ground clearance SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 40 of 962

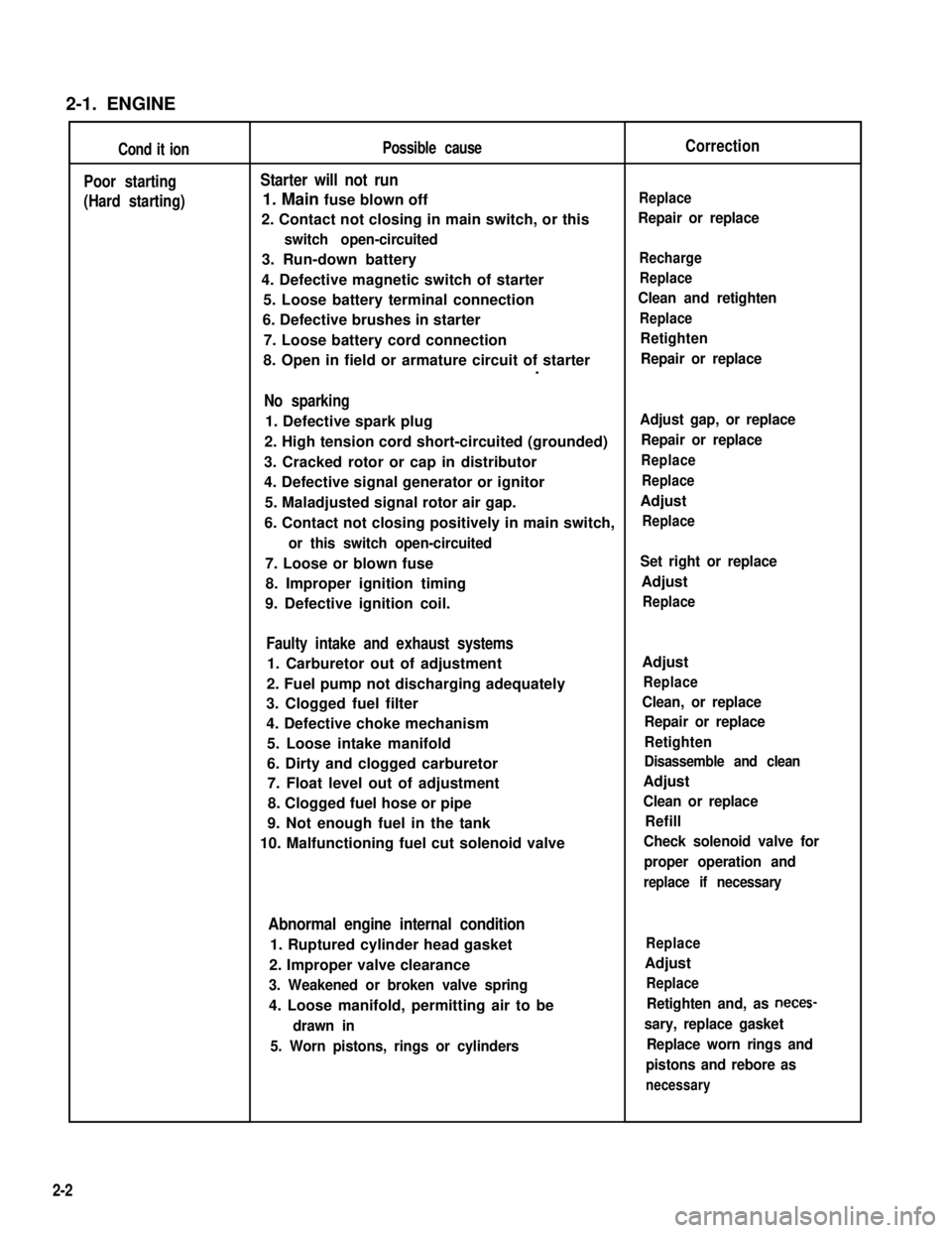

2-1. ENGINE

Cond it ion

Poor starting

(Hard starting)

Possible cause

Starter will not run

1. Main fuse blown off

2. Contact not closing in main switch, or this

switch open-circuited

3. Run-down battery

4. Defective magnetic switch of starter

5. Loose battery terminal connection

6. Defective brushes in starter

7. Loose battery cord connection

8. Open in field or armature circuit of starter.

Correction

Replace

Repair or replace

Recharge

Replace

Clean and retighten

Replace

Retighten

Repair or replace

No sparking

1. Defective spark plugAdjust gap, or replace

2. High tension cord short-circuited (grounded)Repair or replace

3. Cracked rotor or cap in distributorReplace

4. Defective signal generator or ignitorReplace

5. Maladjusted signal rotor air gap.Adjust

6. Contact not closing positively in main switch,Replace

or this switch open-circuited

7. Loose or blown fuseSet right or replace

8. Improper ignition timingAdjust

9. Defective ignition coil.Replace

Faulty intake and exhaust systems

1. Carburetor out of adjustment

2. Fuel pump not discharging adequately

3. Clogged fuel filter

4. Defective choke mechanism

5. Loose intake manifold

6. Dirty and clogged carburetor

7. Float level out of adjustment

8. Clogged fuel hose or pipe

9. Not enough fuel in the tank

10. Malfunctioning fuel cut solenoid valve

Adjust

Replace

Clean, or replace

Repair or replace

Retighten

Disassemble and clean

Adjust

Clean or replace

Refill

Check solenoid valve for

proper operation and

replace if necessary

Abnormal engine internal condition

1. Ruptured cylinder head gasket

2. Improper valve clearance

3. Weakened or broken valve spring

4. Loose manifold, permitting air to be

drawn in

5. Worn pistons, rings or cylinders

Replace

Adjust

Replace

Retighten and, as neces-

sary, replace gasket

Replace worn rings and

pistons and rebore as

necessary

2-2

Page 41 of 962

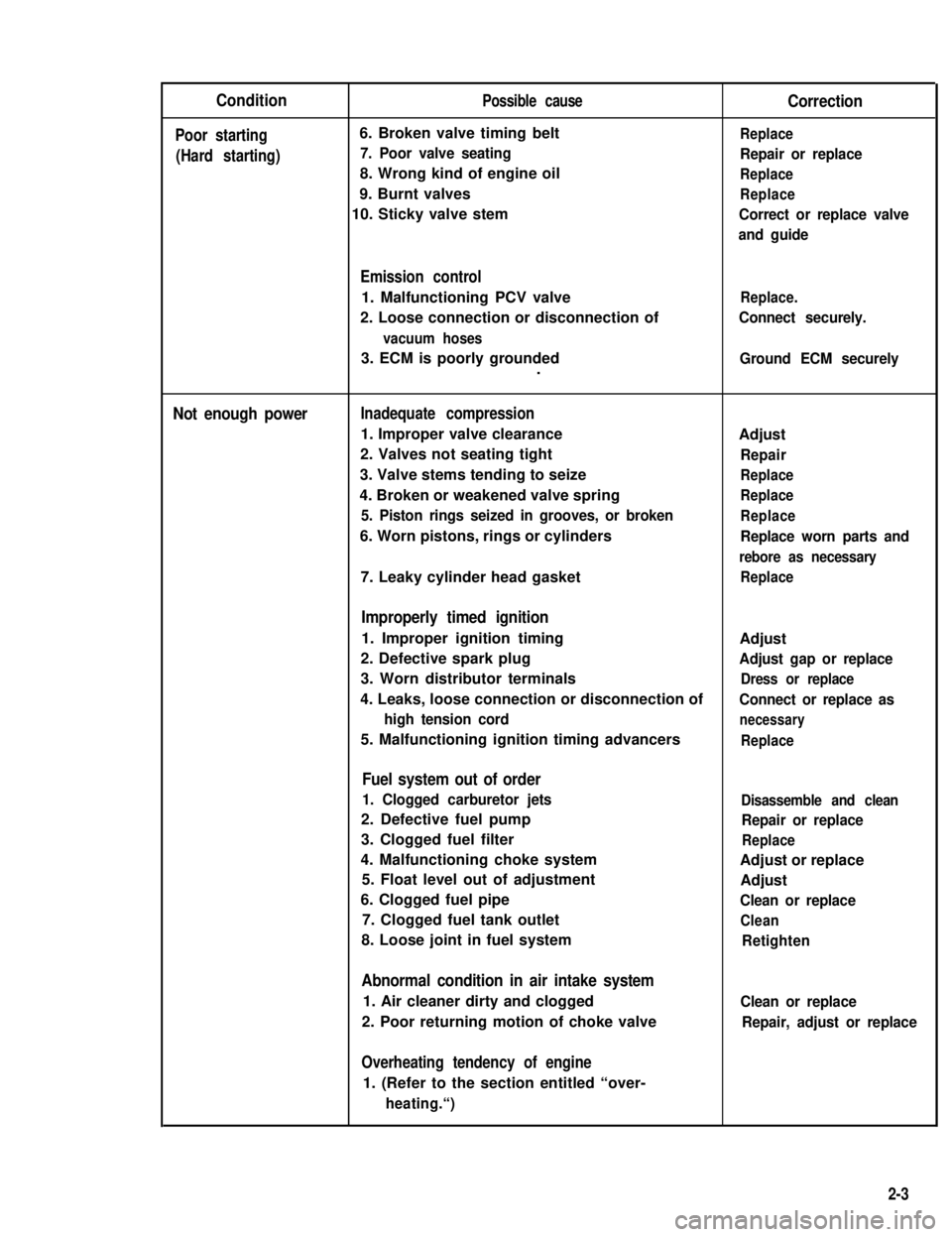

Condition

Poor starting

(Hard starting)

Possible cause

6. Broken valve timing belt

7. Poor valve seating

8. Wrong kind of engine oil

9. Burnt valves

10. Sticky valve stem

Correction

Replace

Repair or replace

Replace

Replace

Correct or replace valve

and guide

Emission control

1. Malfunctioning PCV valve

2. Loose connection or disconnection of

vacuum hoses

Replace.

Connect securely.

3. ECM is poorly grounded.Ground ECM securely

Not enough powerInadequate compression

1. Improper valve clearance

2. Valves not seating tight

3. Valve stems tending to seize

4. Broken or weakened valve spring

5. Piston rings seized in grooves, or broken

6. Worn pistons, rings or cylinders

Adjust

Repair

Replace

Replace

Replace

Replace worn parts and

rebore as necessary

7. Leaky cylinder head gasketReplace

Improperly timed ignition

1. Improper ignition timing

2. Defective spark plug

3. Worn distributor terminals

4. Leaks, loose connection or disconnection of

high tension cord

5. Malfunctioning ignition timing advancers

Adjust

Adjust gap or replace

Dress or replace

Connect or replace as

necessary

Replace

Fuel system out of order

1. Clogged carburetor jets

2. Defective fuel pump

3. Clogged fuel filter

4. Malfunctioning choke system

5. Float level out of adjustment

6. Clogged fuel pipe

7. Clogged fuel tank outlet

8. Loose joint in fuel system

Disassemble and clean

Repair or replace

Replace

Adjust or replace

Adjust

Clean or replace

Clean

Retighten

Abnormal condition in air intake system

1. Air cleaner dirty and clogged

2. Poor returning motion of choke valve

Clean or replace

Repair, adjust or replace

Overheating tendency of engine

1. (Refer to the section entitled “over-

heating.“)

2-3

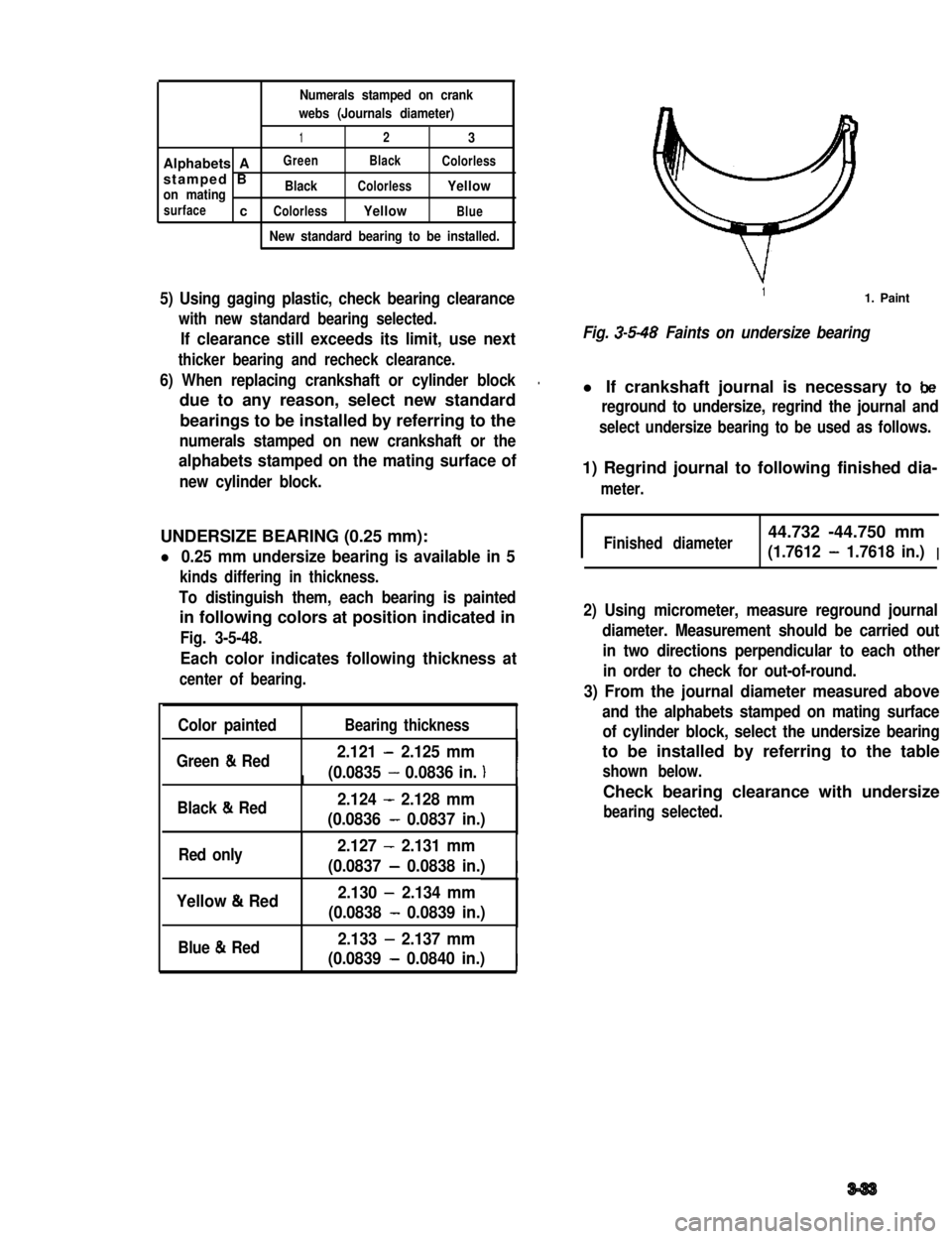

Page 90 of 962

Numerals stamped on crank

webs (Journals diameter)

123

Alphabets AGreenBlackColorless

stamped Bon matingBlackColorlessYellow

surfacecColorlessYellowBlue

New standard bearing to be installed.

5) Using gaging plastic, check bearing clearance

with new standard bearing selected.

If clearance still exceeds its limit, use next

thicker bearing and recheck clearance.

6) When replacing crankshaft or cylinder block.

due to any reason, select new standard

bearings to be installed by referring to the

numerals stamped on new crankshaft or the

alphabets stamped on the mating surface of

new cylinder block.

UNDERSIZE BEARING (0.25 mm):

l 0.25 mm undersize bearing is available in 5

kinds differing in thickness.

To distinguish them, each bearing is painted

in following colors at position indicated in

Fig. 3-5-48.

Each color indicates following thickness at

center of bearing.

Color paintedBearing thicknessI

Green & Red2.121 - 2.125 mm

(0.0835 - 0.0836 in. )III

Black & Red2.124 - 2.128 mm

(0.0836 - 0.0837 in.)

Red only2.127 - 2.131 mm

(0.0837 - 0.0838 in.)I

Yellow & Red2.130 - 2.134 mm

(0.0838 - 0.0839 in.)

Blue & Red2.133 - 2.137 mm

(0.0839 - 0.0840 in.)I

11. Paint

Fig. 3-5-48 Faints on undersize bearing

l If crankshaft journal is necessary to be

reground to undersize, regrind the journal and

select undersize bearing to be used as follows.

1) Regrind journal to following finished dia-

meter.

IFinished diameter44.732 -44.750 mm

(1.7612 - 1.7618 in.)I

2) Using micrometer, measure reground journal

diameter. Measurement should be carried out

in two directions perpendicular to each other

in order to check for out-of-round.

3) From the journal diameter measured above

and the alphabets stamped on mating surface

of cylinder block, select the undersize bearing

to be installed by referring to the table

shown below.

Check bearing clearance with undersize

bearing selected.

3-33

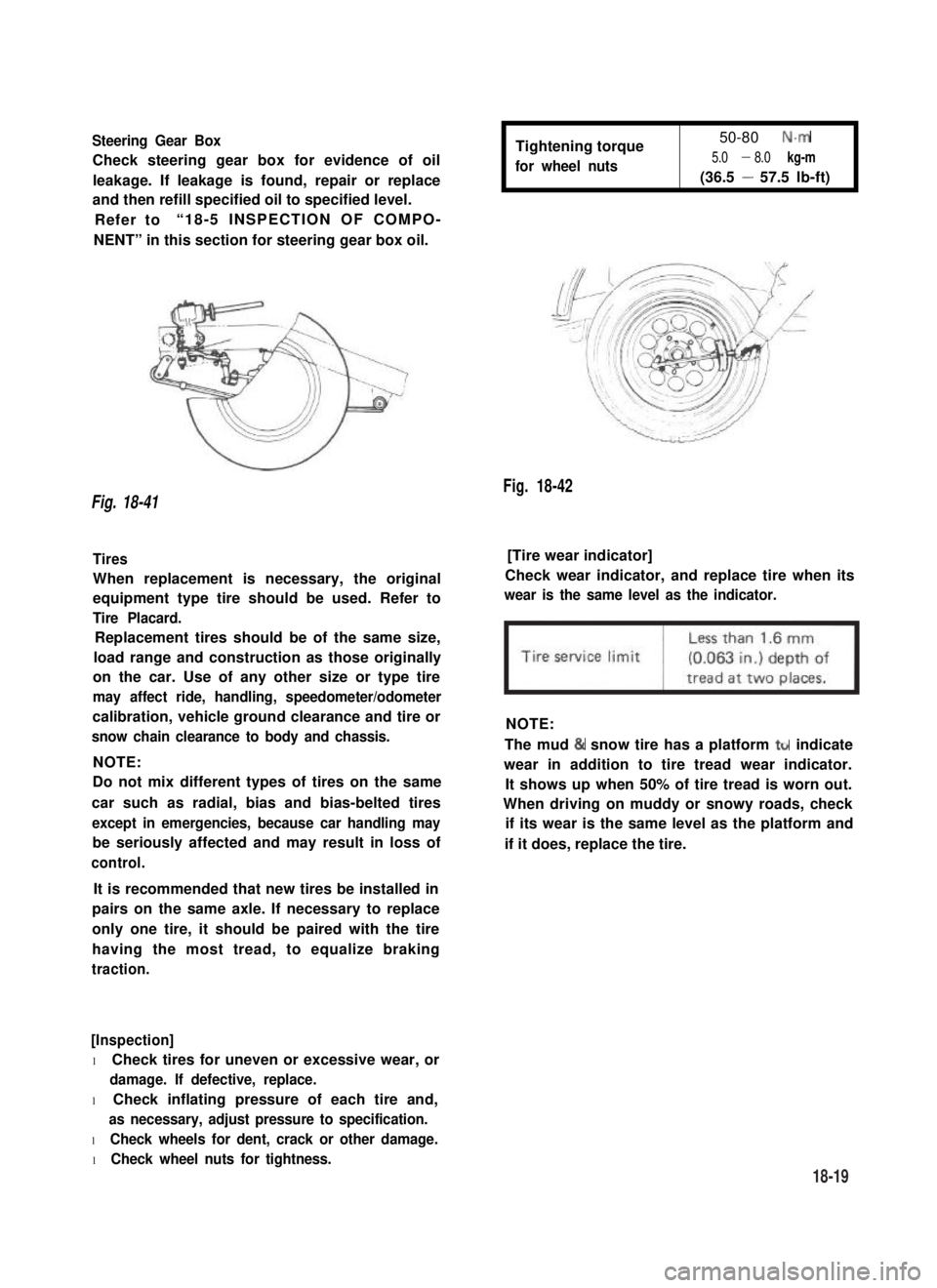

Page 382 of 962

Steering Gear Box

Check steering gear box for evidence of oil

leakage. If leakage is found, repair or replace

and then refill specified oil to specified level.

Refer to“18-5 INSPECTION OF COMPO-

NENT” in this section for steering gear box oil.

Tightening torque

for wheel nuts

50-80 N.m

5.0 - 8.0 kg-m

(36.5 - 57.5 lb-ft)

Fig. 18-42

Fig. 18-41

Tires[Tire wear indicator]

When replacement is necessary, the original

equipment type tire should be used. Refer to

Tire Placard.

Check wear indicator, and replace tire when its

wear is the same level as the indicator.

Replacement tires should be of the same size,

load range and construction as those originally

on the car. Use of any other size or type tire

may affect ride, handling, speedometer/odometer

calibration, vehicle ground clearance and tire or

snow chain clearance to body and chassis.

NOTE:

NOTE:

Do not mix different types of tires on the same

car such as radial, bias and bias-belted tires

except in emergencies, because car handling may

be seriously affected and may result in loss of

control.

The mud & snow tire has a platform ttr indicate

wear in addition to tire tread wear indicator.

It shows up when 50% of tire tread is worn out.

When driving on muddy or snowy roads, check

if its wear is the same level as the platform and

if it does, replace the tire.

It is recommended that new tires be installed in

pairs on the same axle. If necessary to replace

only one tire, it should be paired with the tire

having the most tread, to equalize braking

traction.

[Inspection]

l Check tires for uneven or excessive wear, or

damage. If defective, replace.

l Check inflating pressure of each tire and,

as necessary, adjust pressure to specification.

l Check wheels for dent, crack or other damage.

l Check wheel nuts for tightness.

18-19

Page 383 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual Fig. 18-43 @ Tire tread wear indicator

@ Wear indicating platform

[ Inflation of tires]

l Tire inflation pressures are listed on the

Tire Placard at driver’s side of instrument

panel.

l Tire inflati SUZUKI GRAND VITARA 1987 Service Repair Manual Fig. 18-43 @ Tire tread wear indicator

@ Wear indicating platform

[ Inflation of tires]

l Tire inflation pressures are listed on the

Tire Placard at driver’s side of instrument

panel.

l Tire inflati](/img/20/57437/w960_57437-382.png)

Fig. 18-43 @ Tire tread wear indicator

@ Wear indicating platform

[ Inflation of tires]

l Tire inflation pressures are listed on the

Tire Placard at driver’s side of instrument

panel.

l Tire inflation pressures should be checked

(including spare tire) at least monthly and

when significantly changing the load in the

car.

l Always check tire inflation pressures when

tires are “cold”.

l Always use tire pressure gauge when checking

inflation pressure.

l Be sure to reinstall tire inflation valve caps to

prevent dirt and moisture from getting into

valve core, as they may cause air leakage.

l If air loss occurs while driving, do not drive

on the deflated tire more than is needed to

stop safety. Driving even a short distance on a

deflated tire can damage a tire and wheel

beyond repair.

NOTE:

Before installing wheels, remove any build-up of

corrosion on the wheel mounting surface and

brake drum or disc mounting surface by scraping

and wire brushing. Installing wheels without

good metal-to-metal contact at the mounting

surfaces can cause wheel nuts to loosen, which

can later allow a wheel to come off while the

car is moving.

RADIAL TIRES

.i II

9T

\

I

4-wheels

Fig. 18-44

fT

u

[I

5-wheels

[Wheels]

Wheels must be replaced if they are bent, dented,

have excessive lateral or radial runout, leak air

through welds, have elongated bolt holes, if

lug nuts won’t stay tight, or if they are heavily

rusted. Wheels with greater runout than shown

in below figure may cause objectional vibrations.

Replacement wheels must be equivalent to the

original equipment wheels in load capacity,

diameter,rim width, offset and mounting

configuration. A wheel of improper size or type

may affect wheel and bearing life, brake cooling,

speedometer/odometer calibration, car ground

clearance and tire clearance to the body and

chassis.

[Tire rotation]

“Rotate” tires at the regular intervals in order to

equalize tire wear and thereby make full use of

each tire. Refer to below figure for the scheme

of rotation. Adherence to this scheme prolongs

tire life.

18-20

Page 405 of 962

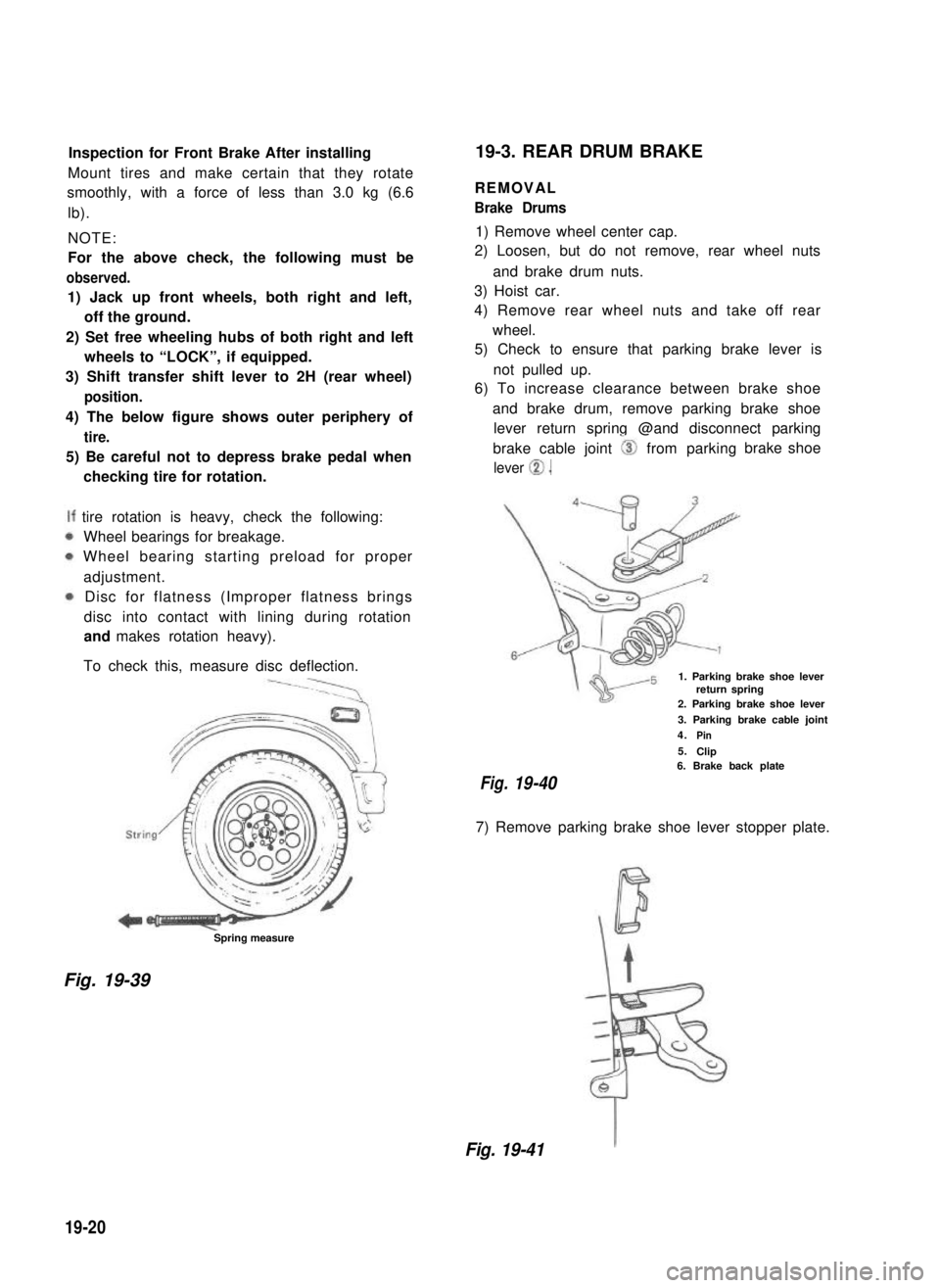

Inspection for Front Brake After installing

Mount tires and make certain that they rotate

smoothly, with a force of less than 3.0 kg (6.6

lb).

NOTE:

For the above check, the following must be

observed.

1) Jack up front wheels, both right and left,

off the ground.

2) Set free wheeling hubs of both right and left

wheels to “LOCK”, if equipped.

3) Shift transfer shift lever to 2H (rear wheel)

position.

4) The below figure shows outer periphery of

tire.

5) Be careful not to depress brake pedal when

checking tire for rotation.

tire rotation is heavy, check the following:

Wheel bearings for breakage.

Wheel bearing starting preload for proper

adjustment.

Disc for flatness (Improper flatness brings

disc into contact with lining during rotation

and makes rotation heavy).

To check this, measure disc deflection.

Spring measure

19-3. REAR DRUM BRAKE

REMOVAL

Brake Drums

1) Remove wheel center cap.

2) Loosen, but do not remove, rear wheel nuts

and brake drum nuts.

3) Hoist car.

4) Remove rear wheel nuts and take off rear

wheel.

5) Check to ensure that parking brake lever is

not pulled up.

6) To increase clearance between brake shoe

and brake drum, remove parking brake shoe

lever return spring @and disconnect parking

brake cable joint 0 from parking

lever 0.

brake shoe

1. Parking brake shoe leverreturn spring2. Parking brake shoe lever

3. Parking brake cable joint

4.Pin

5.Clip6. Brake back plate

Fig.19-40

7) Remove parking brake shoe lever stopper plate.

Fig. 19-39

Fig. 19-41

19-20