Speed SUZUKI GRAND VITARA 2001 2.G User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2001, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2001 2.GPages: 656, PDF Size: 14.31 MB

Page 135 of 656

5E2-10 ANTILOCK BRAKE SYSTEM (ABS)

Diagnostic Trouble Code (DTC) Check (Using

ABS Warning Lamp)

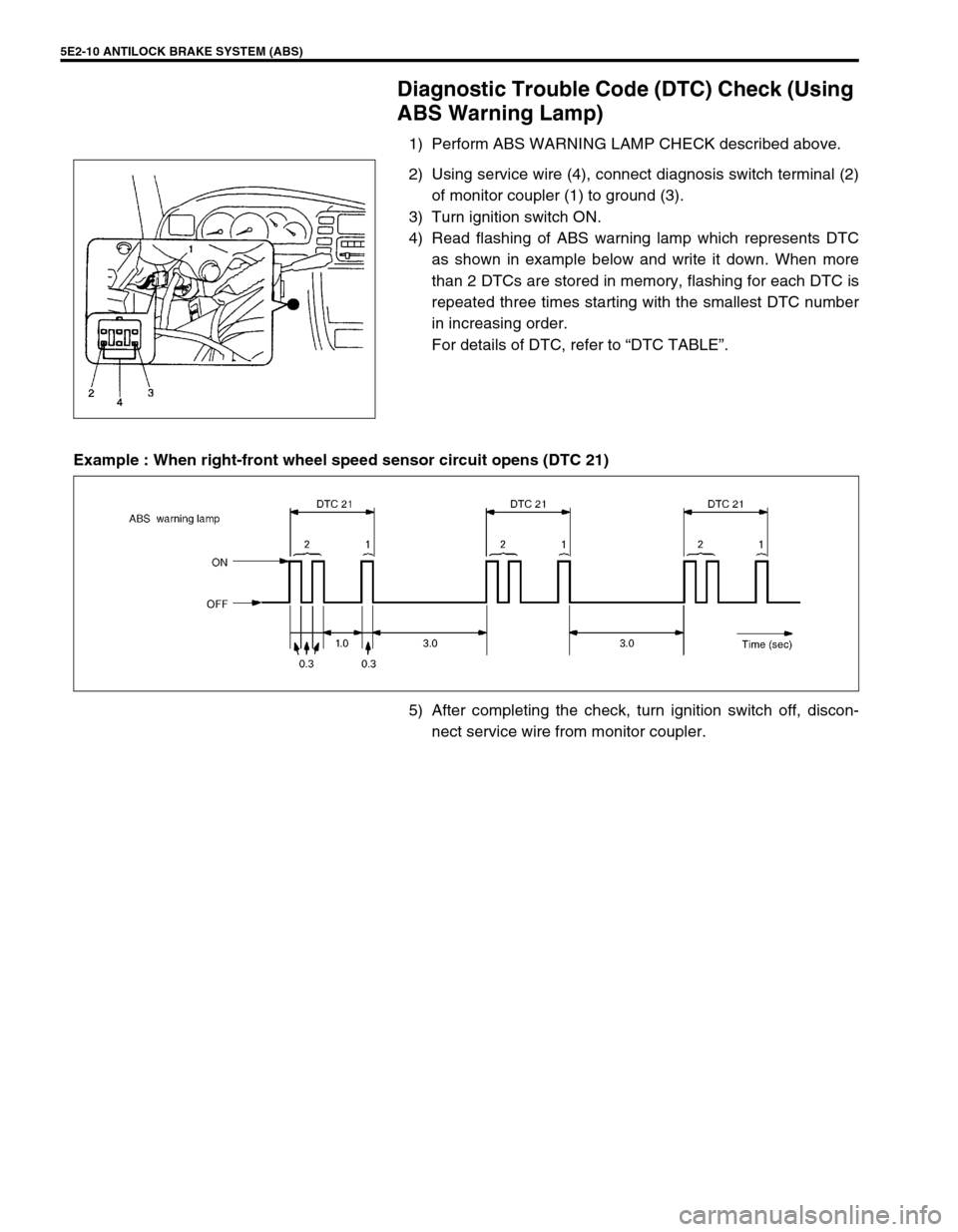

1) Perform ABS WARNING LAMP CHECK described above.

2) Using service wire (4), connect diagnosis switch terminal (2)

of monitor coupler (1) to ground (3).

3) Turn ignition switch ON.

4) Read flashing of ABS warning lamp which represents DTC

as shown in example below and write it down. When more

than 2 DTCs are stored in memory, flashing for each DTC is

repeated three times starting with the smallest DTC number

in increasing order.

For details of DTC, refer to “DTC TABLE”.

Example : When right-front wheel speed sensor circuit opens (DTC 21)

5) After completing the check, turn ignition switch off, discon-

nect service wire from monitor coupler.

Page 137 of 656

5E2-12 ANTILOCK BRAKE SYSTEM (ABS)

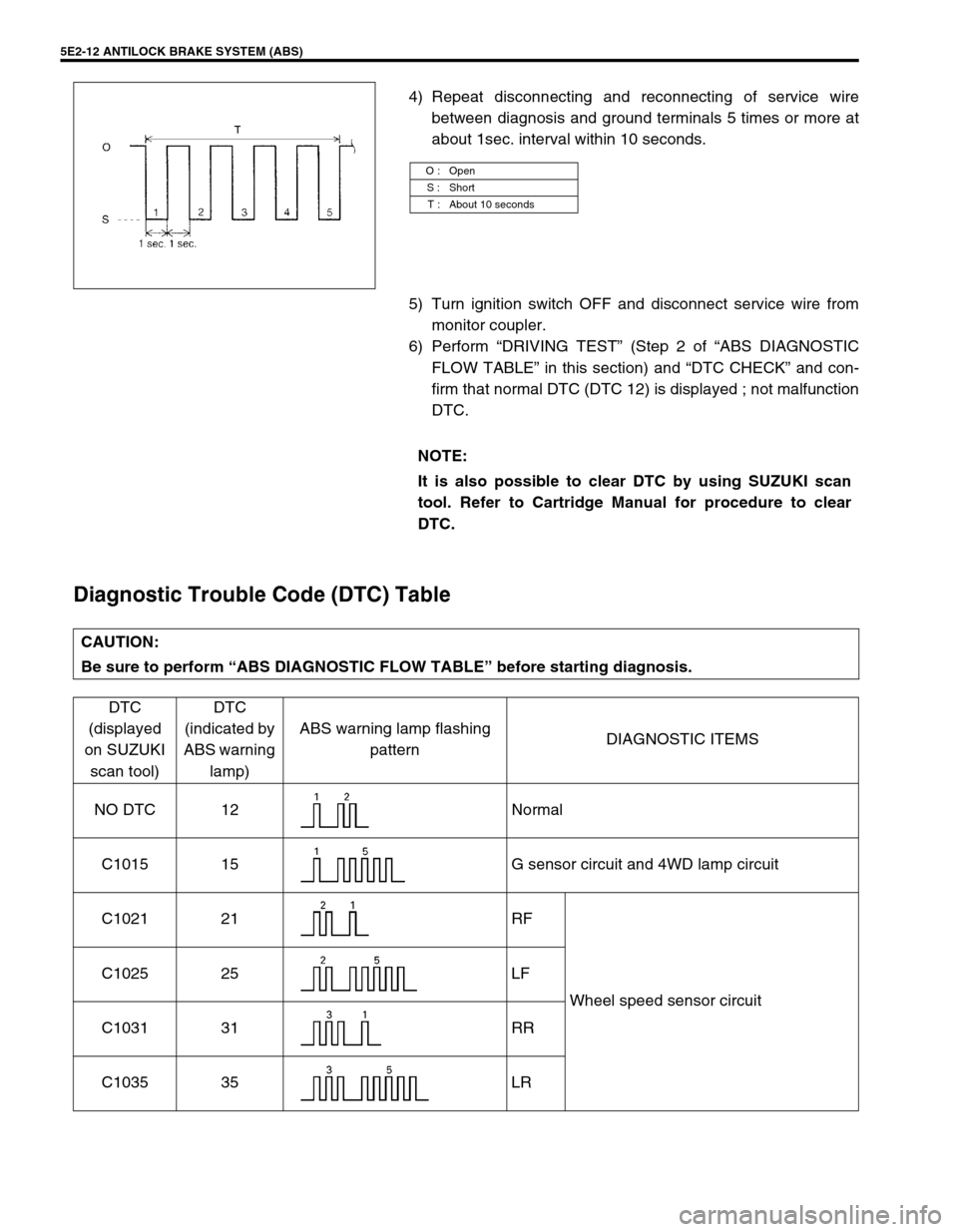

4) Repeat disconnecting and reconnecting of service wire

between diagnosis and ground terminals 5 times or more at

about 1sec. interval within 10 seconds.

5) Turn ignition switch OFF and disconnect service wire from

monitor coupler.

6) Perform “DRIVING TEST” (Step 2 of “ABS DIAGNOSTIC

FLOW TABLE” in this section) and “DTC CHECK” and con-

firm that normal DTC (DTC 12) is displayed ; not malfunction

DTC.

Diagnostic Trouble Code (DTC) Table

O : Open

S : Short

T : About 10 seconds

NOTE:

It is also possible to clear DTC by using SUZUKI scan

tool. Refer to Cartridge Manual for procedure to clear

DTC.

CAUTION:

Be sure to perform “ABS DIAGNOSTIC FLOW TABLE” before starting diagnosis.

DTC

(displayed

on SUZUKI

scan tool)DTC

(indicated by

ABS warning

lamp)ABS warning lamp flashing

patternDIAGNOSTIC ITEMS

NO DTC 12 Normal

C1015 15 G sensor circuit and 4WD lamp circuit

C1021 21 RF

Wheel speed sensor circuit C1025 25 LF

C1031 31 RR

C1035 35 LR

Page 138 of 656

ANTILOCK BRAKE SYSTEM (ABS) 5E2-13

C1022 22 RF

Wheel speed sensor circuit

or sensor ring C1026 26 LF

C1032 32 RR

C1036 36 LR

C1041 41

RFInlet solenoid valve circuit

C1042 42 Outlet solenoid valve circuit

C1045 45

LFInlet solenoid valve circuit

C1046 46 Outlet solenoid valve circuit

C1055 55

REARInlet solenoid valve circuit

C1056 56 Outlet solenoid valve circuit

C1057 57 Power source

C1061 61 ABS pump motor and/or motor relay circuit

C1063 63 Fail safe-relay

C1071 71 ABS control moduleDTC

(displayed

on SUZUKI

scan tool)DTC

(indicated by

ABS warning

lamp)ABS warning lamp flashing

patternDIAGNOSTIC ITEMS

Page 139 of 656

5E2-14 ANTILOCK BRAKE SYSTEM (ABS)

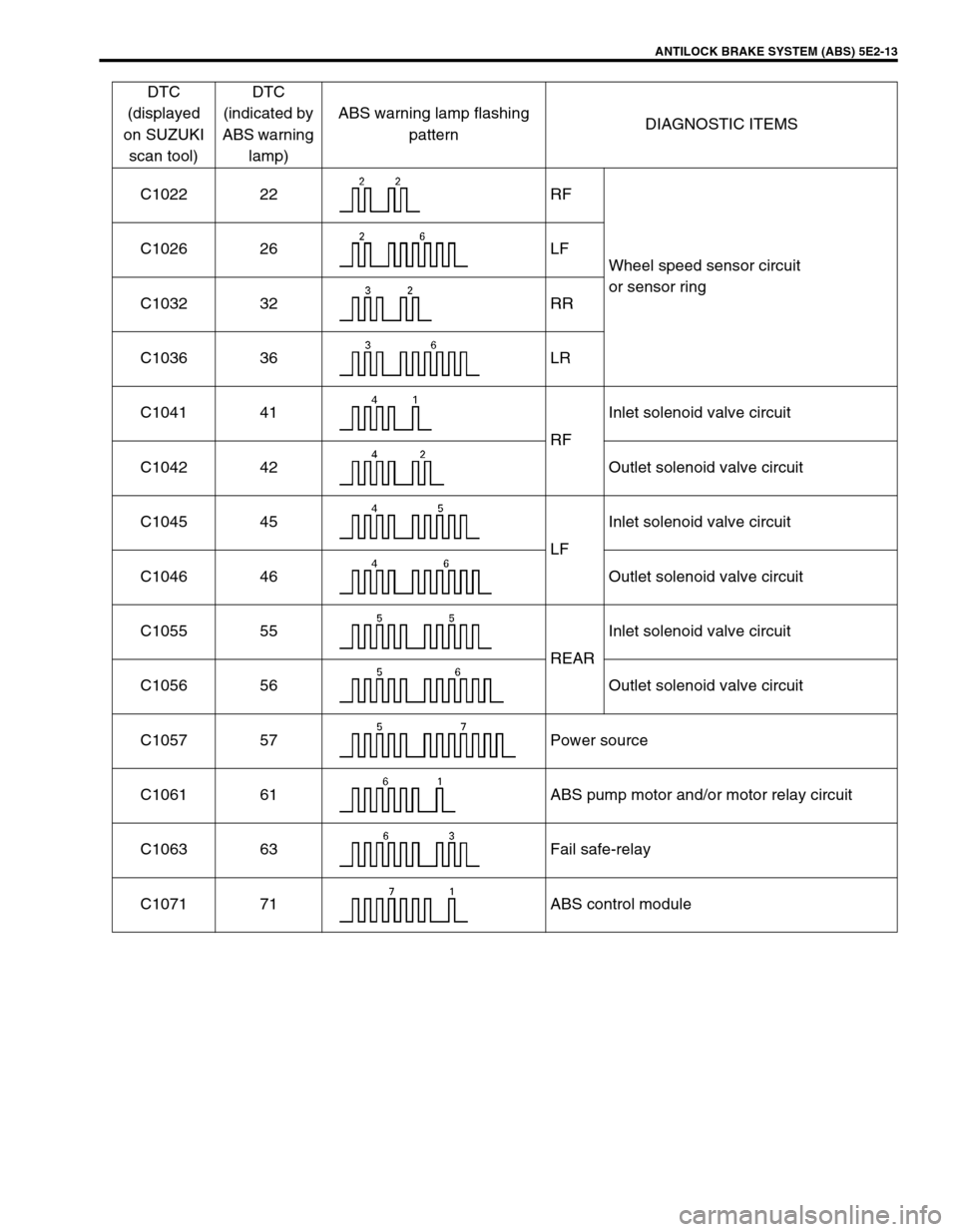

System Circuit

1. Battery 11. ABS fail-safe transistor (Solenoid valve transistor) 21. To ECM and SDM (if equipped)

2. Main fuses 12. ABS pump motor transistor 22. Stop lamp

3. Ignition switch 13. Pump motor 23. Stop lamp switch

4. Circuit fuses 14. Solenoid valves 24. G sensor (For 4WD vehicle only)

5. Combination meter 15. Diagnosis monitor coupler 25. 4WD lamp (For 4WD vehicle only)

6. ABS warning lamp 16. Right-rear wheel speed sensor 26. ECM (PCM) (For 4WD vehicle only)

7. Brake warning lamp (“EBD” warning lamp) 17. Left-rear wheel speed sensor 27. 4WD switch (For 4WD vehicle only)

8. Warning lamp driver module (for ABS) 18. Right-front wheel speed sensor 28. ECM (PCM)

9. ABS hydraulic unit/control module assembly 19. Left-front wheel speed sensor

10. Terminal arrangement of connector E136 for

ABS hydraulic unit/control module assembly20. Data link connector

TERMINAL CIRCUIT TERMINAL CIRCUIT

E1361 Idle up signal

E13614 ABS warning lamp

2 Stop lamp switch 15 Left-front wheel speed sensor (+)

3 Right-front wheel speed sensor (+) 16 Left-front wheel speed sensor (–)

4 Right-front wheel speed sensor (–) 17 4WD switch

5–18 Ignition switch

6 Right-rear wheel speed sensor (–) 19 Left-rear wheel speed sensor (+)

7 Right-rear wheel speed sensor (+) 20 Left-rear wheel speed sensor (–)

8–21 Data link connector

9–22 Ground (for ABS pump motor)

10 Brake warning lamp (EBD warning lamp) 23 ABS pump motor relay

11 G sensor (For 4WD vehicle only) 24 Ground (for ABS control module)

12 Diagnosis switch terminal 25 ABS fail-safe relay

13 Ground (For G sensor) (For 4WD vehicle only)

Page 147 of 656

5E2-22 ANTILOCK BRAKE SYSTEM (ABS)

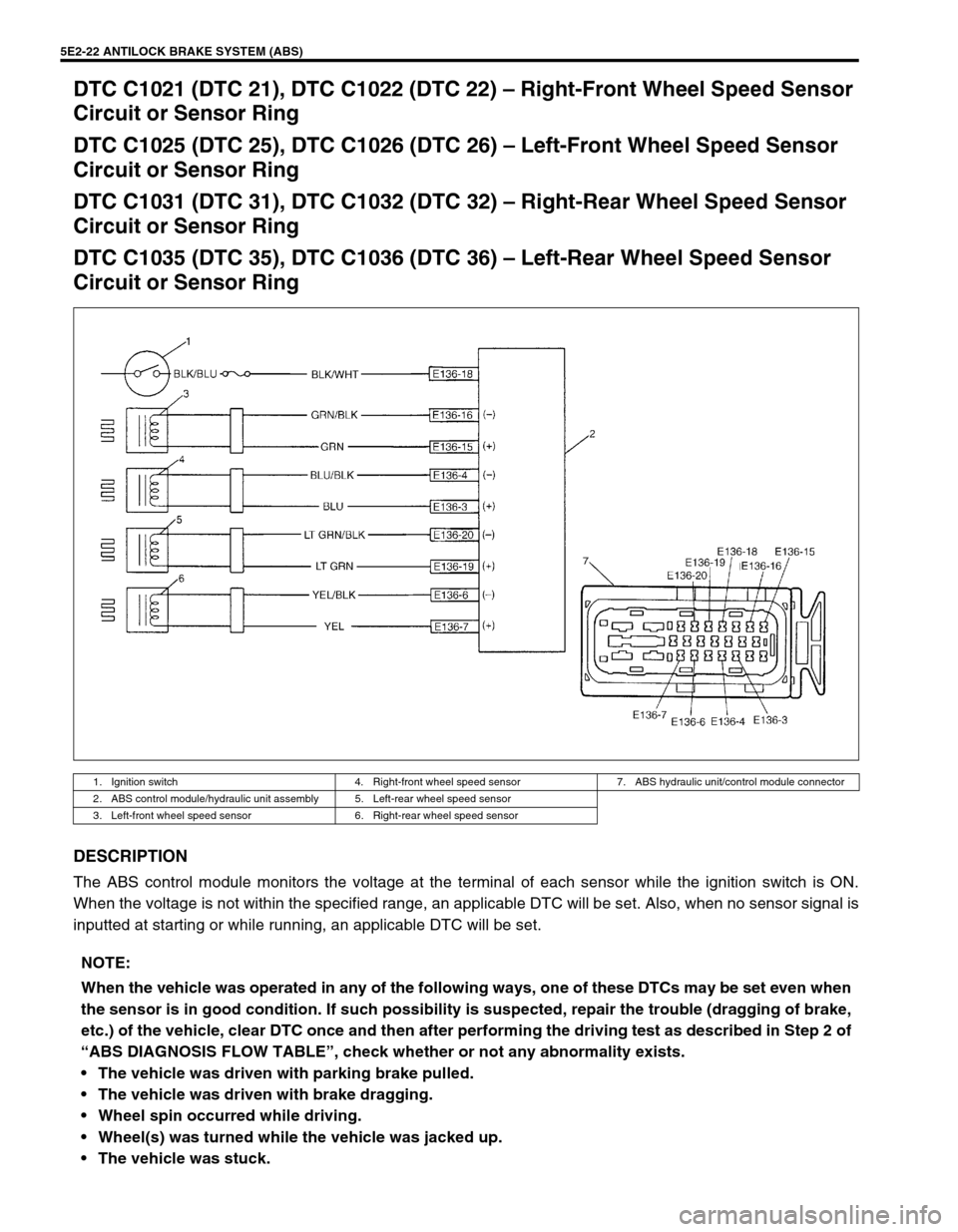

DTC C1021 (DTC 21), DTC C1022 (DTC 22) – Right-Front Wheel Speed Sensor

Circuit or Sensor Ring

DTC C1025 (DTC 25), DTC C1026 (DTC 26) – Left-Front Wheel Speed Sensor

Circuit or Sensor Ring

DTC C1031 (DTC 31), DTC C1032 (DTC 32) – Right-Rear Wheel Speed Sensor

Circuit or Sensor Ring

DTC C1035 (DTC 35), DTC C1036 (DTC 36) – Left-Rear Wheel Speed Sensor

Circuit or Sensor Ring

DESCRIPTION

The ABS control module monitors the voltage at the terminal of each sensor while the ignition switch is ON.

When the voltage is not within the specified range, an applicable DTC will be set. Also, when no sensor signal is

inputted at starting or while running, an applicable DTC will be set.

1. Ignition switch 4. Right-front wheel speed sensor 7. ABS hydraulic unit/control module connector

2. ABS control module/hydraulic unit assembly 5. Left-rear wheel speed sensor

3. Left-front wheel speed sensor 6. Right-rear wheel speed sensor

NOTE:

When the vehicle was operated in any of the following ways, one of these DTCs may be set even when

the sensor is in good condition. If such possibility is suspected, repair the trouble (dragging of brake,

etc.) of the vehicle, clear DTC once and then after performing the driving test as described in Step 2 of

“ABS DIAGNOSIS FLOW TABLE”, check whether or not any abnormality exists.

The vehicle was driven with parking brake pulled.

The vehicle was driven with brake dragging.

Wheel spin occurred while driving.

Wheel(s) was turned while the vehicle was jacked up.

The vehicle was stuck.

Page 148 of 656

ANTILOCK BRAKE SYSTEM (ABS) 5E2-23

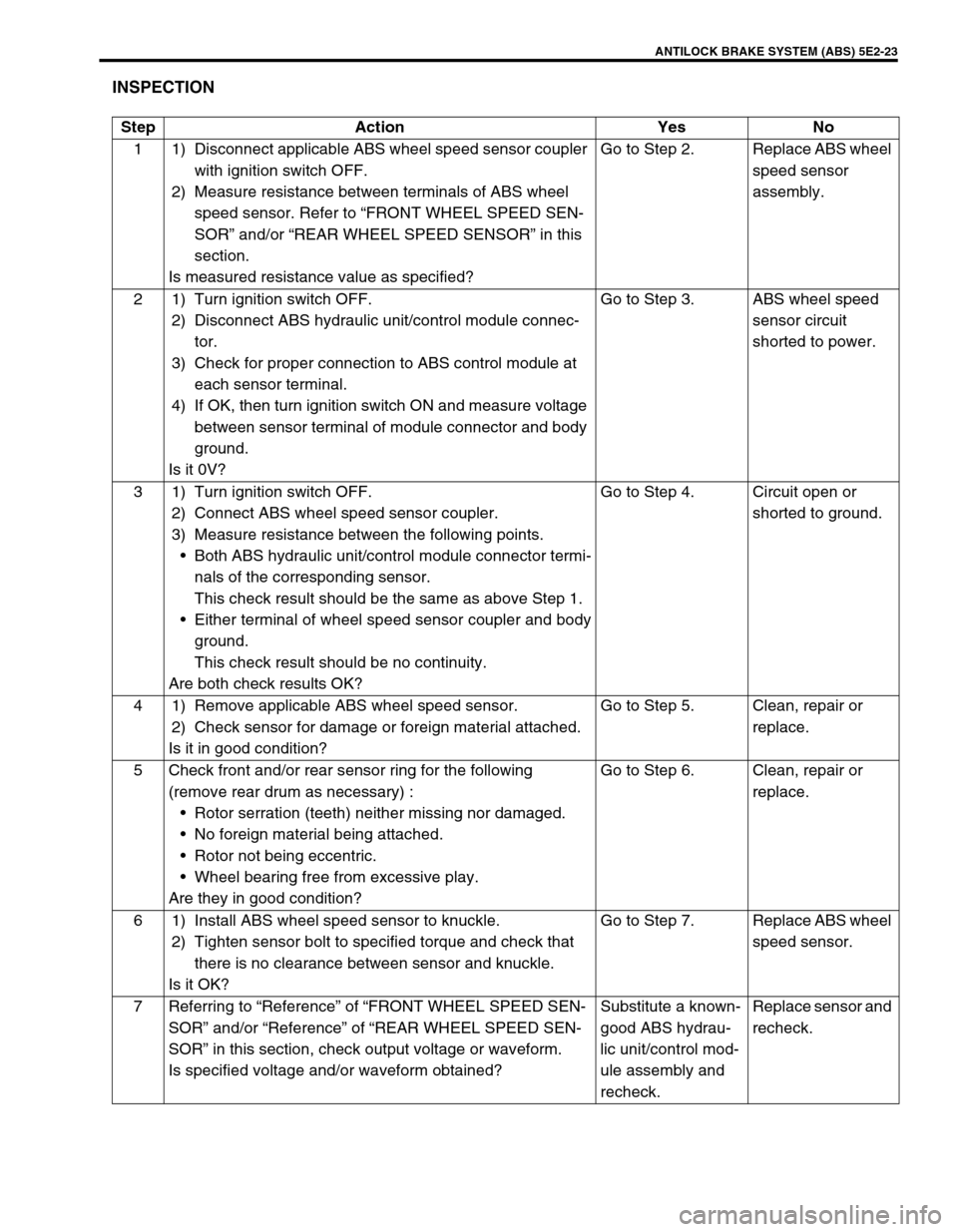

INSPECTION

Step Action Yes No

1 1) Disconnect applicable ABS wheel speed sensor coupler

with ignition switch OFF.

2) Measure resistance between terminals of ABS wheel

speed sensor. Refer to “FRONT WHEEL SPEED SEN-

SOR” and/or “REAR WHEEL SPEED SENSOR” in this

section.

Is measured resistance value as specified?Go to Step 2. Replace ABS wheel

speed sensor

assembly.

2 1) Turn ignition switch OFF.

2) Disconnect ABS hydraulic unit/control module connec-

tor.

3) Check for proper connection to ABS control module at

each sensor terminal.

4) If OK, then turn ignition switch ON and measure voltage

between sensor terminal of module connector and body

ground.

Is it 0V?Go to Step 3. ABS wheel speed

sensor circuit

shorted to power.

3 1) Turn ignition switch OFF.

2) Connect ABS wheel speed sensor coupler.

3) Measure resistance between the following points.

Both ABS hydraulic unit/control module connector termi-

nals of the corresponding sensor.

This check result should be the same as above Step 1.

Either terminal of wheel speed sensor coupler and body

ground.

This check result should be no continuity.

Are both check results OK?Go to Step 4. Circuit open or

shorted to ground.

4 1) Remove applicable ABS wheel speed sensor.

2) Check sensor for damage or foreign material attached.

Is it in good condition?Go to Step 5. Clean, repair or

replace.

5 Check front and/or rear sensor ring for the following

(remove rear drum as necessary) :

Rotor serration (teeth) neither missing nor damaged.

No foreign material being attached.

Rotor not being eccentric.

Wheel bearing free from excessive play.

Are they in good condition?Go to Step 6. Clean, repair or

replace.

6 1) Install ABS wheel speed sensor to knuckle.

2) Tighten sensor bolt to specified torque and check that

there is no clearance between sensor and knuckle.

Is it OK?Go to Step 7. Replace ABS wheel

speed sensor.

7 Referring to “Reference” of “FRONT WHEEL SPEED SEN-

SOR” and/or “Reference” of “REAR WHEEL SPEED SEN-

SOR” in this section, check output voltage or waveform.

Is specified voltage and/or waveform obtained?Substitute a known-

good ABS hydrau-

lic unit/control mod-

ule assembly and

recheck.Replace sensor and

recheck.

Page 159 of 656

5E2-34 ANTILOCK BRAKE SYSTEM (ABS)

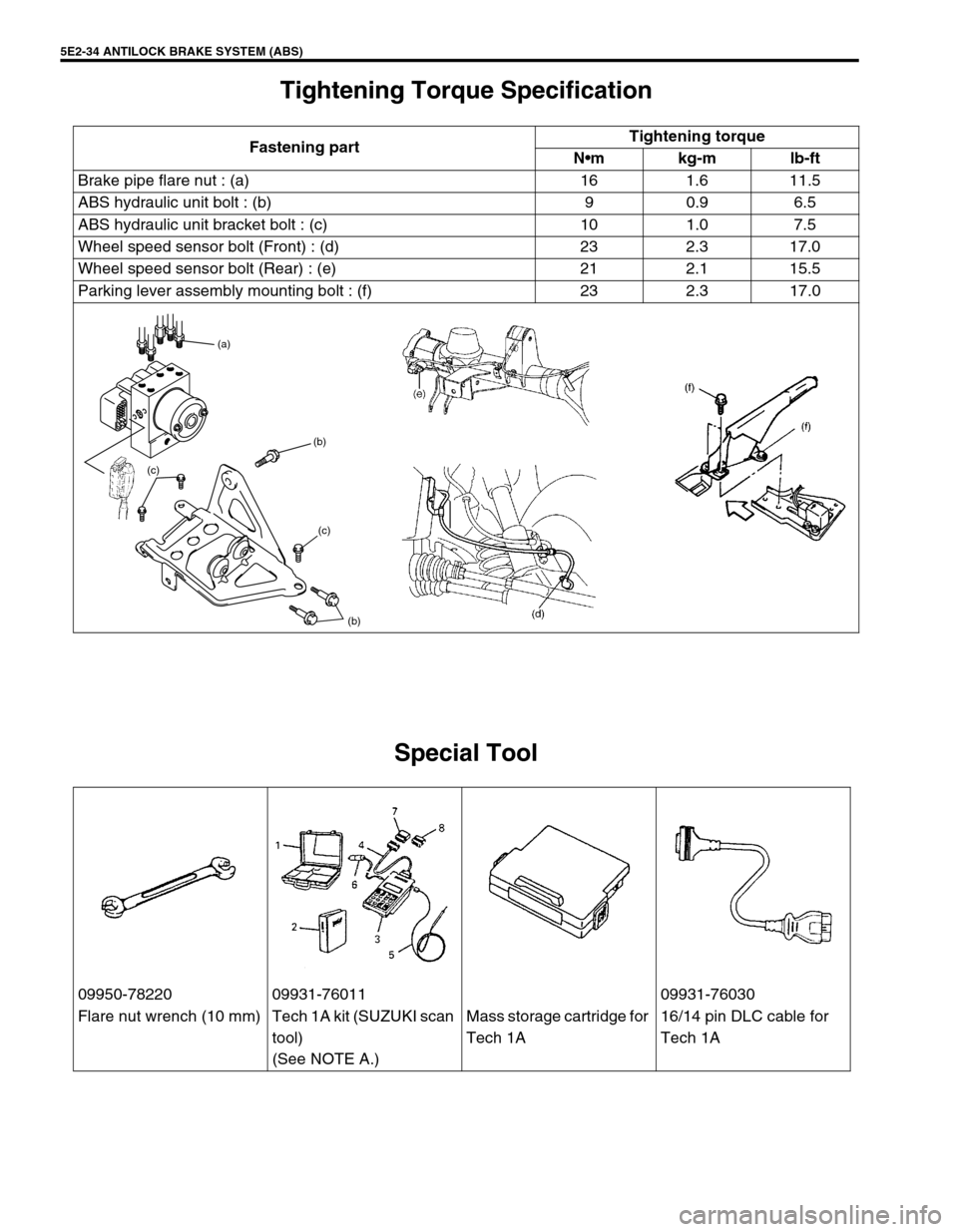

Tightening Torque Specification

Special Tool

Fastening partTightening torque

Nm kg-m lb-ft

Brake pipe flare nut : (a) 16 1.6 11.5

ABS hydraulic unit bolt : (b) 9 0.9 6.5

ABS hydraulic unit bracket bolt : (c) 10 1.0 7.5

Wheel speed sensor bolt (Front) : (d) 23 2.3 17.0

Wheel speed sensor bolt (Rear) : (e) 21 2.1 15.5

Parking lever assembly mounting bolt : (f) 23 2.3 17.0

(b) (b) (a)

(c) (c)

09950-78220 09931-76011 09931-76030

Flare nut wrench (10 mm) Tech 1A kit (SUZUKI scan

tool)

(See NOTE A.)Mass storage cartridge for

Tech 1A16/14 pin DLC cable for

Tech 1A

Page 163 of 656

6-1-2 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

Table A-4 Malfunction Indicator Lamp

Check – MIL Does Not Flash or Just

Remains ON Even with Grounding

Diagnosis Switch Terminal (Vehicle with

Monitor Connector) ................................... 6-1-45

Table A-5 ECM (PCM) Power and Ground

Circuit Check – MIL Doesn’t Light at

Ignition Switch ON and Engine Doesn’t

Start Though It Is Cranked Up .................. 6-1-46

DTC P0100 (DTC No.33, 34) Mass Air

Flow Circuit Malfunction ............................ 6-1-48

DTC P0110 (DTC No.23, 25) Intake Air

Temp. (IAT) Circuit Malfunction ................ 6-1-50

DTC P0115 (DTC No.14, 15) Engine

Coolant Temp. Circuit Malfunction ............ 6-1-52

DTC P0120 (DTC No.21, 22) Throttle

Position Circuit Malfunction....................... 6-1-54

DTC P0121 Throttle Position Circuit

Range/Performance Problem ................... 6-1-56

DTC P0130 (DTC No.13) HO2S-1 (Bank 1)

Circuit Malfunction or No Activity

Detected.................................................... 6-1-58

DTC P0133 HO2S-1 (Bank 1) Circuit Slow

Response .................................................. 6-1-60

DTC P0135 HO2S-1 (Bank 1) Heater

Circuit Malfunction .................................... 6-1-61

DTC P0136 HO2S-2 (Bank 1) Circuit

Malfunction................................................ 6-1-63

DTC P0141 HO2S-2 (Bank 1) Heater

Circuit Malfunction .................................... 6-1-65

DTC P0150 (DTC No.26) HO2S-1 (Bank 2)

Circuit Malfunction or No Activity

Detected.................................................... 6-1-67

DTC P0153 HO2S-1 (Bank 2) Circuit Slow

Response .................................................. 6-1-69

DTC P0155 HO2S-1 (Bank 2) Heater

Circuit Malfunction .................................... 6-1-70

DTC P0156 HO2S-2 (Bank 2) Circuit

Malfunction................................................ 6-1-72

DTC P0161 HO2S-2 (Bank 2) Heater

Circuit Malfunction .................................... 6-1-74

DTC P0171/P0172 Fuel System Too

Lean/Rich (Bank 1) ................................... 6-1-76

DTC P0174/P0175 Fuel System Too

Lean/Rich (Bank 2) ................................... 6-1-78

DTC P0300/P0301/P0302/P0303/P0304/

P0305/P0306 Random Misfire/Cylinder 1

Misfire/Cylinder 2 Misfire/Cylinder 3 Misfire/

Cylinder 4 Misfire Detected/Cylinder 5

Misfire Detected/Cylinder 6 Misfire

Detected.................................................... 6-1-80

DTC P0325 (DTC No.43) Knock Sensor Circuit Malfunction ..................................... 6-1-82

DTC P0335 Crankshaft Position Sensor

Circuit Malfunction ..................................... 6-1-84

DTC P0340 (DTC No.42) Camshaft

Position Sensor Circuit Malfunction ........... 6-1-86

DTC P0400 Exhaust Gas Recirculation

Flow Malfunction ........................................ 6-1-89

DTC P0403 (DTC No.51) Exhaust Gas

Recirculation Circuit Malfunction ............... 6-1-92

DTC P0420 Catalyst System Efficiency

Below Threshold (Bank 1) ......................... 6-1-94

DTC P0430 Catalyst System Efficiency

Below Threshold (Bank 2) ......................... 6-1-96

DTC P0443 Evap Control System Purge

Control Valve Circuit Malfunction............... 6-1-98

Evap canister purge system

inspection ............................................. 6-1-100

Vacuum passage inspection ................ 6-1-100

Vacuum hose inspection ...................... 6-1-101

Evap canister purge valve and its

circuit inspection .................................. 6-1-101

Evap canister purge valve inspection .. 6-1-101

DTC P0460 Fuel Level Sensor Circuit

High Input ................................................ 6-1-103

DTC P0500 (DTC No.24) Vehicle Speed

Sensor Malfunction .................................. 6-1-105

DTC P0505 Idle Air Control System

Malfunction .............................................. 6-1-108

DTC P0601 (DTC No.71) Internal Control

Module Memory Check Sum Error .......... 6-1-110

DTC P1408 Manifold Absolute Pressure

Sensor Circuit Malfunction ....................... 6-1-111

DTC P1450/P1451 Barometric Pressure

Sensor Circuit Malfunction/Performance

Problem ................................................... 6-1-113

DTC P1500 Engine Starter Signal Circuit

Malfunction .............................................. 6-1-114

DTC P1510 Ecm Back-Up Power Supply

Malfunction .............................................. 6-1-115

Table B-1 Fuel Pump Circuit Inspection .. 6-1-116

Table B-2 Fuel Injectors and Circuit

Inspection ................................................ 6-1-117

Table B-3 Fuel Pressure Inspection ........ 6-1-119

Table B-4 Idle Air Control System

Inspection ................................................ 6-1-121

Table B-5 A/C Signal Circuits Inspection

(If Equipped) ............................................ 6-1-123

Table B-6 A/C Condenser Fan Motor

Relay Control System Inspection

(If Equipped) ............................................ 6-1-124

Special Tool ............................................... 6-1-125

Page 168 of 656

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-7

WARM-UP CYCLE

A warm-up cycle means sufficient vehicle operation such that the

coolant temperature has risen by at least 22°C (40°F) from

engine starting and reaches a minimum temperature of 70 °C

(160 °F).

DRIVING CYCLE

A “Driving Cycle” consists of engine startup, driving mode where

a malfunction would be detected if present and engine shutoff.

2 DRIVING CYCLE DETECTION LOGIC

The malfunction detected in the first driving cycle is stored in

ECM (PCM) memory (in the form of pending DTC) but the mal-

function indicator lamp does not light at this time. It lights up at the

second detection of same malfunction also in the next driving

cycle.

PENDING DTC

Pending DTC means a DTC detected and stored temporarily at 1

driving cycle of the DTC which is detected in the 2 driving cycle

detection logic.

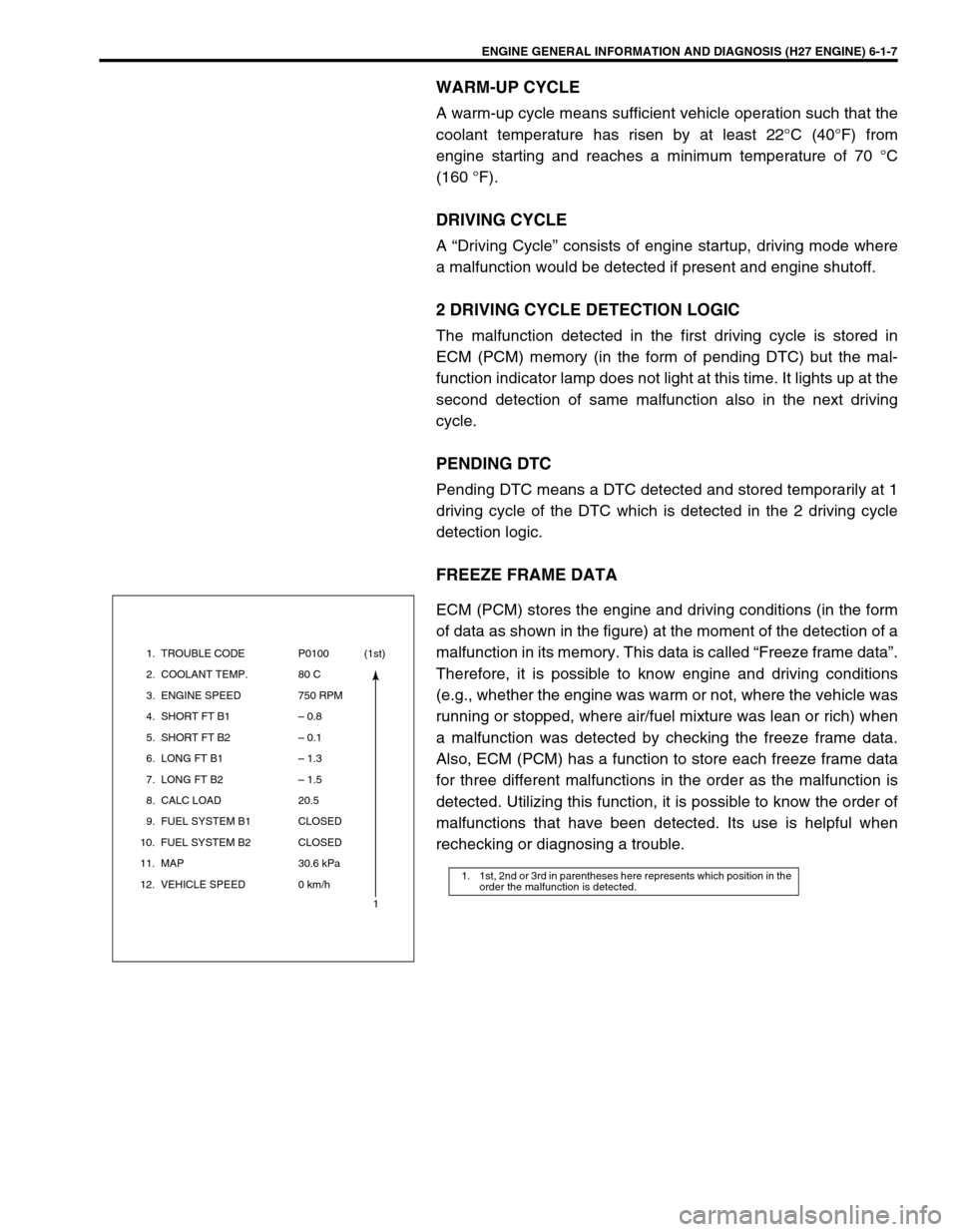

FREEZE FRAME DATA

ECM (PCM) stores the engine and driving conditions (in the form

of data as shown in the figure) at the moment of the detection of a

malfunction in its memory. This data is called “Freeze frame data”.

Therefore, it is possible to know engine and driving conditions

(e.g., whether the engine was warm or not, where the vehicle was

running or stopped, where air/fuel mixture was lean or rich) when

a malfunction was detected by checking the freeze frame data.

Also, ECM (PCM) has a function to store each freeze frame data

for three different malfunctions in the order as the malfunction is

detected. Utilizing this function, it is possible to know the order of

malfunctions that have been detected. Its use is helpful when

rechecking or diagnosing a trouble.

1. 1st, 2nd or 3rd in parentheses here represents which position in the

order the malfunction is detected.

1. TROUBLE CODE

2. COOLANT TEMP.

3. ENGINE SPEED

4. SHORT FT B1

5. SHORT FT B2

6. LONG FT B1

7. LONG FT B2

8. CALC LOAD

9. FUEL SYSTEM B1

10. FUEL SYSTEM B2

11. MAP

12. VEHICLE SPEEDP0100

80 C

750 RPM

– 0.8

– 0.1

– 1.3

– 1.5

20.5

CLOSED

CLOSED

30.6 kPa

0 km/h(1st)

1

Page 175 of 656

6-1-14 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

STEP 6. AND 7. RECHECKING AND RECORD OF DTC

Refer to “DTC Check” in this section for checking procedure.

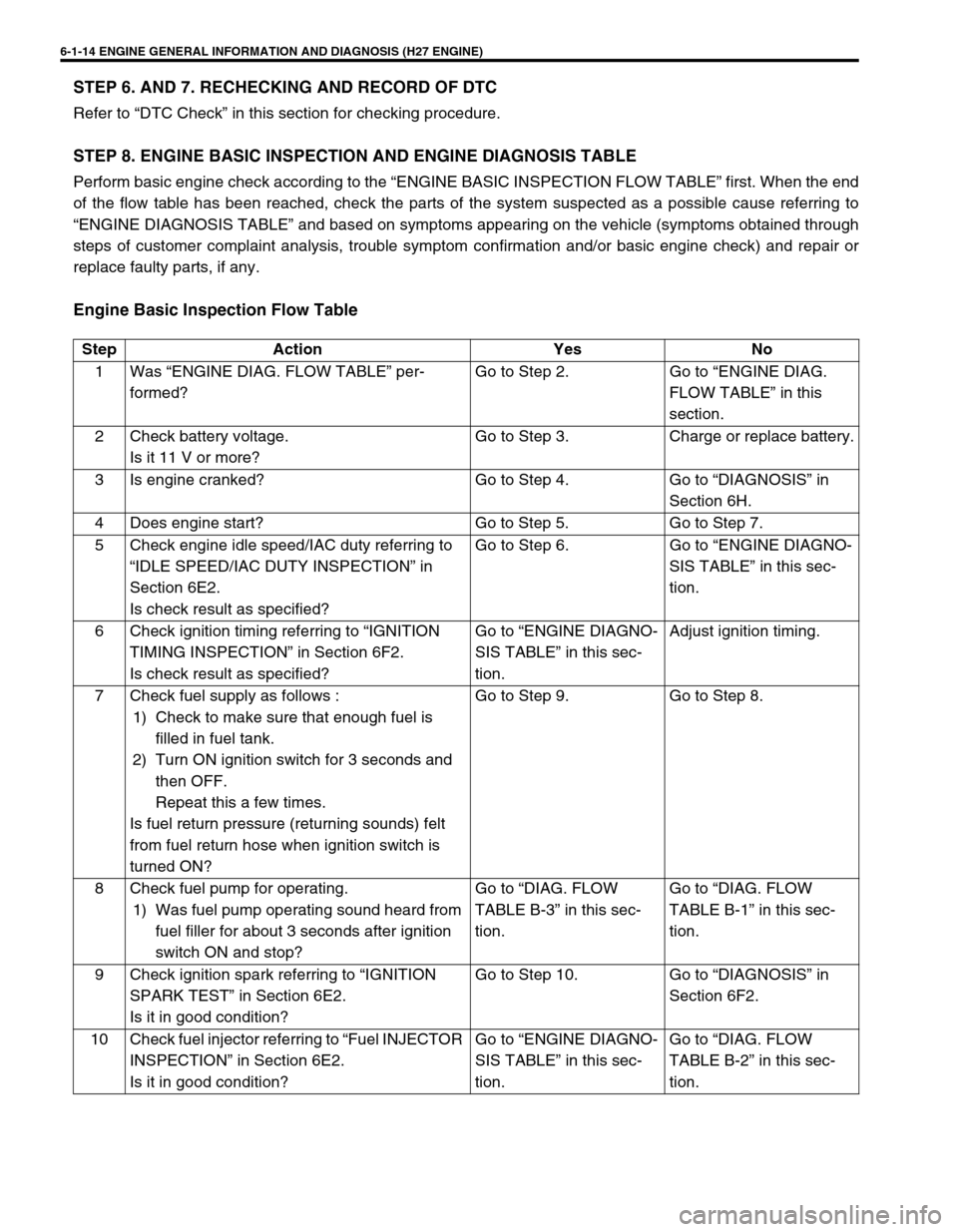

STEP 8. ENGINE BASIC INSPECTION AND ENGINE DIAGNOSIS TABLE

Perform basic engine check according to the “ENGINE BASIC INSPECTION FLOW TABLE” first. When the end

of the flow table has been reached, check the parts of the system suspected as a possible cause referring to

“ENGINE DIAGNOSIS TABLE” and based on symptoms appearing on the vehicle (symptoms obtained through

steps of customer complaint analysis, trouble symptom confirmation and/or basic engine check) and repair or

replace faulty parts, if any.

Engine Basic Inspection Flow Table

Step Action Yes No

1 Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in this

section.

2 Check battery voltage.

Is it 11 V or more?Go to Step 3. Charge or replace battery.

3 Is engine cranked? Go to Step 4. Go to “DIAGNOSIS” in

Section 6H.

4 Does engine start? Go to Step 5. Go to Step 7.

5 Check engine idle speed/IAC duty referring to

“IDLE SPEED/IAC DUTY INSPECTION” in

Section 6E2.

Is check result as specified?Go to Step 6. Go to “ENGINE DIAGNO-

SIS TABLE” in this sec-

tion.

6 Check ignition timing referring to “IGNITION

TIMING INSPECTION” in Section 6F2.

Is check result as specified?Go to “ENGINE DIAGNO-

SIS TABLE” in this sec-

tion.Adjust ignition timing.

7 Check fuel supply as follows :

1) Check to make sure that enough fuel is

filled in fuel tank.

2) Turn ON ignition switch for 3 seconds and

then OFF.

Repeat this a few times.

Is fuel return pressure (returning sounds) felt

from fuel return hose when ignition switch is

turned ON?Go to Step 9. Go to Step 8.

8 Check fuel pump for operating.

1) Was fuel pump operating sound heard from

fuel filler for about 3 seconds after ignition

switch ON and stop?Go to “DIAG. FLOW

TABLE B-3” in this sec-

tion.Go to “DIAG. FLOW

TABLE B-1” in this sec-

tion.

9 Check ignition spark referring to “IGNITION

SPARK TEST” in Section 6E2.

Is it in good condition?Go to Step 10. Go to “DIAGNOSIS” in

Section 6F2.

10 Check fuel injector referring to “Fuel INJECTOR

INSPECTION” in Section 6E2.

Is it in good condition?Go to “ENGINE DIAGNO-

SIS TABLE” in this sec-

tion.Go to “DIAG. FLOW

TABLE B-2” in this sec-

tion.