ignition system SUZUKI GRAND VITARA 2001 2.G Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2001, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2001 2.GPages: 656, PDF Size: 14.31 MB

Page 242 of 656

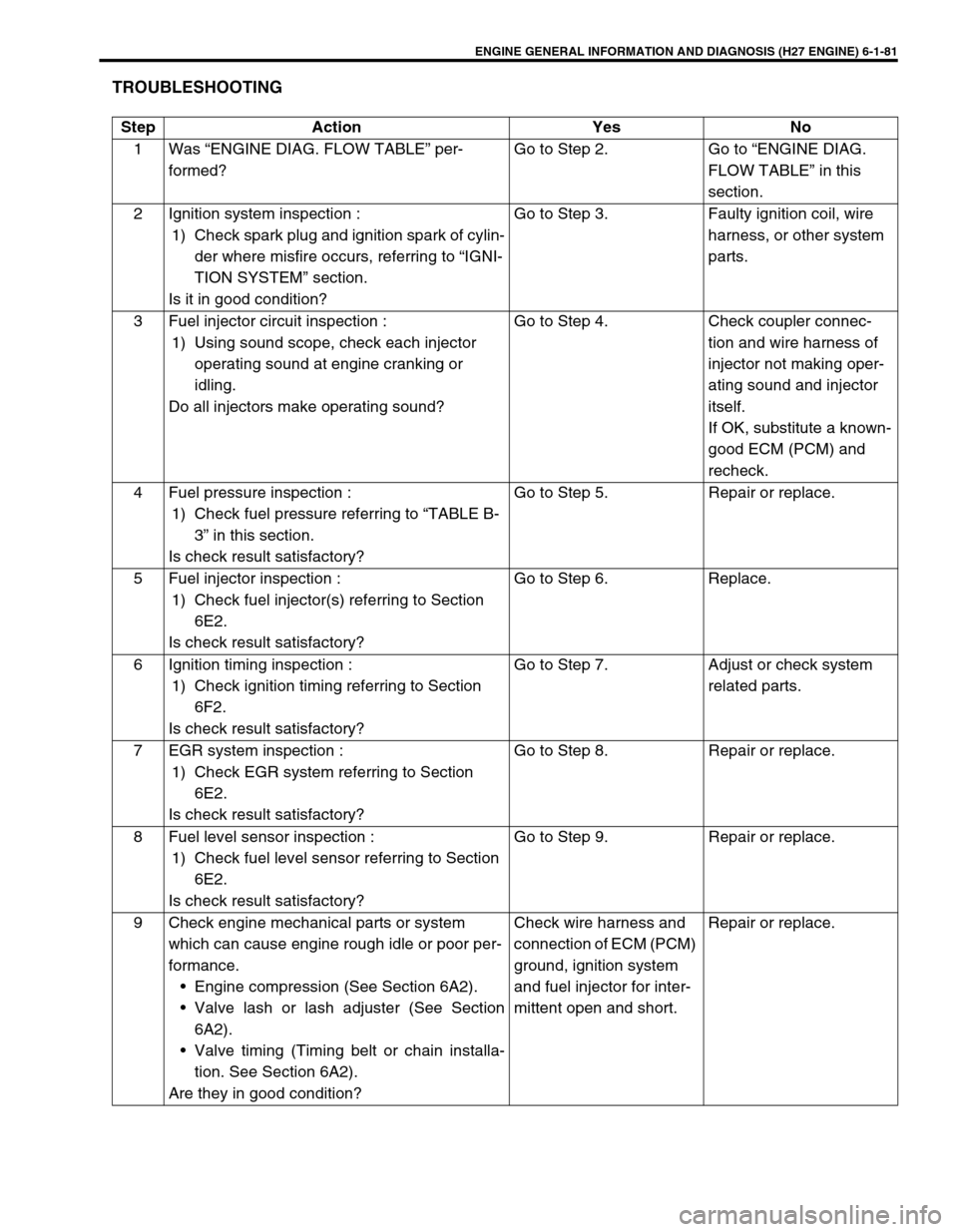

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-81

TROUBLESHOOTING

Step Action Yes No

1 Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in this

section.

2 Ignition system inspection :

1) Check spark plug and ignition spark of cylin-

der where misfire occurs, referring to “IGNI-

TION SYSTEM” section.

Is it in good condition?Go to Step 3. Faulty ignition coil, wire

harness, or other system

parts.

3 Fuel injector circuit inspection :

1) Using sound scope, check each injector

operating sound at engine cranking or

idling.

Do all injectors make operating sound?Go to Step 4. Check coupler connec-

tion and wire harness of

injector not making oper-

ating sound and injector

itself.

If OK, substitute a known-

good ECM (PCM) and

recheck.

4 Fuel pressure inspection :

1) Check fuel pressure referring to “TABLE B-

3” in this section.

Is check result satisfactory?Go to Step 5. Repair or replace.

5 Fuel injector inspection :

1) Check fuel injector(s) referring to Section

6E2.

Is check result satisfactory?Go to Step 6. Replace.

6 Ignition timing inspection :

1) Check ignition timing referring to Section

6F2.

Is check result satisfactory?Go to Step 7. Adjust or check system

related parts.

7 EGR system inspection :

1) Check EGR system referring to Section

6E2.

Is check result satisfactory?Go to Step 8. Repair or replace.

8 Fuel level sensor inspection :

1) Check fuel level sensor referring to Section

6E2.

Is check result satisfactory?Go to Step 9. Repair or replace.

9 Check engine mechanical parts or system

which can cause engine rough idle or poor per-

formance.

• Engine compression (See Section 6A2).

• Valve lash or lash adjuster (See Section

6A2).

• Valve timing (Timing belt or chain installa-

tion. See Section 6A2).

Are they in good condition?Check wire harness and

connection of ECM (PCM)

ground, ignition system

and fuel injector for inter-

mittent open and short.Repair or replace.

Page 251 of 656

6-1-90 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

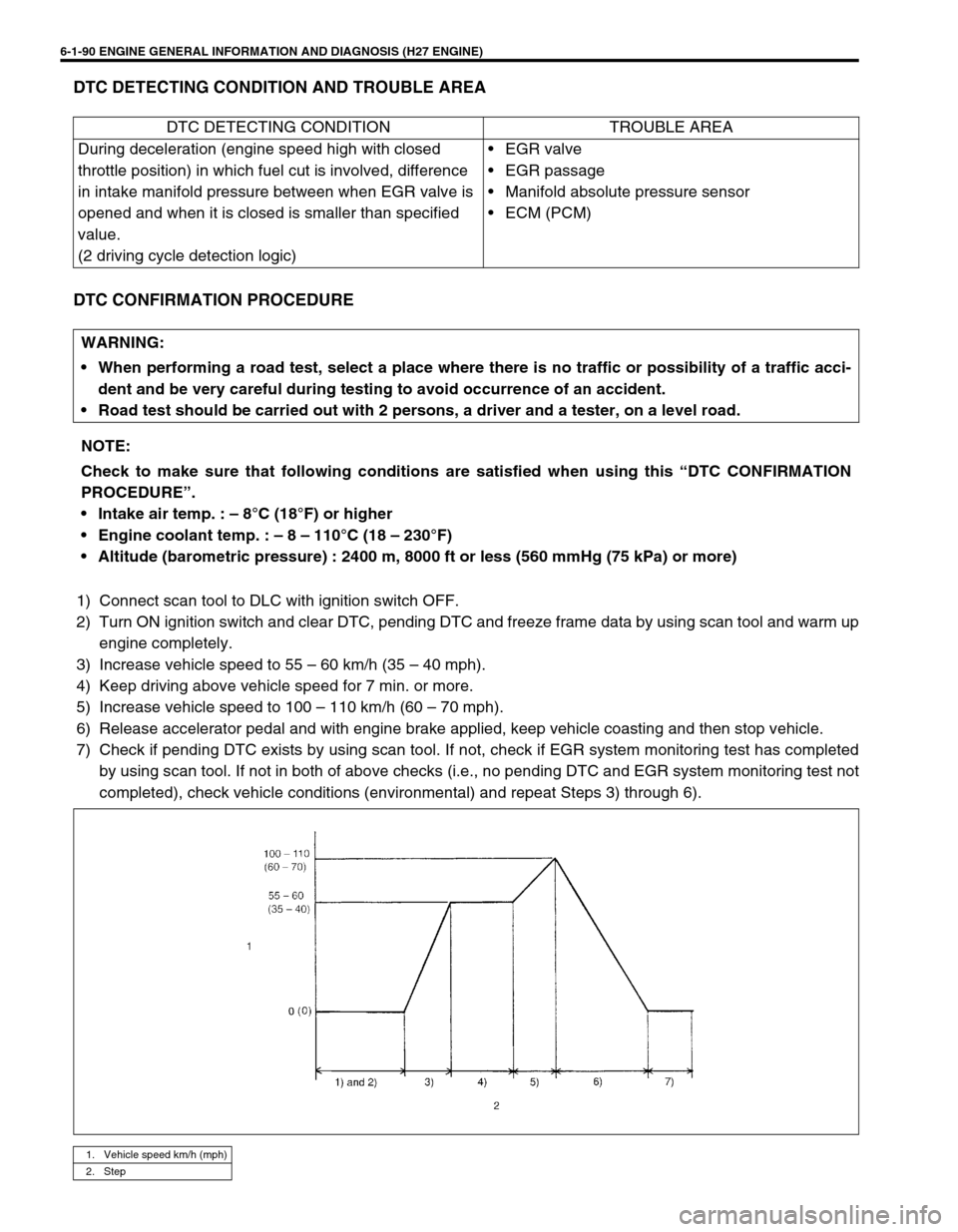

DTC DETECTING CONDITION AND TROUBLE AREA

DTC CONFIRMATION PROCEDURE

1) Connect scan tool to DLC with ignition switch OFF.

2) Turn ON ignition switch and clear DTC, pending DTC and freeze frame data by using scan tool and warm up

engine completely.

3) Increase vehicle speed to 55 – 60 km/h (35 – 40 mph).

4) Keep driving above vehicle speed for 7 min. or more.

5) Increase vehicle speed to 100 – 110 km/h (60 – 70 mph).

6) Release accelerator pedal and with engine brake applied, keep vehicle coasting and then stop vehicle.

7) Check if pending DTC exists by using scan tool. If not, check if EGR system monitoring test has completed

by using scan tool. If not in both of above checks (i.e., no pending DTC and EGR system monitoring test not

completed), check vehicle conditions (environmental) and repeat Steps 3) through 6).DTC DETECTING CONDITION TROUBLE AREA

During deceleration (engine speed high with closed

throttle position) in which fuel cut is involved, difference

in intake manifold pressure between when EGR valve is

opened and when it is closed is smaller than specified

value.

(2 driving cycle detection logic)•EGR valve

• EGR passage

• Manifold absolute pressure sensor

•ECM (PCM)

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

NOTE:

Check to make sure that following conditions are satisfied when using this “DTC CONFIRMATION

PROCEDURE”.

Intake air temp. : – 8°C (18°F) or higher

Engine coolant temp. : – 8 – 110°C (18 – 230°F)

Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg (75 kPa) or more)

1. Vehicle speed km/h (mph)

2. Step

Page 252 of 656

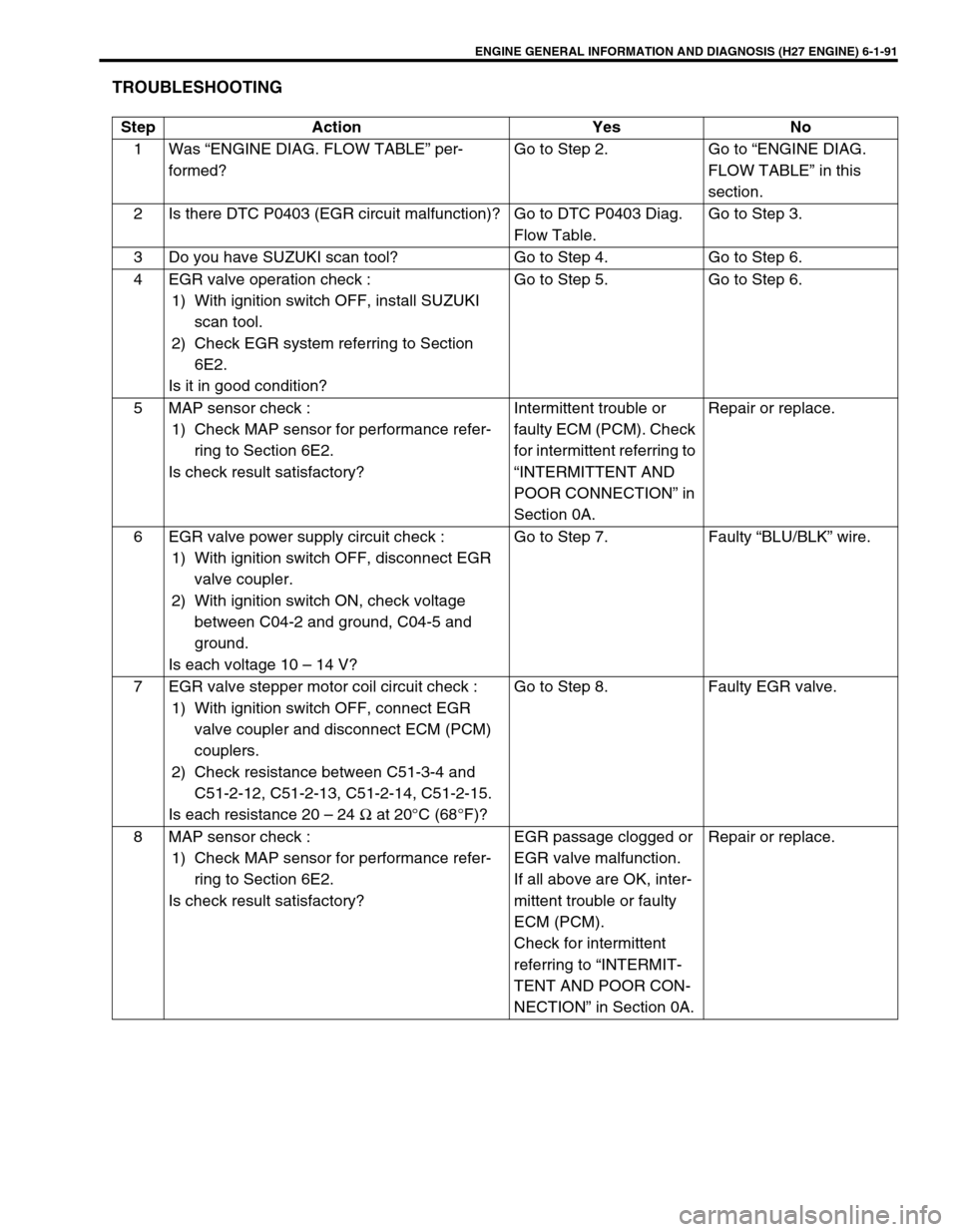

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-91

TROUBLESHOOTING

Step Action Yes No

1 Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in this

section.

2 Is there DTC P0403 (EGR circuit malfunction)? Go to DTC P0403 Diag.

Flow Table.Go to Step 3.

3 Do you have SUZUKI scan tool? Go to Step 4. Go to Step 6.

4 EGR valve operation check :

1) With ignition switch OFF, install SUZUKI

scan tool.

2) Check EGR system referring to Section

6E2.

Is it in good condition?Go to Step 5. Go to Step 6.

5 MAP sensor check :

1) Check MAP sensor for performance refer-

ring to Section 6E2.

Is check result satisfactory?Intermittent trouble or

faulty ECM (PCM). Check

for intermittent referring to

“INTERMITTENT AND

POOR CONNECTION” in

Section 0A.Repair or replace.

6 EGR valve power supply circuit check :

1) With ignition switch OFF, disconnect EGR

valve coupler.

2) With ignition switch ON, check voltage

between C04-2 and ground, C04-5 and

ground.

Is each voltage 10 – 14 V?Go to Step 7. Faulty “BLU/BLK” wire.

7 EGR valve stepper motor coil circuit check :

1) With ignition switch OFF, connect EGR

valve coupler and disconnect ECM (PCM)

couplers.

2) Check resistance between C51-3-4 and

C51-2-12, C51-2-13, C51-2-14, C51-2-15.

Is each resistance 20 – 24 Ω at 20°C (68°F)?Go to Step 8. Faulty EGR valve.

8 MAP sensor check :

1) Check MAP sensor for performance refer-

ring to Section 6E2.

Is check result satisfactory?EGR passage clogged or

EGR valve malfunction.

If all above are OK, inter-

mittent trouble or faulty

ECM (PCM).

Check for intermittent

referring to “INTERMIT-

TENT AND POOR CON-

NECTION” in Section 0A.Repair or replace.

Page 254 of 656

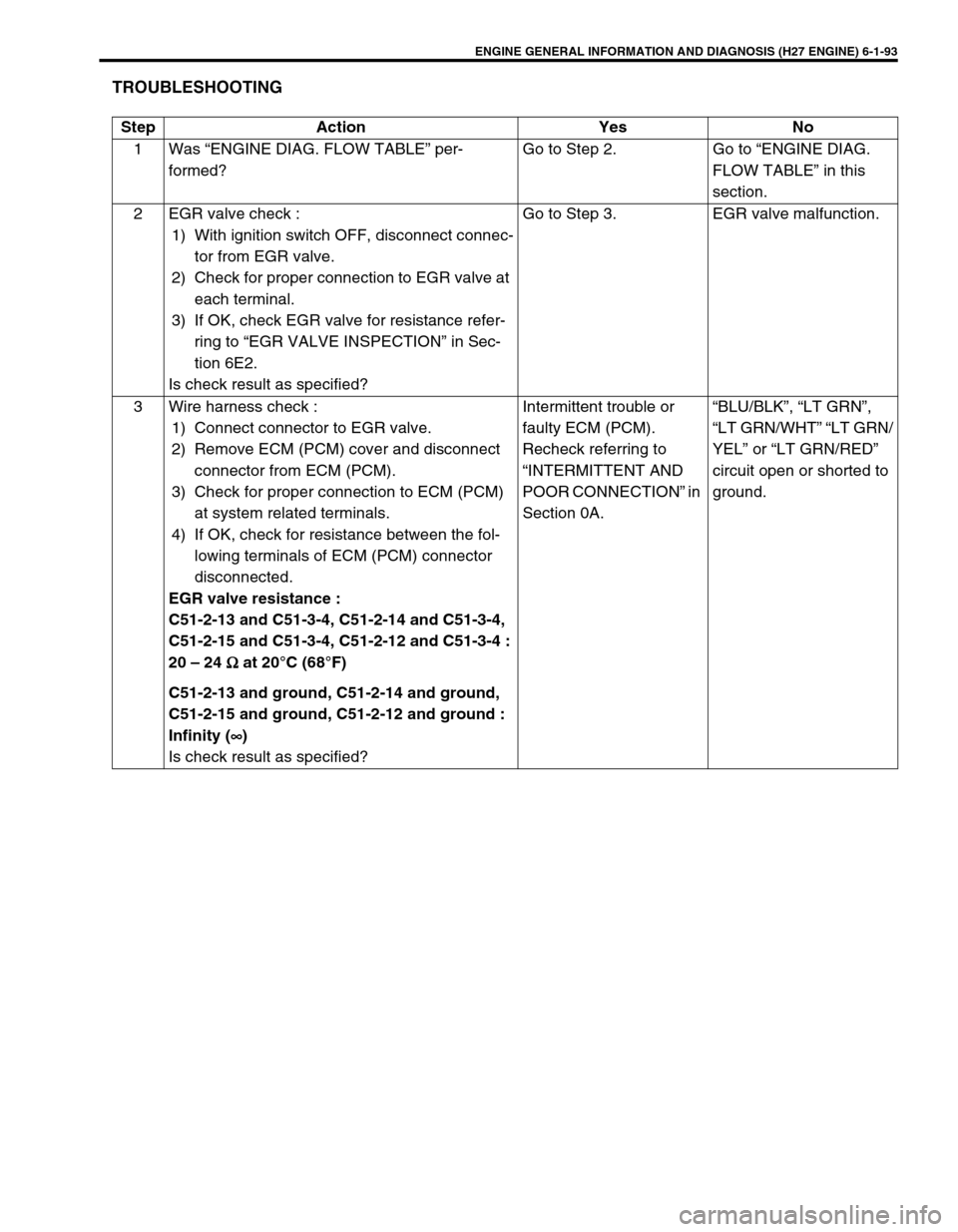

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-93

TROUBLESHOOTING

Step Action Yes No

1 Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in this

section.

2 EGR valve check :

1) With ignition switch OFF, disconnect connec-

tor from EGR valve.

2) Check for proper connection to EGR valve at

each terminal.

3) If OK, check EGR valve for resistance refer-

ring to “EGR VALVE INSPECTION” in Sec-

tion 6E2.

Is check result as specified?Go to Step 3. EGR valve malfunction.

3 Wire harness check :

1) Connect connector to EGR valve.

2) Remove ECM (PCM) cover and disconnect

connector from ECM (PCM).

3) Check for proper connection to ECM (PCM)

at system related terminals.

4) If OK, check for resistance between the fol-

lowing terminals of ECM (PCM) connector

disconnected.

EGR valve resistance :

C51-2-13 and C51-3-4, C51-2-14 and C51-3-4,

C51-2-15 and C51-3-4, C51-2-12 and C51-3-4 :

20 – 24

Ω

ΩΩ Ω at 20°C (68°F)

C51-2-13 and ground, C51-2-14 and ground,

C51-2-15 and ground, C51-2-12 and ground :

Infinity (

∞

∞∞ ∞)

Is check result as specified?Intermittent trouble or

faulty ECM (PCM).

Recheck referring to

“INTERMITTENT AND

POOR CONNECTION” in

Section 0A.“BLU/BLK”, “LT GRN”,

“LT GRN/WHT” “LT GRN/

YEL” or “LT GRN/RED”

circuit open or shorted to

ground.

Page 256 of 656

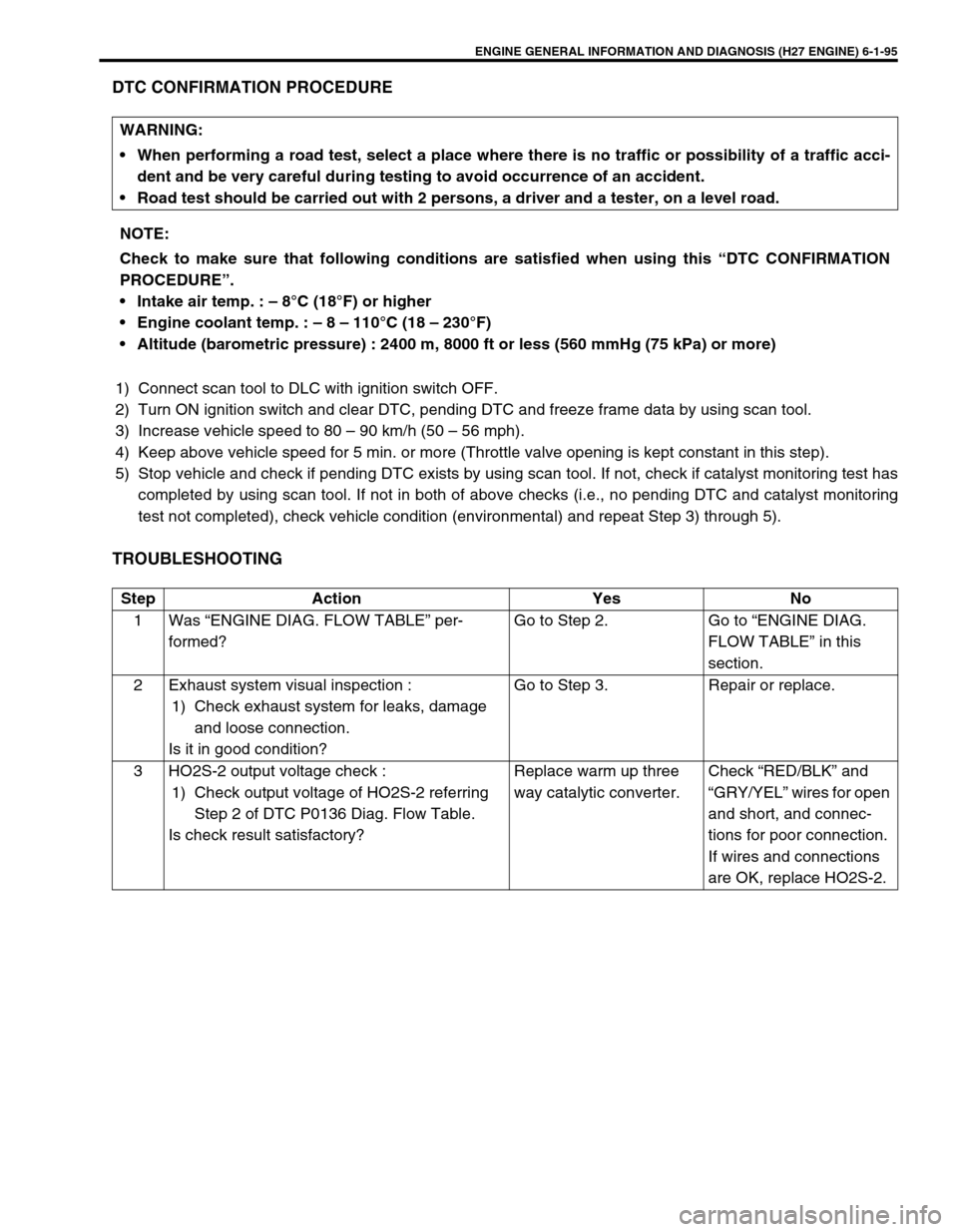

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-95

DTC CONFIRMATION PROCEDURE

1) Connect scan tool to DLC with ignition switch OFF.

2) Turn ON ignition switch and clear DTC, pending DTC and freeze frame data by using scan tool.

3) Increase vehicle speed to 80 – 90 km/h (50 – 56 mph).

4) Keep above vehicle speed for 5 min. or more (Throttle valve opening is kept constant in this step).

5) Stop vehicle and check if pending DTC exists by using scan tool. If not, check if catalyst monitoring test has

completed by using scan tool. If not in both of above checks (i.e., no pending DTC and catalyst monitoring

test not completed), check vehicle condition (environmental) and repeat Step 3) through 5).

TROUBLESHOOTING

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

NOTE:

Check to make sure that following conditions are satisfied when using this “DTC CONFIRMATION

PROCEDURE”.

Intake air temp. : – 8°C (18°F) or higher

Engine coolant temp. : – 8 – 110°C (18 – 230°F)

Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg (75 kPa) or more)

Step Action Yes No

1 Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in this

section.

2 Exhaust system visual inspection :

1) Check exhaust system for leaks, damage

and loose connection.

Is it in good condition?Go to Step 3. Repair or replace.

3 HO2S-2 output voltage check :

1) Check output voltage of HO2S-2 referring

Step 2 of DTC P0136 Diag. Flow Table.

Is check result satisfactory?Replace warm up three

way catalytic converter.Check “RED/BLK” and

“GRY/YEL” wires for open

and short, and connec-

tions for poor connection.

If wires and connections

are OK, replace HO2S-2.

Page 258 of 656

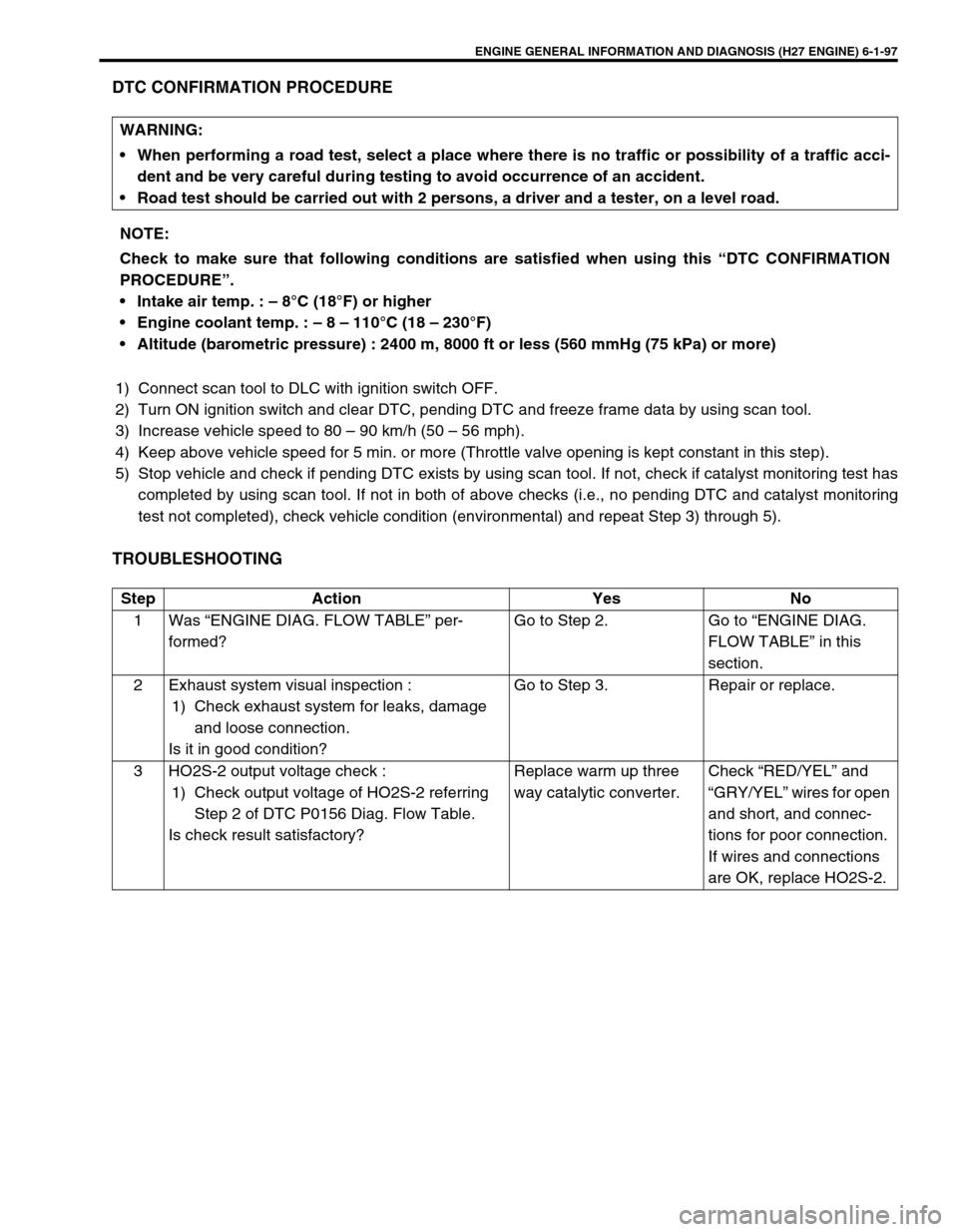

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-97

DTC CONFIRMATION PROCEDURE

1) Connect scan tool to DLC with ignition switch OFF.

2) Turn ON ignition switch and clear DTC, pending DTC and freeze frame data by using scan tool.

3) Increase vehicle speed to 80 – 90 km/h (50 – 56 mph).

4) Keep above vehicle speed for 5 min. or more (Throttle valve opening is kept constant in this step).

5) Stop vehicle and check if pending DTC exists by using scan tool. If not, check if catalyst monitoring test has

completed by using scan tool. If not in both of above checks (i.e., no pending DTC and catalyst monitoring

test not completed), check vehicle condition (environmental) and repeat Step 3) through 5).

TROUBLESHOOTING

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

NOTE:

Check to make sure that following conditions are satisfied when using this “DTC CONFIRMATION

PROCEDURE”.

Intake air temp. : – 8°C (18°F) or higher

Engine coolant temp. : – 8 – 110°C (18 – 230°F)

Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg (75 kPa) or more)

Step Action Yes No

1 Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in this

section.

2 Exhaust system visual inspection :

1) Check exhaust system for leaks, damage

and loose connection.

Is it in good condition?Go to Step 3. Repair or replace.

3 HO2S-2 output voltage check :

1) Check output voltage of HO2S-2 referring

Step 2 of DTC P0156 Diag. Flow Table.

Is check result satisfactory?Replace warm up three

way catalytic converter.Check “RED/YEL” and

“GRY/YEL” wires for open

and short, and connec-

tions for poor connection.

If wires and connections

are OK, replace HO2S-2.

Page 260 of 656

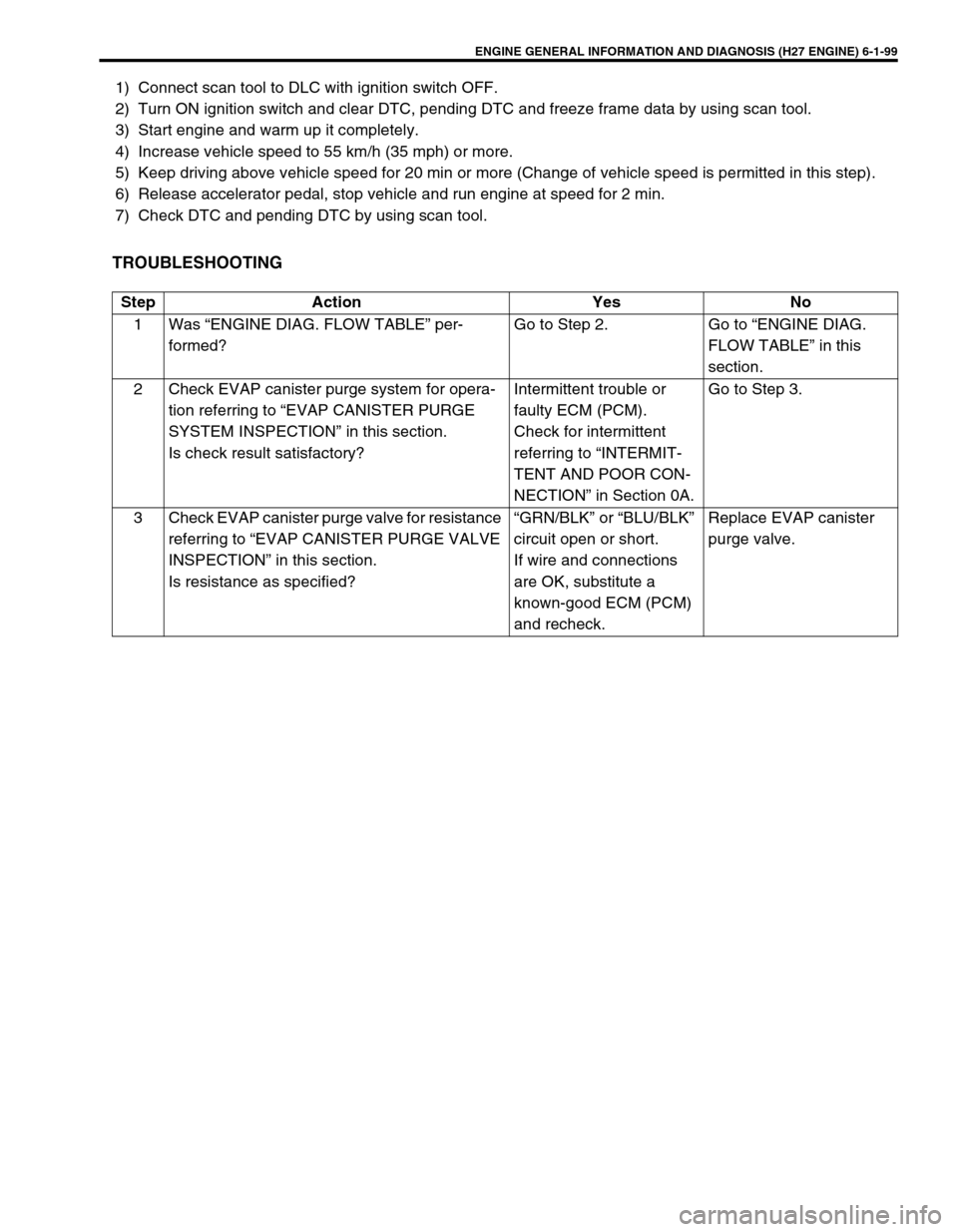

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-99

1) Connect scan tool to DLC with ignition switch OFF.

2) Turn ON ignition switch and clear DTC, pending DTC and freeze frame data by using scan tool.

3) Start engine and warm up it completely.

4) Increase vehicle speed to 55 km/h (35 mph) or more.

5) Keep driving above vehicle speed for 20 min or more (Change of vehicle speed is permitted in this step).

6) Release accelerator pedal, stop vehicle and run engine at speed for 2 min.

7) Check DTC and pending DTC by using scan tool.

TROUBLESHOOTING

Step Action Yes No

1 Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in this

section.

2 Check EVAP canister purge system for opera-

tion referring to “EVAP CANISTER PURGE

SYSTEM INSPECTION” in this section.

Is check result satisfactory?Intermittent trouble or

faulty ECM (PCM).

Check for intermittent

referring to “INTERMIT-

TENT AND POOR CON-

NECTION” in Section 0A.Go to Step 3.

3 Check EVAP canister purge valve for resistance

referring to “EVAP CANISTER PURGE VALVE

INSPECTION” in this section.

Is resistance as specified?“GRN/BLK” or “BLU/BLK”

circuit open or short.

If wire and connections

are OK, substitute a

known-good ECM (PCM)

and recheck.Replace EVAP canister

purge valve.

Page 271 of 656

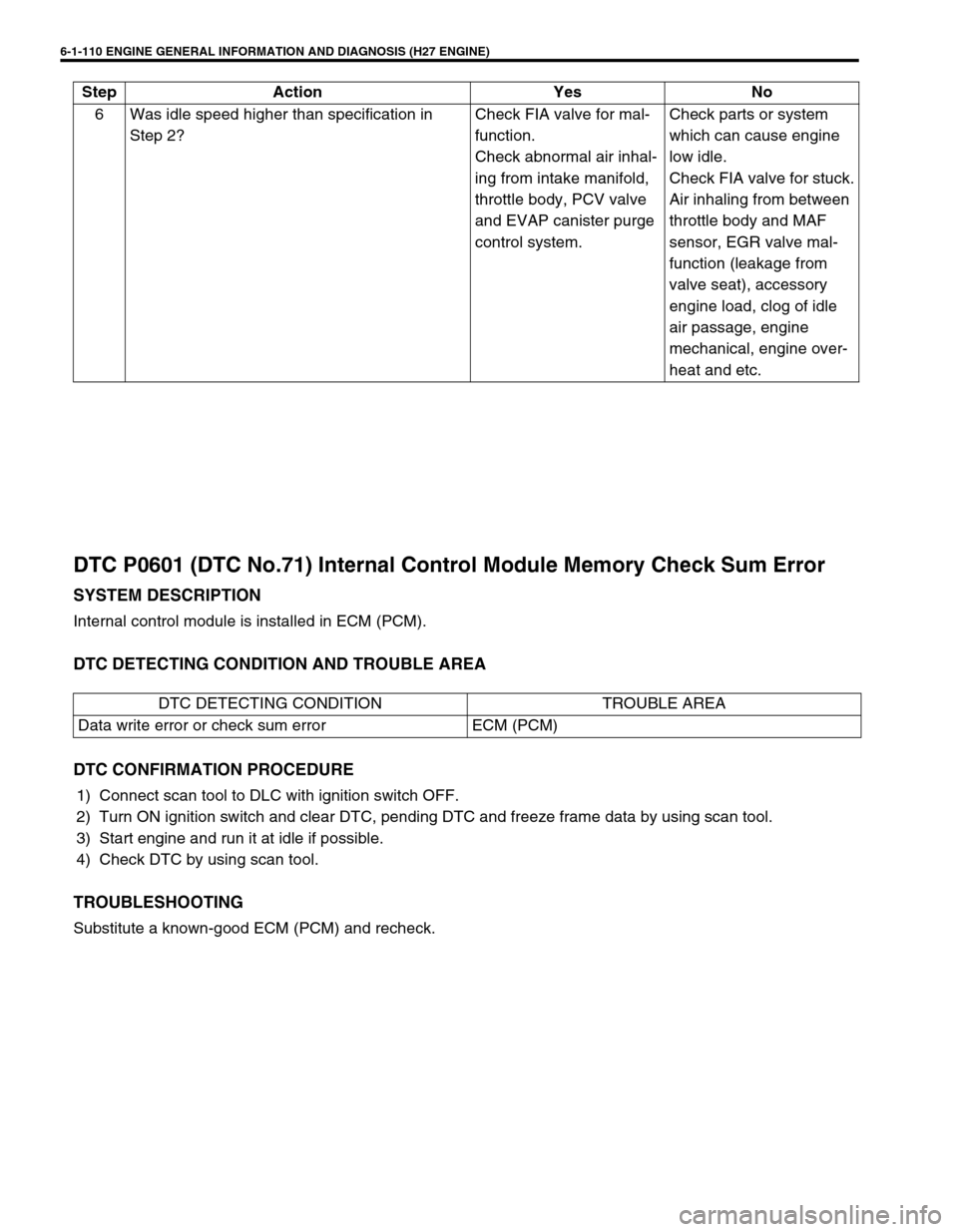

6-1-110 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

DTC P0601 (DTC No.71) Internal Control Module Memory Check Sum Error

SYSTEM DESCRIPTION

Internal control module is installed in ECM (PCM).

DTC DETECTING CONDITION AND TROUBLE AREA

DTC CONFIRMATION PROCEDURE

1) Connect scan tool to DLC with ignition switch OFF.

2) Turn ON ignition switch and clear DTC, pending DTC and freeze frame data by using scan tool.

3) Start engine and run it at idle if possible.

4) Check DTC by using scan tool.

TROUBLESHOOTING

Substitute a known-good ECM (PCM) and recheck.6 Was idle speed higher than specification in

Step 2?Check FIA valve for mal-

function.

Check abnormal air inhal-

ing from intake manifold,

throttle body, PCV valve

and EVAP canister purge

control system.Check parts or system

which can cause engine

low idle.

Check FIA valve for stuck.

Air inhaling from between

throttle body and MAF

sensor, EGR valve mal-

function (leakage from

valve seat), accessory

engine load, clog of idle

air passage, engine

mechanical, engine over-

heat and etc. Step Action Yes No

DTC DETECTING CONDITION TROUBLE AREA

Data write error or check sum error ECM (PCM)

Page 274 of 656

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-113

DTC P1450/P1451 Barometric Pressure Sensor Circuit Malfunction/Perfor-

mance Problem

SYSTEM DESCRIPTION

Barometric pressure sensor is installed in ECM (PCM).

DTC DETECTING CONDITION AND TROUBLE AREA

DTC CONFIRMATION PROCEDURE

For DTC P1450

1) Connect scan tool to DLC with ignition switch OFF.

2) Turn ON ignition switch and clear DTC by using scan tool and run engine for 1 min.

3) Check DTC by using scan tool.

For DTC P1451

1) Connect scan tool to DLC with ignition switch OFF.

2) Turn ON ignition switch and clear DTC, pending DTC and freeze frame data by using scan tool and warm up

engine to normal operating temperature.

3) Increase engine speed to 3,000 r/min. in 3rd gear in case of M/T and “2” range in case of A/T.

4) Release accelerator pedal and with engine brake applied, keep vehicle coasting for 5 sec. or more (keep fuel

cut condition for 5 sec. or more). If fuel cut condition is not kept for 5 sec. or more, coast down a slope in

engine speed 1600 – 3000 r/min for 5 sec. or more.

5) Stop vehicle and run engine at idle.

6) Repeat steps 3) – 5) 2 times.

7) Check pending DTC by using scan tool.

TROUBLESHOOTING (DTC P1450/P1451)

DTC DETECTING CONDITION TROUBLE AREA

DTC P1450 :

Barometric pressure out of specification is detected.•Barometric pressure sensor in ECM

(PCM)

DTC P1451 :

While running under conditions described for “DTC CONFIRMATION

PROCEDURE”, barometric pressure value compared with intake

manifold vacuum value in fuel cut state is not as specified.

(2 driving cycle detection logic)•Manifold absolute pressure sensor

performance problem

•Barometric pressure sensor in ECM

(PCM)

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” performed? Go to Step 2. Go to “ENGINE DIAG. FLOW

TABLE” in this section.

2 Is DTC P1451 set? Go to Step 3. Substitute a known-good

ECM (PCM) and recheck.

3 MAP sensor check :

1) Check MAP sensor and its circuit referring to

Steps 2 and 3 of “DTC P1408 Diag. Flow Table”.

Is check result satisfactory?Substitute a

known-good

ECM (PCM) and

recheck.MAP sensor or its circuit mal-

function.

Page 285 of 656

6-1-124 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

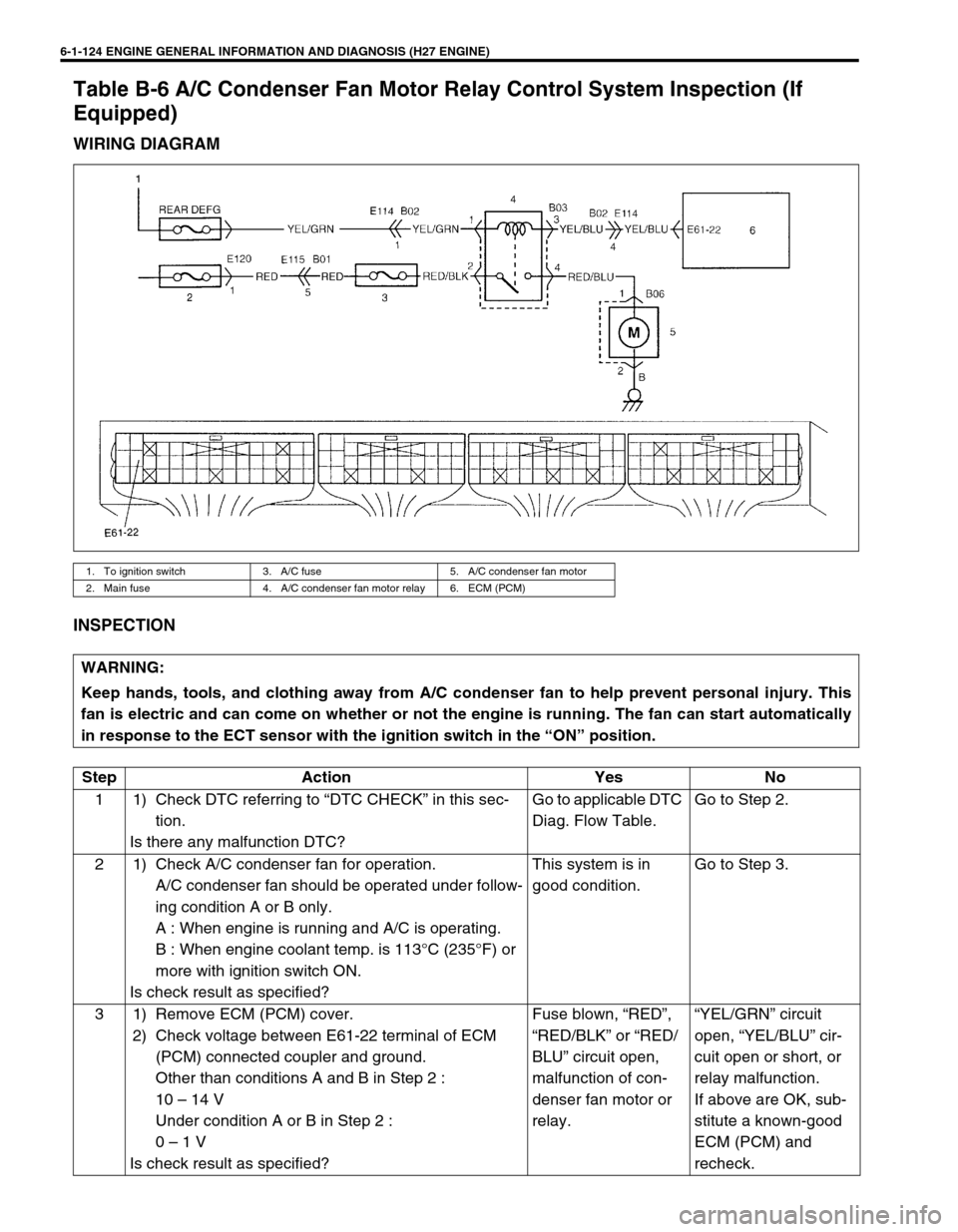

Table B-6 A/C Condenser Fan Motor Relay Control System Inspection (If

Equipped)

WIRING DIAGRAM

INSPECTION

1. To ignition switch 3. A/C fuse 5. A/C condenser fan motor

2. Main fuse 4. A/C condenser fan motor relay 6. ECM (PCM)

WARNING:

Keep hands, tools, and clothing away from A/C condenser fan to help prevent personal injury. This

fan is electric and can come on whether or not the engine is running. The fan can start automatically

in response to the ECT sensor with the ignition switch in the “ON” position.

Step Action Yes No

1 1) Check DTC referring to “DTC CHECK” in this sec-

tion.

Is there any malfunction DTC?Go to applicable DTC

Diag. Flow Table.Go to Step 2.

2 1) Check A/C condenser fan for operation.

A/C condenser fan should be operated under follow-

ing condition A or B only.

A : When engine is running and A/C is operating.

B : When engine coolant temp. is 113°C (235°F) or

more with ignition switch ON.

Is check result as specified?This system is in

good condition.Go to Step 3.

3 1) Remove ECM (PCM) cover.

2) Check voltage between E61-22 terminal of ECM

(PCM) connected coupler and ground.

Other than conditions A and B in Step 2 :

10 – 14 V

Under condition A or B in Step 2 :

0 – 1 V

Is check result as specified?Fuse blown, “RED”,

“RED/BLK” or “RED/

BLU” circuit open,

malfunction of con-

denser fan motor or

relay.“YEL/GRN” circuit

open, “YEL/BLU” cir-

cuit open or short, or

relay malfunction.

If above are OK, sub-

stitute a known-good

ECM (PCM) and

recheck.