check engine SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 3 of 962

SECTION 0

GENERAL, SPECIAL TOOLS AND

SERVICE MATERIALS

CONTENTS

0-1. IDENTIFICATION NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . O-1

0-2. STANDARD SHOP PRACTICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . O-2

0-3.SPECIAL TOOLS.. . . . . . . . . . . . 1.. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0-4.REQUIRED SERVICE MATERIALS . . . . . . . . . . . . . . . . . . . . . s . . . . . O-9

METRIC INFORMATION . . . . . . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . O-12

O-l. IDENTIFICATION NUMBER

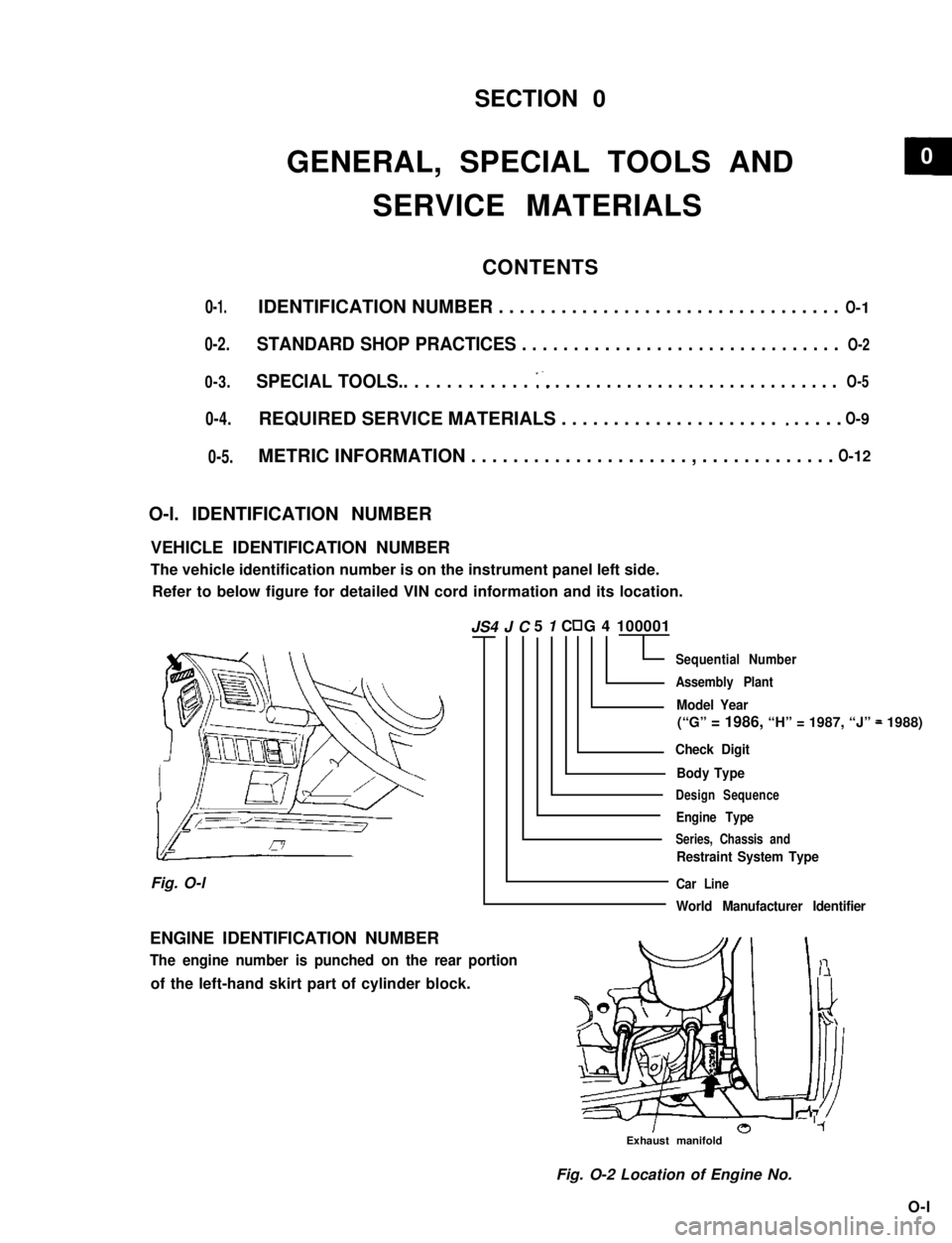

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number is on the instrument panel left side.

Refer to below figure for detailed VIN cord information and its location.

5 1 C G 4 100001

Sequential Number

Assembly Plant

Model Year

(“G” = 1986, “H” = 1987, “J” = 1988)

Check Digit

Body Type

Design Sequence

Engine Type

Series, Chassis and

Restraint System Type

Car Line

World Manufacturer Identifier

Fig. O-l

ENGINE IDENTIFICATION NUMBER

The engine number is punched on the rear portion

of the left-hand skirt part of cylinder block.

Exhaust manifold

Fig. O-2 Location of Engine No.

O-l

JS4 J C

0-5.

O- 5

0

Page 21 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual 1-2. ENGINE AND EMISSION CONTROL

1. WATER PUMP BELT INSPECTION

AND REPLACEMENT

[INSPECTION]

1) Disconnect negative battery lead at battery.

2) Inspect belt for cracks, cuts, deformation,

wear and clea SUZUKI GRAND VITARA 1987 Service Repair Manual 1-2. ENGINE AND EMISSION CONTROL

1. WATER PUMP BELT INSPECTION

AND REPLACEMENT

[INSPECTION]

1) Disconnect negative battery lead at battery.

2) Inspect belt for cracks, cuts, deformation,

wear and clea](/img/20/57437/w960_57437-20.png)

1-2. ENGINE AND EMISSION CONTROL

1. WATER PUMP BELT INSPECTION

AND REPLACEMENT

[INSPECTION]

1) Disconnect negative battery lead at battery.

2) Inspect belt for cracks, cuts, deformation,

wear and cleanliness. If any defect, replace.

Check belt for tension. The belt is in’ proper

tension if it deflects 6 to 9 mm (0.24 - 0.35

in.) under thumb pressure (about 10 kg or

22 lb.)..

Belt tension6 - 9 mm (0.24 - 0.35 in.)

specificationas deflection

pulley

3) If the belt is too tight or too loose, adjust it

to specification by adjusting alternator

position.

4) Tighten alternator adjusting bolt and pivot

bolts.

5) Connect negative battery lead to battery.

[REPLACEMENT]

1) Disconnect negative battery lead at battery.

2) Loosen alternator adjusting bolt and pivot

bolts.

3) Replace water pump belt.

4) Adjust belt tension to specification and

tighten alternator adjusting bolt and pivot

bolts.

5) Connect negative battery lead to battery.

2. CAMSHAFT TIMING BELT INSPECTION

1) Disconnect negative battery lead at battery.

2) Loosen fan drive belt, and remove 4 bolts

securing radiator shroud panel and 4 nuts

securing engine cooling fan & clutch. Then

remove radiator shroud and cooling fan &

clutch at the same time.

3) Remove water pump belt and pump pulley.

4) Remove crankshaft pulley by removing 4

pulley bolts. The crankshaft timing belt

pulley bolt at the center need not be loosen-

ed.2 1

‘31. Key

2. Crankshaft pulley

3. Pulley bolt

1-5

Page 23 of 962

NOTE:

Steps 1) - 6) outlined above must be performed

with ENGINE NOT RUNNING. For step 7),

be sure to have adequate ventilation while

engine is running

It is recommended to use engine oil of SE or

SF class.

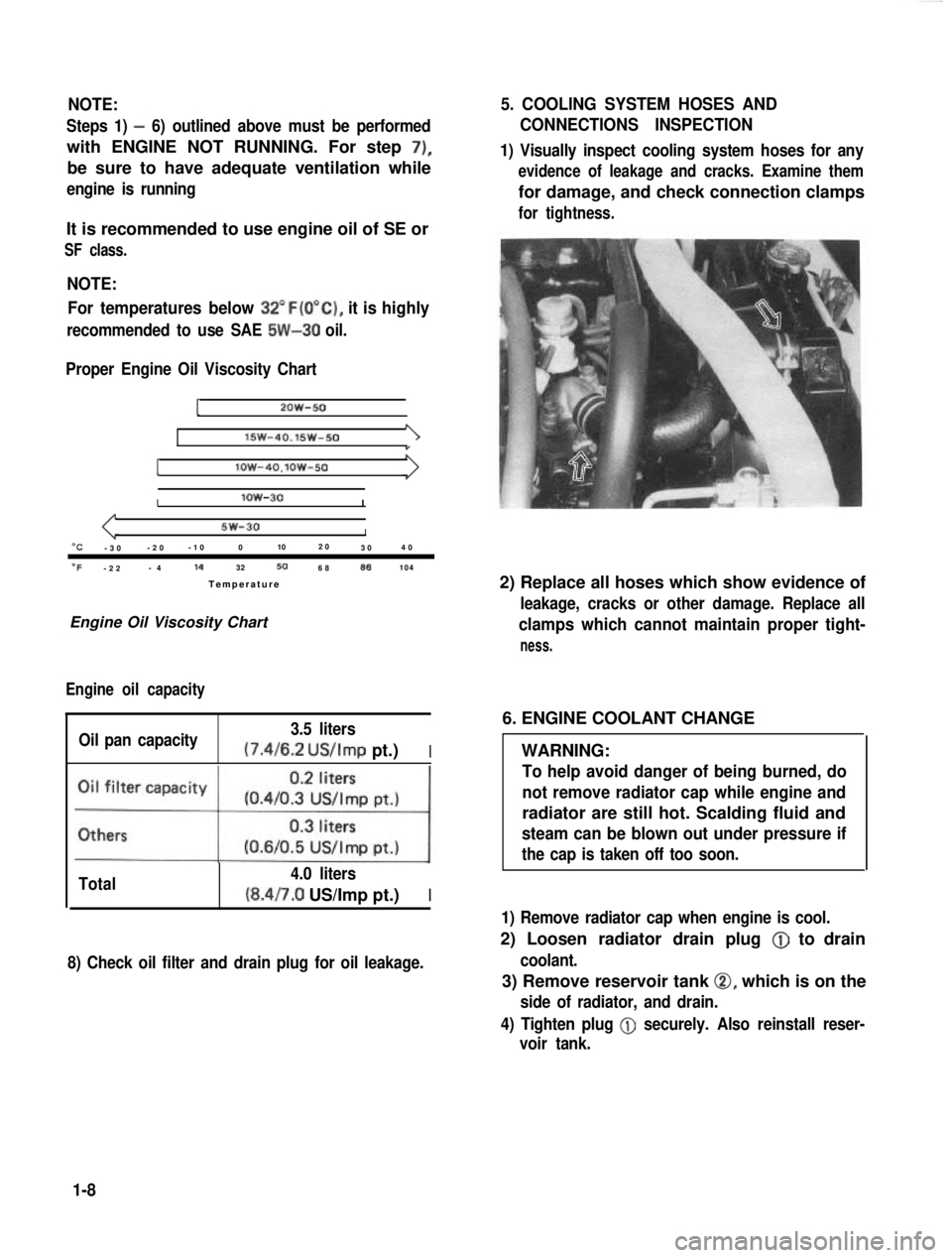

NOTE:For temperatures below

32”F(O”C), it is highly

recommended to use SAE 5W-30 oil.

Proper Engine Oil Viscosity Chart

12OW-50

lSW-40.15w-501

Ilow-4O.lOW-50

Ilow-30I

5w-30I“C-3 0 -2

0 -1

0 0 102

0

30 4

0

OF-2 2 -

4 14

32506886104

Temperatur e

Engine Oil Viscosity Chart

Engine oil capacity

Oil pan capacity 3.5 liters (7.4/6.2

US/Imp pt.)I

Total 4.0 liters(8.4/7.0 US/Imp pt.)I

8) Check oil filter and drain plug for oil leakage.

5. COOLING SYSTEM HOSES AND

CONNECTIONS INSPECTION

1) Visually inspect cooling system hoses for any

evidence of leakage and cracks. Examine them

for damage, and check connection clamps

for tightness.

2) Replace all hoses which show evidence of

leakage, cracks or other damage. Replace all

clamps which cannot maintain proper tight-

ness.

6. ENGINE COOLANT CHANGE

WARNING:

To help avoid danger of being burned, do

not remove radiator cap while engine and

radiator are still hot. Scalding fluid and

steam can be blown out under pressure if

the cap is taken off too soon.

1) Remove radiator cap when engine is cool.

2) Loosen radiator drain plug @

to drain

coolant.

3) Remove reservoir tank 0, which is on the

side of radiator, and drain.

4) Tighten plug

@ securely. Also reinstall reser-

voir tank.

1-8

Page 24 of 962

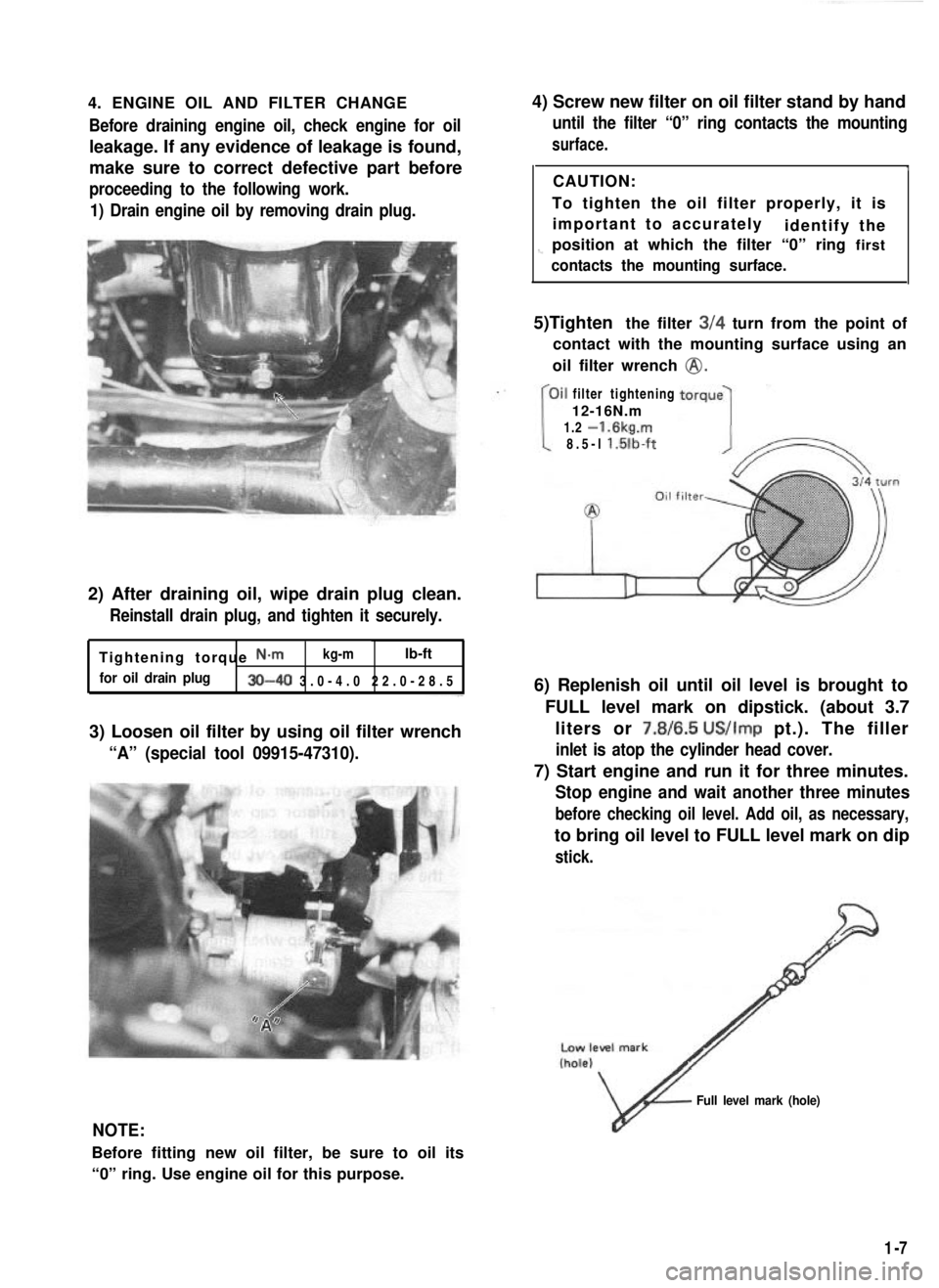

4. ENGINE OIL AND FILTER CHANGEBefore draining engine oil, check engine for oil

leakage. If any evidence of leakage is found,

make sure to correct defective part before

proceeding to the following work.

1) Drain engine oil by removing drain plug.

2) After draining oil, wipe drain plug clean.

Reinstall drain plug, and tighten it securely.

Tightening torque N-m kg-mlb-ft

for oil drain plug30-40 3.0-4.0 22.0-28.

5

3) Loosen oil filter by using oil filter wrench

“A” (special tool 09915-47310).

4) Screw new filter on oil filter stand by hand

until the filter “0” ring contacts the mounting

surface.

ICAUTION:

To tighten the oil filter properly, it is important to accurately identify the

1-position at which the filter “0” ring first

contacts the mounting surface.

5)Tighten the filter 3/4 turn from the point of

contact with the mounting surface using an

oil filter wrench

@.

filter tightening

12-16N.m

1.2

-1.6kg.m

8.5-l l.lilb-ft

6) Replenish oil until oil level is brought to

FULL level mark on dipstick. (about 3.7liters or 7.8/6.5

US/Imp pt.). The filler

inlet is atop the cylinder head cover.

7) Start engine and run it for three minutes.

Stop engine and wait another three minutes

before checking oil level. Add oil, as necessary,

to bring oil level to FULL level mark on dip

stick.

NOTE:

Before fitting new oil filter, be sure to oil its

“0” ring. Use engine oil for this purpose.

v

Full level mark (hole)

1-7

Page 25 of 962

CAUTION:

When changing engine coolant, use mixture

of 56% water and 50% GOLDEN CRUISER

1200for the market where ambient tem-

perature falls lower than -16°C (3°F) in

winter and mixture of 70% water and

30% GOLDEN CRUISER 1200for the

market where ambient temperature doesn’t

fall lower than -16°C (3” F).

Even in a market where no freezing tempe-

rature is anticipated, mixture of 70% water

and 30% GOLDEN CRUISER 1200

should be used for the purpose of corro-

sion protection and lubrication.

7. EXHAUST PIPES AND MOUNTINGS

INSPECTION

1.Drain plug

1. Reservoir tank cap2. Reservoir tank

3. Arrow marks

5) Fill radiator with specified amount of coolant,

and run engine for 2 or 3 minutes at idle.

This drives out any air which may still be

trappedwithincoolingsystem.STOP

ENGINE. Add coolant as necessary until

coolant level reaches the filler throat of

radiator. Reinstall radiator cap.

6) Add coolant to reservoir tank so that the level

aligns with Full mark. Then, reinstall cap

aligning the arrow marks on the tank and cap.

r.

COOLANT CAPACITY

Engine, radiator and4.2 liters

heater(8.9/7.4 US/Imp pt.)

Reservoir tank0.6 liters

(1.3/1.1 US/Imp pt.)

ITotal4.8 liters

(10.1/8.4US/lmp pt.)

WARNING:

To avoid danger of being burned, do not

touch exhaust system when system is hot.

Any service on exhaust system should be

performed when system is cool.

When carrying out periodic maintenance, or the

car is raised for other service, check exhaust

system as follows:

l Check rubber mountings for damage, deterio-

ration, and out of position.

l Check exhaust system for leakage, loose

connections, dents, and damages.

If bolts or nuts are loose, tighten them to

specification. Refer to below chart for torque

specification.

l Check nearby body areas for damaged, miss-

ing, or mispositioned parts, open seams,

holes, loose connections or’ other defects

which could permit exhaust fumes to seep

into the car.

l Make sure that exhaust system components

have enough clearance from the underbody to

avoid overheating and possible damage to the

floor carpet.

l Any defects should be fixed at once.

IBolts and nutTightening torqueI

40-80 N-m

Exhaustpipebolts4.0-6.0 kg-m

29.0-43.0 lb-ft

Muffler nuts

18 - 28 N-m

1.8 - 2.8 kg-m

13.5 - 20.0 lb-ft

Replace center pipe rubber mounting and muffler

rubber mountings with new ones periodically.

l-9

Page 26 of 962

8. PCV VALVE REPLACEMENT

1) Disconnect crankcase ventilation hose from

PCV valve.

2) Remove PCV valve from intake manifold.

3) Wind sealing tape on thread of the new valve

and install it securely.

Tightenlng torque

for PCV valve

15-25 N.m

1.5-2.5 kg-m,

11 .O-18.0 lb-ft

4) Install hose and clamp it securely.

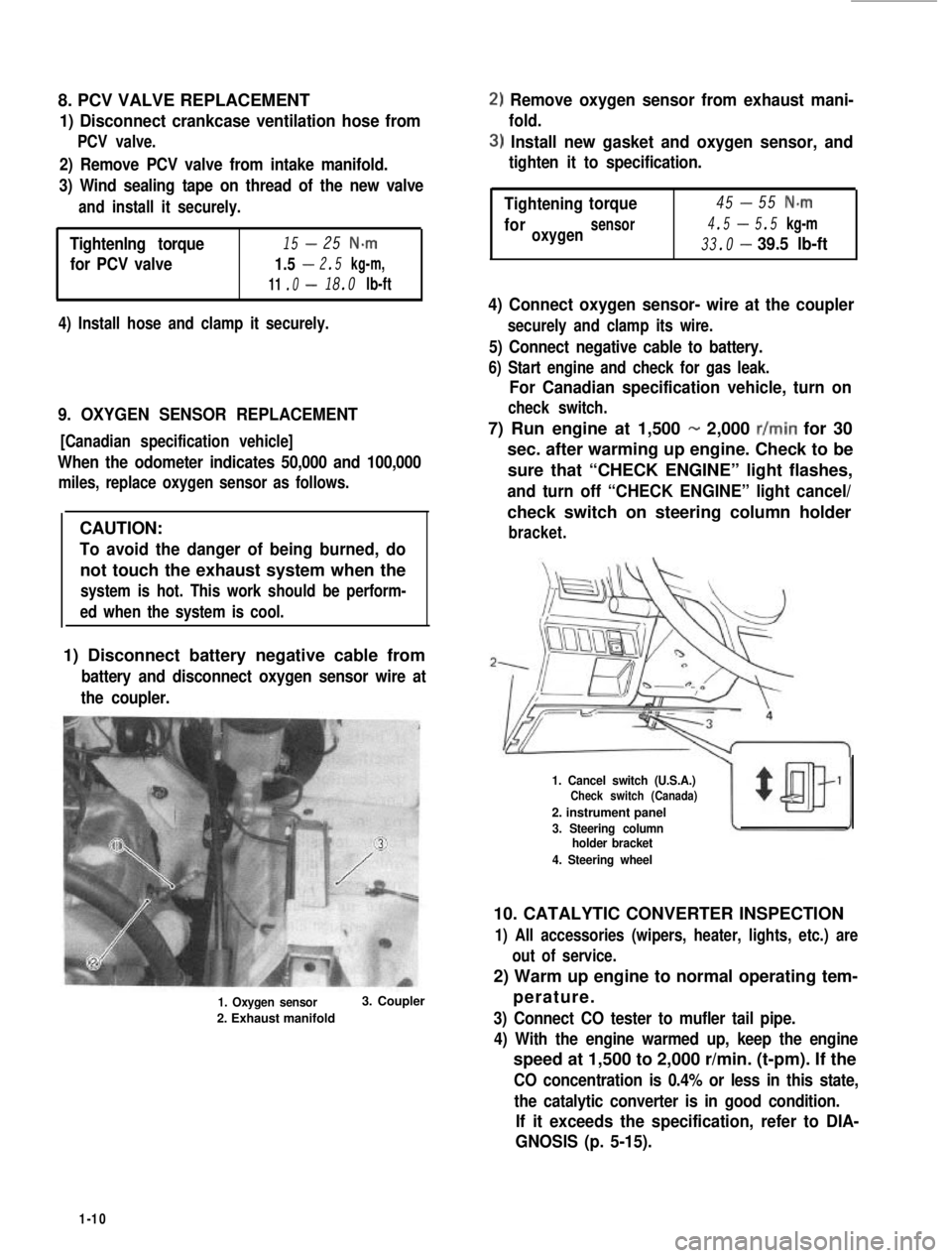

9. OXYGEN SENSOR REPLACEMENT

[Canadian specification vehicle]

When the odometer indicates 50,000 and 100,000

miles, replace oxygen sensor as follows.

CAUTION:

To avoid the danger of being burned, do

not touch the exhaust system when the

system is hot. This work should be perform-

ed when the system is cool.

1) Disconnect battery negative cable from

battery and disconnect oxygen sensor wire at

the coupler.

1. Oxygen sensor

2. Exhaust manifold

3. Coupler

2) Remove oxygen sensor from exhaust mani-

fold.

3) Install new gasket and oxygen sensor, and

tighten it to specification.

-Tightening45torque55 N-m

4.5-foroxygensensor5.5 kg-m

33.0-39.5 lb-ft

4) Connect oxygen sensor- wire at the coupler

securely and clamp its wire.

5) Connect negative cable to battery.

6) Start engine and check for gas leak.

For Canadian specification vehicle, turn on

check switch.

7) Run engine at 1,500 - 2,000 r/min for 30

sec. after warming up engine. Check to be

sure that “CHECK ENGINE” light flashes,

and turn off “CHECK ENGINE” light cancel/

check switch on steering column holder

bracket.

1. Cancel switch (U.S.A.)Check switch (Canada)

2. instrument panel

3. Steering columnholder bracket

4. Steering wheel

10. CATALYTIC CONVERTER INSPECTION

1) All accessories (wipers, heater, lights, etc.) are

out of service.

2) Warm up engine to normal operating tem-

perature.

3) Connect CO tester to mufler tail pipe.

4) With the engine warmed up, keep the engine

speed at 1,500 to 2,000 r/min. (t-pm). If the

CO concentration is 0.4% or less in this state,

the catalytic converter is in good condition.

If it exceeds the specification, refer to DIA-

GNOSIS (p. 5-15).

1-10

Page 27 of 962

1. CHARCOAL CANISTER REPLACEMENT

WARNING:

The following cautions should be always

observed.

l Disconnect negative cable at battery.

l DO NOT smoke and place “NO SMOK-

ING” signs near work area.

l Be sure to have COZ fire extinguisher

handy.

l Wear safety glasses.

l To release the fuel vapor pressure in

fuel tank, remove the fuel tank cap and

then reinstall it.

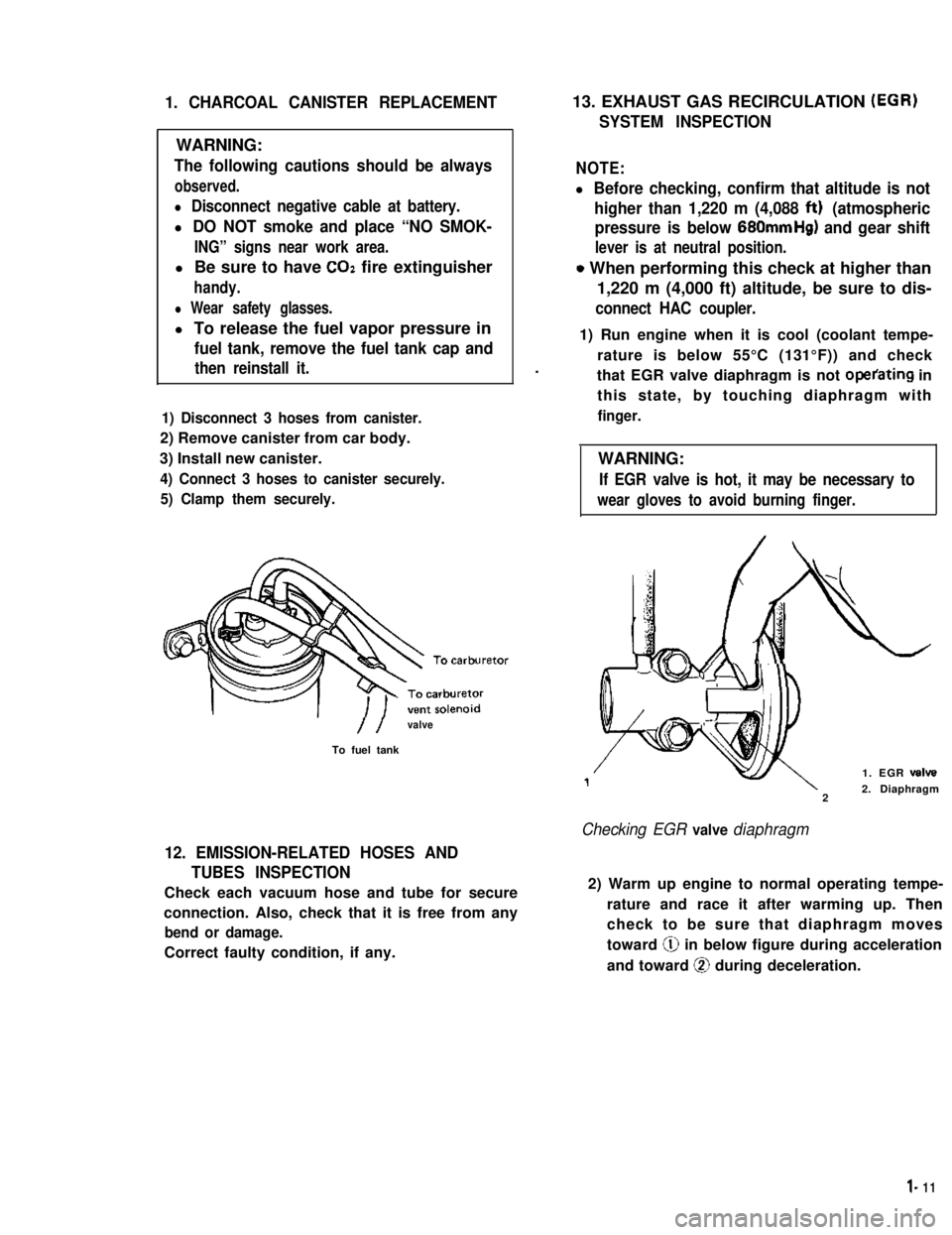

1) Disconnect 3 hoses from canister.

2) Remove canister from car body.

3) Install new canister.

4) Connect 3 hoses to canister securely.

5) Clamp them securely.

//valve

To fuel tank

12. EMISSION-RELATED HOSES AND

TUBES INSPECTION

Check each vacuum hose and tube for secure

connection. Also, check that it is free from any

bend or damage.

Correct faulty condition, if any.

13. EXHAUST GAS RECIRCULATION (EGR)

SYSTEM INSPECTION

NOTE:

l Before checking, confirm that altitude is not

higher than 1,220 m (4,088 ftt) (atmospheric

pressure is below 680mmHg) and gear shift

lever is at neutral position.

o When performing this check at higher than

1,220 m (4,000 ft) altitude, be sure to dis-

connect HAC coupler.

.

1) Run engine when it is cool (coolant tempe-

rature is below 55°C (131°F)) and check

that EGR valve diaphragm is not operating in

this state, by touching diaphragm with

finger.

WARNING:

If EGR valve is hot, it may be necessary to

wear gloves to avoid burning finger.

1. EGR valve

22. Diaphragm

Checking EGR valve diaphragm

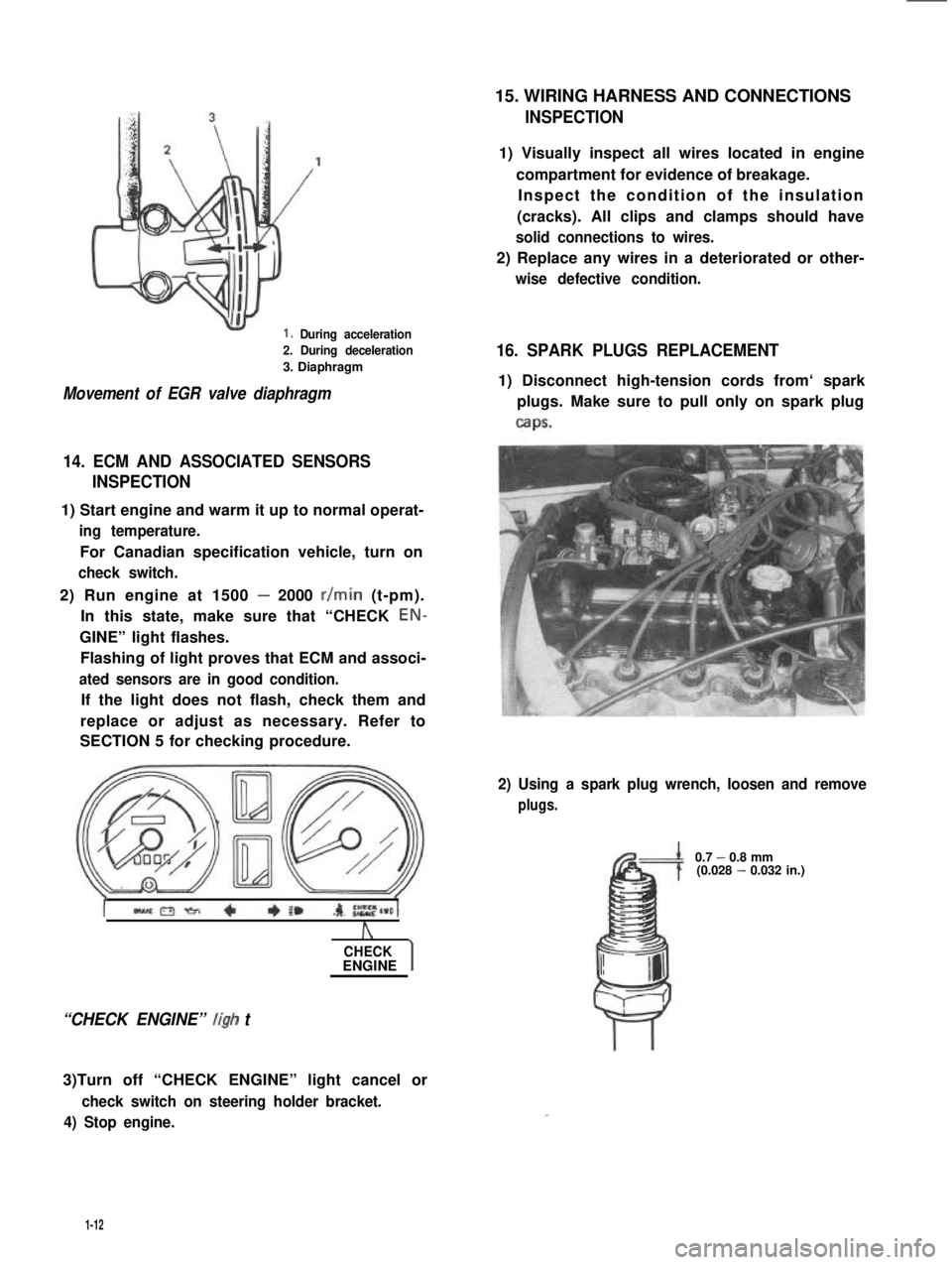

2) Warm up engine to normal operating tempe-

rature and race it after warming up. Then

check to be sure that diaphragm moves

toward @ in below figure during acceleration

and toward @ during deceleration.

l- 11

Page 28 of 962

1. During acceleration

2. During deceleration

3. Diaphragm

Movement of EGR valve diaphragm

14. ECM AND ASSOCIATED SENSORS

INSPECTION

1) Start engine and warm it up to normal operat-

ing temperature.

For Canadian specification vehicle, turn on

check switch.

2) Run engine at 1500 - 2000 r/min (t-pm).

In this state, make sure that “CHECK EON-

GINE” light flashes.

Flashing of light proves that ECM and associ-

ated sensors are in good condition.

If the light does not flash, check them and

replace or adjust as necessary. Refer to

SECTION 5 for checking procedure.

A

CHECKENGINE

“CHECK ENGINE” ligh t

3)Turn off “CHECK ENGINE” light cancel or

check switch on steering holder bracket.

4) Stop engine.

15. WIRING HARNESS AND CONNECTIONS

INSPECTION

1) Visually inspect all wires located in engine

compartment for evidence of breakage.

Inspect the condition of the insulation

(cracks). All clips and clamps should have

solid connections to wires.

2) Replace any wires in a deteriorated or other-

wise defective condition.

16. SPARK PLUGS REPLACEMENT

1) Disconnect high-tension cords from‘ spark

plugs. Make sure to pull only on spark plug

caps.

2) Using a spark plug wrench, loosen and remove

plugs.

0.7 - 0.8 mm(0.028 - 0.032 in.)

1-12

Page 30 of 962

21. FUEL TANK CAP GASKET INSPECTION

AND REPLACEMENT

Visually inspect gasket of fuel tank cap. If it is

damaged or deteriorated, replace it with new

one.

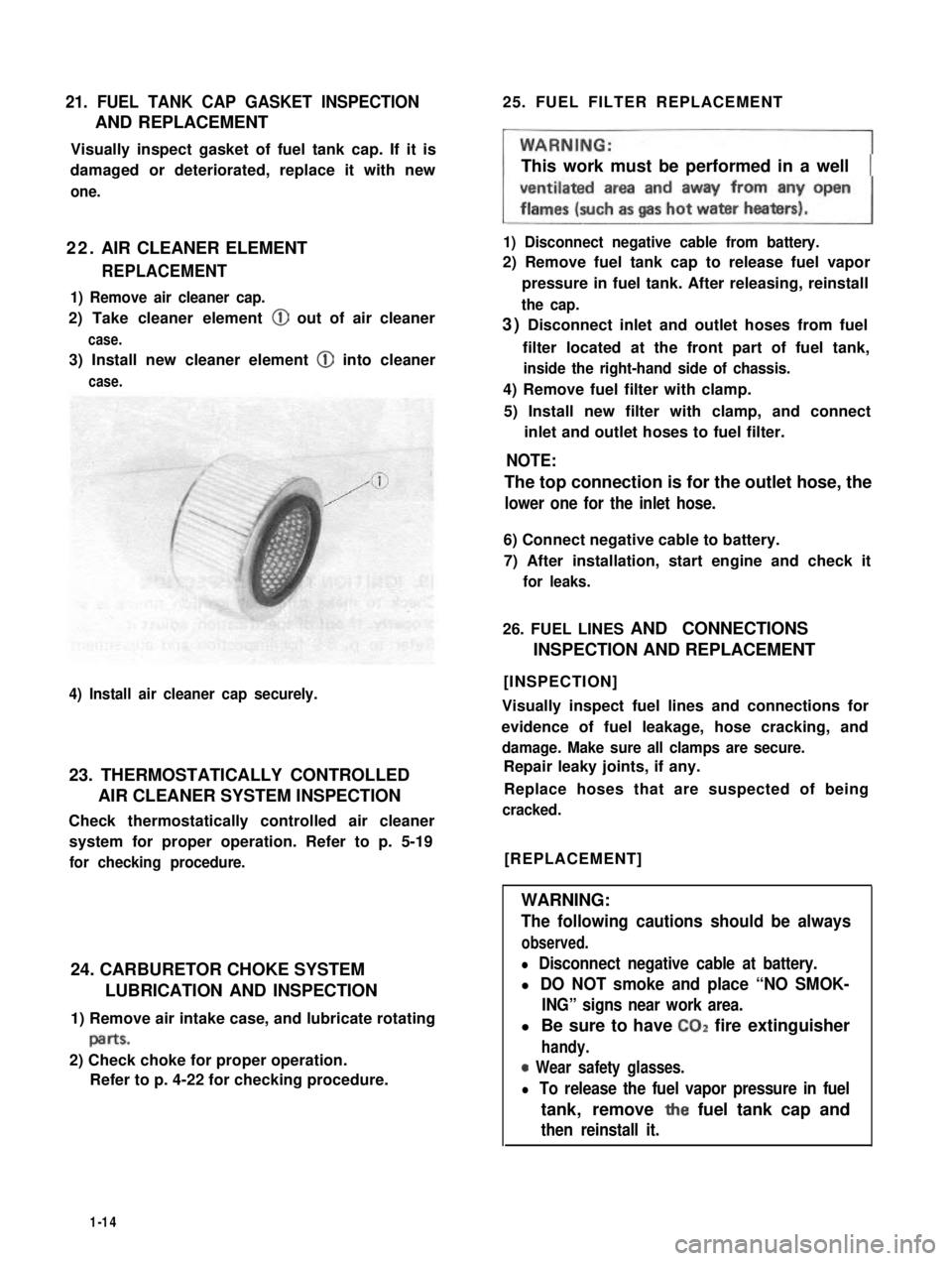

22. AIR CLEANER ELEMENT

REPLACEMENT

1) Remove air cleaner cap.

2) Take cleaner element @ out of air cleaner

case.

3) Install new cleaner element @ into cleaner

case.

4) Install air cleaner cap securely.

23. THERMOSTATICALLY CONTROLLED

AIR CLEANER SYSTEM INSPECTION

Check thermostatically controlled air cleaner

system for proper operation. Refer to p. 5-19

for checking procedure.

24. CARBURETOR CHOKE SYSTEM

LUBRICATION AND INSPECTION

1) Remove air intake case, and lubricate rotating

paItS.

2) Check choke for proper operation.

Refer to p. 4-22 for checking procedure.

25. FUEL FILTER REPLACEMENT

This work must be performed in a well

1) Disconnect negative cable from battery.

2) Remove fuel tank cap to release fuel vapor

pressure in fuel tank. After releasing, reinstall

the cap.

3) Disconnect inlet and outlet hoses from fuel

filter located at the front part of fuel tank,

inside the right-hand side of chassis.

4) Remove fuel filter with clamp.

5) Install new filter with clamp, and connect

inlet and outlet hoses to fuel filter.

NOTE:

The top connection is for the outlet hose, the

lower one for the inlet hose.

6) Connect negative cable to battery.

7) After installation, start engine and check it

for leaks.

26. FUEL LINES AND CONNECTIONS

INSPECTION AND REPLACEMENT

[INSPECTION]

Visually inspect fuel lines and connections for

evidence of fuel leakage, hose cracking, and

damage. Make sure all clamps are secure.

Repair leaky joints, if any.

Replace hoses that are suspected of being

cracked.

[REPLACEMENT]

WARNING:

The following cautions should be always

observed.

l Disconnect negative cable at battery.

l DO NOT smoke and place “NO SMOK-

ING” signs near work area.

l Be sure to have CO2 fire extinguisher

handy.

0 Wear safety glasses.

l To release the fuel vapor pressure in fuel

tank, remove the fuel tank cap and

then reinstall it.

1-14

Page 31 of 962

1) Replace fuel hoses (pipe to fuel pump, pipe to

fuel filter and breather hose) in fuel feed and

return lines with new ones.

2) Remove fuel tank.

3) Replace return hose (tank to return pipe)

with new one.

4) Clamp hoses securely.

5) Install fuel tank referring to p. 4-35.

6) After installation, start engine and check it

for leaks.

27. IDLE SPEED INSPECTION

NOTE:

Before starting engine, place transmission gear

shift lever in “Neutral”, and set parking brake

and block drive wheels.

1) Warm up engine to normal operating tempe-

rature.

2) Check to ensure that idle speed is within

750 - 850 r/min (rpm).

3) If idle speed is not within specified range,

adjust idle speed. Refer to MAINTENANCE

SERVICE (p. 4-26) for procedures to check

and adjust idle speed.

28. IDLE MIXTURE INSPECTION

1) Warm up engine to normal operating tem-

perature.

2) Remove seal rubber of duty check coupler

and connect positive terminal of duty meter

to “Blue/Red” wire and negative terminal to

“Black/Green” wire.

1

1. Duty check coupler

2. Air intake case

3) Set tachometer.

4) Run engine at 1,500 - 2,000 r/min for 30

seconds and bring it to idle speed.

5) Check duty at specified idle speed. If it is out

of specification,adjust it to specification

according to following adjustment procedure.

Specified Duty10-50

at 750 - 850 r/min.I

After inspection, install seal rubber to duty

check coupler.

Idle mixture adjustment procedure is as follows:

1) Remove carburetor from intake manifold

following normal service procedure to gain

access to mixture adjusting screw pin covering

mixture adjusting screw.

2) Drive out mixture adjusting screw pin using

about 4.5 mm (0.18 in) thick iron rod as

shown below.

1-15