Engine fuel SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 648 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-43

Tightening Torque Specifications

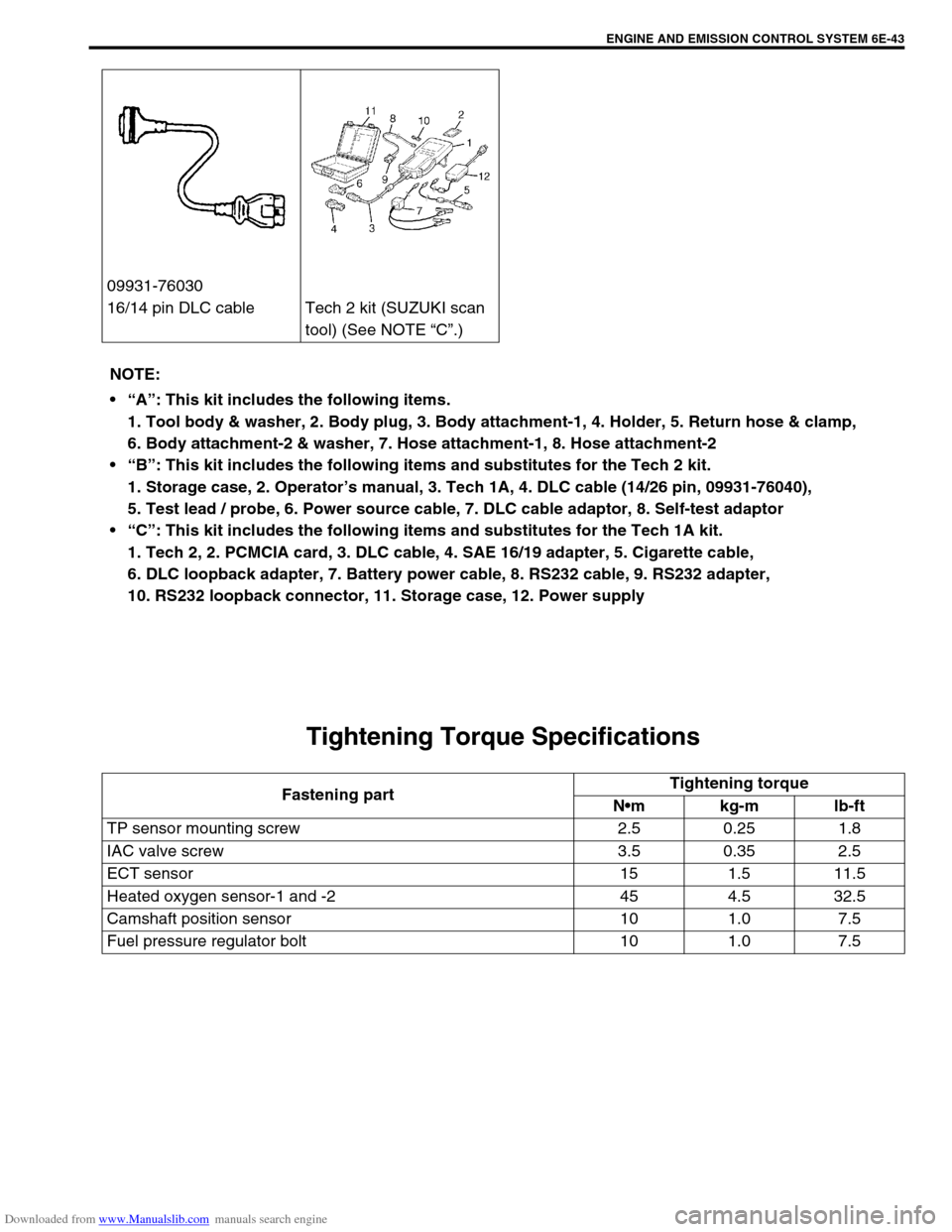

09931-76030

16/14 pin DLC cable Tech 2 kit (SUZUKI scan

tool) (See NOTE “C”.)

NOTE:

“A”: This kit includes the following items.

1. Tool body & washer, 2. Body plug, 3. Body attachment-1, 4. Holder, 5. Return hose & clamp,

6. Body attachment-2 & washer, 7. Hose attachment-1, 8. Hose attachment-2

“B”: This kit includes the following items and substitutes for the Tech 2 kit.

1. Storage case, 2. Operator’s manual, 3. Tech 1A, 4. DLC cable (14/26 pin, 09931-76040),

5. Test lead / probe, 6. Power source cable, 7. DLC cable adaptor, 8. Self-test adaptor

“C”: This kit includes the following items and substitutes for the Tech 1A kit.

1. Tech 2, 2. PCMCIA card, 3. DLC cable, 4. SAE 16/19 adapter, 5. Cigarette cable,

6. DLC loopback adapter, 7. Battery power cable, 8. RS232 cable, 9. RS232 adapter,

10. RS232 loopback connector, 11. Storage case, 12. Power supply

Fastening partTightening torque

Nm kg-m lb-ft

TP sensor mounting screw 2.5 0.25 1.8

IAC valve screw 3.5 0.35 2.5

ECT sensor 15 1.5 11.5

Heated oxygen sensor-1 and -2 45 4.5 32.5

Camshaft position sensor 10 1.0 7.5

Fuel pressure regulator bolt 10 1.0 7.5

Page 652 of 687

Downloaded from www.Manualslib.com manuals search engine IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM 6F-3

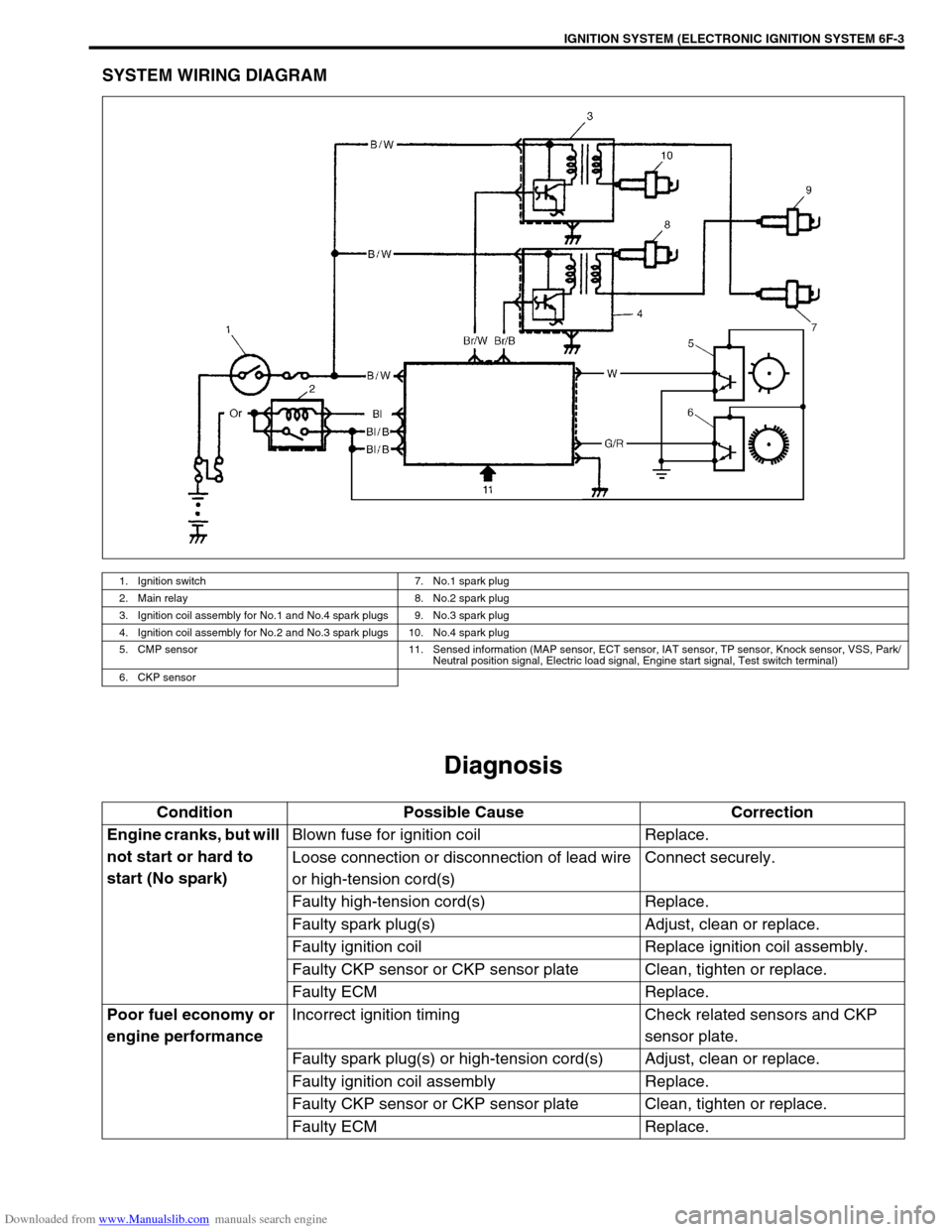

SYSTEM WIRING DIAGRAM

Diagnosis

1. Ignition switch 7. No.1 spark plug

2. Main relay 8. No.2 spark plug

3. Ignition coil assembly for No.1 and No.4 spark plugs 9. No.3 spark plug

4. Ignition coil assembly for No.2 and No.3 spark plugs 10. No.4 spark plug

5. CMP sensor 11. Sensed information (MAP sensor, ECT sensor, IAT sensor, TP sensor, Knock sensor, VSS, Park/

Neutral position signal, Electric load signal, Engine start signal, Test switch terminal)

6. CKP sensor

Condition Possible Cause Correction

Engine cranks, but will

not start or hard to

start (No spark)Blown fuse for ignition coil Replace.

Loose connection or disconnection of lead wire

or high-tension cord(s)Connect securely.

Faulty high-tension cord(s) Replace.

Faulty spark plug(s) Adjust, clean or replace.

Faulty ignition coil Replace ignition coil assembly.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty ECM Replace.

Poor fuel economy or

engine performanceIncorrect ignition timing Check related sensors and CKP

sensor plate.

Faulty spark plug(s) or high-tension cord(s) Adjust, clean or replace.

Faulty ignition coil assembly Replace.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty ECM Replace.

Page 686 of 687

Downloaded from www.Manualslib.com manuals search engine EXHAUST SYSTEM 6K-1

6F1

6F2

6G

6H

7D

7E

7F

7D

7E

7F

8A

8B

8C

8D

8E

9

7A1

6K

7C1

SECTION 6K

EXHAUST SYSTEM

CONTENTS

General Description ........................................6K-1

Maintenance ....................................................6K-1On-Vehicle Service ......................................... 6K-2

Exhaust Manifold .......................................... 6K-2

Exhaust Pipe ................................................. 6K-2

General Description

The exhaust system of this vehicle consists of the exhaust manifold, exhaust center pipe, muffler, seals, etc.

The catalytic converter is an emission control device added to the exhaust system to lower the level of Hydro-

carbon (HC), Carbon Monoxide (CO) and Oxides of Nitrogen (NOx) pollutants in the exhaust gas. The catalyst

in the catalytic converter is of “Three way” type.

Maintenance

At every interval of periodic maintenance service, and when vehicle is raised for other service, check exhaust

system as follows:

Check rubber mountings for damage, deterioration and out of position.

Check exhaust system for leakage, loose connection, dent and damage.

If bolts or nuts are loosened, tighten them to specified torque. Refer to “Components” in this section.

Check nearby body areas for damaged, missing, or mispositioned part, open seam, hole, loose connection

or any other defect which could permit exhaust fumes to seep into vehicle.

Make sure that exhaust system components have enough clearance from underbody to avoid overheating

and possible damage to passenger compartment carpet.

Any defect should be fixed at once. NOTE:

Whether following parts are used in the particular vehicle or not depends on specification. Be sure to

bear this in mind when performing service work.

Three-Way Catalytic Converter (TWC)

CAUTION:

Be sure to use UNLEADED FUEL for the catalytic converter equipped vehicle. Use of LEADED FUEL

will affect performance of the catalytic converter adversely to a great extent.

WARNING:

To avoid danger of being burned, do not touch exhaust system when system is hot.

Any service on exhaust system should be performed when system is cool.