switch SUZUKI GRAND VITARA 1999 2.G User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1999, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1999 2.GPages: 656, PDF Size: 14.31 MB

Page 35 of 656

1B-10 AIR CONDITIONING (OPTIONAL)

Performance Diagnosis

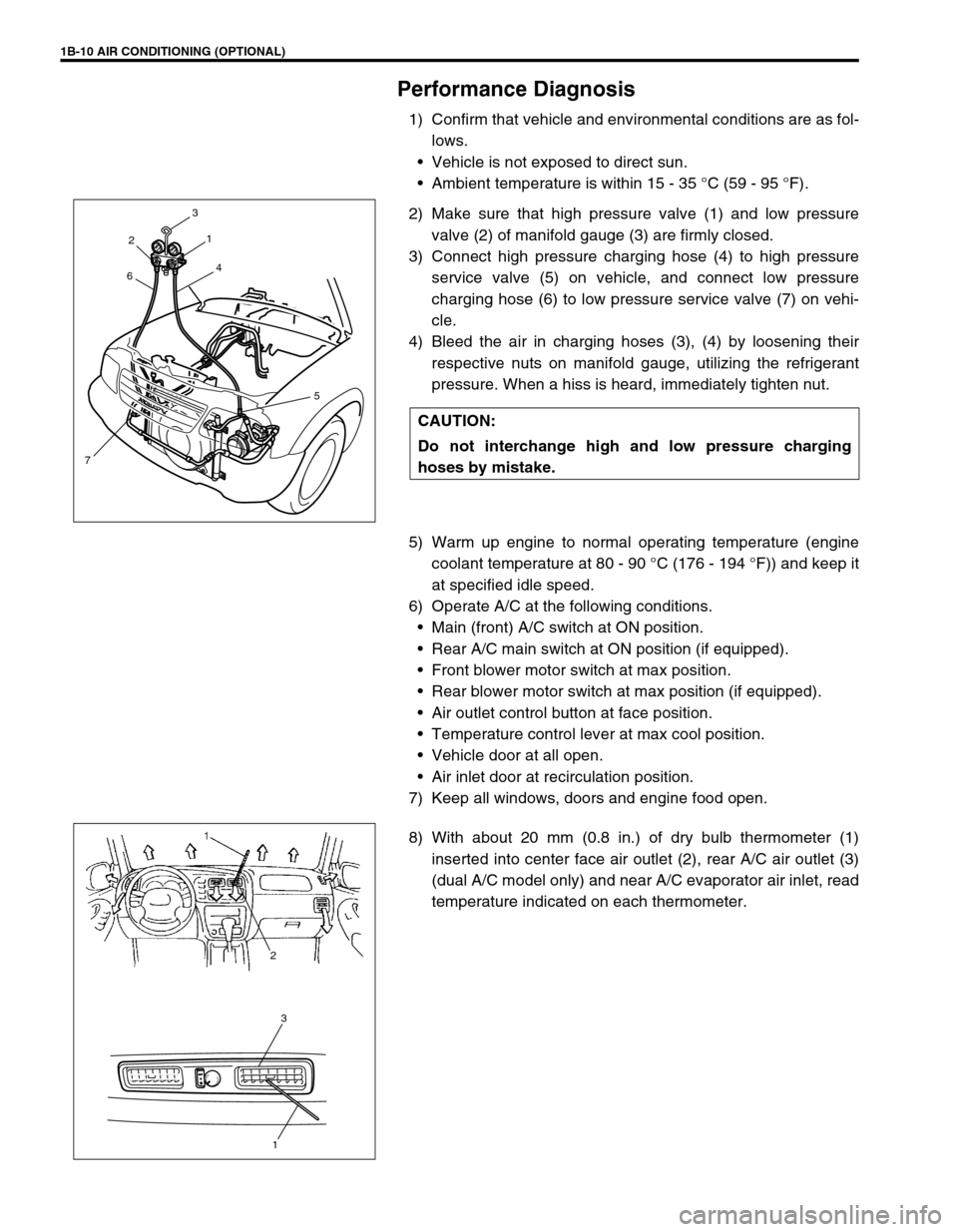

1) Confirm that vehicle and environmental conditions are as fol-

lows.

Vehicle is not exposed to direct sun.

Ambient temperature is within 15 - 35 °C (59 - 95 °F).

2) Make sure that high pressure valve (1) and low pressure

valve (2) of manifold gauge (3) are firmly closed.

3) Connect high pressure charging hose (4) to high pressure

service valve (5) on vehicle, and connect low pressure

charging hose (6) to low pressure service valve (7) on vehi-

cle.

4) Bleed the air in charging hoses (3), (4) by loosening their

respective nuts on manifold gauge, utilizing the refrigerant

pressure. When a hiss is heard, immediately tighten nut.

5) Warm up engine to normal operating temperature (engine

coolant temperature at 80 - 90 °C (176 - 194 °F)) and keep it

at specified idle speed.

6) Operate A/C at the following conditions.

Main (front) A/C switch at ON position.

Rear A/C main switch at ON position (if equipped).

Front blower motor switch at max position.

Rear blower motor switch at max position (if equipped).

Air outlet control button at face position.

Temperature control lever at max cool position.

Vehicle door at all open.

Air inlet door at recirculation position.

7) Keep all windows, doors and engine food open.

8) With about 20 mm (0.8 in.) of dry bulb thermometer (1)

inserted into center face air outlet (2), rear A/C air outlet (3)

(dual A/C model only) and near A/C evaporator air inlet, read

temperature indicated on each thermometer. CAUTION:

Do not interchange high and low pressure charging

hoses by mistake.

2

64

3

75 1

3

1

2

Page 37 of 656

1B-12 AIR CONDITIONING (OPTIONAL)

Performance diagnosis table

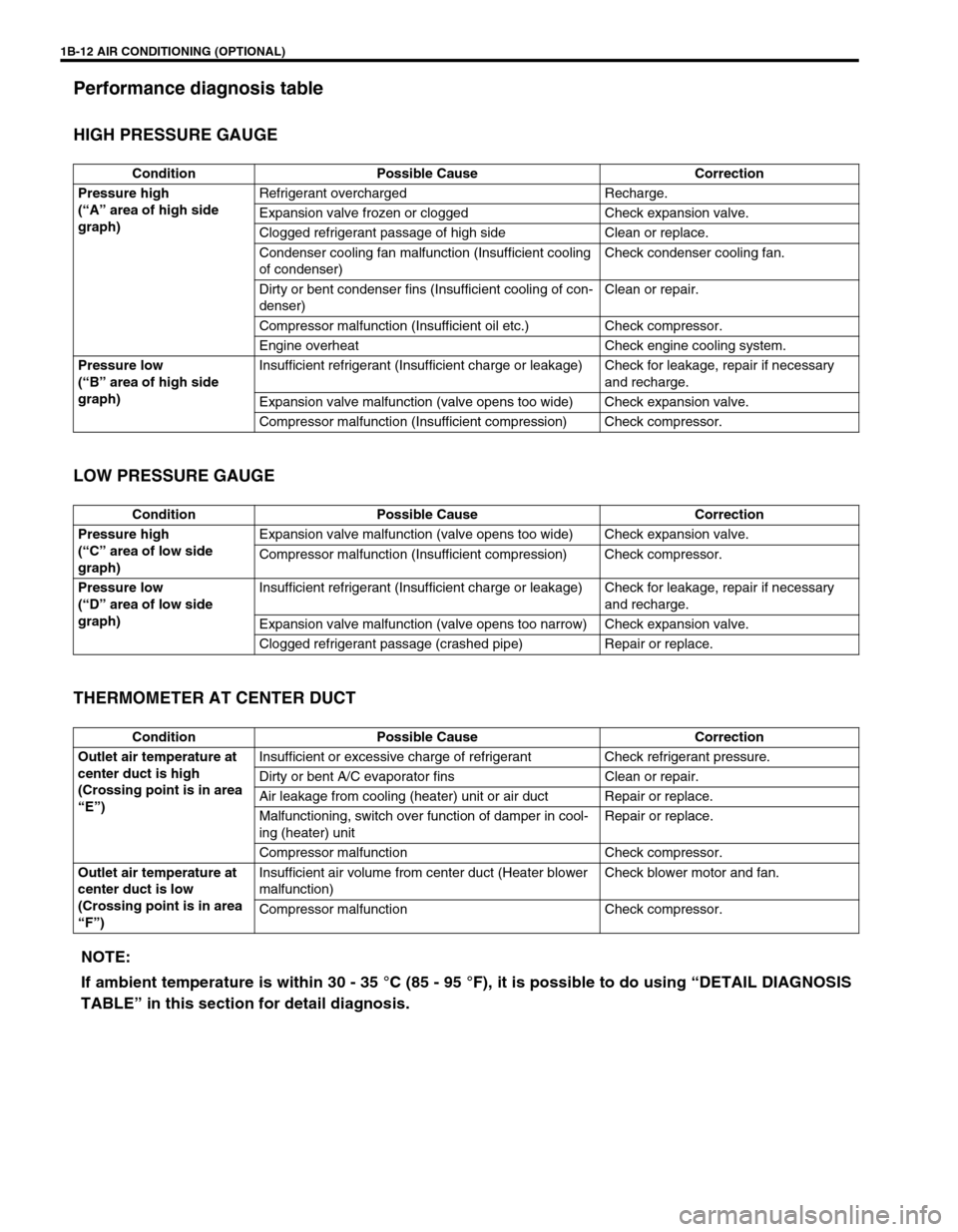

HIGH PRESSURE GAUGE

LOW PRESSURE GAUGE

THERMOMETER AT CENTER DUCT

Condition Possible Cause Correction

Pressure high

(“A” area of high side

graph)Refrigerant overcharged Recharge.

Expansion valve frozen or clogged Check expansion valve.

Clogged refrigerant passage of high side Clean or replace.

Condenser cooling fan malfunction (Insufficient cooling

of condenser)Check condenser cooling fan.

Dirty or bent condenser fins (Insufficient cooling of con-

denser)Clean or repair.

Compressor malfunction (Insufficient oil etc.) Check compressor.

Engine overheat Check engine cooling system.

Pressure low

(“B” area of high side

graph)Insufficient refrigerant (Insufficient charge or leakage) Check for leakage, repair if necessary

and recharge.

Expansion valve malfunction (valve opens too wide) Check expansion valve.

Compressor malfunction (Insufficient compression) Check compressor.

Condition Possible Cause Correction

Pressure high

(“C” area of low side

graph)Expansion valve malfunction (valve opens too wide) Check expansion valve.

Compressor malfunction (Insufficient compression) Check compressor.

Pressure low

(“D” area of low side

graph)Insufficient refrigerant (Insufficient charge or leakage) Check for leakage, repair if necessary

and recharge.

Expansion valve malfunction (valve opens too narrow) Check expansion valve.

Clogged refrigerant passage (crashed pipe) Repair or replace.

Condition Possible Cause Correction

Outlet air temperature at

center duct is high

(Crossing point is in area

“E”)Insufficient or excessive charge of refrigerant Check refrigerant pressure.

Dirty or bent A/C evaporator fins Clean or repair.

Air leakage from cooling (heater) unit or air duct Repair or replace.

Malfunctioning, switch over function of damper in cool-

ing (heater) unitRepair or replace.

Compressor malfunction Check compressor.

Outlet air temperature at

center duct is low

(Crossing point is in area

“F”)Insufficient air volume from center duct (Heater blower

malfunction)Check blower motor and fan.

Compressor malfunction Check compressor.

NOTE:

If ambient temperature is within 30 - 35 °C (85 - 95 °F), it is possible to do using “DETAIL DIAGNOSIS

TABLE” in this section for detail diagnosis.

Page 39 of 656

1B-14 AIR CONDITIONING (OPTIONAL)

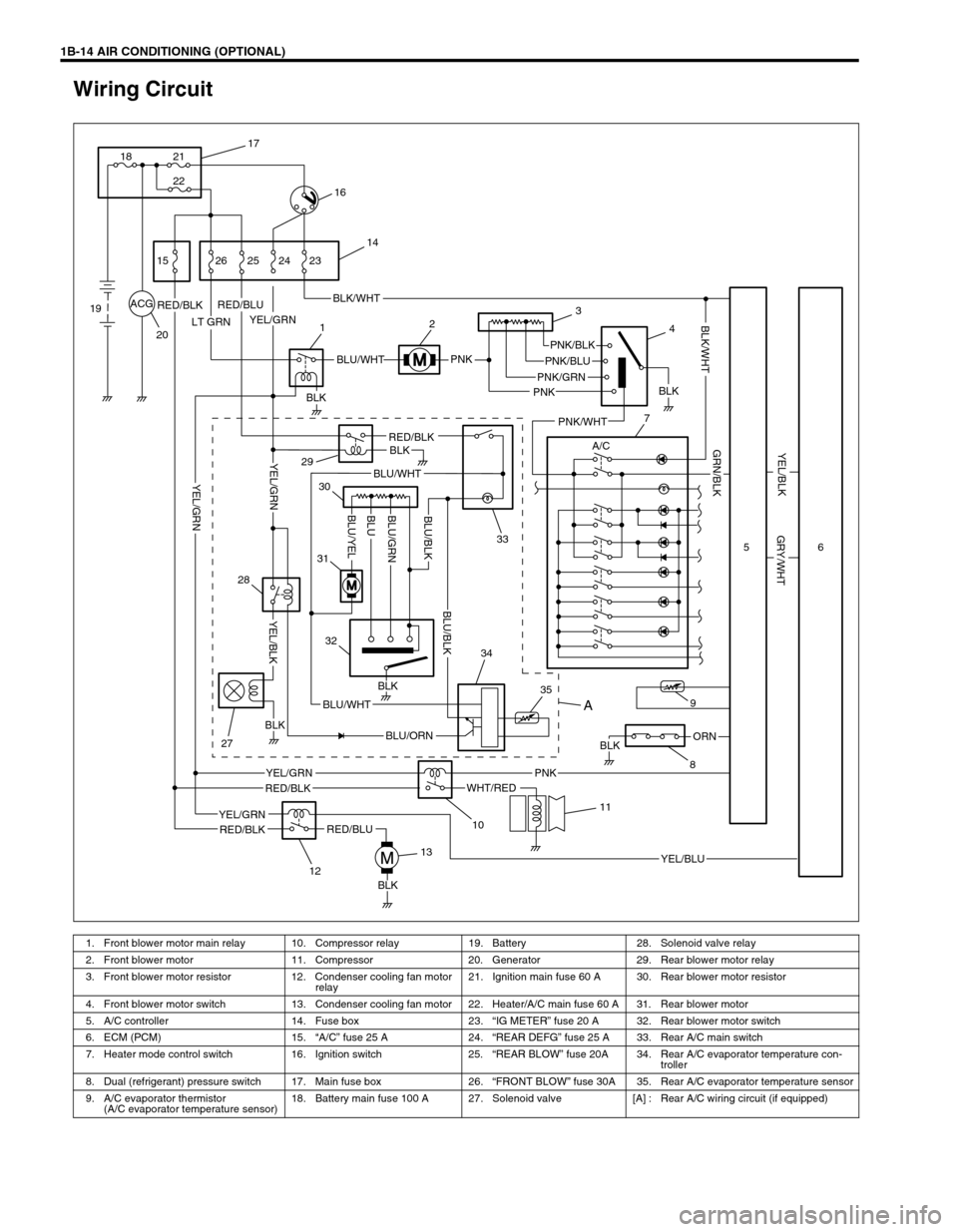

Wiring Circuit

ACG

LT GRN

PNK

PNK

BLKORN

BLK

YEL/GRNRED/BLKBLK/WHT

BLU/WHTPNK/BLK

PNK/GRN

RED/BLK

WHT/RED

YEL/GRN

YEL/BLU

A/C

RED/BLU

RED/BLU

RED/BLKBLK

BLU/ORN

BLU/WHT

BLU/WHT

PNK

PNK/BLU

BLK

PNK/WHT

YEL/BLK

GRY/WHT

GRN/BLK

BLK/WHT

RED/BLK

YEL/GRN

BLK

BLK

BLK

YEL/BLK

YEL/GRN

YEL/GRNBLU/GRN

BLU/YELBLUBLU/BLK

BLU/BLK

17

21

22 18

16

15

19

2026 25 24 23

14

12

29

3

4

7

33 30

31

32

28

27

1213

10

11

35 349

856

A

1. Front blower motor main relay 10. Compressor relay 19. Battery 28. Solenoid valve relay

2. Front blower motor 11. Compressor 20. Generator 29. Rear blower motor relay

3. Front blower motor resistor 12. Condenser cooling fan motor

relay21. Ignition main fuse 60 A 30. Rear blower motor resistor

4. Front blower motor switch 13. Condenser cooling fan motor 22. Heater/A/C main fuse 60 A 31. Rear blower motor

5. A/C controller 14. Fuse box 23.“IG METER” fuse 20 A 32. Rear blower motor switch

6. ECM (PCM) 15.“A/C” fuse 25 A 24.“REAR DEFG” fuse 25 A 33. Rear A/C main switch

7. Heater mode control switch 16. Ignition switch 25.“REAR BLOW” fuse 20A 34. Rear A/C evaporator temperature con-

troller

8. Dual (refrigerant) pressure switch 17. Main fuse box 26.“FRONT BLOW” fuse 30A 35. Rear A/C evaporator temperature sensor

9. A/C evaporator thermistor

(A/C evaporator temperature sensor)18. Battery main fuse 100 A 27. Solenoid valve [A] : Rear A/C wiring circuit (if equipped)

Page 41 of 656

1B-16 AIR CONDITIONING (OPTIONAL)

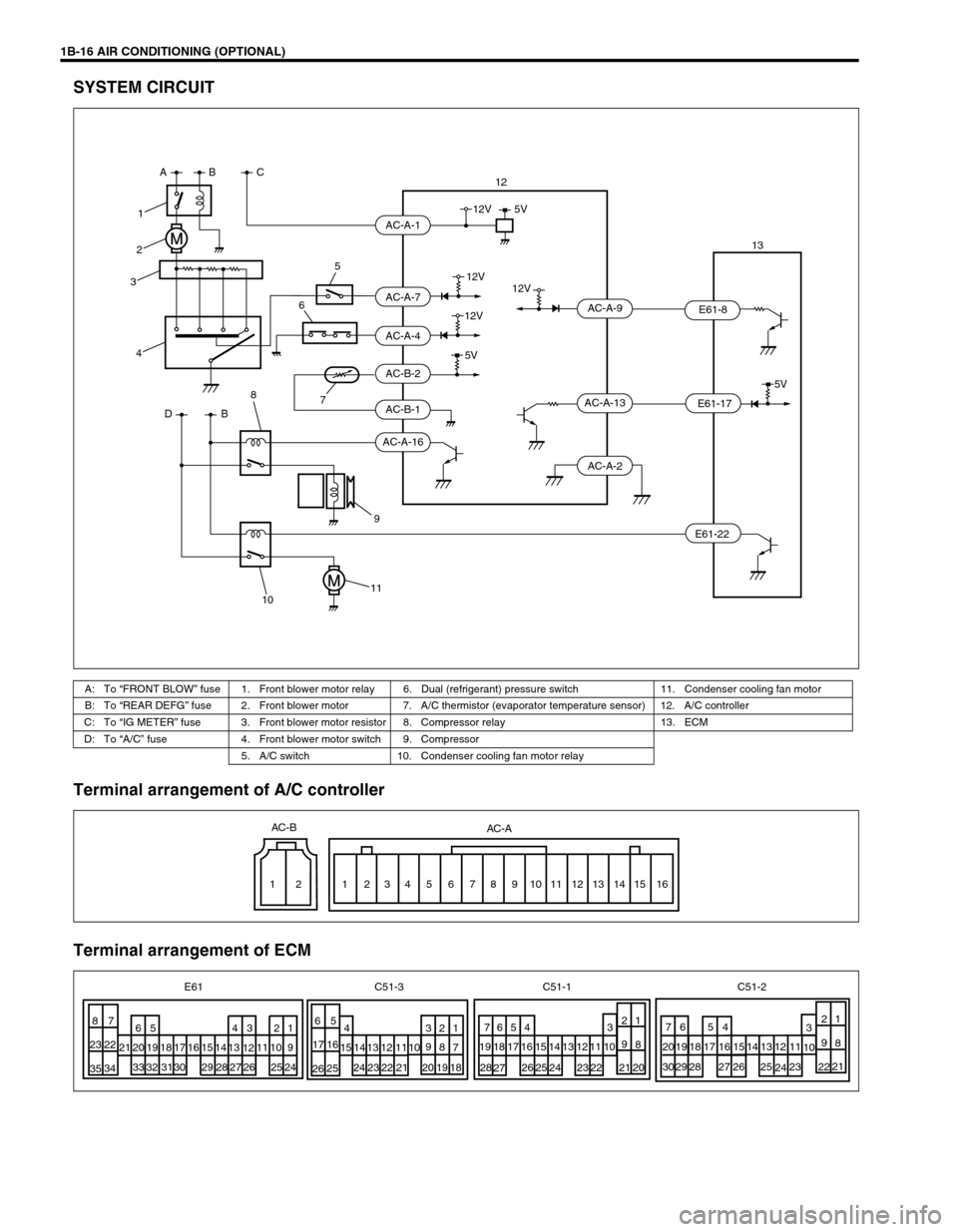

SYSTEM CIRCUIT

Terminal arrangement of A/C controller

Terminal arrangement of ECM

A: To “FRONT BLOW” fuse 1. Front blower motor relay 6. Dual (refrigerant) pressure switch 11. Condenser cooling fan motor

B: To “REAR DEFG” fuse 2. Front blower motor 7. A/C thermistor (evaporator temperature sensor) 12. A/C controller

C: To “IG METER” fuse 3. Front blower motor resistor 8. Compressor relay 13. ECM

D: To “A/C” fuse 4. Front blower motor switch 9. Compressor

5. A/C switch 10. Condenser cooling fan motor relay

5V

12V12V

12V5V

12V

5V

AC-A-1

AC-A-7

AC-A-4

AC-B-2

AC-B-1

AC-A-16AC-A-9

AC-A-2 AC-A-13

E61-8

E61-17

E61-22

A

DBBC

1

2

3

4

7 865

1011912

13

12 12

3

45 6 7 8 9 101112131415 16 AC-B

AC-A

87

22 23

34

3565

16 17

25

262

1

8 9

20

212

1

8 9

21

22 1 2 3 4 5 6

9

24 25 26 27 28 29 30 31 32 3310 11

12 13 14 15 16 17 18 19 20 211 2 3 4

7 8 9

10 11 12 13 14 15

18 19 20 21 22 23 243 4 5 6 7

10 11 12 13 14 15 16 17 18 19

22 23 24 25 26

27 283 4 5 6 7

10 11 12 13 14 15 16 19 18 2017

23

24 25 26 27 29 28 30 E61 C51-3 C51-1 C51-2

Page 42 of 656

AIR CONDITIONING (OPTIONAL) 1B-17

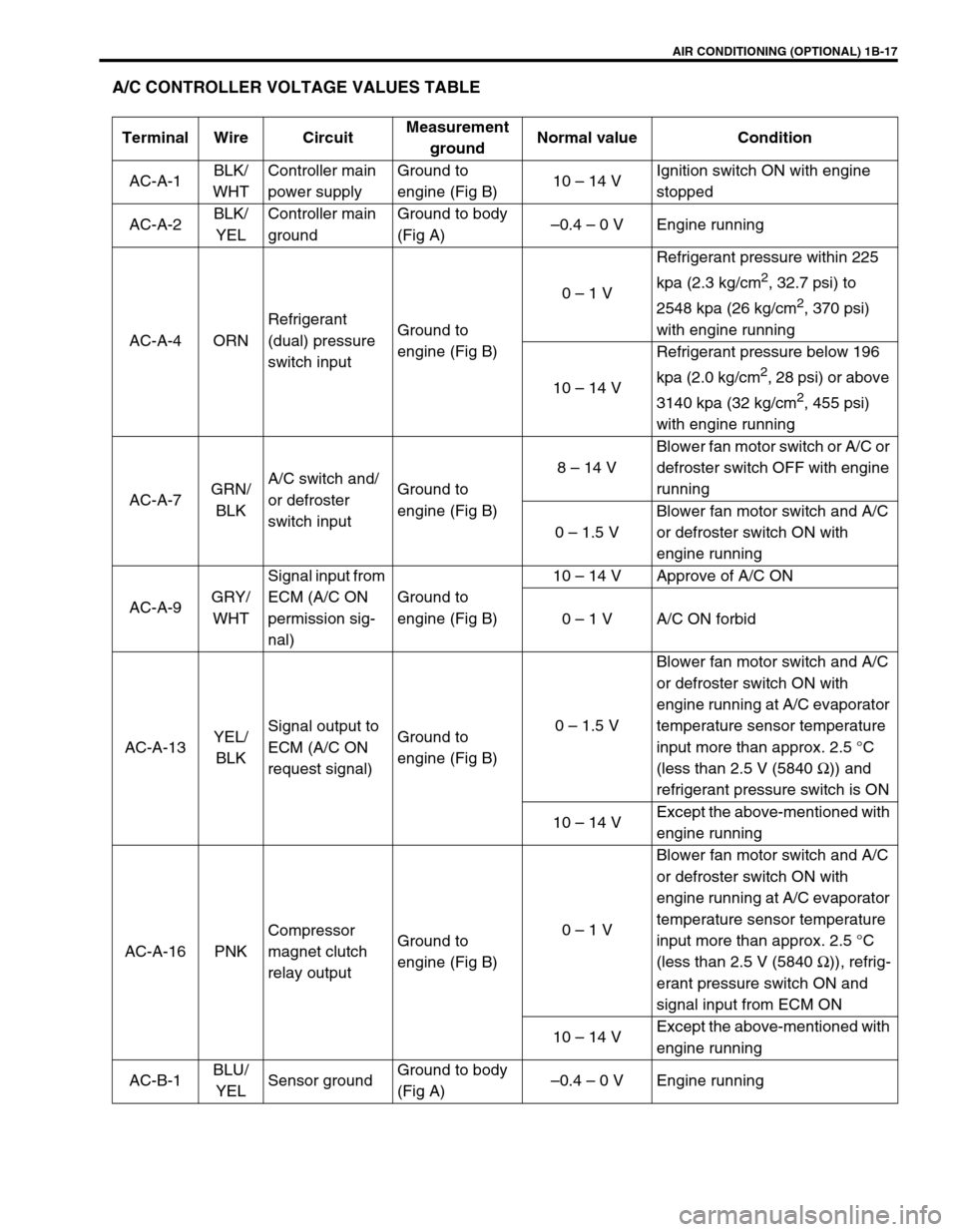

A/C CONTROLLER VOLTAGE VALUES TABLE

Terminal Wire CircuitMeasurement

groundNormal value Condition

AC-A-1BLK/

WHTController main

power supplyGround to

engine (Fig B)10 – 14 VIgnition switch ON with engine

stopped

AC-A-2BLK/

YELController main

groundGround to body

(Fig A)–0.4 – 0 V Engine running

AC-A-4 ORNRefrigerant

(dual) pressure

switch inputGround to

engine (Fig B)0 – 1 VRefrigerant pressure within 225

kpa (2.3 kg/cm

2, 32.7 psi) to

2548 kpa (26 kg/cm

2, 370 psi)

with engine running

10 – 14 VRefrigerant pressure below 196

kpa (2.0 kg/cm

2, 28 psi) or above

3140 kpa (32 kg/cm

2, 455 psi)

with engine running

AC-A-7GRN/

BLKA/C switch and/

or defroster

switch inputGround to

engine (Fig B)8 – 14 VBlower fan motor switch or A/C or

defroster switch OFF with engine

running

0 – 1.5 VBlower fan motor switch and A/C

or defroster switch ON with

engine running

AC-A-9GRY/

WHTSignal input from

ECM (A/C ON

permission sig-

nal)Ground to

engine (Fig B)10 – 14 V Approve of A/C ON

0 – 1 V A/C ON forbid

AC-A-13YEL/

BLKSignal output to

ECM (A/C ON

request signal)Ground to

engine (Fig B)0 – 1.5 VBlower fan motor switch and A/C

or defroster switch ON with

engine running at A/C evaporator

temperature sensor temperature

input more than approx. 2.5 °C

(less than 2.5 V (5840 Ω)) and

refrigerant pressure switch is ON

10 – 14 VExcept the above-mentioned with

engine running

AC-A-16 PNKCompressor

magnet clutch

relay outputGround to

engine (Fig B)0 – 1 VBlower fan motor switch and A/C

or defroster switch ON with

engine running at A/C evaporator

temperature sensor temperature

input more than approx. 2.5 °C

(less than 2.5 V (5840 Ω)), refrig-

erant pressure switch ON and

signal input from ECM ON

10 – 14 VExcept the above-mentioned with

engine running

AC-B-1BLU/

YELSensor groundGround to body

(Fig A)–0.4 – 0 V Engine running

Page 43 of 656

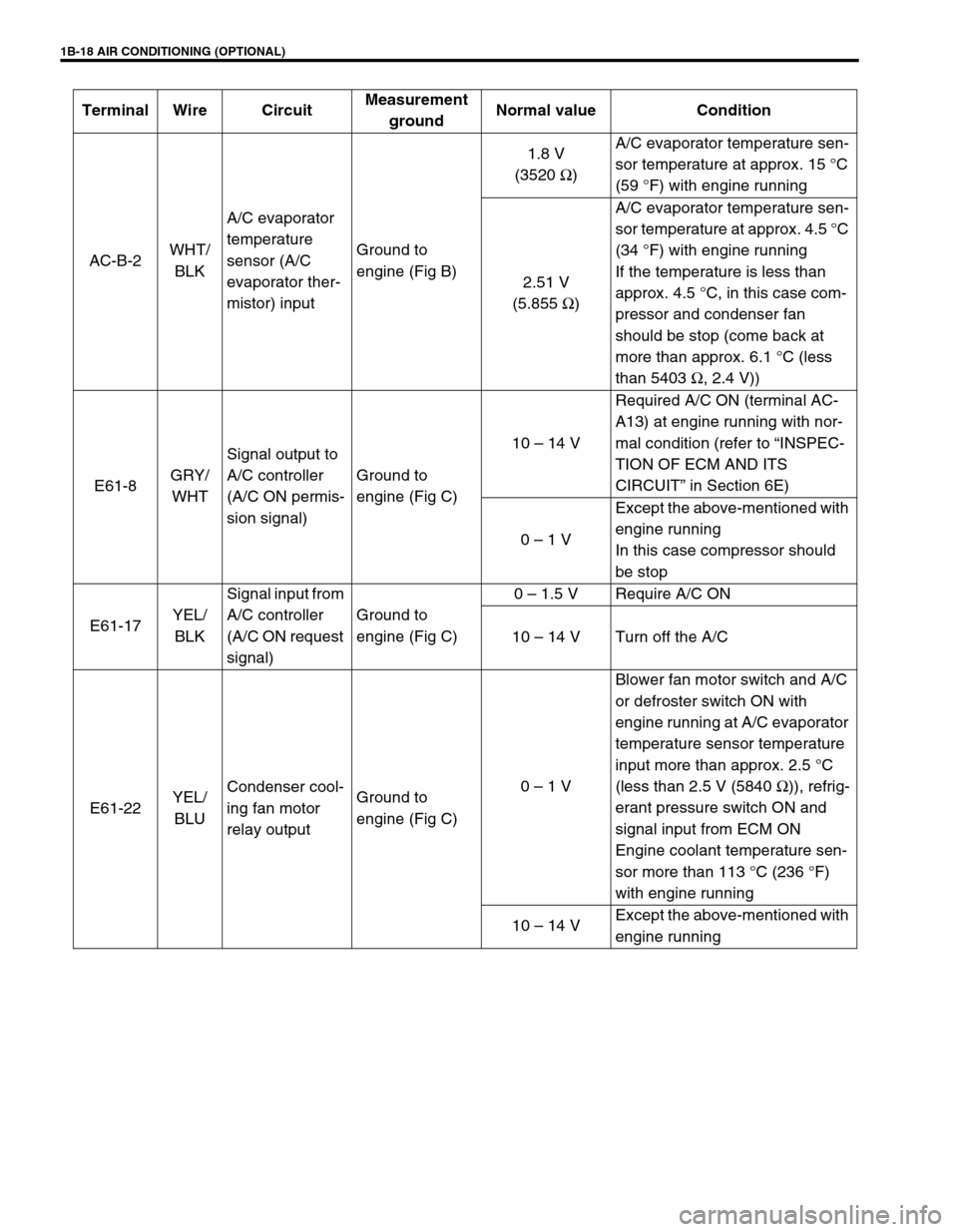

1B-18 AIR CONDITIONING (OPTIONAL)

Terminal Wire CircuitMeasurement

groundNormal value Condition

AC-B-2WHT/

BLKA/C evaporator

temperature

sensor (A/C

evaporator ther-

mistor) inputGround to

engine (Fig B)1.8 V

(3520 Ω)A/C evaporator temperature sen-

sor temperature at approx. 15 °C

(59 °F) with engine running

2.51 V

(5.855 Ω)A/C evaporator temperature sen-

sor temperature at approx. 4.5 °C

(34 °F) with engine running

If the temperature is less than

approx. 4.5 °C, in this case com-

pressor and condenser fan

should be stop (come back at

more than approx. 6.1 °C (less

than 5403 Ω, 2.4 V))

E61-8GRY/

WHTSignal output to

A/C controller

(A/C ON permis-

sion signal)Ground to

engine (Fig C)10 – 14 VRequired A/C ON (terminal AC-

A13) at engine running with nor-

mal condition (refer to “INSPEC-

TION OF ECM AND ITS

CIRCUIT” in Section 6E)

0 – 1 VExcept the above-mentioned with

engine running

In this case compressor should

be stop

E61-17YEL/

BLKSignal input from

A/C controller

(A/C ON request

signal)Ground to

engine (Fig C)0 – 1.5 V Require A/C ON

10 – 14 V Turn off the A/C

E61-22YEL/

BLUCondenser cool-

ing fan motor

relay outputGround to

engine (Fig C)0 – 1 VBlower fan motor switch and A/C

or defroster switch ON with

engine running at A/C evaporator

temperature sensor temperature

input more than approx. 2.5 °C

(less than 2.5 V (5840 Ω)), refrig-

erant pressure switch ON and

signal input from ECM ON

Engine coolant temperature sen-

sor more than 113 °C (236 °F)

with engine running

10 – 14 VExcept the above-mentioned with

engine running

Page 50 of 656

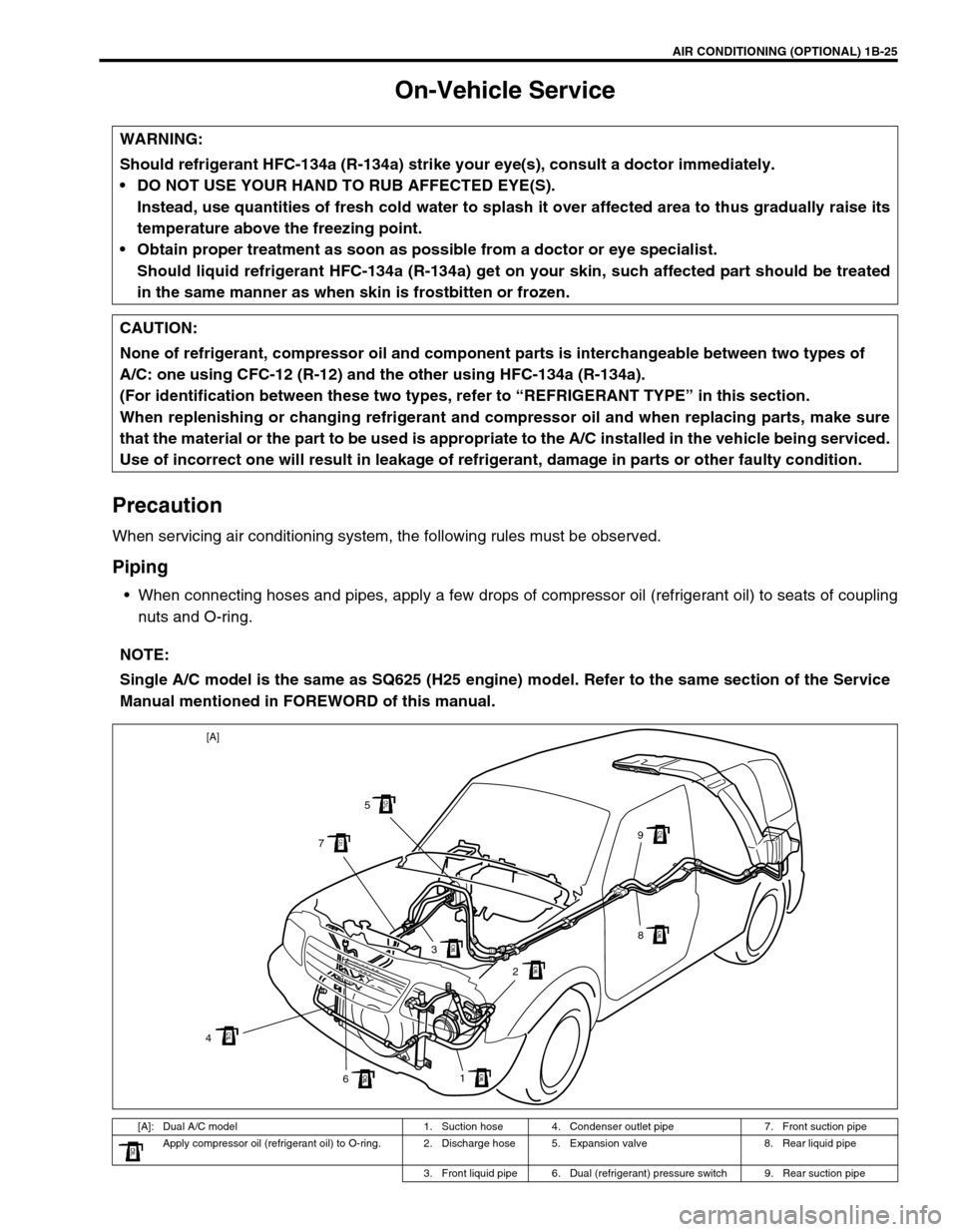

AIR CONDITIONING (OPTIONAL) 1B-25

On-Vehicle Service

Precaution

When servicing air conditioning system, the following rules must be observed.

Piping

When connecting hoses and pipes, apply a few drops of compressor oil (refrigerant oil) to seats of coupling

nuts and O-ring. WARNING:

Should refrigerant HFC-134a (R-134a) strike your eye(s), consult a doctor immediately.

DO NOT USE YOUR HAND TO RUB AFFECTED EYE(S).

Instead, use quantities of fresh cold water to splash it over affected area to thus gradually raise its

temperature above the freezing point.

Obtain proper treatment as soon as possible from a doctor or eye specialist.

Should liquid refrigerant HFC-134a (R-134a) get on your skin, such affected part should be treated

in the same manner as when skin is frostbitten or frozen.

CAUTION:

None of refrigerant, compressor oil and component parts is interchangeable between two types of

A/C: one using CFC-12 (R-12) and the other using HFC-134a (R-134a).

(For identification between these two types, refer to “REFRIGERANT TYPE” in this section.

When replenishing or changing refrigerant and compressor oil and when replacing parts, make sure

that the material or the part to be used is appropriate to the A/C installed in the vehicle being serviced.

Use of incorrect one will result in leakage of refrigerant, damage in parts or other faulty condition.

NOTE:

Single A/C model is the same as SQ625 (H25 engine) model. Refer to the same section of the Service

Manual mentioned in FOREWORD of this manual.

[A]: Dual A/C model 1. Suction hose 4. Condenser outlet pipe 7. Front suction pipe

Apply compressor oil (refrigerant oil) to O-ring. 2. Discharge hose 5. Expansion valve 8. Rear liquid pipe

3. Front liquid pipe 6. Dual (refrigerant) pressure switch 9. Rear suction pipe

1

6 43 75

9

8

2 [A]

Page 59 of 656

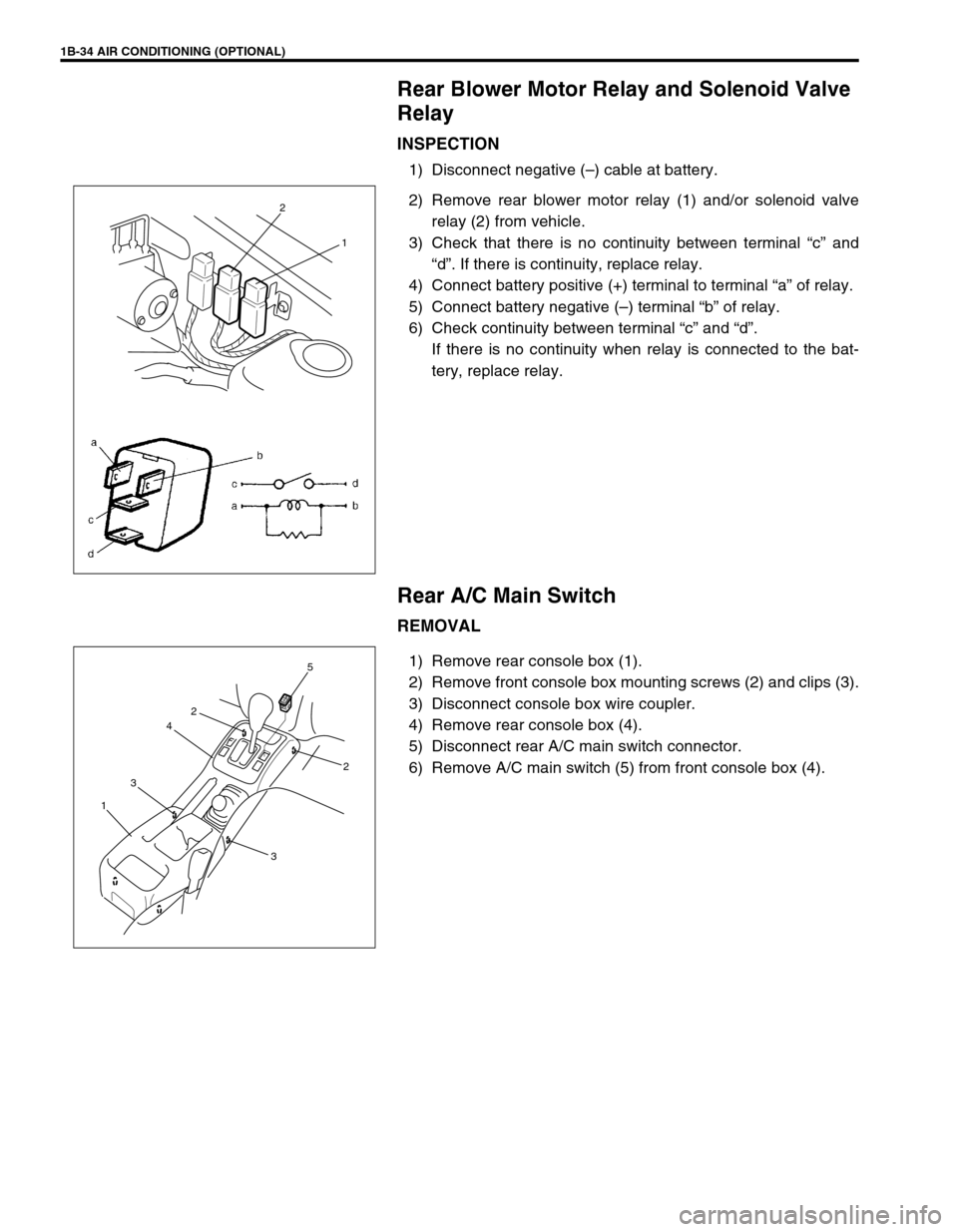

1B-34 AIR CONDITIONING (OPTIONAL)

Rear Blower Motor Relay and Solenoid Valve

Relay

INSPECTION

1) Disconnect negative (–) cable at battery.

2) Remove rear blower motor relay (1) and/or solenoid valve

relay (2) from vehicle.

3) Check that there is no continuity between terminal “c” and

“d”. If there is continuity, replace relay.

4) Connect battery positive (+) terminal to terminal “a” of relay.

5) Connect battery negative (–) terminal “b” of relay.

6) Check continuity between terminal “c” and “d”.

If there is no continuity when relay is connected to the bat-

tery, replace relay.

Rear A/C Main Switch

REMOVAL

1) Remove rear console box (1).

2) Remove front console box mounting screws (2) and clips (3).

3) Disconnect console box wire coupler.

4) Remove rear console box (4).

5) Disconnect rear A/C main switch connector.

6) Remove A/C main switch (5) from front console box (4).

2

1

2

4

3

15

2

3

Page 60 of 656

AIR CONDITIONING (OPTIONAL) 1B-35

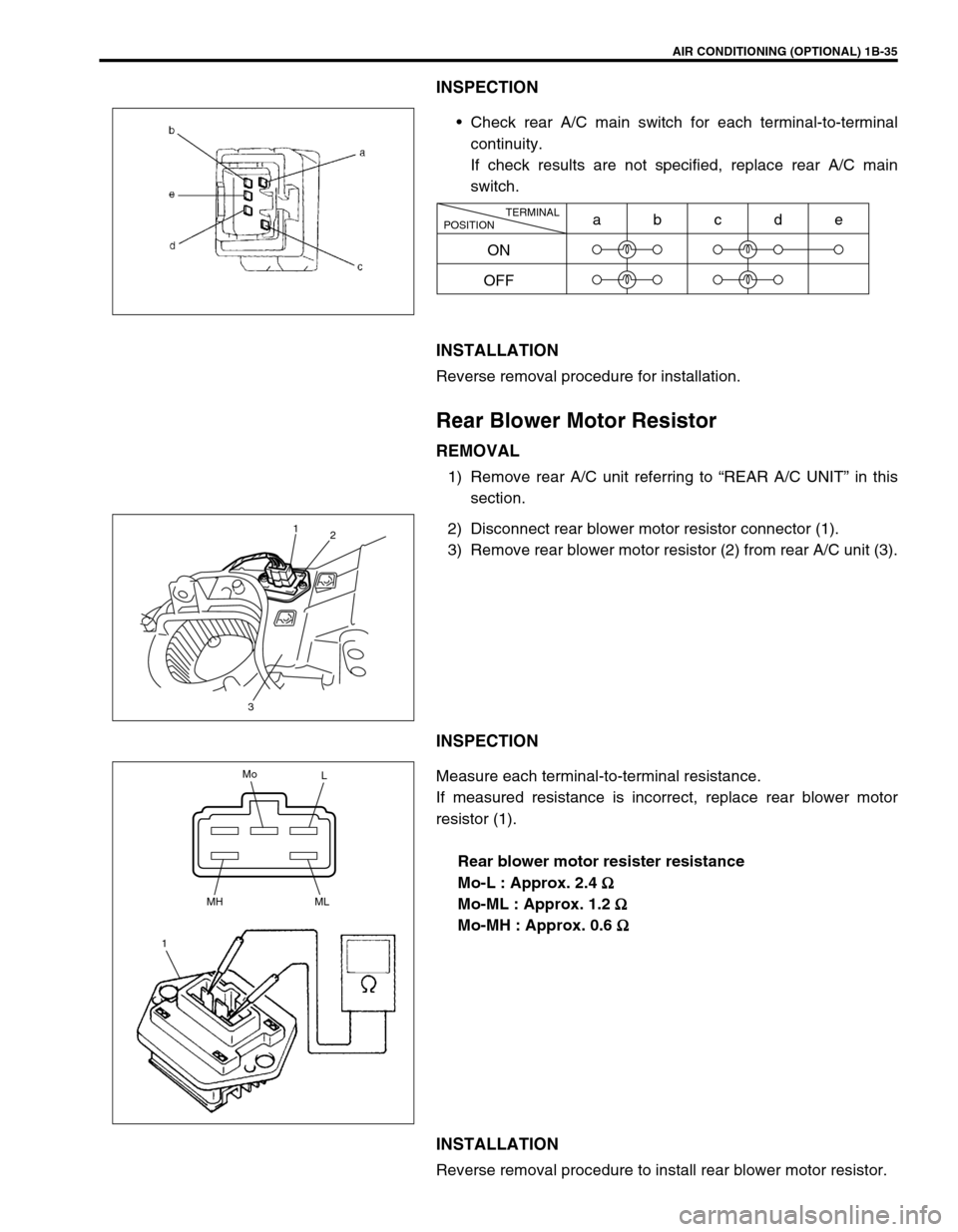

INSPECTION

Check rear A/C main switch for each terminal-to-terminal

continuity.

If check results are not specified, replace rear A/C main

switch.

INSTALLATION

Reverse removal procedure for installation.

Rear Blower Motor Resistor

REMOVAL

1) Remove rear A/C unit referring to “REAR A/C UNIT” in this

section.

2) Disconnect rear blower motor resistor connector (1).

3) Remove rear blower motor resistor (2) from rear A/C unit (3).

INSPECTION

Measure each terminal-to-terminal resistance.

If measured resistance is incorrect, replace rear blower motor

resistor (1).

Rear blower motor resister resistance

Mo-L : Approx. 2.4

Ω

ΩΩ Ω

Mo-ML : Approx. 1.2

Ω

ΩΩ Ω

Mo-MH : Approx. 0.6

Ω

ΩΩ Ω

INSTALLATION

Reverse removal procedure to install rear blower motor resistor.

TERMINAL

POSITION

ON

OFFabcde

1

2

3

Mo

L

MH

1ML

Page 61 of 656

1B-36 AIR CONDITIONING (OPTIONAL)

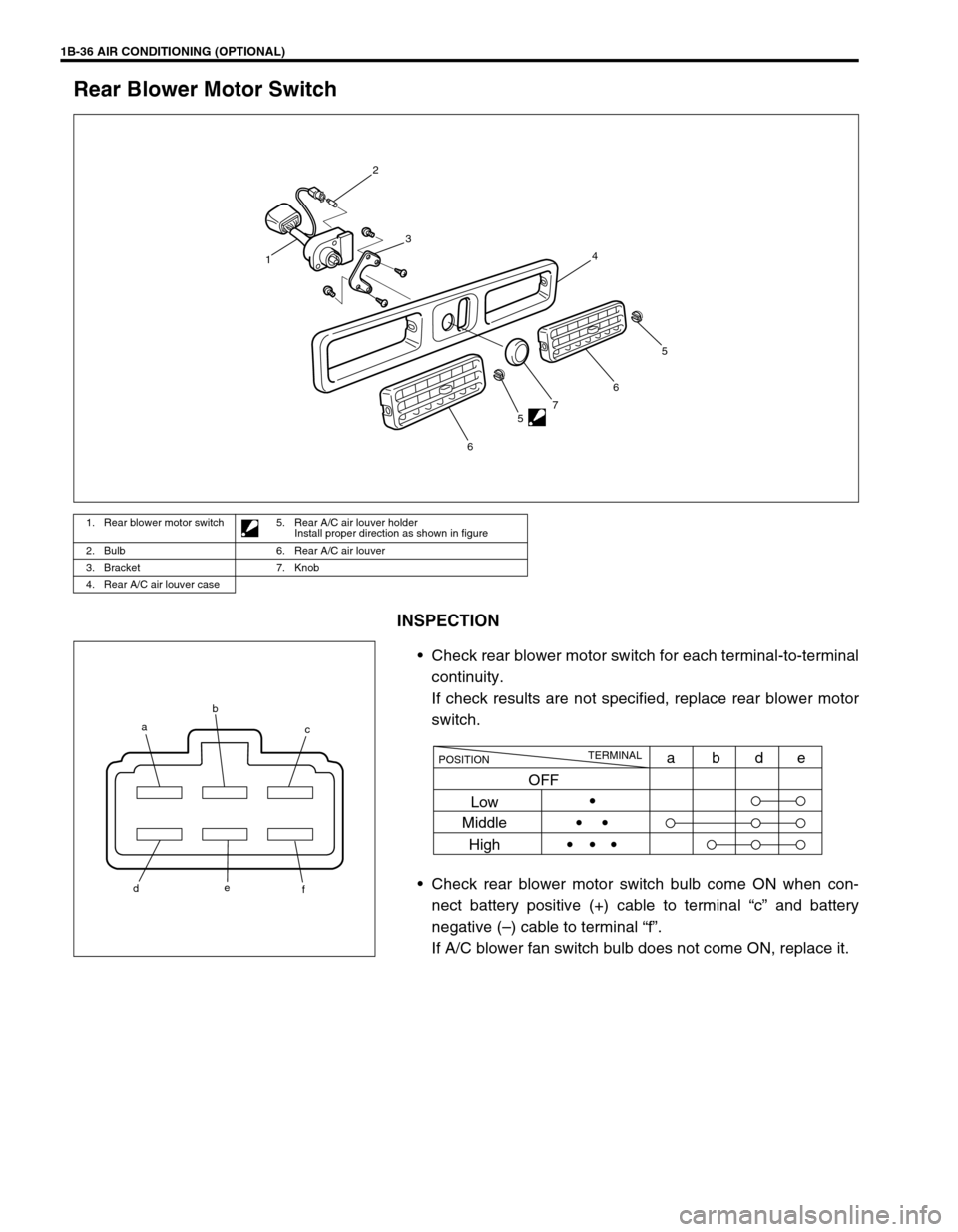

Rear Blower Motor Switch

INSPECTION

Check rear blower motor switch for each terminal-to-terminal

continuity.

If check results are not specified, replace rear blower motor

switch.

Check rear blower motor switch bulb come ON when con-

nect battery positive (+) cable to terminal “c” and battery

negative (–) cable to terminal “f”.

If A/C blower fan switch bulb does not come ON, replace it.

1. Rear blower motor switch 5. Rear A/C air louver holder

Install proper direction as shown in figure

2. Bulb 6. Rear A/C air louver

3. Bracket 7. Knob

4. Rear A/C air louver case

2

13

4

66

7

55

ab

f e

dc

TERMINAL

POSITION

Low

Middle

Highabde

OFF