clock SUZUKI JIMNY 2005 3.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 522 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-41

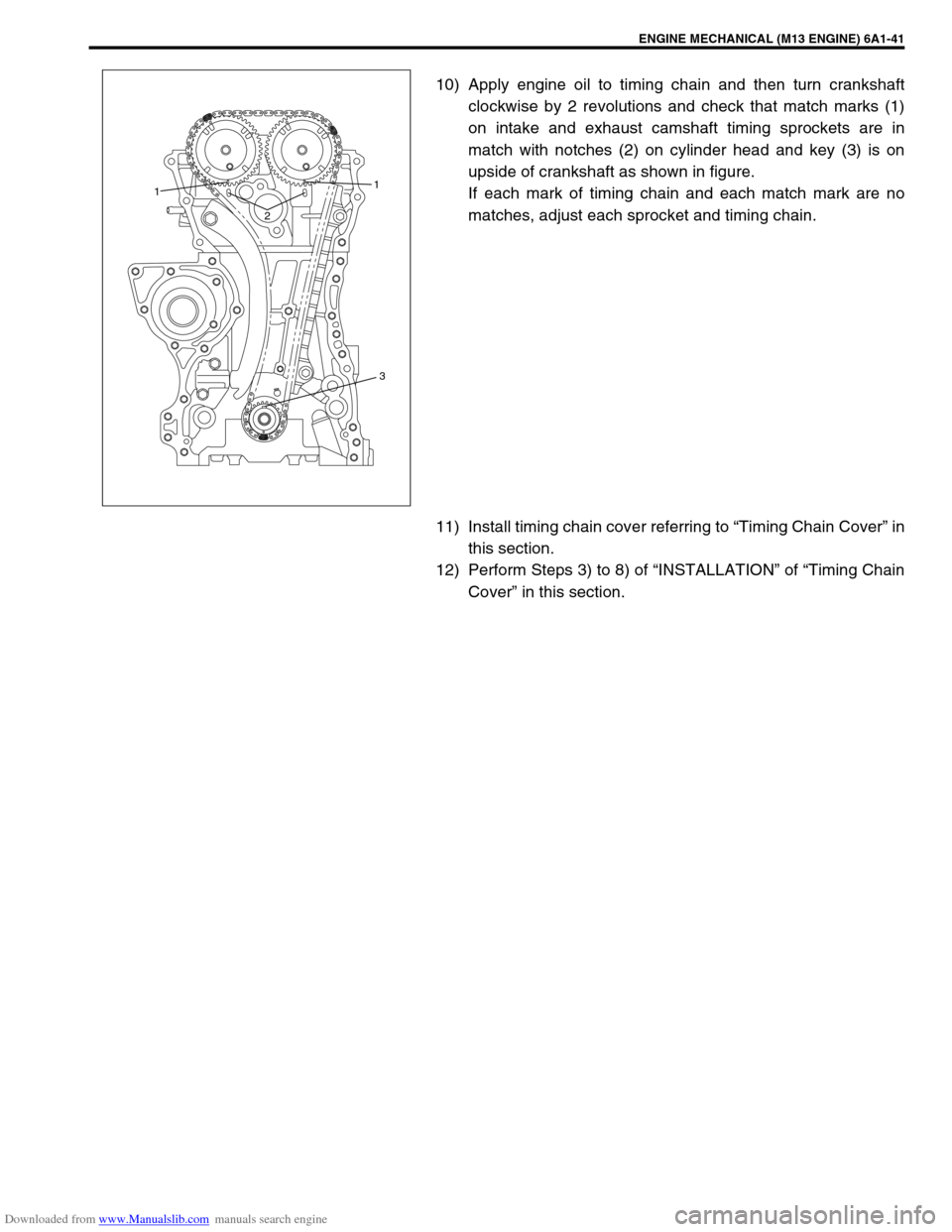

10) Apply engine oil to timing chain and then turn crankshaft

clockwise by 2 revolutions and check that match marks (1)

on intake and exhaust camshaft timing sprockets are in

match with notches (2) on cylinder head and key (3) is on

upside of crankshaft as shown in figure.

If each mark of timing chain and each match mark are no

matches, adjust each sprocket and timing chain.

11) Install timing chain cover referring to “Timing Chain Cover” in

this section.

12) Perform Steps 3) to 8) of “INSTALLATION” of “Timing Chain

Cover” in this section.

21

1

3

Page 635 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-30 ENGINE AND EMISSION CONTROL SYSTEM

Throttle position sensor (TP sensor)

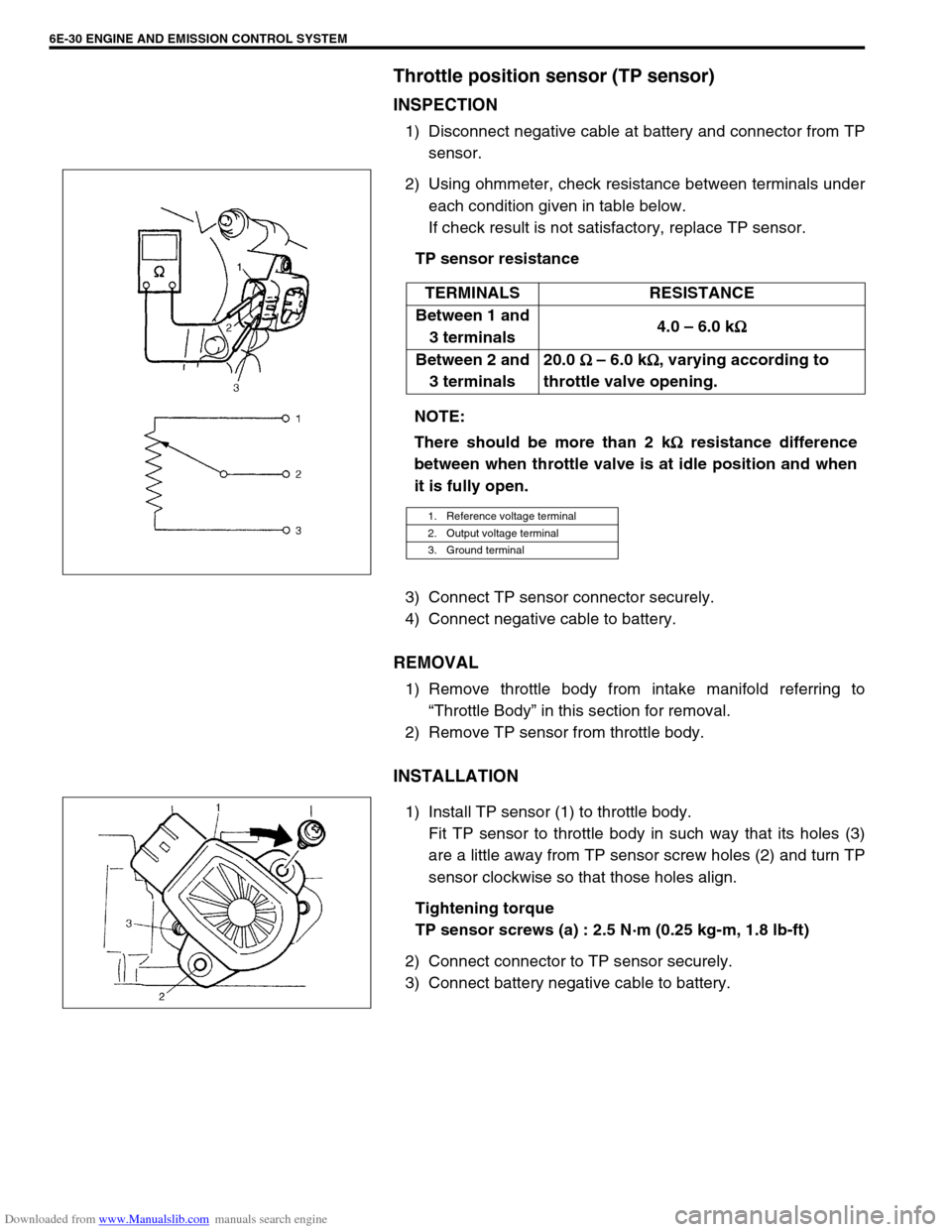

INSPECTION

1) Disconnect negative cable at battery and connector from TP

sensor.

2) Using ohmmeter, check resistance between terminals under

each condition given in table below.

If check result is not satisfactory, replace TP sensor.

TP sensor resistance

3) Connect TP sensor connector securely.

4) Connect negative cable to battery.

REMOVAL

1) Remove throttle body from intake manifold referring to

“Throttle Body” in this section for removal.

2) Remove TP sensor from throttle body.

INSTALLATION

1) Install TP sensor (1) to throttle body.

Fit TP sensor to throttle body in such way that its holes (3)

are a little away from TP sensor screw holes (2) and turn TP

sensor clockwise so that those holes align.

Tightening torque

TP sensor screws (a) : 2.5 N·m (0.25 kg-m, 1.8 lb-ft)

2) Connect connector to TP sensor securely.

3) Connect battery negative cable to battery.TERMINALS RESISTANCE

Between 1 and

3 terminals4.0 – 6.0 k

Ω

ΩΩ Ω

Between 2 and

3 terminals20.0

Ω

ΩΩ Ω – 6.0 k

Ω

ΩΩ Ω, varying according to

throttle valve opening.

NOTE:

There should be more than 2 k

Ω

ΩΩ Ω resistance difference

between when throttle valve is at idle position and when

it is fully open.

1. Reference voltage terminal

2. Output voltage terminal

3. Ground terminal

Page 666 of 687

Downloaded from www.Manualslib.com manuals search engine CRANKING SYSTEM 6G-7

Specifications

Voltage 12 volts

Output 0.9 kW 1.2 kW

Rating 30 seconds

Direction of rotation Clockwise as viewed from pinion side

Brush length 12.3 mm (0.48 in.) 12.3 mm (0.48 in.)

Number of pinion teeth 8

Performance Condition Guarantee

Around at

20° C (68 °F)No load characteristic 11.0 V90 A maximum

2,800 rpm minimum90 A maximum

2,500 rpm minimum

Load characteristic8.0 V

200 A4.8 N·m (0.48 kg-m,

3.5 lb-ft) minimum

1,260 rpm minimum–

7.5 V

300 A–10.5 N·m (1.05 kg-m,

7.6 lb-ft) minimum

880 rpm minimum

Locked rotor current3.5 V550 A maximum

12.2 N·m (1.22 kg-m,

8.8 lb-ft) minimum–

4.0 V–760 A maximum

19.5 N·m (1.95 kg-m,

14.1 lb-ft) minimum

Magnetic switch operating voltage 8 volts maximum

Page 684 of 687

Downloaded from www.Manualslib.com manuals search engine CHARGING SYSTEM 6H-17

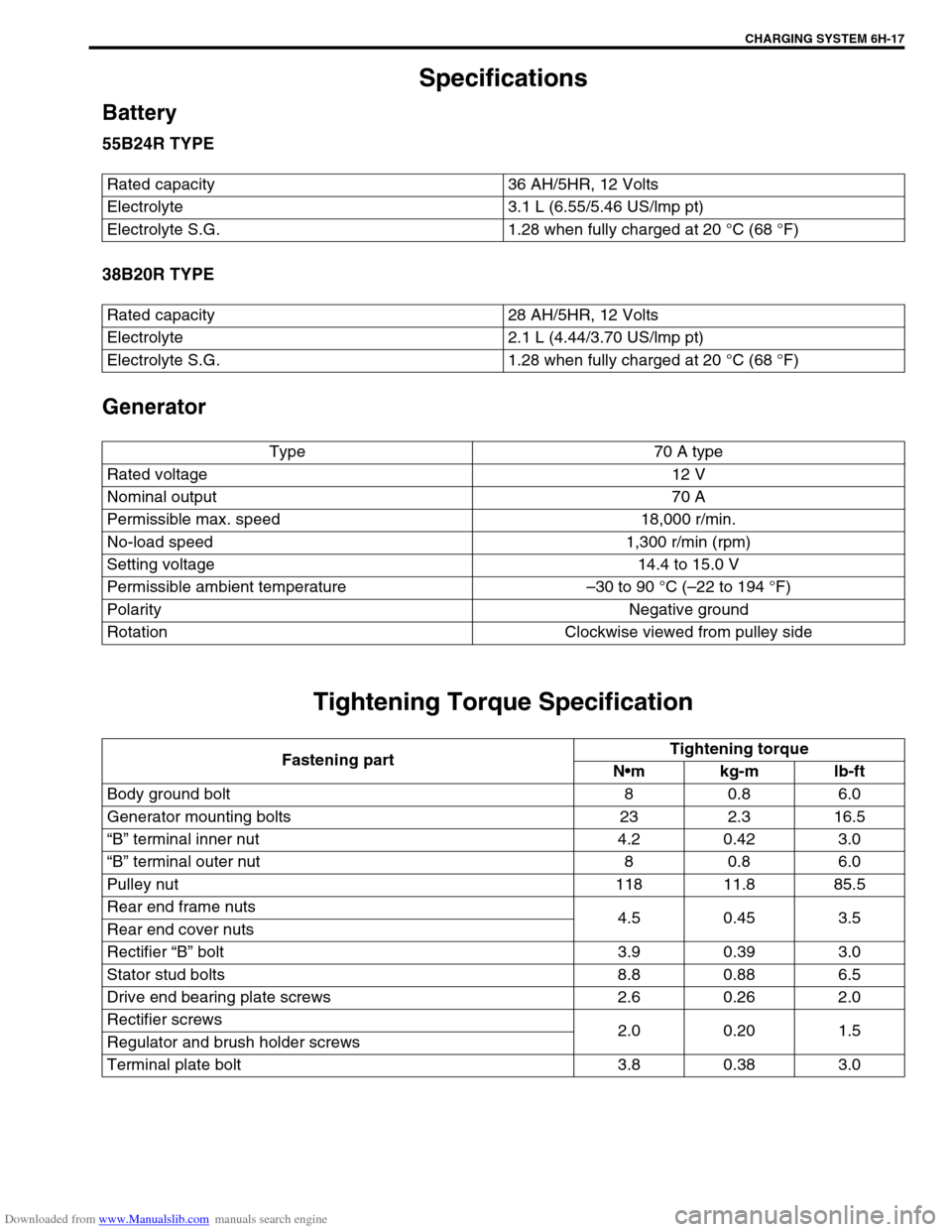

Specifications

Battery

55B24R TYPE

38B20R TYPE

Generator

Tightening Torque Specification

Rated capacity 36 AH/5HR, 12 Volts

Electrolyte 3.1 L (6.55/5.46 US/lmp pt)

Electrolyte S.G. 1.28 when fully charged at 20 °C (68 °F)

Rated capacity 28 AH/5HR, 12 Volts

Electrolyte 2.1 L (4.44/3.70 US/lmp pt)

Electrolyte S.G. 1.28 when fully charged at 20 °C (68 °F)

Type 70 A type

Rated voltage 12 V

Nominal output 70 A

Permissible max. speed 18,000 r/min.

No-load speed 1,300 r/min (rpm)

Setting voltage 14.4 to 15.0 V

Permissible ambient temperature–30 to 90 °C (–22 to 194 °F)

Polarity Negative ground

Rotation Clockwise viewed from pulley side

Fastening partTightening torque

Nm kg-m lb-ft

Body ground bolt 8 0.8 6.0

Generator mounting bolts 23 2.3 16.5

“B” terminal inner nut 4.2 0.42 3.0

“B” terminal outer nut 8 0.8 6.0

Pulley nut 118 11.8 85.5

Rear end frame nuts

4.50.453.5

Rear end cover nuts

Rectifier “B” bolt 3.9 0.39 3.0

Stator stud bolts 8.8 0.88 6.5

Drive end bearing plate screws 2.6 0.26 2.0

Rectifier screws

2.00.201.5

Regulator and brush holder screws

Terminal plate bolt 3.8 0.38 3.0