bolts SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 674 of 687

Downloaded from www.Manualslib.com manuals search engine CHARGING SYSTEM 6H-7

How to use the temperature-corrected state-of-charge

graph

Suppose your S.G. reading is 1.28 and the battery temperature is

–5 °C (23 °F). Locate the intersection of the –5 °C line and the

1.28 S.G. line.

The intersection is within the “A” zone (shaded area in the graph)

and that means CHARGED STATE.

To know how much the battery is charged, draw a line parallel to

the zone demarcation line and extend it to the right till it meets

with the percentage scale. In the present example, the line meets

at about 85% point on the percentage scale. Therefore, the bat-

tery is charged up to the 85% level.

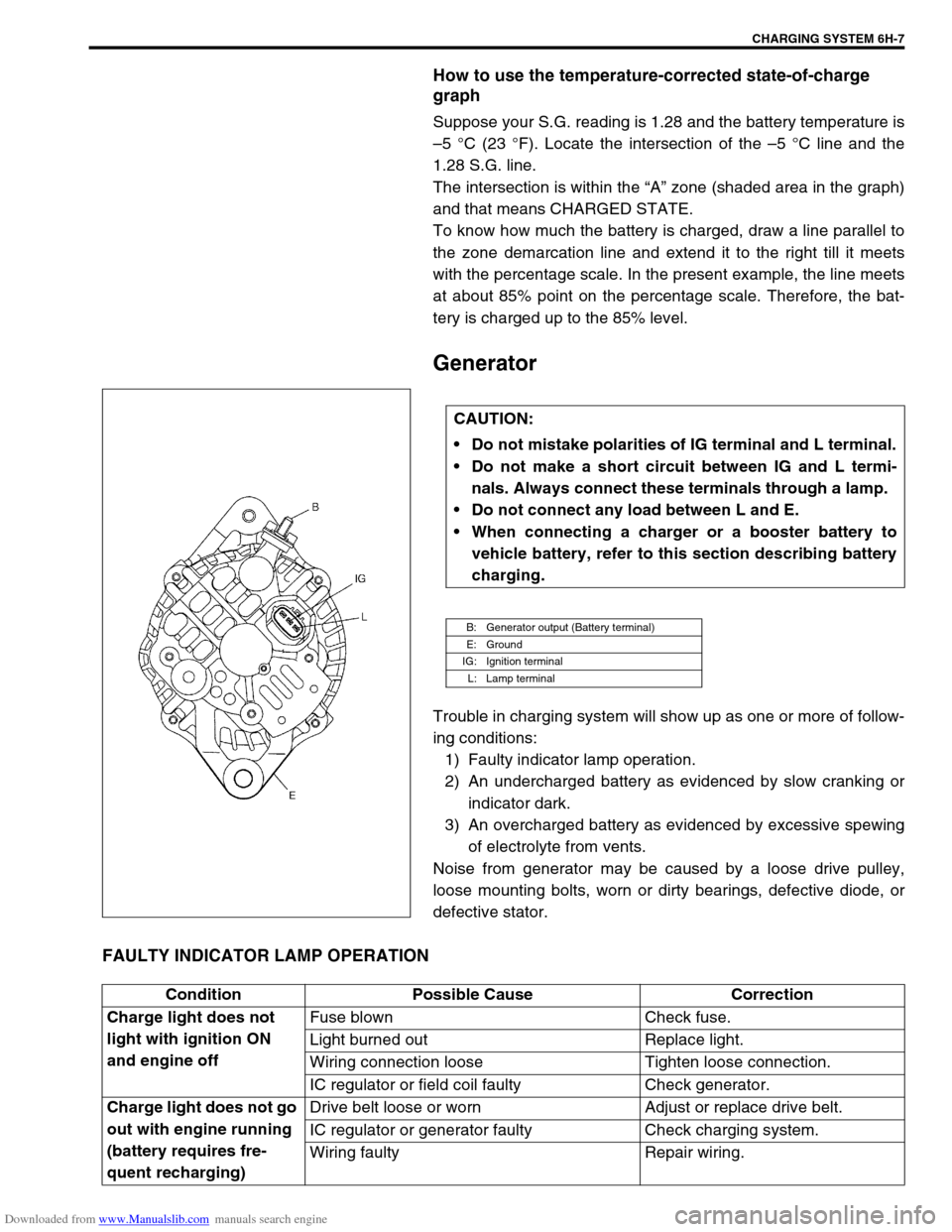

Generator

Trouble in charging system will show up as one or more of follow-

ing conditions:

1) Faulty indicator lamp operation.

2) An undercharged battery as evidenced by slow cranking or

indicator dark.

3) An overcharged battery as evidenced by excessive spewing

of electrolyte from vents.

Noise from generator may be caused by a loose drive pulley,

loose mounting bolts, worn or dirty bearings, defective diode, or

defective stator.

FAULTY INDICATOR LAMP OPERATION

CAUTION:

Do not mistake polarities of IG terminal and L terminal.

Do not make a short circuit between IG and L termi-

nals. Always connect these terminals through a lamp.

Do not connect any load between L and E.

When connecting a charger or a booster battery to

vehicle battery, refer to this section describing battery

charging.

B: Generator output (Battery terminal)

E: Ground

IG: Ignition terminal

L: Lamp terminal

Condition Possible Cause Correction

Charge light does not

light with ignition ON

and engine offFuse blown Check fuse.

Light burned out Replace light.

Wiring connection loose Tighten loose connection.

IC regulator or field coil faulty Check generator.

Charge light does not go

out with engine running

(battery requires fre-

quent recharging)Drive belt loose or worn Adjust or replace drive belt.

IC regulator or generator faulty Check charging system.

Wiring faulty Repair wiring.

Page 679 of 687

Downloaded from www.Manualslib.com manuals search engine 6H-12 CHARGING SYSTEM

Unit Repair Overhaul

Generator

Dismounting

1) Disconnect negative (–) cable (2) at battery (1).

2) Remove bolts (2) and then canister (1) together with its

bracket.

3) Disconnect “B” terminal wire (3) and coupler (2) from gener-

ator (1).

4) Remove generator belt. Refer to “Water Pump Belt and

Cooling Fan” in Section 6B.

5) Remove generator.

1. Generator adjusting bolt

2. Generator pivot bolt

3.“B” terminal

Page 680 of 687

Downloaded from www.Manualslib.com manuals search engine CHARGING SYSTEM 6H-13

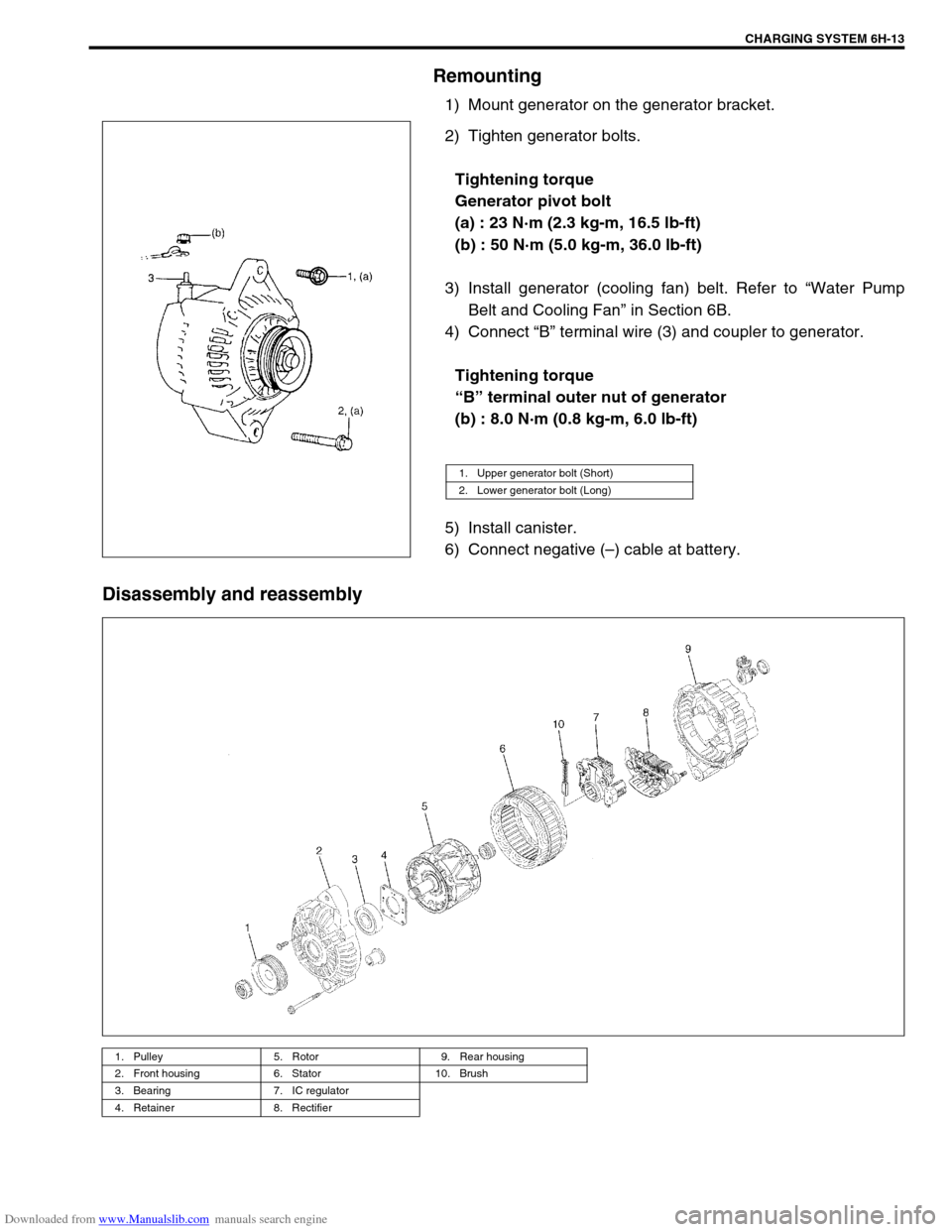

Remounting

1) Mount generator on the generator bracket.

2) Tighten generator bolts.

Tightening torque

Generator pivot bolt

(a) : 23 N·m (2.3 kg-m, 16.5 lb-ft)

(b) : 50 N·m (5.0 kg-m, 36.0 lb-ft)

3) Install generator (cooling fan) belt. Refer to “Water Pump

Belt and Cooling Fan” in Section 6B.

4) Connect “B” terminal wire (3) and coupler to generator.

Tightening torque

“B” terminal outer nut of generator

(b) : 8.0 N·m (0.8 kg-m, 6.0 lb-ft)

5) Install canister.

6) Connect negative (–) cable at battery.

Disassembly and reassembly

1. Upper generator bolt (Short)

2. Lower generator bolt (Long)

1. Pulley 5. Rotor 9. Rear housing

2. Front housing 6. Stator 10. Brush

3. Bearing 7. IC regulator

4. Retainer 8. Rectifier

Page 684 of 687

Downloaded from www.Manualslib.com manuals search engine CHARGING SYSTEM 6H-17

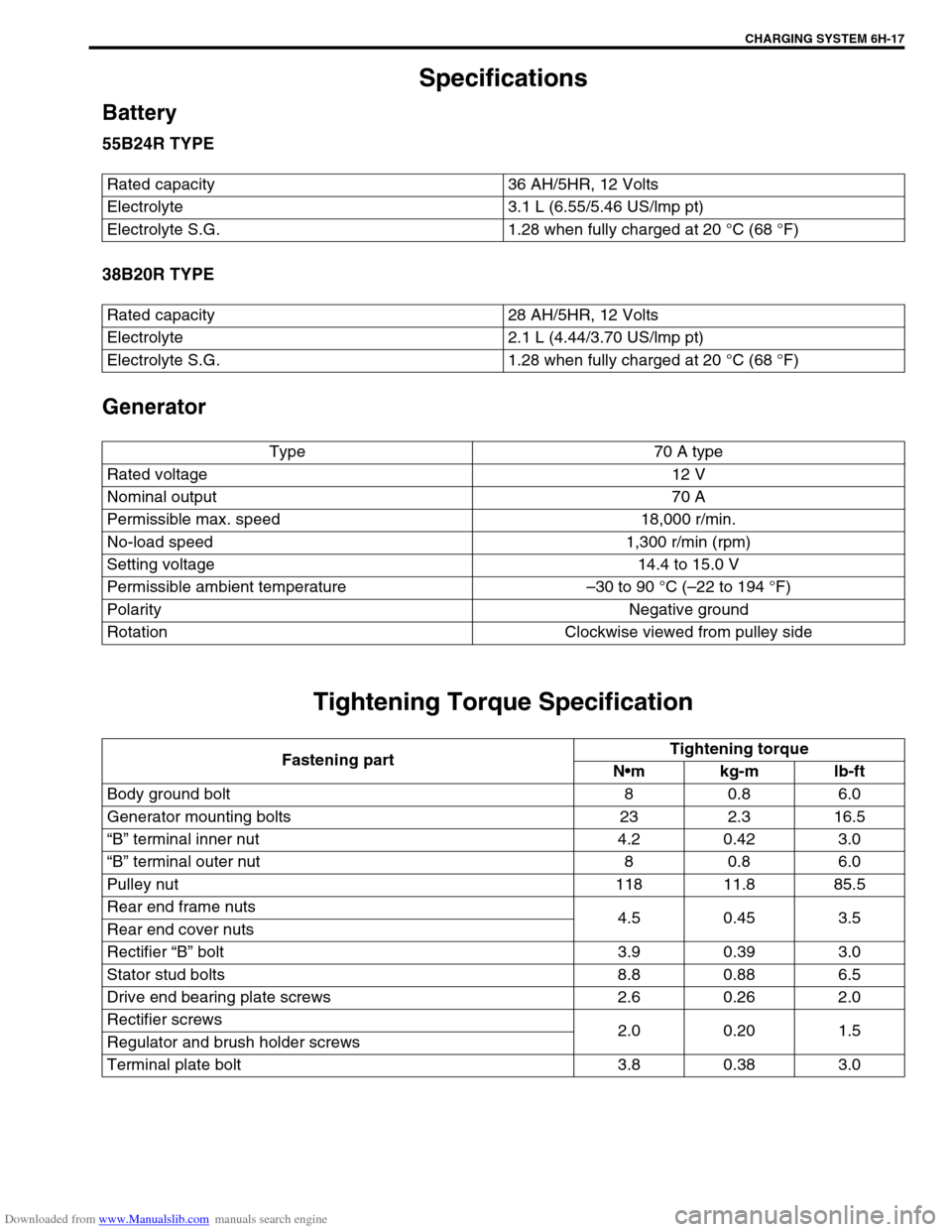

Specifications

Battery

55B24R TYPE

38B20R TYPE

Generator

Tightening Torque Specification

Rated capacity 36 AH/5HR, 12 Volts

Electrolyte 3.1 L (6.55/5.46 US/lmp pt)

Electrolyte S.G. 1.28 when fully charged at 20 °C (68 °F)

Rated capacity 28 AH/5HR, 12 Volts

Electrolyte 2.1 L (4.44/3.70 US/lmp pt)

Electrolyte S.G. 1.28 when fully charged at 20 °C (68 °F)

Type 70 A type

Rated voltage 12 V

Nominal output 70 A

Permissible max. speed 18,000 r/min.

No-load speed 1,300 r/min (rpm)

Setting voltage 14.4 to 15.0 V

Permissible ambient temperature–30 to 90 °C (–22 to 194 °F)

Polarity Negative ground

Rotation Clockwise viewed from pulley side

Fastening partTightening torque

Nm kg-m lb-ft

Body ground bolt 8 0.8 6.0

Generator mounting bolts 23 2.3 16.5

“B” terminal inner nut 4.2 0.42 3.0

“B” terminal outer nut 8 0.8 6.0

Pulley nut 118 11.8 85.5

Rear end frame nuts

4.50.453.5

Rear end cover nuts

Rectifier “B” bolt 3.9 0.39 3.0

Stator stud bolts 8.8 0.88 6.5

Drive end bearing plate screws 2.6 0.26 2.0

Rectifier screws

2.00.201.5

Regulator and brush holder screws

Terminal plate bolt 3.8 0.38 3.0

Page 686 of 687

Downloaded from www.Manualslib.com manuals search engine EXHAUST SYSTEM 6K-1

6F1

6F2

6G

6H

7D

7E

7F

7D

7E

7F

8A

8B

8C

8D

8E

9

7A1

6K

7C1

SECTION 6K

EXHAUST SYSTEM

CONTENTS

General Description ........................................6K-1

Maintenance ....................................................6K-1On-Vehicle Service ......................................... 6K-2

Exhaust Manifold .......................................... 6K-2

Exhaust Pipe ................................................. 6K-2

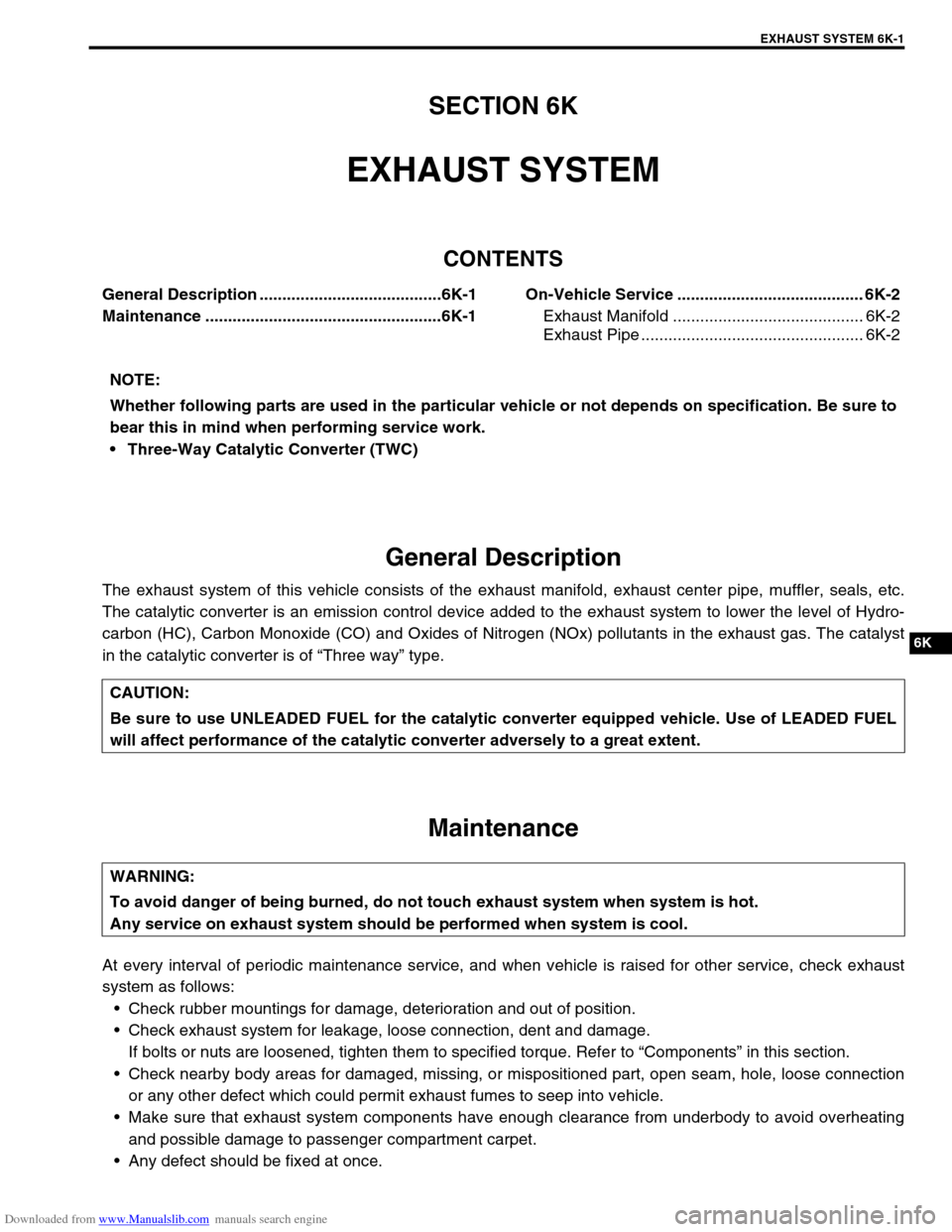

General Description

The exhaust system of this vehicle consists of the exhaust manifold, exhaust center pipe, muffler, seals, etc.

The catalytic converter is an emission control device added to the exhaust system to lower the level of Hydro-

carbon (HC), Carbon Monoxide (CO) and Oxides of Nitrogen (NOx) pollutants in the exhaust gas. The catalyst

in the catalytic converter is of “Three way” type.

Maintenance

At every interval of periodic maintenance service, and when vehicle is raised for other service, check exhaust

system as follows:

Check rubber mountings for damage, deterioration and out of position.

Check exhaust system for leakage, loose connection, dent and damage.

If bolts or nuts are loosened, tighten them to specified torque. Refer to “Components” in this section.

Check nearby body areas for damaged, missing, or mispositioned part, open seam, hole, loose connection

or any other defect which could permit exhaust fumes to seep into vehicle.

Make sure that exhaust system components have enough clearance from underbody to avoid overheating

and possible damage to passenger compartment carpet.

Any defect should be fixed at once. NOTE:

Whether following parts are used in the particular vehicle or not depends on specification. Be sure to

bear this in mind when performing service work.

Three-Way Catalytic Converter (TWC)

CAUTION:

Be sure to use UNLEADED FUEL for the catalytic converter equipped vehicle. Use of LEADED FUEL

will affect performance of the catalytic converter adversely to a great extent.

WARNING:

To avoid danger of being burned, do not touch exhaust system when system is hot.

Any service on exhaust system should be performed when system is cool.

Page 687 of 687

Downloaded from www.Manualslib.com manuals search engine 6K-2 EXHAUST SYSTEM

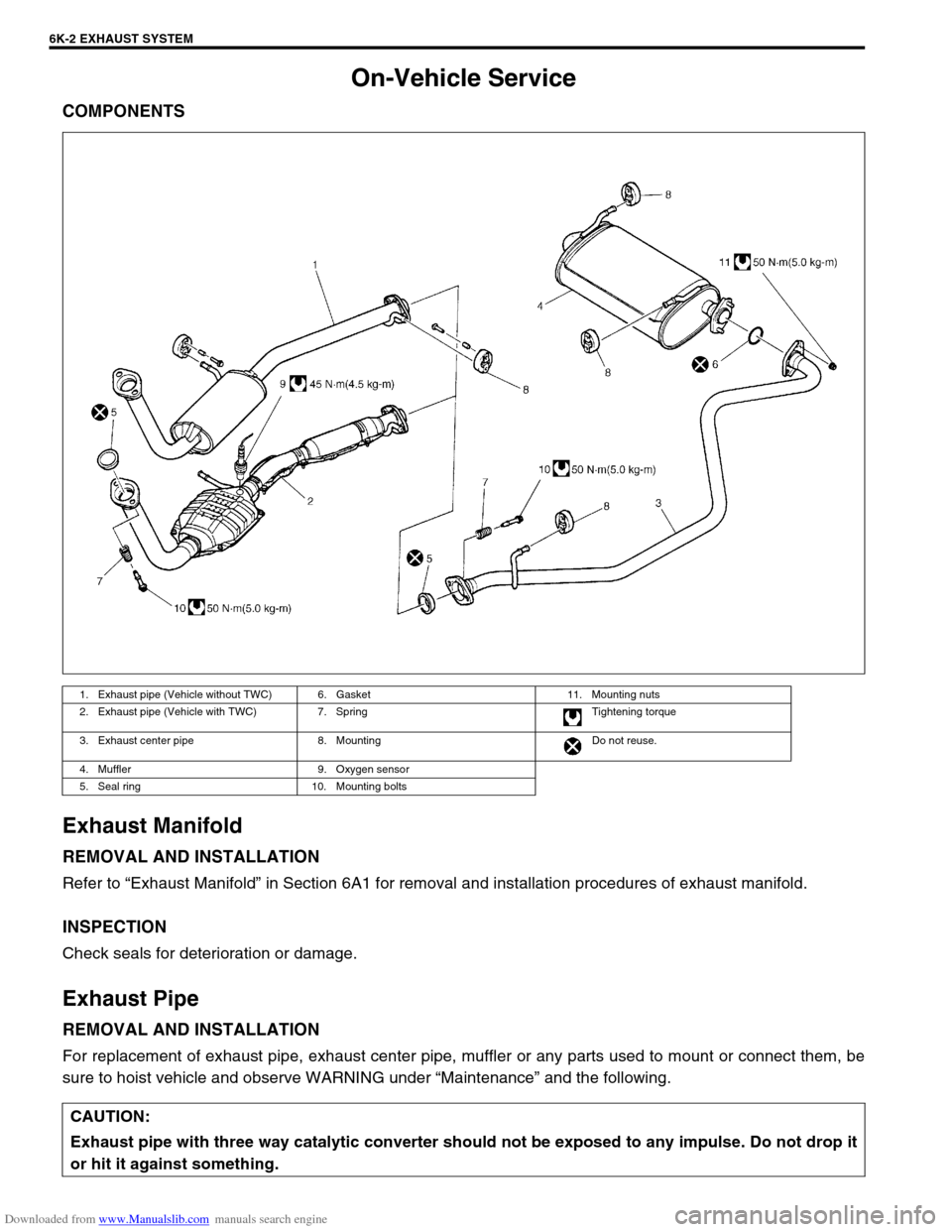

On-Vehicle Service

COMPONENTS

Exhaust Manifold

REMOVAL AND INSTALLATION

Refer to “Exhaust Manifold” in Section 6A1 for removal and installation procedures of exhaust manifold.

INSPECTION

Check seals for deterioration or damage.

Exhaust Pipe

REMOVAL AND INSTALLATION

For replacement of exhaust pipe, exhaust center pipe, muffler or any parts used to mount or connect them, be

sure to hoist vehicle and observe WARNING under “Maintenance” and the following.

1. Exhaust pipe (Vehicle without TWC) 6. Gasket 11. Mounting nuts

2. Exhaust pipe (Vehicle with TWC) 7. Spring Tightening torque

3. Exhaust center pipe 8. Mounting Do not reuse.

4. Muffler 9. Oxygen sensor

5. Seal ring 10. Mounting bolts

CAUTION:

Exhaust pipe with three way catalytic converter should not be exposed to any impulse. Do not drop it

or hit it against something.