charging system SUZUKI GRAND VITARA 2001 2.G Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2001, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2001 2.GPages: 656, PDF Size: 14.31 MB

Page 401 of 656

6H-4 CHARGING SYSTEM

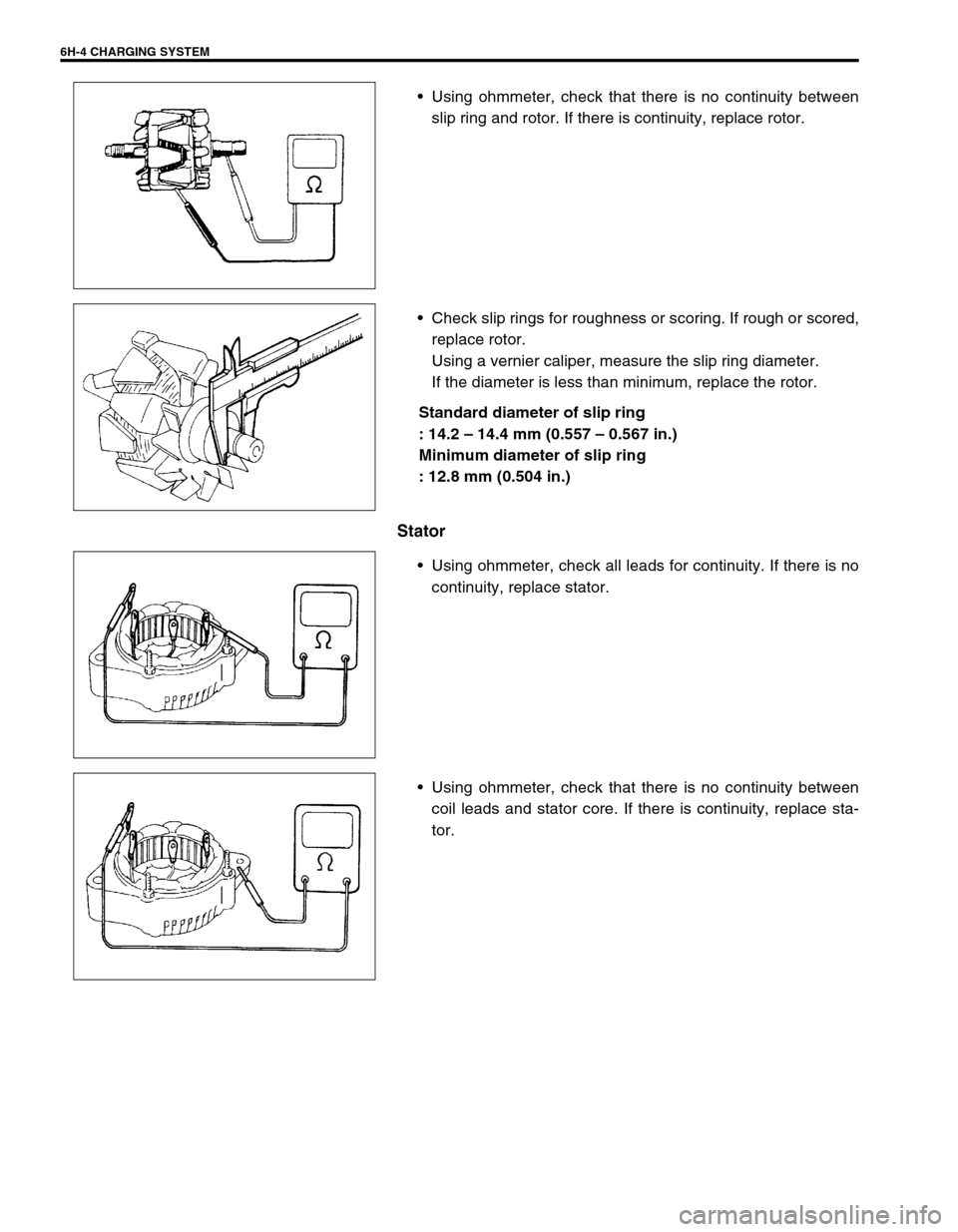

•Using ohmmeter, check that there is no continuity between

slip ring and rotor. If there is continuity, replace rotor.

•Check slip rings for roughness or scoring. If rough or scored,

replace rotor.

Using a vernier caliper, measure the slip ring diameter.

If the diameter is less than minimum, replace the rotor.

Standard diameter of slip ring

: 14.2 – 14.4 mm (0.557 – 0.567 in.)

Minimum diameter of slip ring

: 12.8 mm (0.504 in.)

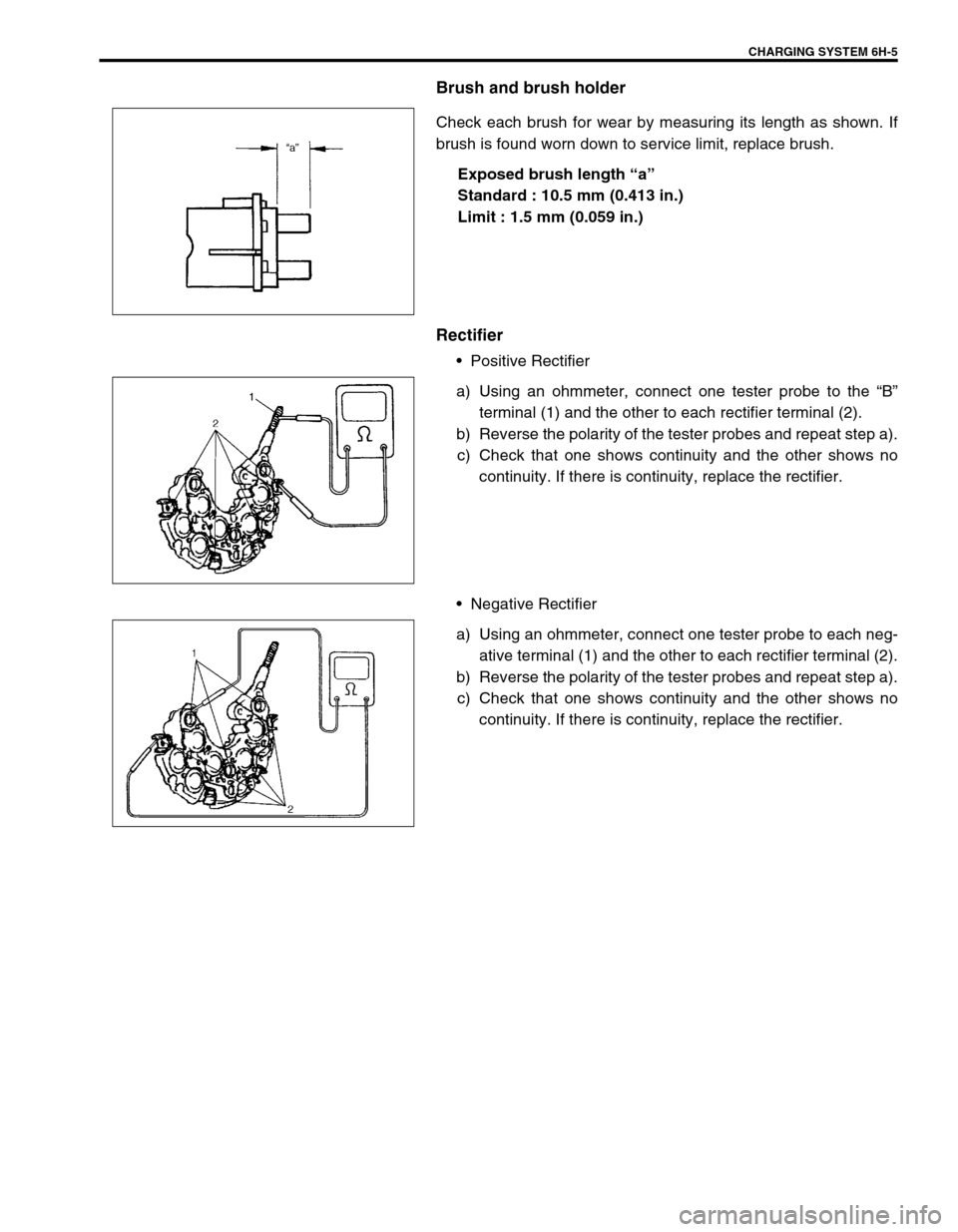

Stator

•Using ohmmeter, check all leads for continuity. If there is no

continuity, replace stator.

•Using ohmmeter, check that there is no continuity between

coil leads and stator core. If there is continuity, replace sta-

tor.

Page 402 of 656

CHARGING SYSTEM 6H-5

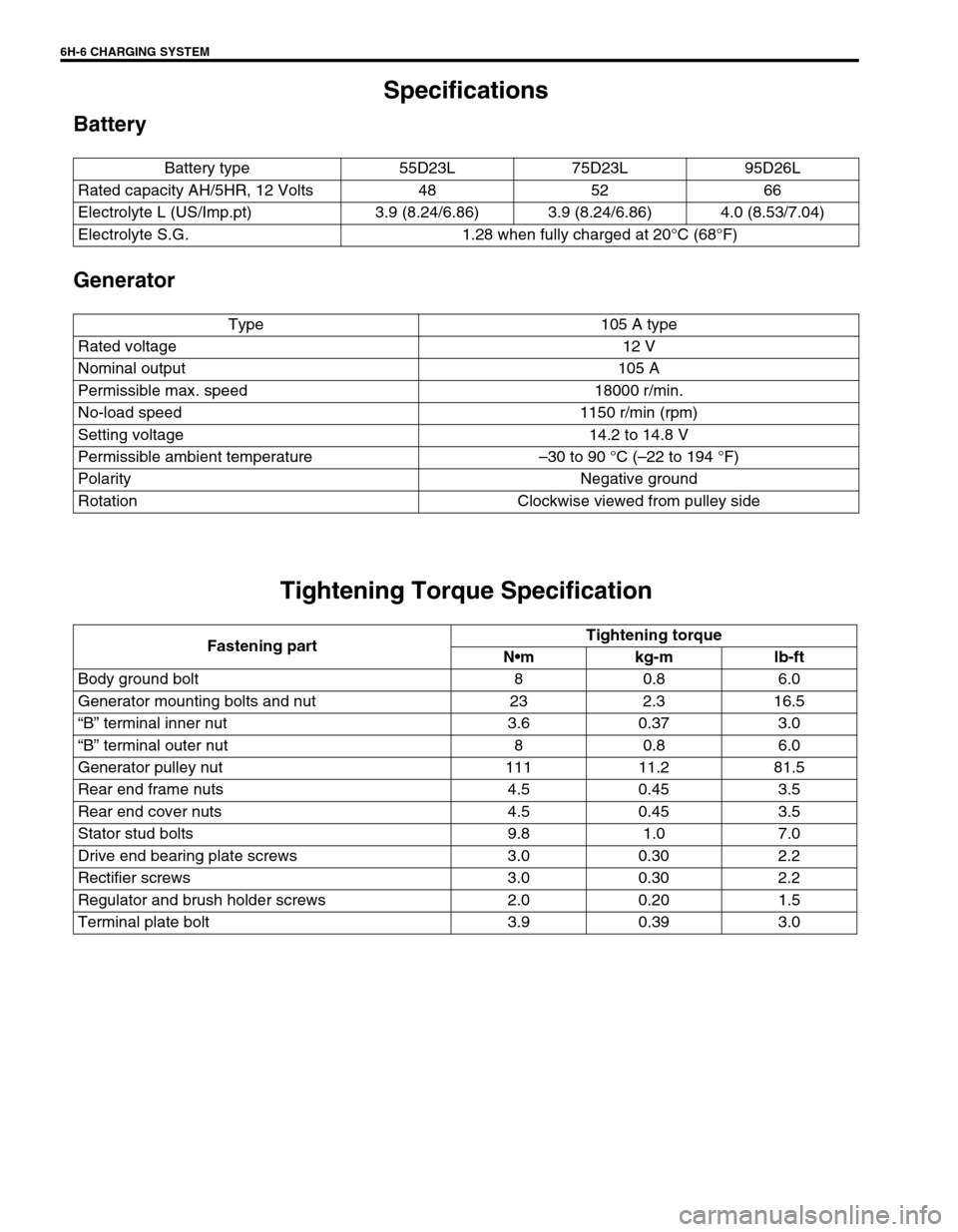

Brush and brush holder

Check each brush for wear by measuring its length as shown. If

brush is found worn down to service limit, replace brush.

Exposed brush length “a”

Standard : 10.5 mm (0.413 in.)

Limit : 1.5 mm (0.059 in.)

Rectifier

•Positive Rectifier

a) Using an ohmmeter, connect one tester probe to the “B”

terminal (1) and the other to each rectifier terminal (2).

b) Reverse the polarity of the tester probes and repeat step a).

c) Check that one shows continuity and the other shows no

continuity. If there is continuity, replace the rectifier.

•Negative Rectifier

a) Using an ohmmeter, connect one tester probe to each neg-

ative terminal (1) and the other to each rectifier terminal (2).

b) Reverse the polarity of the tester probes and repeat step a).

c) Check that one shows continuity and the other shows no

continuity. If there is continuity, replace the rectifier.

Page 403 of 656

6H-6 CHARGING SYSTEM

Specifications

Battery

Generator

Tightening Torque Specification

Battery type 55D23L 75D23L 95D26L

Rated capacity AH/5HR, 12 Volts 48 52 66

Electrolyte L (US/Imp.pt) 3.9 (8.24/6.86) 3.9 (8.24/6.86) 4.0 (8.53/7.04)

Electrolyte S.G. 1.28 when fully charged at 20°C (68°F)

Type 105 A type

Rated voltage 12 V

Nominal output 105 A

Permissible max. speed 18000 r/min.

No-load speed 1150 r/min (rpm)

Setting voltage 14.2 to 14.8 V

Permissible ambient temperature–30 to 90 °C (–22 to 194 °F)

Polarity Negative ground

Rotation Clockwise viewed from pulley side

Fastening partTightening torque

Nm kg-m lb-ft

Body ground bolt 8 0.8 6.0

Generator mounting bolts and nut 23 2.3 16.5

“B” terminal inner nut 3.6 0.37 3.0

“B” terminal outer nut 8 0.8 6.0

Generator pulley nut 111 11.2 81.5

Rear end frame nuts 4.5 0.45 3.5

Rear end cover nuts 4.5 0.45 3.5

Stator stud bolts 9.8 1.0 7.0

Drive end bearing plate screws 3.0 0.30 2.2

Rectifier screws 3.0 0.30 2.2

Regulator and brush holder screws 2.0 0.20 1.5

Terminal plate bolt 3.9 0.39 3.0

Page 611 of 656

10B-34 AIR BAG SYSTEM

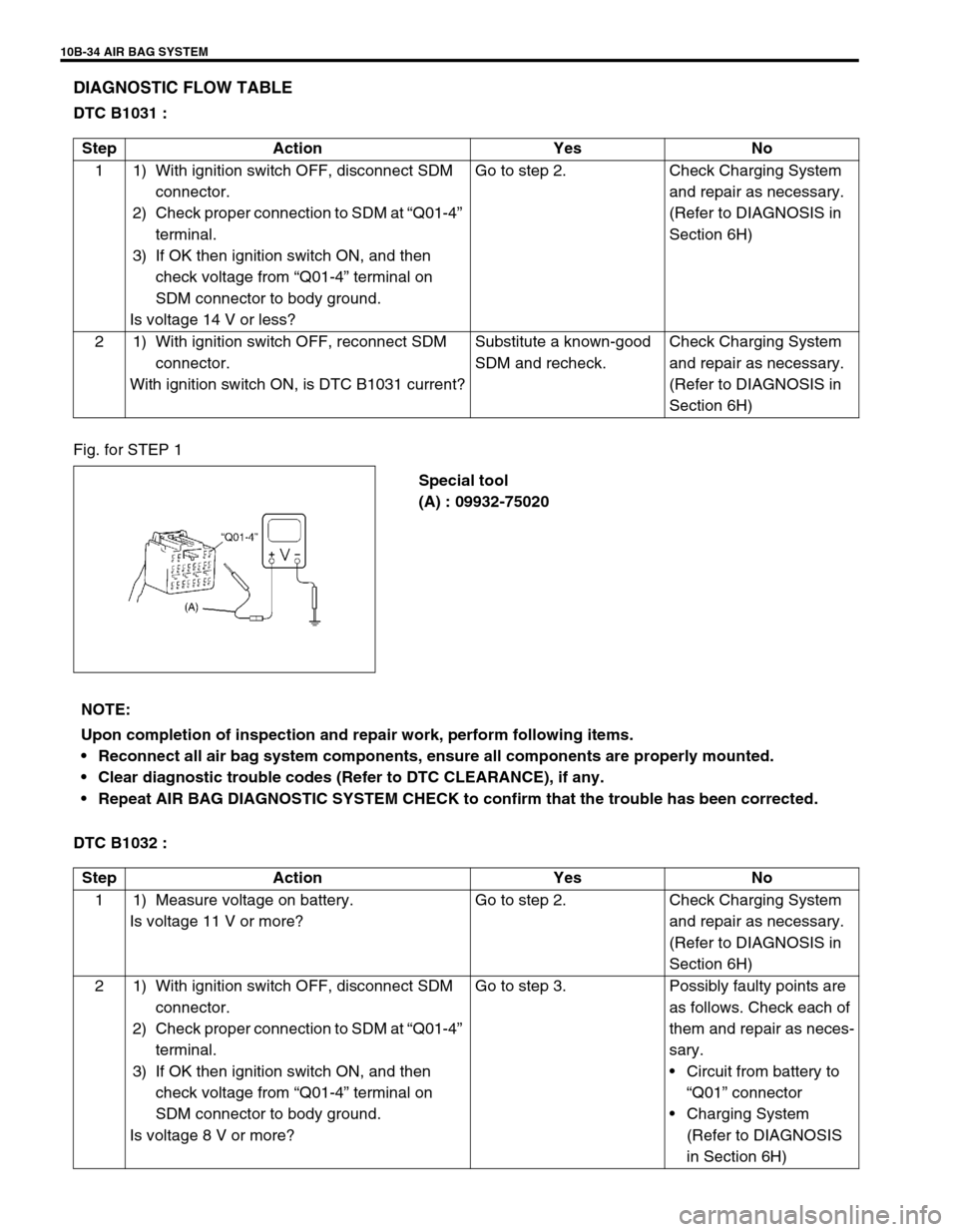

DIAGNOSTIC FLOW TABLE

DTC B1031 :

Fig. for STEP 1

Special tool

(A) : 09932-75020

DTC B1032 :Step Action Yes No

1 1) With ignition switch OFF, disconnect SDM

connector.

2) Check proper connection to SDM at “Q01-4”

terminal.

3) If OK then ignition switch ON, and then

check voltage from “Q01-4” terminal on

SDM connector to body ground.

Is voltage 14 V or less?Go to step 2. Check Charging System

and repair as necessary.

(Refer to DIAGNOSIS in

Section 6H)

2 1) With ignition switch OFF, reconnect SDM

connector.

With ignition switch ON, is DTC B1031 current?Substitute a known-good

SDM and recheck.Check Charging System

and repair as necessary.

(Refer to DIAGNOSIS in

Section 6H)

NOTE:

Upon completion of inspection and repair work, perform following items.

Reconnect all air bag system components, ensure all components are properly mounted.

Clear diagnostic trouble codes (Refer to DTC CLEARANCE), if any.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.

Step Action Yes No

1 1) Measure voltage on battery.

Is voltage 11 V or more?Go to step 2. Check Charging System

and repair as necessary.

(Refer to DIAGNOSIS in

Section 6H)

2 1) With ignition switch OFF, disconnect SDM

connector.

2) Check proper connection to SDM at “Q01-4”

terminal.

3) If OK then ignition switch ON, and then

check voltage from “Q01-4” terminal on

SDM connector to body ground.

Is voltage 8 V or more?Go to step 3. Possibly faulty points are

as follows. Check each of

them and repair as neces-

sary.

•Circuit from battery to

“Q01” connector

•Charging System

(Refer to DIAGNOSIS

in Section 6H)

Page 612 of 656

AIR BAG SYSTEM 10B-35

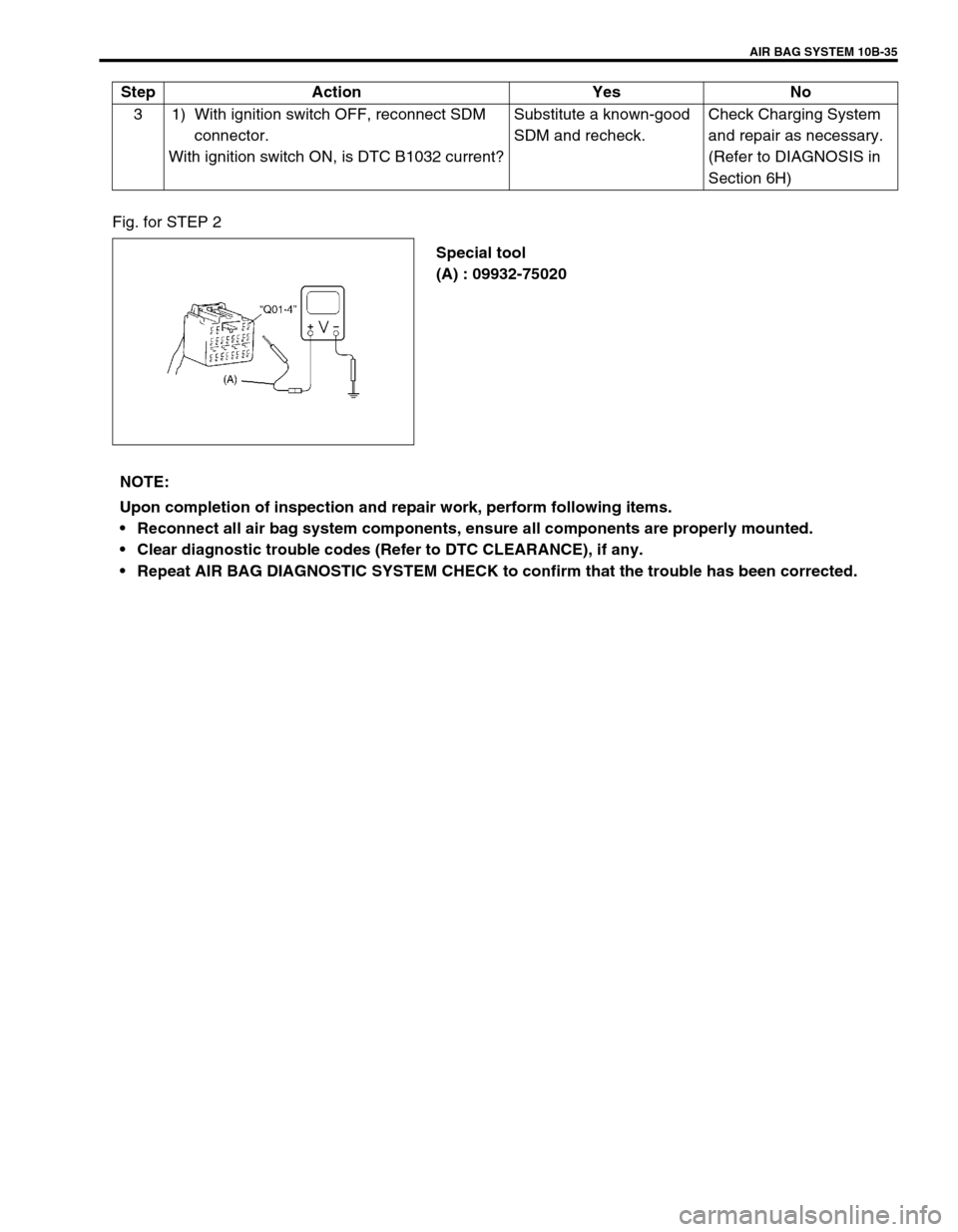

Fig. for STEP 2

Special tool

(A) : 09932-75020 3 1) With ignition switch OFF, reconnect SDM

connector.

With ignition switch ON, is DTC B1032 current?Substitute a known-good

SDM and recheck.Check Charging System

and repair as necessary.

(Refer to DIAGNOSIS in

Section 6H) Step Action Yes No

NOTE:

Upon completion of inspection and repair work, perform following items.

Reconnect all air bag system components, ensure all components are properly mounted.

Clear diagnostic trouble codes (Refer to DTC CLEARANCE), if any.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.