height SUZUKI JIMNY 2005 3.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 512 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-31

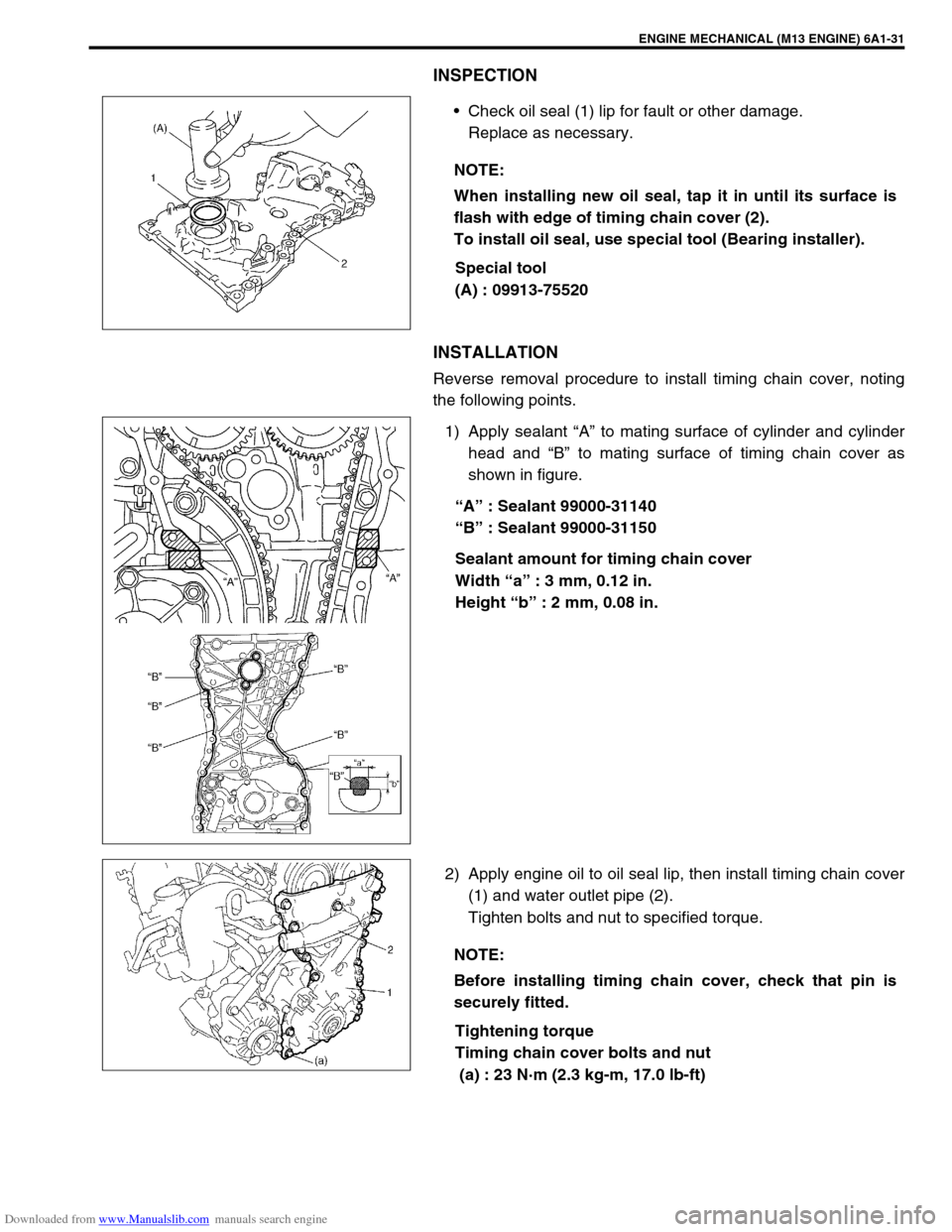

INSPECTION

Check oil seal (1) lip for fault or other damage.

Replace as necessary.

Special tool

(A) : 09913-75520

INSTALLATION

Reverse removal procedure to install timing chain cover, noting

the following points.

1) Apply sealant “A” to mating surface of cylinder and cylinder

head and “B” to mating surface of timing chain cover as

shown in figure.

“A” : Sealant 99000-31140

“B” : Sealant 99000-31150

Sealant amount for timing chain cover

Width “a” : 3 mm, 0.12 in.

Height “b” : 2 mm, 0.08 in.

2) Apply engine oil to oil seal lip, then install timing chain cover

(1) and water outlet pipe (2).

Tighten bolts and nut to specified torque.

Tightening torque

Timing chain cover bolts and nut

(a) : 23 N·m (2.3 kg-m, 17.0 lb-ft) NOTE:

When installing new oil seal, tap it in until its surface is

flash with edge of timing chain cover (2).

To install oil seal, use special tool (Bearing installer).

NOTE:

Before installing timing chain cover, check that pin is

securely fitted.

Page 524 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-43

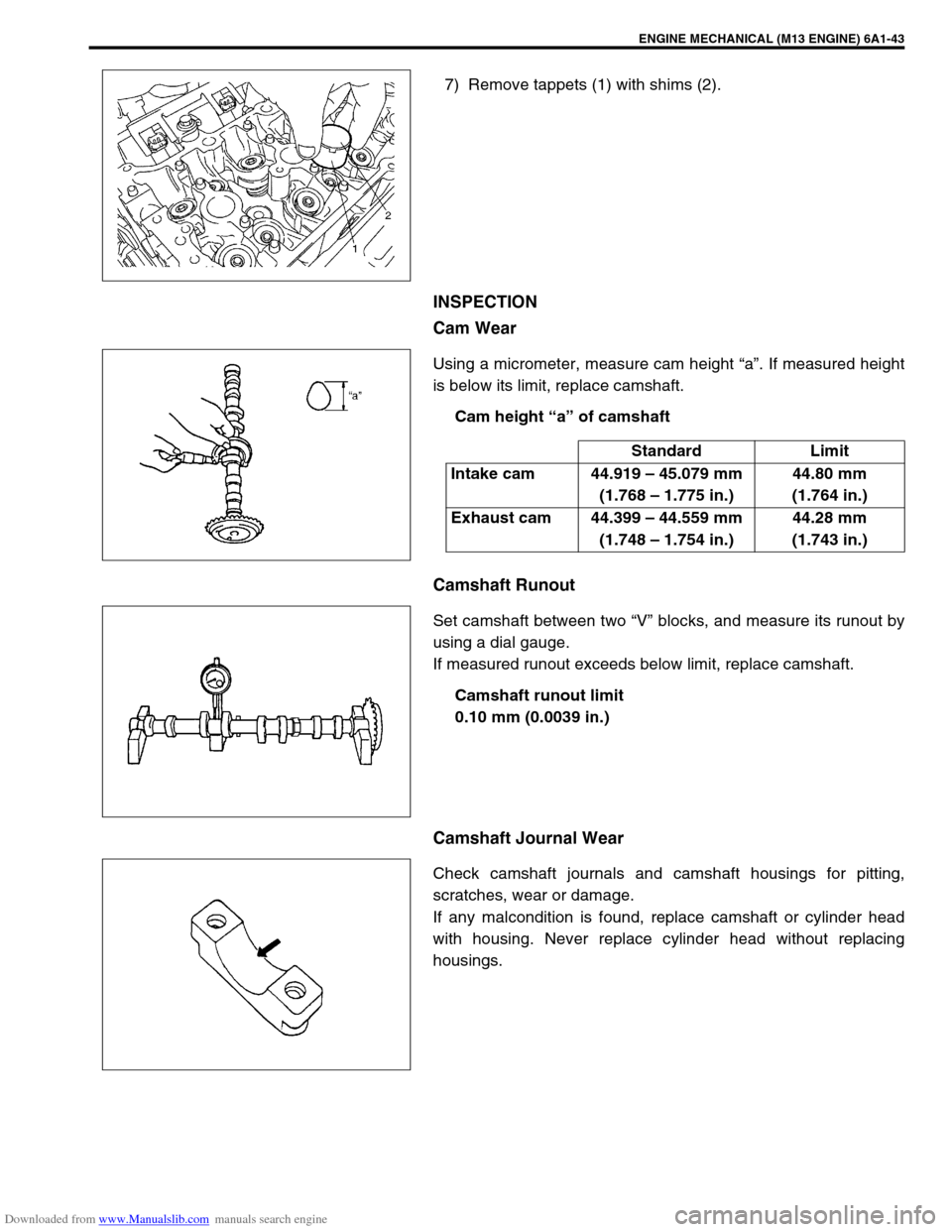

7) Remove tappets (1) with shims (2).

INSPECTION

Cam Wear

Using a micrometer, measure cam height “a”. If measured height

is below its limit, replace camshaft.

Cam height “a” of camshaft

Camshaft Runout

Set camshaft between two “V” blocks, and measure its runout by

using a dial gauge.

If measured runout exceeds below limit, replace camshaft.

Camshaft runout limit

0.10 mm (0.0039 in.)

Camshaft Journal Wear

Check camshaft journals and camshaft housings for pitting,

scratches, wear or damage.

If any malcondition is found, replace camshaft or cylinder head

with housing. Never replace cylinder head without replacing

housings.

Standard Limit

Intake cam 44.919 – 45.079 mm

(1.768 – 1.775 in.)44.80 mm

(1.764 in.)

Exhaust cam 44.399 – 44.559 mm

(1.748 – 1.754 in.)44.28 mm

(1.743 in.)

Page 572 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-91

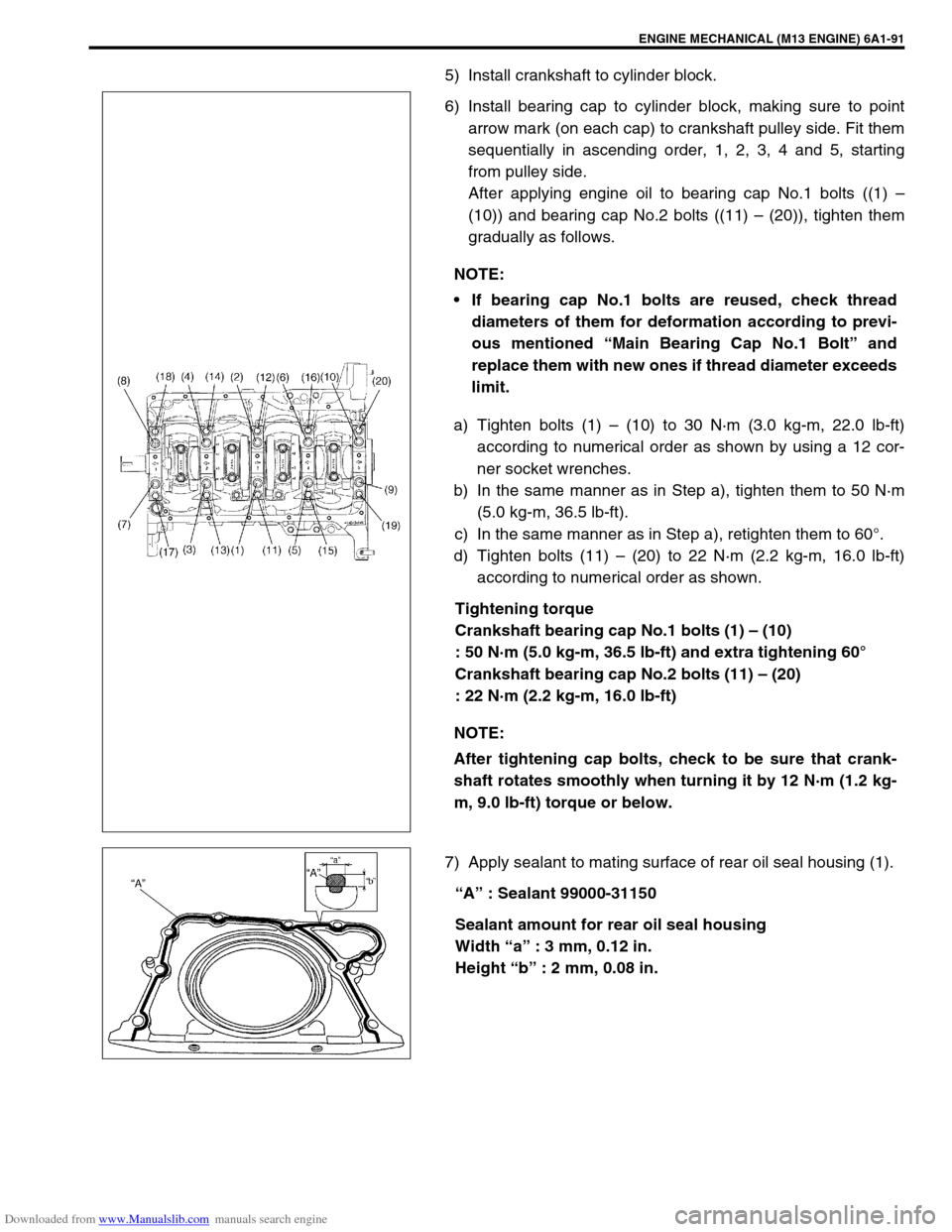

5) Install crankshaft to cylinder block.

6) Install bearing cap to cylinder block, making sure to point

arrow mark (on each cap) to crankshaft pulley side. Fit them

sequentially in ascending order, 1, 2, 3, 4 and 5, starting

from pulley side.

After applying engine oil to bearing cap No.1 bolts ((1) –

(10)) and bearing cap No.2 bolts ((11) – (20)), tighten them

gradually as follows.

a) Tighten bolts (1) – (10) to 30 N·m (3.0 kg-m, 22.0 lb-ft)

according to numerical order as shown by using a 12 cor-

ner socket wrenches.

b) In the same manner as in Step a), tighten them to 50 N·m

(5.0 kg-m, 36.5 lb-ft).

c) In the same manner as in Step a), retighten them to 60°.

d) Tighten bolts (11) – (20) to 22 N·m (2.2 kg-m, 16.0 lb-ft)

according to numerical order as shown.

Tightening torque

Crankshaft bearing cap No.1 bolts (1) – (10)

: 50 N·m (5.0 kg-m, 36.5 lb-ft) and extra tightening 60°

Crankshaft bearing cap No.2 bolts (11) – (20)

: 22 N·m (2.2 kg-m, 16.0 lb-ft)

7) Apply sealant to mating surface of rear oil seal housing (1).

“A” : Sealant 99000-31150

Sealant amount for rear oil seal housing

Width “a” : 3 mm, 0.12 in.

Height “b” : 2 mm, 0.08 in. NOTE:

If bearing cap No.1 bolts are reused, check thread

diameters of them for deformation according to previ-

ous mentioned “Main Bearing Cap No.1 Bolt” and

replace them with new ones if thread diameter exceeds

limit.

NOTE:

After tightening cap bolts, check to be sure that crank-

shaft rotates smoothly when turning it by 12 N·m (1.2 kg-

m, 9.0 lb-ft) torque or below.

Page 593 of 687

Downloaded from www.Manualslib.com manuals search engine 6B-16 ENGINE COOLING

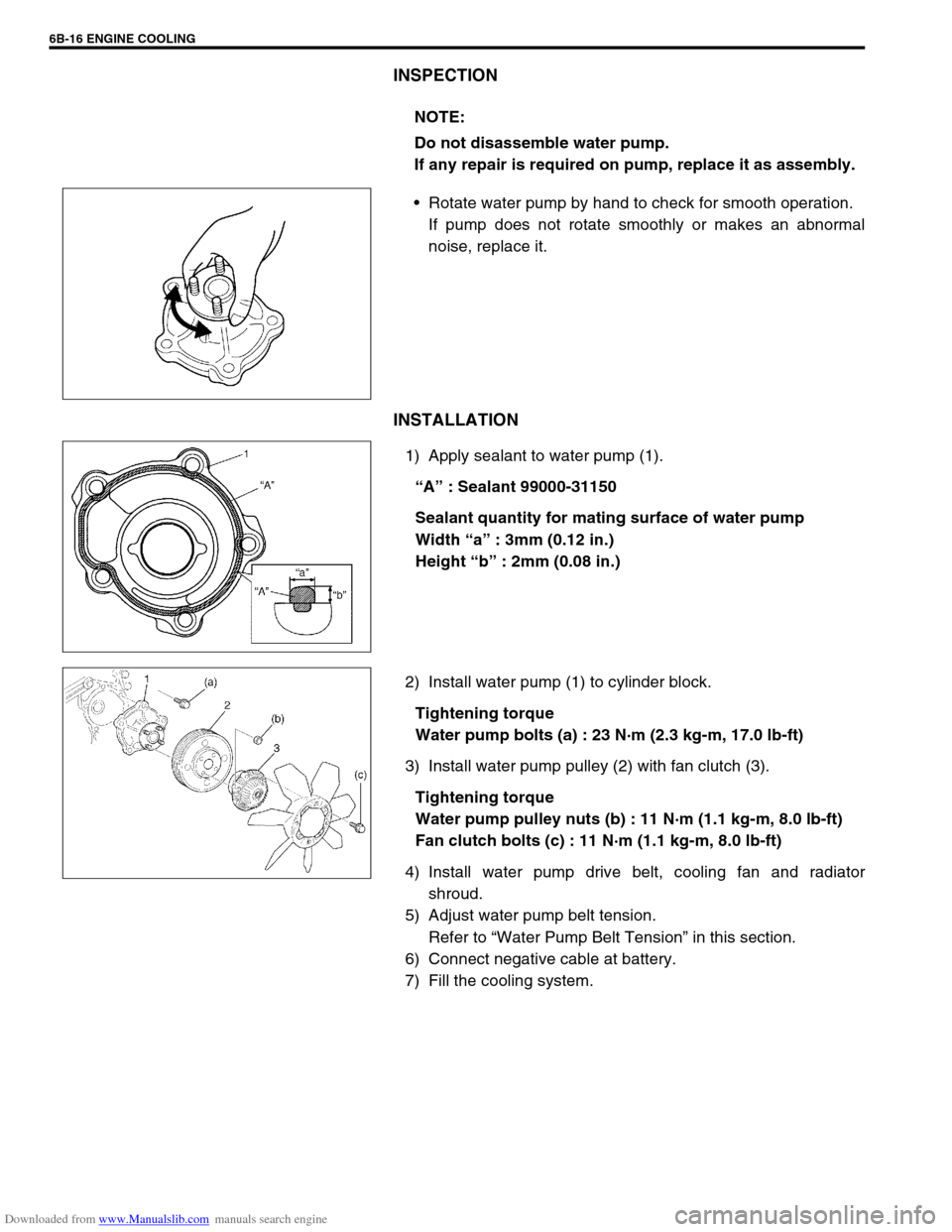

INSPECTION

Rotate water pump by hand to check for smooth operation.

If pump does not rotate smoothly or makes an abnormal

noise, replace it.

INSTALLATION

1) Apply sealant to water pump (1).

“A” : Sealant 99000-31150

Sealant quantity for mating surface of water pump

Width “a” : 3mm (0.12 in.)

Height “b” : 2mm (0.08 in.)

2) Install water pump (1) to cylinder block.

Tightening torque

Water pump bolts (a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

3) Install water pump pulley (2) with fan clutch (3).

Tightening torque

Water pump pulley nuts (b) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

Fan clutch bolts (c) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

4) Install water pump drive belt, cooling fan and radiator

shroud.

5) Adjust water pump belt tension.

Refer to “Water Pump Belt Tension” in this section.

6) Connect negative cable at battery.

7) Fill the cooling system.NOTE:

Do not disassemble water pump.

If any repair is required on pump, replace it as assembly.

Page 620 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-15

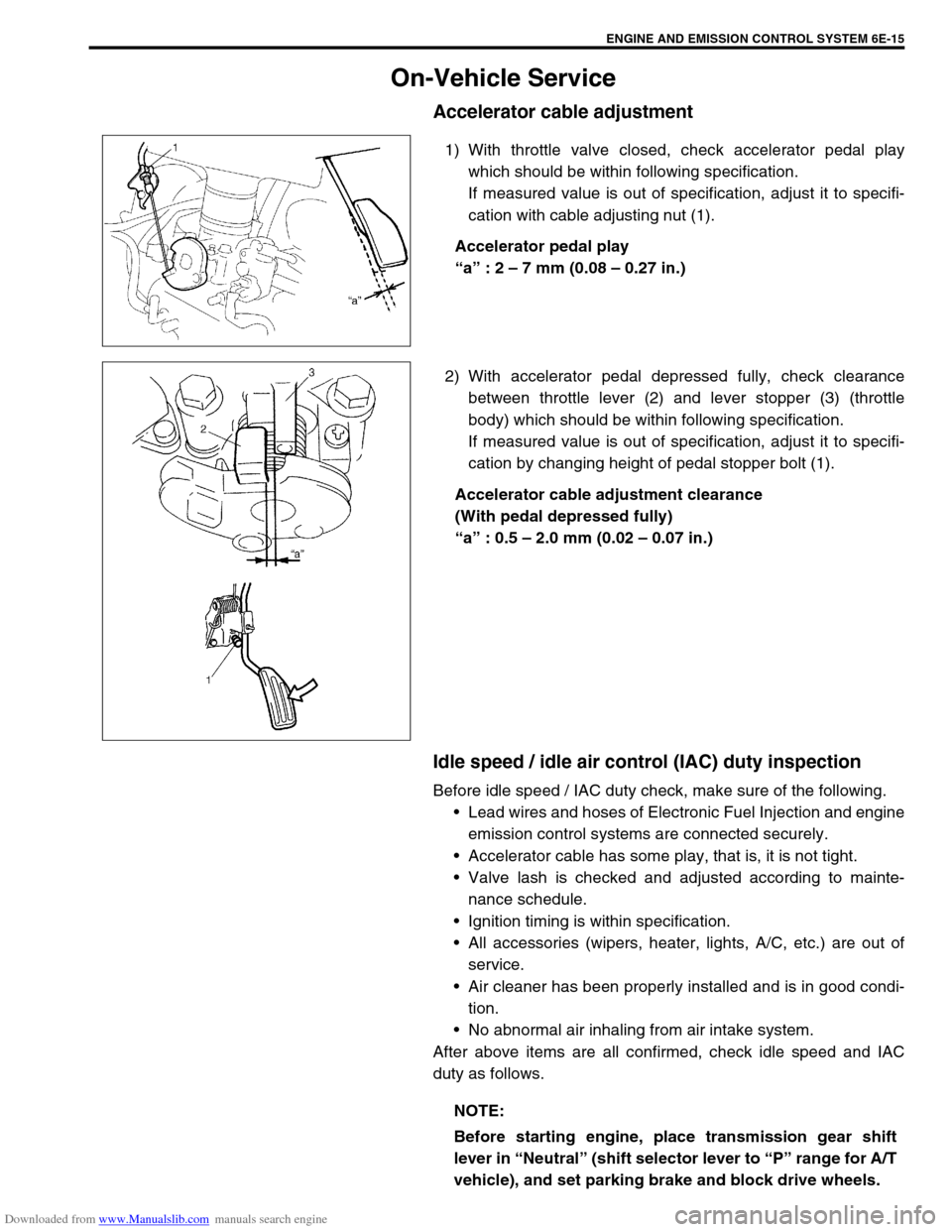

On-Vehicle Service

Accelerator cable adjustment

1) With throttle valve closed, check accelerator pedal play

which should be within following specification.

If measured value is out of specification, adjust it to specifi-

cation with cable adjusting nut (1).

Accelerator pedal play

“a” : 2 – 7 mm (0.08 – 0.27 in.)

2) With accelerator pedal depressed fully, check clearance

between throttle lever (2) and lever stopper (3) (throttle

body) which should be within following specification.

If measured value is out of specification, adjust it to specifi-

cation by changing height of pedal stopper bolt (1).

Accelerator cable adjustment clearance

(With pedal depressed fully)

“a” : 0.5 – 2.0 mm (0.02 – 0.07 in.)

Idle speed / idle air control (IAC) duty inspection

Before idle speed / IAC duty check, make sure of the following.

Lead wires and hoses of Electronic Fuel Injection and engine

emission control systems are connected securely.

Accelerator cable has some play, that is, it is not tight.

Valve lash is checked and adjusted according to mainte-

nance schedule.

Ignition timing is within specification.

All accessories (wipers, heater, lights, A/C, etc.) are out of

service.

Air cleaner has been properly installed and is in good condi-

tion.

No abnormal air inhaling from air intake system.

After above items are all confirmed, check idle speed and IAC

duty as follows.

NOTE:

Before starting engine, place transmission gear shift

lever in “Neutral” (shift selector lever to “P” range for A/T

vehicle), and set parking brake and block drive wheels.