fuse SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 40 of 962

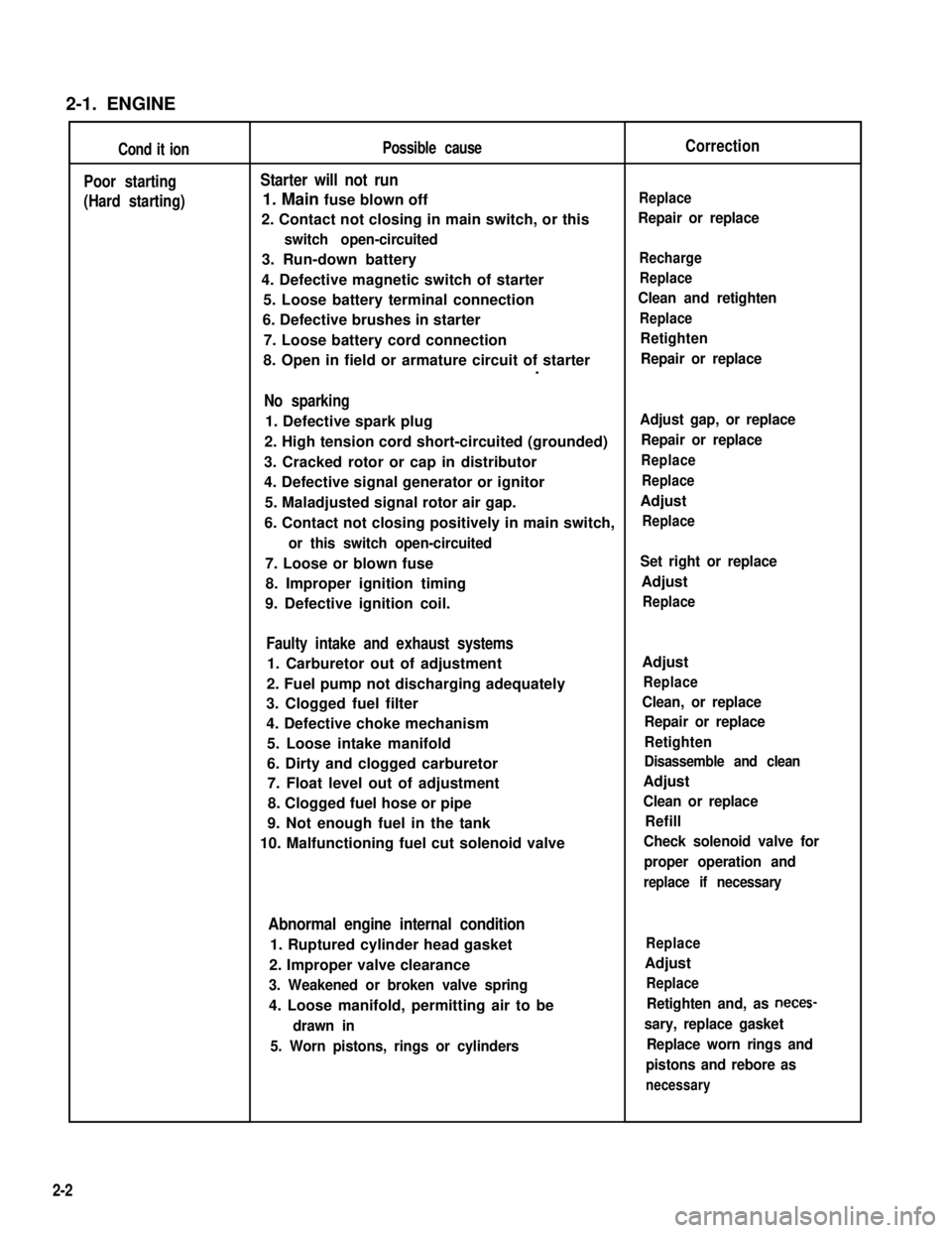

2-1. ENGINE

Cond it ion

Poor starting

(Hard starting)

Possible cause

Starter will not run

1. Main fuse blown off

2. Contact not closing in main switch, or this

switch open-circuited

3. Run-down battery

4. Defective magnetic switch of starter

5. Loose battery terminal connection

6. Defective brushes in starter

7. Loose battery cord connection

8. Open in field or armature circuit of starter.

Correction

Replace

Repair or replace

Recharge

Replace

Clean and retighten

Replace

Retighten

Repair or replace

No sparking

1. Defective spark plugAdjust gap, or replace

2. High tension cord short-circuited (grounded)Repair or replace

3. Cracked rotor or cap in distributorReplace

4. Defective signal generator or ignitorReplace

5. Maladjusted signal rotor air gap.Adjust

6. Contact not closing positively in main switch,Replace

or this switch open-circuited

7. Loose or blown fuseSet right or replace

8. Improper ignition timingAdjust

9. Defective ignition coil.Replace

Faulty intake and exhaust systems

1. Carburetor out of adjustment

2. Fuel pump not discharging adequately

3. Clogged fuel filter

4. Defective choke mechanism

5. Loose intake manifold

6. Dirty and clogged carburetor

7. Float level out of adjustment

8. Clogged fuel hose or pipe

9. Not enough fuel in the tank

10. Malfunctioning fuel cut solenoid valve

Adjust

Replace

Clean, or replace

Repair or replace

Retighten

Disassemble and clean

Adjust

Clean or replace

Refill

Check solenoid valve for

proper operation and

replace if necessary

Abnormal engine internal condition

1. Ruptured cylinder head gasket

2. Improper valve clearance

3. Weakened or broken valve spring

4. Loose manifold, permitting air to be

drawn in

5. Worn pistons, rings or cylinders

Replace

Adjust

Replace

Retighten and, as neces-

sary, replace gasket

Replace worn rings and

pistons and rebore as

necessary

2-2

Page 55 of 962

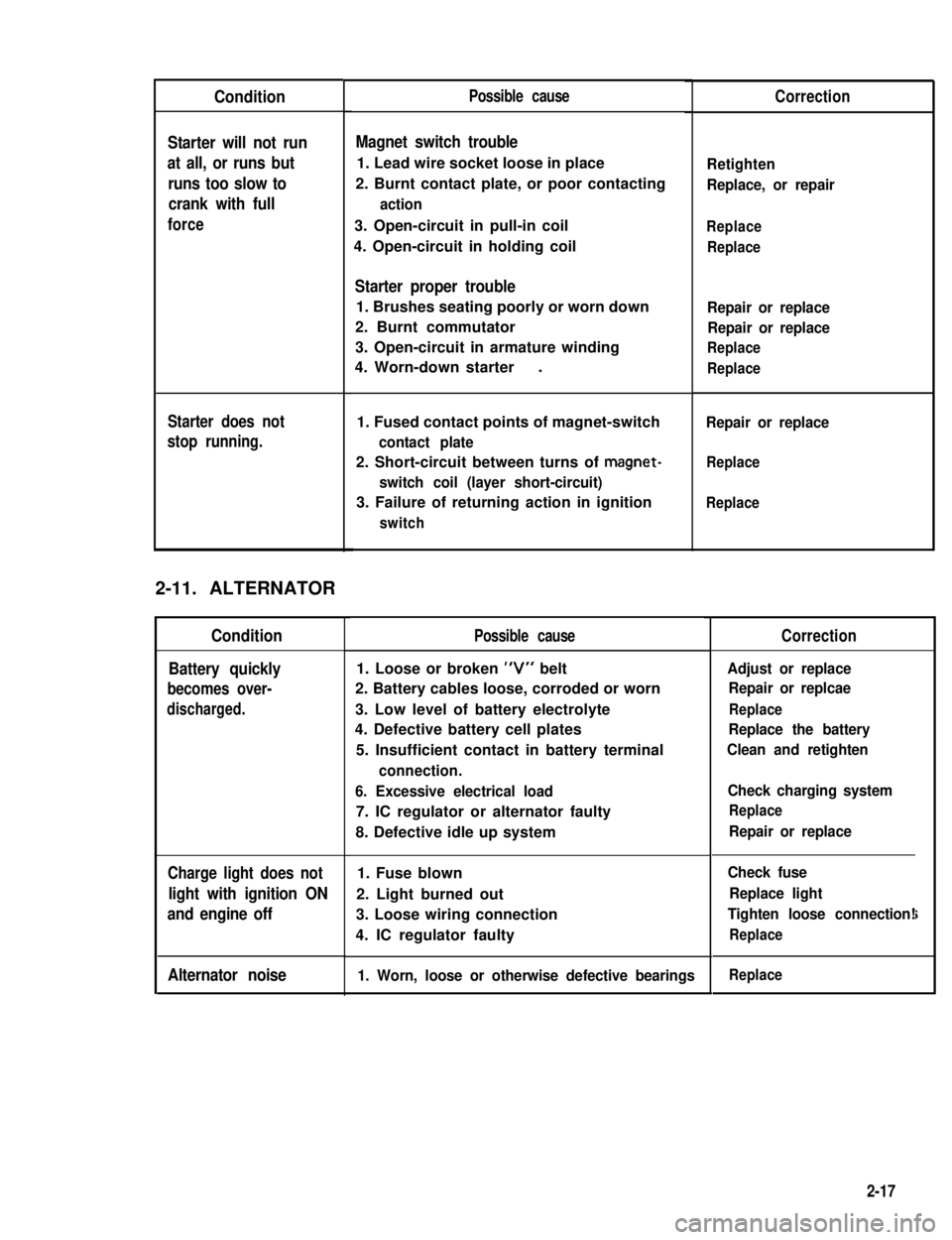

Condition

Starter will not run

at all, or runs but

runs too slow to

crank with full

force

Starter does not

stop running.

2-11. ALTERNATOR

Condition

Battery quickly

becomes over-

discharged.

Charge light does not

light with ignition ON

and engine off

Alternator noise

Possible cause

Magnet switch trouble

1. Lead wire socket loose in place

2. Burnt contact plate, or poor contacting

action

3. Open-circuit in pull-in coil

4. Open-circuit in holding coil

Starter proper trouble

1. Brushes seating poorly or worn down

2. Burnt commutator

3. Open-circuit in armature winding

4. Worn-down starter.

1. Fused contact points of magnet-switch

contact plate

2. Short-circuit between turns of magnet-

switch coil (layer short-circuit)

3. Failure of returning action in ignition

switch

Possible cause

1. Loose or broken “V” belt

2. Battery cables loose, corroded or worn

3. Low level of battery electrolyte

4. Defective battery cell plates

5. Insufficient contact in battery terminal

connection.

6. Excessive electrical load

7. IC regulator or alternator faulty

8. Defective idle up system

1. Fuse blown

2. Light burned out

3. Loose wiring connection

4. IC regulator faulty

1. Worn, loose or otherwise defective bearings

Correction

Retighten

Replace, or repair

Replace

Replace

Repair or replace

Repair or replace

Replace

Replace

Repair or replace

Replace

Replace

Correction

Adjust or replace

Repair or replcae

Replace

Replace the battery

Clean and retighten

Check charging system

Replace

Repair or replace

Check fuse

Replace light

Tighten loose connection!

Replace

i

Replace

2-17

Page 56 of 962

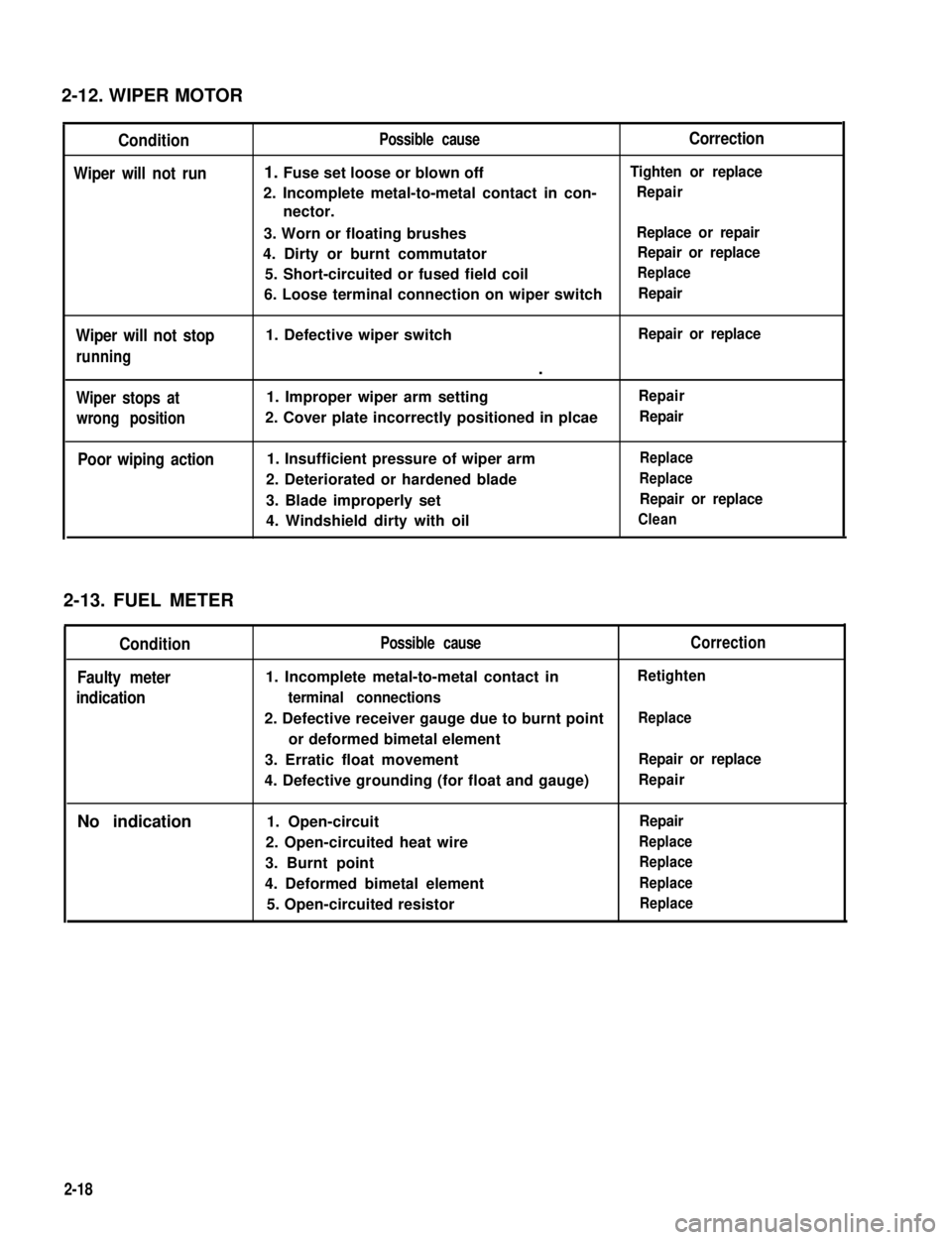

2-12. WIPER MOTOR

Condition

Wiper will not run

Wiper will not stop

running

Wiper stops at

wrong position

Poor wiping action

Possible causeCorrection

1. Fuse set loose or blown offTighten or replace

2. Incomplete metal-to-metal contact in con-

nector.

Repair

3. Worn or floating brushesReplace or repair

4. Dirty or burnt commutatorRepair or replace

5. Short-circuited or fused field coilReplace

6. Loose terminal connection on wiper switchRepair

1. Defective wiper switchRepair or replace

.

1. Improper wiper arm settingRepair

2. Cover plate incorrectly positioned in plcaeRepair

1. Insufficient pressure of wiper armReplace

2. Deteriorated or hardened bladeReplace

3. Blade improperly setRepair or replace

4. Windshield dirty with oilClean

2-13. FUEL METER

Condition

Faulty meter

indication

No indication

Possible cause

1. Incomplete metal-to-metal contact in

terminal connections

2. Defective receiver gauge due to burnt point

or deformed bimetal element

3. Erratic float movement

4. Defective grounding (for float and gauge)

1. Open-circuit

2. Open-circuited heat wire

3. Burnt point

4. Deformed bimetal element

5. Open-circuited resistor

Correction

Retighten

Replace

Repair or replace

Repair

Repair

Replace

Replace

Replace

Replace

2-18

Page 147 of 962

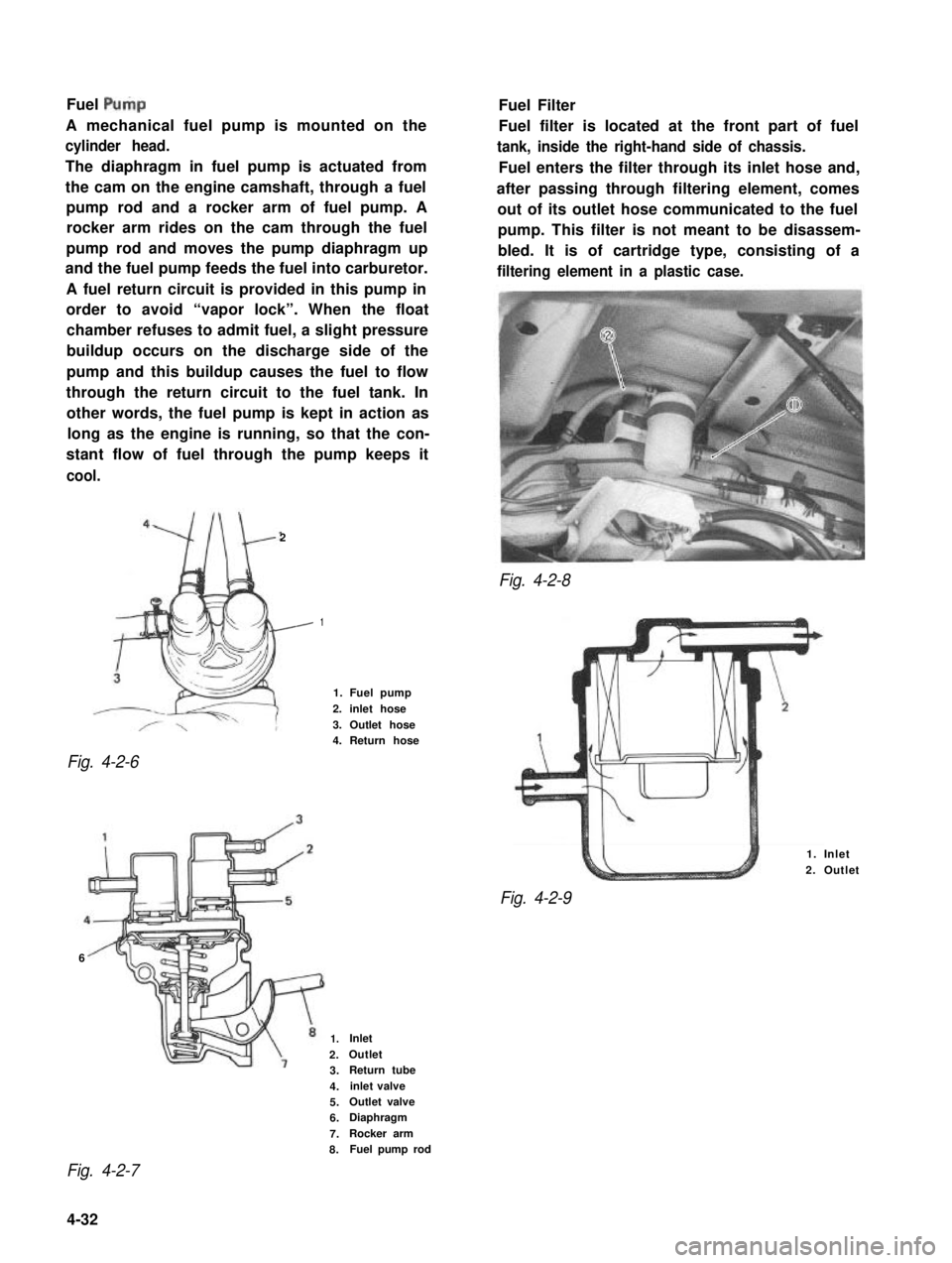

Fuel Pulp

A mechanical fuel pump is mounted on the

cylinder head.

The diaphragm in fuel pump is actuated from

the cam on the engine camshaft, through a fuel

pump rod and a rocker arm of fuel pump. A

rocker arm rides on the cam through the fuel

pump rod and moves the pump diaphragm up

and the fuel pump feeds the fuel into carburetor.

A fuel return circuit is provided in this pump in

order to avoid “vapor lock”. When the float

chamber refuses to admit fuel, a slight pressure

buildup occurs on the discharge side of the

pump and this buildup causes the fuel to flow

through the return circuit to the fuel tank. In

other words, the fuel pump is kept in action as

long as the engine is running, so that the con-

stant flow of fuel through the pump keeps it

cool.

2

Fig. 4-2-8

Fig. 4-2-6

Fuel Filter

Fuel filter is located at the front part of fuel

tank, inside the right-hand side of chassis.

Fuel enters the filter through its inlet hose and,

after passing through filtering element, comes

out of its outlet hose communicated to the fuel

pump. This filter is not meant to be disassem-

bled. It is of cartridge type, consisting of a

filtering element in a plastic case.

1

1. Fuel pump

2. inlet hose

3. Outlet hose4. Return hose

6

1. Inlet

2. Outlet

Fig. 4-2-9

1.Inlet

2.Outlet

3.Return tube

4.inlet valve

5.Outlet valve

6.Diaphragm

7.Rocker arm

8.Fuel pump rod

Fig. 4-2-7

4-32

Page 237 of 962

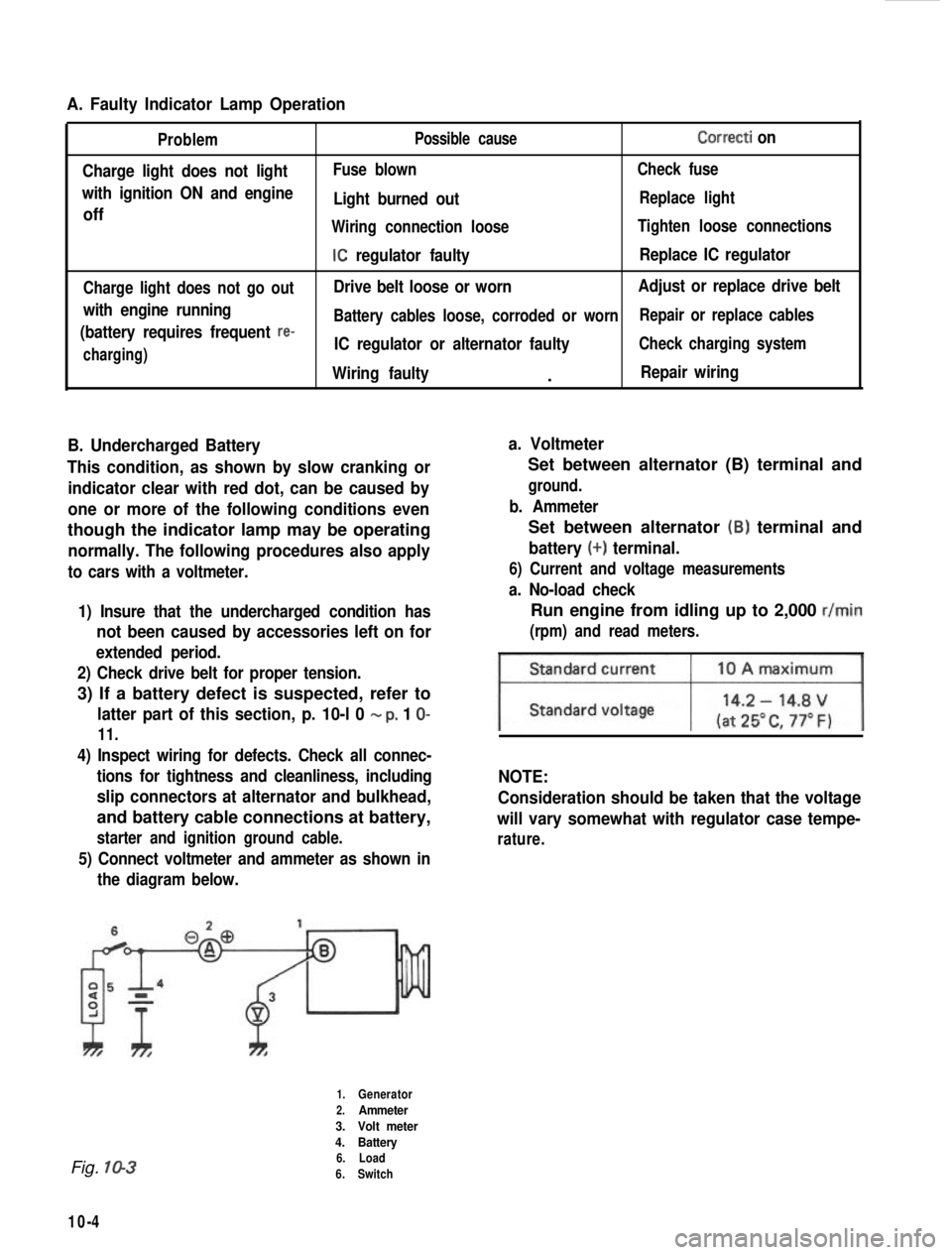

A. Faulty Indicator Lamp Operation

Problem

Charge light does not light

with ignition ON and engine

off

Charge light does not go out

with engine running

(battery requires frequent

re-

charging) Possible cause

Correcti on

Fuse blown

Check fuse

Light burned outReplace light

Wiring connection loose Tighten loose connections

IC regulator faultyReplace IC regulator

Drive belt loose or worn Adjust or replace drive belt

Battery cables loose, corroded or worn Repair or replace cables

IC regulator or alternator faultyCheck charging system

Wiring faulty.Repair wiring

B. Undercharged Battery a. Voltmeter

This condition, as shown by slow cranking or indicator clear with red dot, can be caused by

one or more of the following conditions even

though the indicator lamp may be operating

normally. The following procedures also apply

to cars with a voltmeter.

1) Insure that the undercharged condition has

not been caused by accessories left on for

extended period.

2) Check drive belt for proper tension.

3) If a battery defect is suspected, refer to

latter part of this section, p. 10-l 0 - p, 1 O-

11.

4) Inspect wiring for defects. Check all connec- tions for tightness and cleanliness, including

slip connectors at alternator and bulkhead,

and battery cable connections at battery,

starter and ignition ground cable.

5) Connect voltmeter and ammeter as shown inthe diagram below.

Set between alternator (B) terminal and

ground.

b. Ammeter

Set between alternator (B) terminal and

battery (+) terminal.

6) Current and voltage measurements

a. No-load check

Run engine from idling up to 2,000 r/min

(rpm) and read meters.

NOTE:

Consideration should be taken that the voltage

will vary somewhat with regulator case tempe-

rature.

Fig. 10-3

10-4

1.Generator

2.Ammeter

3. Volt meter

4. Battery

6. Load

6. Switch

Page 448 of 962

21-1.COMBINATION METER..................................

21-2.HEAD LIGHT..........................................

21-3.TURN SIGNAL LIGHT AND HAZARD WARNING LIGHT.......

21-4.WINDSHIELD WIPER MOTOR.............................

21-5.WATER TEMPERATURE METER AND GAUGE...............

21-6.FUEL LEVEL METER AND GAUGE........................

21-7.BRAKE WARNING LAMP ...............................

21-8.OIL PRESSURE LAMP..................................

4 WHEEL DRIVE LAMP.................................

21-10. SEAT BELT WARNING LAMP/BUZZER.....................

...................

...~I-I

.....

21-14. .............................................

21-15. WIRING HARNESS ROUTING............................

21-16. WIRING DIAGRAM....................................

SECTION 21

BODY ELECTRICAL EQUIPMENT

CONTENTS

21-9.

21-11. MAIN SWITCH KEY WARNING BUZZER

21-12. ILUMINATION CONTROLLER..............................................

21-13. REAR DEFOGGER ( hard-top )......................................

FUSE BOX

21-2

21-4

21-7

21-9

21-11

21-12

21-13

21-14

21-15

21-15

21-16

21-16

21-16

21-18

21-19

21-22

21-1

Page 451 of 962

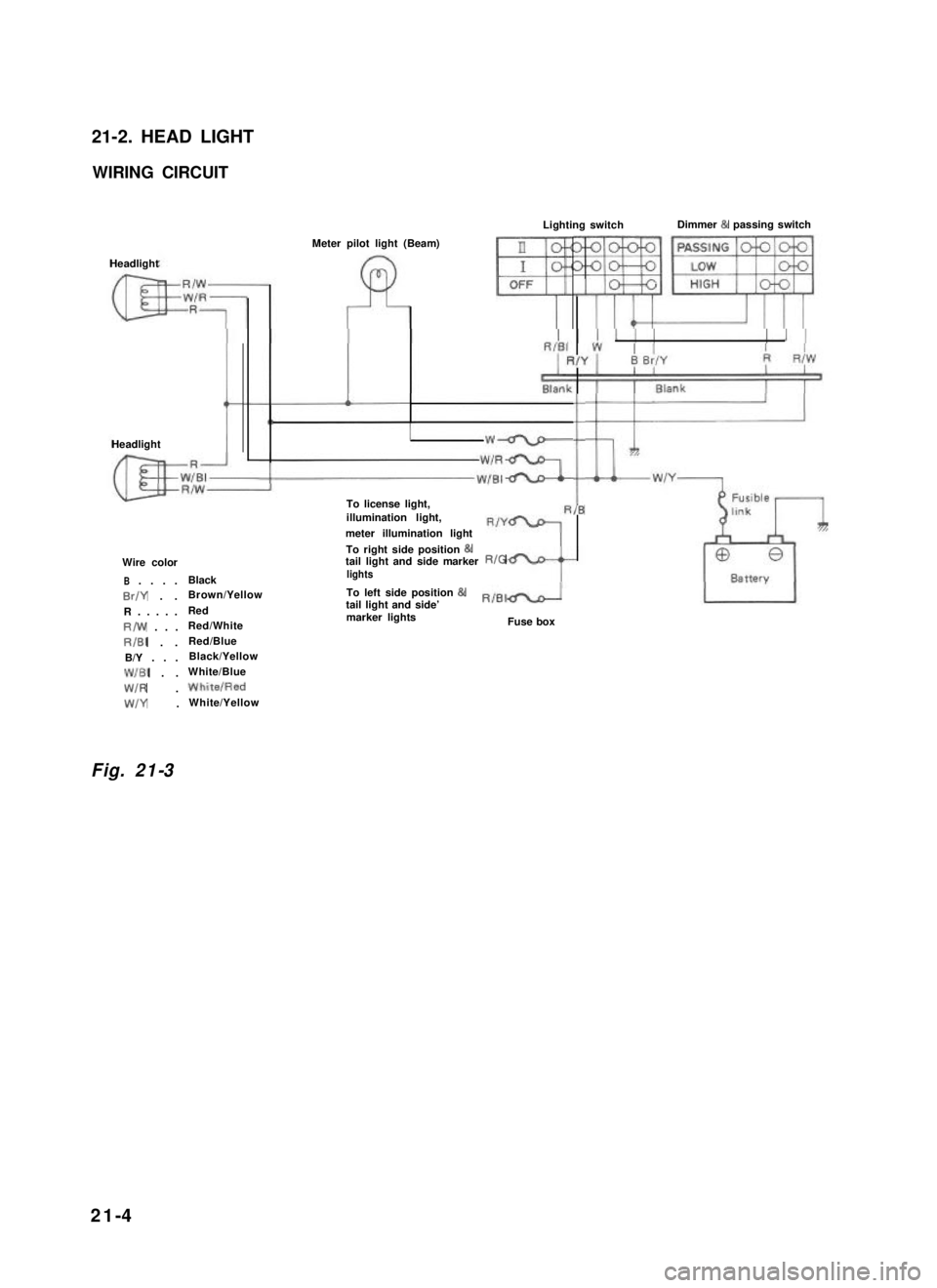

21-2. HEAD LIGHT

WIRING CIRCUIT

Headlight

HeadlightI

Meter pilot light (Beam)II

I

4

Lighting switchDimmer & passing switch

To license light,illumination light,

meter illumination light

Wire color

B. . . .Black

Br/Y . .Brown/Yellow

R.....Red

R/w . . .Red/White

RIBI . .Red/Blue

B/Y . . .Black/Yellow

WIBI . .White/Blue

W/R .WhitelRed

W/Y .White/Yellow

To right side position &tail light and side markerRIGlights

iIB

To left side position 81tail light and side’RIBId

marker lightsFuse box

Fig. 21-3

21-4

Page 454 of 962

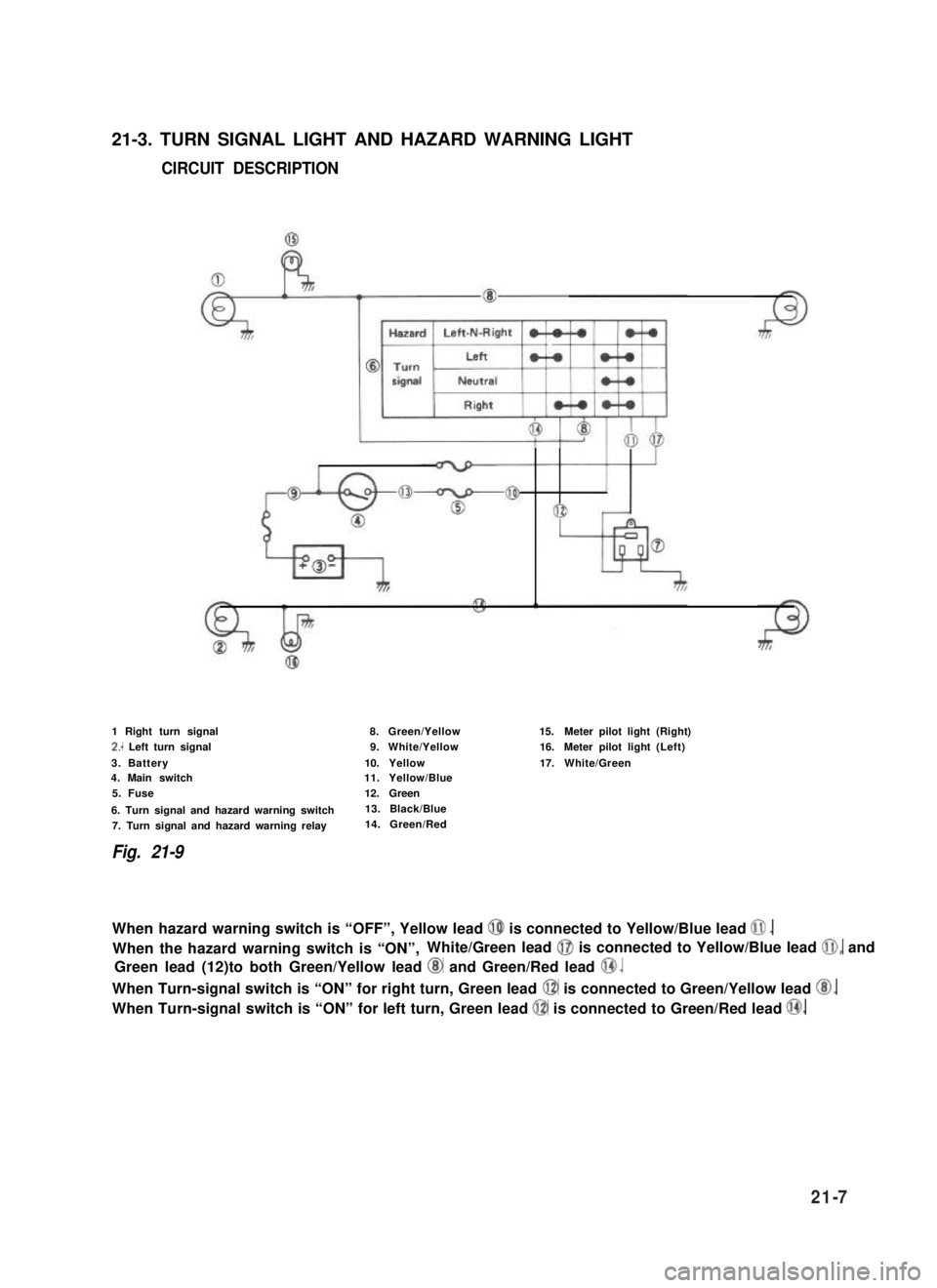

21-3. TURN SIGNAL LIGHT AND HAZARD WARNING LIGHT

CIRCUIT DESCRIPTION

1 Right turn signal

2.. Left turn signal

3. Battery4. Main switch

5. Fuse

6. Turn signal and hazard warning switch

7. Turn signal and hazard warning relay

Fig. 21-9

8.Green/Yellow

9.White/Yellow

10.Yellow11.Yellow/Blue

12.Green

13. Black/Blue

14. Green/Red

15.Meter pilot light(Right)

16.Meter pilot light(Left)

17.White/Green

When hazard warning switch is “OFF”, Yellow lead @ is connected to Yellow/Blue lead 0.

When the hazard warning switch is “ON”,White/Green lead @I is connected to Yellow/Blue lead @I, and

Green lead (12)to both Green/Yellow lead @ and Green/Red lead @.

When Turn-signal switch is “ON” for right turn, Green lead @ is connected to Green/Yellow lead @.

When Turn-signal switch is “ON” for left turn, Green lead @ is connected to Green/Red lead @.

21-7

Page 456 of 962

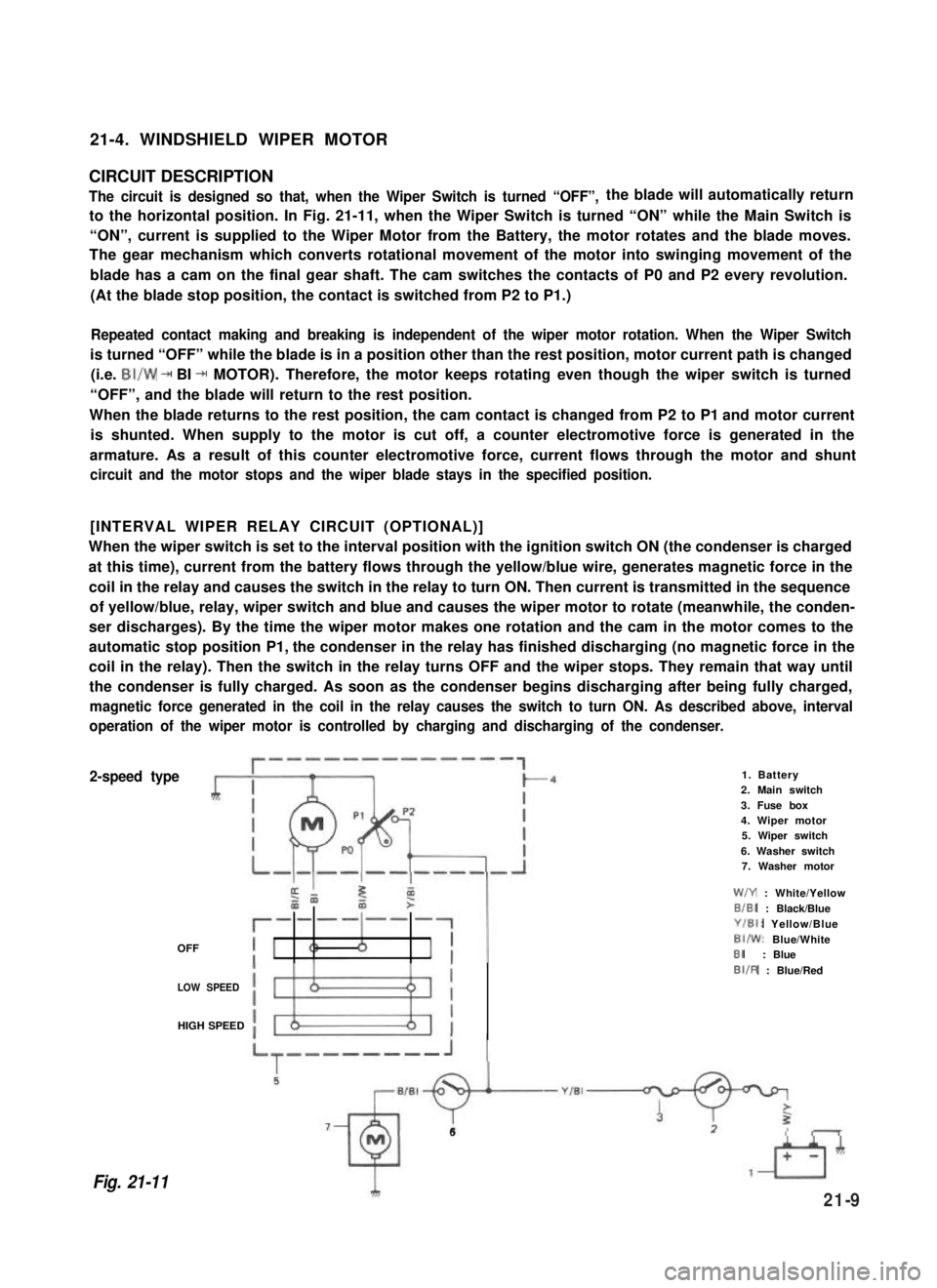

21-4. WINDSHIELD WIPER MOTOR

CIRCUIT DESCRIPTION

The circuit is designed so that, when the Wiper Switch is turned “OFF”,the blade will automatically return

to the horizontal position. In Fig. 21-11, when the Wiper Switch is turned “ON” while the Main Switch is

“ON”, current is supplied to the Wiper Motor from the Battery, the motor rotates and the blade moves.

The gear mechanism which converts rotational movement of the motor into swinging movement of the

blade has a cam on the final gear shaft. The cam switches the contacts of P0 and P2 every revolution.

(At the blade stop position, the contact is switched from P2 to P1.)

Repeated contact making and breaking is independent of the wiper motor rotation. When the Wiper Switch

is turned “OFF” while the blade is in a position other than the rest position, motor current path is changed

(i.e. BI/W + BI + MOTOR). Therefore, the motor keeps rotating even though the wiper switch is turned

“OFF”, and the blade will return to the rest position.

When the blade returns to the rest position, the cam contact is changed from P2 to P1 and motor current

is shunted. When supply to the motor is cut off, a counter electromotive force is generated in the

armature. As a result of this counter electromotive force, current flows through the motor and shunt

circuit and the motor stops and the wiper blade stays in the specified position.

[INTERVAL WIPER RELAY CIRCUIT (OPTIONAL)]

When the wiper switch is set to the interval position with the ignition switch ON (the condenser is charged

at this time), current from the battery flows through the yellow/blue wire, generates magnetic force in the

coil in the relay and causes the switch in the relay to turn ON. Then current is transmitted in the sequence

of yellow/blue, relay, wiper switch and blue and causes the wiper motor to rotate (meanwhile, the conden-

ser discharges). By the time the wiper motor makes one rotation and the cam in the motor comes to the

automatic stop position P1, the condenser in the relay has finished discharging (no magnetic force in the

coil in the relay). Then the switch in the relay turns OFF and the wiper stops. They remain that way until

the condenser is fully charged. As soon as the condenser begins discharging after being fully charged,

magnetic force generated in the coil in the relay causes the switch to turn ON. As described above, interval

operation of the wiper motor is controlled by charging and discharging of the condenser.

2-speed type

OFF

1. Battery2. Main switch

3. Fuse box4. Wiper motor5. Wiper switch

6. Washer switch7. Washer motor

W/Y : White/Yellow

B/BI : Black/Blue

Y/El: Yellow/Blue

BI/W: Blue/WhiteBI: Blue

LOW SPEED

BIIR : Blue/Red

HIGH SPEED

Fig. 21-11

6

21-9

Page 457 of 962

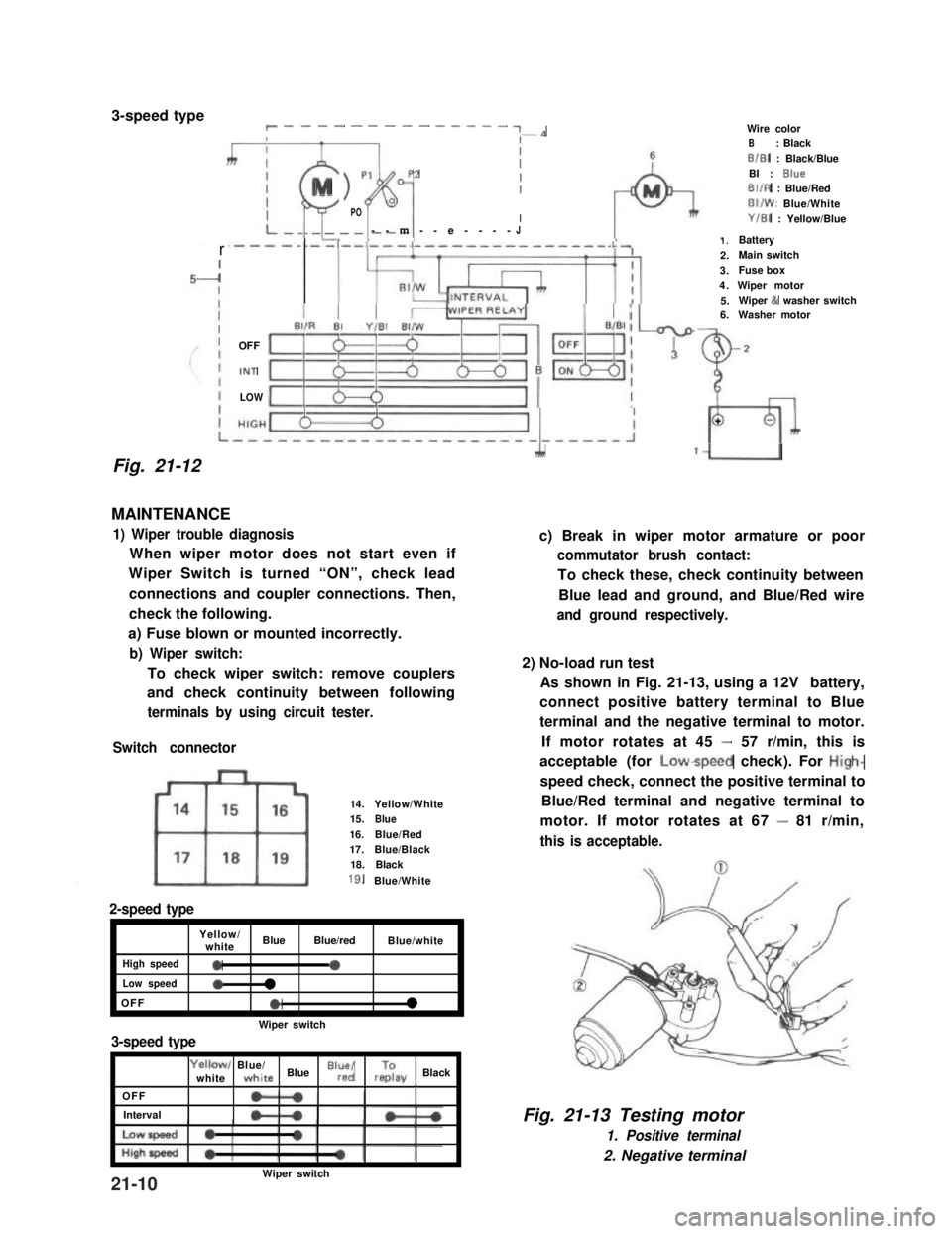

3-speed typer __-- - ---- - ---- ~-*

Fig. 21-12

rI-I

III

MI > p1p2

fil

II0POI--m--e----J

OFF

IN1

LOW

MAINTENANCE

1) Wiper trouble diagnosis

When wiper motor does not start even if

Wiper Switch is turned “ON”, check lead

connections and coupler connections. Then,

check the following.

a) Fuse blown or mounted incorrectly.

b) Wiper switch:

To check wiper switch: remove couplers

and check continuity between following

terminals by using circuit tester.

Switch connector

14.Yellow/White15.Blue16.Blue/Red17.Blue/Black18.Black

18.Blue/White

2-speed type

Yellow/whiteBlueBlue/redBlue/white

High speed0a

Low speed0l

OFFel

Wiper switch

3-speed type

OFF

Interval

Yellowl Blue/whitewhite Blue “lr”,“d/ rzay Black

1.Battery2.Main switch3.Fuse box4.Wiper motor5.Wiper & washer switch6.Washer motor

Wire colorB: BlackB/B1 : Black/BlueBI : BlueBIIR : Blue/RedBI/W: Blue/WhiteY/B1 : Yellow/Blue

2

L

+

A‘U

c) Break in wiper motor armature or poor

commutator brush contact:

To check these, check continuity between

Blue lead and ground, and Blue/Red wire

and ground respectively.

2) No-load run test

As shown in Fig. 21-13, using a 12V battery,

connect positive battery terminal to Blue

terminal and the negative terminal to motor.

If motor rotates at 45 - 57 r/min, this is

acceptable (for Lowspeed check). For High-

speed check, connect the positive terminal to

Blue/Red terminal and negative terminal to

motor. If motor rotates at 67 - 81 r/min,

this is acceptable.

Fig. 21-13 Testing motor

1. Positive terminal

2. Negative terminal

Wiper switch21-10