Drive shift SUZUKI GRAND VITARA 2001 2.G User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2001, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2001 2.GPages: 656, PDF Size: 14.31 MB

Page 429 of 656

7B1-20 AUTOMATIC TRANSMISSION (4 A/T)

Table A-2 : No Gear Shift to O/D

SYSTEM DESCRIPTION

PCM does not shift to O/D gear under any of the following conditions.

•O/D off switch : ON

•4WD LOW switch : ON

•Cruise control module : O/D OFF command signal is output (if equipped).

•ECT : ECT < 30 °C (86 °F)

TROUBLESHOOTING

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 person, a driver and tester, on a level road.

Step Action Yes No

1Was “AUTOMATIC TRANSMISSION DIAG-

NOSTIC FLOW TABLE” performed?Go to Step 2. Go to “AUTOMATIC

TRANSMISSION DIAG-

NOSTIC FLOW TABLE” in

this section.

2 ECT check :

1) Warm up engine to normal operating tem-

perature.

2) Check ECT using scan tool.

Is ECT more than 30 °C (86 °F)?Go to Step 3. Faulty ECT sensor, its cir-

cuit or engine cooling sys-

tem.

If OK, substitute a known-

good PCM and recheck.

3 Perform running test under the following condi-

tions and check voltage between C51-1-2 termi-

nal of PCM coupler and ground, C51-1-1

terminal of PCM coupler and ground.

•O/D off switch OFF (“O/D OFF” lamp OFF).

•Normal mode in “D” range.

•Transfer “2H” position.

•Cruise control is not operated (if equipped).

•Drive vehicle with 4th gear condition refer-

ring to “Gear shift diagram” in this section.

Is each voltage about 0 V?Faulty shift solenoid valve,

its circuit or transmission“GRN” wire or “GRN/

RED” wire shorted to

power circuit.

If OK, go to Step 4.

4 O/D off switch signal inspection :

With ignition switch ON, check voltage between

E61-33 terminal of PCM coupler and ground.

“O/D” cut switch specification

“O/D” cut switch OFF : Battery voltage

“O/D” cut switch ON : 0 V

Is the result as specified?Go to Step 5. Faulty O/D off switch or its

circuit.

If OK, substitute a known-

good PCM and recheck.

Page 436 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-27

DTC CONFIRMATION PROCEDURE

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC, pending DTC and freeze frame data in PCM memory by using scan tool and start engine.

3) Shift A/T selector lever to each of L, 2, D, N, R and P ranges for 30 seconds each.

4) Increase vehicle speed to about 70 km/h (45 mile/h) in D range.

5) Keep driving above vehicle speed for 30 seconds.

6) Release accelerator pedal, decrease vehicle speed and stop vehicle.

7) Check DTC and/or pending DTC.

TROUBLESHOOTING

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Step Action Yes No

1Was “A/T DIAGNOSTIC FLOW TABLE” in this section

performed?Go to Step 2. Go to “A/T DIAGNOS-

TIC FLOW TABLE” in

this section.

2 Do you have SUZUKI scan tool? Go to Step 3. Go to Step 4.

3 Check Transmission range switch (sensor) circuit for

operation.

Check by using SUZUKI scan tool :

1) Connect SUZUKI scan tool to DLC with ignition

switch OFF.

2) Turn ignition switch ON and check transmission

range signal (P, R, N, D, 2 or L) on display when

shifting select lever to each range.

Is applicable range indicated?

Are check results satisfactory?Intermittent trouble.

Check for intermittent

referring to “INTER-

MITTENT AND POOR

CONNECTION” in

Section 0A.Go to Step 5.

4 Check Transmission range switch (sensor) circuit for

operation.

Check by not using SUZUKI scan tool :

1) Turn ignition switch ON.

2) Check voltage at terminals C51-1-6, C51-1-7,

C51-1-18, C51-1-19, C51-1-27 and C51-1-28

respectively with select lever shifted to each

range.

Taking terminal C51-1-28 as an example, is battery

voltage indicated only when select lever is shifted to

“2” range and 0 V for other ranges as shown in figure?

Check voltage at other terminals likewise, referring to

figure.

Are check results satisfactory?Intermittent trouble.

Check for intermittent

referring to “INTER-

MITTENT AND POOR

CONNECTION” in

Section 0A.Go to Step 5.

5 Check select cable for adjustment referring to

“SELECT CABLE ADJUSTMENT” in this section.

Is it adjusted correctly?Go to Step 6. Adjust.

Page 439 of 656

7B1-30 AUTOMATIC TRANSMISSION (4 A/T)

DTC CONFIRMATION PROCEDURE

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC, pending DTC and freeze frame data by using scan tool.

3) Start engine and turn O/D cut switch ON.

4) Shift select lever to D range and start vehicle.

5) Keep vehicle speed at higher than 10 km/h (7 mile/h) with 1st gear in D range for 2 sec. or more.

6) Increase vehicle speed and keep it at higher than 20 km/h (13 mile/h) with 2nd gear in D range for 2 sec. or

more.

7) Increase vehicle speed and keep it at higher than 30 km/h (20 mile/h) with 3rd gear in D range for 2 sec. or

more.

8) Stop vehicle.

9) Check DTC and/or pending DTC.

TROUBLESHOOTING

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Step Action Yes No

1Was “A/T DIAGNOSTIC FLOW TABLE” in this

section performed?Go to Step 2. Go to “A/T DIAGNOSTIC

FLOW TABLE” in this sec-

tion.

2 Input shaft speed sensor circuit check :

1) Remove PCM cover.

2) With ignition switch OFF, disconnect PCM

connectors.

3) Check for proper connection to input shaft

speed sensor at C51-1-10 and C51-1-11

terminals.

4) If OK, check resistance of sensor circuit.

Input shaft speed sensor resistance :

Resistance between C51-1-10 and C51-1-11

530 – 650 Ω

ΩΩ Ω (at 20 °C (68 °F))

Resistance between C51-1-10/C51-1-11 and

ground :

1 MΩ

ΩΩ Ω or more

Are check results satisfactory?Go to Step 4. Go to Step 3.

3 Input shaft speed sensor check :

1) With ignition switch OFF, disconnect input

shaft speed sensor connector.

2) Check for proper connection to input shaft

speed sensor at each terminals.

3) If OK, then check resistance of input shaft

speed sensor.

Are measured values as specified in Step 2?“BLU/GRN” or “BLU/YEL”

wire open or shorted to

ground.Replace input shaft speed

sensor.

Page 441 of 656

7B1-32 AUTOMATIC TRANSMISSION (4 A/T)

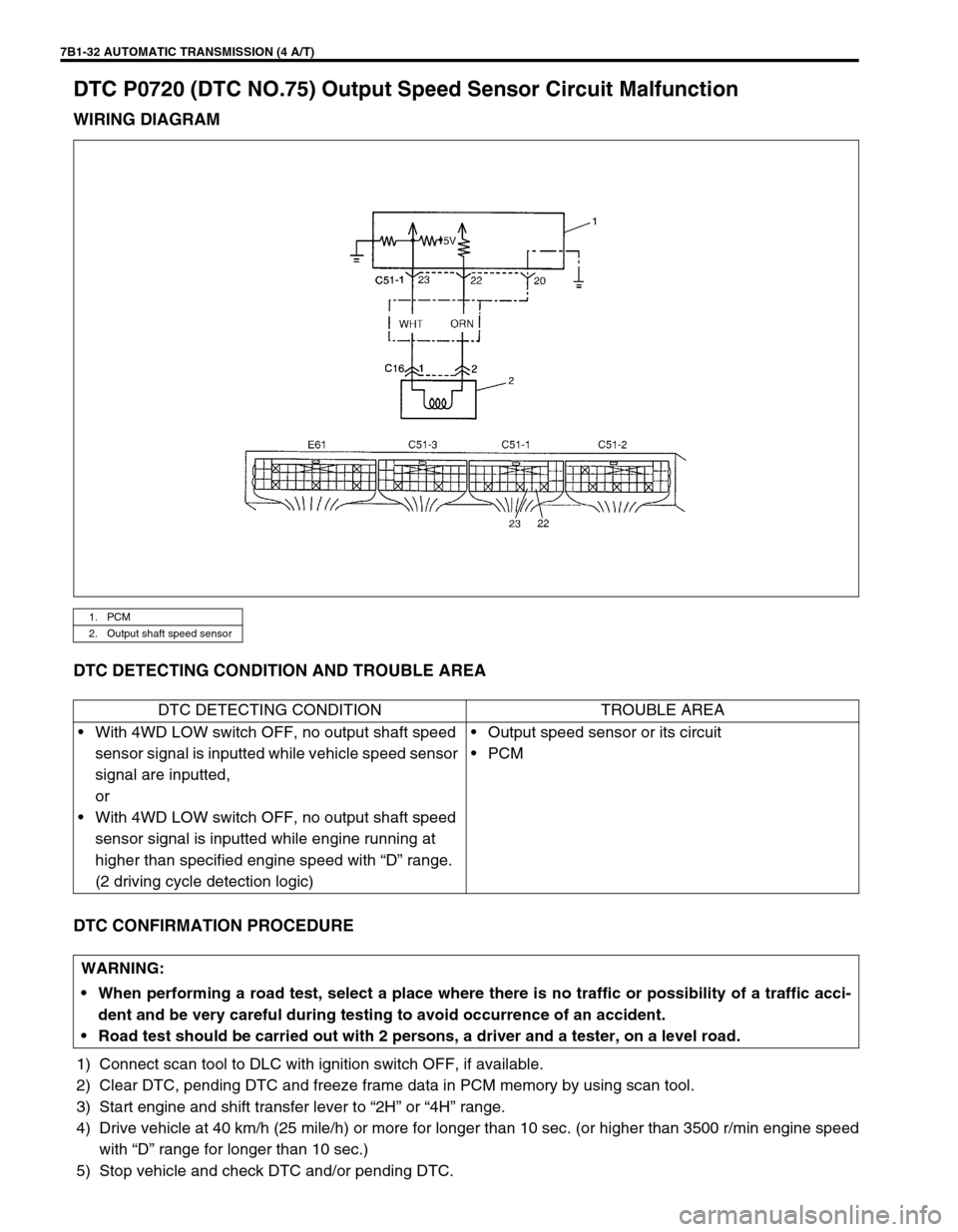

DTC P0720 (DTC NO.75) Output Speed Sensor Circuit Malfunction

WIRING DIAGRAM

DTC DETECTING CONDITION AND TROUBLE AREA

DTC CONFIRMATION PROCEDURE

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC, pending DTC and freeze frame data in PCM memory by using scan tool.

3) Start engine and shift transfer lever to “2H” or “4H” range.

4) Drive vehicle at 40 km/h (25 mile/h) or more for longer than 10 sec. (or higher than 3500 r/min engine speed

with “D” range for longer than 10 sec.)

5) Stop vehicle and check DTC and/or pending DTC.

1. PCM

2. Output shaft speed sensor

DTC DETECTING CONDITION TROUBLE AREA

•With 4WD LOW switch OFF, no output shaft speed

sensor signal is inputted while vehicle speed sensor

signal are inputted,

or

•With 4WD LOW switch OFF, no output shaft speed

sensor signal is inputted while engine running at

higher than specified engine speed with “D” range.

(2 driving cycle detection logic)•Output speed sensor or its circuit

•PCM

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Page 444 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-35

DTC CONFIRMATION PROCEDURE

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC, pending DTC and freeze frame data in PCM memory by using scan tool.

3) Start engine, warm it up to normal operating temperature and shift transfer lever to “2H” or “4H” range.

4) Shift selector lever in D range and keep it there for 10 seconds.

5) Increase vehicle speed to about 80 km/h (50 mile/h) in 4th gear and in D range.

6) Keep driving at above speed for 20 seconds.

7) Release accelerator pedal, decrease vehicle speed and stop vehicle.

8) Check DTC and/or pending DTC.

TROUBLESHOOTING

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Step Action Yes No

1Was “A/T DIAGNOSTIC FLOW TABLE” in this

section performed?Go to Step 2. Go to “A/T DIAGNOSTIC

FLOW TABLE” in this sec-

tion.

2 Check TCC solenoid circuit for short.

1) Turn ignition switch OFF and disconnect

PCM connectors.

2) Check for proper connection to PCM at ter-

minal C51-1-8.

3) If OK, then turn ignition switch ON and mea-

sure voltage between terminal C51-1-8 of

disconnected PCM connector and ground.

Is it about 0 V?Go to Step 3.“GRN/YEL” circuit shorted

to power circuit.

3 Check TCC solenoid circuit for open or short.

1) Turn ignition switch OFF.

2) Measure resistance between terminal C51-

1-8 of disconnected PCM connector and

ground.

Is it 11 – 15 Ω (at 20 °C (68 °F))?Intermittent trouble or

faulty PCM.

Check for intermittent

referring to “INTERMIT-

TENT AND POOR CON-

NECTION” in Section 0A.“GRN/YEL” circuit open or

shorted to ground.

If wire and connections

are OK, replace TCC

solenoid.

Page 446 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-37

DTC CONFIRMATION PROCEDURE

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC, pending DTC and freeze frame data in PCM memory by using scan tool.

3) Start engine and shift transfer lever to “2H” or “4H” range.

4) Shift selector lever in D range and keep it for 10 seconds.

5) Drive vehicle about 30 km/h (20 mile/h) with 2nd gear in “D” range for 10 seconds.

6) Increase vehicle speed to about 80 km/h (50 mile/h) with 4th gear in D range and keep it for 10 seconds.

7) Release accelerator pedal, decrease vehicle speed and stop vehicle.

8) Check DTC and/or pending DTC.

TROUBLESHOOTING

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Step Action Yes No

1Was “A/T DIAGNOSTIC FLOW TABLE” in this

section performed?Go to Step 2. Go to “A/T DIAGNOSTIC

FLOW TABLE” in this sec-

tion.

2 Check shift solenoid circuit for short.

1) Turn ignition switch OFF and disconnect

PCM connectors.

2) Check for proper connection to PCM at ter-

minals C51-1-2 or C51-1-1.

3) If OK, then turn ignition switch ON and mea-

sure voltage between terminal C51-1-2 or

C51-1-1 of disconnected PCM connector

and ground.

Is it about 0 V?Go to Step 3.“GRN” or “GRN/RED“ cir-

cuit shorted to power cir-

cuit.

3 Check shift solenoid circuit for open or short.

1) Turn ignition switch OFF.

2) Measure resistance between terminal C51-

1-2 or C51-1-1 of disconnected PCM con-

nector and ground.

Is it 11 – 15 Ω (at 20 °C (68 °F))?Intermittent trouble or

faulty PCM.

Check for intermittent

referring to “INTERMIT-

TENT AND POOR CON-

NECTION” in Section 0A.“GRN” or “GRN/RED“ cir-

cuit open or shorted to

ground.

If wire and connections

are OK, replace malfunc-

tion shift solenoid.

Page 449 of 656

7B1-40 AUTOMATIC TRANSMISSION (4 A/T)

TROUBLESHOOTING

Road Test

This test is to check if upshift and downshift take place at specified speed while actually driving vehicle on a

level road.

1) Warm up engine.

2) With engine running at idle, shift select lever “D”.

3) Accelerate vehicle speed by depressing accelerator pedal gradually.

4) While driving in “D” range, check if gear shift occurs properly as shown in “GEAR SHIFT DIAGRAM” in this

section.

TROUBLESHOOTING

Condition Possible cause

Line pressure higher than standard level in each

range•Malfunctioning regulator valve

•Malfunctioning throttle valve

•Maladjusted A/T throttle cable

Line pressure lower than standard level in each

range•Defective O/D clutch

•Defective oil pump

•Malfunctioning throttle valve

•Malfunctioning regulator value

•Maladjusted A/T throttle cable

Line pressure lower than standard level only in

“D” range•Fluid leakage from forward clutch

•Defective O/D clutch

•Leakage from “D” range fluid pressure circuit

Line pressure lower than standard level only in

“R” range•Fluid leakage from direct clutch

•Defective O/D clutch

•Fluid leakage from reverse brake

•Fluid leakage from “R” range fluid circuit

WARNING:

Carry out test in very little traffic area to prevent an accident.

Test requires 2 persons, a driver and a tester.

Condition Possible cause

When 1 → 2 upshift fails to occur 1–2 shift valve stuck

When 2 → 3 upshift fails to occur 2–3 shift valve stuck

When 3 → O/D upshift fails to occur 3–4 shift valve stuck

When gear shift point is incorrect•Maladjusted throttle cable

•Defective shift solenoid valve -A or -B

•1–2, 2–3 or 3–4 shift valve not operating properly

Page 450 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-41

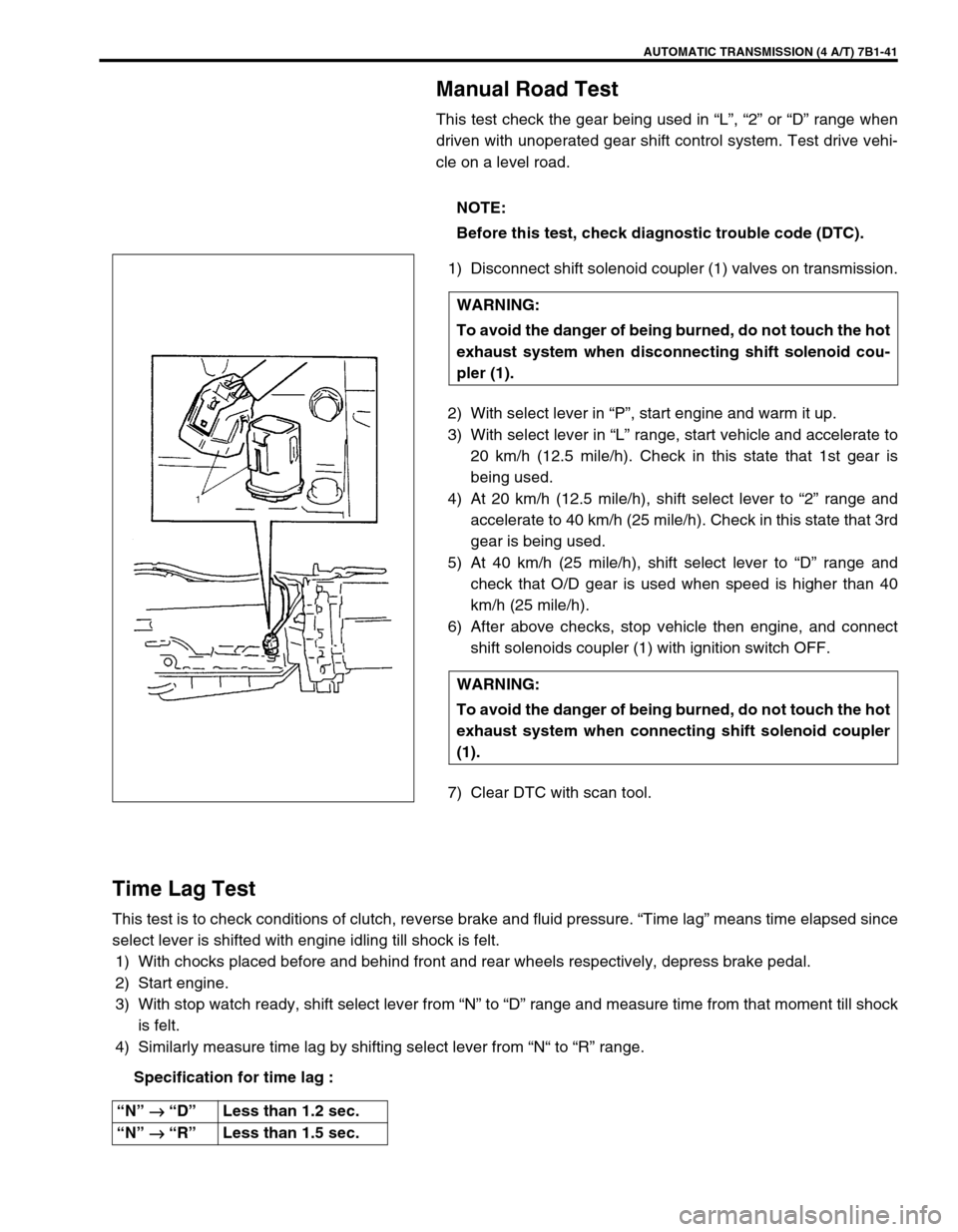

Manual Road Test

This test check the gear being used in “L”, “2” or “D” range when

driven with unoperated gear shift control system. Test drive vehi-

cle on a level road.

1) Disconnect shift solenoid coupler (1) valves on transmission.

2) With select lever in “P”, start engine and warm it up.

3) With select lever in “L” range, start vehicle and accelerate to

20 km/h (12.5 mile/h). Check in this state that 1st gear is

being used.

4) At 20 km/h (12.5 mile/h), shift select lever to “2” range and

accelerate to 40 km/h (25 mile/h). Check in this state that 3rd

gear is being used.

5) At 40 km/h (25 mile/h), shift select lever to “D” range and

check that O/D gear is used when speed is higher than 40

km/h (25 mile/h).

6) After above checks, stop vehicle then engine, and connect

shift solenoids coupler (1) with ignition switch OFF.

7) Clear DTC with scan tool.

Time Lag Test

This test is to check conditions of clutch, reverse brake and fluid pressure. “Time lag” means time elapsed since

select lever is shifted with engine idling till shock is felt.

1) With chocks placed before and behind front and rear wheels respectively, depress brake pedal.

2) Start engine.

3) With stop watch ready, shift select lever from “N” to “D” range and measure time from that moment till shock

is felt.

4) Similarly measure time lag by shifting select lever from “N“ to “R” range.

Specification for time lag :NOTE:

Before this test, check diagnostic trouble code (DTC).

WARNING:

To avoid the danger of being burned, do not touch the hot

exhaust system when disconnecting shift solenoid cou-

pler (1).

WARNING:

To avoid the danger of being burned, do not touch the hot

exhaust system when connecting shift solenoid coupler

(1).

“N” →

→→ → “D”Less than 1.2 sec.

“N” →

→→ → “R”Less than 1.5 sec.

Page 452 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-43

On-Vehicle Service

Maintenance Service

Fluid level

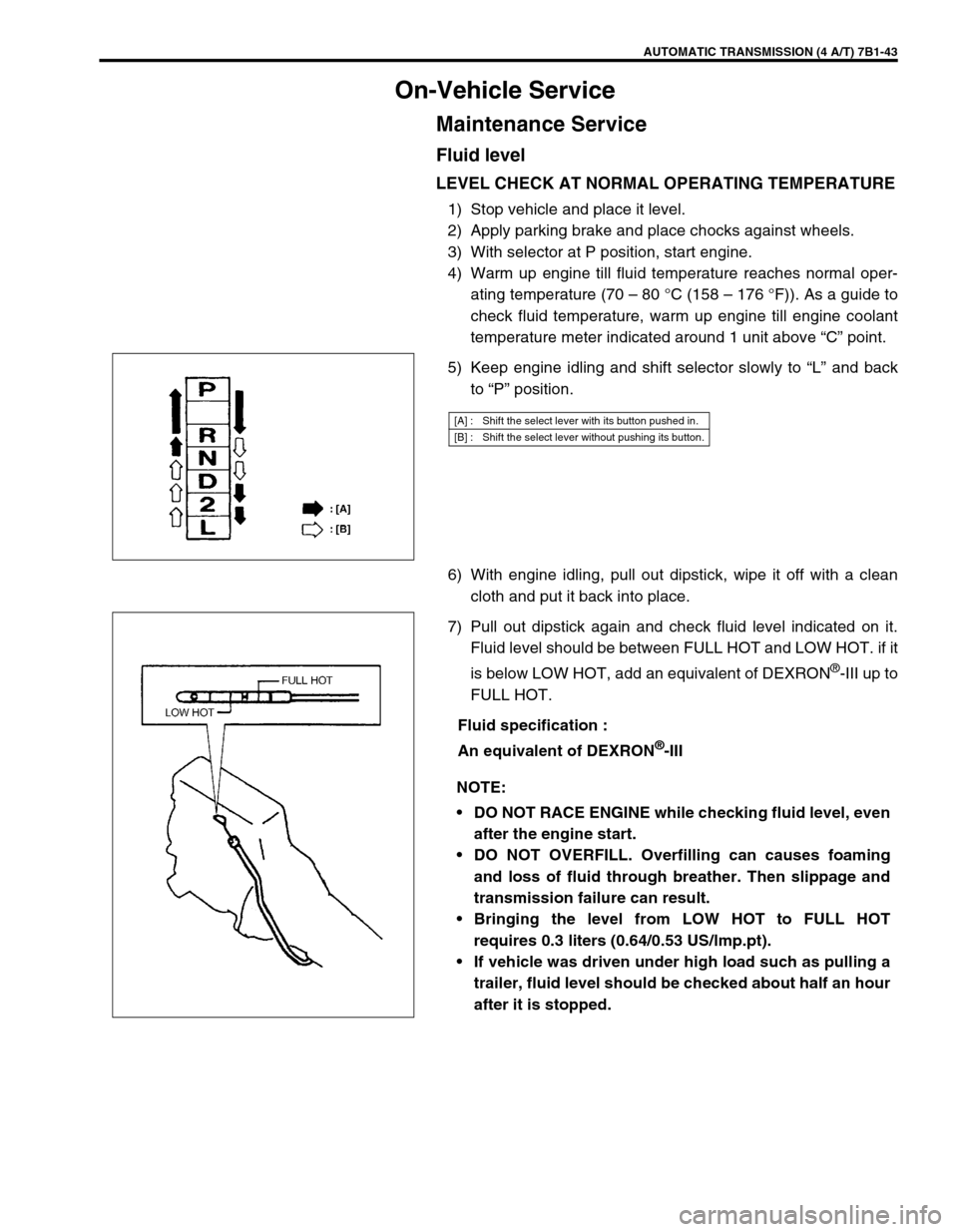

LEVEL CHECK AT NORMAL OPERATING TEMPERATURE

1) Stop vehicle and place it level.

2) Apply parking brake and place chocks against wheels.

3) With selector at P position, start engine.

4) Warm up engine till fluid temperature reaches normal oper-

ating temperature (70 – 80 °C (158 – 176 °F)). As a guide to

check fluid temperature, warm up engine till engine coolant

temperature meter indicated around 1 unit above “C” point.

5) Keep engine idling and shift selector slowly to “L” and back

to “P” position.

6) With engine idling, pull out dipstick, wipe it off with a clean

cloth and put it back into place.

7) Pull out dipstick again and check fluid level indicated on it.

Fluid level should be between FULL HOT and LOW HOT. if it

is below LOW HOT, add an equivalent of DEXRON

®-III up to

FULL HOT.

Fluid specification :

An equivalent of DEXRON

®-III

[A] : Shift the select lever with its button pushed in.

[B] : Shift the select lever without pushing its button.

NOTE:

DO NOT RACE ENGINE while checking fluid level, even

after the engine start.

DO NOT OVERFILL. Overfilling can causes foaming

and loss of fluid through breather. Then slippage and

transmission failure can result.

Bringing the level from LOW HOT to FULL HOT

requires 0.3 liters (0.64/0.53 US/lmp.pt).

If vehicle was driven under high load such as pulling a

trailer, fluid level should be checked about half an hour

after it is stopped.

Page 455 of 656

7B1-46 AUTOMATIC TRANSMISSION (4 A/T)

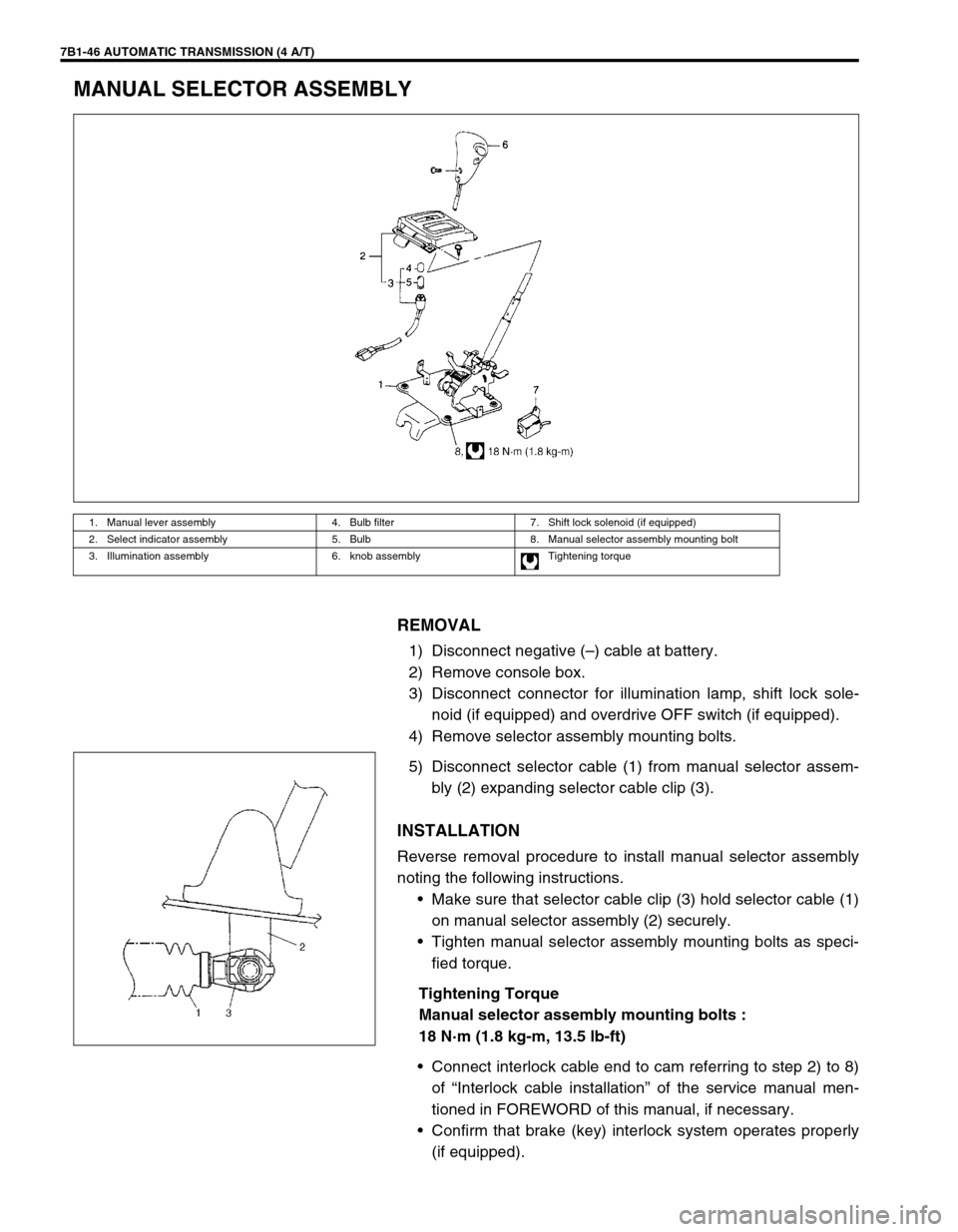

MANUAL SELECTOR ASSEMBLY

REMOVAL

1) Disconnect negative (–) cable at battery.

2) Remove console box.

3) Disconnect connector for illumination lamp, shift lock sole-

noid (if equipped) and overdrive OFF switch (if equipped).

4) Remove selector assembly mounting bolts.

5) Disconnect selector cable (1) from manual selector assem-

bly (2) expanding selector cable clip (3).

INSTALLATION

Reverse removal procedure to install manual selector assembly

noting the following instructions.

•Make sure that selector cable clip (3) hold selector cable (1)

on manual selector assembly (2) securely.

•Tighten manual selector assembly mounting bolts as speci-

fied torque.

Tightening Torque

Manual selector assembly mounting bolts :

18 N·m (1.8 kg-m, 13.5 lb-ft)

•Connect interlock cable end to cam referring to step 2) to 8)

of “Interlock cable installation” of the service manual men-

tioned in FOREWORD of this manual, if necessary.

•Confirm that brake (key) interlock system operates properly

(if equipped).

1. Manual lever assembly 4. Bulb filter 7. Shift lock solenoid (if equipped)

2. Select indicator assembly 5. Bulb 8. Manual selector assembly mounting bolt

3. Illumination assembly 6. knob assembly Tightening torque