battery SUZUKI JIMNY 2005 3.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 639 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-34 ENGINE AND EMISSION CONTROL SYSTEM

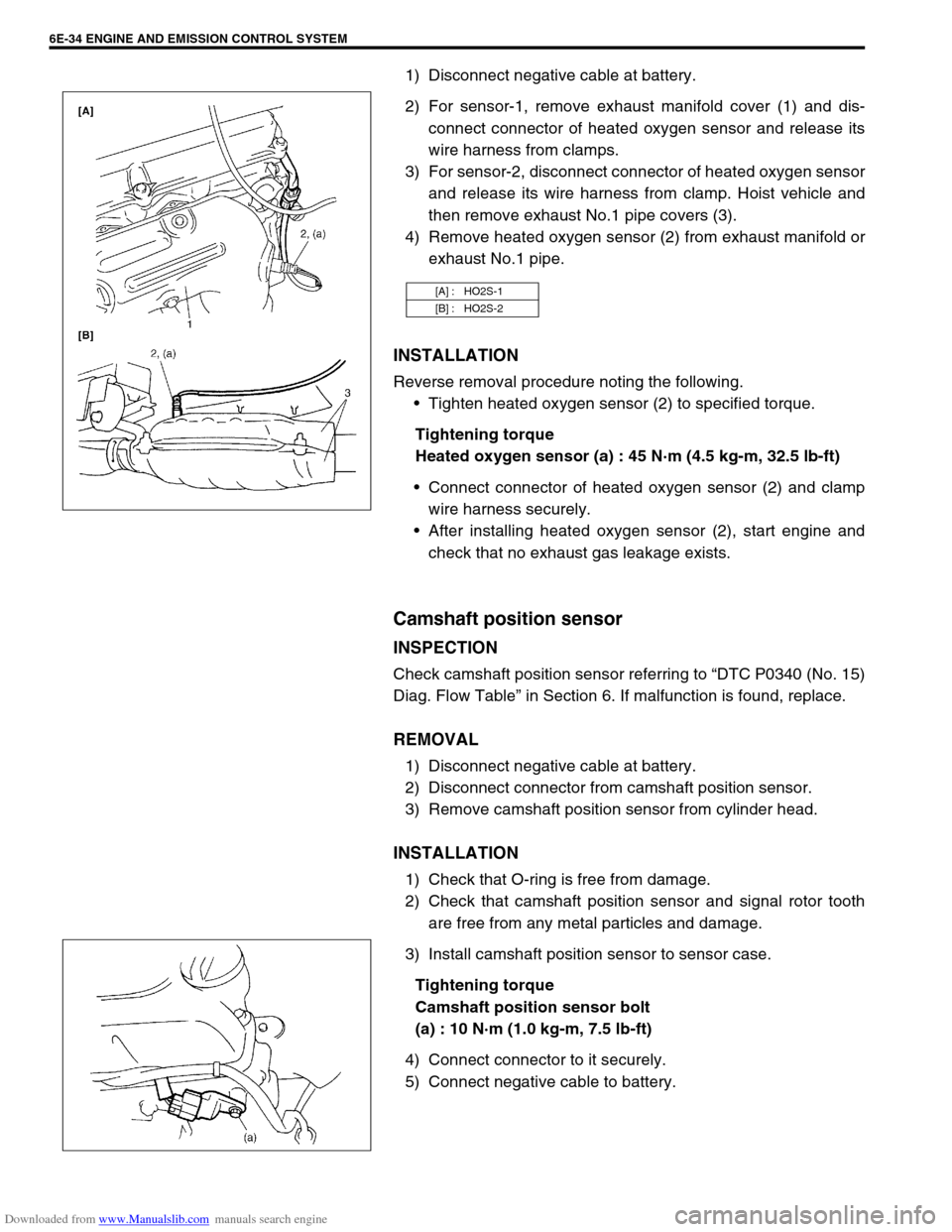

1) Disconnect negative cable at battery.

2) For sensor-1, remove exhaust manifold cover (1) and dis-

connect connector of heated oxygen sensor and release its

wire harness from clamps.

3) For sensor-2, disconnect connector of heated oxygen sensor

and release its wire harness from clamp. Hoist vehicle and

then remove exhaust No.1 pipe covers (3).

4) Remove heated oxygen sensor (2) from exhaust manifold or

exhaust No.1 pipe.

INSTALLATION

Reverse removal procedure noting the following.

Tighten heated oxygen sensor (2) to specified torque.

Tightening torque

Heated oxygen sensor (a) : 45 N·m (4.5 kg-m, 32.5 lb-ft)

Connect connector of heated oxygen sensor (2) and clamp

wire harness securely.

After installing heated oxygen sensor (2), start engine and

check that no exhaust gas leakage exists.

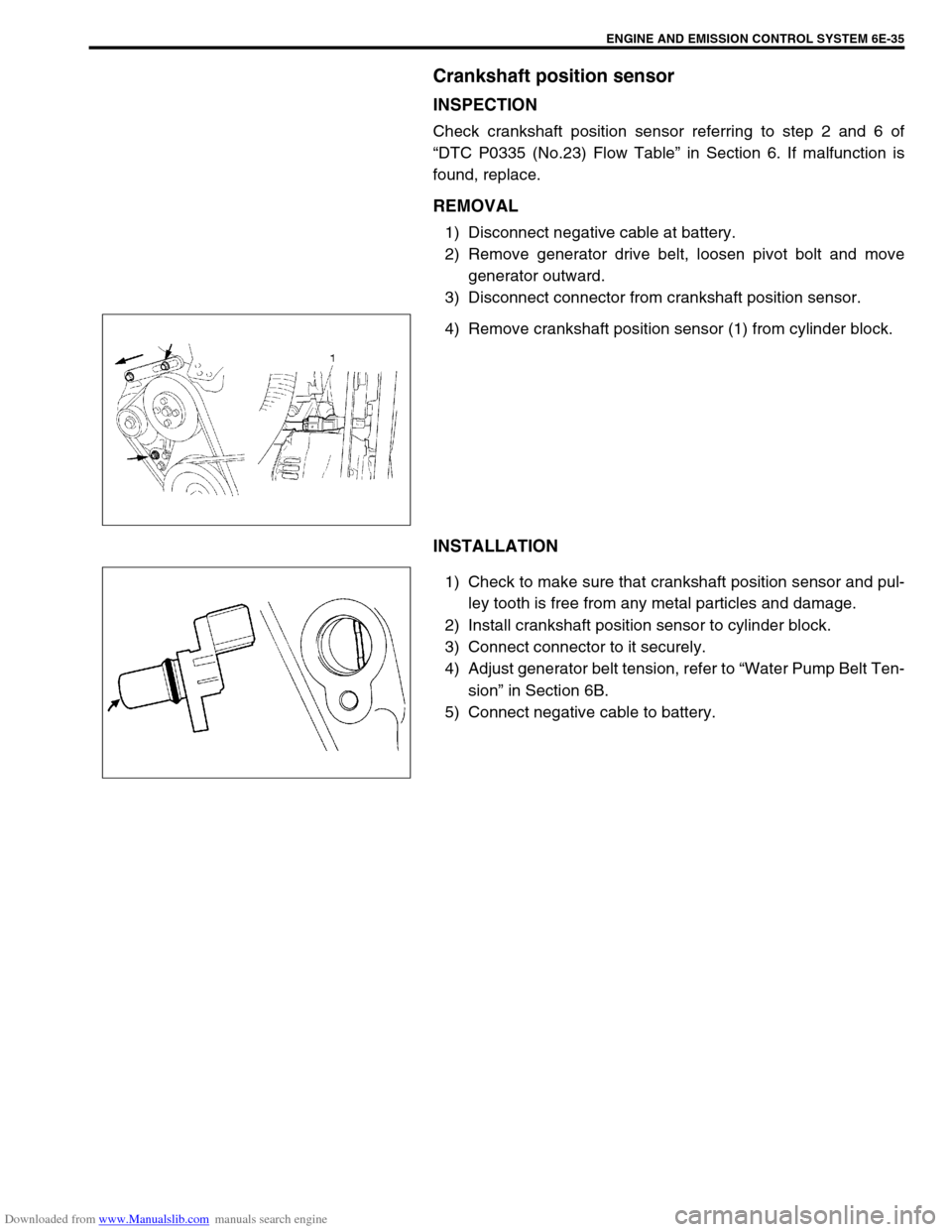

Camshaft position sensor

INSPECTION

Check camshaft position sensor referring to “DTC P0340 (No. 15)

Diag. Flow Table” in Section 6. If malfunction is found, replace.

REMOVAL

1) Disconnect negative cable at battery.

2) Disconnect connector from camshaft position sensor.

3) Remove camshaft position sensor from cylinder head.

INSTALLATION

1) Check that O-ring is free from damage.

2) Check that camshaft position sensor and signal rotor tooth

are free from any metal particles and damage.

3) Install camshaft position sensor to sensor case.

Tightening torque

Camshaft position sensor bolt

(a) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

4) Connect connector to it securely.

5) Connect negative cable to battery.

[A] : HO2S-1

[B] : HO2S-2

Page 640 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-35

Crankshaft position sensor

INSPECTION

Check crankshaft position sensor referring to step 2 and 6 of

“DTC P0335 (No.23) Flow Table” in Section 6. If malfunction is

found, replace.

REMOVAL

1) Disconnect negative cable at battery.

2) Remove generator drive belt, loosen pivot bolt and move

generator outward.

3) Disconnect connector from crankshaft position sensor.

4) Remove crankshaft position sensor (1) from cylinder block.

INSTALLATION

1) Check to make sure that crankshaft position sensor and pul-

ley tooth is free from any metal particles and damage.

2) Install crankshaft position sensor to cylinder block.

3) Connect connector to it securely.

4) Adjust generator belt tension, refer to “Water Pump Belt Ten-

sion” in Section 6B.

5) Connect negative cable to battery.

Page 641 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-36 ENGINE AND EMISSION CONTROL SYSTEM

Vehicle speed sensor (VSS)

INSPECTION

Check vehicle speed sensor referring to step 7 of “DTC P0500

(No.16) Flow Table” in Section 6. If malfunction is found, replace.

Fuel level sensor (GAUGE)

INSPECTION

Refer to “Fuel Meter / Fuel Gauge Unit” in Section 8.

REMOVAL / INSTALLATION

Refer to “Fuel Pump Assembly” in Section 6C.

Knock sensor

INSPECTION

Check knock sensor referring to “DTC P0325 (No.17) Flow Table”

in Section 6. If malfunction is found, replace.

REMOVAL / INSTALLATION

Refer to “Knock Sensor” in Section 6A1.

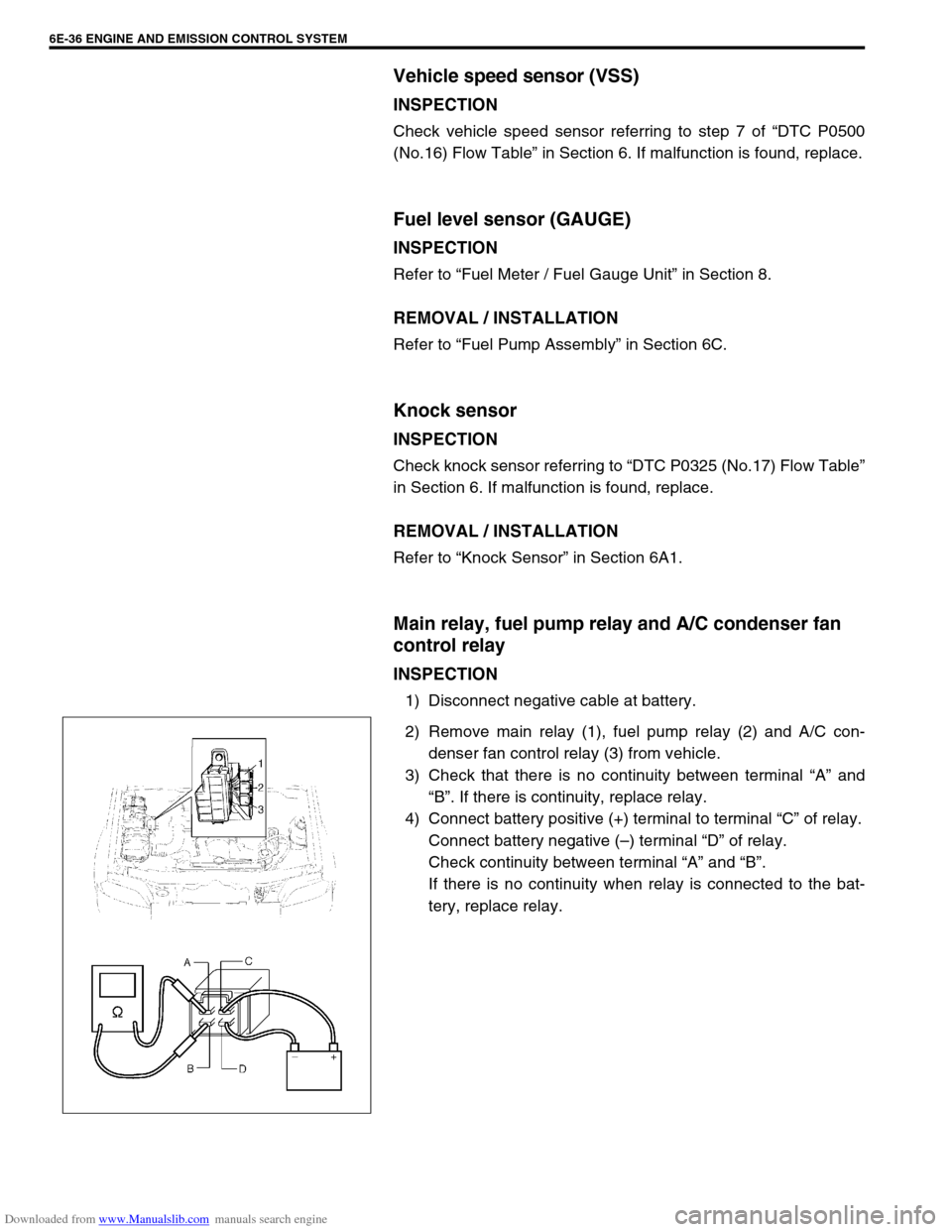

Main relay, fuel pump relay and A/C condenser fan

control relay

INSPECTION

1) Disconnect negative cable at battery.

2) Remove main relay (1), fuel pump relay (2) and A/C con-

denser fan control relay (3) from vehicle.

3) Check that there is no continuity between terminal “A” and

“B”. If there is continuity, replace relay.

4) Connect battery positive (+) terminal to terminal “C” of relay.

Connect battery negative (–) terminal “D” of relay.

Check continuity between terminal “A” and “B”.

If there is no continuity when relay is connected to the bat-

tery, replace relay.

Page 643 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-38 ENGINE AND EMISSION CONTROL SYSTEM

2) Connect battery (3) to A/C condenser fan motor coupler (2)

as shown in figure, then check that the A/C condenser fan

motor (1) operates smoothly.

If A/C condenser fan motor does not operate smoothly,

replace motor.

Reference current data of A/C condenser fan motor

Approx. 6.7 – 8.3 A at 12 V

Output signals of throttle valve opening and engine

coolant temp. (Vehicle with A/T only)

THROTTLE VALVE OPENING SIGNAL INSPECTION

Check throttle valve opening (throttle position) signal referring to

step 1 of “DTC P1700 (No.32 or 33) Flow Table” in Section 7B.

If check result is not satisfactory, check each wire harness, circuit

connections and TP sensor.

ENGINE COOLANT TEMP. SIGNAL INSPECTION

Check engine coolant temp. signal referring to step 1 of “DTC

P1709 (No.51) Flow Table” in Section 7B.

If check result is not satisfactory, check each wire harness, circuit

connection and ECT sensor.

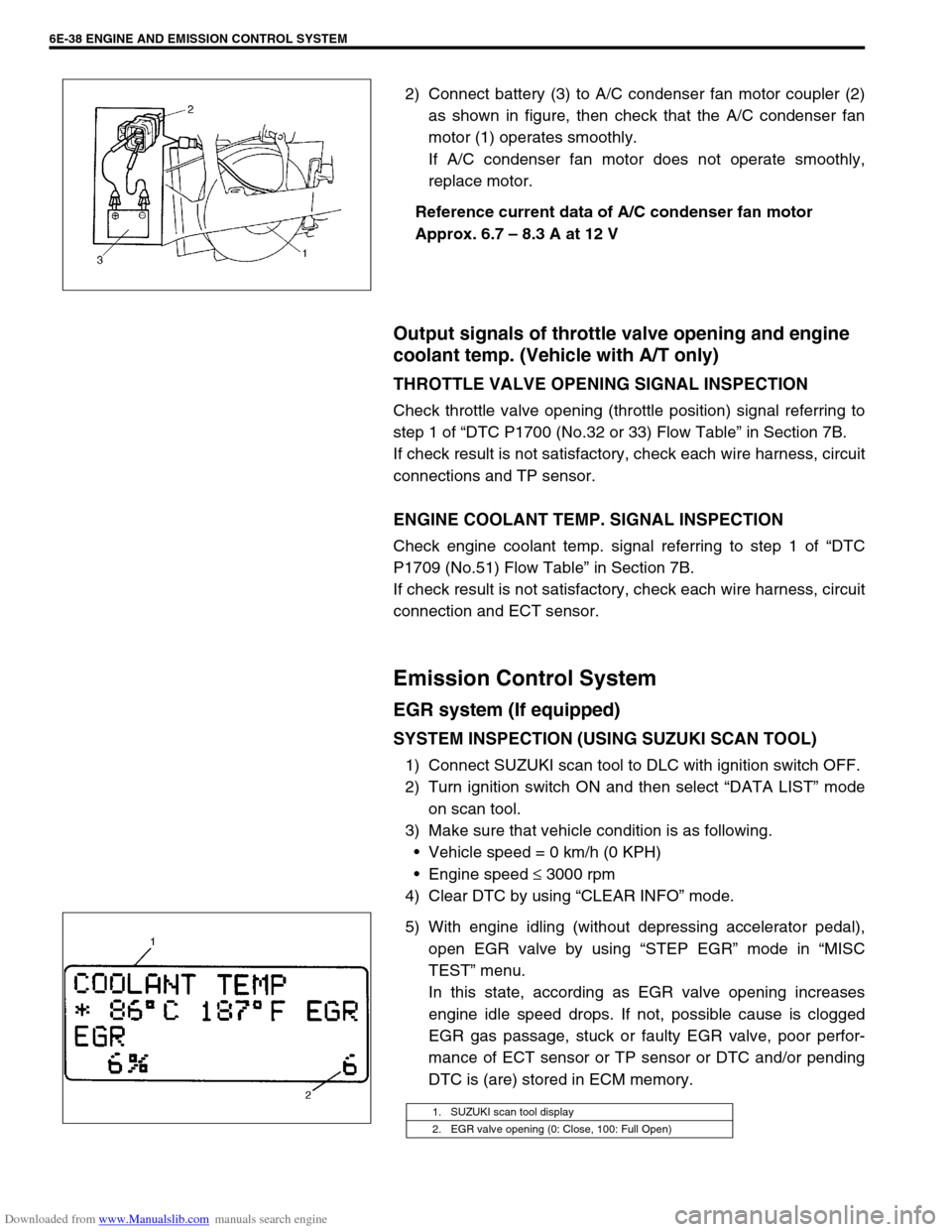

Emission Control System

EGR system (If equipped)

SYSTEM INSPECTION (USING SUZUKI SCAN TOOL)

1) Connect SUZUKI scan tool to DLC with ignition switch OFF.

2) Turn ignition switch ON and then select “DATA LIST” mode

on scan tool.

3) Make sure that vehicle condition is as following.

Vehicle speed = 0 km/h (0 KPH)

Engine speed ≤ 3000 rpm

4) Clear DTC by using “CLEAR INFO” mode.

5) With engine idling (without depressing accelerator pedal),

open EGR valve by using “STEP EGR” mode in “MISC

TEST” menu.

In this state, according as EGR valve opening increases

engine idle speed drops. If not, possible cause is clogged

EGR gas passage, stuck or faulty EGR valve, poor perfor-

mance of ECT sensor or TP sensor or DTC and/or pending

DTC is (are) stored in ECM memory.

1. SUZUKI scan tool display

2. EGR valve opening (0: Close, 100: Full Open)

Page 644 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-39

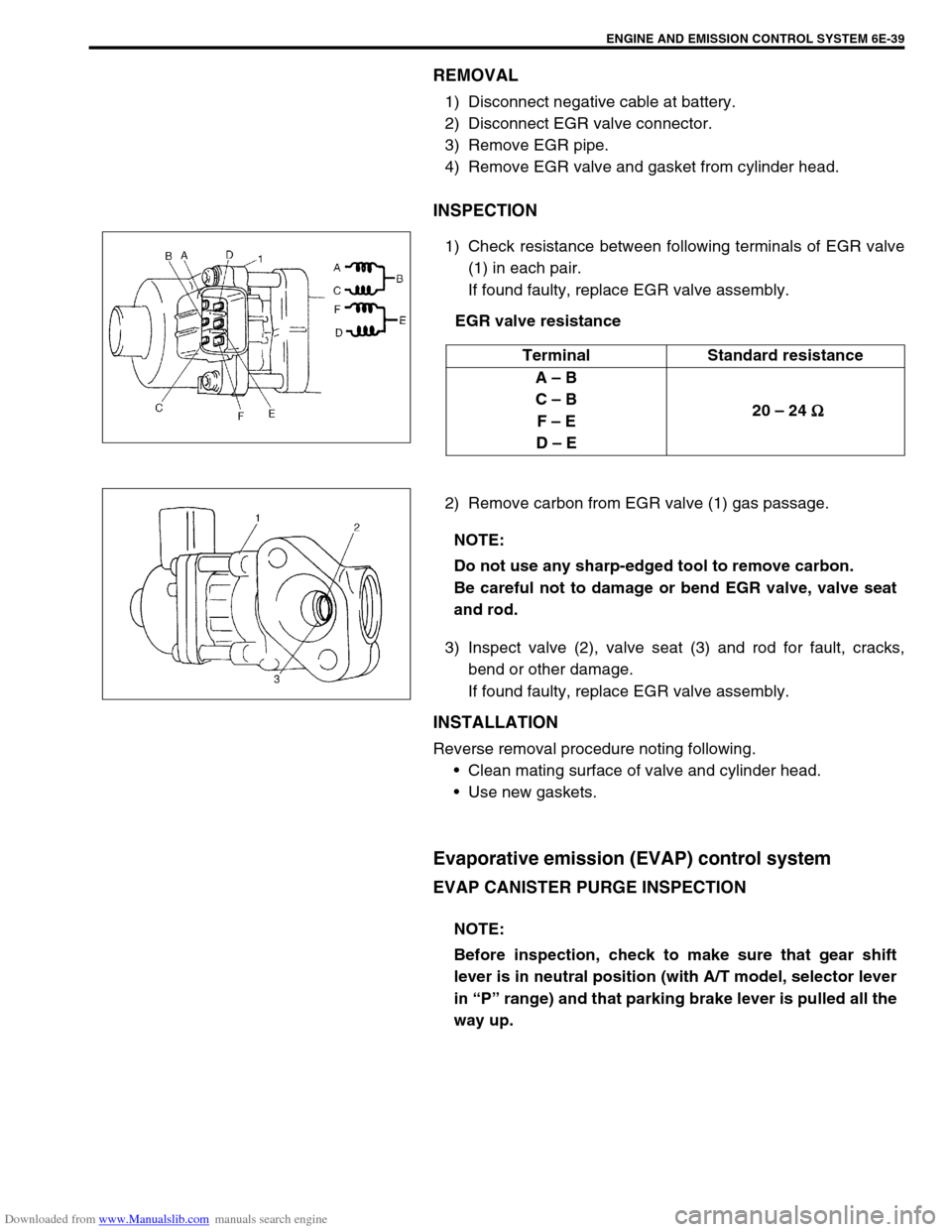

REMOVAL

1) Disconnect negative cable at battery.

2) Disconnect EGR valve connector.

3) Remove EGR pipe.

4) Remove EGR valve and gasket from cylinder head.

INSPECTION

1) Check resistance between following terminals of EGR valve

(1) in each pair.

If found faulty, replace EGR valve assembly.

EGR valve resistance

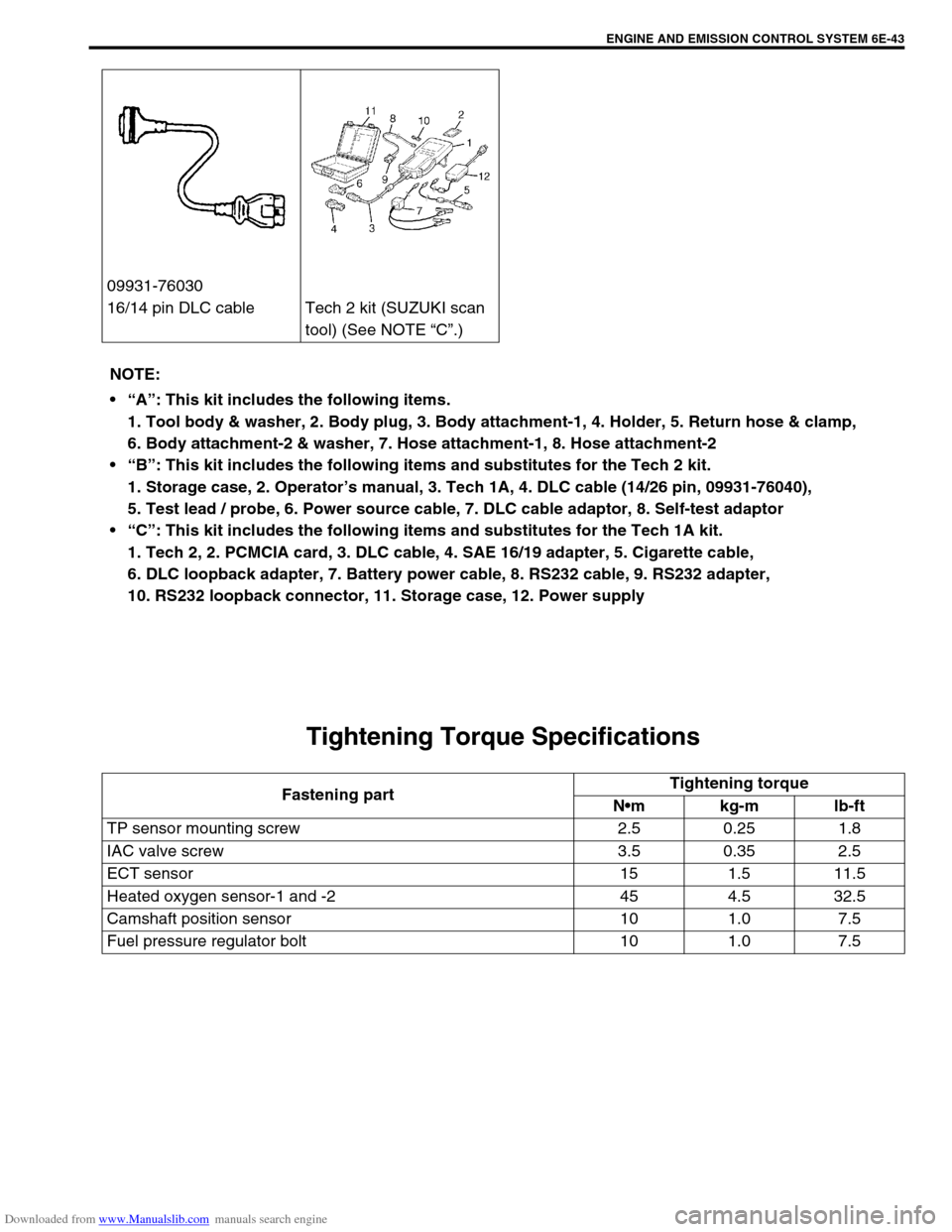

2) Remove carbon from EGR valve (1) gas passage.

3) Inspect valve (2), valve seat (3) and rod for fault, cracks,

bend or other damage.

If found faulty, replace EGR valve assembly.

INSTALLATION

Reverse removal procedure noting following.

Clean mating surface of valve and cylinder head.

Use new gaskets.

Evaporative emission (EVAP) control system

EVAP CANISTER PURGE INSPECTION

Terminal Standard resistance

A – B

C – B

F – E

D – E 20 – 24

Ω

ΩΩ Ω

NOTE:

Do not use any sharp-edged tool to remove carbon.

Be careful not to damage or bend EGR valve, valve seat

and rod.

NOTE:

Before inspection, check to make sure that gear shift

lever is in neutral position (with A/T model, selector lever

in “P” range) and that parking brake lever is pulled all the

way up.

Page 648 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-43

Tightening Torque Specifications

09931-76030

16/14 pin DLC cable Tech 2 kit (SUZUKI scan

tool) (See NOTE “C”.)

NOTE:

“A”: This kit includes the following items.

1. Tool body & washer, 2. Body plug, 3. Body attachment-1, 4. Holder, 5. Return hose & clamp,

6. Body attachment-2 & washer, 7. Hose attachment-1, 8. Hose attachment-2

“B”: This kit includes the following items and substitutes for the Tech 2 kit.

1. Storage case, 2. Operator’s manual, 3. Tech 1A, 4. DLC cable (14/26 pin, 09931-76040),

5. Test lead / probe, 6. Power source cable, 7. DLC cable adaptor, 8. Self-test adaptor

“C”: This kit includes the following items and substitutes for the Tech 1A kit.

1. Tech 2, 2. PCMCIA card, 3. DLC cable, 4. SAE 16/19 adapter, 5. Cigarette cable,

6. DLC loopback adapter, 7. Battery power cable, 8. RS232 cable, 9. RS232 adapter,

10. RS232 loopback connector, 11. Storage case, 12. Power supply

Fastening partTightening torque

Nm kg-m lb-ft

TP sensor mounting screw 2.5 0.25 1.8

IAC valve screw 3.5 0.35 2.5

ECT sensor 15 1.5 11.5

Heated oxygen sensor-1 and -2 45 4.5 32.5

Camshaft position sensor 10 1.0 7.5

Fuel pressure regulator bolt 10 1.0 7.5

Page 650 of 687

Downloaded from www.Manualslib.com manuals search engine IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM) 6F-1

6G

6F2

6G

6H

7D

7E

7F

7A1

7A1

7D

7E

7F

8A

8B

8C

8D

8E

6K

6F

7A

10

10A

10B

SECTION 6F

IGNITION SYSTEM

(ELECTRONIC IGNITION SYSTEM)

CONTENTS

General Description ........................................ 6F-2

Diagnosis ......................................................... 6F-3

On-Vehicle Service.......................................... 6F-5

Ignition Spark Test ........................................ 6F-5

High-tension Cords ....................................... 6F-5

Spark Plugs ................................................... 6F-6Ignition Coil Assembly (Including Ignitor) ...... 6F-7

Crankshaft Position Sensor (CKP Sensor) ... 6F-8

Ignition Timing............................................... 6F-8

Special Tools ................................................. 6F-10

Tightening Torque Specification ................. 6F-10

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 656 of 687

Downloaded from www.Manualslib.com manuals search engine IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM 6F-7

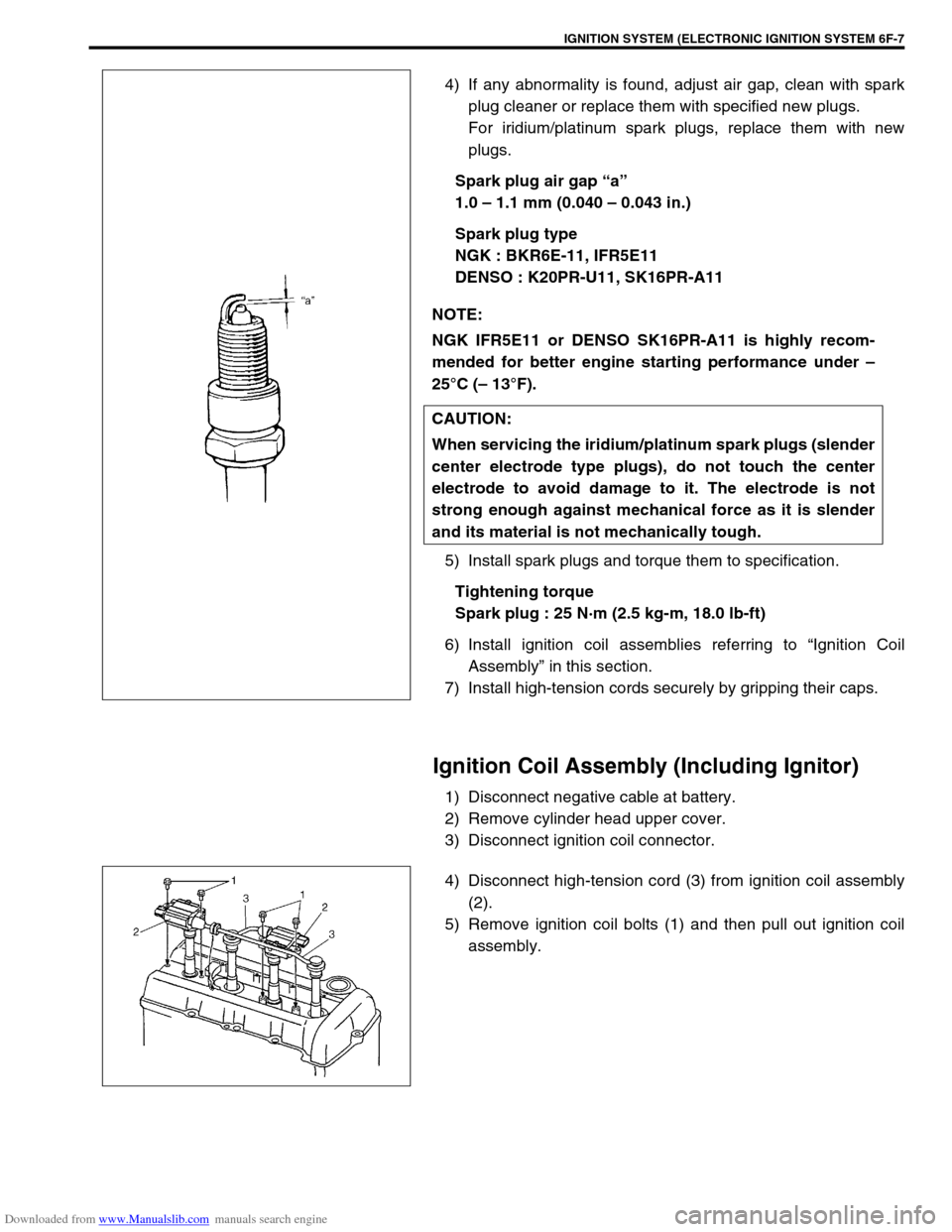

4) If any abnormality is found, adjust air gap, clean with spark

plug cleaner or replace them with specified new plugs.

For iridium/platinum spark plugs, replace them with new

plugs.

Spark plug air gap “a”

1.0 – 1.1 mm (0.040 – 0.043 in.)

Spark plug type

NGK : BKR6E-11, IFR5E11

DENSO : K20PR-U11, SK16PR-A11

5) Install spark plugs and torque them to specification.

Tightening torque

Spark plug : 25 N·m (2.5 kg-m, 18.0 lb-ft)

6) Install ignition coil assemblies referring to “Ignition Coil

Assembly” in this section.

7) Install high-tension cords securely by gripping their caps.

Ignition Coil Assembly (Including Ignitor)

1) Disconnect negative cable at battery.

2) Remove cylinder head upper cover.

3) Disconnect ignition coil connector.

4) Disconnect high-tension cord (3) from ignition coil assembly

(2).

5) Remove ignition coil bolts (1) and then pull out ignition coil

assembly. NOTE:

NGK IFR5E11 or DENSO SK16PR-A11 is highly recom-

mended for better engine starting performance under –

25°C (– 13°F).

CAUTION:

When servicing the iridium/platinum spark plugs (slender

center electrode type plugs), do not touch the center

electrode to avoid damage to it. The electrode is not

strong enough against mechanical force as it is slender

and its material is not mechanically tough.

Page 659 of 687

Downloaded from www.Manualslib.com manuals search engine 6F-10 IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM)

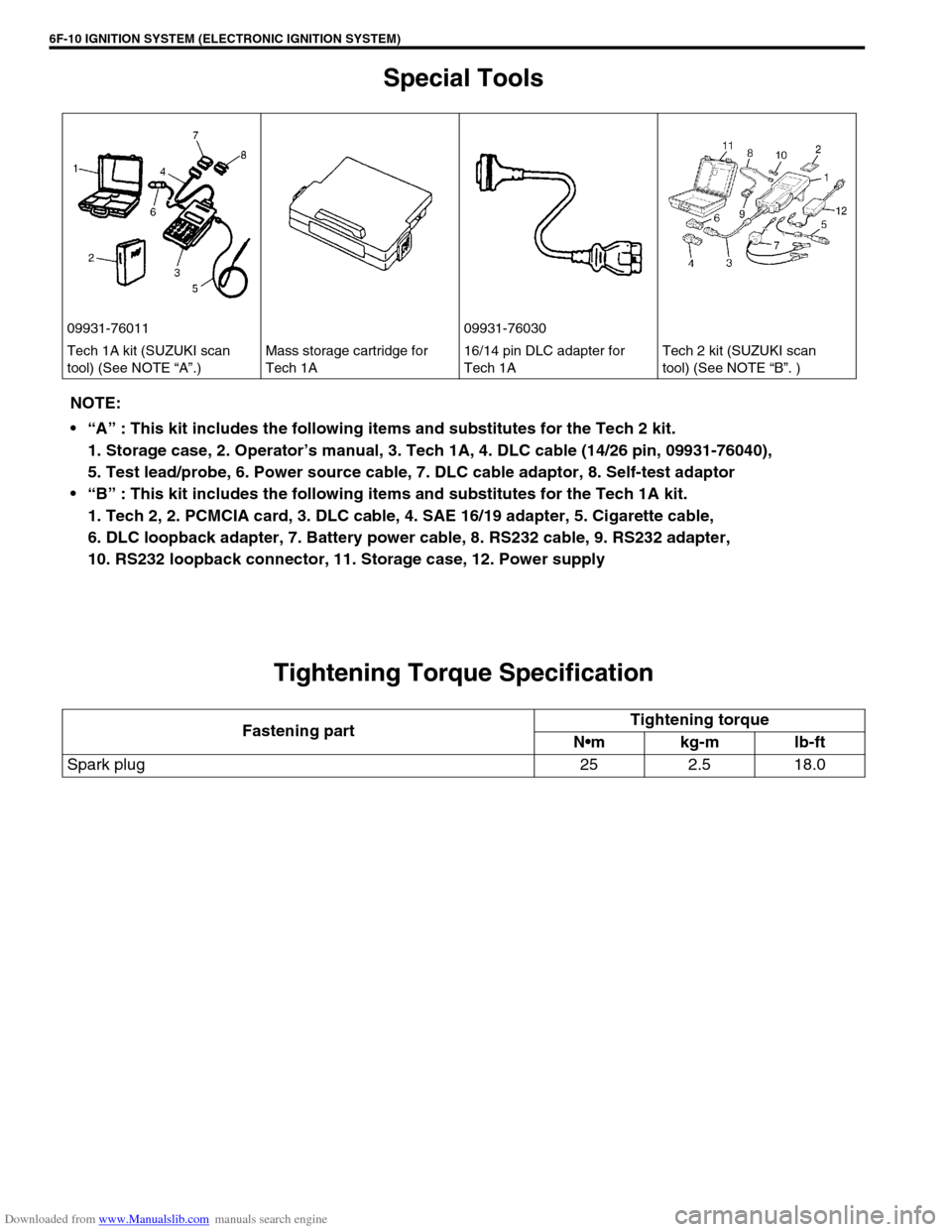

Special Tools

Tightening Torque Specification

09931-76011 09931-76030

Tech 1A kit (SUZUKI scan

tool) (See NOTE “A”.)Mass storage cartridge for

Tech 1A16/14 pin DLC adapter for

Tech 1ATech 2 kit (SUZUKI scan

tool) (See NOTE “B”. )

NOTE:

“A” : This kit includes the following items and substitutes for the Tech 2 kit.

1. Storage case, 2. Operator’s manual, 3. Tech 1A, 4. DLC cable (14/26 pin, 09931-76040),

5. Test lead/probe, 6. Power source cable, 7. DLC cable adaptor, 8. Self-test adaptor

“B” : This kit includes the following items and substitutes for the Tech 1A kit.

1. Tech 2, 2. PCMCIA card, 3. DLC cable, 4. SAE 16/19 adapter, 5. Cigarette cable,

6. DLC loopback adapter, 7. Battery power cable, 8. RS232 cable, 9. RS232 adapter,

10. RS232 loopback connector, 11. Storage case, 12. Power supply

Fastening partTightening torque

Nm kg-m lb-ft

Spark plug 25 2.5 18.0

Page 660 of 687

Downloaded from www.Manualslib.com manuals search engine CRANKING SYSTEM 6G-1

6F1

6F2

6H

7C1

7D

7E

7C1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

6G

7A1

10A

10B

SECTION 6G

CRANKING SYSTEM

CONTENTS

General Description ....................................... 6G-2

Cranking Circuit ............................................ 6G-2

Diagnosis ........................................................ 6G-2

Diagnosis Table ........................................... 6G-2Performance Test .........................................6G-4

On-Vehicle Service .........................................6G-5

Starting Motor ...............................................6G-5

Specifications..................................................6G-7

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

Starting motor varies depending on specifications, etc. Therefore, be sure to check model and speci-

fication of vehicle being serviced before replacing parts.