ron SUZUKI GRAND VITARA 2012 Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2012, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2012Pages: 337, PDF Size: 6.21 MB

Page 256 of 337

7-7INSPECTION AND MAINTENANCE

79K21-03E

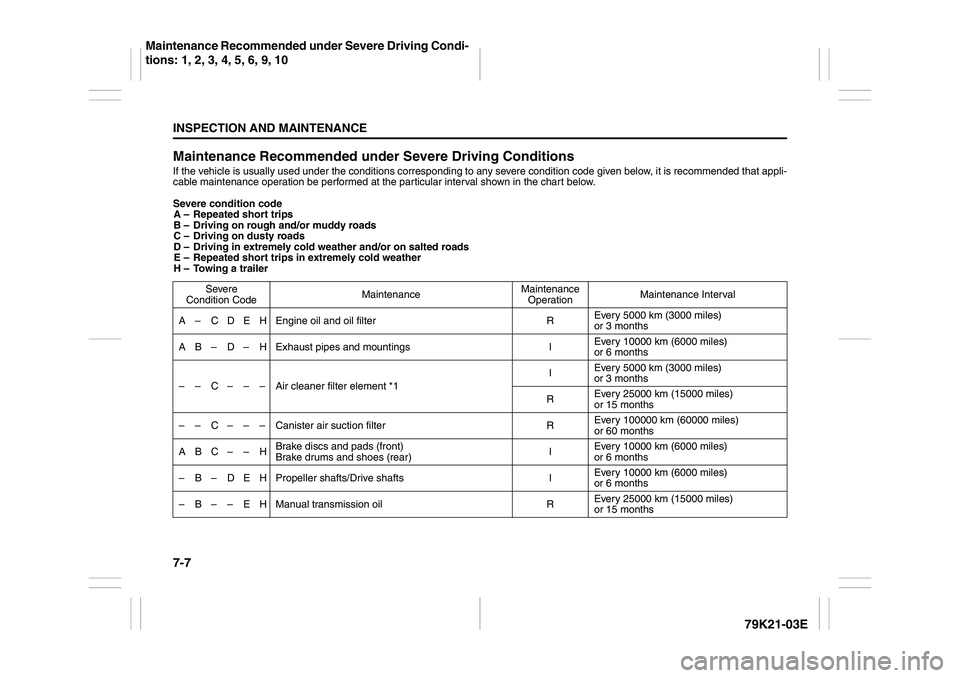

Maintenance Recommended under Severe Driving ConditionsIf the vehicle is usually used under the conditions corresponding to any severe condition code given below, it is recommended that appli-

cable maintenance operation be performed at the particular interval shown in the chart below.

Severe condition code

A – Repeated short trips

B – Driving on rough and/or muddy roads

C – Driving on dusty roads

D – Driving in extremely cold weather and/or on salted roads

E – Repeated short trips in extremely cold weather

H – Towing a trailer

Severe

Condition CodeMaintenanceMaintenance

OperationMaintenance Interval

A – C D E H Engine oil and oil filter REvery 5000 km (3000 miles)

or 3 months

A B – D – H Exhaust pipes and mountings IEvery 10000 km (6000 miles)

or 6 months

– – C – – – Air cleaner filter element *1IEvery 5000 km (3000 miles)

or 3 months

REvery 25000 km (15000 miles)

or 15 months

– – C – – – Canister air suction filter REvery 100000 km (60000 miles)

or 60 months

ABC– – HBrake discs and pads (front)

Brake drums and shoes (rear)IEvery 10000 km (6000 miles)

or 6 months

– B – D E H Propeller shafts/Drive shafts IEvery 10000 km (6000 miles)

or 6 months

– B – – E H Manual transmission oil REvery 25000 km (15000 miles)

or 15 months

Maintenance Recommended under Severe Driving Condi-

tions: 1, 2, 3, 4, 5, 6, 9, 10

Page 266 of 337

7-17INSPECTION AND MAINTENANCE

79K21-03E

65D434

You should inspect spark plugs periodically

for carbon deposits. When carbon accu-

mulates on a spark plug, a strong spark

may not be produced. Remove carbon

deposits with a wire or pin and adjust the

spark plug gap.

To access the spark plugs:

1) Remove the engine cover.

2) Disconnect the coupler (1) while push-

ing the release lever.

3) Remove the bolt.

4) Pull the ignition coil out.

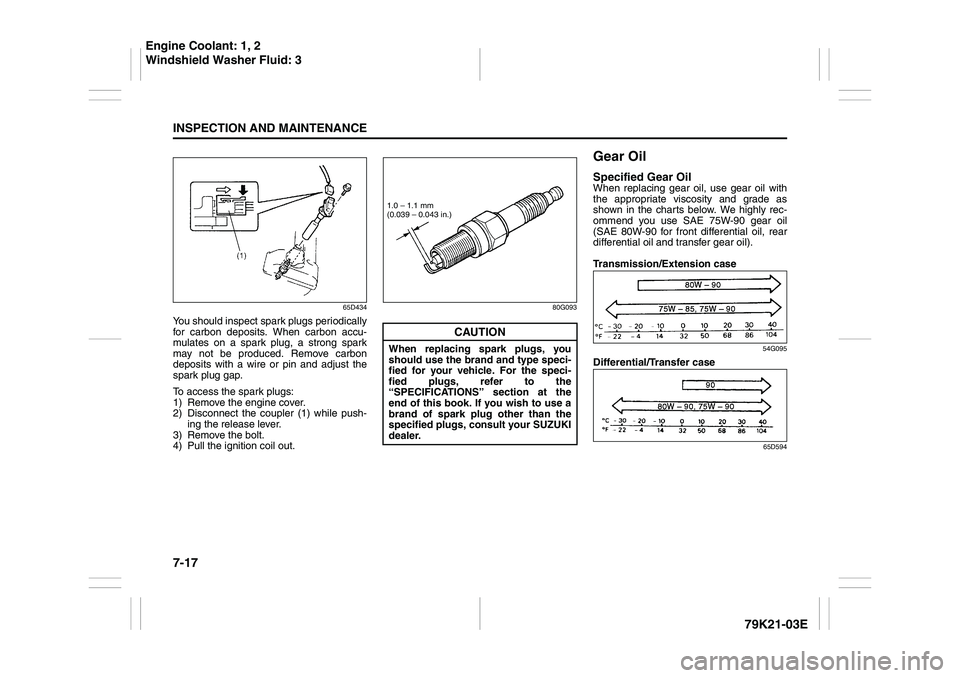

80G093

Gear OilSpecified Gear OilWhen replacing gear oil, use gear oil with

the appropriate viscosity and grade as

shown in the charts below. We highly rec-

ommend you use SAE 75W-90 gear oil

(SAE 80W-90 for front differential oil, rear

differential oil and transfer gear oil).

Transmission/Extension case

54G095

Differential/Transfer case

65D594

CAUTION

When replacing spark plugs, you

should use the brand and type speci-

fied for your vehicle. For the speci-

fied plugs, refer to the

“SPECIFICATIONS” section at the

end of this book. If you wish to use a

brand of spark plug other than the

specified plugs, consult your SUZUKI

dealer.1.0 – 1.1 mm

(0.039 – 0.043 in.)

Engine Coolant: 1, 2

Windshield Washer Fluid: 3

Page 267 of 337

7-18

INSPECTION AND MAINTENANCE

79K21-03E

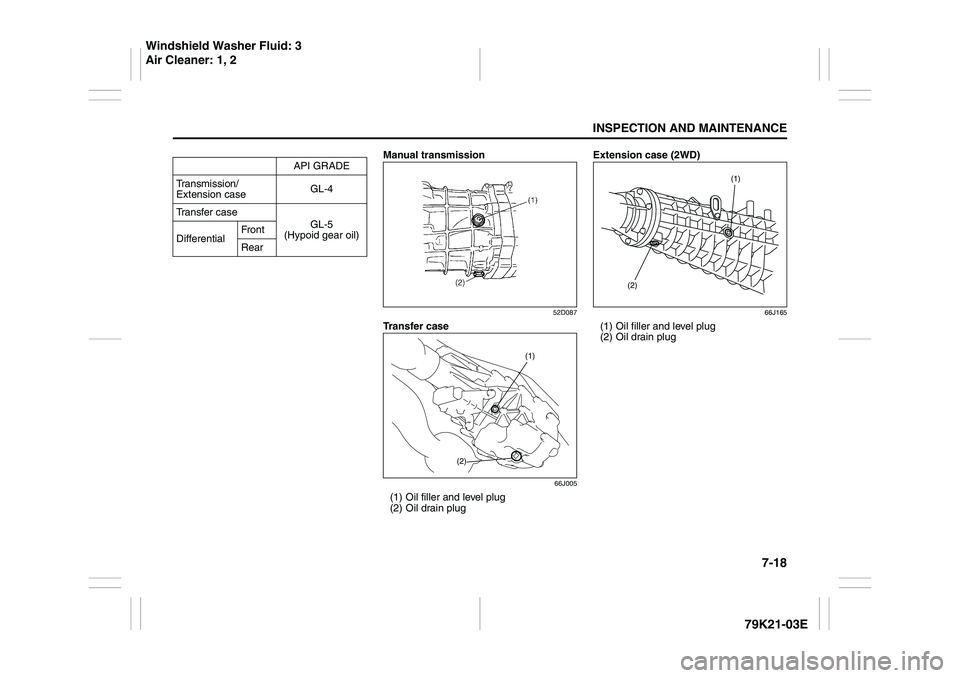

Manual transmission

52D087

Transfer case

66J005

(1) Oil filler and level plug

(2) Oil drain plugExtension case (2WD)

66J165

(1) Oil filler and level plug

(2) Oil drain plug API GRADE

Transmission/

Extension caseGL-4

Transfer case

GL-5

(Hypoid gear oil)

DifferentialFront

Rear

(1)

(2)

(2)(1)

Windshield Washer Fluid: 3

Air Cleaner: 1, 2

Page 268 of 337

7-19INSPECTION AND MAINTENANCE

79K21-03E

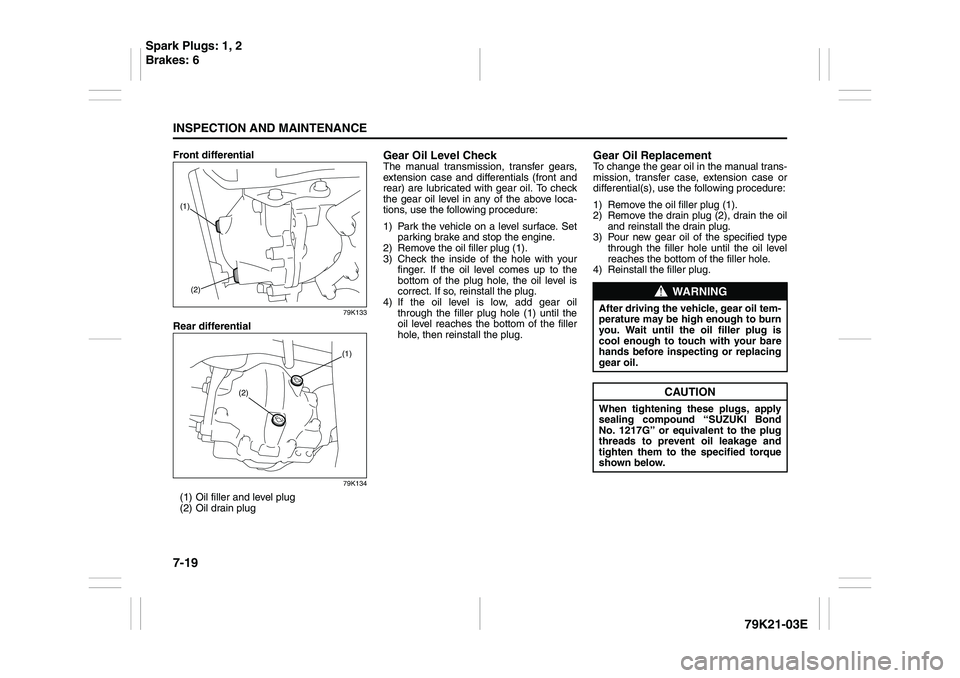

Front differential

79K133

Rear differential

79K134

(1) Oil filler and level plug

(2) Oil drain plug

Gear Oil Level CheckThe manual transmission, transfer gears,

extension case and differentials (front and

rear) are lubricated with gear oil. To check

the gear oil level in any of the above loca-

tions, use the following procedure:

1) Park the vehicle on a level surface. Set

parking brake and stop the engine.

2) Remove the oil filler plug (1).

3) Check the inside of the hole with your

finger. If the oil level comes up to the

bottom of the plug hole, the oil level is

correct. If so, reinstall the plug.

4) If the oil level is low, add gear oil

through the filler plug hole (1) until the

oil level reaches the bottom of the filler

hole, then reinstall the plug.

Gear Oil ReplacementTo change the gear oil in the manual trans-

mission, transfer case, extension case or

differential(s), use the following procedure:

1) Remove the oil filler plug (1).

2) Remove the drain plug (2), drain the oil

and reinstall the drain plug.

3) Pour new gear oil of the specified type

through the filler hole until the oil level

reaches the bottom of the filler hole.

4) Reinstall the filler plug.

(1)

(2)

(1)

(2)

WARNING

After driving the vehicle, gear oil tem-

perature may be high enough to burn

you. Wait until the oil filler plug is

cool enough to touch with your bare

hands before inspecting or replacing

gear oil.

CAUTION

When tightening these plugs, apply

sealing compound “SUZUKI Bond

No. 1217G” or equivalent to the plug

threads to prevent oil leakage and

tighten them to the specified torque

shown below.

Spark Plugs: 1, 2

Brakes: 6

Page 269 of 337

7-20

INSPECTION AND MAINTENANCE

79K21-03E

Tightening torque

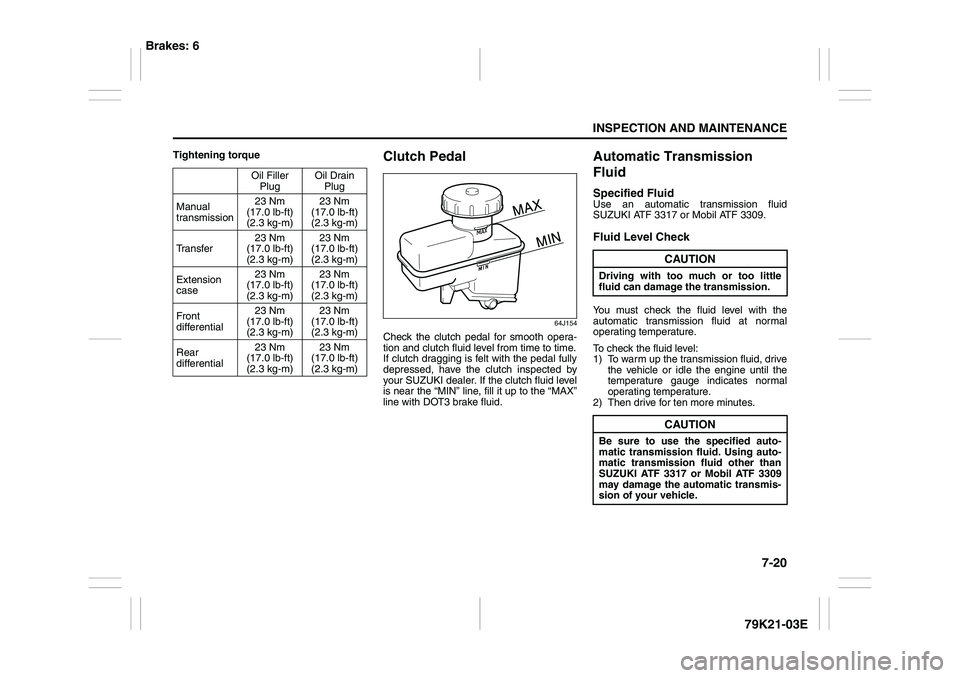

Clutch Pedal

64J154

Check the clutch pedal for smooth opera-

tion and clutch fluid level from time to time.

If clutch dragging is felt with the pedal fully

depressed, have the clutch inspected by

your SUZUKI dealer. If the clutch fluid level

is near the “MIN” line, fill it up to the “MAX”

line with DOT3 brake fluid.

Automatic Transmission

FluidSpecified FluidUse an automatic transmission fluid

SUZUKI ATF 3317 or Mobil ATF 3309.Fluid Level CheckYou must check the fluid level with the

automatic transmission fluid at normal

operating temperature.

To check the fluid level:

1) To warm up the transmission fluid, drive

the vehicle or idle the engine until the

temperature gauge indicates normal

operating temperature.

2) Then drive for ten more minutes. Oil Filler

PlugOil Drain

Plug

Manual

transmission23 Nm

(17.0 lb-ft)

(2.3 kg-m) 23 Nm

(17.0 lb-ft)

(2.3 kg-m)

Tr a n s f e r23 Nm

(17.0 lb-ft)

(2.3 kg-m) 23 Nm

(17.0 lb-ft)

(2.3 kg-m)

Extension

case23 Nm

(17.0 lb-ft)

(2.3 kg-m) 23 Nm

(17.0 lb-ft)

(2.3 kg-m)

Front

differential23 Nm

(17.0 lb-ft)

(2.3 kg-m) 23 Nm

(17.0 lb-ft)

(2.3 kg-m)

Rear

differential23 Nm

(17.0 lb-ft)

(2.3 kg-m) 23 Nm

(17.0 lb-ft)

(2.3 kg-m)

CAUTION

Driving with too much or too little

fluid can damage the transmission.

CAUTION

Be sure to use the specified auto-

matic transmission fluid. Using auto-

matic transmission fluid other than

SUZUKI ATF 3317 or Mobil ATF 3309

may damage the automatic transmis-

sion of your vehicle.

Brakes: 6

Page 273 of 337

7-24

INSPECTION AND MAINTENANCE

79K21-03E

Parking Brake Lever

60A226

Check the parking brake for proper adjust-

ment by counting the number of clicks

made by the ratchet teeth as you slowly

pull up on the parking brake lever to the

point of full engagement. The parking

brake lever should stop between the speci-

fied ratchet teeth and the rear wheels

should be securely locked. If the parking

brake is not properly adjusted or the

brakes drag after the lever has been fully

released, have the parking brake inspected

and/or adjusted by your SUZUKI dealer.

Steering Wheel

78K080

Check the play of the steering wheel by

gently turning it from left to right and mea-

suring the distance that it moves before

you feel slight resistance. The play should

be between the specified values. Check

that the steering wheel turns easily and

smoothly without rattling by turning it all the

way to the right and to the left while driving

very slowly in an open area. If the amount

of free play is outside the specification or

you find anything else to be wrong, an

inspection must be performed by your

SUZUKI dealer.

Power Steering (if equipped)

64J155

(1) UPPER

(2) LOWER

Check the steering box case, vane pump

and hose connections for leaks or damage.Power Steering FluidCheck the fluid level by looking at the res-

ervoir in the engine compartment when the

fluid is cold (about room temperature).

Check that the fluid level is between the (1)

and (2) lines. If the fluid level is near the (2)

line, fill it up to the (1) line with an auto-

matic transmission fluid equivalent to ATF

DEXRON

®-II (Esso JWS 2326) or

DEXRON®-III. Do not overfill. Ratchet tooth specification “b”

5th – 7th

200 N (44 lbs, 20 kg)

“b”

EXAMPLE

Steering wheel play “c”

0 – 30 mm (0.0 – 1.2 in.)

“c”

EXAMPLE

(1)

(2)

Tires: 6

Page 276 of 337

7-27INSPECTION AND MAINTENANCE

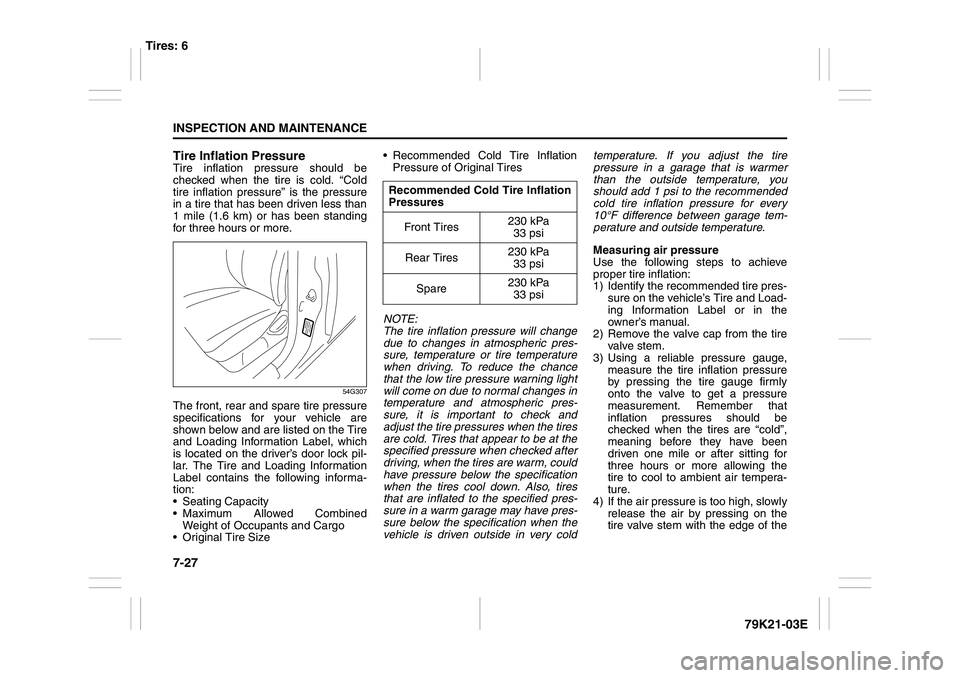

79K21-03E Tire Inflation Pressure

Tire inflation pressure should be

checked when the tire is cold. “Cold

tire inflation pressure” is the pressure

in a tire that has been driven less than

1 mile (1.6 km) or has been standing

for three hours or more.

54G307

The front, rear and spare tire pressure

specifications for your vehicle are

shown below and are listed on the Tire

and Loading Information Label, which

is located on the driver’s door lock pil-

lar. The Tire and Loading Information

Label contains the following informa-

tion:

Seating Capacity

Maximum Allowed Combined

Weight of Occupants and Cargo

Original Tire Size Recommended Cold Tire Inflation

Pressure of Original Tires

NOTE:

The tire inflation pressure will change

due to changes in atmospheric pres-

sure, temperature or tire temperature

when driving. To reduce the chance

that the low tire pressure warning light

will come on due to normal changes in

temperature and atmospheric pres-

sure, it is important to check and

adjust the tire pressures when the tires

are cold. Tires that appear to be at the

specified pressure when checked after

driving, when the tires are warm, could

have pressure below the specification

when the tires cool down. Also, tires

that are inflated to the specified pres-

sure in a warm garage may have pres-

sure below the specification when the

vehicle is driven outside in very coldtemperature. If you adjust the tire

pressure in a garage that is warmer

than the outside temperature, you

should add 1 psi to the recommended

cold tire inflation pressure for every

10°F difference between garage tem-

perature and outside temperature.

Measuring air pressure

Use the following steps to achieve

proper tire inflation:

1) Identify the recommended tire pres-

sure on the vehicle’s Tire and Load-

ing Information Label or in the

owner’s manual.

2) Remove the valve cap from the tire

valve stem.

3) Using a reliable pressure gauge,

measure the tire inflation pressure

by pressing the tire gauge firmly

onto the valve to get a pressure

measurement. Remember that

inflation pressures should be

checked when the tires are “cold”,

meaning before they have been

driven one mile or after sitting for

three hours or more allowing the

tire to cool to ambient air tempera-

ture.

4) If the air pressure is too high, slowly

release the air by pressing on the

tire valve stem with the edge of the

Recommended Cold Tire Inflation

Pressures

Front Tires230 kPa

33 psi

Rear Tires230 kPa

33 psi

Spare230 kPa

33 psi

Tires: 6

Page 280 of 337

7-31INSPECTION AND MAINTENANCE

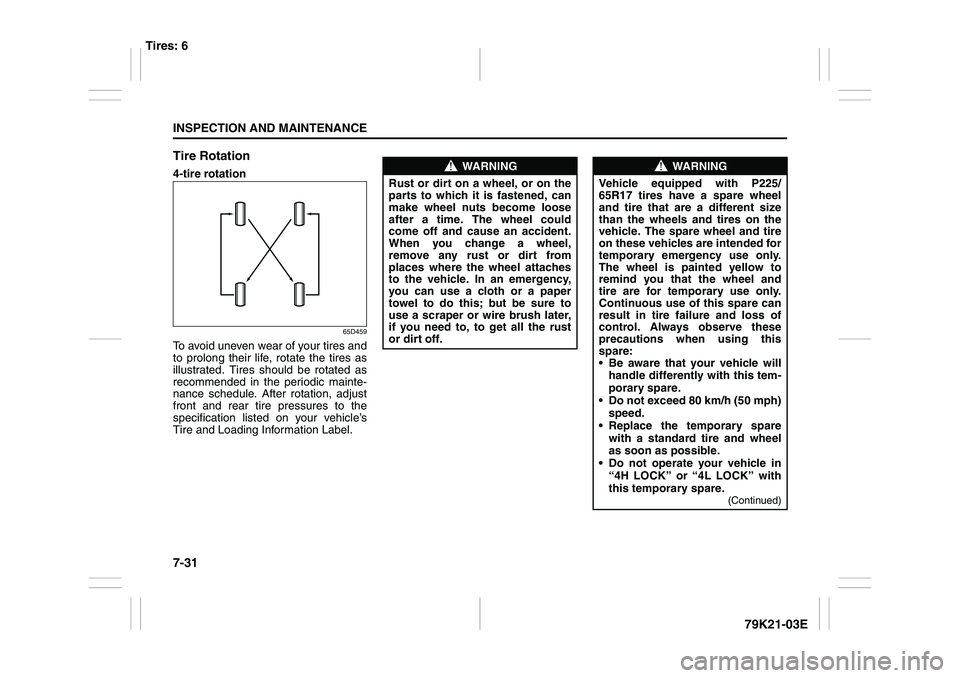

79K21-03E Tire Rotation

4-tire rotation

65D459

To avoid uneven wear of your tires and

to prolong their life, rotate the tires as

illustrated. Tires should be rotated as

recommended in the periodic mainte-

nance schedule. After rotation, adjust

front and rear tire pressures to the

specification listed on your vehicle’s

Tire and Loading Information Label.

WARNING

Rust or dirt on a wheel, or on the

parts to which it is fastened, can

make wheel nuts become loose

after a time. The wheel could

come off and cause an accident.

When you change a wheel,

remove any rust or dirt from

places where the wheel attaches

to the vehicle. In an emergency,

you can use a cloth or a paper

towel to do this; but be sure to

use a scraper or wire brush later,

if you need to, to get all the rust

or dirt off.

WARNING

Vehicle equipped with P225/

65R17 tires have a spare wheel

and tire that are a different size

than the wheels and tires on the

vehicle. The spare wheel and tire

on these vehicles are intended for

temporary emergency use only.

The wheel is painted yellow to

remind you that the wheel and

tire are for temporary use only.

Continuous use of this spare can

result in tire failure and loss of

control. Always observe these

precautions when using this

spare:

Be aware that your vehicle will

handle differently with this tem-

porary spare.

Do not exceed 80 km/h (50 mph)

speed.

Replace the temporary spare

with a standard tire and wheel

as soon as possible.

Do not operate your vehicle in

“4H LOCK” or “4L LOCK” with

this temporary spare.

(Continued)

Tires: 6

Page 282 of 337

7-33INSPECTION AND MAINTENANCE

79K21-03E

Recommended Inflation Pressure –

the cold tire inflation pressure recom-

mended by a manufacturer.

Rim – metal support for a tire or tire

and tube assembly upon which the tire

beads are seated.

Vehicle Capacity Weight – the rated

cargo and luggage load plus 68 kilo-

grams (150 lbs) times the vehicle’s

designated seating capacity.

Vehicle Maximum Load on the Tire –

the load on an individual tire that is

determined by distributing to each axle

its share of the maximum loaded vehi-

cle weight and dividing by two.

Vehicle Normal Load on the Tire – the

load on an individual tire that is deter-

mined by distributing to each axle its

share of the curb weight, accessory

weight, and normal occupant weight

(distributed in accordance with Table 1

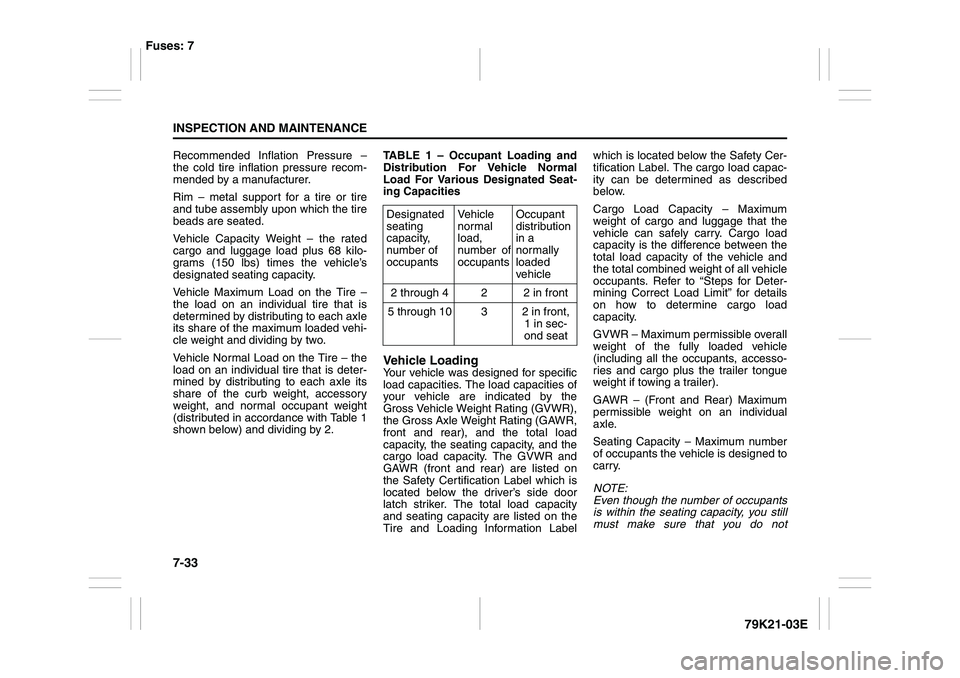

shown below) and dividing by 2.TABLE 1 – Occupant Loading and

Distribution For Vehicle Normal

Load For Various Designated Seat-

ing Capacities

Vehicle LoadingYour vehicle was designed for specific

load capacities. The load capacities of

your vehicle are indicated by the

Gross Vehicle Weight Rating (GVWR),

the Gross Axle Weight Rating (GAWR,

front and rear), and the total load

capacity, the seating capacity, and the

cargo load capacity. The GVWR and

GAWR (front and rear) are listed on

the Safety Certification Label which is

located below the driver’s side door

latch striker. The total load capacity

and seating capacity are listed on the

Tire and Loading Information Labelwhich is located below the Safety Cer-

tification Label. The cargo load capac-

ity can be determined as described

below.

Cargo Load Capacity – Maximum

weight of cargo and luggage that the

vehicle can safely carry. Cargo load

capacity is the difference between the

total load capacity of the vehicle and

the total combined weight of all vehicle

occupants. Refer to “Steps for Deter-

mining Correct Load Limit” for details

on how to determine cargo load

capacity.

GVWR – Maximum permissible overall

weight of the fully loaded vehicle

(including all the occupants, accesso-

ries and cargo plus the trailer tongue

weight if towing a trailer).

GAWR – (Front and Rear) Maximum

permissible weight on an individual

axle.

Seating Capacity – Maximum number

of occupants the vehicle is designed to

carry.

NOTE:

Even though the number of occupants

is within the seating capacity, you still

must make sure that you do not Designated

seating

capacity,

number of

occupantsVehicle

normal

load,

number of

occupantsOccupant

distribution

in a

normally

loaded

vehicle

2 through 4 2 2 in front

5 through 10 3 2 in front,

1 in sec-

ond seat

Fuses: 7

Page 283 of 337

7-34

INSPECTION AND MAINTENANCE

79K21-03E

exceed the total load capacity of the

vehicle.

Total Load Capacity – Maximum per-

missible weight a vehicle can carry

including the weight of all the occu-

pants, accessories, cargo, plus trailer

tongue weight (if towing a trailer).

The weight of any accessories already

installed on your vehicle at the time of

purchase, or that you or the dealer

install after purchase, must be sub-

tracted from the total load capacity to

determine how much capacity remains

available for occupants, cargo, and

trailer tongue weight (if towing a

trailer). Contact your dealer for further

information.

Actual weight of the loaded vehicle

and actual loads at the front and rear

axles can only be determined by

weighing the vehicle using a vehicle

scale. To measure the weight and

load, try making your vehicle to a high-

way weighing station, shipping com-

pany or inspection station for trucks,

etc. Compare these weights to the

GVWR and GAWR (front and rear)

listed on the Safety Certification Label.

If the gross vehicle weight or the load

on either axle exceeds these ratings,

you must remove enough weight tobring the load down to the rated

capacity.

Steps for Determining Correct Load

Limit

1) Locate the statement “The com-

bined weight of occupants and

cargo should never exceed XXX kg

or XXX lbs” on your vehicle’s plac-

ard.

2) Determine the combined weight of

the driver and passengers that will

be riding in your vehicle.

3) Subtract the combined weight of

the driver and passengers from

XXX kg or XXX lbs.

4) The resulting figure equals the

available amount of cargo and lug-

gage load capacity. For example, if

the “XXX” amount equals 1400 lbs

and there will be five 150 lb passen-

WARNING

Never overload your vehicle.

Overloading your vehicle can

cause damage to your tires and

lead to poor steering and braking

which can result in an accident.

The gross vehicle weight (sum of

the weights of the loaded vehicle,

driver and passengers) must

never exceed the Gross Vehicle

Weight Rating (GVWR) listed on

the Safety Certification Label. In

addition, never distribute a load

so that the weight on either the

front or rear axle exceeds the

Gross Axle Weight Rating

(GAWR) listed on the Safety Certi-

fication Label.

WARNING

Always distribute cargo evenly.

To avoid personal injury or

damage to your vehicle, always

secure cargo to prevent it from

shifting if the vehicle moves

suddenly.

Place heavier objects on the

floor and as far forward in the

cargo area as possible. Never

pile cargo higher than the top of

the seatbacks.

Fuses: 7