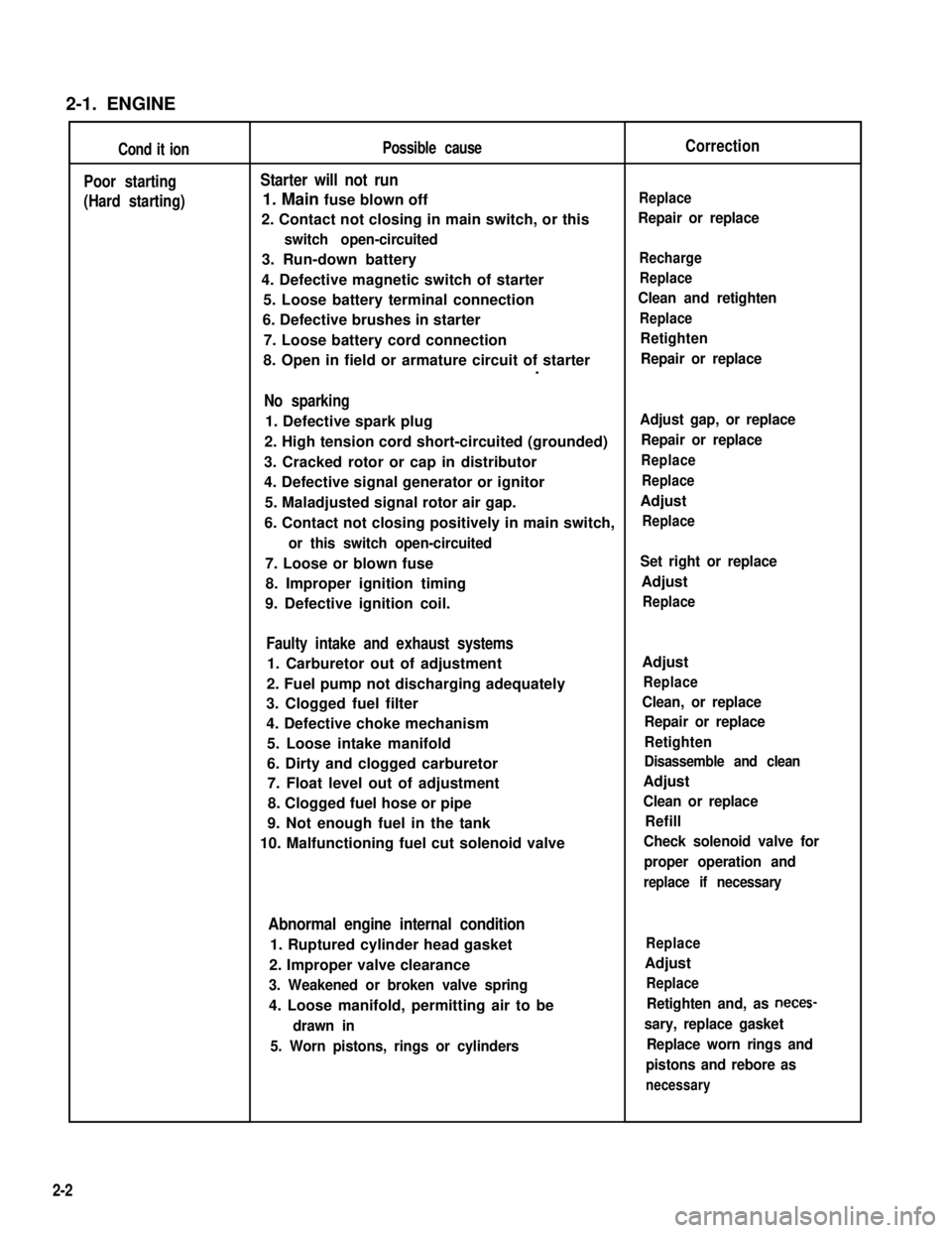

2-1. ENGINE

Cond it ion

Poor starting

(Hard starting)

Possible cause

Starter will not run

1. Main fuse blown off

2. Contact not closing in main switch, or this

switch open-circuited

3. Run-down battery

4. Defective magnetic switch of starter

5. Loose battery terminal connection

6. Defective brushes in starter

7. Loose battery cord connection

8. Open in field or armature circuit of starter.

Correction

Replace

Repair or replace

Recharge

Replace

Clean and retighten

Replace

Retighten

Repair or replace

No sparking

1. Defective spark plugAdjust gap, or replace

2. High tension cord short-circuited (grounded)Repair or replace

3. Cracked rotor or cap in distributorReplace

4. Defective signal generator or ignitorReplace

5. Maladjusted signal rotor air gap.Adjust

6. Contact not closing positively in main switch,Replace

or this switch open-circuited

7. Loose or blown fuseSet right or replace

8. Improper ignition timingAdjust

9. Defective ignition coil.Replace

Faulty intake and exhaust systems

1. Carburetor out of adjustment

2. Fuel pump not discharging adequately

3. Clogged fuel filter

4. Defective choke mechanism

5. Loose intake manifold

6. Dirty and clogged carburetor

7. Float level out of adjustment

8. Clogged fuel hose or pipe

9. Not enough fuel in the tank

10. Malfunctioning fuel cut solenoid valve

Adjust

Replace

Clean, or replace

Repair or replace

Retighten

Disassemble and clean

Adjust

Clean or replace

Refill

Check solenoid valve for

proper operation and

replace if necessary

Abnormal engine internal condition

1. Ruptured cylinder head gasket

2. Improper valve clearance

3. Weakened or broken valve spring

4. Loose manifold, permitting air to be

drawn in

5. Worn pistons, rings or cylinders

Replace

Adjust

Replace

Retighten and, as neces-

sary, replace gasket

Replace worn rings and

pistons and rebore as

necessary

2-2

Page 41 of 962

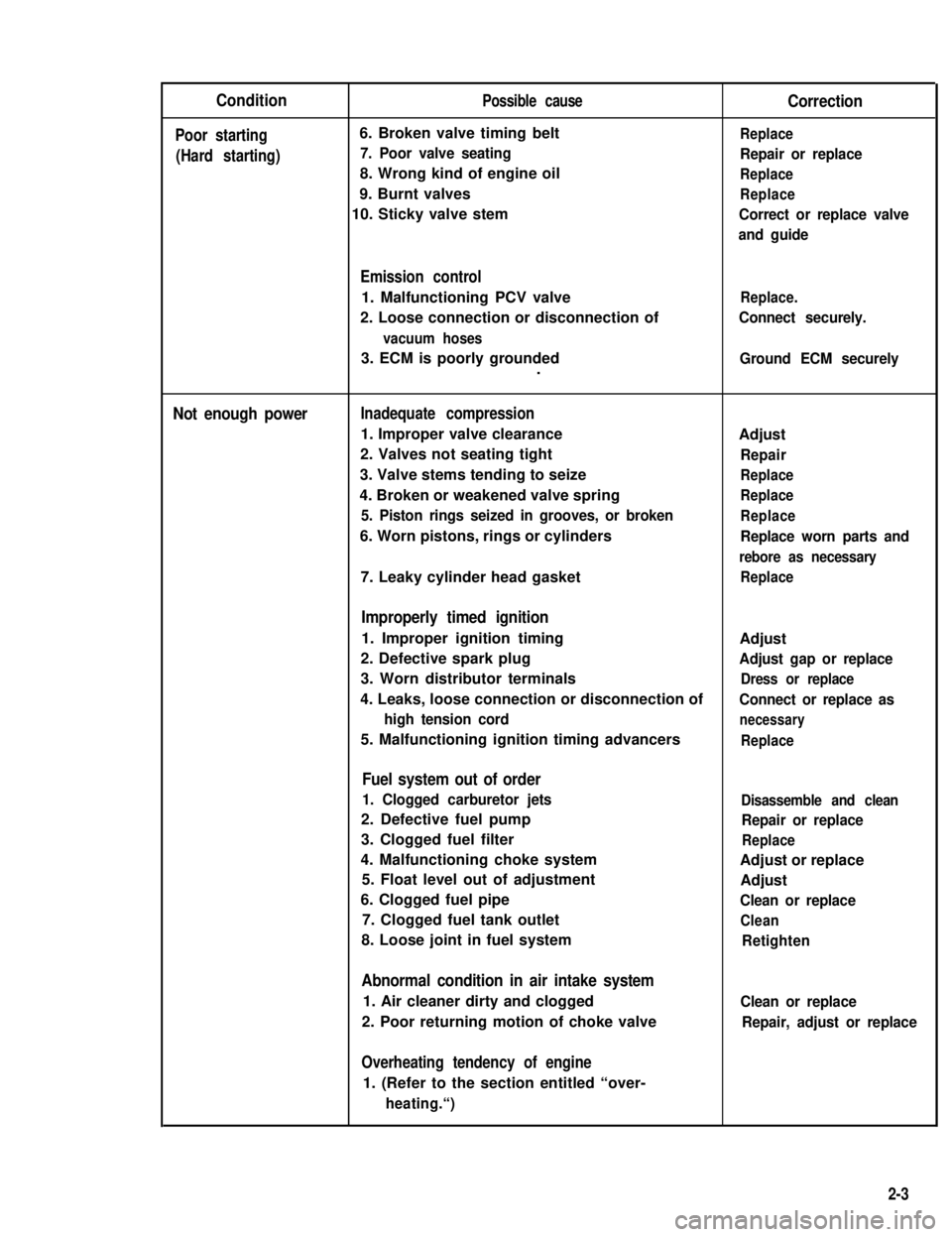

Condition

Poor starting

(Hard starting)

Possible cause

6. Broken valve timing belt

7. Poor valve seating

8. Wrong kind of engine oil

9. Burnt valves

10. Sticky valve stem

Correction

Replace

Repair or replace

Replace

Replace

Correct or replace valve

and guide

Emission control

1. Malfunctioning PCV valve

2. Loose connection or disconnection of

vacuum hoses

Replace.

Connect securely.

3. ECM is poorly grounded.Ground ECM securely

Not enough powerInadequate compression

1. Improper valve clearance

2. Valves not seating tight

3. Valve stems tending to seize

4. Broken or weakened valve spring

5. Piston rings seized in grooves, or broken

6. Worn pistons, rings or cylinders

Adjust

Repair

Replace

Replace

Replace

Replace worn parts and

rebore as necessary

7. Leaky cylinder head gasketReplace

Improperly timed ignition

1. Improper ignition timing

2. Defective spark plug

3. Worn distributor terminals

4. Leaks, loose connection or disconnection of

high tension cord

5. Malfunctioning ignition timing advancers

Adjust

Adjust gap or replace

Dress or replace

Connect or replace as

necessary

Replace

Fuel system out of order

1. Clogged carburetor jets

2. Defective fuel pump

3. Clogged fuel filter

4. Malfunctioning choke system

5. Float level out of adjustment

6. Clogged fuel pipe

7. Clogged fuel tank outlet

8. Loose joint in fuel system

Disassemble and clean

Repair or replace

Replace

Adjust or replace

Adjust

Clean or replace

Clean

Retighten

Abnormal condition in air intake system

1. Air cleaner dirty and clogged

2. Poor returning motion of choke valve

Clean or replace

Repair, adjust or replace

Overheating tendency of engine

1. (Refer to the section entitled “over-

heating.“)

2-3

Page 42 of 962

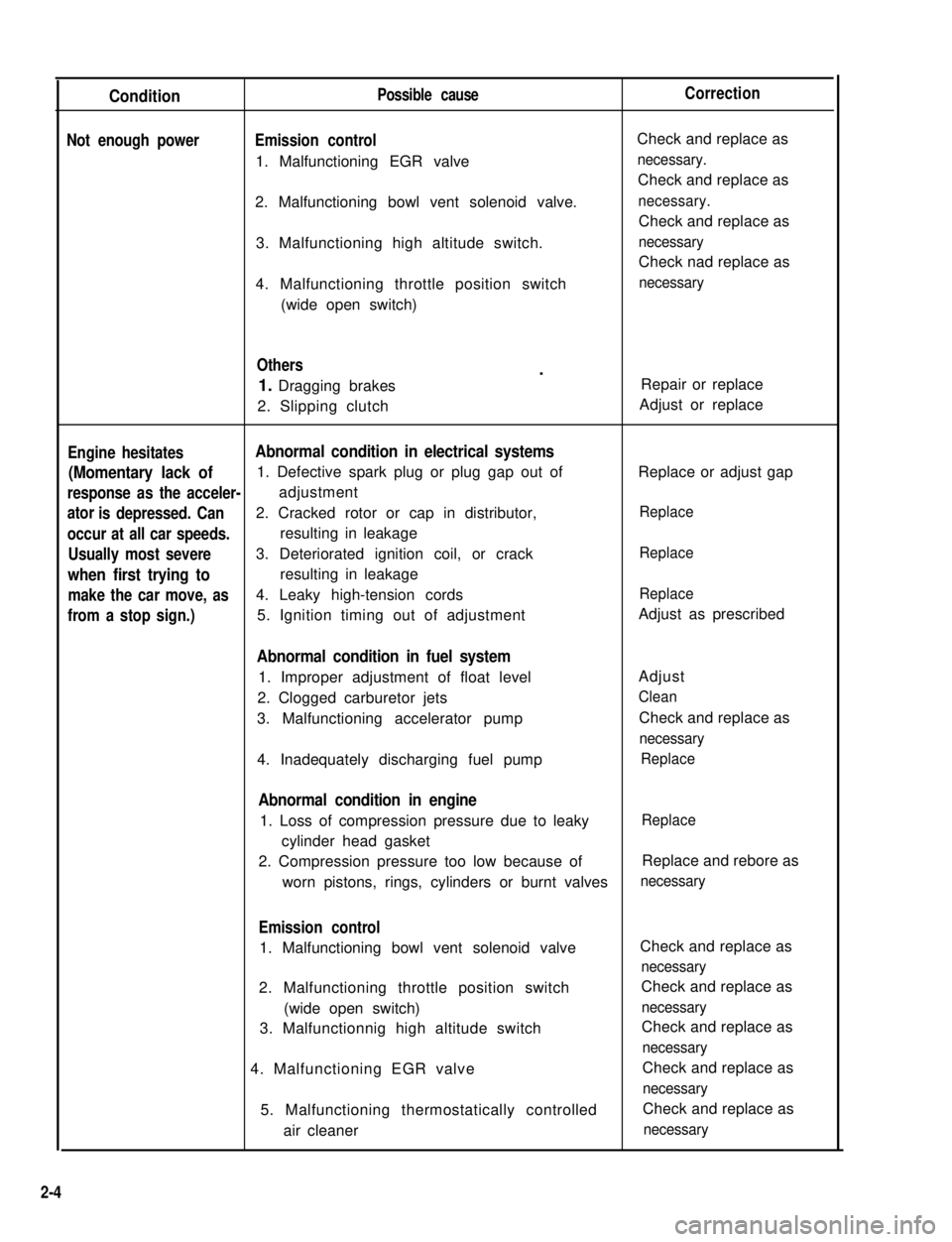

ConditionPossible causeCorrection

Not enough powerEmission control

1. Malfunctioning EGR valve

Check and replace as

necessary.

Check and replace as

2. Malfunctioning bowl vent solenoid valve.necessary.

Check and replace as

3. Malfunctioning high altitude switch.necessary

Check nad replace as

4. Malfunctioning throttle position switch

(wide open switch)

necessary

Others

1. Dragging brakes

2. Slipping clutch

.Repair or replace

Adjust or replace

Engine hesitatesAbnormal condition in electrical systems

(Momentary lack of1. Defective spark plug or plug gap out ofReplace or adjust gap

response as the acceler-

ator

adjustment

is depressed. Can2. Cracked rotor or cap in distributor,Replace

occur at all car speeds.resulting in leakage

Usually most severe3. Deteriorated ignition coil, or crackReplace

when first trying toresulting in leakage

make the car move, as4. Leaky high-tension cordsReplace

from a stop sign.)5. Ignition timing out of adjustmentAdjust as prescribed

Abnormal condition in fuel system

1. Improper adjustment of float level

2. Clogged carburetor jets

3. Malfunctioning accelerator pump

Adjust

Clean

Check and replace as

necessary

4. Inadequately discharging fuel pumpReplace

Abnormal condition in engine

1. Loss of compression pressure due to leaky

cylinder head gasket

Replace

2. Compression pressure too low because ofReplace and rebore as

worn pistons, rings, cylinders or burnt valvesnecessary

Emission control

1. Malfunctioning bowl vent solenoid valveCheck and replace as

necessary

2. Malfunctioning throttle position switch

(wide open switch)

3. Malfunctionnig high altitude switch

4. Malfunctioning EGR valve

Check and replace as

necessary

Check and replace as

necessary

Check and replace as

necessary

5. Malfunctioning thermostatically controlled

air cleaner

Check and replace as

necessary

2-4

Page 43 of 962

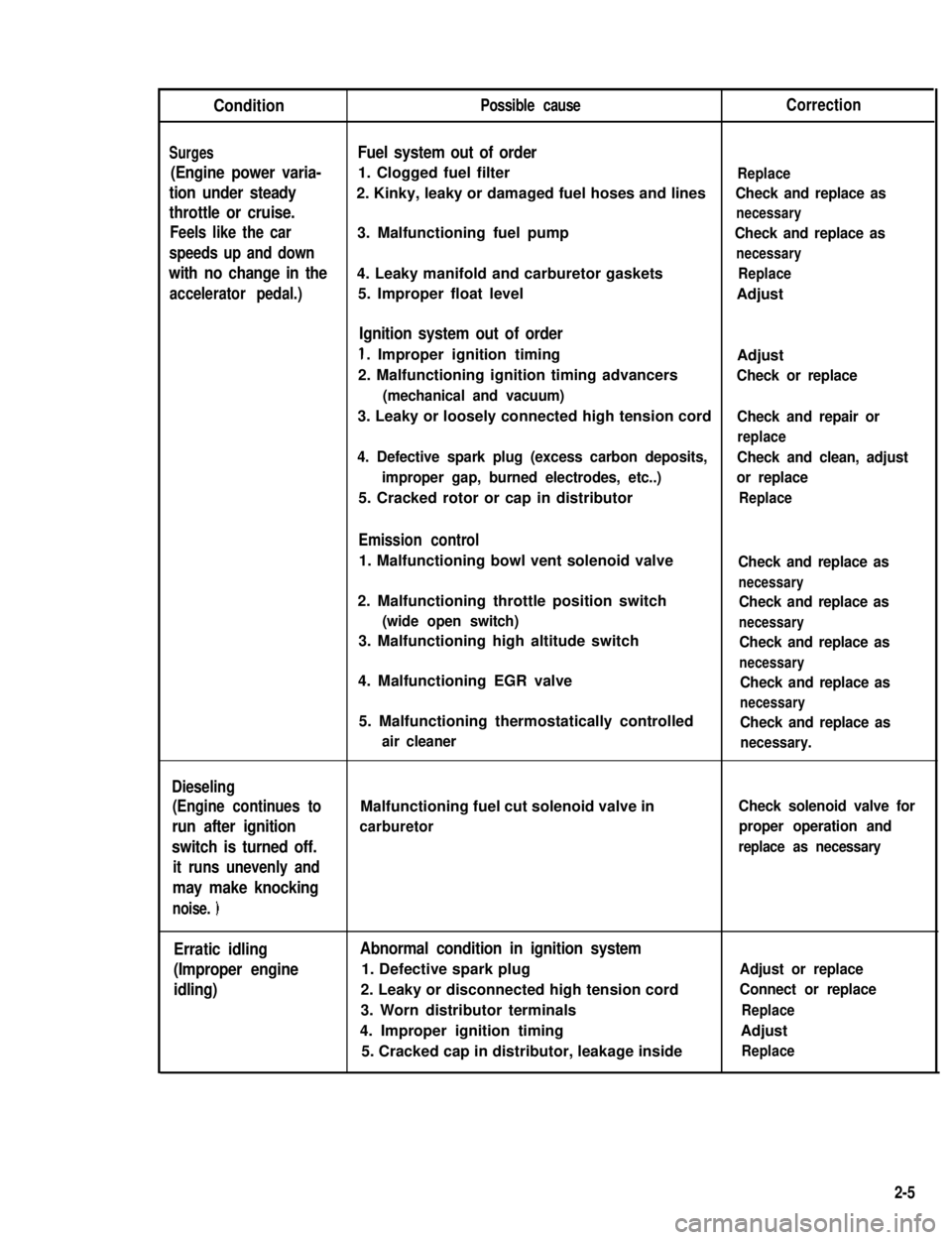

ConditionPossible causeCorrection

SurgesFuel system out of order

(Engine power varia- 1. Clogged fuel filterReplace

tion under steady2. Kinky, leaky or damaged fuel hoses and linesCheck and replace as

throttle or cruise.necessary

Feels like the car3. Malfunctioning fuel pumpCheck and replace as

speeds up and downnecessary

with no change in the4. Leaky manifold and carburetor gasketsReplace

accelerator pedal.)5. Improper float levelAdjust

Ignition system out of order

1. Improper ignition timing

2. Malfunctioning ignition timing advancers

(mechanical and vacuum)

Adjust

Check or replace

3. Leaky or loosely connected high tension cordCheck and repair or

replace

4. Defective spark plug (excess carbon deposits,Check and clean, adjust

improper gap, burned electrodes, etc..)or replace

5. Cracked rotor or cap in distributorReplace

Emission control

1. Malfunctioning bowl vent solenoid valve

2. Malfunctioning throttle position switch

(wide open switch)

3. Malfunctioning high altitude switch

4. Malfunctioning EGR valve

5. Malfunctioning thermostatically controlled

air cleaner

Check and replace as

necessary

Check and replace as

necessary

Check and replace as

necessary

Check and replace as

necessary

Check and replace as

necessary.

Dieseling

(Engine continues to

run after ignition

switch is turned off.

it runs unevenly and

may make knocking

noise. )

Malfunctioning fuel cut solenoid valve in

carburetor

Check solenoid valve for

proper operation and

replace as necessary

Erratic idling

(Improper engine

idling)

Abnormal condition in ignition system

1. Defective spark plug

2. Leaky or disconnected high tension cord

3. Worn distributor terminals

4. Improper ignition timing

5. Cracked cap in distributor, leakage inside

Adjust or replace

Connect or replace

Replace

Adjust

Replace

2-5