Drive shift SUZUKI GRAND VITARA 2001 2.G Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2001, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2001 2.GPages: 656, PDF Size: 14.31 MB

Page 87 of 656

3C1-12 AIR BAG STEERING WHEEL AND COLUMN

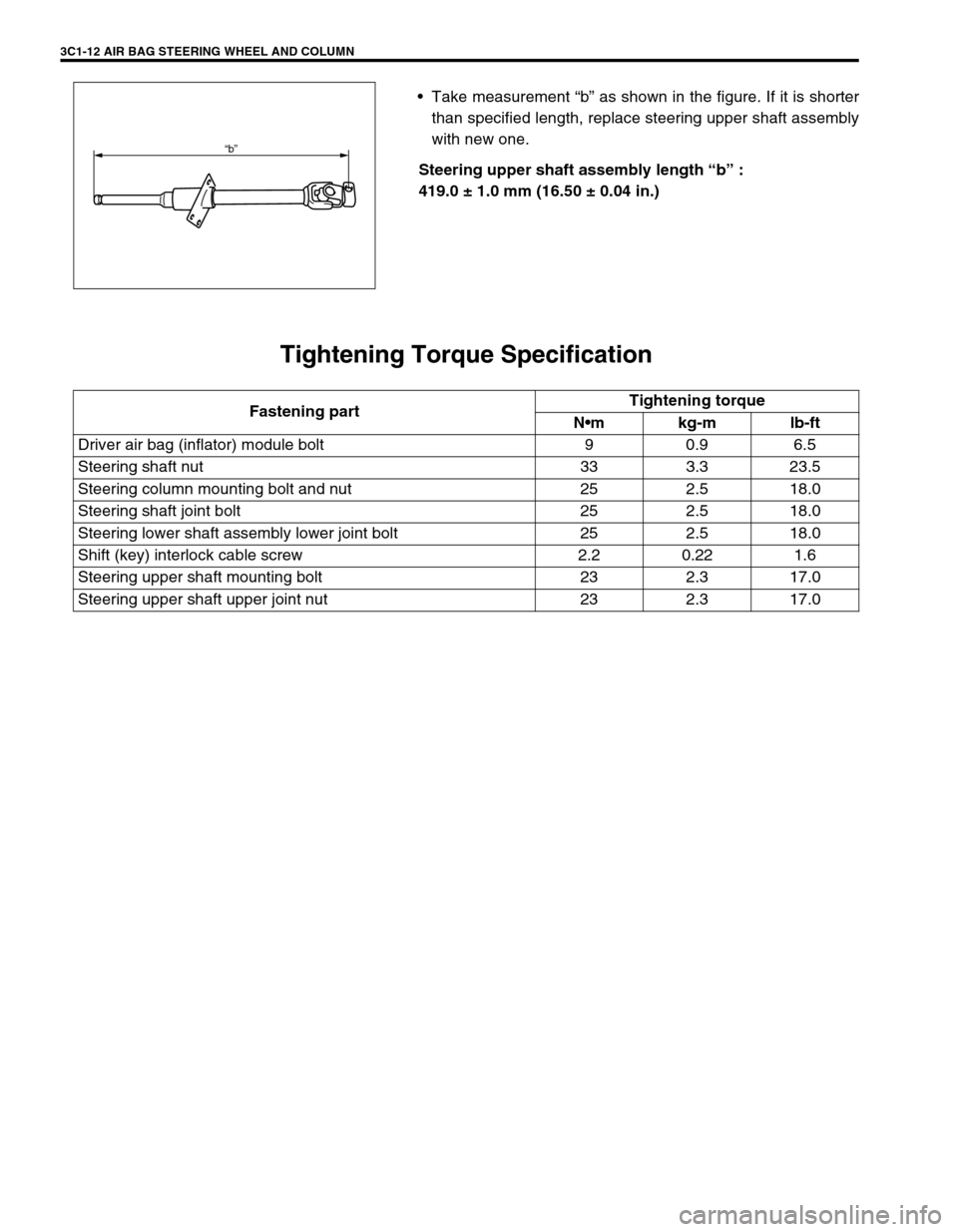

Take measurement “b” as shown in the figure. If it is shorter

than specified length, replace steering upper shaft assembly

with new one.

Steering upper shaft assembly length “b” :

419.0 ± 1.0 mm (16.50 ± 0.04 in.)

Tightening Torque Specification

“b”

Fastening partTightening torque

Nm kg-m lb-ft

Driver air bag (inflator) module bolt 9 0.9 6.5

Steering shaft nut 33 3.3 23.5

Steering column mounting bolt and nut 25 2.5 18.0

Steering shaft joint bolt 25 2.5 18.0

Steering lower shaft assembly lower joint bolt 25 2.5 18.0

Shift (key) interlock cable screw 2.2 0.22 1.6

Steering upper shaft mounting bolt 23 2.3 17.0

Steering upper shaft upper joint nut 23 2.3 17.0

Page 166 of 656

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-5

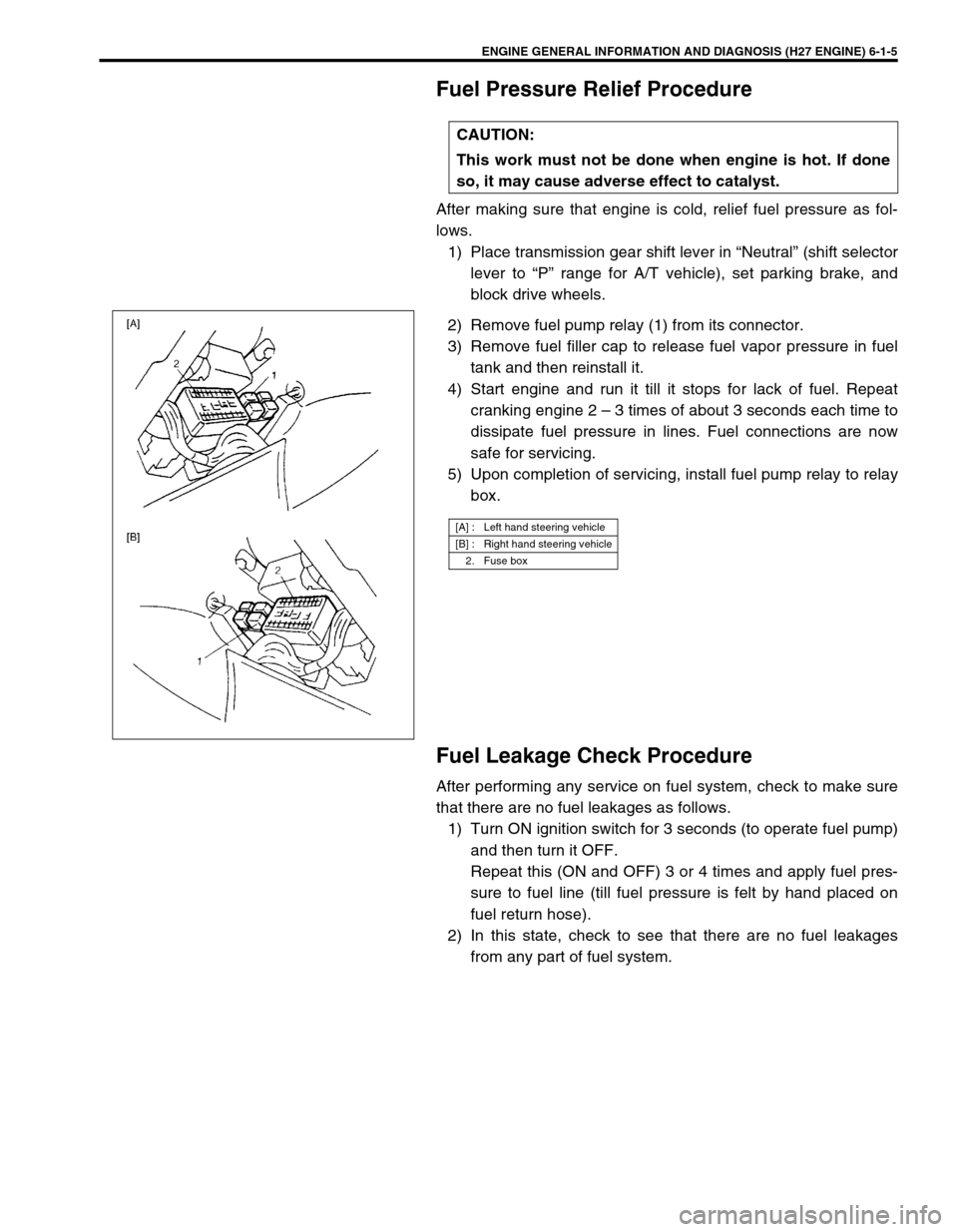

Fuel Pressure Relief Procedure

After making sure that engine is cold, relief fuel pressure as fol-

lows.

1) Place transmission gear shift lever in “Neutral” (shift selector

lever to “P” range for A/T vehicle), set parking brake, and

block drive wheels.

2) Remove fuel pump relay (1) from its connector.

3) Remove fuel filler cap to release fuel vapor pressure in fuel

tank and then reinstall it.

4) Start engine and run it till it stops for lack of fuel. Repeat

cranking engine 2 – 3 times of about 3 seconds each time to

dissipate fuel pressure in lines. Fuel connections are now

safe for servicing.

5) Upon completion of servicing, install fuel pump relay to relay

box.

Fuel Leakage Check Procedure

After performing any service on fuel system, check to make sure

that there are no fuel leakages as follows.

1) Turn ON ignition switch for 3 seconds (to operate fuel pump)

and then turn it OFF.

Repeat this (ON and OFF) 3 or 4 times and apply fuel pres-

sure to fuel line (till fuel pressure is felt by hand placed on

fuel return hose).

2) In this state, check to see that there are no fuel leakages

from any part of fuel system. CAUTION:

This work must not be done when engine is hot. If done

so, it may cause adverse effect to catalyst.

[A] : Left hand steering vehicle

[B] : Right hand steering vehicle

2. Fuse box

Page 184 of 656

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-23

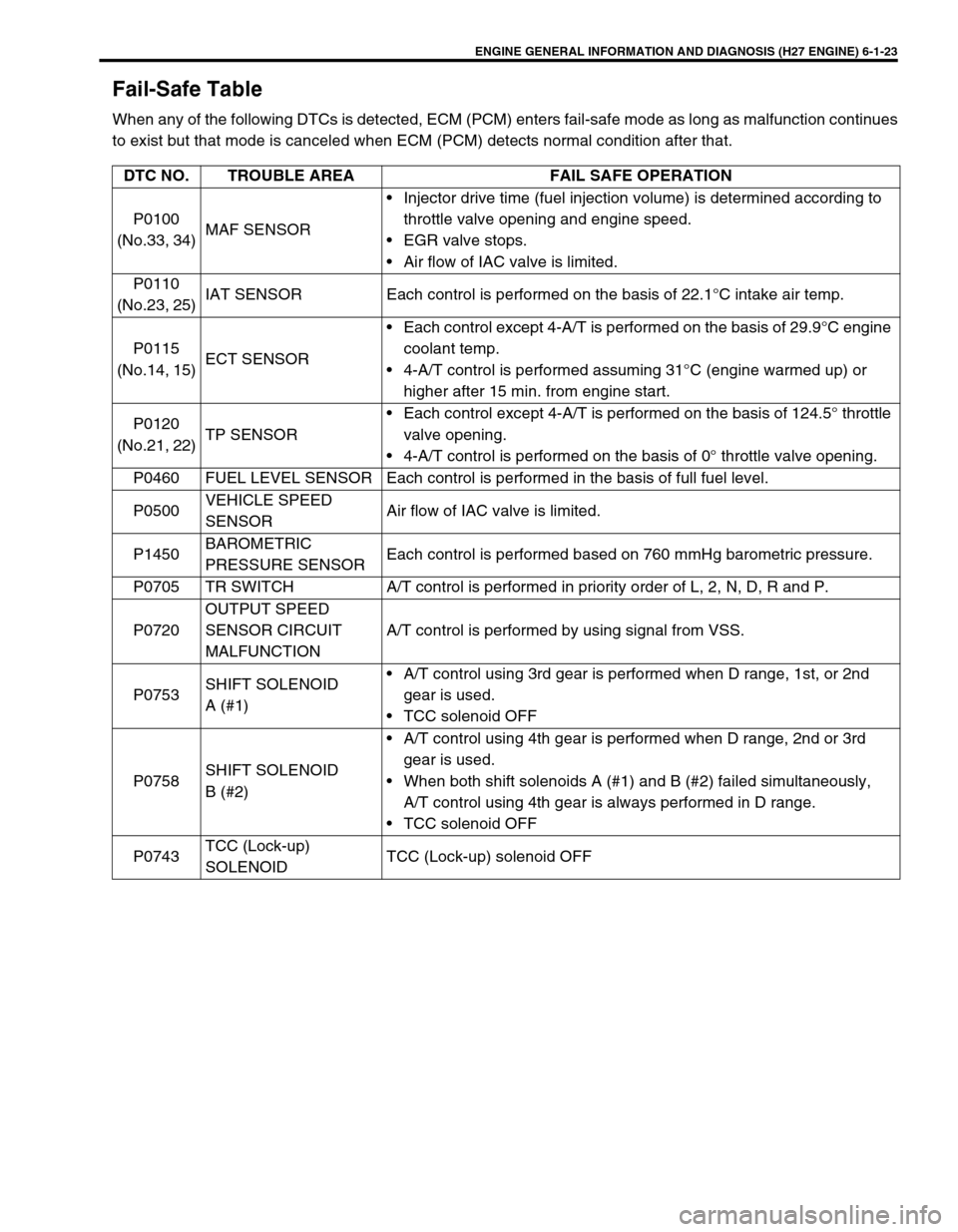

Fail-Safe Table

When any of the following DTCs is detected, ECM (PCM) enters fail-safe mode as long as malfunction continues

to exist but that mode is canceled when ECM (PCM) detects normal condition after that.

DTC NO. TROUBLE AREA FAIL SAFE OPERATION

P0100

(No.33, 34)MAF SENSOR• Injector drive time (fuel injection volume) is determined according to

throttle valve opening and engine speed.

• EGR valve stops.

• Air flow of IAC valve is limited.

P0110

(No.23, 25)IAT SENSOR Each control is performed on the basis of 22.1°C intake air temp.

P0115

(No.14, 15)ECT SENSOR• Each control except 4-A/T is performed on the basis of 29.9°C engine

coolant temp.

• 4-A/T control is performed assuming 31°C (engine warmed up) or

higher after 15 min. from engine start.

P0120

(No.21, 22)TP SENSOR• Each control except 4-A/T is performed on the basis of 124.5° throttle

valve opening.

• 4-A/T control is performed on the basis of 0° throttle valve opening.

P0460 FUEL LEVEL SENSOR Each control is performed in the basis of full fuel level.

P0500VEHICLE SPEED

SENSORAir flow of IAC valve is limited.

P1450BAROMETRIC

PRESSURE SENSOREach control is performed based on 760 mmHg barometric pressure.

P0705 TR SWITCH A/T control is performed in priority order of L, 2, N, D, R and P.

P0720OUTPUT SPEED

SENSOR CIRCUIT

MALFUNCTIONA/T control is performed by using signal from VSS.

P0753SHIFT SOLENOID

A (#1)• A/T control using 3rd gear is performed when D range, 1st, or 2nd

gear is used.

• TCC solenoid OFF

P0758SHIFT SOLENOID

B (#2)• A/T control using 4th gear is performed when D range, 2nd or 3rd

gear is used.

• When both shift solenoids A (#1) and B (#2) failed simultaneously,

A/T control using 4th gear is always performed in D range.

• TCC solenoid OFF

P0743TCC (Lock-up)

SOLENOIDTCC (Lock-up) solenoid OFF

Page 187 of 656

6-1-26 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

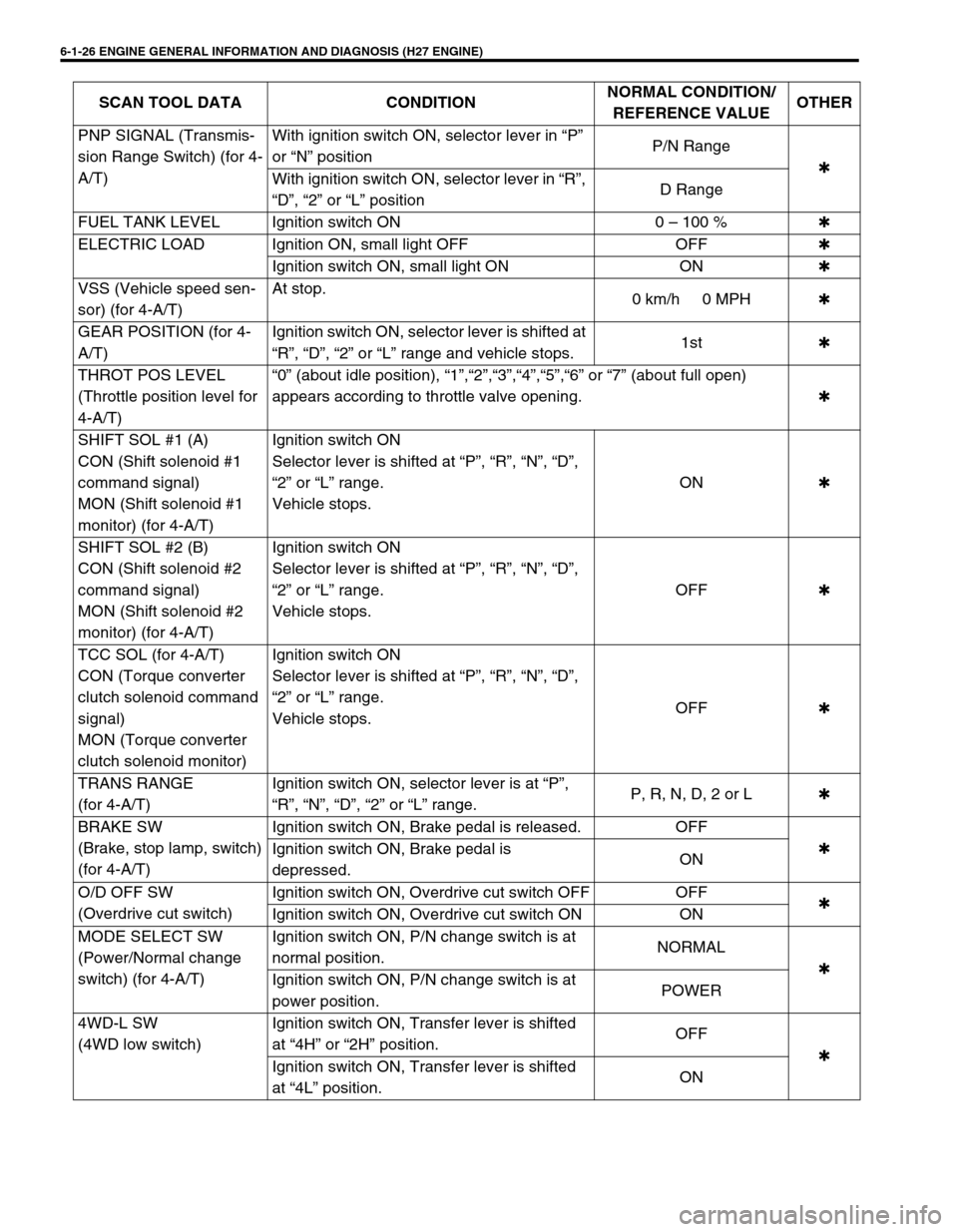

PNP SIGNAL (Transmis-

sion Range Switch) (for 4-

A/T)With ignition switch ON, selector lever in “P”

or “N” positionP/N Range

✱

With ignition switch ON, selector lever in “R”,

“D”, “2” or “L” positionD Range

FUEL TANK LEVEL Ignition switch ON 0 – 100 %✱

ELECTRIC LOAD Ignition ON, small light OFF OFF✱

Ignition switch ON, small light ON ON✱

VSS (Vehicle speed sen-

sor) (for 4-A/T)At stop.

0 km/h 0 MPH✱

GEAR POSITION (for 4-

A/T)Ignition switch ON, selector lever is shifted at

“R”, “D”, “2” or “L” range and vehicle stops.1st✱

THROT POS LEVEL

(Throttle position level for

4-A/T)“0” (about idle position), “1”,“2”,“3”,“4”,“5”,“6” or “7” (about full open)

appears according to throttle valve opening.✱

SHIFT SOL #1 (A)

CON (Shift solenoid #1

command signal)

MON (Shift solenoid #1

monitor) (for 4-A/T)Ignition switch ON

Selector lever is shifted at “P”, “R”, “N”, “D”,

“2” or “L” range.

Vehicle stops.ON✱

SHIFT SOL #2 (B)

CON (Shift solenoid #2

command signal)

MON (Shift solenoid #2

monitor) (for 4-A/T)Ignition switch ON

Selector lever is shifted at “P”, “R”, “N”, “D”,

“2” or “L” range.

Vehicle stops.OFF✱

TCC SOL (for 4-A/T)

CON (Torque converter

clutch solenoid command

signal)

MON (Torque converter

clutch solenoid monitor)Ignition switch ON

Selector lever is shifted at “P”, “R”, “N”, “D”,

“2” or “L” range.

Vehicle stops.OFF✱

TRANS RANGE

(for 4-A/T)Ignition switch ON, selector lever is at “P”,

“R”, “N”, “D”, “2” or “L” range.P, R, N, D, 2 or L✱

BRAKE SW

(Brake, stop lamp, switch)

(for 4-A/T)Ignition switch ON, Brake pedal is released. OFF

✱

Ignition switch ON, Brake pedal is

depressed.ON

O/D OFF SW

(Overdrive cut switch)Ignition switch ON, Overdrive cut switch OFF OFF

✱

Ignition switch ON, Overdrive cut switch ON ON

MODE SELECT SW

(Power/Normal change

switch) (for 4-A/T)Ignition switch ON, P/N change switch is at

normal position.NORMAL

✱

Ignition switch ON, P/N change switch is at

power position.POWER

4WD-L SW

(4WD low switch)Ignition switch ON, Transfer lever is shifted

at “4H” or “2H” position.OFF

✱

Ignition switch ON, Transfer lever is shifted

at “4L” position.ON SCAN TOOL DATA CONDITIONNORMAL CONDITION/

REFERENCE VALUEOTHER

Page 191 of 656

6-1-30 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

SHIFT SOL #2 CON/MON (Shift Solenoid #2, B Command/monitor, ON/OFF)

CON-ON : ON command being output to shift solenoid #2, B.

CON-OFF : ON command not being output.

MON-ON : Electricity being passed to shift solenoid #2, B.

MON-OFF : Electricity not being passed.

TCC SOL CON/MON (Torque Converter Clutch Solenoid Command/monitor, ON/OFF)

CON-ON : ON command being output to TCC solenoid.

CON-OFF : ON command not being output.

MON-ON : Electricity being passed to TCC solenoid.

MON-OFF : Electricity not being passed.

TRANS RANGE (Transmission Range, P, R, N, D, 2 or L)

It indicates transmission range according to transmission range switch signal.

BRAKE SW (Brake, Stop Lamp, Switch, ON/OFF)

OFF : Brake pedal is released.

ON : Brake pedal is depressed.

O/D OFF SW (Overdrive Cut Switch, ON/OFF)

OFF : Overdrive cut switch OFF.

ON : Overdrive cut switch ON.

MODE SELECT SW (Power/normal Change Switch, Power/normal)

POWER : Switch button is at POWER position.

NORMAL : Switch button is at NORMAL position.

4WD-L SW (4WD-LOW Switch, ON/OFF)

ON : Transfer lever is shifted to 4L position.

OFF : Transfer lever is shifted to 4H or 2H position.

Page 348 of 656

ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE) 6E2-15

Idle Speed/Idle Air Control (IAC) Duty Inspec-

tion

Before idle speed/IAC duty check, make sure of the following.

•Lead wires and hoses of engine/emission control systems

are connected securely.

•Accelerator cable is adjusted.

•Ignition timing is within specification.

•All accessories (wipers, heater, lights, A/C, etc.) are out of

service.

•Air cleaner has been properly installed and is in good condi-

tion.

•ECM (PCM) does not detect any malfunction DTC.

After above items are all confirmed, check idle speed and IAC

duty as follows.

[Using SUZUKI scan tool]

1) Connect SUZUKI scan tool to DLC with ignition switch OFF.

Special tool

(A) : SUZUKI scan tool

2) Warm up engine to normal operating temperature.

3) Check IAC duty and idle speed by using “Data List” mode of

SUZUKI scan tool.

Engine idle speed:

A/C OFF: 700 ± 50 r/min.

A/C ON: 750 ± 50 r/min.

IAC duty at specified idle speed:

5 – 40 % (at A/C OFF)

4) If duty and/or idle speed is out of specifications, check idle

air control system referring to “DIAG. FLOW TABLE B-4” in

Section 6-1.

5) Check that specified engine idle speed is obtained with A/C

ON if vehicle is equipped with A/C. If not, check A/C ON sig-

nal circuit and idle air control system. NOTE:

Before starting engine, place transmission gear shift

lever in “Neutral” (shift selector lever to “P” range for A/T

vehicle), and set parking brake and block drive wheels.

Page 411 of 656

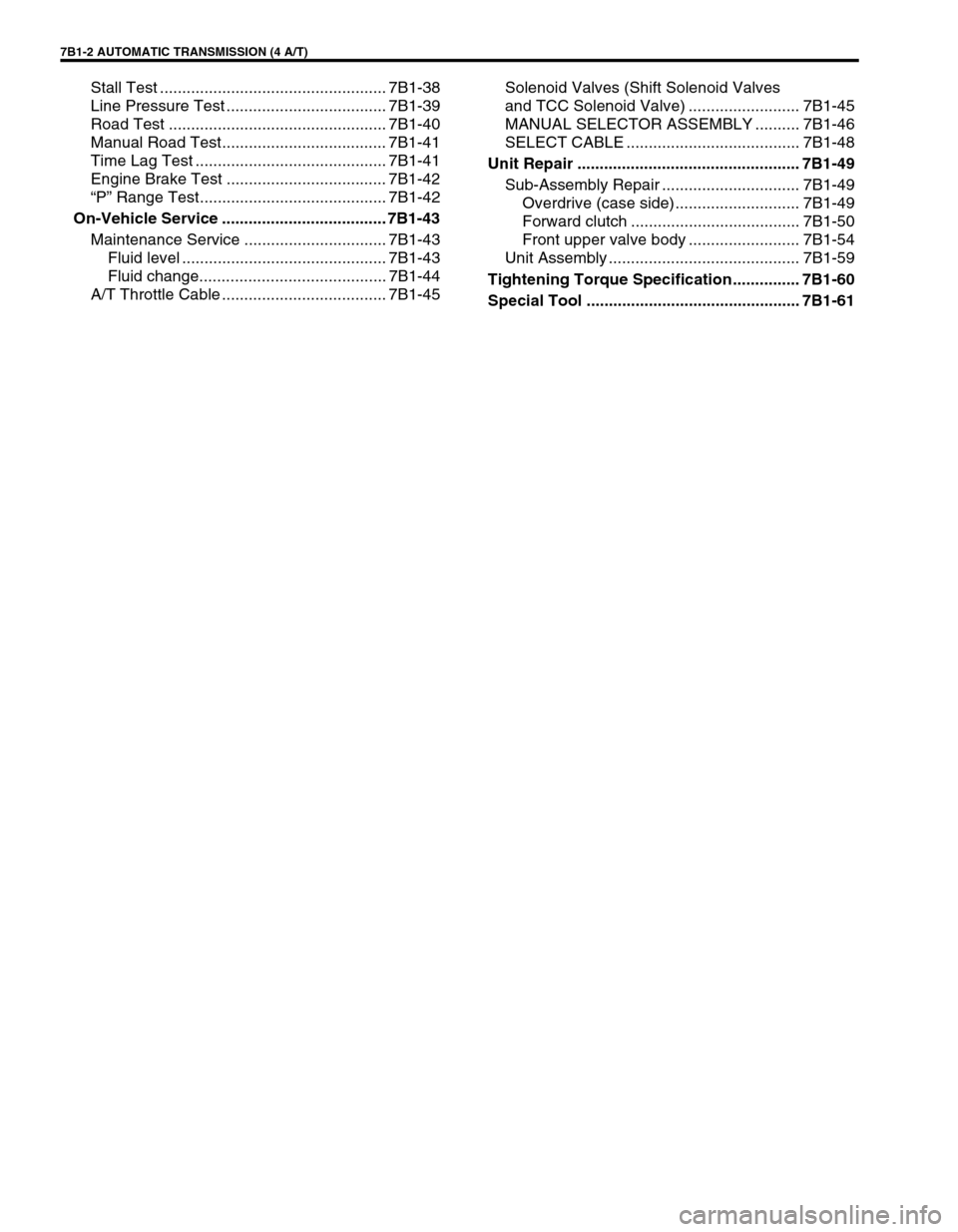

7B1-2 AUTOMATIC TRANSMISSION (4 A/T)

Stall Test ................................................... 7B1-38

Line Pressure Test .................................... 7B1-39

Road Test ................................................. 7B1-40

Manual Road Test..................................... 7B1-41

Time Lag Test ........................................... 7B1-41

Engine Brake Test .................................... 7B1-42

“P” Range Test.......................................... 7B1-42

On-Vehicle Service ..................................... 7B1-43

Maintenance Service ................................ 7B1-43

Fluid level .............................................. 7B1-43

Fluid change.......................................... 7B1-44

A/T Throttle Cable ..................................... 7B1-45Solenoid Valves (Shift Solenoid Valves

and TCC Solenoid Valve) ......................... 7B1-45

MANUAL SELECTOR ASSEMBLY .......... 7B1-46

SELECT CABLE ....................................... 7B1-48

Unit Repair .................................................. 7B1-49

Sub-Assembly Repair ............................... 7B1-49

Overdrive (case side) ............................ 7B1-49

Forward clutch ...................................... 7B1-50

Front upper valve body ......................... 7B1-54

Unit Assembly ........................................... 7B1-59

Tightening Torque Specification............... 7B1-60

Special Tool ................................................ 7B1-61

Page 412 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-3

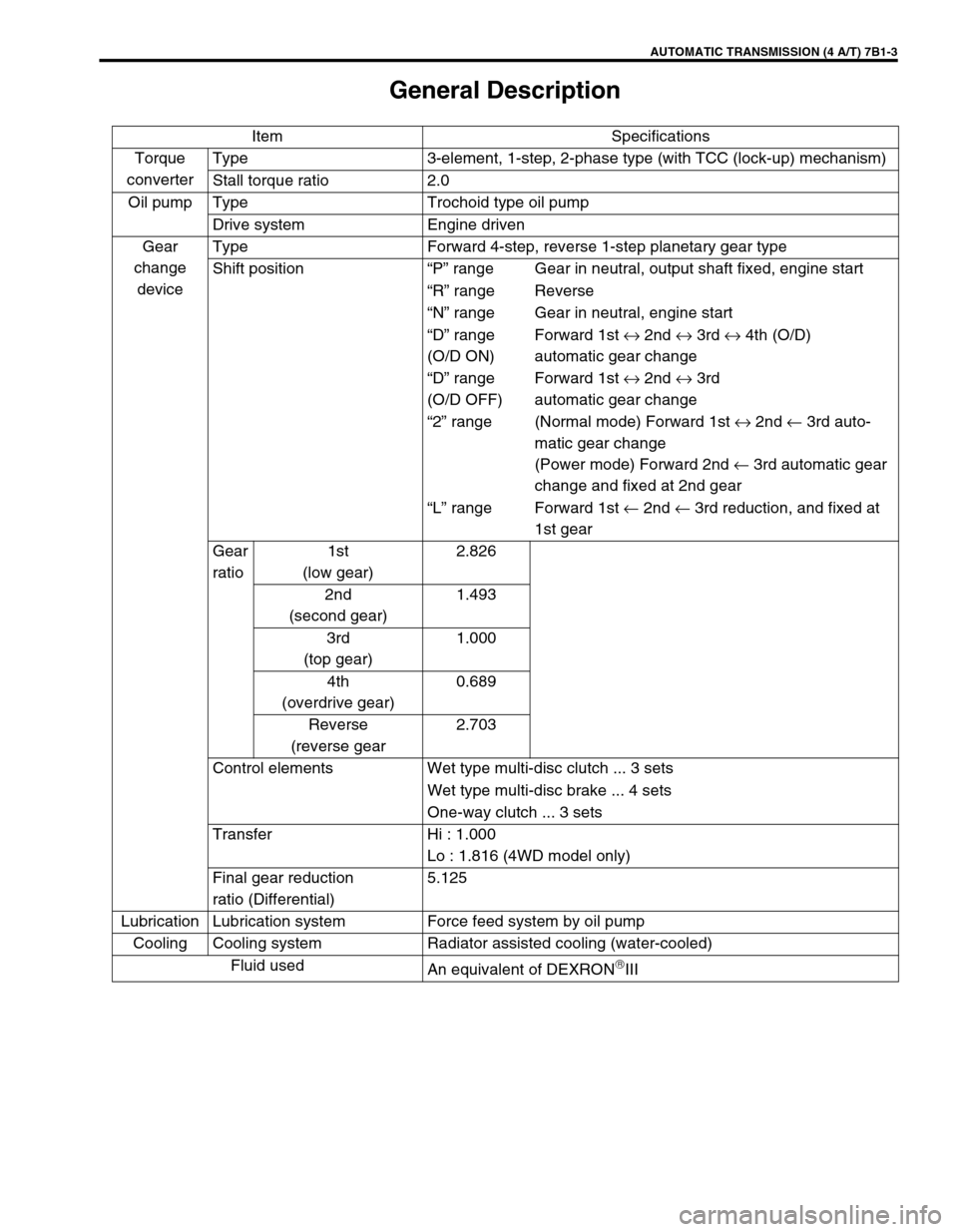

General Description

Item Specifications

Torque

converterType 3-element, 1-step, 2-phase type (with TCC (lock-up) mechanism)

Stall torque ratio 2.0

Oil pump Type Trochoid type oil pump

Drive system Engine driven

Gear

change

deviceType Forward 4-step, reverse 1-step planetary gear type

Shift position“P” range Gear in neutral, output shaft fixed, engine start

“R” range Reverse

“N” range Gear in neutral, engine start

“D” range

(O/D ON)Forward 1st ↔ 2nd ↔ 3rd ↔ 4th (O/D)

automatic gear change

“D” range

(O/D OFF)Forward 1st ↔ 2nd ↔ 3rd

automatic gear change

“2” range (Normal mode) Forward 1st ↔ 2nd ← 3rd auto-

matic gear change

(Power mode) Forward 2nd ← 3rd automatic gear

change and fixed at 2nd gear

“L” range Forward 1st ← 2nd ← 3rd reduction, and fixed at

1st gear

Gear

ratio1st

(low gear)2.826

2nd

(second gear)1.493

3rd

(top gear)1.000

4th

(overdrive gear)0.689

Reverse

(reverse gear2.703

Control elements Wet type multi-disc clutch ... 3 sets

Wet type multi-disc brake ... 4 sets

One-way clutch ... 3 sets

Transfer Hi : 1.000

Lo : 1.816 (4WD model only)

Final gear reduction

ratio (Differential)5.125

Lubrication Lubrication system Force feed system by oil pump

Cooling Cooling system Radiator assisted cooling (water-cooled)

Fluid used

An equivalent of DEXRON

III

Page 425 of 656

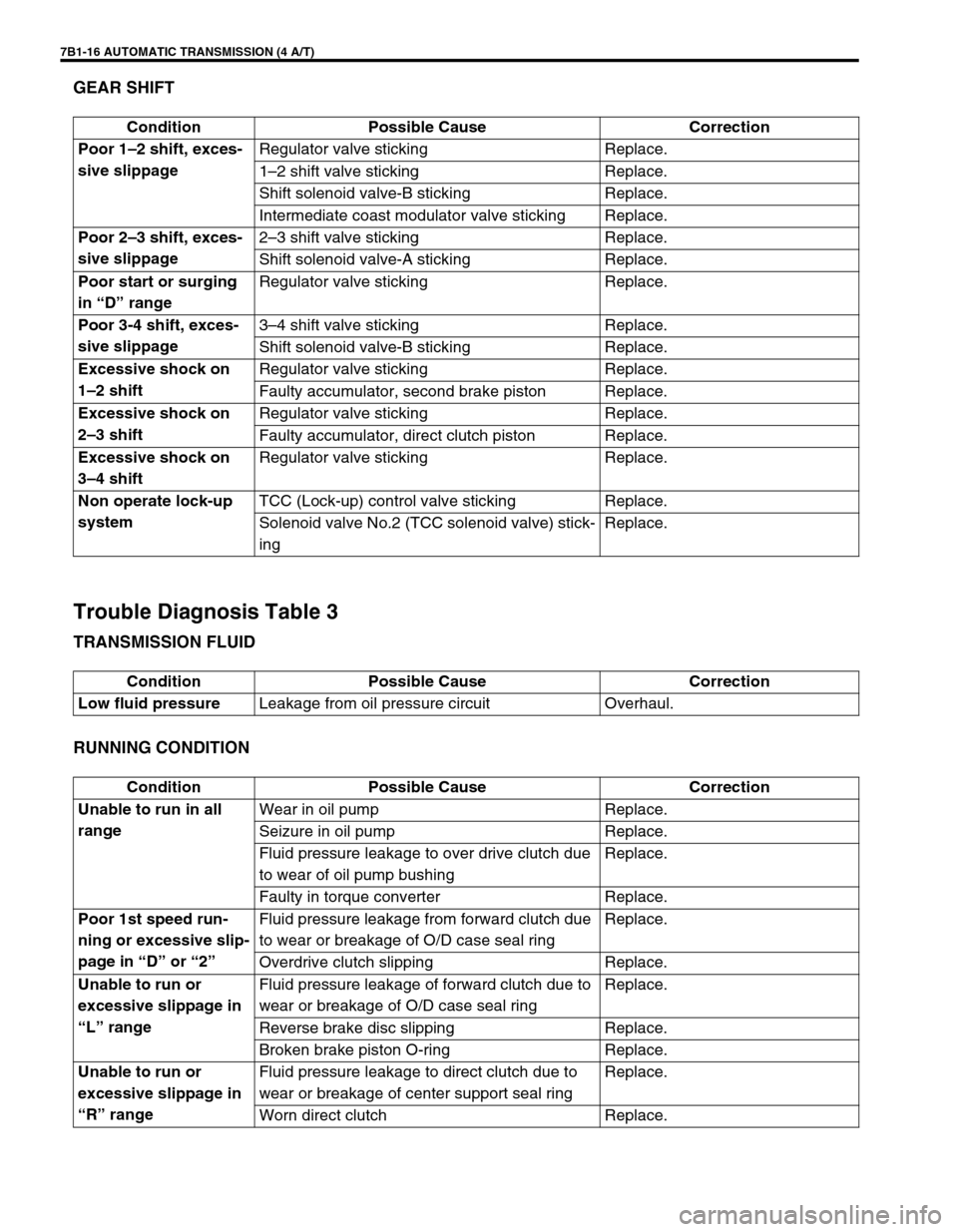

7B1-16 AUTOMATIC TRANSMISSION (4 A/T)

GEAR SHIFT

Trouble Diagnosis Table 3

TRANSMISSION FLUID

RUNNING CONDITION

Condition Possible Cause Correction

Poor 1–2 shift, exces-

sive slippageRegulator valve sticking Replace.

1–2 shift valve sticking Replace.

Shift solenoid valve-B sticking Replace.

Intermediate coast modulator valve sticking Replace.

Poor 2–3 shift, exces-

sive slippage2–3 shift valve sticking Replace.

Shift solenoid valve-A sticking Replace.

Poor start or surging

in “D” rangeRegulator valve sticking Replace.

Poor 3-4 shift, exces-

sive slippage3–4 shift valve sticking Replace.

Shift solenoid valve-B sticking Replace.

Excessive shock on

1–2 shiftRegulator valve sticking Replace.

Faulty accumulator, second brake piston Replace.

Excessive shock on

2–3 shiftRegulator valve sticking Replace.

Faulty accumulator, direct clutch piston Replace.

Excessive shock on

3–4 shiftRegulator valve sticking Replace.

Non operate lock-up

systemTCC (Lock-up) control valve sticking Replace.

Solenoid valve No.2 (TCC solenoid valve) stick-

ingReplace.

Condition Possible Cause Correction

Low fluid pressureLeakage from oil pressure circuit Overhaul.

Condition Possible Cause Correction

Unable to run in all

rangeWear in oil pump Replace.

Seizure in oil pump Replace.

Fluid pressure leakage to over drive clutch due

to wear of oil pump bushingReplace.

Faulty in torque converter Replace.

Poor 1st speed run-

ning or excessive slip-

page in “D” or “2”Fluid pressure leakage from forward clutch due

to wear or breakage of O/D case seal ringReplace.

Overdrive clutch slipping Replace.

Unable to run or

excessive slippage in

“L” rangeFluid pressure leakage of forward clutch due to

wear or breakage of O/D case seal ringReplace.

Reverse brake disc slipping Replace.

Broken brake piston O-ring Replace.

Unable to run or

excessive slippage in

“R” rangeFluid pressure leakage to direct clutch due to

wear or breakage of center support seal ringReplace.

Worn direct clutch Replace.

Page 426 of 656

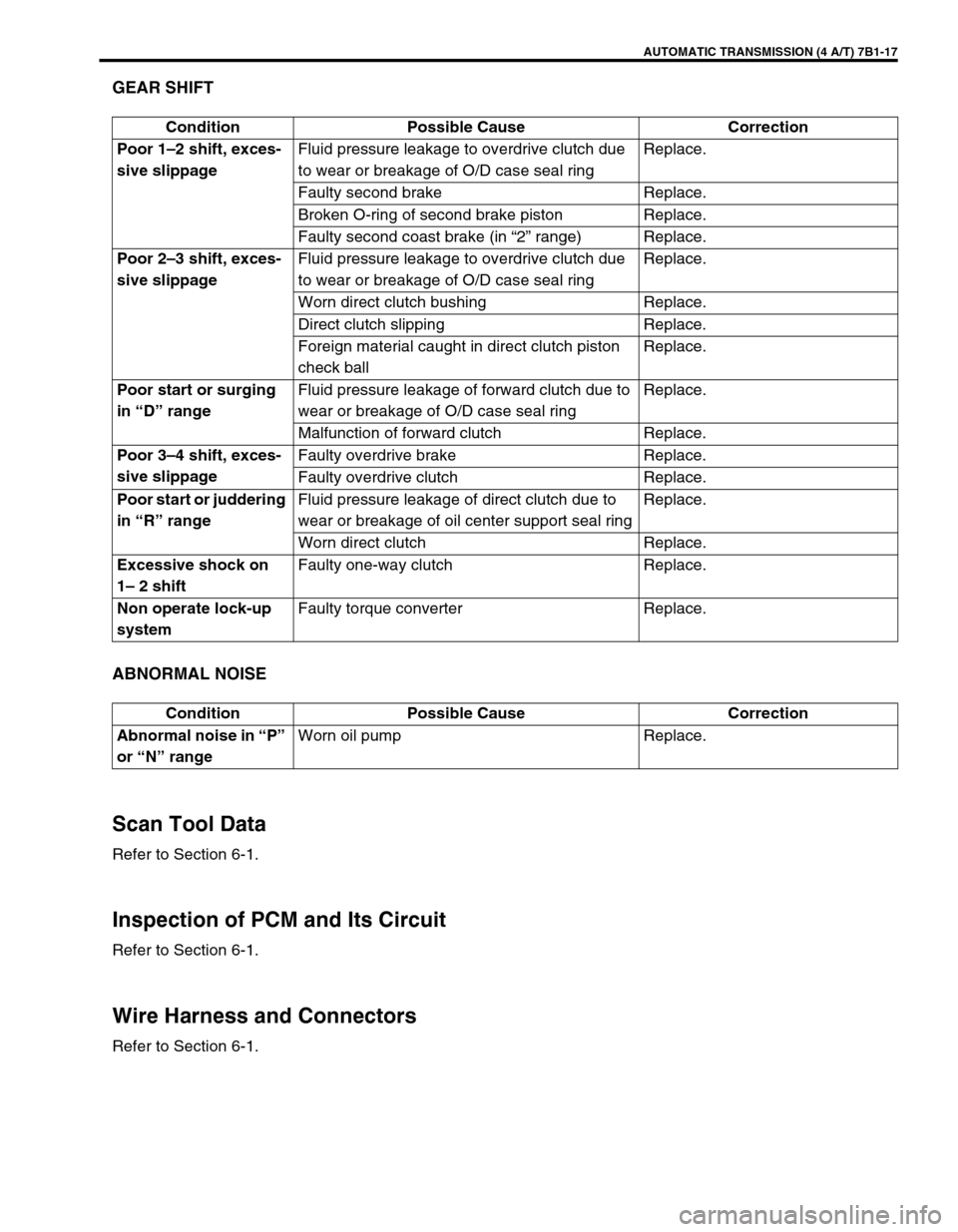

AUTOMATIC TRANSMISSION (4 A/T) 7B1-17

GEAR SHIFT

ABNORMAL NOISE

Scan Tool Data

Refer to Section 6-1.

Inspection of PCM and Its Circuit

Refer to Section 6-1.

Wire Harness and Connectors

Refer to Section 6-1.Condition Possible Cause Correction

Poor 1–2 shift, exces-

sive slippageFluid pressure leakage to overdrive clutch due

to wear or breakage of O/D case seal ringReplace.

Faulty second brake Replace.

Broken O-ring of second brake piston Replace.

Faulty second coast brake (in “2” range) Replace.

Poor 2–3 shift, exces-

sive slippageFluid pressure leakage to overdrive clutch due

to wear or breakage of O/D case seal ringReplace.

Worn direct clutch bushing Replace.

Direct clutch slipping Replace.

Foreign material caught in direct clutch piston

check ballReplace.

Poor start or surging

in “D” rangeFluid pressure leakage of forward clutch due to

wear or breakage of O/D case seal ringReplace.

Malfunction of forward clutch Replace.

Poor 3–4 shift, exces-

sive slippageFaulty overdrive brake Replace.

Faulty overdrive clutch Replace.

Poor start or juddering

in “R” rangeFluid pressure leakage of direct clutch due to

wear or breakage of oil center support seal ringReplace.

Worn direct clutch Replace.

Excessive shock on

1– 2 shiftFaulty one-way clutch Replace.

Non operate lock-up

systemFaulty torque converter Replace.

Condition Possible Cause Correction

Abnormal noise in “P”

or “N” rangeWorn oil pump Replace.