diff SUZUKI GRAND VITARA 2001 2.G Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2001, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2001 2.GPages: 656, PDF Size: 14.31 MB

Page 575 of 656

10A-6 SEAT BELT

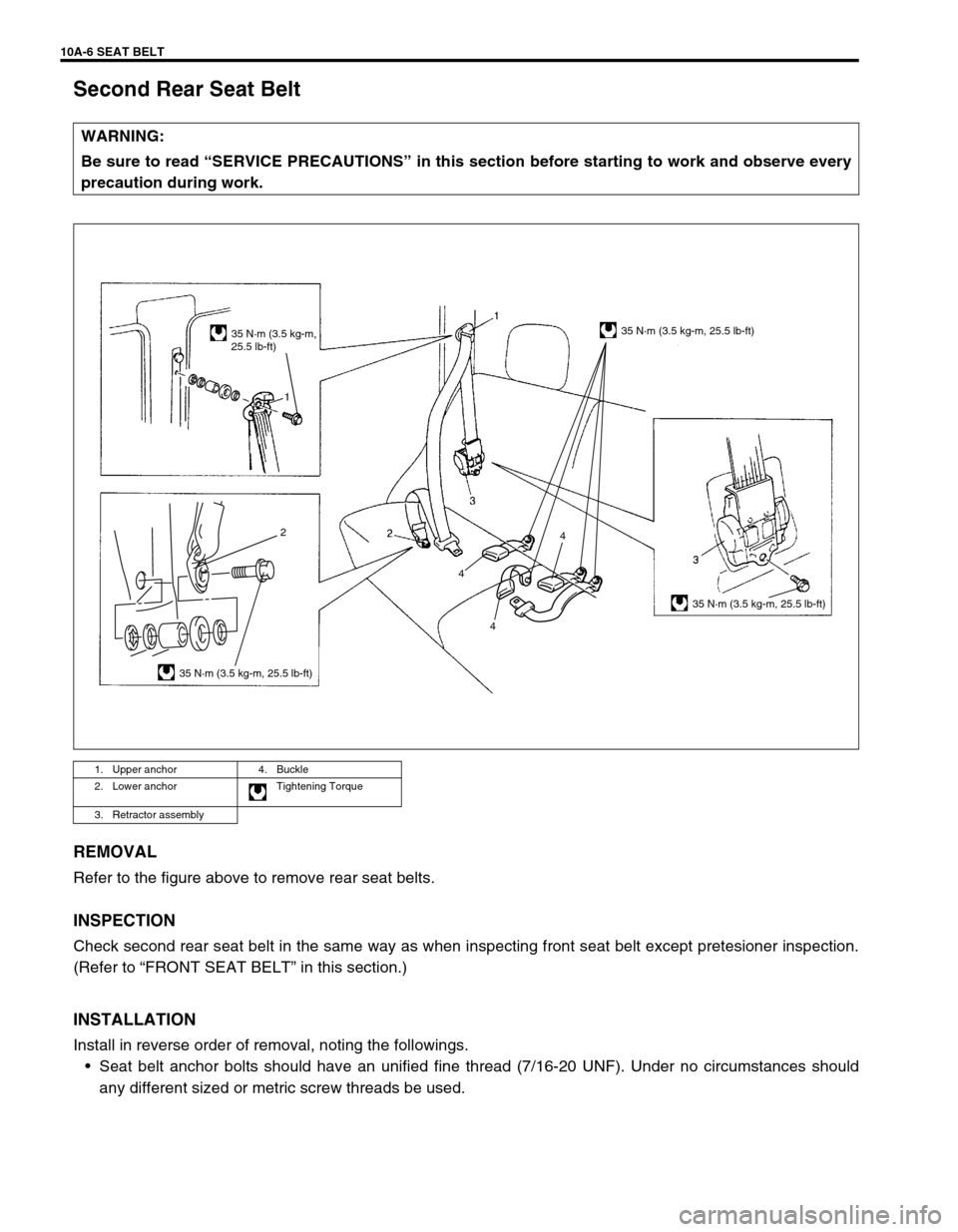

Second Rear Seat Belt

REMOVAL

Refer to the figure above to remove rear seat belts.

INSPECTION

Check second rear seat belt in the same way as when inspecting front seat belt except pretesioner inspection.

(Refer to “FRONT SEAT BELT” in this section.)

INSTALLATION

Install in reverse order of removal, noting the followings.

•Seat belt anchor bolts should have an unified fine thread (7/16-20 UNF). Under no circumstances should

any different sized or metric screw threads be used. WARNING:

Be sure to read “SERVICE PRECAUTIONS” in this section before starting to work and observe every

precaution during work.

1. Upper anchor 4. Buckle

2. Lower anchor Tightening Torque

3. Retractor assembly

2

35 N·m (3.5 kg-m, 25.5 lb-ft)

35 N·m (3.5 kg-m, 25.5 lb-ft)

35 N·m (3.5 kg-m, 25.5 lb-ft)

35 N·m (3.5 kg-m,

25.5 lb-ft)

4

4

4

Page 576 of 656

SEAT BELT 10A-7

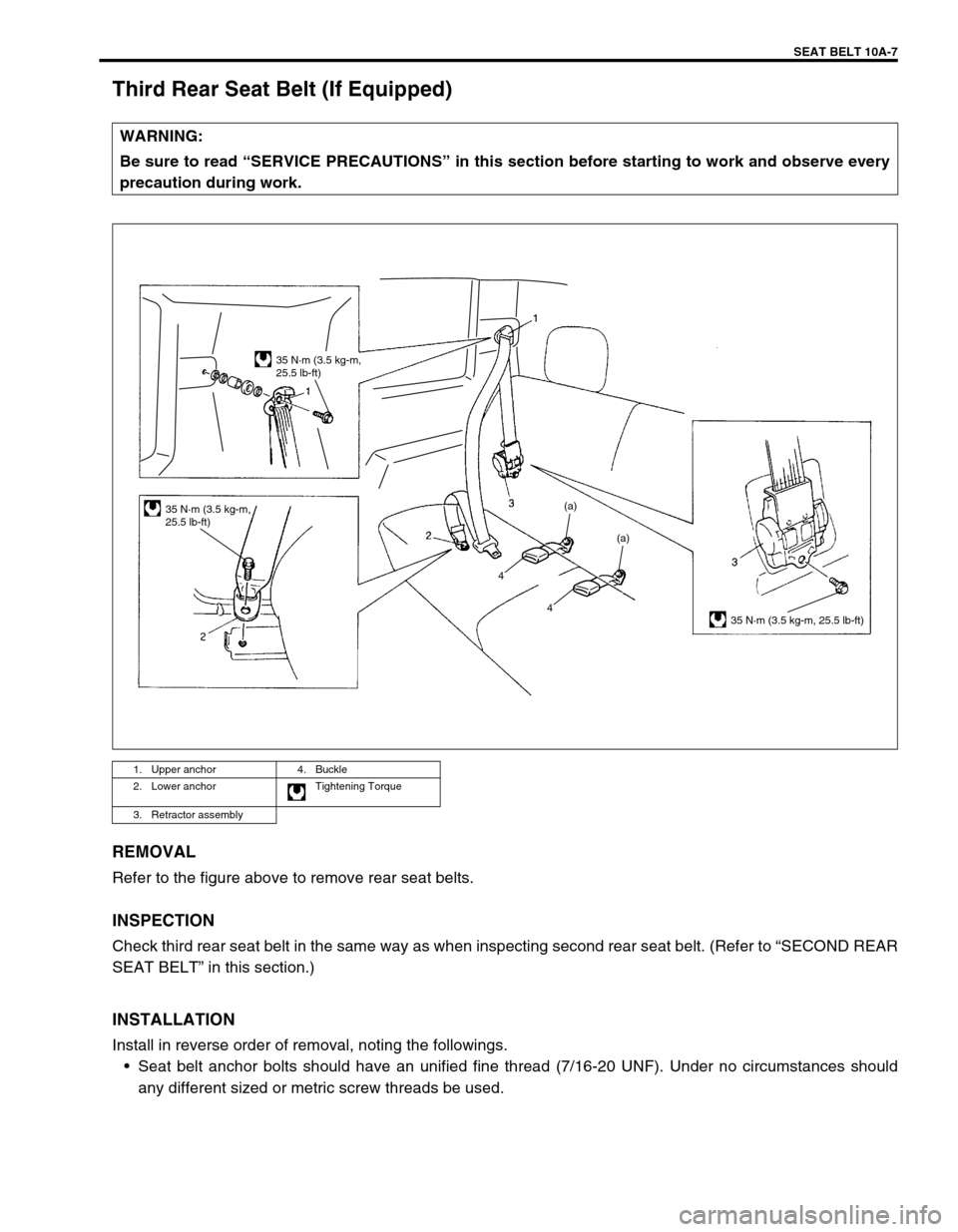

Third Rear Seat Belt (If Equipped)

REMOVAL

Refer to the figure above to remove rear seat belts.

INSPECTION

Check third rear seat belt in the same way as when inspecting second rear seat belt. (Refer to “SECOND REAR

SEAT BELT” in this section.)

INSTALLATION

Install in reverse order of removal, noting the followings.

•Seat belt anchor bolts should have an unified fine thread (7/16-20 UNF). Under no circumstances should

any different sized or metric screw threads be used. WARNING:

Be sure to read “SERVICE PRECAUTIONS” in this section before starting to work and observe every

precaution during work.

1. Upper anchor 4. Buckle

2. Lower anchor Tightening Torque

3. Retractor assembly

35 N·m (3.5 kg-m,

25.5 lb-ft)

35 N·m (3.5 kg-m,

25.5 lb-ft)

35 N·m (3.5 kg-m, 25.5 lb-ft)

4

4

(a)

(a)

Page 579 of 656

10B-2 AIR BAG SYSTEM

DTC B1031 – Power Source Voltage

High........................................................... 10B-33

DTC B1032 – Power Source Voltage

Low ........................................................... 10B-33

DTC B1035 – RH Forward Sensor Circuit

Open or Short to Ground .......................... 10B-36

DTC B1036 – RH Forward Sensor Circuit

Short Between Two Wires or Short to

Power Circuit............................................. 10B-36

DTC B1037 – LH Forward Sensor Circuit

Open or Short to Ground .......................... 10B-36

DTC B1038 – LH Forward Sensor Circuit

Short Between Two Wires or Short to

Power Circuit............................................. 10B-36

DTC B1041 – Driver Pretensioner Initiator

Circuit Resistance High............................. 10B-40

DTC B1042 – Driver Pretensioner Initiator

Circuit Resistance Low ............................. 10B-40

DTC B1043 – Driver Pretensioner Initiator

Circuit Short to Ground ............................. 10B-40

DTC B1044 – Driver Pretensioner Initiator

Circuit Short to Power Circuit .................... 10B-40

DTC B1045 – Passenger Pretensioner

Initiator Circuit Resistance High ................ 10B-40

DTC B1046 – Passenger Pretensioner

Initiator Circuit Resistance Low................. 10B-40

DTC B1047 – Passenger Pretensioner

Initiator Circuit Short to Ground ................ 10B-40

DTC B1048 – Passenger Pretensioner

Initiator Circuit Short to Power Circuit ....... 10B-40

DTC B1051 – Frontal Crash Detected

(System Activation Command Outputted). 10B-46DTC B1061 – “AIR BAG” Warning Lamp

Circuit Failure............................................ 10B-47

DTC B1071 – Internal SDM Fault ............. 10B-48

DTC B1013 – System Specifications

Different from SDM Specifications ............ 10B-48

On-Vehicle Service ..................................... 10B-49

Service Precautions .................................. 10B-49

Service and diagnosis ........................... 10B-49

Disabling air bag system ....................... 10B-50

Enabling air bag system........................ 10B-50

Handling and storage ............................ 10B-51

Repairs and Inspections Required after

an Accident ............................................... 10B-56

Accident with deployment/activation -

component replacement ....................... 10B-56

Accident with or without deployment/

activation - component inspections....... 10B-57

SDM .......................................................... 10B-60

Forward Sensor ........................................ 10B-62

Seat Belt Pretensioner .............................. 10B-64

Air Bag (Inflator) Module and Seat Belt

Pretensioner Disposal................................ 10B-65

Deployment/Activation Outside Vehicle .... 10B-66

Deployment/Activation Inside Vehicle....... 10B-72

Deployed Air Bag (Inflator) Module and

Activated Seat Belt Pretensioner

Disposal .................................................... 10B-76

Tightening Torque Specification............... 10B-77

Special Tool ................................................ 10B-77

Page 592 of 656

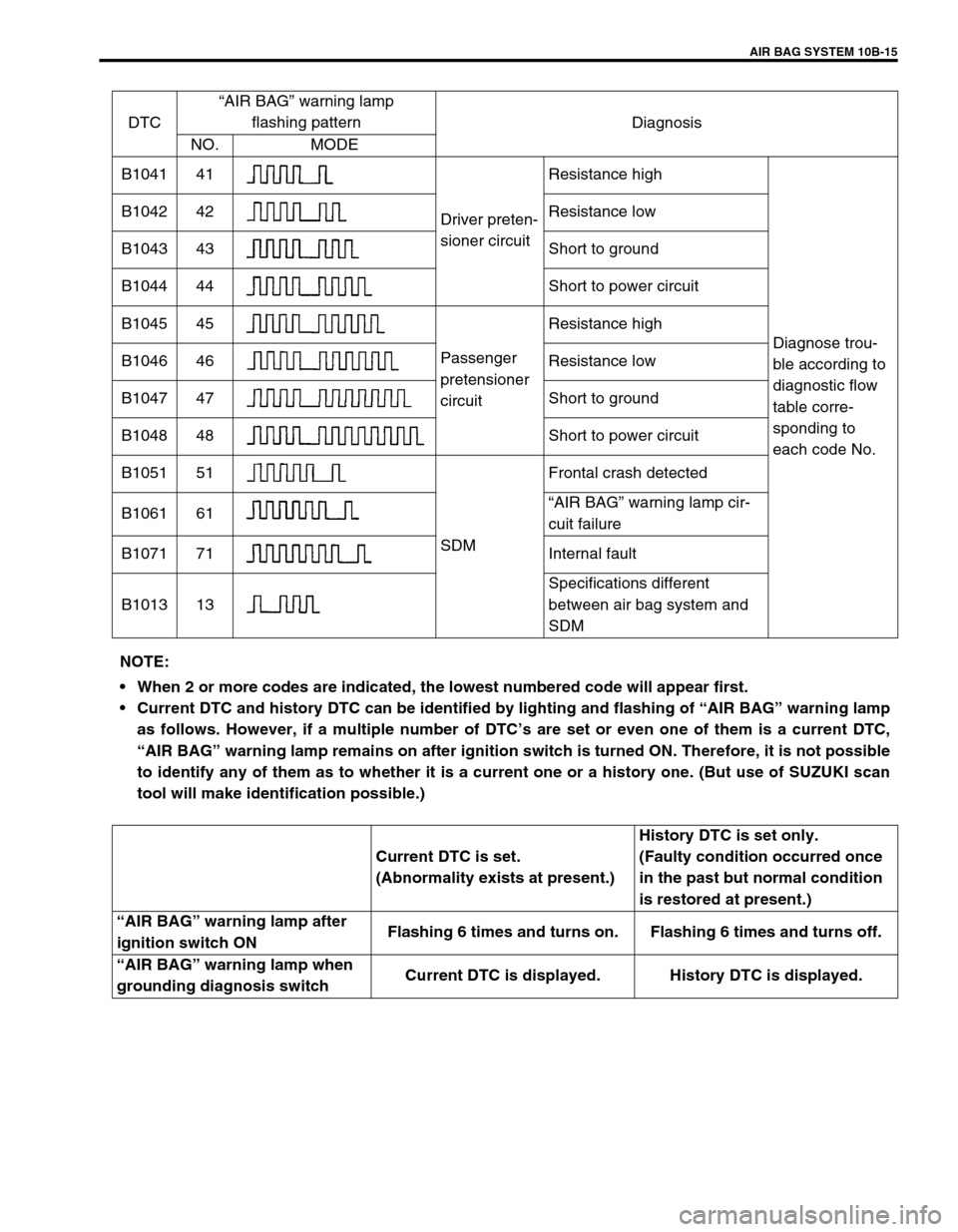

AIR BAG SYSTEM 10B-15

DTC“AIR BAG” warning lamp

flashing pattern

Diagnosis

NO. MODE

B1041 41

Driver preten-

sioner circuitResistance high

Diagnose trou-

ble according to

diagnostic flow

table corre-

sponding to

each code No. B1042 42 Resistance low

B1043 43 Short to ground

B1044 44 Short to power circuit

B1045 45

Passenger

pretensioner

circuitResistance high

B1046 46 Resistance low

B1047 47 Short to ground

B1048 48 Short to power circuit

B1051 51

SDMFrontal crash detected

B1061 61“AIR BAG” warning lamp cir-

cuit failure

B1071 71 Internal fault

B1013 13Specifications different

between air bag system and

SDM

NOTE:

When 2 or more codes are indicated, the lowest numbered code will appear first.

Current DTC and history DTC can be identified by lighting and flashing of “AIR BAG” warning lamp

as follows. However, if a multiple number of DTC’s are set or even one of them is a current DTC,

“AIR BAG” warning lamp remains on after ignition switch is turned ON. Therefore, it is not possible

to identify any of them as to whether it is a current one or a history one. (But use of SUZUKI scan

tool will make identification possible.)

Current DTC is set.

(Abnormality exists at present.)History DTC is set only.

(Faulty condition occurred once

in the past but normal condition

is restored at present.)

“AIR BAG” warning lamp after

ignition switch ONFlashing 6 times and turns on. Flashing 6 times and turns off.

“AIR BAG” warning lamp when

grounding diagnosis switchCurrent DTC is displayed. History DTC is displayed.

Page 625 of 656

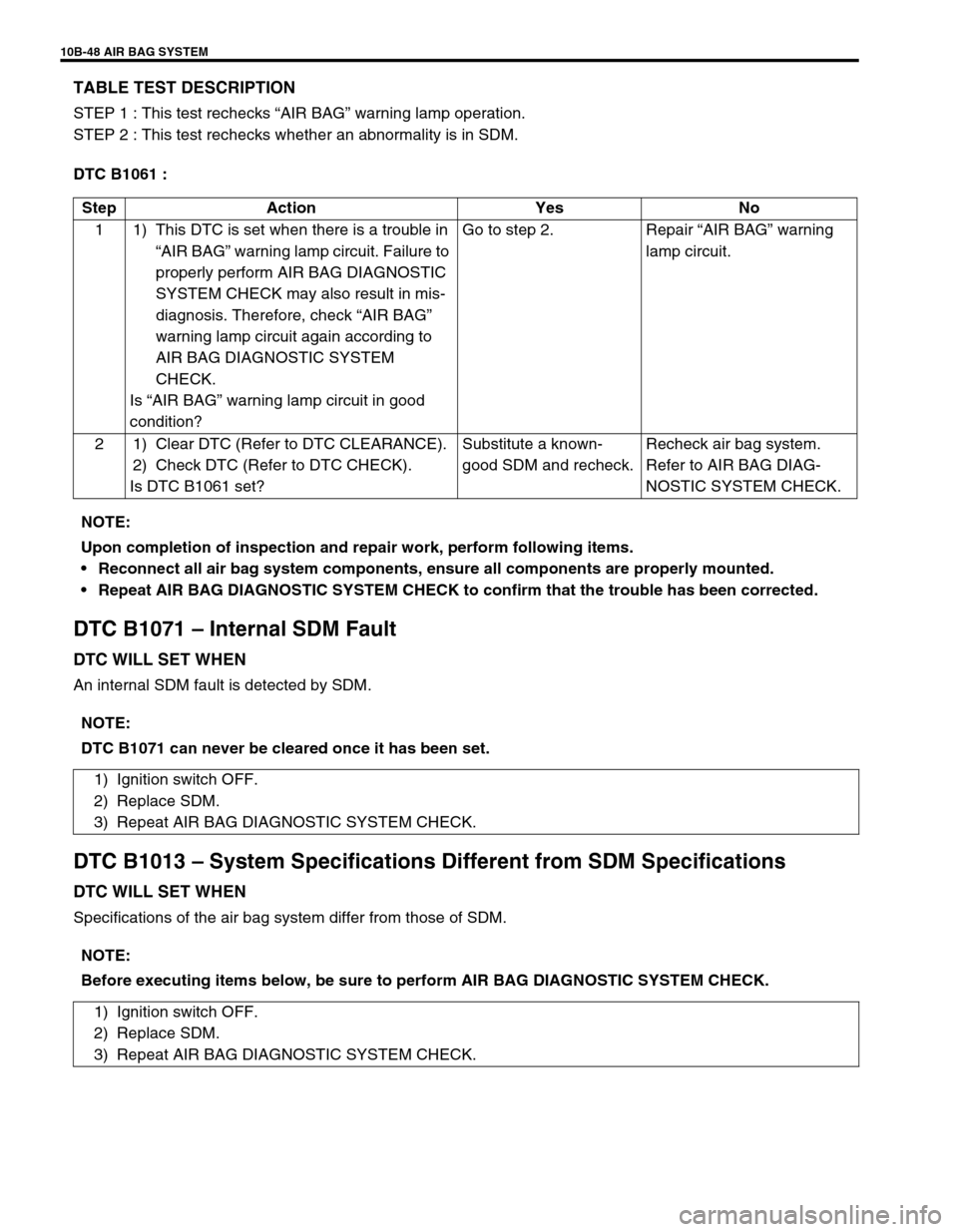

10B-48 AIR BAG SYSTEM

TABLE TEST DESCRIPTION

STEP 1 : This test rechecks “AIR BAG” warning lamp operation.

STEP 2 : This test rechecks whether an abnormality is in SDM.

DTC B1061 :

DTC B1071 – Internal SDM Fault

DTC WILL SET WHEN

An internal SDM fault is detected by SDM.

DTC B1013 – System Specifications Different from SDM Specifications

DTC WILL SET WHEN

Specifications of the air bag system differ from those of SDM.Step Action Yes No

1 1) This DTC is set when there is a trouble in

“AIR BAG” warning lamp circuit. Failure to

properly perform AIR BAG DIAGNOSTIC

SYSTEM CHECK may also result in mis-

diagnosis. Therefore, check “AIR BAG”

warning lamp circuit again according to

AIR BAG DIAGNOSTIC SYSTEM

CHECK.

Is “AIR BAG” warning lamp circuit in good

condition?Go to step 2. Repair “AIR BAG” warning

lamp circuit.

2 1) Clear DTC (Refer to DTC CLEARANCE).

2) Check DTC (Refer to DTC CHECK).

Is DTC B1061 set?Substitute a known-

good SDM and recheck.Recheck air bag system.

Refer to AIR BAG DIAG-

NOSTIC SYSTEM CHECK.

NOTE:

Upon completion of inspection and repair work, perform following items.

Reconnect all air bag system components, ensure all components are properly mounted.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.

NOTE:

DTC B1071 can never be cleared once it has been set.

1) Ignition switch OFF.

2) Replace SDM.

3) Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK.

NOTE:

Before executing items below, be sure to perform AIR BAG DIAGNOSTIC SYSTEM CHECK.

1) Ignition switch OFF.

2) Replace SDM.

3) Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK.

Page 632 of 656

AIR BAG SYSTEM 10B-55

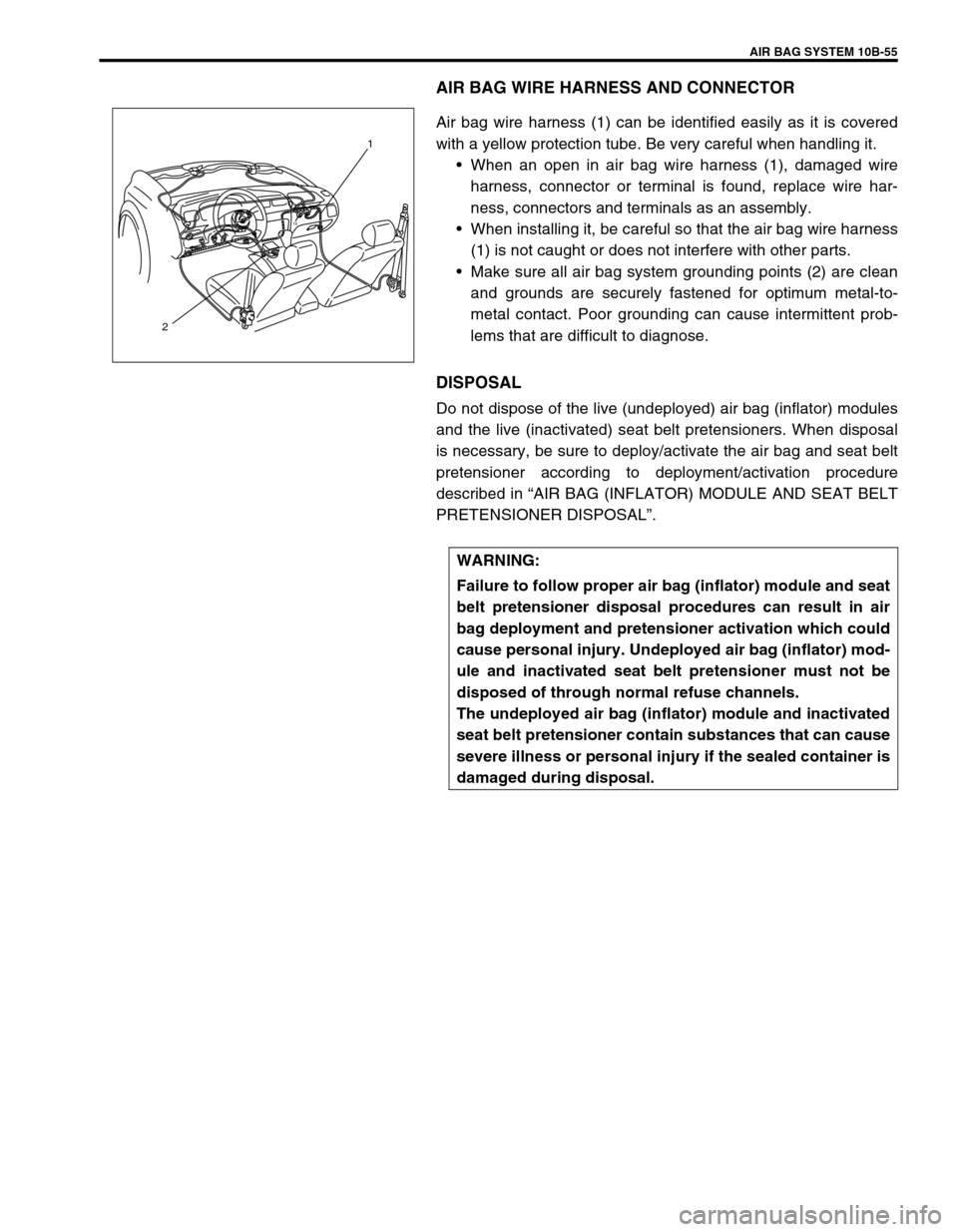

AIR BAG WIRE HARNESS AND CONNECTOR

Air bag wire harness (1) can be identified easily as it is covered

with a yellow protection tube. Be very careful when handling it.

•When an open in air bag wire harness (1), damaged wire

harness, connector or terminal is found, replace wire har-

ness, connectors and terminals as an assembly.

•When installing it, be careful so that the air bag wire harness

(1) is not caught or does not interfere with other parts.

•Make sure all air bag system grounding points (2) are clean

and grounds are securely fastened for optimum metal-to-

metal contact. Poor grounding can cause intermittent prob-

lems that are difficult to diagnose.

DISPOSAL

Do not dispose of the live (undeployed) air bag (inflator) modules

and the live (inactivated) seat belt pretensioners. When disposal

is necessary, be sure to deploy/activate the air bag and seat belt

pretensioner according to deployment/activation procedure

described in “AIR BAG (INFLATOR) MODULE AND SEAT BELT

PRETENSIONER DISPOSAL”.

15

21

WARNING:

Failure to follow proper air bag (inflator) module and seat

belt pretensioner disposal procedures can result in air

bag deployment and pretensioner activation which could

cause personal injury. Undeployed air bag (inflator) mod-

ule and inactivated seat belt pretensioner must not be

disposed of through normal refuse channels.

The undeployed air bag (inflator) module and inactivated

seat belt pretensioner contain substances that can cause

severe illness or personal injury if the sealed container is

damaged during disposal.