warning SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 4 of 962

O-2. STANDARD SHOP PRACTICES

1. Protect painted surfaces of the body, and

avoid staining or tearing seats. When working

on fenders and seats, be sure to cover them

up with sheets.

2. Disconnect negative terminal connection of

the battery when working on any electrical

part or component. This is necessary for

avoiding electrical shocks and short-circuit-

ing, and is very simple to accomplish: merely

loosen wing nut on negative terminal and

separate cable from terminal post.

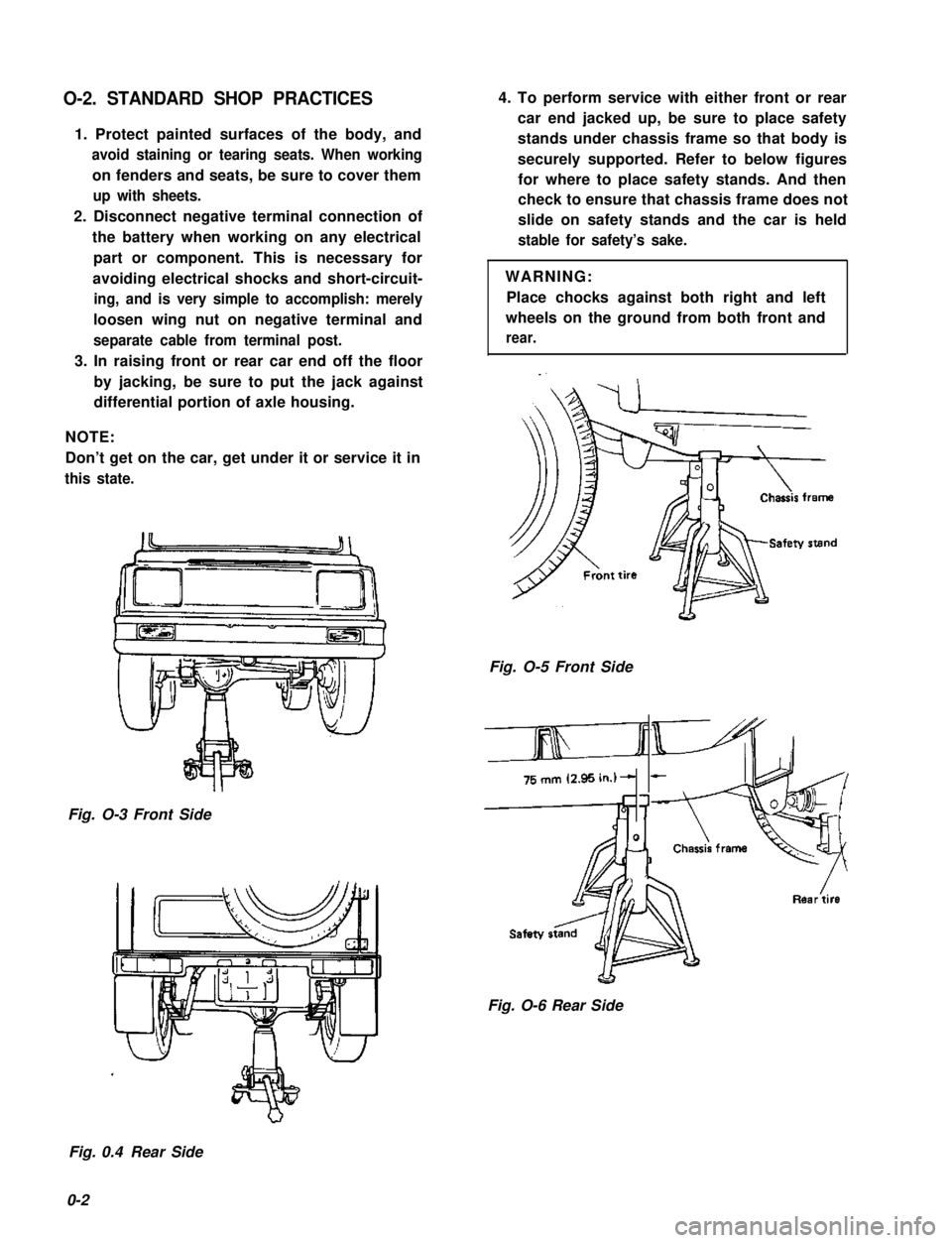

3. In raising front or rear car end off the floor

by jacking, be sure to put the jack against

differential portion of axle housing.

NOTE:

Don’t get on the car, get under it or service it in

this state.

Fig. O-3 Front Side

4. To perform service with either front or rear

car end jacked up, be sure to place safety

stands under chassis frame so that body is

securely supported. Refer to below figures

for where to place safety stands. And then

check to ensure that chassis frame does not

slide on safety stands and the car is held

stable for safety’s sake.

WARNING:

Place chocks against both right and left

wheels on the ground from both front and

rear.

Fig. O-5 Front Side

&

Fig. O-6 Rear Side

Fig. 0.4 Rear Side

0-2

Page 5 of 962

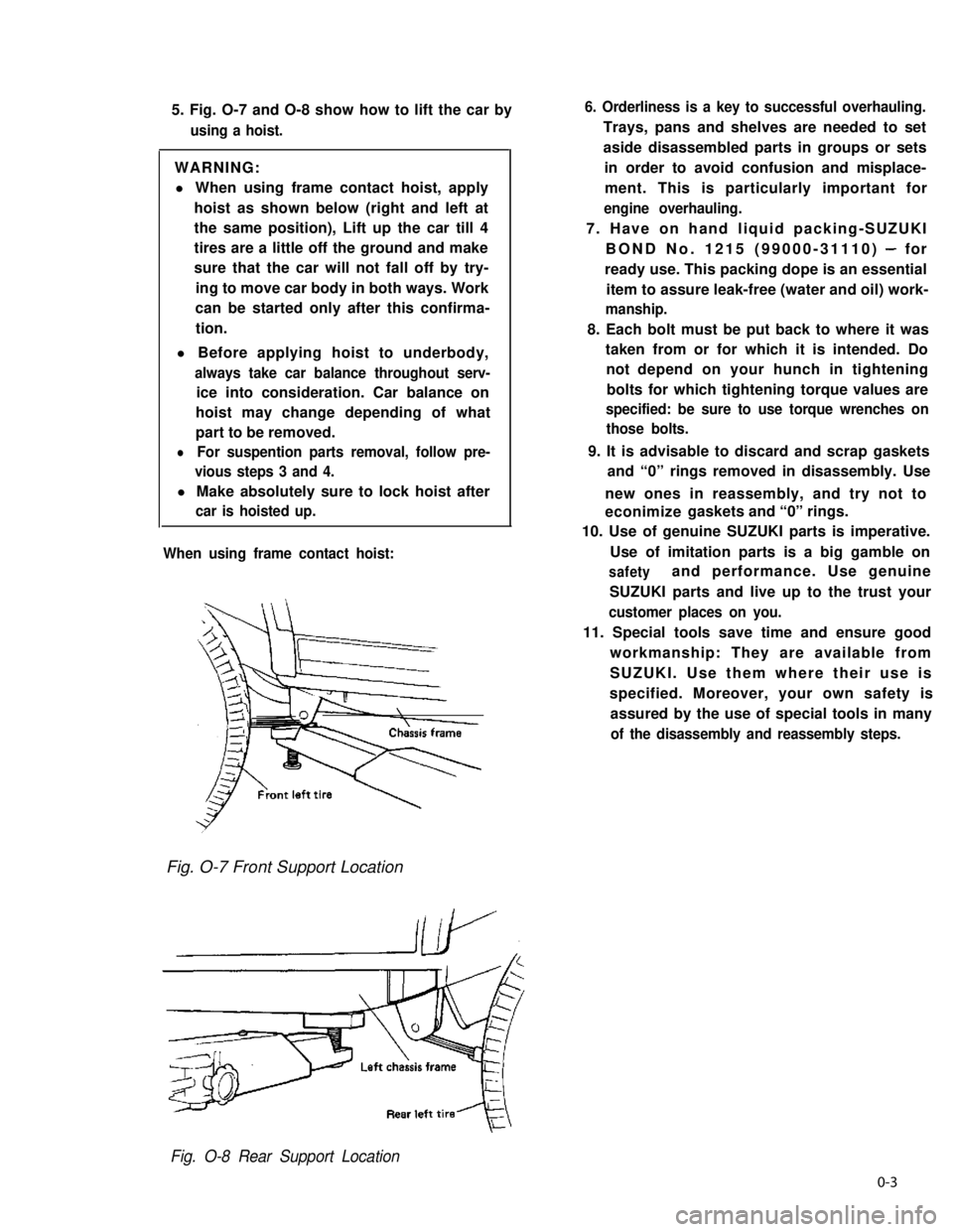

5. Fig. O-7 and O-8 show how to lift the car by

using a hoist.

WARNING:

l When using frame contact hoist, apply

hoist as shown below (right and left at

the same position), Lift up the car till 4

tires are a little off the ground and make

sure that the car will not fall off by try-

ing to move car body in both ways. Work

can be started only after this confirma-

tion.

l Before applying hoist to underbody,

always take car balance throughout serv-

ice into consideration. Car balance on

hoist may change depending of what

part to be removed.

lFor suspention parts removal, follow pre-

vious steps 3 and 4.

l Make absolutely sure to lock hoist after

car is hoisted up.

When using frame contact hoist:

6. Orderliness is a key to successful overhauling.

Trays, pans and shelves are needed to set

aside disassembled parts in groups or sets

in order to avoid confusion and misplace-

ment. This is particularly important for

engine overhauling.

7. Have on hand liquid packing-SUZUKI

BOND No. 1215 (99000-31110) - for

ready use. This packing dope is an essential

item to assure leak-free (water and oil) work-

manship.

8. Each bolt must be put back to where it was

taken from or for which it is intended. Do

not depend on your hunch in tightening

bolts for which tightening torque values are

specified: be sure to use torque wrenches on

those bolts.

9. It is advisable to discard and scrap gaskets

and “0” rings removed in disassembly. Use

new ones in reassembly, and try not to

econimize gaskets and “0” rings.

10. Use of genuine SUZUKI parts is imperative.

Use of imitation parts is a big gamble on

safetyand performance. Use genuine

SUZUKI parts and live up to the trust your

customer places on you.

11. Special tools save time and ensure good

workmanship: They are available from

SUZUKI. Use them where their use is

specified. Moreover, your own safety is

assured by the use of special tools in many

of the disassembly and reassembly steps.

Fig. O-7 Front Support Location

Fig. O-8 Rear Support Location

0-3

Page 23 of 962

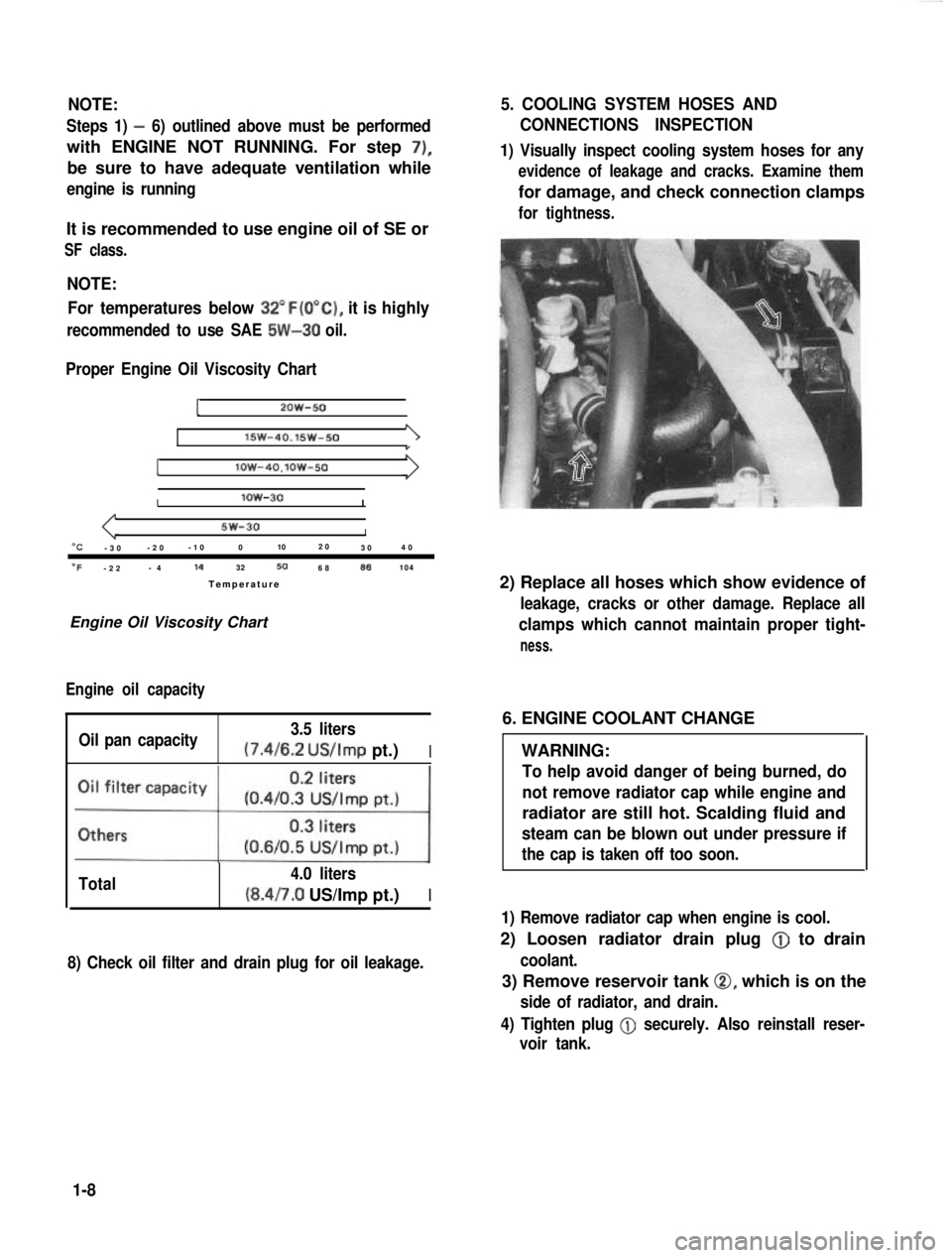

NOTE:

Steps 1) - 6) outlined above must be performed

with ENGINE NOT RUNNING. For step 7),

be sure to have adequate ventilation while

engine is running

It is recommended to use engine oil of SE or

SF class.

NOTE:For temperatures below

32”F(O”C), it is highly

recommended to use SAE 5W-30 oil.

Proper Engine Oil Viscosity Chart

12OW-50

lSW-40.15w-501

Ilow-4O.lOW-50

Ilow-30I

5w-30I“C-3 0 -2

0 -1

0 0 102

0

30 4

0

OF-2 2 -

4 14

32506886104

Temperatur e

Engine Oil Viscosity Chart

Engine oil capacity

Oil pan capacity 3.5 liters (7.4/6.2

US/Imp pt.)I

Total 4.0 liters(8.4/7.0 US/Imp pt.)I

8) Check oil filter and drain plug for oil leakage.

5. COOLING SYSTEM HOSES AND

CONNECTIONS INSPECTION

1) Visually inspect cooling system hoses for any

evidence of leakage and cracks. Examine them

for damage, and check connection clamps

for tightness.

2) Replace all hoses which show evidence of

leakage, cracks or other damage. Replace all

clamps which cannot maintain proper tight-

ness.

6. ENGINE COOLANT CHANGE

WARNING:

To help avoid danger of being burned, do

not remove radiator cap while engine and

radiator are still hot. Scalding fluid and

steam can be blown out under pressure if

the cap is taken off too soon.

1) Remove radiator cap when engine is cool.

2) Loosen radiator drain plug @

to drain

coolant.

3) Remove reservoir tank 0, which is on the

side of radiator, and drain.

4) Tighten plug

@ securely. Also reinstall reser-

voir tank.

1-8

Page 25 of 962

CAUTION:

When changing engine coolant, use mixture

of 56% water and 50% GOLDEN CRUISER

1200for the market where ambient tem-

perature falls lower than -16°C (3°F) in

winter and mixture of 70% water and

30% GOLDEN CRUISER 1200for the

market where ambient temperature doesn’t

fall lower than -16°C (3” F).

Even in a market where no freezing tempe-

rature is anticipated, mixture of 70% water

and 30% GOLDEN CRUISER 1200

should be used for the purpose of corro-

sion protection and lubrication.

7. EXHAUST PIPES AND MOUNTINGS

INSPECTION

1.Drain plug

1. Reservoir tank cap2. Reservoir tank

3. Arrow marks

5) Fill radiator with specified amount of coolant,

and run engine for 2 or 3 minutes at idle.

This drives out any air which may still be

trappedwithincoolingsystem.STOP

ENGINE. Add coolant as necessary until

coolant level reaches the filler throat of

radiator. Reinstall radiator cap.

6) Add coolant to reservoir tank so that the level

aligns with Full mark. Then, reinstall cap

aligning the arrow marks on the tank and cap.

r.

COOLANT CAPACITY

Engine, radiator and4.2 liters

heater(8.9/7.4 US/Imp pt.)

Reservoir tank0.6 liters

(1.3/1.1 US/Imp pt.)

ITotal4.8 liters

(10.1/8.4US/lmp pt.)

WARNING:

To avoid danger of being burned, do not

touch exhaust system when system is hot.

Any service on exhaust system should be

performed when system is cool.

When carrying out periodic maintenance, or the

car is raised for other service, check exhaust

system as follows:

l Check rubber mountings for damage, deterio-

ration, and out of position.

l Check exhaust system for leakage, loose

connections, dents, and damages.

If bolts or nuts are loose, tighten them to

specification. Refer to below chart for torque

specification.

l Check nearby body areas for damaged, miss-

ing, or mispositioned parts, open seams,

holes, loose connections or’ other defects

which could permit exhaust fumes to seep

into the car.

l Make sure that exhaust system components

have enough clearance from the underbody to

avoid overheating and possible damage to the

floor carpet.

l Any defects should be fixed at once.

IBolts and nutTightening torqueI

40-80 N-m

Exhaustpipebolts4.0-6.0 kg-m

29.0-43.0 lb-ft

Muffler nuts

18 - 28 N-m

1.8 - 2.8 kg-m

13.5 - 20.0 lb-ft

Replace center pipe rubber mounting and muffler

rubber mountings with new ones periodically.

l-9

Page 27 of 962

1. CHARCOAL CANISTER REPLACEMENT

WARNING:

The following cautions should be always

observed.

l Disconnect negative cable at battery.

l DO NOT smoke and place “NO SMOK-

ING” signs near work area.

l Be sure to have COZ fire extinguisher

handy.

l Wear safety glasses.

l To release the fuel vapor pressure in

fuel tank, remove the fuel tank cap and

then reinstall it.

1) Disconnect 3 hoses from canister.

2) Remove canister from car body.

3) Install new canister.

4) Connect 3 hoses to canister securely.

5) Clamp them securely.

//valve

To fuel tank

12. EMISSION-RELATED HOSES AND

TUBES INSPECTION

Check each vacuum hose and tube for secure

connection. Also, check that it is free from any

bend or damage.

Correct faulty condition, if any.

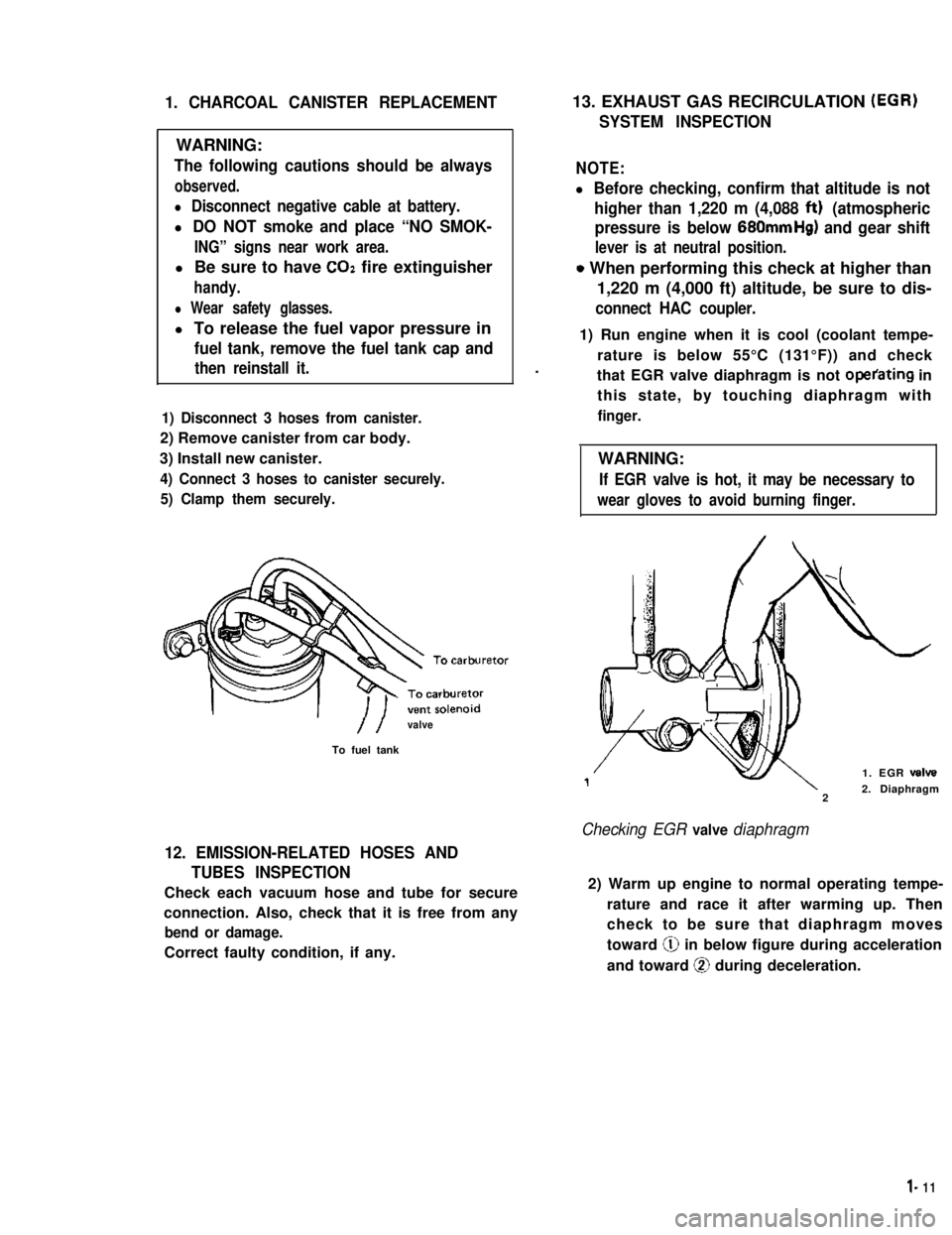

13. EXHAUST GAS RECIRCULATION (EGR)

SYSTEM INSPECTION

NOTE:

l Before checking, confirm that altitude is not

higher than 1,220 m (4,088 ftt) (atmospheric

pressure is below 680mmHg) and gear shift

lever is at neutral position.

o When performing this check at higher than

1,220 m (4,000 ft) altitude, be sure to dis-

connect HAC coupler.

.

1) Run engine when it is cool (coolant tempe-

rature is below 55°C (131°F)) and check

that EGR valve diaphragm is not operating in

this state, by touching diaphragm with

finger.

WARNING:

If EGR valve is hot, it may be necessary to

wear gloves to avoid burning finger.

1. EGR valve

22. Diaphragm

Checking EGR valve diaphragm

2) Warm up engine to normal operating tempe-

rature and race it after warming up. Then

check to be sure that diaphragm moves

toward @ in below figure during acceleration

and toward @ during deceleration.

l- 11

Page 30 of 962

21. FUEL TANK CAP GASKET INSPECTION

AND REPLACEMENT

Visually inspect gasket of fuel tank cap. If it is

damaged or deteriorated, replace it with new

one.

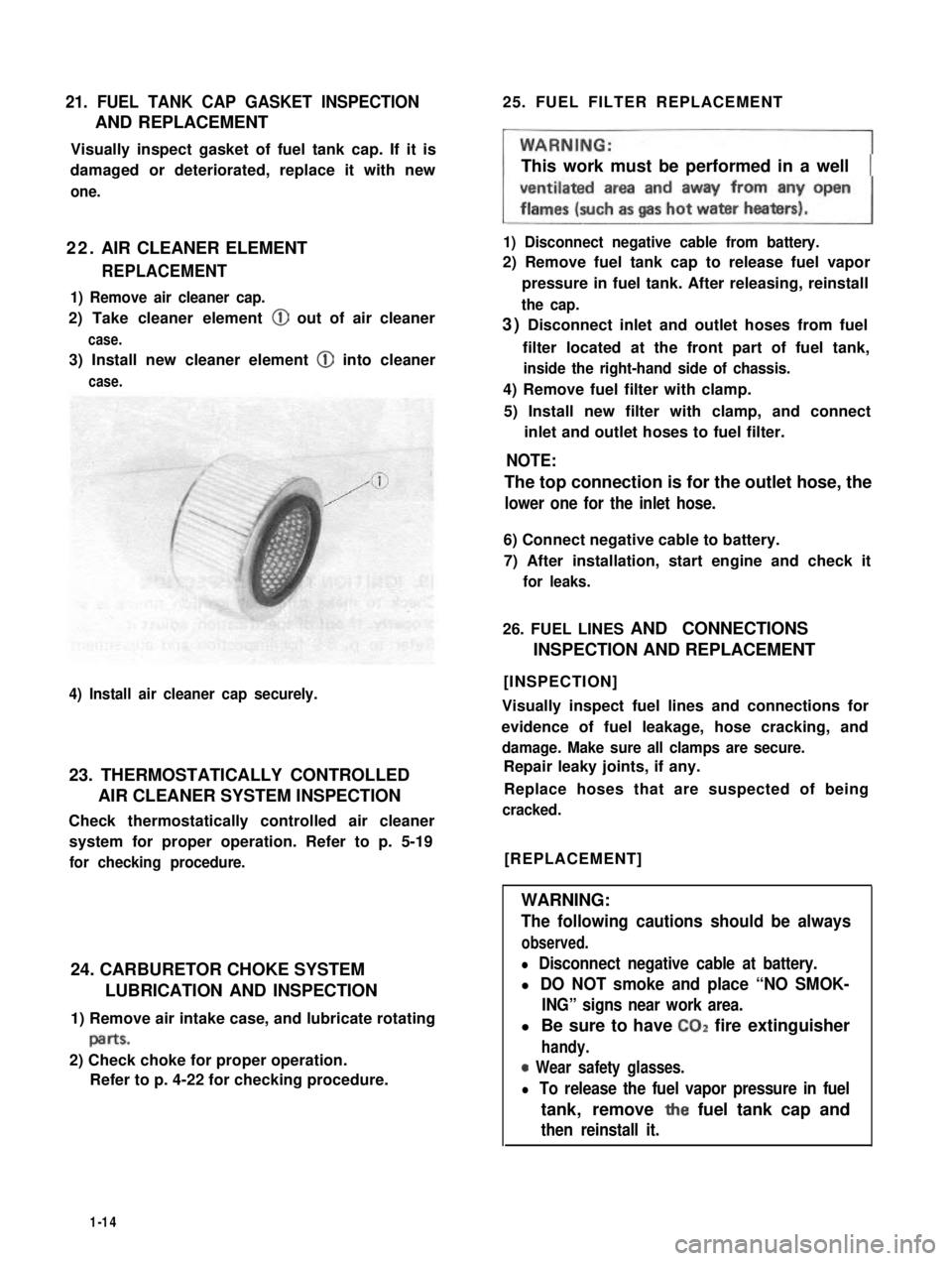

22. AIR CLEANER ELEMENT

REPLACEMENT

1) Remove air cleaner cap.

2) Take cleaner element @ out of air cleaner

case.

3) Install new cleaner element @ into cleaner

case.

4) Install air cleaner cap securely.

23. THERMOSTATICALLY CONTROLLED

AIR CLEANER SYSTEM INSPECTION

Check thermostatically controlled air cleaner

system for proper operation. Refer to p. 5-19

for checking procedure.

24. CARBURETOR CHOKE SYSTEM

LUBRICATION AND INSPECTION

1) Remove air intake case, and lubricate rotating

paItS.

2) Check choke for proper operation.

Refer to p. 4-22 for checking procedure.

25. FUEL FILTER REPLACEMENT

This work must be performed in a well

1) Disconnect negative cable from battery.

2) Remove fuel tank cap to release fuel vapor

pressure in fuel tank. After releasing, reinstall

the cap.

3) Disconnect inlet and outlet hoses from fuel

filter located at the front part of fuel tank,

inside the right-hand side of chassis.

4) Remove fuel filter with clamp.

5) Install new filter with clamp, and connect

inlet and outlet hoses to fuel filter.

NOTE:

The top connection is for the outlet hose, the

lower one for the inlet hose.

6) Connect negative cable to battery.

7) After installation, start engine and check it

for leaks.

26. FUEL LINES AND CONNECTIONS

INSPECTION AND REPLACEMENT

[INSPECTION]

Visually inspect fuel lines and connections for

evidence of fuel leakage, hose cracking, and

damage. Make sure all clamps are secure.

Repair leaky joints, if any.

Replace hoses that are suspected of being

cracked.

[REPLACEMENT]

WARNING:

The following cautions should be always

observed.

l Disconnect negative cable at battery.

l DO NOT smoke and place “NO SMOK-

ING” signs near work area.

l Be sure to have CO2 fire extinguisher

handy.

0 Wear safety glasses.

l To release the fuel vapor pressure in fuel

tank, remove the fuel tank cap and

then reinstall it.

1-14

Page 35 of 962

3) Install spindle, bearings, wheel hub, bearing

nut and brake disc referring to INSTALLA-

TION (p. 17-12) of SECTION 17.

4) Adjust bearing preload and then tighten

bearing lock nut to specification. Refer to

MAINTENANCE (p. 17-21) of SECTION 17.

5) Install drive flange or free wheeling hub (if

equipped), brake caliper with mounting and

wheel referring to INSTALLATION (p. 17-

12) of SECTION 17.

For tightening torque of each bolt and nut,

refer to torque table (p. 17-26) of SECTION

17.

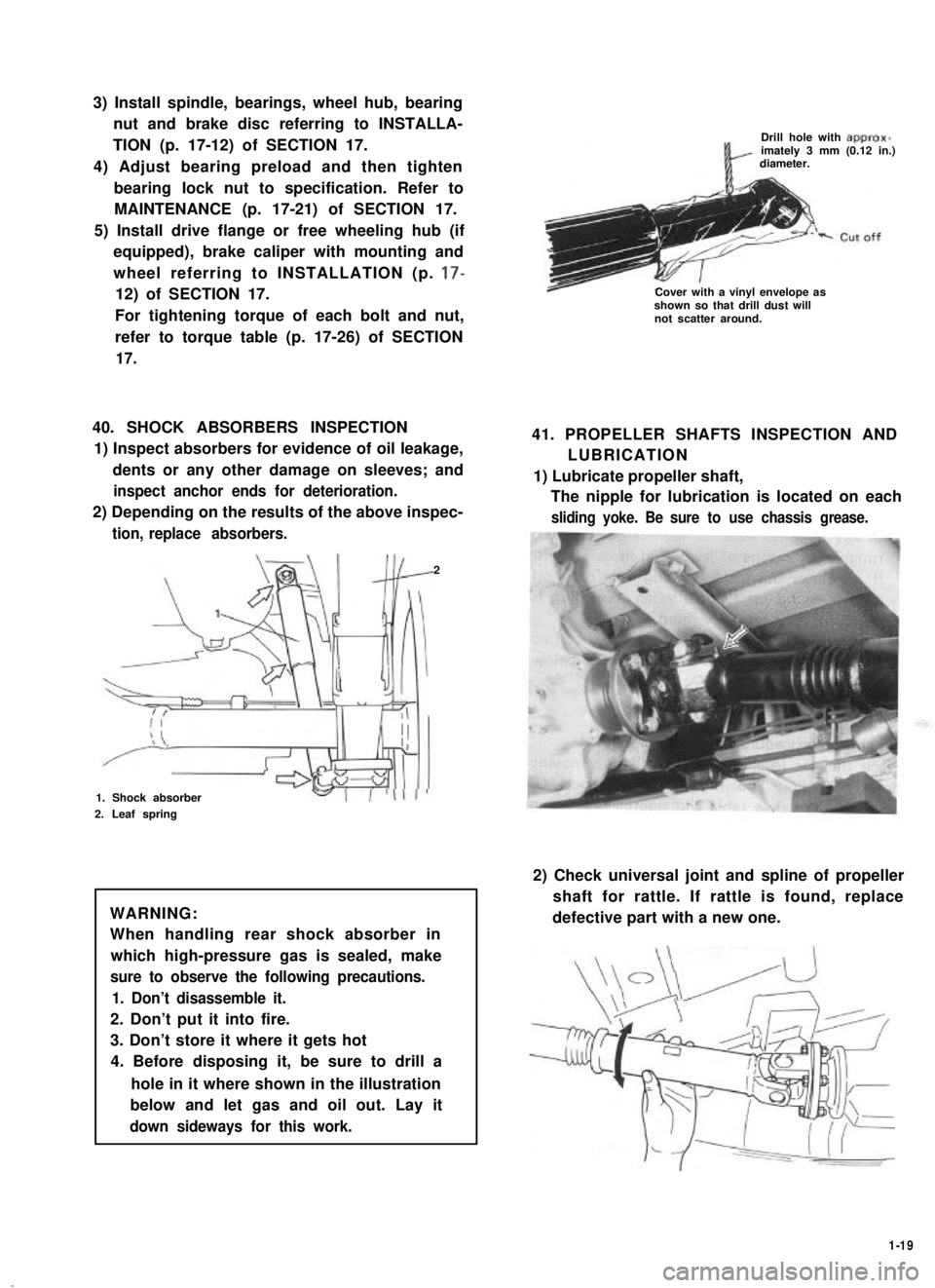

40. SHOCK ABSORBERS INSPECTION

1) Inspect absorbers for evidence of oil leakage,

dents or any other damage on sleeves; and

inspect anchor ends for deterioration.

2) Depending on the results of the above inspec-

tion, replace absorbers.

2

1. Shock absorber

2. Leaf spring

WARNING:

When handling rear shock absorber in

which high-pressure gas is sealed, make

sure to observe the following precautions.

1. Don’t disassemble it.

2. Don’t put it into fire.

3. Don’t store it where it gets hot

4. Before disposing it, be sure to drill a

hole in it where shown in the illustration

below and let gas and oil out. Lay it

down sideways for this work.

Drill hole with approx-imately 3 mm (0.12 in.)diameter.

Cover with a vinyl envelope asshown so that drill dust willnot scatter around.

41. PROPELLER SHAFTS INSPECTION AND

LUBRICATION

1) Lubricate propeller shaft,

The nipple for lubrication is located on each

sliding yoke. Be sure to use chassis grease.

2) Check universal joint and spline of propeller

shaft for rattle. If rattle is found, replace

defective part with a new one.

1-19

Page 38 of 962

FINAL INSPECTION

Carry out road test in safe place.

WARNING:

When carrying out the following road

tests, select a safe place where no man or

no running car is seen so as to prevent any

accident.

1) Engine start

Check engine start for readiness.

2) Clutch

Check the following:

l that clutch is completely released when

depressing clutch pedal,

l that no slipping clutch occurs when releas-

ing pedal and accelerating,

l and that clutch itself is free from any

abnormal condition.

3) Gearshift Lever (Transmission and Transfer)

Check gearshift lever for smooth shifting

to all positions and for good performance of

transmission and transfer in any position.

4) Brake

[Foot brake]

Check the following when depressing brake

pedal while driving;

l that brake works properly,

l that it is free from noise,

l and that braking force applies equally on

all wheels.

[Parking brake]

Check to ensure that parking brake is fully

effective when the car is stopped on the slop

and brake lever is pulled all the way.

5) Steering

Check to ensure that steering wheel is free

from instability, or abnormally heavy feeling

while driving.

1-22

Page 51 of 962

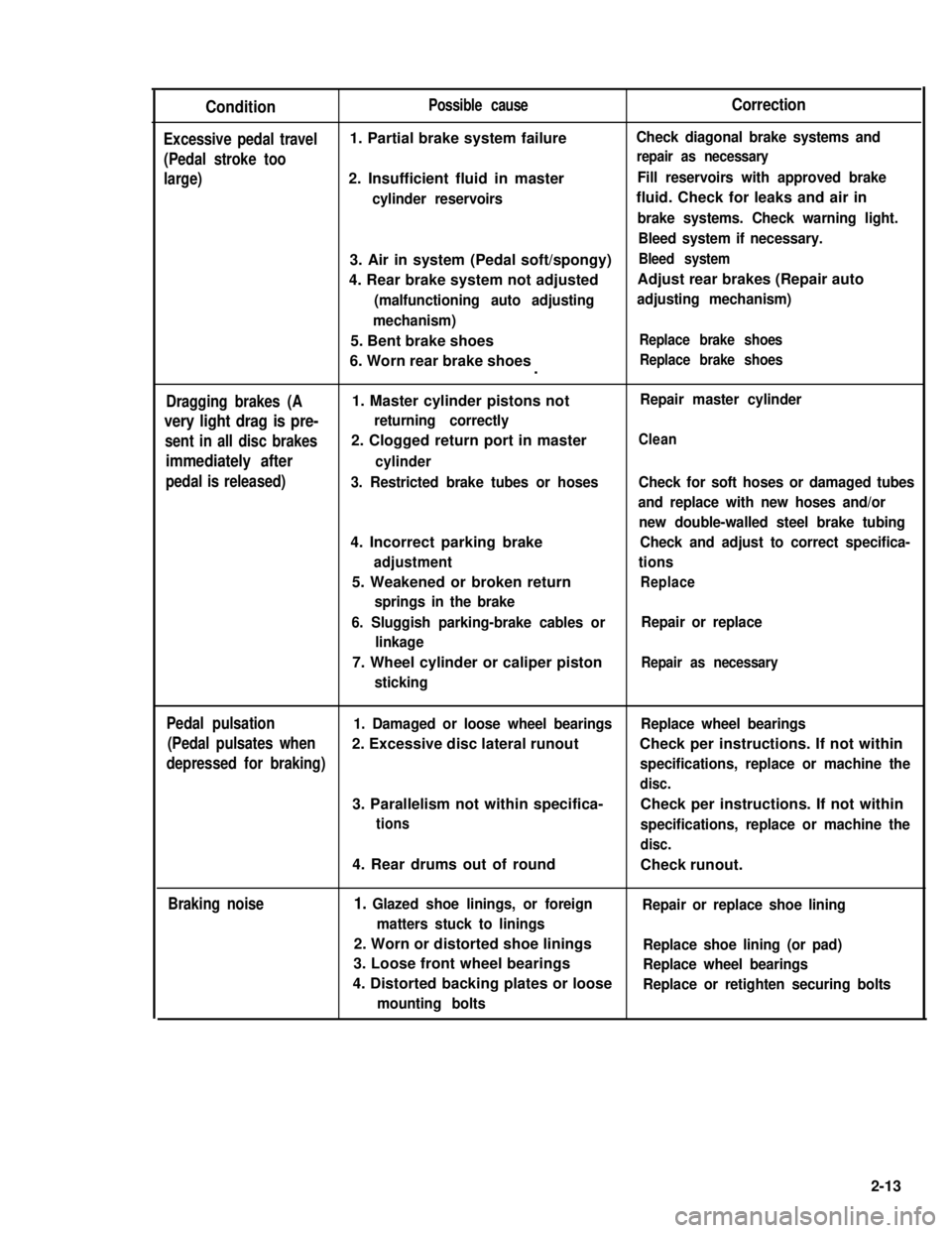

Condition

Excessive pedal travel

(Pedal stroke too

large)

Possible cause

1. Partial brake system failure

2. Insufficient fluid in master

cylinder reservoirs

Correction

Check diagonal brake systems and

repair as necessary

Fill reservoirs with approved brake

fluid. Check for leaks and air in

brake systems. Check warning light.

Bleed system if necessary.

3. Air in system (Pedal soft/spongy)Bleed system

4. Rear brake system not adjustedAdjust rear brakes (Repair auto

(malfunctioning auto adjustingadjusting mechanism)

mechanism)

5. Bent brake shoesReplace brake shoes

6. Worn rear brake shoesReplace brake shoes.

Dragging brakes (A

very light drag is pre-

sent in all disc brakes

immediately after

pedal is released)

1. Master cylinder pistons not

returning correctly

2. Clogged return port in master

cylinder

3. Restricted brake tubes or hoses

4. Incorrect parking brake

adjustment

5. Weakened or broken return

springs in the brake

Repair master cylinder

Clean

Check for soft hoses or damaged tubes

and replace with new hoses and/or

new double-walled steel brake tubing

Check and adjust to correct specifica-

tions

Replace

6. Sluggish parking-brake cables or

linkage

Repair or replace

7. Wheel cylinder or caliper piston

sticking

Repair as necessary

Pedal pulsation1. Damaged or loose wheel bearingsReplace wheel bearings

(Pedal pulsates when2. Excessive disc lateral runout Check per instructions. If not within

depressed for braking)specifications, replace or machine the

disc.

3. Parallelism not within specifica-Check per instructions. If not within

tionsspecifications, replace or machine the

disc.

4. Rear drums out of roundCheck runout.

Braking noise1. Glazed shoe linings, or foreignRepair or replace shoe lining

matters stuck to linings

2. Worn or distorted shoe liningsReplace shoe lining (or pad)

3. Loose front wheel bearingsReplace wheel bearings

4. Distorted backing plates or looseReplace or retighten securing bolts

mounting bolts

2-13

Page 127 of 962

REMOVAL AND INSTALLATION

Removal and installation of carburetor

place where no fire is used around.

Removal

1) Disconnect negative battery cord from

battery.

2) Drain coolant.

WARNING:

To help avoid the danger of being burned,

do not remove the drain plug and the

radiator cap while the engine and radiator

are still hot. Scalding fluid and steam can

be blown out under pressure if the plug

and cap are taken off too soon.

3) Remove air intake case from carburetor.

4) Disconnect micro switches, switch vent sole-

noid valve, fuel cut solenoid valve and MCSV

lead wires at their couplers.

5) Disconnect VSV coupler from VSV.

6) Detach bracket with EGR modulator and

TWSV from carburetor.

1. Bracket3.EGRmodulator2. Twsv

Fig. 4- 1-16

7) Disconnect water inlet and outlet hoses from

carburetor.

8) Disconnect accelerator cable from carburetor.

9) Disconnect vacuum hoses from idle up

actuator and carburetor.

10) To release the pressure in fuel tank, remove

fuel tank filler cap and then, reinstall it.

11) Disconnect fuel inlet hose from carburetor.

12) Check all around carburetor for any other

parts required to be removed or disconnect-

ed for removal of carburetor and remove or

disconnect whatever necessary.

13) Remove carburetor from intake manifold.

Fig. 4- 7- 17

Installation

Install in the reverse order of removal using care

for the following.

l Install carburetor to intake manifold.

Tighten 4 carburetor nuts to the specified

torque.

Tightening torque

for nuts13.5 - 20.0 lb-ft

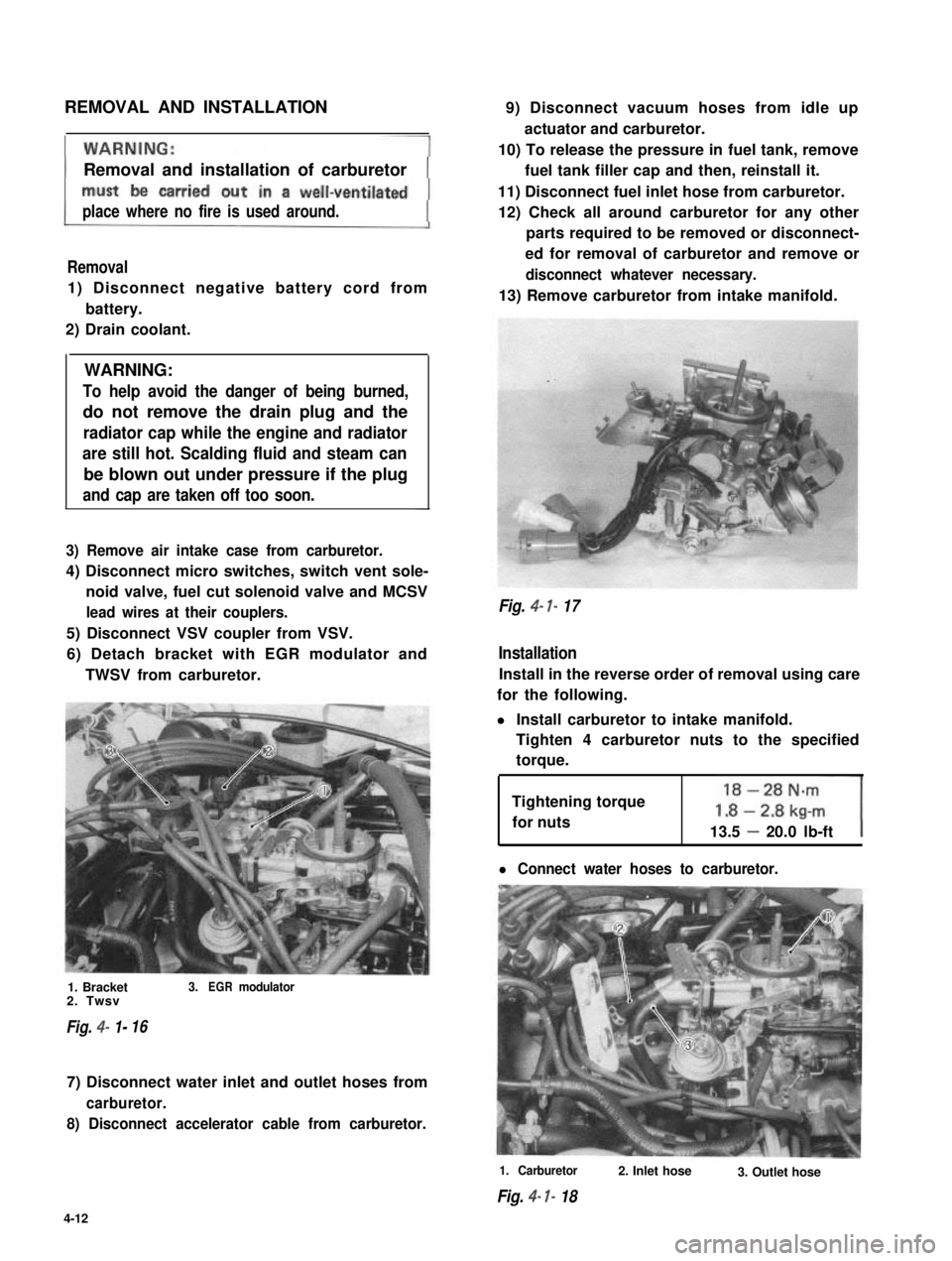

l Connect water hoses to carburetor.

1. Carburetor

Fig. 4- I- 18

2. Inlet hose3. Outlet hose

4-12