battery SUZUKI JIMNY 2005 3.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 390 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-33

Inspection of ECM and Its Circuits

ECM and its circuits can be checked at ECM wiring connectors by

measuring voltage and resistance.

VOLTAGE CHECK

1) Remove ECM from body referring to Section 6E.

2) Check voltage at each terminal of connectors connected.CAUTION:

ECM cannot be checked by itself. It is strictly prohibited

to connect voltmeter or ohmmeter to ECM with connector

disconnected from it.

NOTE:

As each terminal voltage is affected by the battery volt-

age, confirm that it is 11 V or more when ignition switch

is ON.

1. ECM

2. ECM connectors (Viewed from harness side)

Page 406 of 687

![SUZUKI JIMNY 2005 3.G Service Repair Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-49

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 33 Check Wire Harness.

1) Disconnect MAP sensor conne SUZUKI JIMNY 2005 3.G Service Repair Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-49

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 33 Check Wire Harness.

1) Disconnect MAP sensor conne](/img/20/7588/w960_7588-405.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-49

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 33 Check Wire Harness.

1) Disconnect MAP sensor connector with

ignition switch OFF.

2) Check for proper connection of MAP sensor

at “G” and “B/Bl” wire terminals.

3) If OK, then with ignition switch ON, check

voltage at each of “Lg/R” and “G” wire termi-

nals and body ground. See Fig. 2.

Is voltage about 4 – 6 V at each terminal?Go to Step 4.“Lg/R” wire open or

shorted to ground circuit

or shorted to power circuit

(See NOTE), “G” wire

open or shorted to

ground, poor E19-26 con-

nection or E19-22 con-

nection.

If wire and connection are

OK, confirm that MAP

sensor is normal and then

substitute a known-good

ECM and recheck.

4 Check MAP sensor according to “MAP Sensor

Individual Check” below.

Is it in good condition?“Lg/R” wire shorted to “G”

wire, “B/Bl” wire open,

poor E19-10 connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.Replace MAP sensor. Step Action Yes No

NOTE:

When battery voltage is applied to “Lg/R” wire, it is possible that MAP sensor is also faulty.

Page 460 of 687

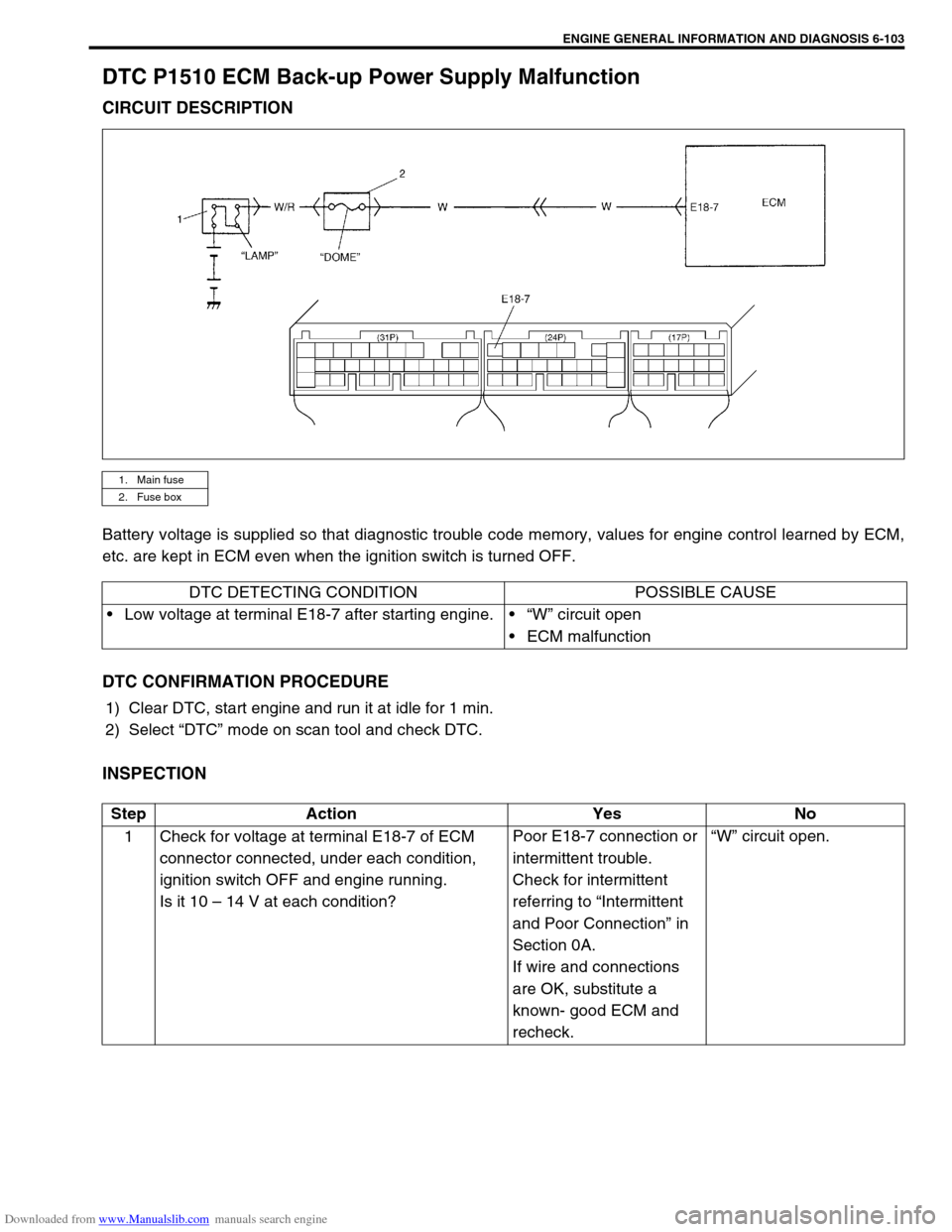

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-103

DTC P1510 ECM Back-up Power Supply Malfunction

CIRCUIT DESCRIPTION

Battery voltage is supplied so that diagnostic trouble code memory, values for engine control learned by ECM,

etc. are kept in ECM even when the ignition switch is turned OFF.

DTC CONFIRMATION PROCEDURE

1) Clear DTC, start engine and run it at idle for 1 min.

2) Select “DTC” mode on scan tool and check DTC.

INSPECTION

1. Main fuse

2. Fuse box

DTC DETECTING CONDITION POSSIBLE CAUSE

Low voltage at terminal E18-7 after starting engine.“W” circuit open

ECM malfunction

Step Action Yes No

1 Check for voltage at terminal E18-7 of ECM

connector connected, under each condition,

ignition switch OFF and engine running.

Is it 10 – 14 V at each condition?Poor E18-7 connection or

intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection” in

Section 0A.

If wire and connections

are OK, substitute a

known- good ECM and

recheck.“W” circuit open.

Page 468 of 687

![SUZUKI JIMNY 2005 3.G Service Repair Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-111

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 3 / [C] Fig. 3 for Step 44 Check Fuel Pump Relay for SUZUKI JIMNY 2005 3.G Service Repair Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-111

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 3 / [C] Fig. 3 for Step 44 Check Fuel Pump Relay for](/img/20/7588/w960_7588-467.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-111

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 3 / [C] Fig. 3 for Step 44 Check Fuel Pump Relay for Operation.

1) Check resistance between each two termi-

nals of fuel pump relay. See Fig.3.

Fuel pump relay resistance

Between terminals “A” and “B” : Infinity

Between terminals “C” and “D”: 100 – 150

Ω

ΩΩ Ω

2) Check that there is continuity between ter-

minals “A” and “B” when battery is con-

nected to terminals “C” and “D”. See Fig. 3.

Is fuel pump relay in good condition?“W/G” circuit open or poor

E18-19 connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.Replace fuel pump

relay. Step Action Yes No

CAUTION:

Check to make sure that connection is made between correct terminals. Wrong connection can cause

damage to ECM, wire harness, etc.

Page 478 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-121

TAble B-7 A/C Condenser Fan Control System Check

INSPECTION

Step Action Yes No

1 Check Fan Control System.

1) Connect scan tool to DLC with ignition switch OFF. See

Fig. 1.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Warm up engine until coolant temp. is 110 °C, 230 °F or

higher and A/C switch turn OFF. (If engine coolant temp.

does not rise, check engine cooling system or ECT sen-

sor.)

Is A/C condenser fan started when engine coolant temp.

reached above temp.?A/C condenser fan con-

trol system is in good

condition.Go to Step 2.

2 Check A/C Condenser Fan Relay and Its Circuit.

1) Check DTC and pending DTC with scan tool.

Is DTC P0481 displayed?Go to DTC P0481 Diag.

Flow Table.Go to Step 3.

3 Check A/C Condenser Fan Relay (1).

1) Turn ignition switch OFF and remove A/C condenser fan

relay.

2) Check for proper connection to relay at terminals “A”

and “B”.

3) If OK, check that there is continuity between “A” and “B”

when battery is connected to terminals “C” and “D”. See

Fig. 2.

Is check result satisfactory?Go to Step 4. Replace A/C

condenser fan

relay.

Page 479 of 687

![SUZUKI JIMNY 2005 3.G Service Repair Manual Downloaded from www.Manualslib.com manuals search engine 6-122 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[A] Fig. 1 for Step 1 / [B] Fig. 2 for Step 3

Fig. 3 for Step 44 Check A/C Condenser Fan (1).

1) SUZUKI JIMNY 2005 3.G Service Repair Manual Downloaded from www.Manualslib.com manuals search engine 6-122 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[A] Fig. 1 for Step 1 / [B] Fig. 2 for Step 3

Fig. 3 for Step 44 Check A/C Condenser Fan (1).

1)](/img/20/7588/w960_7588-478.png)

Downloaded from www.Manualslib.com manuals search engine 6-122 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[A] Fig. 1 for Step 1 / [B] Fig. 2 for Step 3

Fig. 3 for Step 44 Check A/C Condenser Fan (1).

1) Turn ignition switch OFF.

2) Disconnect fan motor connector (2).

3) Check for proper connection to motor at “R/Bl” and “B”

terminals.

4) If OK, connect battery to motor and check for operation.

See Fig. 3.

Is it in good condition?“R”, “R/Bl” or “B” circuit

open.Replace A/C

condenser fan

motor. Step Action Yes No

Page 480 of 687

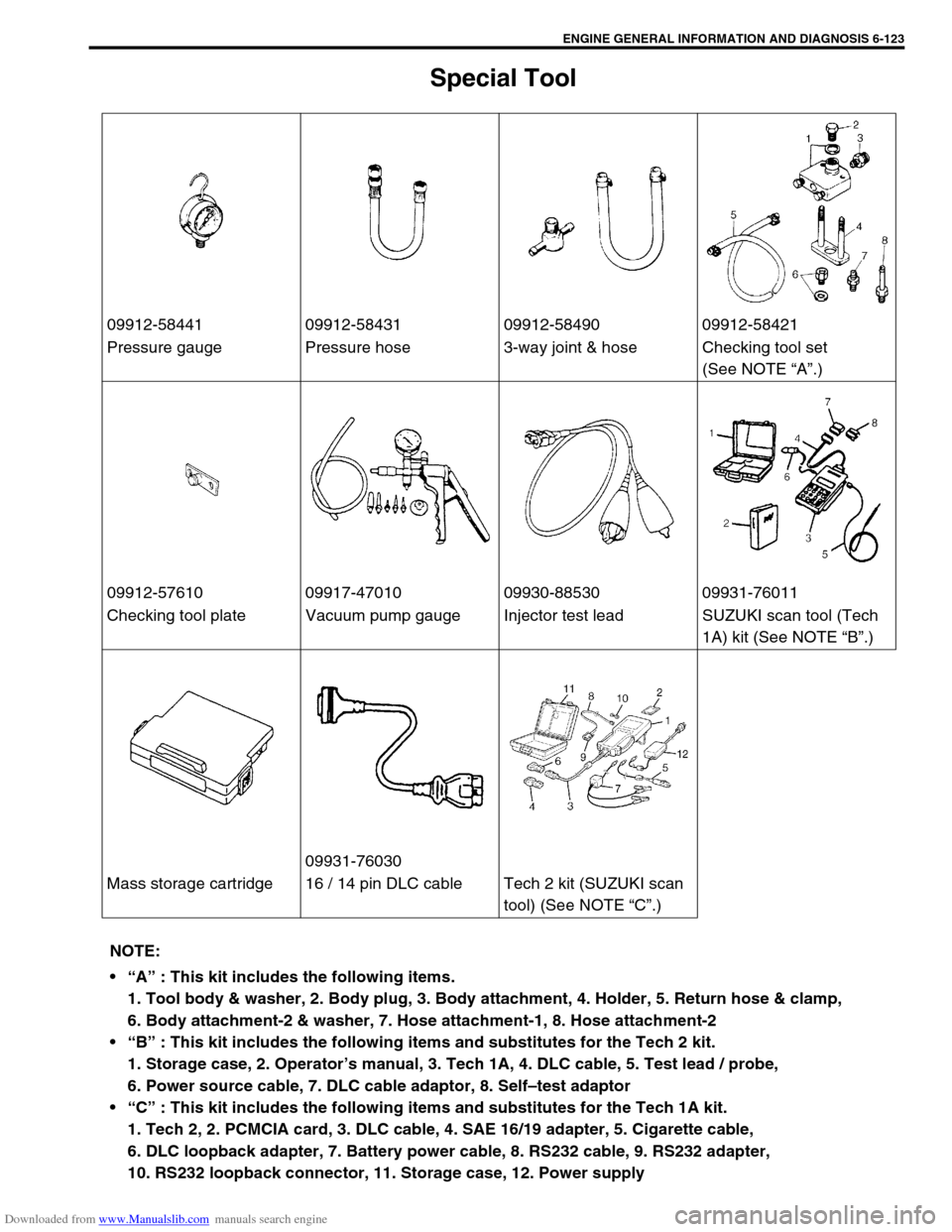

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-123

Special Tool

09912-58441 09912-58431 09912-58490 09912-58421

Pressure gauge Pressure hose 3-way joint & hose Checking tool set

(See NOTE “A”.)

09912-57610 09917-47010 09930-88530 09931-76011

Checking tool plate Vacuum pump gauge Injector test lead SUZUKI scan tool (Tech

1A) kit (See NOTE “B”.)

09931-76030

Mass storage cartridge 16 / 14 pin DLC cable Tech 2 kit (SUZUKI scan

tool) (See NOTE “C”.)

NOTE:

“A” : This kit includes the following items.

1. Tool body & washer, 2. Body plug, 3. Body attachment, 4. Holder, 5. Return hose & clamp,

6. Body attachment-2 & washer, 7. Hose attachment-1, 8. Hose attachment-2

“B” : This kit includes the following items and substitutes for the Tech 2 kit.

1. Storage case, 2. Operator’s manual, 3. Tech 1A, 4. DLC cable, 5. Test lead / probe,

6. Power source cable, 7. DLC cable adaptor, 8. Self–test adaptor

“C” : This kit includes the following items and substitutes for the Tech 1A kit.

1. Tech 2, 2. PCMCIA card, 3. DLC cable, 4. SAE 16/19 adapter, 5. Cigarette cable,

6. DLC loopback adapter, 7. Battery power cable, 8. RS232 cable, 9. RS232 adapter,

10. RS232 loopback connector, 11. Storage case, 12. Power supply

Page 482 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-1

6F1

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8C

6A1

8E

9

9

10B

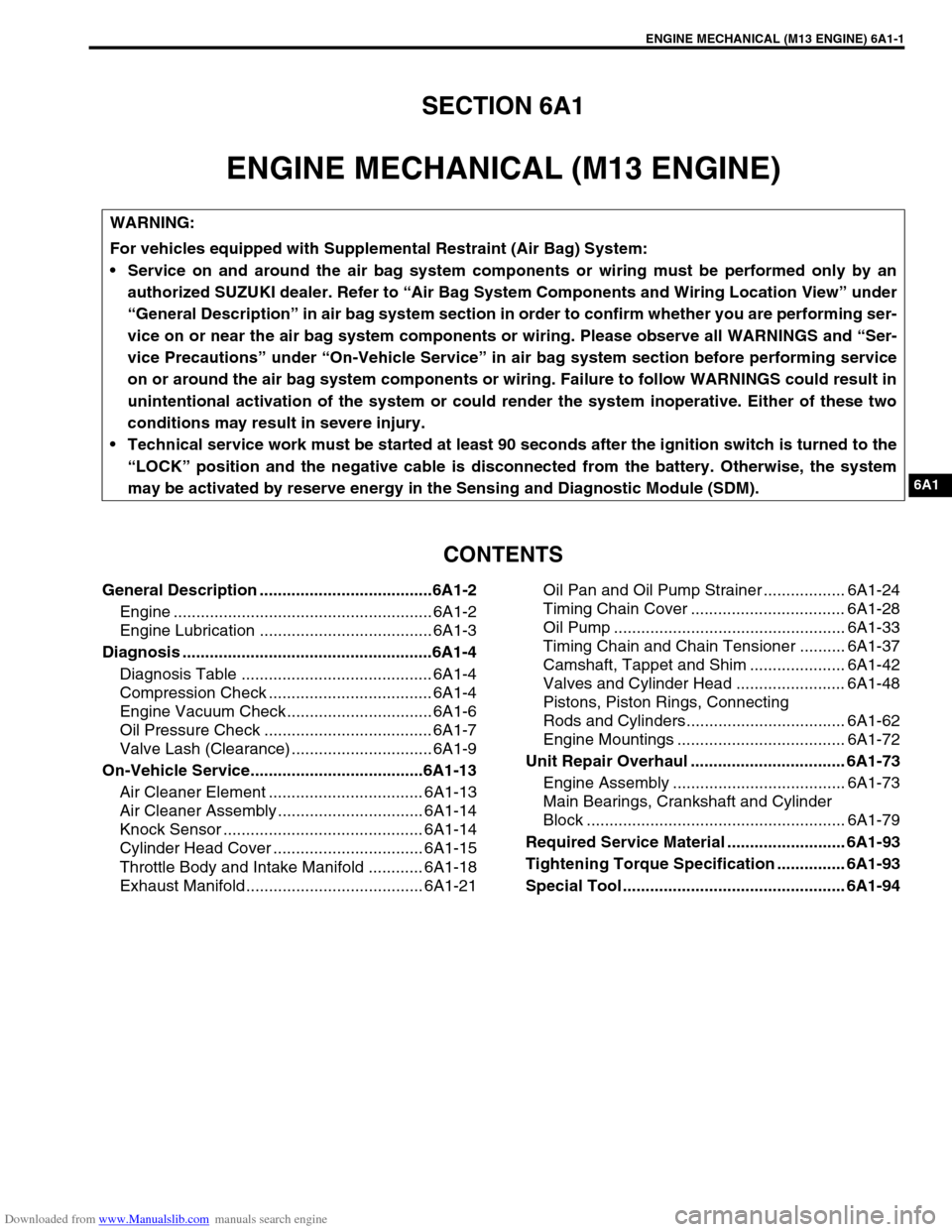

SECTION 6A1

ENGINE MECHANICAL (M13 ENGINE)

CONTENTS

General Description ......................................6A1-2

Engine ......................................................... 6A1-2

Engine Lubrication ...................................... 6A1-3

Diagnosis .......................................................6A1-4

Diagnosis Table .......................................... 6A1-4

Compression Check .................................... 6A1-4

Engine Vacuum Check ................................ 6A1-6

Oil Pressure Check ..................................... 6A1-7

Valve Lash (Clearance) ............................... 6A1-9

On-Vehicle Service......................................6A1-13

Air Cleaner Element .................................. 6A1-13

Air Cleaner Assembly ................................ 6A1-14

Knock Sensor ............................................ 6A1-14

Cylinder Head Cover ................................. 6A1-15

Throttle Body and Intake Manifold ............ 6A1-18

Exhaust Manifold ....................................... 6A1-21Oil Pan and Oil Pump Strainer .................. 6A1-24

Timing Chain Cover .................................. 6A1-28

Oil Pump ................................................... 6A1-33

Timing Chain and Chain Tensioner .......... 6A1-37

Camshaft, Tappet and Shim ..................... 6A1-42

Valves and Cylinder Head ........................ 6A1-48

Pistons, Piston Rings, Connecting

Rods and Cylinders................................... 6A1-62

Engine Mountings ..................................... 6A1-72

Unit Repair Overhaul .................................. 6A1-73

Engine Assembly ...................................... 6A1-73

Main Bearings, Crankshaft and Cylinder

Block ......................................................... 6A1-79

Required Service Material .......................... 6A1-93

Tightening Torque Specification ............... 6A1-93

Special Tool ................................................. 6A1-94

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 486 of 687

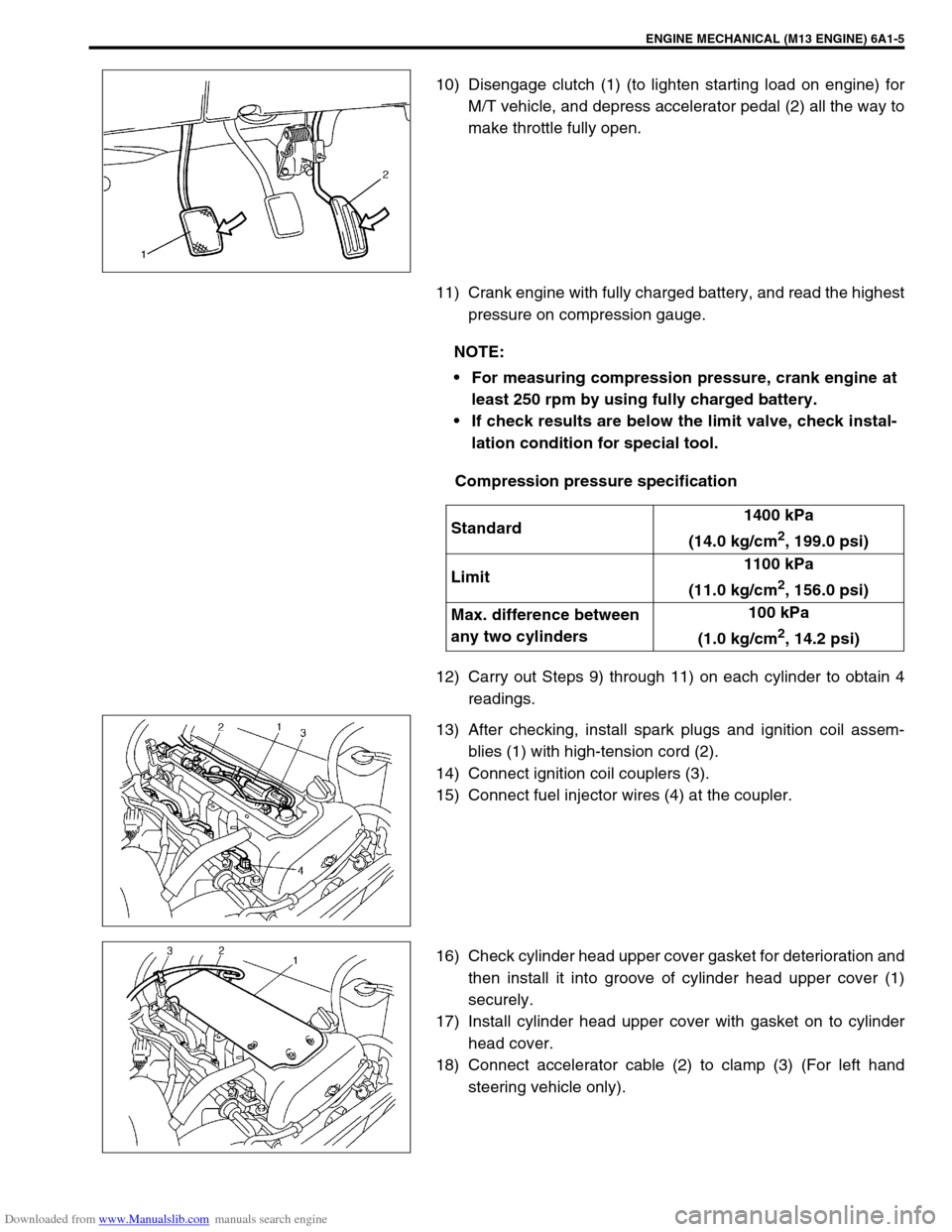

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-5

10) Disengage clutch (1) (to lighten starting load on engine) for

M/T vehicle, and depress accelerator pedal (2) all the way to

make throttle fully open.

11) Crank engine with fully charged battery, and read the highest

pressure on compression gauge.

Compression pressure specification

12) Carry out Steps 9) through 11) on each cylinder to obtain 4

readings.

13) After checking, install spark plugs and ignition coil assem-

blies (1) with high-tension cord (2).

14) Connect ignition coil couplers (3).

15) Connect fuel injector wires (4) at the coupler.

16) Check cylinder head upper cover gasket for deterioration and

then install it into groove of cylinder head upper cover (1)

securely.

17) Install cylinder head upper cover with gasket on to cylinder

head cover.

18) Connect accelerator cable (2) to clamp (3) (For left hand

steering vehicle only).

NOTE:

For measuring compression pressure, crank engine at

least 250 rpm by using fully charged battery.

If check results are below the limit valve, check instal-

lation condition for special tool.

Standard1400 kPa

(14.0 kg/cm

2, 199.0 psi)

Limit1100 kPa

(11.0 kg/cm

2, 156.0 psi)

Max. difference between

any two cylinders100 kPa

(1.0 kg/cm

2, 14.2 psi)

Page 490 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-9

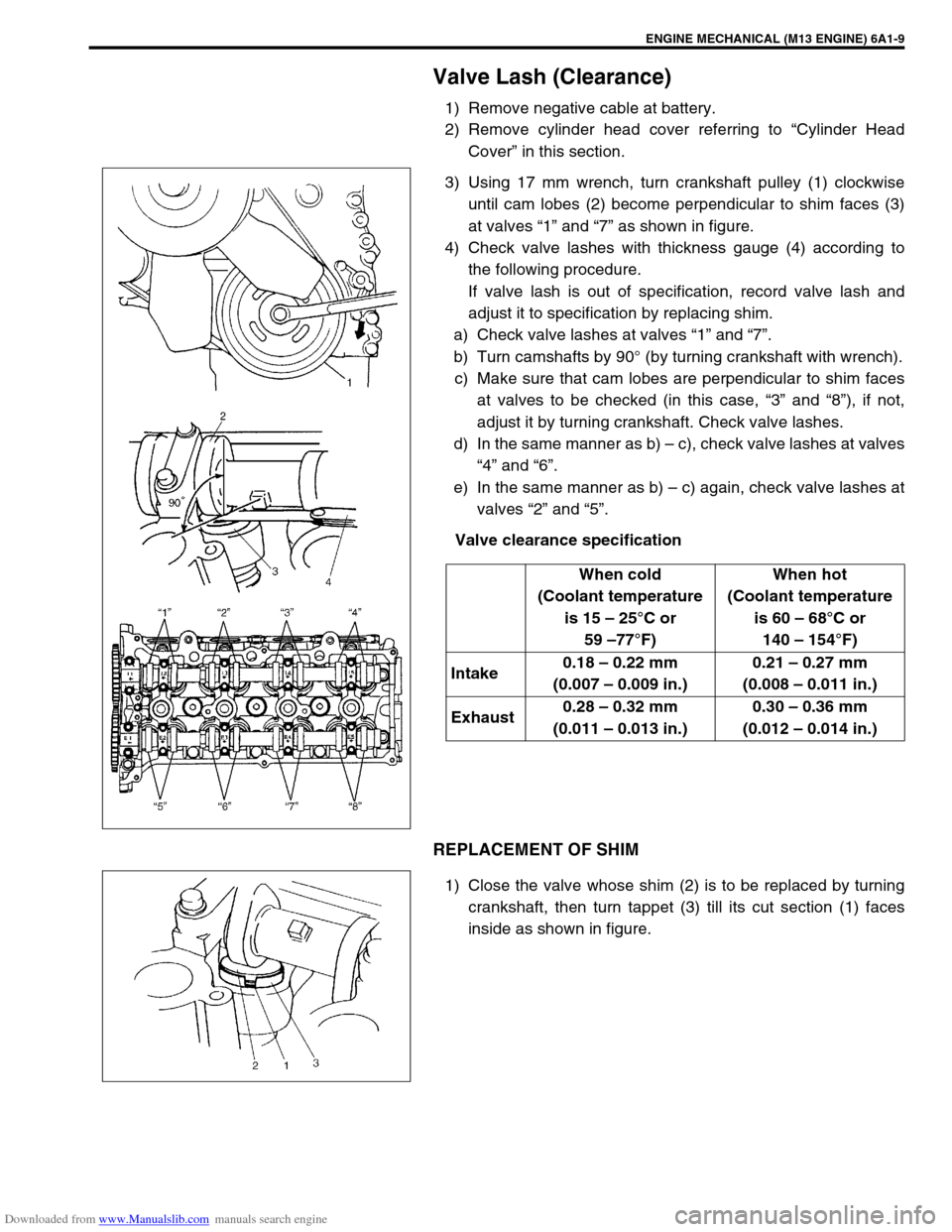

Valve Lash (Clearance)

1) Remove negative cable at battery.

2) Remove cylinder head cover referring to “Cylinder Head

Cover” in this section.

3) Using 17 mm wrench, turn crankshaft pulley (1) clockwise

until cam lobes (2) become perpendicular to shim faces (3)

at valves “1” and “7” as shown in figure.

4) Check valve lashes with thickness gauge (4) according to

the following procedure.

If valve lash is out of specification, record valve lash and

adjust it to specification by replacing shim.

a) Check valve lashes at valves “1” and “7”.

b) Turn camshafts by 90° (by turning crankshaft with wrench).

c) Make sure that cam lobes are perpendicular to shim faces

at valves to be checked (in this case, “3” and “8”), if not,

adjust it by turning crankshaft. Check valve lashes.

d) In the same manner as b) – c), check valve lashes at valves

“4” and “6”.

e) In the same manner as b) – c) again, check valve lashes at

valves “2” and “5”.

Valve clearance specification

REPLACEMENT OF SHIM

1) Close the valve whose shim (2) is to be replaced by turning

crankshaft, then turn tappet (3) till its cut section (1) faces

inside as shown in figure.When cold

(Coolant temperature

is 15 – 25°C or

59 –77°F)When hot

(Coolant temperature

is 60 – 68°C or

140 – 154°F)

Intake0.18 – 0.22 mm

(0.007 – 0.009 in.)0.21 – 0.27 mm

(0.008 – 0.011 in.)

Exhaust0.28 – 0.32 mm

(0.011 – 0.013 in.)0.30 – 0.36 mm

(0.012 – 0.014 in.)