check engine SUZUKI GRAND VITARA 1999 2.G Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1999, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1999 2.GPages: 656, PDF Size: 14.31 MB

Page 453 of 656

7B1-44 AUTOMATIC TRANSMISSION (4 A/T)

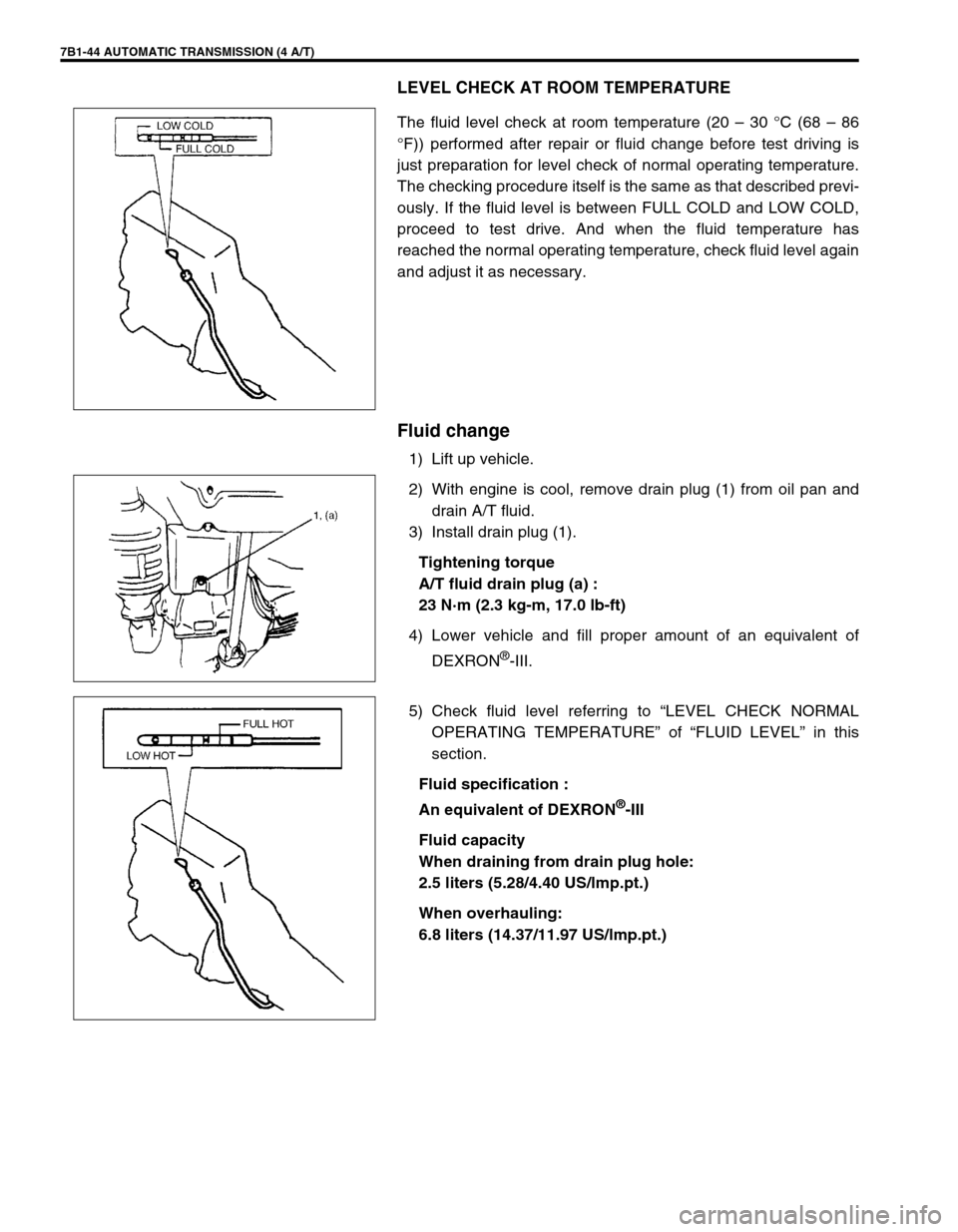

LEVEL CHECK AT ROOM TEMPERATURE

The fluid level check at room temperature (20 – 30 °C (68 – 86

°F)) performed after repair or fluid change before test driving is

just preparation for level check of normal operating temperature.

The checking procedure itself is the same as that described previ-

ously. If the fluid level is between FULL COLD and LOW COLD,

proceed to test drive. And when the fluid temperature has

reached the normal operating temperature, check fluid level again

and adjust it as necessary.

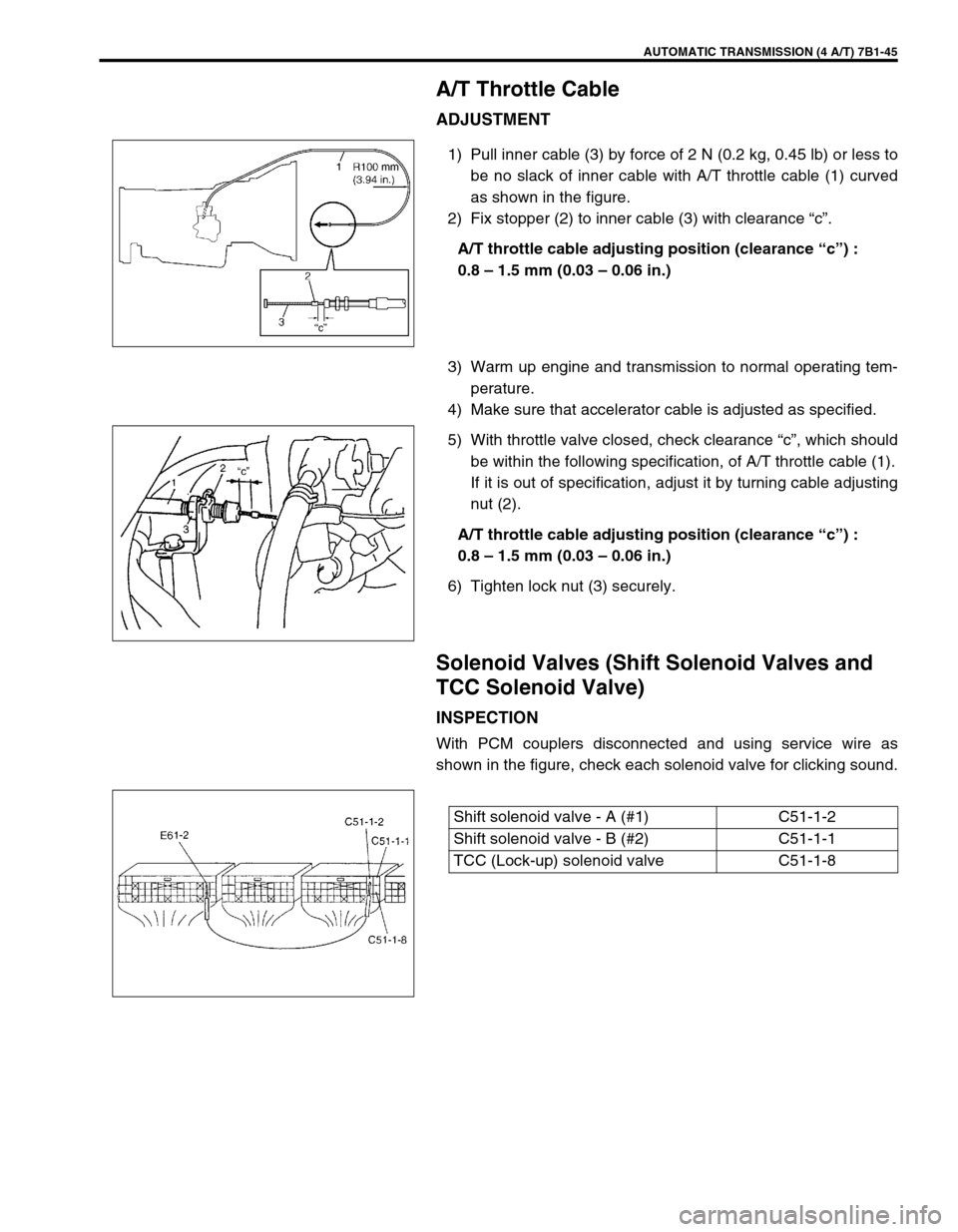

Fluid change

1) Lift up vehicle.

2) With engine is cool, remove drain plug (1) from oil pan and

drain A/T fluid.

3) Install drain plug (1).

Tightening torque

A/T fluid drain plug (a) :

23 N·m (2.3 kg-m, 17.0 lb-ft)

4) Lower vehicle and fill proper amount of an equivalent of

DEXRON

®-III.

5) Check fluid level referring to “LEVEL CHECK NORMAL

OPERATING TEMPERATURE” of “FLUID LEVEL” in this

section.

Fluid specification :

An equivalent of DEXRON

®-III

Fluid capacity

When draining from drain plug hole:

2.5 liters (5.28/4.40 US/lmp.pt.)

When overhauling:

6.8 liters (14.37/11.97 US/lmp.pt.)

Page 454 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-45

A/T Throttle Cable

ADJUSTMENT

1) Pull inner cable (3) by force of 2 N (0.2 kg, 0.45 lb) or less to

be no slack of inner cable with A/T throttle cable (1) curved

as shown in the figure.

2) Fix stopper (2) to inner cable (3) with clearance “c”.

A/T throttle cable adjusting position (clearance “c”) :

0.8 – 1.5 mm (0.03 – 0.06 in.)

3) Warm up engine and transmission to normal operating tem-

perature.

4) Make sure that accelerator cable is adjusted as specified.

5) With throttle valve closed, check clearance “c”, which should

be within the following specification, of A/T throttle cable (1).

If it is out of specification, adjust it by turning cable adjusting

nut (2).

A/T throttle cable adjusting position (clearance “c”) :

0.8 – 1.5 mm (0.03 – 0.06 in.)

6) Tighten lock nut (3) securely.

Solenoid Valves (Shift Solenoid Valves and

TCC Solenoid Valve)

INSPECTION

With PCM couplers disconnected and using service wire as

shown in the figure, check each solenoid valve for clicking sound.

Shift solenoid valve - A (#1) C51-1-2

Shift solenoid valve - B (#2) C51-1-1

TCC (Lock-up) solenoid valve C51-1-8

Page 477 of 656

7E-4 DIFFERENTIAL (FRONT)

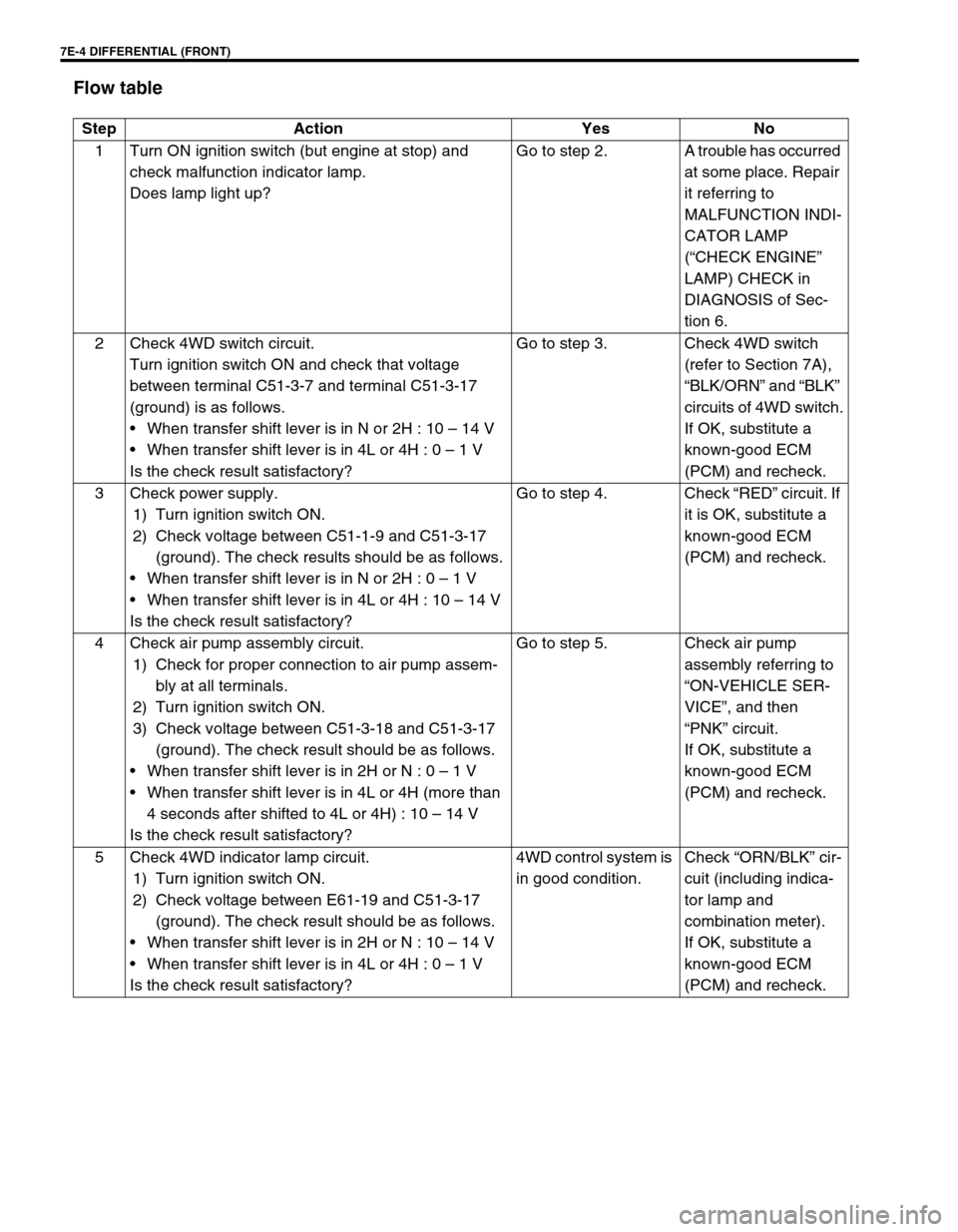

Flow table

Step Action Yes No

1 Turn ON ignition switch (but engine at stop) and

check malfunction indicator lamp.

Does lamp light up?Go to step 2. A trouble has occurred

at some place. Repair

it referring to

MALFUNCTION INDI-

CATOR LAMP

(“CHECK ENGINE”

LAMP) CHECK in

DIAGNOSIS of Sec-

tion 6.

2 Check 4WD switch circuit.

Turn ignition switch ON and check that voltage

between terminal C51-3-7 and terminal C51-3-17

(ground) is as follows.

When transfer shift lever is in N or 2H : 10 – 14 V

When transfer shift lever is in 4L or 4H : 0 – 1 V

Is the check result satisfactory?Go to step 3. Check 4WD switch

(refer to Section 7A),

“BLK/ORN” and “BLK”

circuits of 4WD switch.

If OK, substitute a

known-good ECM

(PCM) and recheck.

3 Check power supply.

1) Turn ignition switch ON.

2) Check voltage between C51-1-9 and C51-3-17

(ground). The check results should be as follows.

When transfer shift lever is in N or 2H : 0 – 1 V

When transfer shift lever is in 4L or 4H : 10 – 14 V

Is the check result satisfactory?Go to step 4. Check “RED” circuit. If

it is OK, substitute a

known-good ECM

(PCM) and recheck.

4 Check air pump assembly circuit.

1) Check for proper connection to air pump assem-

bly at all terminals.

2) Turn ignition switch ON.

3) Check voltage between C51-3-18 and C51-3-17

(ground). The check result should be as follows.

When transfer shift lever is in 2H or N : 0 – 1 V

When transfer shift lever is in 4L or 4H (more than

4 seconds after shifted to 4L or 4H) : 10 – 14 V

Is the check result satisfactory?Go to step 5. Check air pump

assembly referring to

“ON-VEHICLE SER-

VICE”, and then

“PNK” circuit.

If OK, substitute a

known-good ECM

(PCM) and recheck.

5 Check 4WD indicator lamp circuit.

1) Turn ignition switch ON.

2) Check voltage between E61-19 and C51-3-17

(ground). The check result should be as follows.

When transfer shift lever is in 2H or N : 10 – 14 V

When transfer shift lever is in 4L or 4H : 0 – 1 V

Is the check result satisfactory?4WD control system is

in good condition.Check “ORN/BLK” cir-

cuit (including indica-

tor lamp and

combination meter).

If OK, substitute a

known-good ECM

(PCM) and recheck.

Page 489 of 656

7F-4 DIFFERENTIAL (REAR)

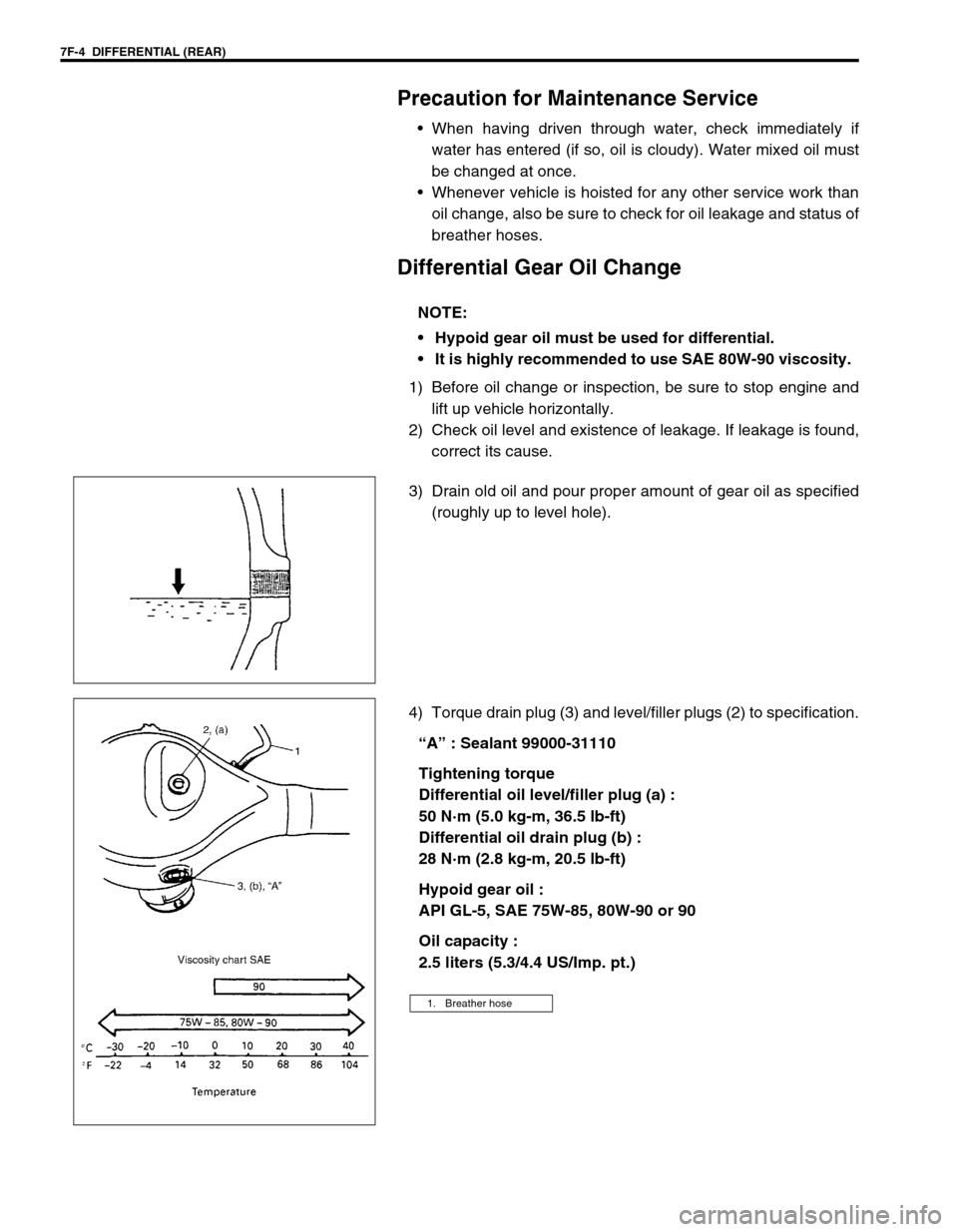

Precaution for Maintenance Service

•When having driven through water, check immediately if

water has entered (if so, oil is cloudy). Water mixed oil must

be changed at once.

•Whenever vehicle is hoisted for any other service work than

oil change, also be sure to check for oil leakage and status of

breather hoses.

Differential Gear Oil Change

1) Before oil change or inspection, be sure to stop engine and

lift up vehicle horizontally.

2) Check oil level and existence of leakage. If leakage is found,

correct its cause.

3) Drain old oil and pour proper amount of gear oil as specified

(roughly up to level hole).

4) Torque drain plug (3) and level/filler plugs (2) to specification.

“A” : Sealant 99000-31110

Tightening torque

Differential oil level/filler plug (a) :

50 N·m (5.0 kg-m, 36.5 lb-ft)

Differential oil drain plug (b) :

28 N·m (2.8 kg-m, 20.5 lb-ft)

Hypoid gear oil :

API GL-5, SAE 75W-85, 80W-90 or 90

Oil capacity :

2.5 liters (5.3/4.4 US/Imp. pt.) NOTE:

Hypoid gear oil must be used for differential.

It is highly recommended to use SAE 80W-90 viscosity.

1. Breather hose

Page 514 of 656

![SUZUKI GRAND VITARA 1999 2.G Owners Manual INSTRUMENTATION/DRIVER INFORMATION 8C-3

COMBINATION METER INTERNAL CIRCUITS

COMBINATION METER COUPLERS

[A] : Coupler A [B] : Coupler B [C] : Coupler C

1. To Cruise control module (if equipped) GRY/YE SUZUKI GRAND VITARA 1999 2.G Owners Manual INSTRUMENTATION/DRIVER INFORMATION 8C-3

COMBINATION METER INTERNAL CIRCUITS

COMBINATION METER COUPLERS

[A] : Coupler A [B] : Coupler B [C] : Coupler C

1. To Cruise control module (if equipped) GRY/YE](/img/20/7583/w960_7583-513.png)

INSTRUMENTATION/DRIVER INFORMATION 8C-3

COMBINATION METER INTERNAL CIRCUITS

COMBINATION METER COUPLERS

[A] : Coupler A [B] : Coupler B [C] : Coupler C

1. To Cruise control module (if equipped) GRY/YEL 1. To door switch (drive side) BLK/BLU 1. To ground BLK

2. Blank–2. To transmission range switch

(A/T vehicle only, if equipped) LGRN/BLU 2. To ECM (PCM for A/T vehicle) BRN

3. To ignition switch BLK/WHT 3. To transmission range switch

(A/T vehicle only, if equipped) 2GRN/ORN 3. To ignition switch PPL/RED

4. Blank–4. To transmission range switch

(A/T vehicle only, if equipped) DYEL/GRN 4. To brake fluid level switch RED/BLK

5. To ABS control module (if equipped) BLU/ORN 5. To transmission range switch

(A/T vehicle only, if equipped) NORN/BLU 5. To parking brake switch PPL

6. To PCM (A/T vehicle only) GRY/BLU 6. To transmission range switch

(A/T vehicle only, if equipped) PORN/GRN 6. To seat belt switch GRY/RED

7. To ABS control module (if equipped) BRN 7. To transmission range switch

(A/T vehicle only, if equipped) RRED 7. To generator WHT/RED

8. To VSS BLU/YEL 8. To illumination control module RED/GRN 8. To engine oil pressure switch YEL/BLK

9. To combination switch GRN/RED 9. To PCM (A/T vehicle only) WHT/BLK 9. To combination switch RED/YEL

10. To air bag SDM BLU 10. To ECT sensor YEL/WHT 10. To ignition switch BLU/RED

11. To main fuse WHT/BLU 11. To fuel level gauge BLU/WHT

12. To fuse box WHT 12. To ground BLU/YEL

13. To combination switch RED 13. To combination switch GRN/YEL

14. To immobilizer control module

(if equipped)PPL

15. To ECM (PCM for A/T vehicle) PPL/YEL

16. To ECM (PCM for A/T vehicle) ORN/BLK

P R N D 2 LCRUISEPOWER4WDSPEED

METERTACHO

METERFUEL

METERTEMP.

METER

A-11

A-13 A-8 B-12 B-11 C-8 A-15 A-6 A-1 B-9 A-16 A-14 C-7 C-1 A-10 C-3 C-4 C-5 A-7 A-5 B-8 B-1B-10 C-2 A-12 A-3B-13 B-2 B-3 B-4 B-5 B- B-6 C-9 C-10 A-9ABS circuit EBD circuit Air bag circuit

or ABS or BRAKE

if equipped

or CHECK

ENGINE

NOTE:

Terminal arrangement of coupler viewed from harness side.

Page 516 of 656

INSTRUMENTATION/DRIVER INFORMATION 8C-5

Engine Coolant Temperature (ECT) Meter and

Sensor

Engine coolant temperature sensor

REMOVAL AND INSTALLATION

Refer to “ECT SENSOR” in Section 6E2.

Oil Pressure Light

Oil pressure switch

REMOVAL AND INSTALLATION

Refer to “OIL PRESSURE CHECK” in Section 6A2.

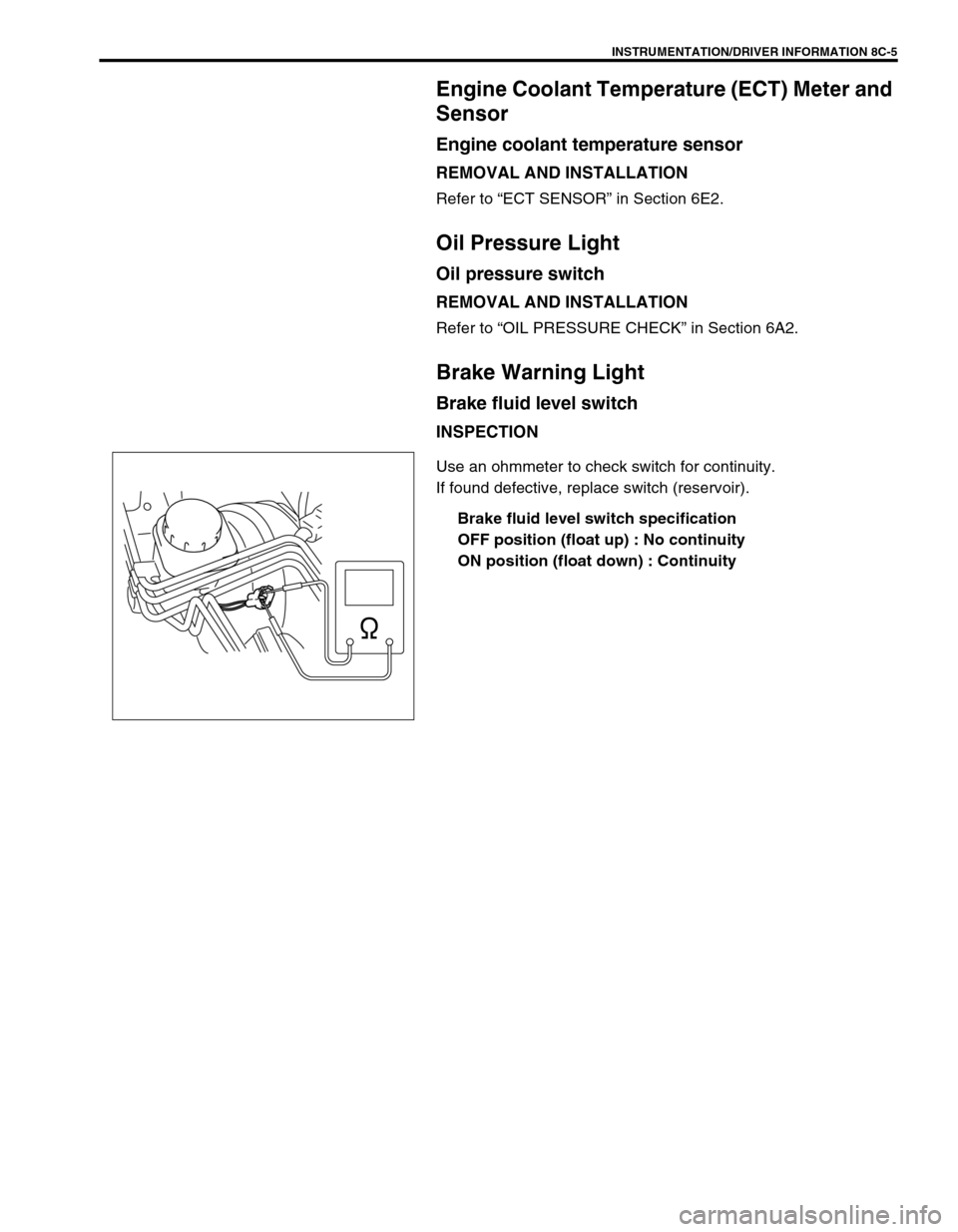

Brake Warning Light

Brake fluid level switch

INSPECTION

Use an ohmmeter to check switch for continuity.

If found defective, replace switch (reservoir).

Brake fluid level switch specification

OFF position (float up) : No continuity

ON position (float down) : Continuity

Page 598 of 656

AIR BAG SYSTEM 10B-21

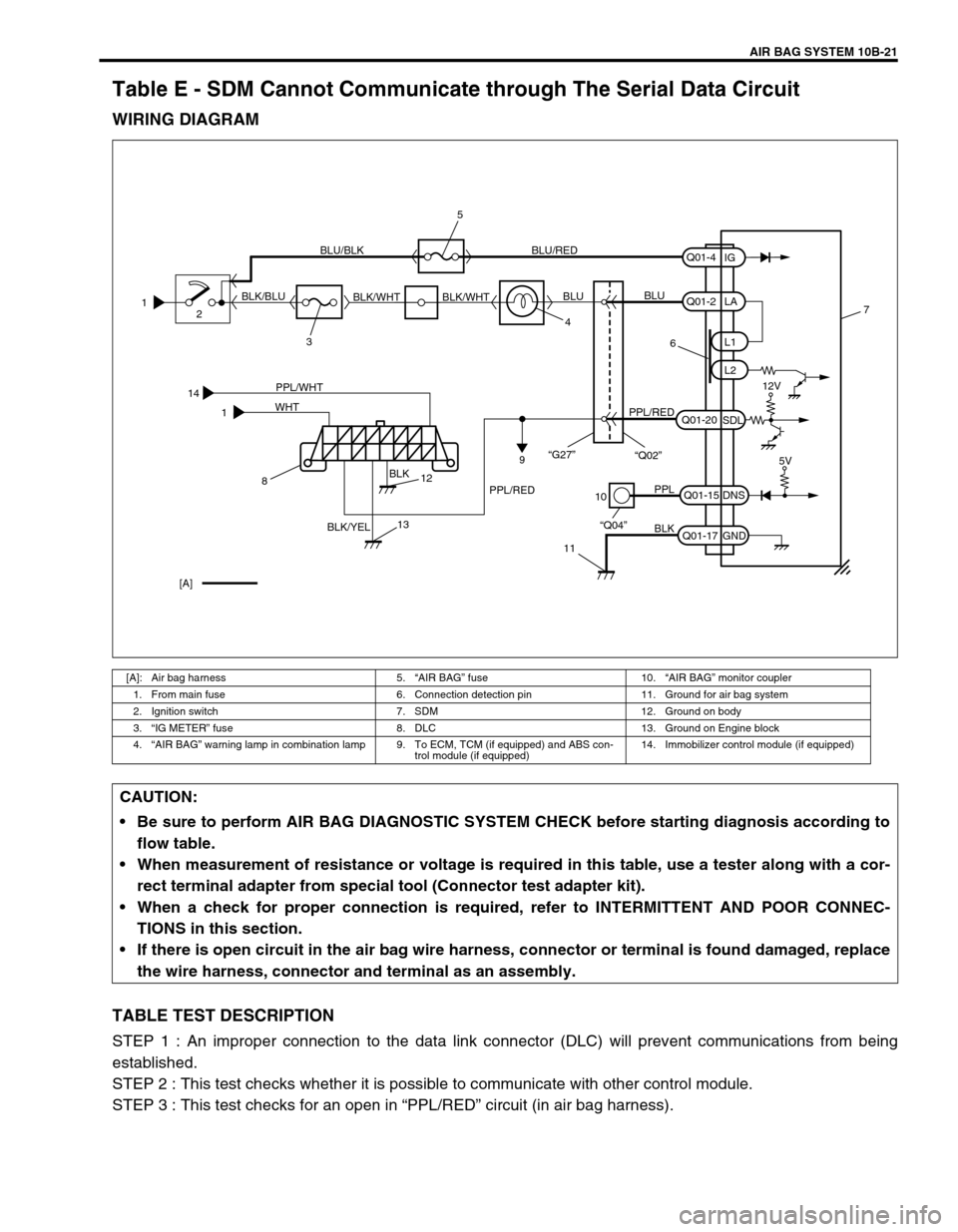

Table E - SDM Cannot Communicate through The Serial Data Circuit

WIRING DIAGRAM

TABLE TEST DESCRIPTION

STEP 1 : An improper connection to the data link connector (DLC) will prevent communications from being

established.

STEP 2 : This test checks whether it is possible to communicate with other control module.

STEP 3 : This test checks for an open in “PPL/RED” circuit (in air bag harness).

[A]: Air bag harness 5.“AIR BAG” fuse 10.“AIR BAG” monitor coupler

1. From main fuse 6. Connection detection pin 11. Ground for air bag system

2. Ignition switch 7. SDM 12. Ground on body

3.“IG METER” fuse 8. DLC 13. Ground on Engine block

4.“AIR BAG” warning lamp in combination lamp 9. To ECM, TCM (if equipped) and ABS con-

trol module (if equipped)14. Immobilizer control module (if equipped)

14

1PPL/WHT

BLK

BLK/YEL WHT

10

11

PPL

BLK

“Q04”Q01-15

Q01-17DNS

GND7

[A]5V

812

13

1

2

34 BLK/BLUBLU/BLK BLU/RED

BLK/WHT BLK/WHTBLUBLU

6

PPL/REDPPL/RED

9

Q01-2

Q01-20L1

L2

SDLLA

Q01-4

IG

12V

“G27”

“Q02”

5

CAUTION:

Be sure to perform AIR BAG DIAGNOSTIC SYSTEM CHECK before starting diagnosis according to

flow table.

When measurement of resistance or voltage is required in this table, use a tester along with a cor-

rect terminal adapter from special tool (Connector test adapter kit).

When a check for proper connection is required, refer to INTERMITTENT AND POOR CONNEC-

TIONS in this section.

If there is open circuit in the air bag wire harness, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.