Pressure sensor SUZUKI GRAND VITARA 2001 2.G Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2001, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2001 2.GPages: 656, PDF Size: 14.31 MB

Page 30 of 656

![SUZUKI GRAND VITARA 2001 2.G Owners Manual AIR CONDITIONING (OPTIONAL) 1B-5

[A] : Dual A/C LH steering model 4. Condenser 11. Low pressure charge valve

[B] : Dual A/C RH steering model 5. Sight glass 12. Floor liquid pipe

[C] : Single A/C LH s SUZUKI GRAND VITARA 2001 2.G Owners Manual AIR CONDITIONING (OPTIONAL) 1B-5

[A] : Dual A/C LH steering model 4. Condenser 11. Low pressure charge valve

[B] : Dual A/C RH steering model 5. Sight glass 12. Floor liquid pipe

[C] : Single A/C LH s](/img/20/7584/w960_7584-29.png)

AIR CONDITIONING (OPTIONAL) 1B-5

[A] : Dual A/C LH steering model 4. Condenser 11. Low pressure charge valve

[B] : Dual A/C RH steering model 5. Sight glass 12. Floor liquid pipe

[C] : Single A/C LH steering model 6. Refrigerant (dual) pressure sensor 13. Floor suction pipe

[D] : Single A/C RH steering model 7. Discharge pipe 14. Rear A/C unit

1. Front cooling unit 8. Liquid pipe 15. Rear A/C duct No.1

2. Heater unit 9. Suction pipe 16. Rear A/C duct No.2

3. Compressor 10. High pressure charge valve

[A]

[B]

[C][D]

10

7

9 3 4 6 5 1181

213

12 16

1514

1 2

13

12 16

1514

7

10

5

6

4

38

9 11

1 2

7

10

5

6

4

38

9 11

10

7

9 3 4 6 5 1181

2

Page 31 of 656

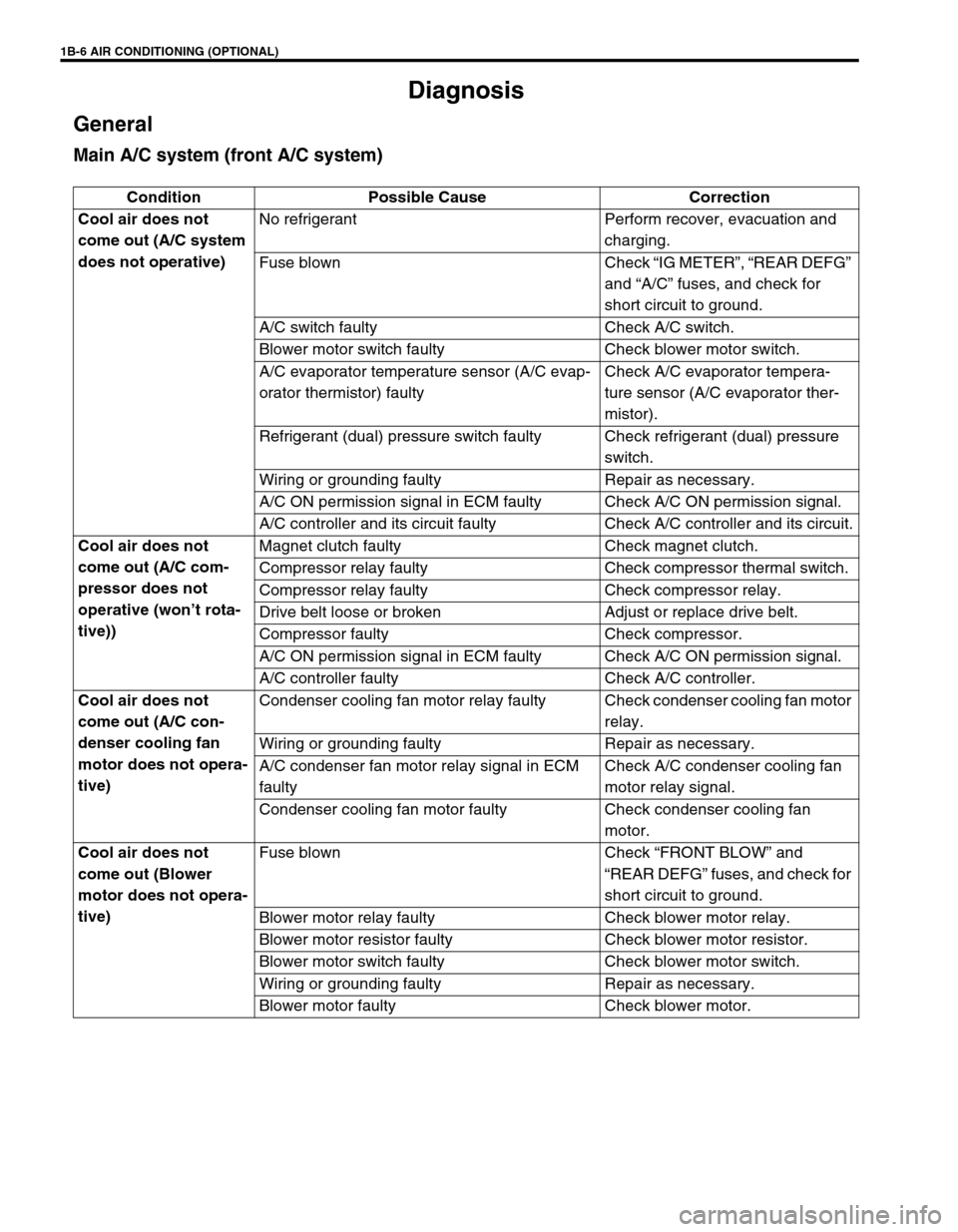

1B-6 AIR CONDITIONING (OPTIONAL)

Diagnosis

General

Main A/C system (front A/C system)

Condition Possible Cause Correction

Cool air does not

come out (A/C system

does not operative)No refrigerant Perform recover, evacuation and

charging.

Fuse blown Check “IG METER”, “REAR DEFG”

and “A/C” fuses, and check for

short circuit to ground.

A/C switch faulty Check A/C switch.

Blower motor switch faulty Check blower motor switch.

A/C evaporator temperature sensor (A/C evap-

orator thermistor) faultyCheck A/C evaporator tempera-

ture sensor (A/C evaporator ther-

mistor).

Refrigerant (dual) pressure switch faulty Check refrigerant (dual) pressure

switch.

Wiring or grounding faulty Repair as necessary.

A/C ON permission signal in ECM faulty Check A/C ON permission signal.

A/C controller and its circuit faulty Check A/C controller and its circuit.

Cool air does not

come out (A/C com-

pressor does not

operative (won’t rota-

tive))Magnet clutch faulty Check magnet clutch.

Compressor relay faulty Check compressor thermal switch.

Compressor relay faulty Check compressor relay.

Drive belt loose or broken Adjust or replace drive belt.

Compressor faulty Check compressor.

A/C ON permission signal in ECM faulty Check A/C ON permission signal.

A/C controller faulty Check A/C controller.

Cool air does not

come out (A/C con-

denser cooling fan

motor does not opera-

tive)Condenser cooling fan motor relay faulty Check condenser cooling fan motor

relay.

Wiring or grounding faulty Repair as necessary.

A/C condenser fan motor relay signal in ECM

faultyCheck A/C condenser cooling fan

motor relay signal.

Condenser cooling fan motor faulty Check condenser cooling fan

motor.

Cool air does not

come out (Blower

motor does not opera-

tive)Fuse blown Check “FRONT BLOW” and

“REAR DEFG” fuses, and check for

short circuit to ground.

Blower motor relay faulty Check blower motor relay.

Blower motor resistor faulty Check blower motor resistor.

Blower motor switch faulty Check blower motor switch.

Wiring or grounding faulty Repair as necessary.

Blower motor faulty Check blower motor.

Page 39 of 656

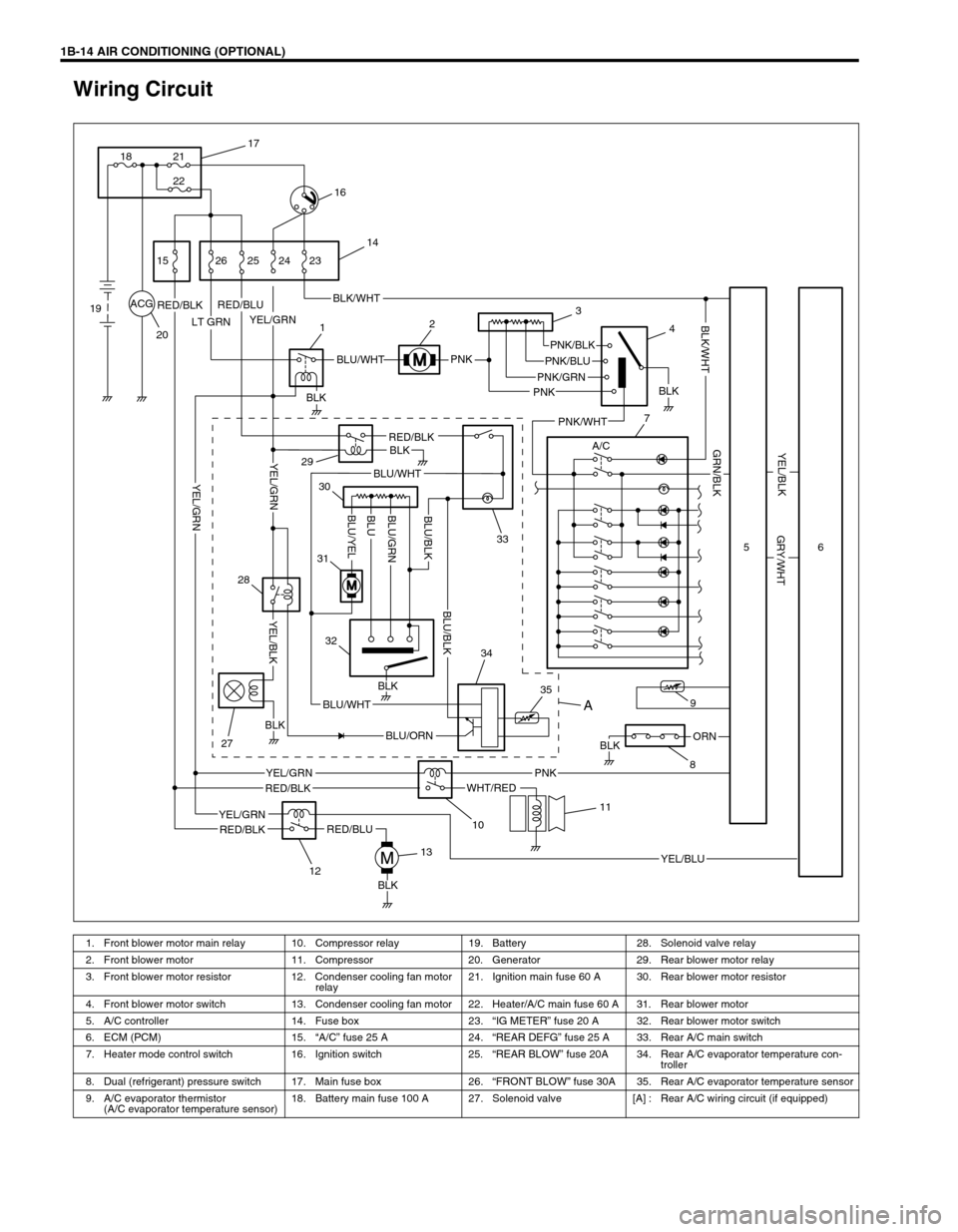

1B-14 AIR CONDITIONING (OPTIONAL)

Wiring Circuit

ACG

LT GRN

PNK

PNK

BLKORN

BLK

YEL/GRNRED/BLKBLK/WHT

BLU/WHTPNK/BLK

PNK/GRN

RED/BLK

WHT/RED

YEL/GRN

YEL/BLU

A/C

RED/BLU

RED/BLU

RED/BLKBLK

BLU/ORN

BLU/WHT

BLU/WHT

PNK

PNK/BLU

BLK

PNK/WHT

YEL/BLK

GRY/WHT

GRN/BLK

BLK/WHT

RED/BLK

YEL/GRN

BLK

BLK

BLK

YEL/BLK

YEL/GRN

YEL/GRNBLU/GRN

BLU/YELBLUBLU/BLK

BLU/BLK

17

21

22 18

16

15

19

2026 25 24 23

14

12

29

3

4

7

33 30

31

32

28

27

1213

10

11

35 349

856

A

1. Front blower motor main relay 10. Compressor relay 19. Battery 28. Solenoid valve relay

2. Front blower motor 11. Compressor 20. Generator 29. Rear blower motor relay

3. Front blower motor resistor 12. Condenser cooling fan motor

relay21. Ignition main fuse 60 A 30. Rear blower motor resistor

4. Front blower motor switch 13. Condenser cooling fan motor 22. Heater/A/C main fuse 60 A 31. Rear blower motor

5. A/C controller 14. Fuse box 23.“IG METER” fuse 20 A 32. Rear blower motor switch

6. ECM (PCM) 15.“A/C” fuse 25 A 24.“REAR DEFG” fuse 25 A 33. Rear A/C main switch

7. Heater mode control switch 16. Ignition switch 25.“REAR BLOW” fuse 20A 34. Rear A/C evaporator temperature con-

troller

8. Dual (refrigerant) pressure switch 17. Main fuse box 26.“FRONT BLOW” fuse 30A 35. Rear A/C evaporator temperature sensor

9. A/C evaporator thermistor

(A/C evaporator temperature sensor)18. Battery main fuse 100 A 27. Solenoid valve [A] : Rear A/C wiring circuit (if equipped)

Page 41 of 656

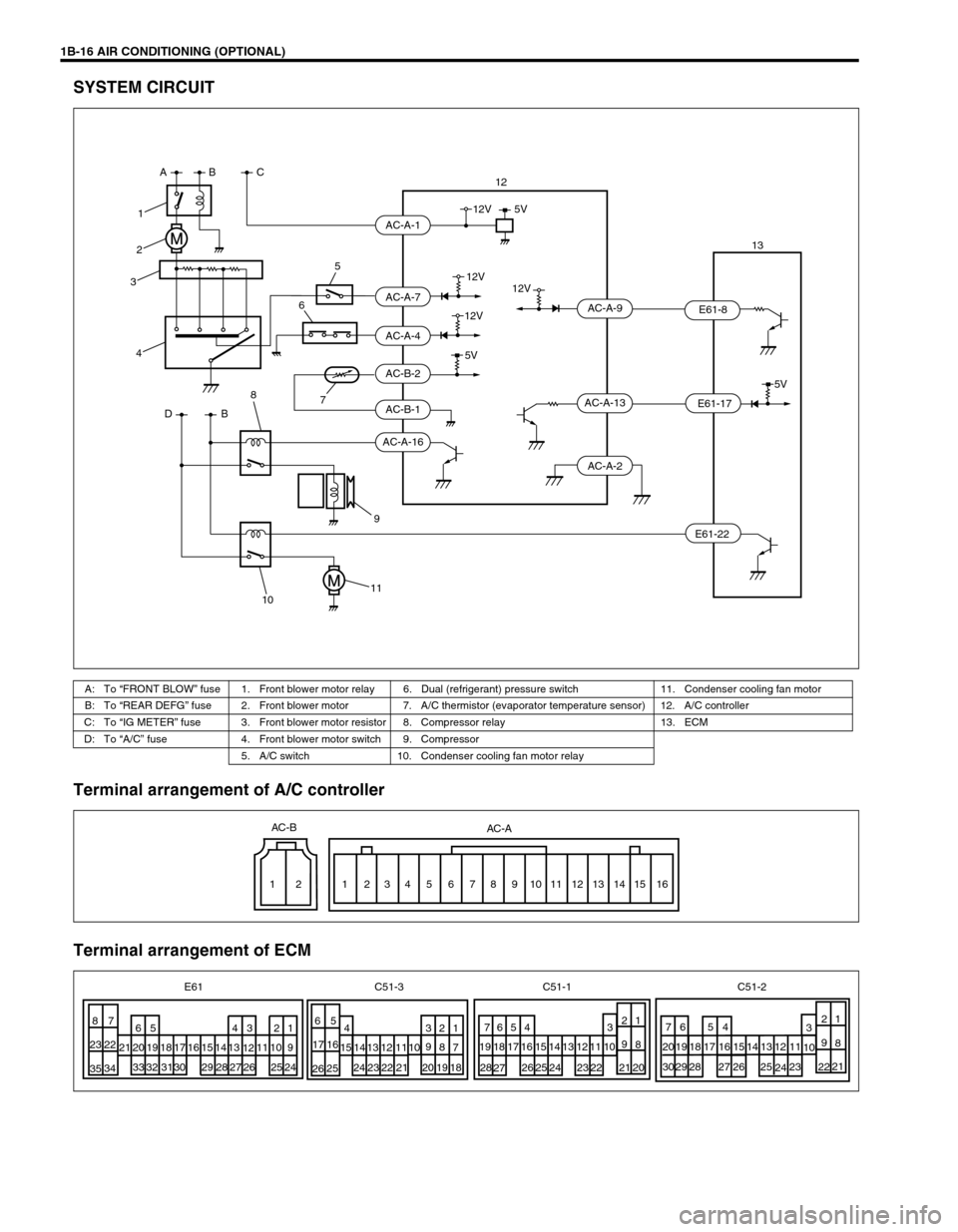

1B-16 AIR CONDITIONING (OPTIONAL)

SYSTEM CIRCUIT

Terminal arrangement of A/C controller

Terminal arrangement of ECM

A: To “FRONT BLOW” fuse 1. Front blower motor relay 6. Dual (refrigerant) pressure switch 11. Condenser cooling fan motor

B: To “REAR DEFG” fuse 2. Front blower motor 7. A/C thermistor (evaporator temperature sensor) 12. A/C controller

C: To “IG METER” fuse 3. Front blower motor resistor 8. Compressor relay 13. ECM

D: To “A/C” fuse 4. Front blower motor switch 9. Compressor

5. A/C switch 10. Condenser cooling fan motor relay

5V

12V12V

12V5V

12V

5V

AC-A-1

AC-A-7

AC-A-4

AC-B-2

AC-B-1

AC-A-16AC-A-9

AC-A-2 AC-A-13

E61-8

E61-17

E61-22

A

DBBC

1

2

3

4

7 865

1011912

13

12 12

3

45 6 7 8 9 101112131415 16 AC-B

AC-A

87

22 23

34

3565

16 17

25

262

1

8 9

20

212

1

8 9

21

22 1 2 3 4 5 6

9

24 25 26 27 28 29 30 31 32 3310 11

12 13 14 15 16 17 18 19 20 211 2 3 4

7 8 9

10 11 12 13 14 15

18 19 20 21 22 23 243 4 5 6 7

10 11 12 13 14 15 16 17 18 19

22 23 24 25 26

27 283 4 5 6 7

10 11 12 13 14 15 16 19 18 2017

23

24 25 26 27 29 28 30 E61 C51-3 C51-1 C51-2

Page 42 of 656

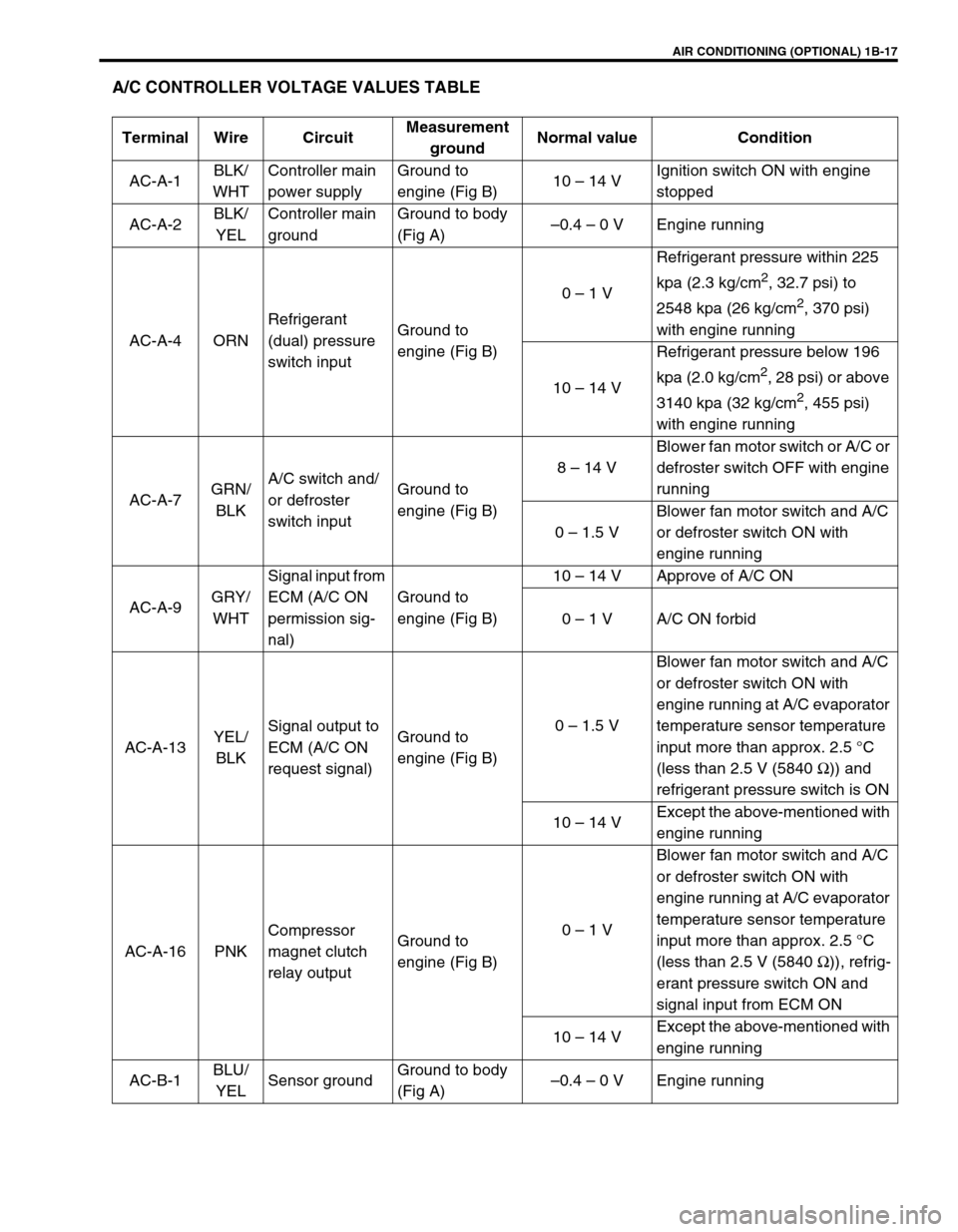

AIR CONDITIONING (OPTIONAL) 1B-17

A/C CONTROLLER VOLTAGE VALUES TABLE

Terminal Wire CircuitMeasurement

groundNormal value Condition

AC-A-1BLK/

WHTController main

power supplyGround to

engine (Fig B)10 – 14 VIgnition switch ON with engine

stopped

AC-A-2BLK/

YELController main

groundGround to body

(Fig A)–0.4 – 0 V Engine running

AC-A-4 ORNRefrigerant

(dual) pressure

switch inputGround to

engine (Fig B)0 – 1 VRefrigerant pressure within 225

kpa (2.3 kg/cm

2, 32.7 psi) to

2548 kpa (26 kg/cm

2, 370 psi)

with engine running

10 – 14 VRefrigerant pressure below 196

kpa (2.0 kg/cm

2, 28 psi) or above

3140 kpa (32 kg/cm

2, 455 psi)

with engine running

AC-A-7GRN/

BLKA/C switch and/

or defroster

switch inputGround to

engine (Fig B)8 – 14 VBlower fan motor switch or A/C or

defroster switch OFF with engine

running

0 – 1.5 VBlower fan motor switch and A/C

or defroster switch ON with

engine running

AC-A-9GRY/

WHTSignal input from

ECM (A/C ON

permission sig-

nal)Ground to

engine (Fig B)10 – 14 V Approve of A/C ON

0 – 1 V A/C ON forbid

AC-A-13YEL/

BLKSignal output to

ECM (A/C ON

request signal)Ground to

engine (Fig B)0 – 1.5 VBlower fan motor switch and A/C

or defroster switch ON with

engine running at A/C evaporator

temperature sensor temperature

input more than approx. 2.5 °C

(less than 2.5 V (5840 Ω)) and

refrigerant pressure switch is ON

10 – 14 VExcept the above-mentioned with

engine running

AC-A-16 PNKCompressor

magnet clutch

relay outputGround to

engine (Fig B)0 – 1 VBlower fan motor switch and A/C

or defroster switch ON with

engine running at A/C evaporator

temperature sensor temperature

input more than approx. 2.5 °C

(less than 2.5 V (5840 Ω)), refrig-

erant pressure switch ON and

signal input from ECM ON

10 – 14 VExcept the above-mentioned with

engine running

AC-B-1BLU/

YELSensor groundGround to body

(Fig A)–0.4 – 0 V Engine running

Page 43 of 656

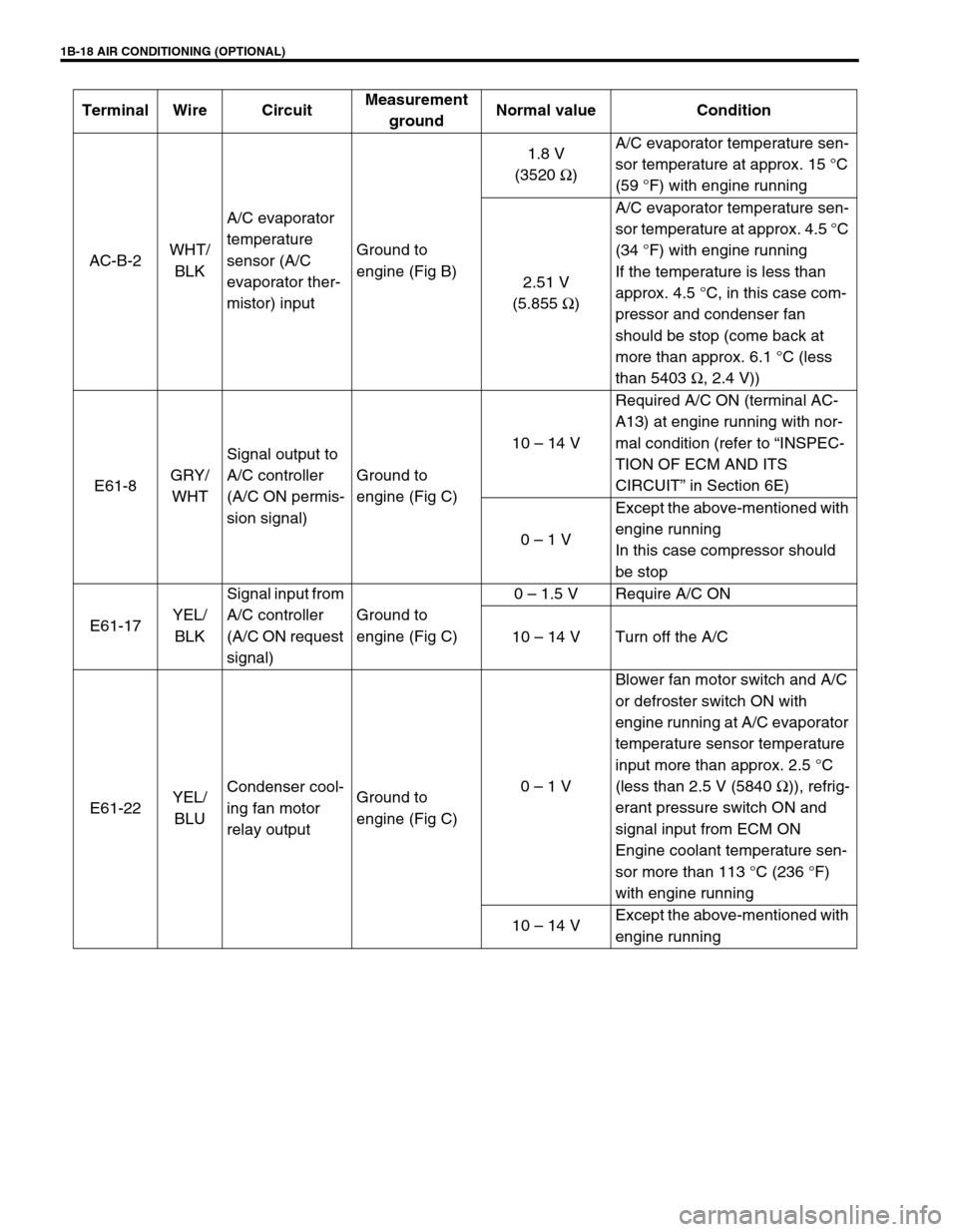

1B-18 AIR CONDITIONING (OPTIONAL)

Terminal Wire CircuitMeasurement

groundNormal value Condition

AC-B-2WHT/

BLKA/C evaporator

temperature

sensor (A/C

evaporator ther-

mistor) inputGround to

engine (Fig B)1.8 V

(3520 Ω)A/C evaporator temperature sen-

sor temperature at approx. 15 °C

(59 °F) with engine running

2.51 V

(5.855 Ω)A/C evaporator temperature sen-

sor temperature at approx. 4.5 °C

(34 °F) with engine running

If the temperature is less than

approx. 4.5 °C, in this case com-

pressor and condenser fan

should be stop (come back at

more than approx. 6.1 °C (less

than 5403 Ω, 2.4 V))

E61-8GRY/

WHTSignal output to

A/C controller

(A/C ON permis-

sion signal)Ground to

engine (Fig C)10 – 14 VRequired A/C ON (terminal AC-

A13) at engine running with nor-

mal condition (refer to “INSPEC-

TION OF ECM AND ITS

CIRCUIT” in Section 6E)

0 – 1 VExcept the above-mentioned with

engine running

In this case compressor should

be stop

E61-17YEL/

BLKSignal input from

A/C controller

(A/C ON request

signal)Ground to

engine (Fig C)0 – 1.5 V Require A/C ON

10 – 14 V Turn off the A/C

E61-22YEL/

BLUCondenser cool-

ing fan motor

relay outputGround to

engine (Fig C)0 – 1 VBlower fan motor switch and A/C

or defroster switch ON with

engine running at A/C evaporator

temperature sensor temperature

input more than approx. 2.5 °C

(less than 2.5 V (5840 Ω)), refrig-

erant pressure switch ON and

signal input from ECM ON

Engine coolant temperature sen-

sor more than 113 °C (236 °F)

with engine running

10 – 14 VExcept the above-mentioned with

engine running

Page 128 of 656

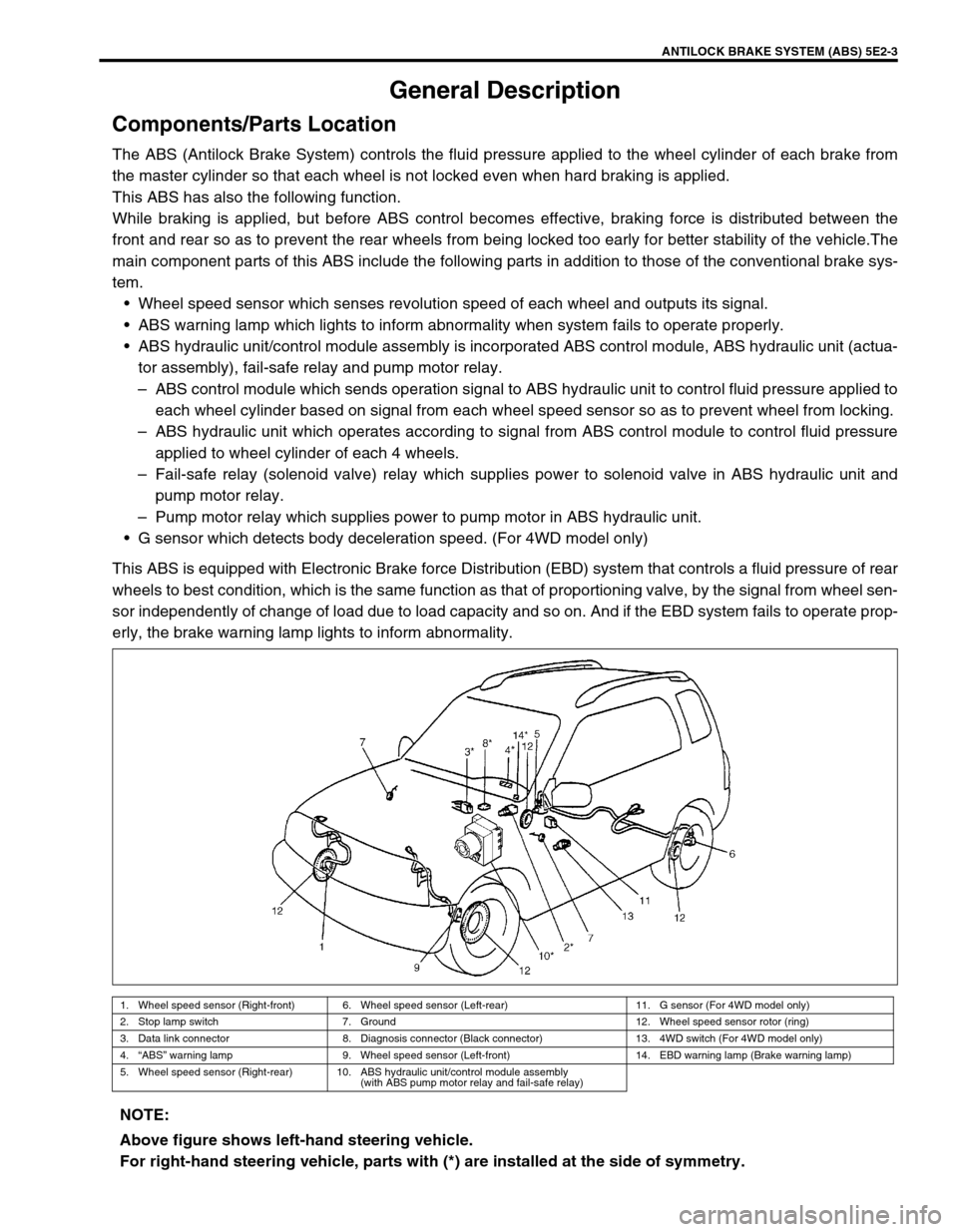

ANTILOCK BRAKE SYSTEM (ABS) 5E2-3

General Description

Components/Parts Location

The ABS (Antilock Brake System) controls the fluid pressure applied to the wheel cylinder of each brake from

the master cylinder so that each wheel is not locked even when hard braking is applied.

This ABS has also the following function.

While braking is applied, but before ABS control becomes effective, braking force is distributed between the

front and rear so as to prevent the rear wheels from being locked too early for better stability of the vehicle.The

main component parts of this ABS include the following parts in addition to those of the conventional brake sys-

tem.

Wheel speed sensor which senses revolution speed of each wheel and outputs its signal.

ABS warning lamp which lights to inform abnormality when system fails to operate properly.

ABS hydraulic unit/control module assembly is incorporated ABS control module, ABS hydraulic unit (actua-

tor assembly), fail-safe relay and pump motor relay.

–ABS control module which sends operation signal to ABS hydraulic unit to control fluid pressure applied to

each wheel cylinder based on signal from each wheel speed sensor so as to prevent wheel from locking.

–ABS hydraulic unit which operates according to signal from ABS control module to control fluid pressure

applied to wheel cylinder of each 4 wheels.

–Fail-safe relay (solenoid valve) relay which supplies power to solenoid valve in ABS hydraulic unit and

pump motor relay.

–Pump motor relay which supplies power to pump motor in ABS hydraulic unit.

G sensor which detects body deceleration speed. (For 4WD model only)

This ABS is equipped with Electronic Brake force Distribution (EBD) system that controls a fluid pressure of rear

wheels to best condition, which is the same function as that of proportioning valve, by the signal from wheel sen-

sor independently of change of load due to load capacity and so on. And if the EBD system fails to operate prop-

erly, the brake warning lamp lights to inform abnormality.

1. Wheel speed sensor (Right-front) 6. Wheel speed sensor (Left-rear) 11. G sensor (For 4WD model only)

2. Stop lamp switch 7. Ground 12. Wheel speed sensor rotor (ring)

3. Data link connector 8. Diagnosis connector (Black connector) 13. 4WD switch (For 4WD model only)

4.“ABS” warning lamp 9. Wheel speed sensor (Left-front) 14. EBD warning lamp (Brake warning lamp)

5. Wheel speed sensor (Right-rear) 10. ABS hydraulic unit/control module assembly

(with ABS pump motor relay and fail-safe relay)

NOTE:

Above figure shows left-hand steering vehicle.

For right-hand steering vehicle, parts with (*) are installed at the side of symmetry.

Page 162 of 656

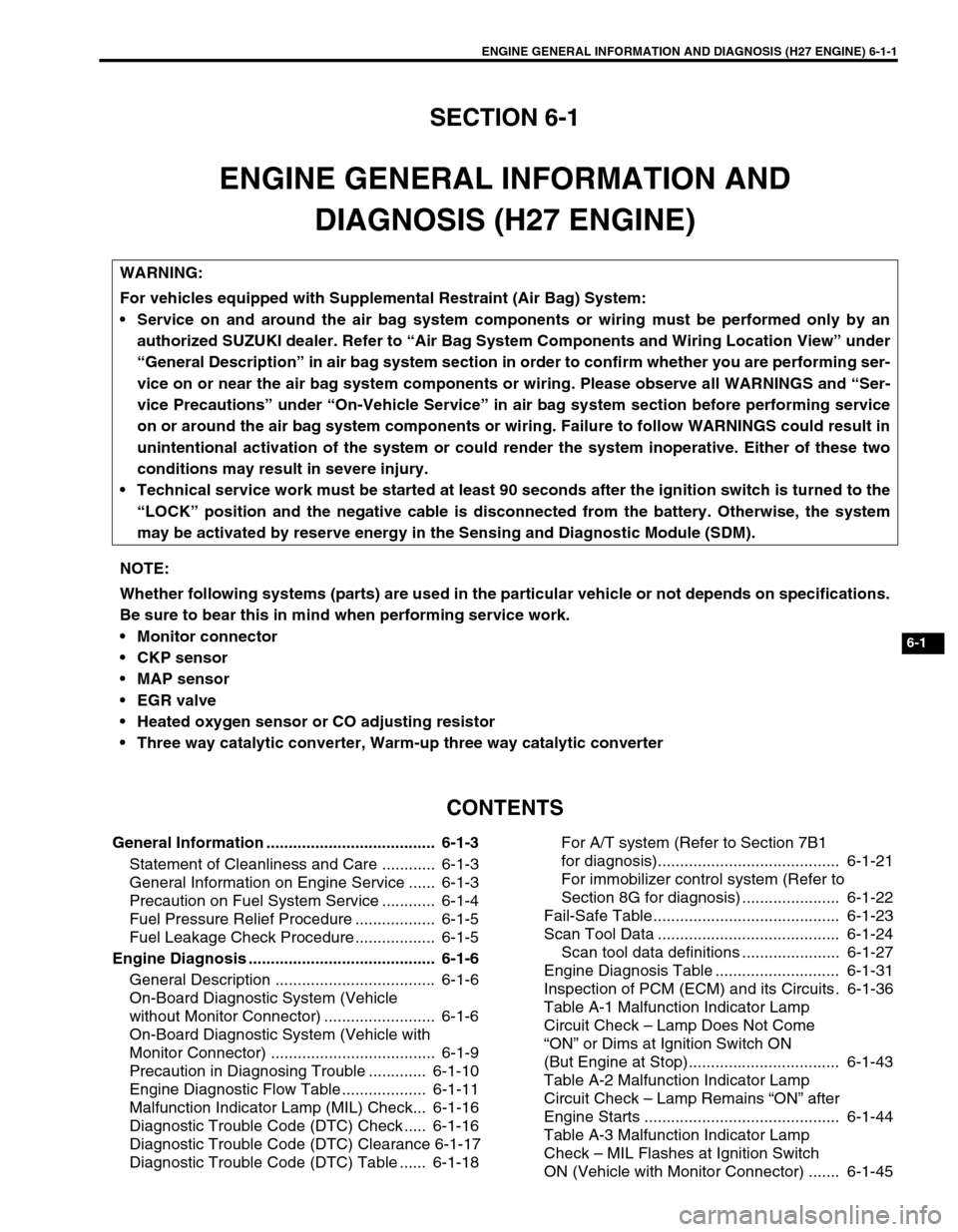

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-1

6-1

SECTION 6-1

ENGINE GENERAL INFORMATION AND

DIAGNOSIS (H27 ENGINE)

CONTENTS

General Information ...................................... 6-1-3

Statement of Cleanliness and Care ............ 6-1-3

General Information on Engine Service ...... 6-1-3

Precaution on Fuel System Service ............ 6-1-4

Fuel Pressure Relief Procedure .................. 6-1-5

Fuel Leakage Check Procedure .................. 6-1-5

Engine Diagnosis .......................................... 6-1-6

General Description .................................... 6-1-6

On-Board Diagnostic System (Vehicle

without Monitor Connector) ......................... 6-1-6

On-Board Diagnostic System (Vehicle with

Monitor Connector) ..................................... 6-1-9

Precaution in Diagnosing Trouble ............. 6-1-10

Engine Diagnostic Flow Table ................... 6-1-11

Malfunction Indicator Lamp (MIL) Check... 6-1-16

Diagnostic Trouble Code (DTC) Check ..... 6-1-16

Diagnostic Trouble Code (DTC) Clearance 6-1-17

Diagnostic Trouble Code (DTC) Table ...... 6-1-18For A/T system (Refer to Section 7B1

for diagnosis)......................................... 6-1-21

For immobilizer control system (Refer to

Section 8G for diagnosis) ...................... 6-1-22

Fail-Safe Table.......................................... 6-1-23

Scan Tool Data ......................................... 6-1-24

Scan tool data definitions ...................... 6-1-27

Engine Diagnosis Table ............................ 6-1-31

Inspection of PCM (ECM) and its Circuits. 6-1-36

Table A-1 Malfunction Indicator Lamp

Circuit Check – Lamp Does Not Come

“ON” or Dims at Ignition Switch ON

(But Engine at Stop).................................. 6-1-43

Table A-2 Malfunction Indicator Lamp

Circuit Check – Lamp Remains “ON” after

Engine Starts ............................................ 6-1-44

Table A-3 Malfunction Indicator Lamp

Check – MIL Flashes at Ignition Switch

ON (Vehicle with Monitor Connector) ....... 6-1-45 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

Whether following systems (parts) are used in the particular vehicle or not depends on specifications.

Be sure to bear this in mind when performing service work.

Monitor connector

CKP sensor

MAP sensor

EGR valve

Heated oxygen sensor or CO adjusting resistor

Three way catalytic converter, Warm-up three way catalytic converter

Page 163 of 656

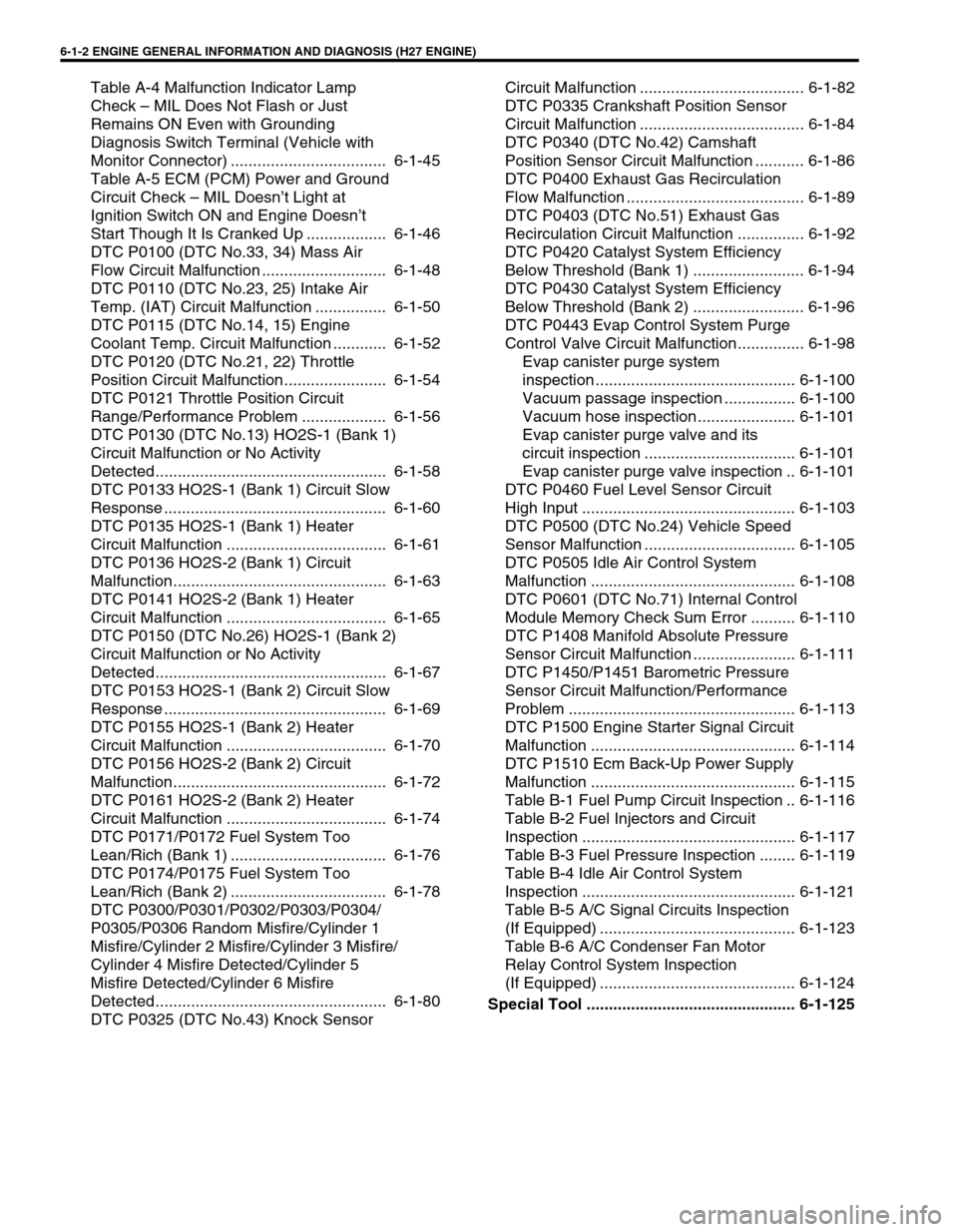

6-1-2 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

Table A-4 Malfunction Indicator Lamp

Check – MIL Does Not Flash or Just

Remains ON Even with Grounding

Diagnosis Switch Terminal (Vehicle with

Monitor Connector) ................................... 6-1-45

Table A-5 ECM (PCM) Power and Ground

Circuit Check – MIL Doesn’t Light at

Ignition Switch ON and Engine Doesn’t

Start Though It Is Cranked Up .................. 6-1-46

DTC P0100 (DTC No.33, 34) Mass Air

Flow Circuit Malfunction ............................ 6-1-48

DTC P0110 (DTC No.23, 25) Intake Air

Temp. (IAT) Circuit Malfunction ................ 6-1-50

DTC P0115 (DTC No.14, 15) Engine

Coolant Temp. Circuit Malfunction ............ 6-1-52

DTC P0120 (DTC No.21, 22) Throttle

Position Circuit Malfunction....................... 6-1-54

DTC P0121 Throttle Position Circuit

Range/Performance Problem ................... 6-1-56

DTC P0130 (DTC No.13) HO2S-1 (Bank 1)

Circuit Malfunction or No Activity

Detected.................................................... 6-1-58

DTC P0133 HO2S-1 (Bank 1) Circuit Slow

Response .................................................. 6-1-60

DTC P0135 HO2S-1 (Bank 1) Heater

Circuit Malfunction .................................... 6-1-61

DTC P0136 HO2S-2 (Bank 1) Circuit

Malfunction................................................ 6-1-63

DTC P0141 HO2S-2 (Bank 1) Heater

Circuit Malfunction .................................... 6-1-65

DTC P0150 (DTC No.26) HO2S-1 (Bank 2)

Circuit Malfunction or No Activity

Detected.................................................... 6-1-67

DTC P0153 HO2S-1 (Bank 2) Circuit Slow

Response .................................................. 6-1-69

DTC P0155 HO2S-1 (Bank 2) Heater

Circuit Malfunction .................................... 6-1-70

DTC P0156 HO2S-2 (Bank 2) Circuit

Malfunction................................................ 6-1-72

DTC P0161 HO2S-2 (Bank 2) Heater

Circuit Malfunction .................................... 6-1-74

DTC P0171/P0172 Fuel System Too

Lean/Rich (Bank 1) ................................... 6-1-76

DTC P0174/P0175 Fuel System Too

Lean/Rich (Bank 2) ................................... 6-1-78

DTC P0300/P0301/P0302/P0303/P0304/

P0305/P0306 Random Misfire/Cylinder 1

Misfire/Cylinder 2 Misfire/Cylinder 3 Misfire/

Cylinder 4 Misfire Detected/Cylinder 5

Misfire Detected/Cylinder 6 Misfire

Detected.................................................... 6-1-80

DTC P0325 (DTC No.43) Knock Sensor Circuit Malfunction ..................................... 6-1-82

DTC P0335 Crankshaft Position Sensor

Circuit Malfunction ..................................... 6-1-84

DTC P0340 (DTC No.42) Camshaft

Position Sensor Circuit Malfunction ........... 6-1-86

DTC P0400 Exhaust Gas Recirculation

Flow Malfunction ........................................ 6-1-89

DTC P0403 (DTC No.51) Exhaust Gas

Recirculation Circuit Malfunction ............... 6-1-92

DTC P0420 Catalyst System Efficiency

Below Threshold (Bank 1) ......................... 6-1-94

DTC P0430 Catalyst System Efficiency

Below Threshold (Bank 2) ......................... 6-1-96

DTC P0443 Evap Control System Purge

Control Valve Circuit Malfunction............... 6-1-98

Evap canister purge system

inspection ............................................. 6-1-100

Vacuum passage inspection ................ 6-1-100

Vacuum hose inspection ...................... 6-1-101

Evap canister purge valve and its

circuit inspection .................................. 6-1-101

Evap canister purge valve inspection .. 6-1-101

DTC P0460 Fuel Level Sensor Circuit

High Input ................................................ 6-1-103

DTC P0500 (DTC No.24) Vehicle Speed

Sensor Malfunction .................................. 6-1-105

DTC P0505 Idle Air Control System

Malfunction .............................................. 6-1-108

DTC P0601 (DTC No.71) Internal Control

Module Memory Check Sum Error .......... 6-1-110

DTC P1408 Manifold Absolute Pressure

Sensor Circuit Malfunction ....................... 6-1-111

DTC P1450/P1451 Barometric Pressure

Sensor Circuit Malfunction/Performance

Problem ................................................... 6-1-113

DTC P1500 Engine Starter Signal Circuit

Malfunction .............................................. 6-1-114

DTC P1510 Ecm Back-Up Power Supply

Malfunction .............................................. 6-1-115

Table B-1 Fuel Pump Circuit Inspection .. 6-1-116

Table B-2 Fuel Injectors and Circuit

Inspection ................................................ 6-1-117

Table B-3 Fuel Pressure Inspection ........ 6-1-119

Table B-4 Idle Air Control System

Inspection ................................................ 6-1-121

Table B-5 A/C Signal Circuits Inspection

(If Equipped) ............................................ 6-1-123

Table B-6 A/C Condenser Fan Motor

Relay Control System Inspection

(If Equipped) ............................................ 6-1-124

Special Tool ............................................... 6-1-125

Page 182 of 656

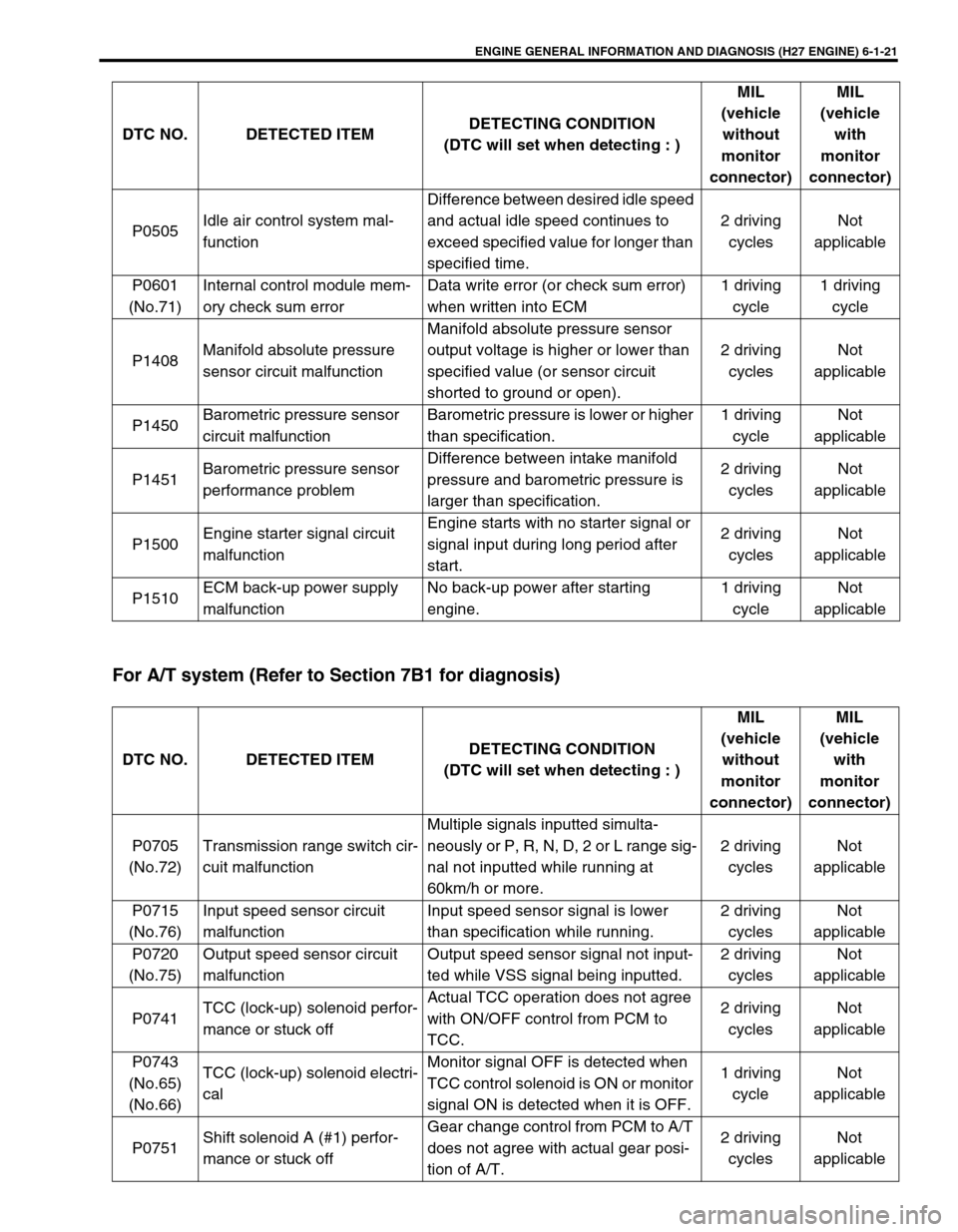

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-21

For A/T system (Refer to Section 7B1 for diagnosis)

P0505Idle air control system mal-

functionDifference between desired idle speed

and actual idle speed continues to

exceed specified value for longer than

specified time.2 driving

cyclesNot

applicable

P0601

(No.71)Internal control module mem-

ory check sum errorData write error (or check sum error)

when written into ECM1 driving

cycle1 driving

cycle

P1408Manifold absolute pressure

sensor circuit malfunctionManifold absolute pressure sensor

output voltage is higher or lower than

specified value (or sensor circuit

shorted to ground or open).2 driving

cyclesNot

applicable

P1450Barometric pressure sensor

circuit malfunctionBarometric pressure is lower or higher

than specification.1 driving

cycleNot

applicable

P1451Barometric pressure sensor

performance problemDifference between intake manifold

pressure and barometric pressure is

larger than specification.2 driving

cyclesNot

applicable

P1500Engine starter signal circuit

malfunctionEngine starts with no starter signal or

signal input during long period after

start.2 driving

cyclesNot

applicable

P1510ECM back-up power supply

malfunctionNo back-up power after starting

engine.1 driving

cycleNot

applicable DTC NO. DETECTED ITEMDETECTING CONDITION

(DTC will set when detecting : )MIL

(vehicle

without

monitor

connector)MIL

(vehicle

with

monitor

connector)

DTC NO. DETECTED ITEMDETECTING CONDITION

(DTC will set when detecting : )MIL

(vehicle

without

monitor

connector)MIL

(vehicle

with

monitor

connector)

P0705

(No.72)Transmission range switch cir-

cuit malfunctionMultiple signals inputted simulta-

neously or P, R, N, D, 2 or L range sig-

nal not inputted while running at

60km/h or more.2 driving

cyclesNot

applicable

P0715

(No.76)Input speed sensor circuit

malfunctionInput speed sensor signal is lower

than specification while running.2 driving

cyclesNot

applicable

P0720

(No.75)Output speed sensor circuit

malfunctionOutput speed sensor signal not input-

ted while VSS signal being inputted.2 driving

cyclesNot

applicable

P0741TCC (lock-up) solenoid perfor-

mance or stuck offActual TCC operation does not agree

with ON/OFF control from PCM to

TCC.2 driving

cyclesNot

applicable

P0743

(No.65)

(No.66)TCC (lock-up) solenoid electri-

calMonitor signal OFF is detected when

TCC control solenoid is ON or monitor

signal ON is detected when it is OFF.1 driving

cycleNot

applicable

P0751Shift solenoid A (#1) perfor-

mance or stuck offGear change control from PCM to A/T

does not agree with actual gear posi-

tion of A/T.2 driving

cyclesNot

applicable