ignition system SUZUKI GRAND VITARA 2001 2.G Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2001, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2001 2.GPages: 656, PDF Size: 14.31 MB

Page 288 of 656

ENGINE MECHANICAL (H27 ENGINE) 6A2-1

6A2

SECTION 6A2

ENGINE MECHANICAL (H27 ENGINE)

CONTENTS

On-Vehicle Service........................................6A2-2

Throttle Body and Intake Manifold .............. 6A2-2

Exhaust Manifold ......................................... 6A2-9

LH (No.1) Bank 2nd Timing Chain

and Chain Tensioner ................................. 6A2-13

Camshaft and Valve Lash Adjuster ........... 6A2-14

Valves and Cylinder Heads ....................... 6A2-17

Piston, Piston Rings, Connecting Rodsand Cylinders ............................................ 6A2-21

Unit Repair Overhaul .................................. 6A2-26

Engine Assembly ...................................... 6A2-26

Main Bearings, Crankshaft

and Cylinder Block .................................... 6A2-30

Special Tool ................................................. 6A2-36

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

For the descriptions (items) not found in this section, refer to the same section of service manual

mentioned in the FOREWORD of this manual.

Whether following systems (parts) are used in the particular vehicle or not depends on specifica-

tions. Be sure to bear this in mind when performing service work.

–EGR valve

–Warm up three way catalytic converter

–Heated oxygen sensor(s)

–Three way catalytic converter

–CKP sensor

–MAP sensor

Page 307 of 656

6A2-20 ENGINE MECHANICAL (H27 ENGINE)

12) Install oil pan and oil pump strainer.

Refer to “OIL PAN AND OIL PUMP STRAINER” in this sec-

tion.

13) Install cylinder head cover.

Refer to “CYLINDER HEAD COVER” in this section.

14) Install exhaust manifold.

Refer to “EXHAUST MANIFOLD” in this section.

15) Install radiator outlet pipe, radiator, cooling fan and water

hose.

Refer to “COOLING WATER PIPES OR HOSES”, “RADIA-

TOR” and “COOLING FAN AND FAN CLUTCH” in Section

6B.

16) Install throttle body and intake manifold.

Refer to “THROTTLE BODY AND INTAKE MANIFOLD” in

this section.

17) Adjust water pump drive belt tension.

Refer to “COOLING FAN BELT TENSION CHECK AND

ADJUSTMENT” in Section 6B.

18) Adjust power steering pump drive belt tension.

Refer to “POWER STEERING PUMP DRIVE BELT” in Sec-

tion 3B1.

19) Adjust accelerator cable play and A/T throttle cable play.

Refer to “ACCELERATOR CABLE ADJUSTMENT” and “A/T

THROTTLE CABLE ADJUSTMENT (A/T VEHICLE)” in Sec-

tion 6E2.

20) Check to ensure that all removed parts are back in place.

Reinstall any necessary parts which have not been rein-

stalled.

21) Refill engine with engine oil, referring to “ENGINE OIL

CHANGE” in Section 0B.

22) Refill cooling system referring to “COOLING SYSTEM

FLUSH AND REFILL” in Section 6B.

23) Refill front differential housing with gear oil if drained, refer-

ring to “MAINTENANCE SERVICE” in Section 7E.

24) Connect negative cable at battery.

25) Check ignition timing and adjust as necessary, referring to

“IGNITION TIMING CHECK AND ADJUSTMENT” in Section

6F2.

26) Verify that there is no fuel leakage, water leakage, oil leak-

age and exhaust gas leakage at each connection.

27) Check wheel alignment, referring to “STEERING ANGLE” in

Section 3A.

Page 334 of 656

ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE) 6E2-1

6E2

SECTION 6E2

ENGINE AND EMISSION CONTROL SYSTEM

(SEQUENTIAL MULTIPORT FUEL INJECTION

FOR H27 ENGINE)

CONTENTS

General Description ..................................... 6E2-2

System Flow ............................................... 6E2-3

System Diagram ......................................... 6E2-4

Air Intake System ....................................... 6E2-6

Fuel Delivery System ................................. 6E2-7

Electronic Control System .......................... 6E2-8

Engine and Emission Control Input/Output

Table ........................................................ 6E2-12

Diagnosis .................................................... 6E2-12

On-Vehicle Service..................................... 6E2-13

General .................................................... 6E2-13

Accelerator Cable Adjustment .................. 6E2-14

A/T Throttle Cable Adjustment

(A/T Vehicle) ............................................ 6E2-14Idle Speed/Idle Air Control (IAC) Duty

Inspection................................................. 6E2-15

[Using SUZUKI scan tool] .................... 6E2-15

[Not using SUZUKI scan tool]

(vehicle with monitor connector) .......... 6E2-16

Idle mixture inspection/adjustment

(vehicle without heated oxygen sensor) 6E2-17

Air Intake System ..................................... 6E2-18

Throttle body ........................................ 6E2-18

Idle air control valve (IAC valve) .......... 6E2-21

Fast idle air valve ................................. 6E2-22

Fuel Delivery System ............................... 6E2-23

Fuel pressure inspection ...................... 6E2-23

Fuel pump ............................................ 6E2-24

Fuel pressure regulator ........................ 6E2-25 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

Whether following systems (parts) are used in the particular vehicle or not depends on specifications.

Be sure to bear this in mind when performing service work.

Monitor connector

CKP sensor

MAP sensor

EGR valve

Heated oxygen sensor or CO adjusting resistor

Three way catalytic converter, Warm-up three way catalytic converter

Page 338 of 656

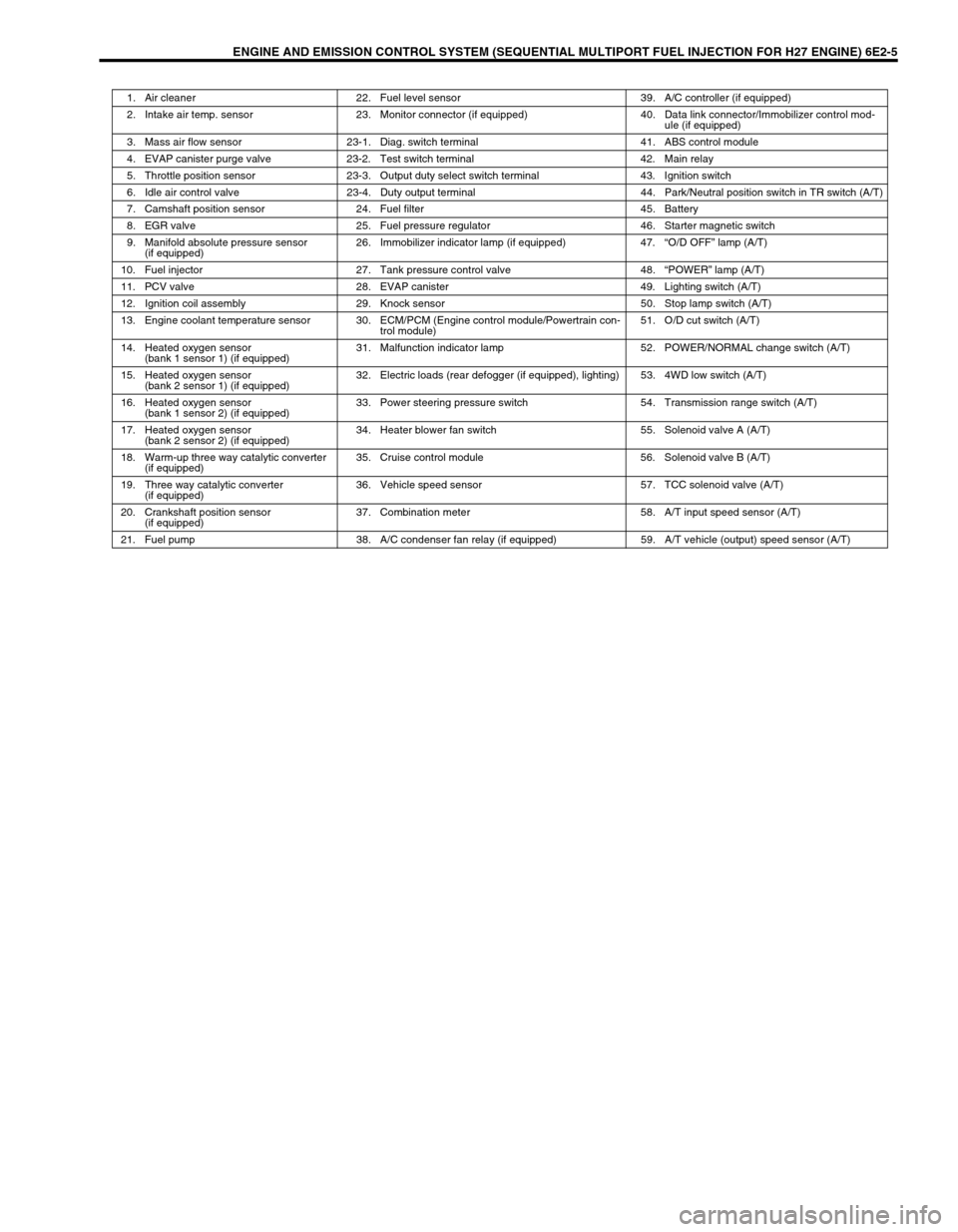

ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE) 6E2-5

1. Air cleaner 22. Fuel level sensor 39. A/C controller (if equipped)

2. Intake air temp. sensor 23. Monitor connector (if equipped) 40. Data link connector/Immobilizer control mod-

ule (if equipped)

3. Mass air flow sensor 23-1. Diag. switch terminal 41. ABS control module

4. EVAP canister purge valve 23-2. Test switch terminal 42. Main relay

5. Throttle position sensor 23-3. Output duty select switch terminal 43. Ignition switch

6. Idle air control valve 23-4. Duty output terminal 44. Park/Neutral position switch in TR switch (A/T)

7. Camshaft position sensor 24. Fuel filter 45. Battery

8. EGR valve 25. Fuel pressure regulator 46. Starter magnetic switch

9. Manifold absolute pressure sensor

(if equipped)26. Immobilizer indicator lamp (if equipped) 47.“O/D OFF” lamp (A/T)

10. Fuel injector 27. Tank pressure control valve 48.“POWER” lamp (A/T)

11. PCV valve 28. EVAP canister 49. Lighting switch (A/T)

12. Ignition coil assembly 29. Knock sensor 50. Stop lamp switch (A/T)

13. Engine coolant temperature sensor 30. ECM/PCM (Engine control module/Powertrain con-

trol module)51. O/D cut switch (A/T)

14. Heated oxygen sensor

(bank 1 sensor 1) (if equipped)31. Malfunction indicator lamp 52. POWER/NORMAL change switch (A/T)

15. Heated oxygen sensor

(bank 2 sensor 1) (if equipped)32. Electric loads (rear defogger (if equipped), lighting) 53. 4WD low switch (A/T)

16. Heated oxygen sensor

(bank 1 sensor 2) (if equipped)33. Power steering pressure switch 54. Transmission range switch (A/T)

17. Heated oxygen sensor

(bank 2 sensor 2) (if equipped)34. Heater blower fan switch 55. Solenoid valve A (A/T)

18. Warm-up three way catalytic converter

(if equipped)35. Cruise control module 56. Solenoid valve B (A/T)

19. Three way catalytic converter

(if equipped)36. Vehicle speed sensor 57. TCC solenoid valve (A/T)

20. Crankshaft position sensor

(if equipped)37. Combination meter 58. A/T input speed sensor (A/T)

21. Fuel pump 38. A/C condenser fan relay (if equipped) 59. A/T vehicle (output) speed sensor (A/T)

Page 341 of 656

6E2-8 ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE)

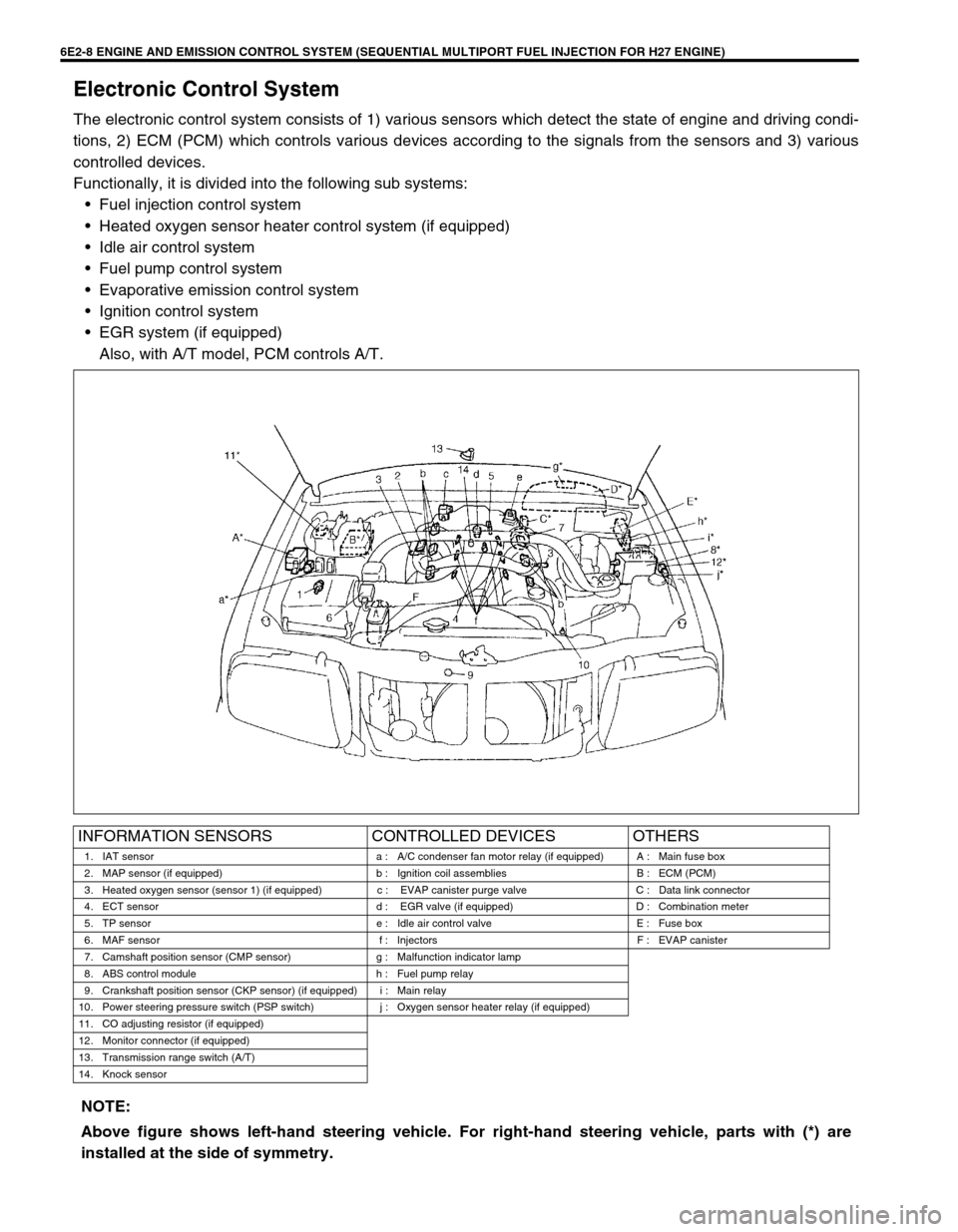

Electronic Control System

The electronic control system consists of 1) various sensors which detect the state of engine and driving condi-

tions, 2) ECM (PCM) which controls various devices according to the signals from the sensors and 3) various

controlled devices.

Functionally, it is divided into the following sub systems:

•Fuel injection control system

•Heated oxygen sensor heater control system (if equipped)

•Idle air control system

•Fuel pump control system

•Evaporative emission control system

•Ignition control system

•EGR system (if equipped)

Also, with A/T model, PCM controls A/T.

INFORMATION SENSORS CONTROLLED DEVICES OTHERS

1. IAT sensor a : A/C condenser fan motor relay (if equipped) A : Main fuse box

2. MAP sensor (if equipped) b : Ignition coil assemblies B : ECM (PCM)

3. Heated oxygen sensor (sensor 1) (if equipped) c : EVAP canister purge valve C : Data link connector

4. ECT sensor d : EGR valve (if equipped) D : Combination meter

5. TP sensor e : Idle air control valve E : Fuse box

6. MAF sensor f : Injectors F : EVAP canister

7. Camshaft position sensor (CMP sensor) g : Malfunction indicator lamp

8. ABS control module h : Fuel pump relay

9. Crankshaft position sensor (CKP sensor) (if equipped) i : Main relay

10. Power steering pressure switch (PSP switch) j : Oxygen sensor heater relay (if equipped)

11. CO adjusting resistor (if equipped)

12. Monitor connector (if equipped)

13. Transmission range switch (A/T)

14. Knock sensor

NOTE:

Above figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are

installed at the side of symmetry.

Page 343 of 656

6E2-10 ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE)

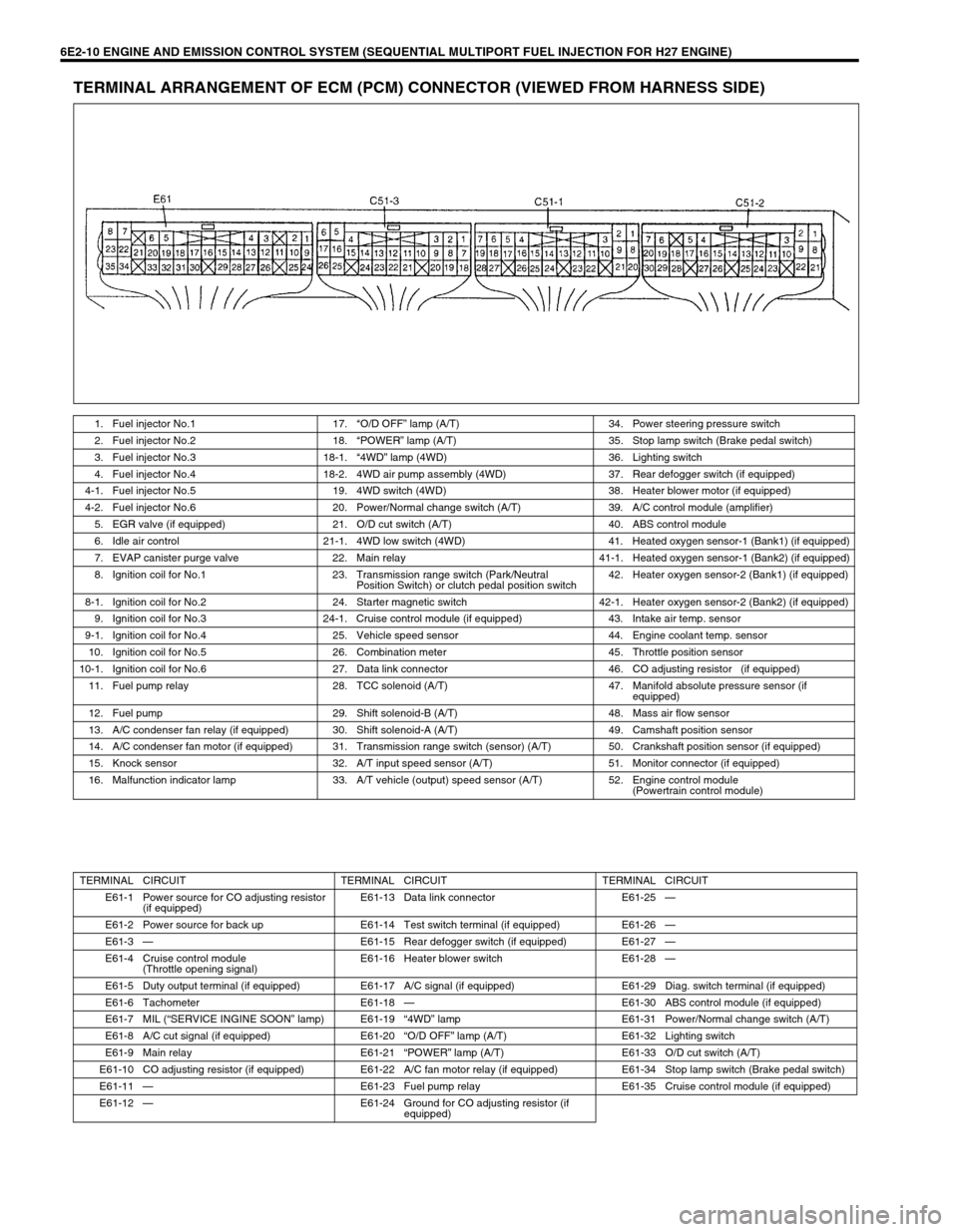

TERMINAL ARRANGEMENT OF ECM (PCM) CONNECTOR (VIEWED FROM HARNESS SIDE)

1. Fuel injector No.1 17.“O/D OFF” lamp (A/T) 34. Power steering pressure switch

2. Fuel injector No.2 18.“POWER” lamp (A/T) 35. Stop lamp switch (Brake pedal switch)

3. Fuel injector No.3 18-1.“4WD” lamp (4WD) 36. Lighting switch

4. Fuel injector No.4 18-2. 4WD air pump assembly (4WD) 37. Rear defogger switch (if equipped)

4-1. Fuel injector No.5 19. 4WD switch (4WD) 38. Heater blower motor (if equipped)

4-2. Fuel injector No.6 20. Power/Normal change switch (A/T) 39. A/C control module (amplifier)

5. EGR valve (if equipped) 21. O/D cut switch (A/T) 40. ABS control module

6. Idle air control 21-1. 4WD low switch (4WD) 41. Heated oxygen sensor-1 (Bank1) (if equipped)

7. EVAP canister purge valve 22. Main relay 41-1. Heated oxygen sensor-1 (Bank2) (if equipped)

8. Ignition coil for No.1 23. Transmission range switch (Park/Neutral

Position Switch) or clutch pedal position switch42. Heater oxygen sensor-2 (Bank1) (if equipped)

8-1. Ignition coil for No.2 24. Starter magnetic switch 42-1. Heater oxygen sensor-2 (Bank2) (if equipped)

9. Ignition coil for No.3 24-1. Cruise control module (if equipped) 43. Intake air temp. sensor

9-1. Ignition coil for No.4 25. Vehicle speed sensor 44. Engine coolant temp. sensor

10. Ignition coil for No.5 26. Combination meter 45. Throttle position sensor

10-1. Ignition coil for No.6 27. Data link connector 46. CO adjusting resistor (if equipped)

11. Fuel pump relay 28. TCC solenoid (A/T) 47. Manifold absolute pressure sensor (if

equipped)

12. Fuel pump 29. Shift solenoid-B (A/T) 48. Mass air flow sensor

13. A/C condenser fan relay (if equipped) 30. Shift solenoid-A (A/T) 49. Camshaft position sensor

14. A/C condenser fan motor (if equipped) 31. Transmission range switch (sensor) (A/T) 50. Crankshaft position sensor (if equipped)

15. Knock sensor 32. A/T input speed sensor (A/T) 51. Monitor connector (if equipped)

16. Malfunction indicator lamp 33. A/T vehicle (output) speed sensor (A/T) 52. Engine control module

(Powertrain control module)

TERMINAL CIRCUIT TERMINAL CIRCUIT TERMINAL CIRCUIT

E61-1 Power source for CO adjusting resistor

(if equipped)E61-13 Data link connector E61-25—

E61-2 Power source for back up E61-14 Test switch terminal (if equipped) E61-26—

E61-3—E61-15 Rear defogger switch (if equipped) E61-27—

E61-4 Cruise control module

(Throttle opening signal)E61-16 Heater blower switch E61-28—

E61-5 Duty output terminal (if equipped) E61-17 A/C signal (if equipped) E61-29 Diag. switch terminal (if equipped)

E61-6 Tachometer E61-18—E61-30 ABS control module (if equipped)

E61-7 MIL (“SERVICE INGINE SOON” lamp) E61-19“4WD” lamp E61-31 Power/Normal change switch (A/T)

E61-8 A/C cut signal (if equipped) E61-20“O/D OFF” lamp (A/T) E61-32 Lighting switch

E61-9 Main relay E61-21“POWER” lamp (A/T) E61-33 O/D cut switch (A/T)

E61-10 CO adjusting resistor (if equipped) E61-22 A/C fan motor relay (if equipped) E61-34 Stop lamp switch (Brake pedal switch)

E61-11—E61-23 Fuel pump relay E61-35 Cruise control module (if equipped)

E61-12—E61-24 Ground for CO adjusting resistor (if

equipped)

Page 344 of 656

ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE) 6E2-11

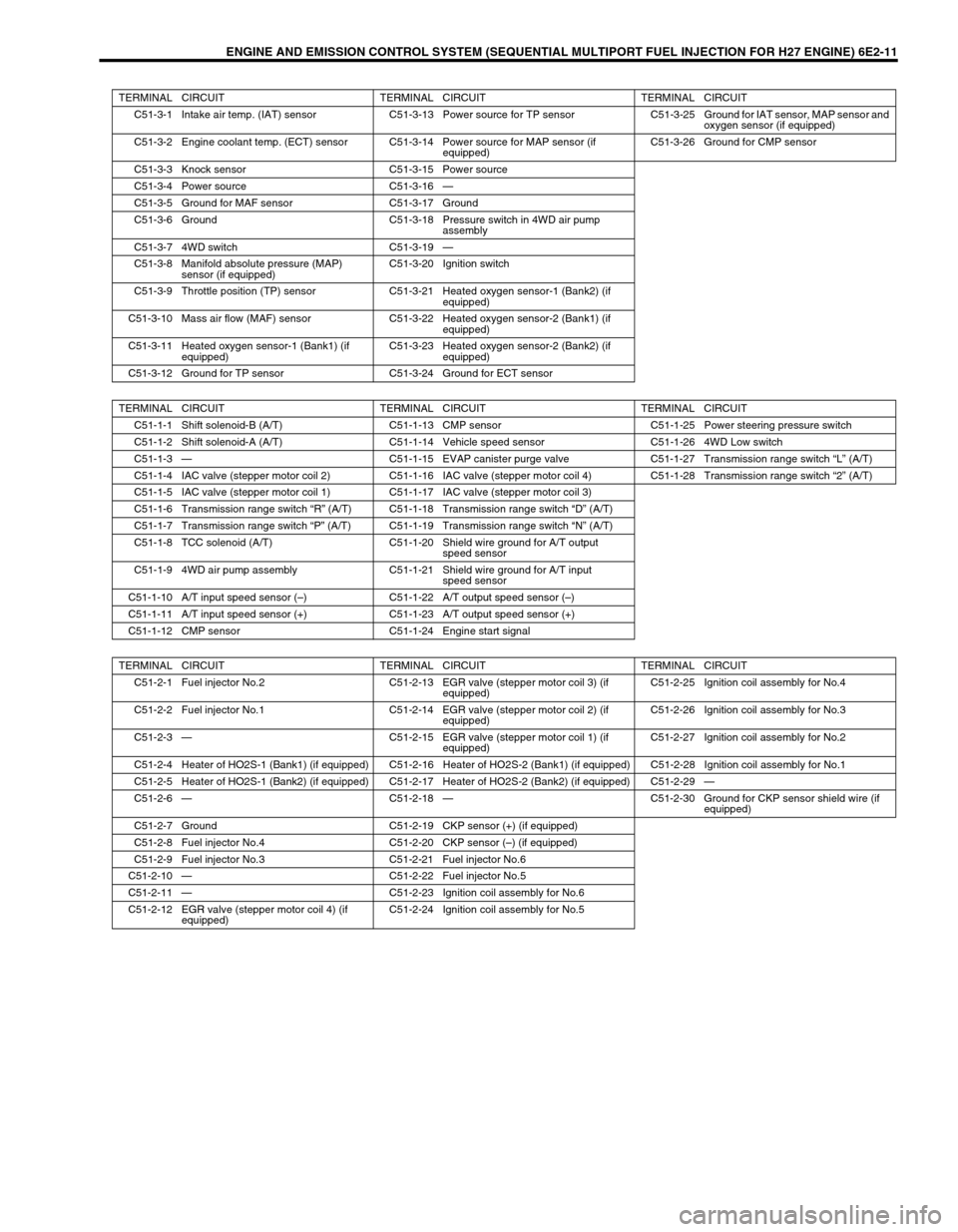

TERMINAL CIRCUIT TERMINAL CIRCUIT TERMINAL CIRCUIT

C51-3-1 Intake air temp. (IAT) sensor C51-3-13 Power source for TP sensor C51-3-25 Ground for IAT sensor, MAP sensor and

oxygen sensor (if equipped)

C51-3-2 Engine coolant temp. (ECT) sensor C51-3-14 Power source for MAP sensor (if

equipped)C51-3-26 Ground for CMP sensor

C51-3-3 Knock sensor C51-3-15 Power source

C51-3-4 Power source C51-3-16—

C51-3-5 Ground for MAF sensor C51-3-17 Ground

C51-3-6 Ground C51-3-18 Pressure switch in 4WD air pump

assembly

C51-3-7 4WD switch C51-3-19—

C51-3-8 Manifold absolute pressure (MAP)

sensor (if equipped)C51-3-20 Ignition switch

C51-3-9 Throttle position (TP) sensor C51-3-21 Heated oxygen sensor-1 (Bank2) (if

equipped)

C51-3-10 Mass air flow (MAF) sensor C51-3-22 Heated oxygen sensor-2 (Bank1) (if

equipped)

C51-3-11 Heated oxygen sensor-1 (Bank1) (if

equipped)C51-3-23 Heated oxygen sensor-2 (Bank2) (if

equipped)

C51-3-12 Ground for TP sensor C51-3-24 Ground for ECT sensor

TERMINAL CIRCUIT TERMINAL CIRCUIT TERMINAL CIRCUIT

C51-1-1 Shift solenoid-B (A/T) C51-1-13 CMP sensor C51-1-25 Power steering pressure switch

C51-1-2 Shift solenoid-A (A/T) C51-1-14 Vehicle speed sensor C51-1-26 4WD Low switch

C51-1-3—C51-1-15 EVAP canister purge valve C51-1-27 Transmission range switch “L” (A/T)

C51-1-4 IAC valve (stepper motor coil 2) C51-1-16 IAC valve (stepper motor coil 4) C51-1-28 Transmission range switch “2” (A/T)

C51-1-5 IAC valve (stepper motor coil 1) C51-1-17 IAC valve (stepper motor coil 3)

C51-1-6 Transmission range switch “R” (A/T) C51-1-18 Transmission range switch “D” (A/T)

C51-1-7 Transmission range switch “P” (A/T) C51-1-19 Transmission range switch “N” (A/T)

C51-1-8 TCC solenoid (A/T) C51-1-20 Shield wire ground for A/T output

speed sensor

C51-1-9 4WD air pump assembly C51-1-21 Shield wire ground for A/T input

speed sensor

C51-1-10 A/T input speed sensor (–) C51-1-22 A/T output speed sensor (–)

C51-1-11 A/T input speed sensor (+) C51-1-23 A/T output speed sensor (+)

C51-1-12 CMP sensor C51-1-24 Engine start signal

TERMINAL CIRCUIT TERMINAL CIRCUIT TERMINAL CIRCUIT

C51-2-1 Fuel injector No.2 C51-2-13 EGR valve (stepper motor coil 3) (if

equipped)C51-2-25 Ignition coil assembly for No.4

C51-2-2 Fuel injector No.1 C51-2-14 EGR valve (stepper motor coil 2) (if

equipped)C51-2-26 Ignition coil assembly for No.3

C51-2-3—C51-2-15 EGR valve (stepper motor coil 1) (if

equipped)C51-2-27 Ignition coil assembly for No.2

C51-2-4 Heater of HO2S-1 (Bank1) (if equipped) C51-2-16 Heater of HO2S-2 (Bank1) (if equipped) C51-2-28 Ignition coil assembly for No.1

C51-2-5 Heater of HO2S-1 (Bank2) (if equipped) C51-2-17 Heater of HO2S-2 (Bank2) (if equipped) C51-2-29—

C51-2-6—C51-2-18—C51-2-30 Ground for CKP sensor shield wire (if

equipped)

C51-2-7 Ground C51-2-19 CKP sensor (+) (if equipped)

C51-2-8 Fuel injector No.4 C51-2-20 CKP sensor (–) (if equipped)

C51-2-9 Fuel injector No.3 C51-2-21 Fuel injector No.6

C51-2-10—C51-2-22 Fuel injector No.5

C51-2-11—C51-2-23 Ignition coil assembly for No.6

C51-2-12 EGR valve (stepper motor coil 4) (if

equipped)C51-2-24 Ignition coil assembly for No.5

Page 345 of 656

6E2-12 ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE)

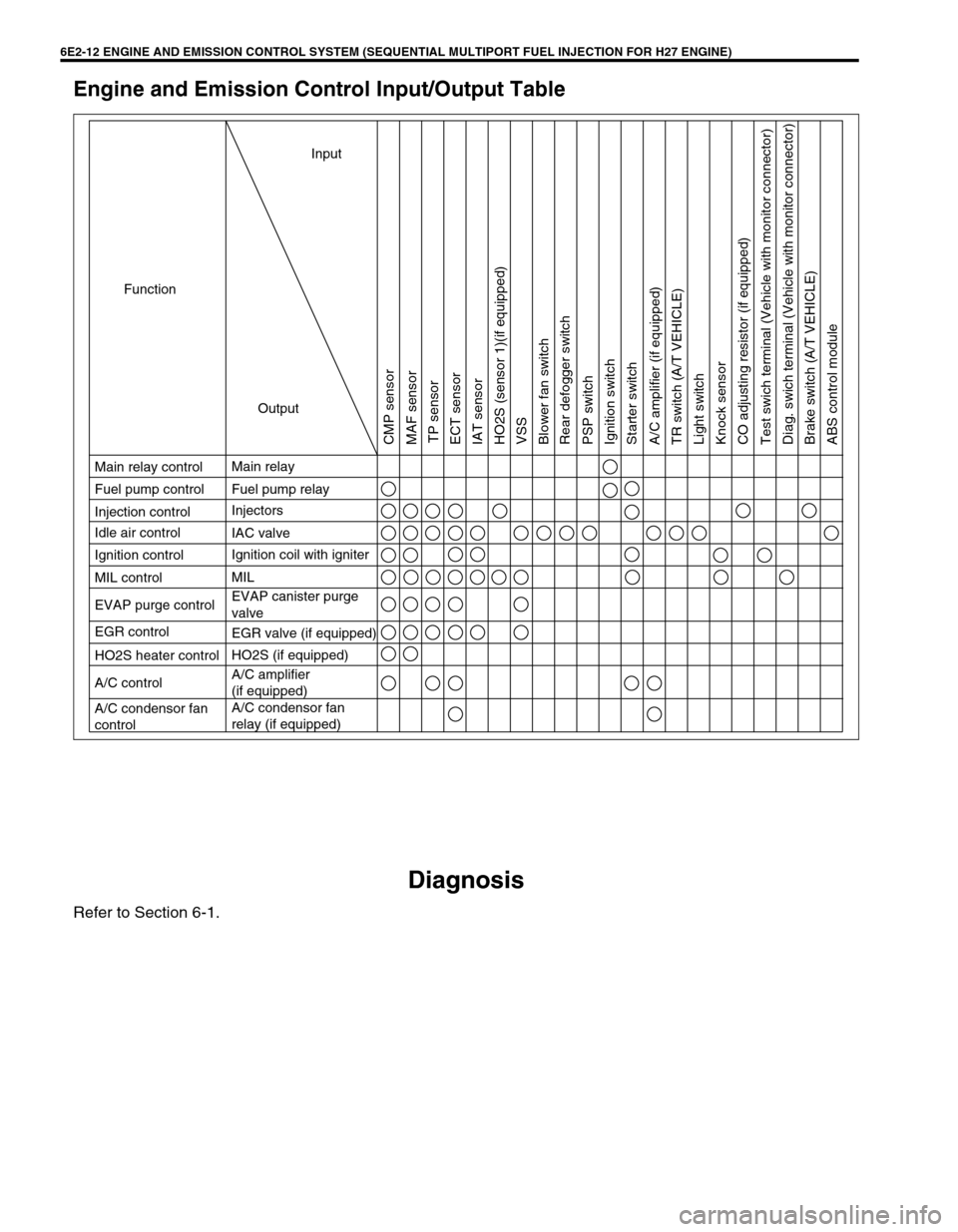

Engine and Emission Control Input/Output Table

Diagnosis

Refer to Section 6-1.

Ignition coil with igniter

HO2S heater control

Input

Output Function

Main relay control

Fuel pump control

Injection control

Ignition control

MIL control Idle air control

EVAP purge control

EGR control

A/C control

A/C condensor fan

controlMain relay

Fuel pump relay

Injectors

MIL

EVAP canister purge

valve IAC valve

EGR valve (if equipped)

HO2S (if equipped)

A/C amplifier

(if equipped)

A/C condensor fan

relay (if equipped)

CMP sensor

MAF sensor

TP sensor

ECT sensor

IAT sensor

HO2S (sensor 1)(if equipped)

VSS

Blower fan switch

Rear defogger switch

PSP switch

Ignition switch

Starter switch

A/C amplifier (if equipped)

TR switch (A/T VEHICLE)

Light switch

Knock sensor

CO adjusting resistor (if equipped)

Test swich terminal (Vehicle with monitor connector)

Diag. swich terminal (Vehicle with monitor connector)

Brake switch (A/T VEHICLE)

ABS control module

Page 348 of 656

ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE) 6E2-15

Idle Speed/Idle Air Control (IAC) Duty Inspec-

tion

Before idle speed/IAC duty check, make sure of the following.

•Lead wires and hoses of engine/emission control systems

are connected securely.

•Accelerator cable is adjusted.

•Ignition timing is within specification.

•All accessories (wipers, heater, lights, A/C, etc.) are out of

service.

•Air cleaner has been properly installed and is in good condi-

tion.

•ECM (PCM) does not detect any malfunction DTC.

After above items are all confirmed, check idle speed and IAC

duty as follows.

[Using SUZUKI scan tool]

1) Connect SUZUKI scan tool to DLC with ignition switch OFF.

Special tool

(A) : SUZUKI scan tool

2) Warm up engine to normal operating temperature.

3) Check IAC duty and idle speed by using “Data List” mode of

SUZUKI scan tool.

Engine idle speed:

A/C OFF: 700 ± 50 r/min.

A/C ON: 750 ± 50 r/min.

IAC duty at specified idle speed:

5 – 40 % (at A/C OFF)

4) If duty and/or idle speed is out of specifications, check idle

air control system referring to “DIAG. FLOW TABLE B-4” in

Section 6-1.

5) Check that specified engine idle speed is obtained with A/C

ON if vehicle is equipped with A/C. If not, check A/C ON sig-

nal circuit and idle air control system. NOTE:

Before starting engine, place transmission gear shift

lever in “Neutral” (shift selector lever to “P” range for A/T

vehicle), and set parking brake and block drive wheels.

Page 355 of 656

6E2-22 ENGINE AND EMISSION CONTROL SYSTEM (SEQUENTIAL MULTIPORT FUEL INJECTION FOR H27 ENGINE)

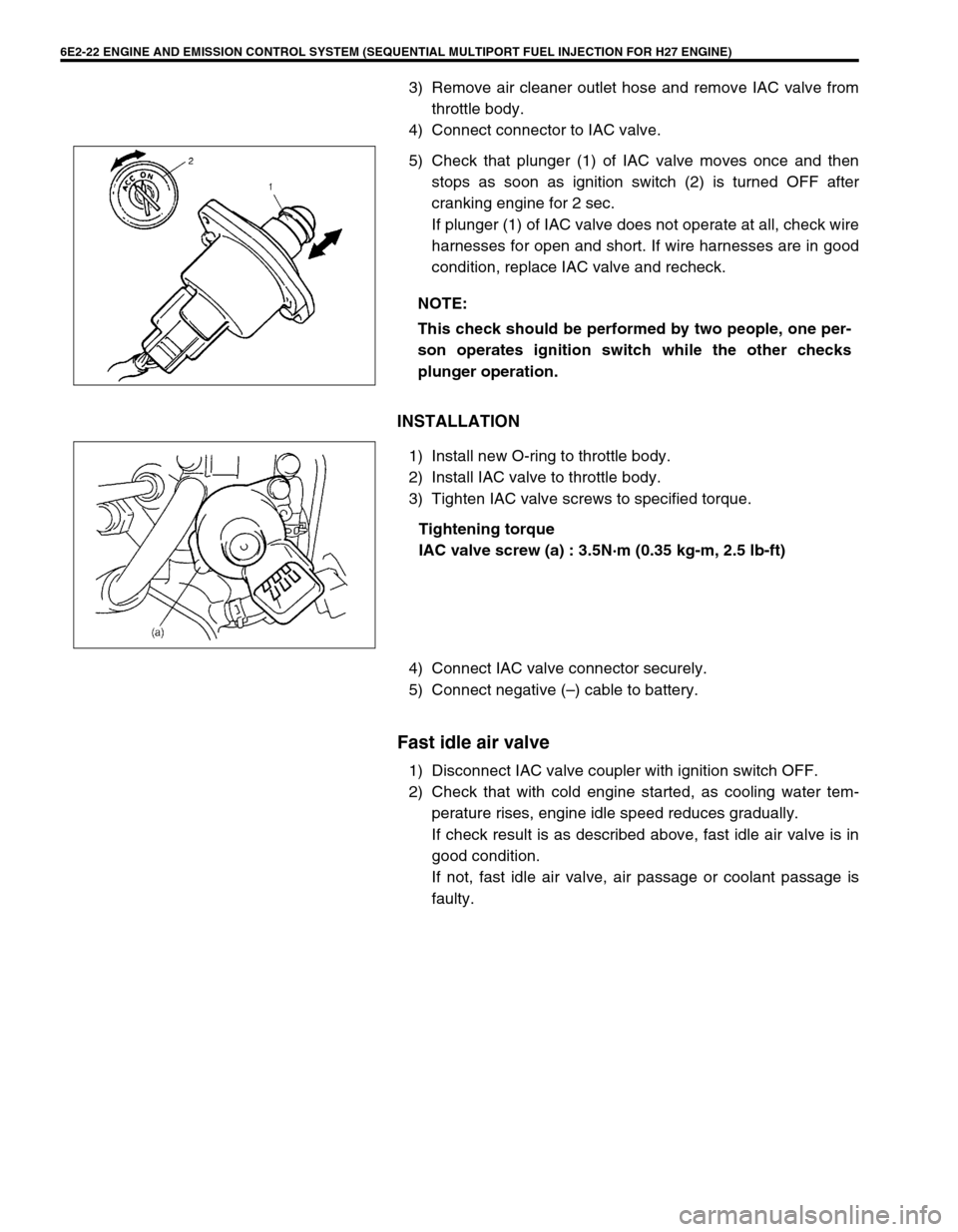

3) Remove air cleaner outlet hose and remove IAC valve from

throttle body.

4) Connect connector to IAC valve.

5) Check that plunger (1) of IAC valve moves once and then

stops as soon as ignition switch (2) is turned OFF after

cranking engine for 2 sec.

If plunger (1) of IAC valve does not operate at all, check wire

harnesses for open and short. If wire harnesses are in good

condition, replace IAC valve and recheck.

INSTALLATION

1) Install new O-ring to throttle body.

2) Install IAC valve to throttle body.

3) Tighten IAC valve screws to specified torque.

Tightening torque

IAC valve screw (a) : 3.5N·m (0.35 kg-m, 2.5 lb-ft)

4) Connect IAC valve connector securely.

5) Connect negative (–) cable to battery.

Fast idle air valve

1) Disconnect IAC valve coupler with ignition switch OFF.

2) Check that with cold engine started, as cooling water tem-

perature rises, engine idle speed reduces gradually.

If check result is as described above, fast idle air valve is in

good condition.

If not, fast idle air valve, air passage or coolant passage is

faulty. NOTE:

This check should be performed by two people, one per-

son operates ignition switch while the other checks

plunger operation.