lock SUZUKI JIMNY 2005 3.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 28 of 687

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION 0A-23

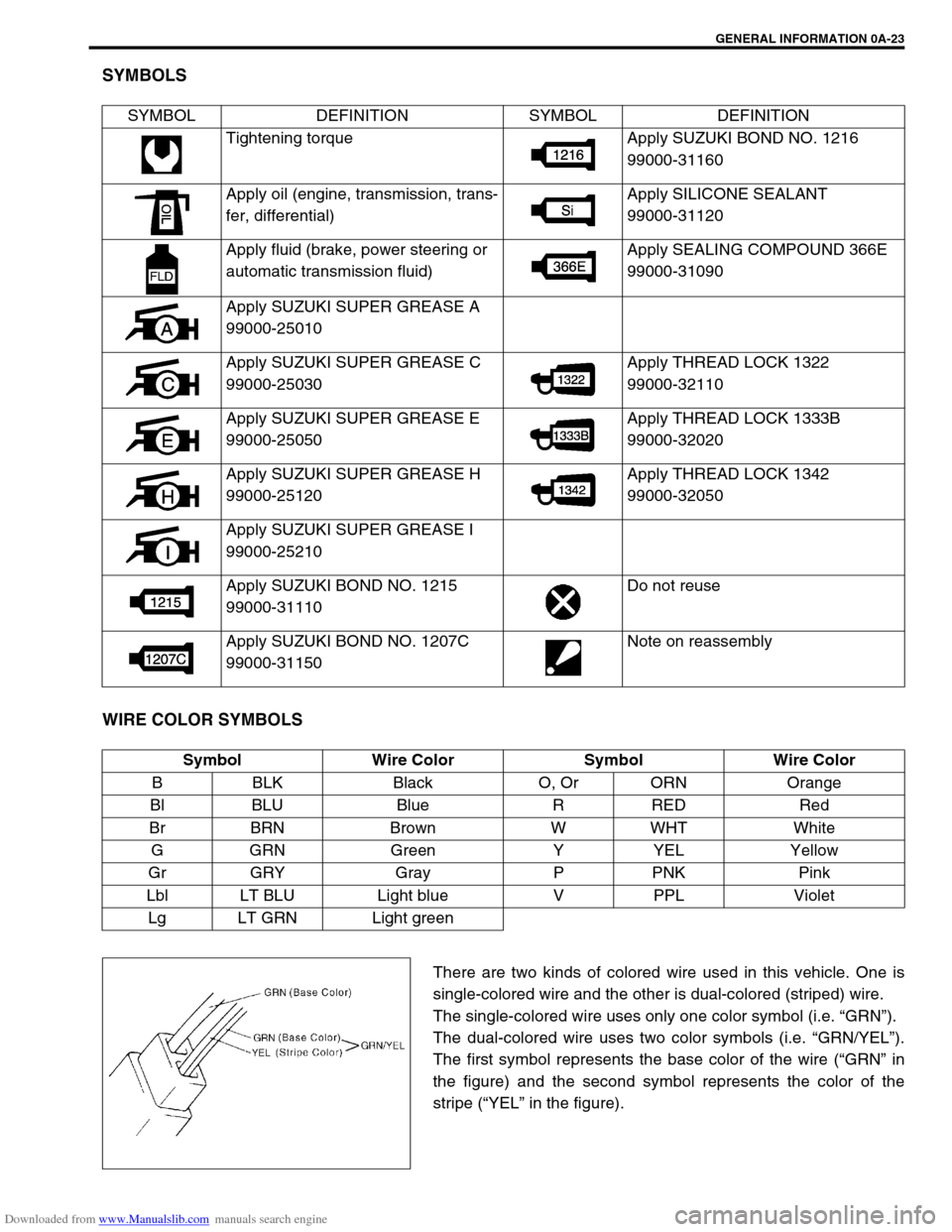

SYMBOLS

WIRE COLOR SYMBOLS

There are two kinds of colored wire used in this vehicle. One is

single-colored wire and the other is dual-colored (striped) wire.

The single-colored wire uses only one color symbol (i.e. “GRN”).

The dual-colored wire uses two color symbols (i.e. “GRN/YEL”).

The first symbol represents the base color of the wire (“GRN” in

the figure) and the second symbol represents the color of the

stripe (“YEL” in the figure). SYMBOL DEFINITION SYMBOL DEFINITION

Tightening torque Apply SUZUKI BOND NO. 1216

99000-31160

Apply oil (engine, transmission, trans-

fer, differential)Apply SILICONE SEALANT

99000-31120

Apply fluid (brake, power steering or

automatic transmission fluid)Apply SEALING COMPOUND 366E

99000-31090

Apply SUZUKI SUPER GREASE A

99000-25010

Apply SUZUKI SUPER GREASE C

99000-25030Apply THREAD LOCK 1322

99000-32110

Apply SUZUKI SUPER GREASE E

99000-25050Apply THREAD LOCK 1333B

99000-32020

Apply SUZUKI SUPER GREASE H

99000-25120Apply THREAD LOCK 1342

99000-32050

Apply SUZUKI SUPER GREASE I

99000-25210

Apply SUZUKI BOND NO. 1215

99000-31110Do not reuse

Apply SUZUKI BOND NO. 1207C

99000-31150Note on reassembly

Symbol Wire Color Symbol Wire Color

B BLK Black O, Or ORN Orange

Bl BLU Blue R RED Red

Br BRN Brown W WHT White

GGRN Green Y YEL Yellow

Gr GRY Gray P PNK Pink

Lbl LT BLU Light blue V PPL Violet

Lg LT GRN Light green

Page 29 of 687

Downloaded from www.Manualslib.com manuals search engine 0A-24 GENERAL INFORMATION

Fasteners Information

Metric Fasteners

Most of the fasteners used for this vehicle are metric fasteners. When replacing any fasteners, it is most impor-

tant that replacement fasteners be the correct diameter, thread pitch and strength.

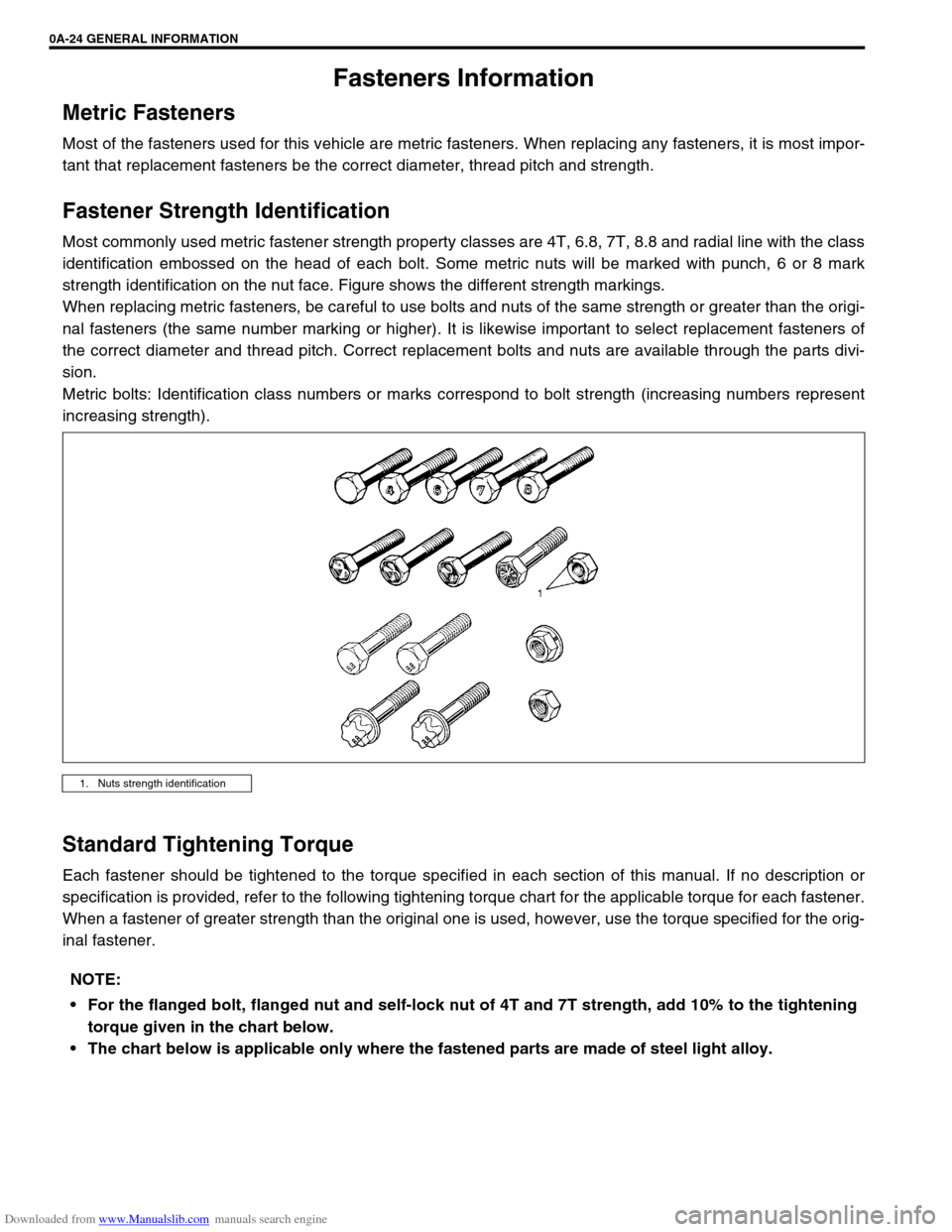

Fastener Strength Identification

Most commonly used metric fastener strength property classes are 4T, 6.8, 7T, 8.8 and radial line with the class

identification embossed on the head of each bolt. Some metric nuts will be marked with punch, 6 or 8 mark

strength identification on the nut face. Figure shows the different strength markings.

When replacing metric fasteners, be careful to use bolts and nuts of the same strength or greater than the origi-

nal fasteners (the same number marking or higher). It is likewise important to select replacement fasteners of

the correct diameter and thread pitch. Correct replacement bolts and nuts are available through the parts divi-

sion.

Metric bolts: Identification class numbers or marks correspond to bolt strength (increasing numbers represent

increasing strength).

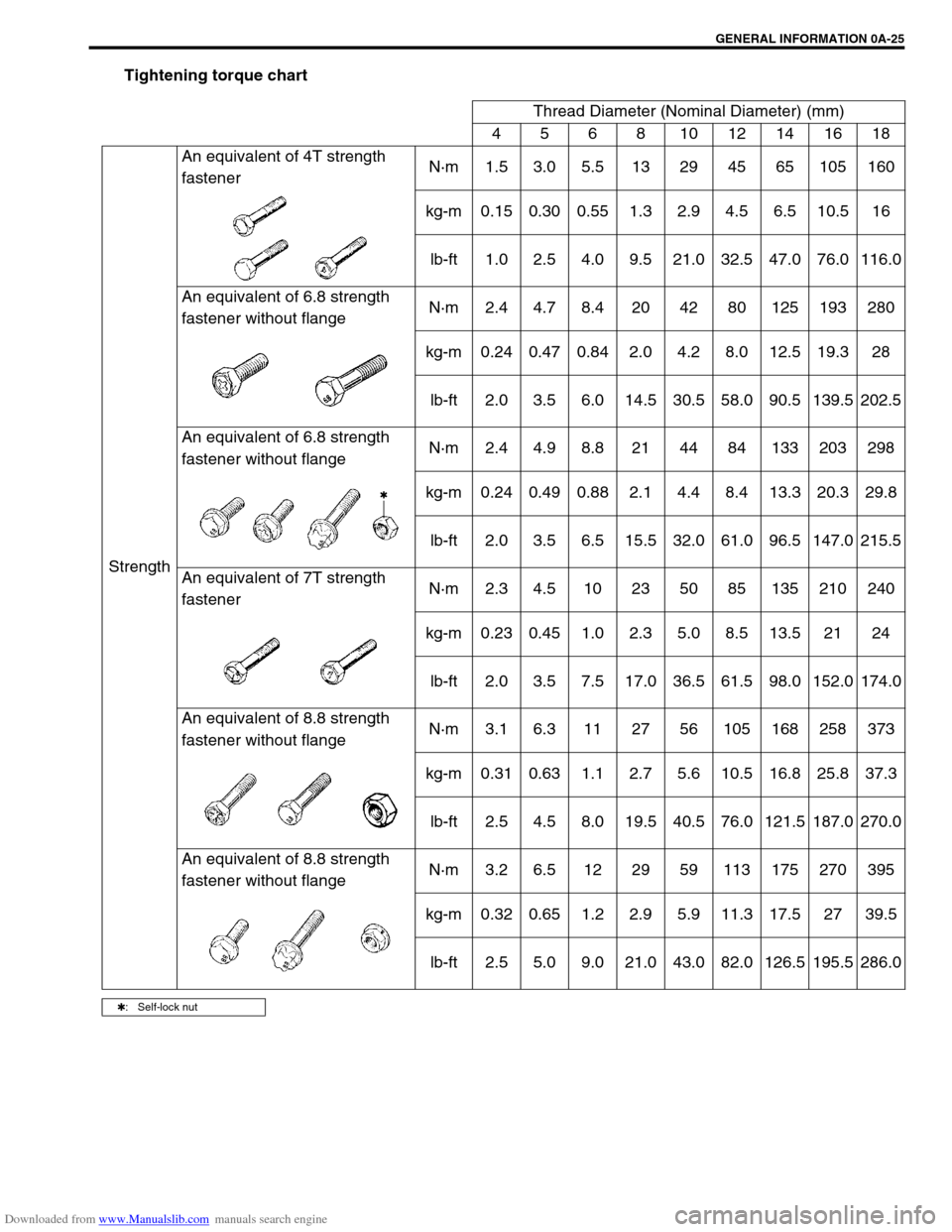

Standard Tightening Torque

Each fastener should be tightened to the torque specified in each section of this manual. If no description or

specification is provided, refer to the following tightening torque chart for the applicable torque for each fastener.

When a fastener of greater strength than the original one is used, however, use the torque specified for the orig-

inal fastener.

1. Nuts strength identification

NOTE:

For the flanged bolt, flanged nut and self-lock nut of 4T and 7T strength, add 10% to the tightening

torque given in the chart below.

The chart below is applicable only where the fastened parts are made of steel light alloy.

Page 30 of 687

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION 0A-25

Tightening torque chart

Thread Diameter (Nominal Diameter) (mm)

4 5 6 8 10 12 14 16 18

StrengthAn equivalent of 4T strength

fastenerN·m 1.5 3.0 5.5 13 29 45 65 105 160

kg-m 0.15 0.30 0.55 1.3 2.9 4.5 6.5 10.5 16

lb-ft 1.0 2.5 4.0 9.5 21.0 32.5 47.0 76.0 116.0

An equivalent of 6.8 strength

fastener without flangeN·m 2.4 4.7 8.4 20 42 80 125 193 280

kg-m 0.24 0.47 0.84 2.0 4.2 8.0 12.5 19.3 28

lb-ft 2.0 3.5 6.0 14.5 30.5 58.0 90.5 139.5 202.5

An equivalent of 6.8 strength

fastener without flangeN·m 2.4 4.9 8.8 21 44 84 133 203 298

kg-m 0.24 0.49 0.88 2.1 4.4 8.4 13.3 20.3 29.8

lb-ft 2.0 3.5 6.5 15.5 32.0 61.0 96.5 147.0 215.5

An equivalent of 7T strength

fastenerN·m 2.3 4.5 10 23 50 85 135 210 240

kg-m 0.23 0.45 1.0 2.3 5.0 8.5 13.5 21 24

lb-ft 2.0 3.5 7.5 17.0 36.5 61.5 98.0 152.0 174.0

An equivalent of 8.8 strength

fastener without flangeN·m 3.1 6.3 11 27 56 105 168 258 373

kg-m 0.31 0.63 1.1 2.7 5.6 10.5 16.8 25.8 37.3

lb-ft 2.5 4.5 8.0 19.5 40.5 76.0 121.5 187.0 270.0

An equivalent of 8.8 strength

fastener without flangeN·m 3.2 6.5 12 29 59 113 175 270 395

kg-m 0.32 0.65 1.2 2.9 5.9 11.3 17.5 27 39.5

lb-ft 2.5 5.0 9.0 21.0 43.0 82.0 126.5 195.5 286.0

✱: Self-lock nut

Page 32 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-1

0A 6F1

0B

0B

6G

1A 6H

1B 6K

37A

3A 7A1

3B1 7B1

3C1 7C1

3D 7D

3E 7E

3F 7F

4A2 8A

4B 8B

8C

58D

5A 8E

5B

5C 9

5E

5E1 10

10A

610B

6-1

6A1

6A2

6A4

6B

6C

6E1

6E2

SECTION 0B

MAINTENANCE AND LUBRICATION

CONTENTS

Maintenance Schedule .................................. 0B-2

Maintenance Schedule Under Normal

Driving Conditions ........................................ 0B-2

Maintenance Recommended Under Severe

Driving Conditions ........................................ 0B-4

Maintenance Service...................................... 0B-5

Engine .......................................................... 0B-5

Drive Belt .................................................. 0B-5

Valve Lash................................................ 0B-6

Engine Oil and Filter ................................. 0B-6

Engine Coolant ......................................... 0B-8

Exhaust System ....................................... 0B-8

Ignition System ............................................. 0B-9

Spark Plugs .............................................. 0B-9

Fuel System ................................................. 0B-9

Air Cleaner Filter ...................................... 0B-9

Fuel Lines and Connections ................... 0B-10

Fuel Filter ............................................... 0B-10

Fuel Tank ............................................... 0B-10

Emission Control System ........................... 0B-10

Crankcase Ventilation Hoses and

Connections ........................................... 0B-10

PCV (Positive Crankcase Ventilation)

Valve ..................................................... 0B-11Fuel Evaporative Emission Control

System ................................................... 0B-11

Chassis and Body ...................................... 0B-11

Clutch ..................................................... 0B-11

Brake Discs and Pads ............................ 0B-11

Brake Drums and Shoes ........................ 0B-12

Brake Hoses and Pipes.......................... 0B-12

Brake Fluid ............................................. 0B-12

Parking Brake Lever and Cable ............. 0B-13

Tires/Wheels .......................................... 0B-13

Suspension System ............................... 0B-14

Propeller Shafts...................................... 0B-15

Manual Transmission Oil........................ 0B-16

Automatic Transmission Fluid ................ 0B-16

Transfer and Differential Oil ................... 0B-17

Steering System ..................................... 0B-18

Steering Knuckle Seal ............................ 0B-18

Power Steering (P/S) System

(if equipped) ........................................... 0B-19

All Hinges, Latches and Locks ............... 0B-19

Final Inspection............................................ 0B-20

Recommended Fluids and Lubricants ....... 0B-22

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 34 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-3

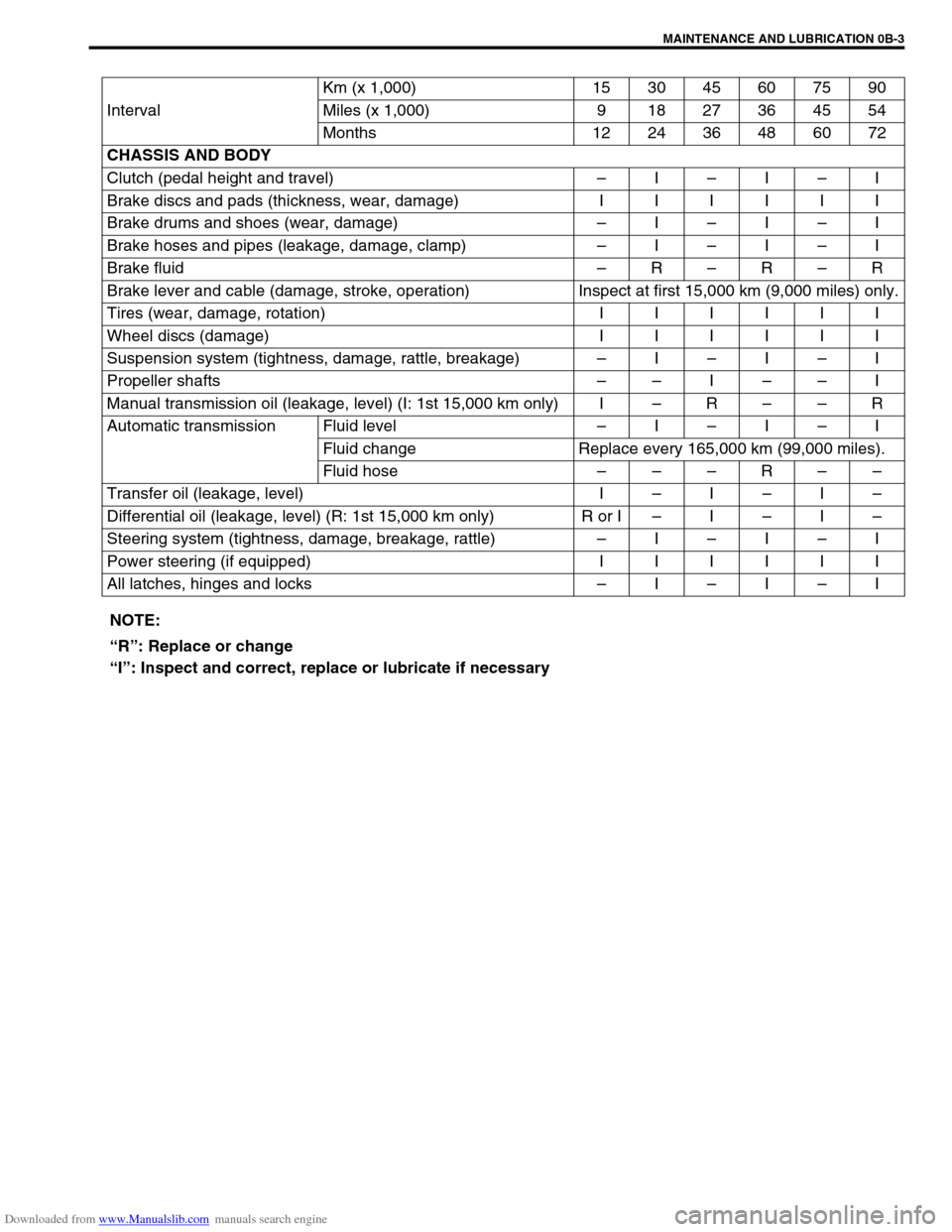

IntervalKm (x 1,000) 153045607590

Miles (x 1,000) 9 18 27 36 45 54

Months 12 24 36 48 60 72

CHASSIS AND BODY

Clutch (pedal height and travel)–I–I–I

Brake discs and pads (thickness, wear, damage) I I I I I I

Brake drums and shoes (wear, damage)–I–I–I

Brake hoses and pipes (leakage, damage, clamp)–I–I–I

Brake fluid–R–R–R

Brake lever and cable (damage, stroke, operation) Inspect at first 15,000 km (9,000 miles) only.

Tires (wear, damage, rotation) I I I I I I

Wheel discs (damage) I I I I I I

Suspension system (tightness, damage, rattle, breakage)–I–I–I

Propeller shafts––I––I

Manual transmission oil (leakage, level) (I: 1st 15,000 km only) I–R––R

Automatic transmission Fluid level–I–I–I

Fluid change Replace every 165,000 km (99,000 miles).

Fluid hose–––R––

Transfer oil (leakage, level) I–I–I–

Differential oil (leakage, level) (R: 1st 15,000 km only) R or I–I–I–

Steering system (tightness, damage, breakage, rattle)–I–I–I

Power steering (if equipped) I I I I I I

All latches, hinges and locks–I–I–I

NOTE:

“R”: Replace or change

“I”: Inspect and correct, replace or lubricate if necessary

Page 50 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-19

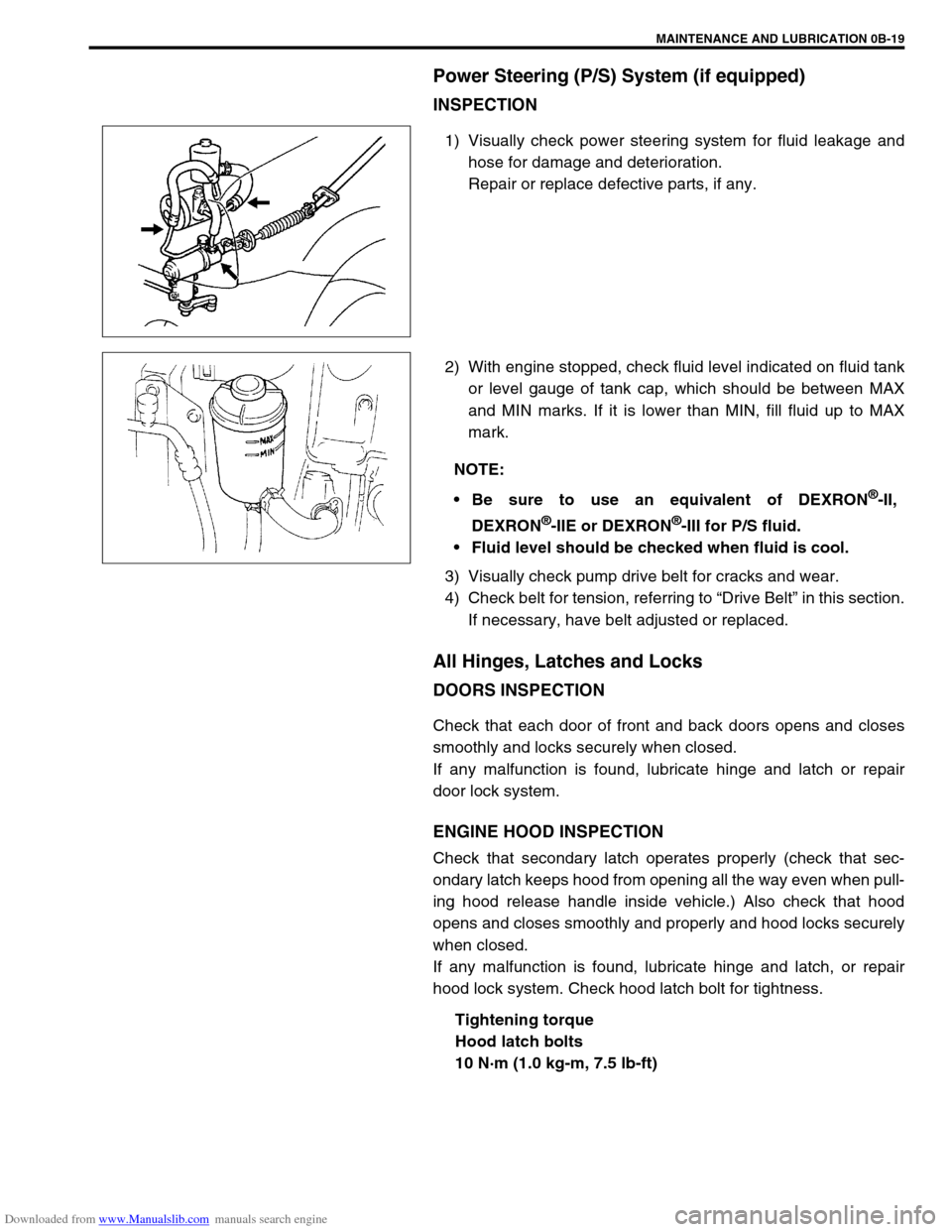

Power Steering (P/S) System (if equipped)

INSPECTION

1) Visually check power steering system for fluid leakage and

hose for damage and deterioration.

Repair or replace defective parts, if any.

2) With engine stopped, check fluid level indicated on fluid tank

or level gauge of tank cap, which should be between MAX

and MIN marks. If it is lower than MIN, fill fluid up to MAX

mark.

3) Visually check pump drive belt for cracks and wear.

4) Check belt for tension, referring to “Drive Belt” in this section.

If necessary, have belt adjusted or replaced.

All Hinges, Latches and Locks

DOORS INSPECTION

Check that each door of front and back doors opens and closes

smoothly and locks securely when closed.

If any malfunction is found, lubricate hinge and latch or repair

door lock system.

ENGINE HOOD INSPECTION

Check that secondary latch operates properly (check that sec-

ondary latch keeps hood from opening all the way even when pull-

ing hood release handle inside vehicle.) Also check that hood

opens and closes smoothly and properly and hood locks securely

when closed.

If any malfunction is found, lubricate hinge and latch, or repair

hood lock system. Check hood latch bolt for tightness.

Tightening torque

Hood latch bolts

10 N·m (1.0 kg-m, 7.5 lb-ft)

NOTE:

Be sure to use an equivalent of DEXRON

®-II,

DEXRON

®-IIE or DEXRON®-III for P/S fluid.

Fluid level should be checked when fluid is cool.

Page 51 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-20 MAINTENANCE AND LUBRICATION

Final Inspection

SEATS

Check that seat slides smoothly and locks securely at any position. Also check that reclining mechanism of front

seat back allows it to be locked at any angle.

SEAT BELT

Inspect belt system including webbing, buckles, latch plates, retractors and anchors for damage or wear.

If “REPLACE BELT” label on front seat belt is visible, replace belt. Check that seat belt is securely locked.

BATTERY ELECTROLYTE LEVEL CHECK

Check that the electrolyte level of all battery cells is between the upper and lower level lines on the case. If bat-

tery is equipped with built-in indicator, check battery condition by the indicator.

ACCELERATOR PEDAL OPERATION

Check that pedal operates smoothly without getting caught or interfered by any other part.

ENGINE START

Check engine start for readiness.

On automatic transmission vehicles, try to start the engine in each select lever position. The starting motor

should crank only in “P” (Park) or “N” (Neutral).

On manual transmission vehicles, place the shift lever in “Neutral,” depress clutch pedal fully any try to start.

EXHAUST SYSTEM CHECK

Check for leakage, cracks or loose supports.

CLUTCH (FOR MANUAL TRANSMISSION)

Check for the following.

Clutch is completely released when depressing clutch pedal,

No slipping clutch occurs when releasing pedal and accelerating.

Clutch itself is free from any abnormal condition. WARNING:

When carrying out road tests, select a safe place where no man or no running vehicle is seen so as to

prevent any accident.

WARNING:

Before performing the following check, be sure to have enough room around the vehicle. Then, firmly

apply both the parking brake and the regular brakes. Do not use the accelerator pedal. If the engine

starts, be ready to turn off the ignition promptly. Take these precautions because the vehicle could

move without warning and possibly cause personal injury or property damage.

Page 53 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-22 MAINTENANCE AND LUBRICATION

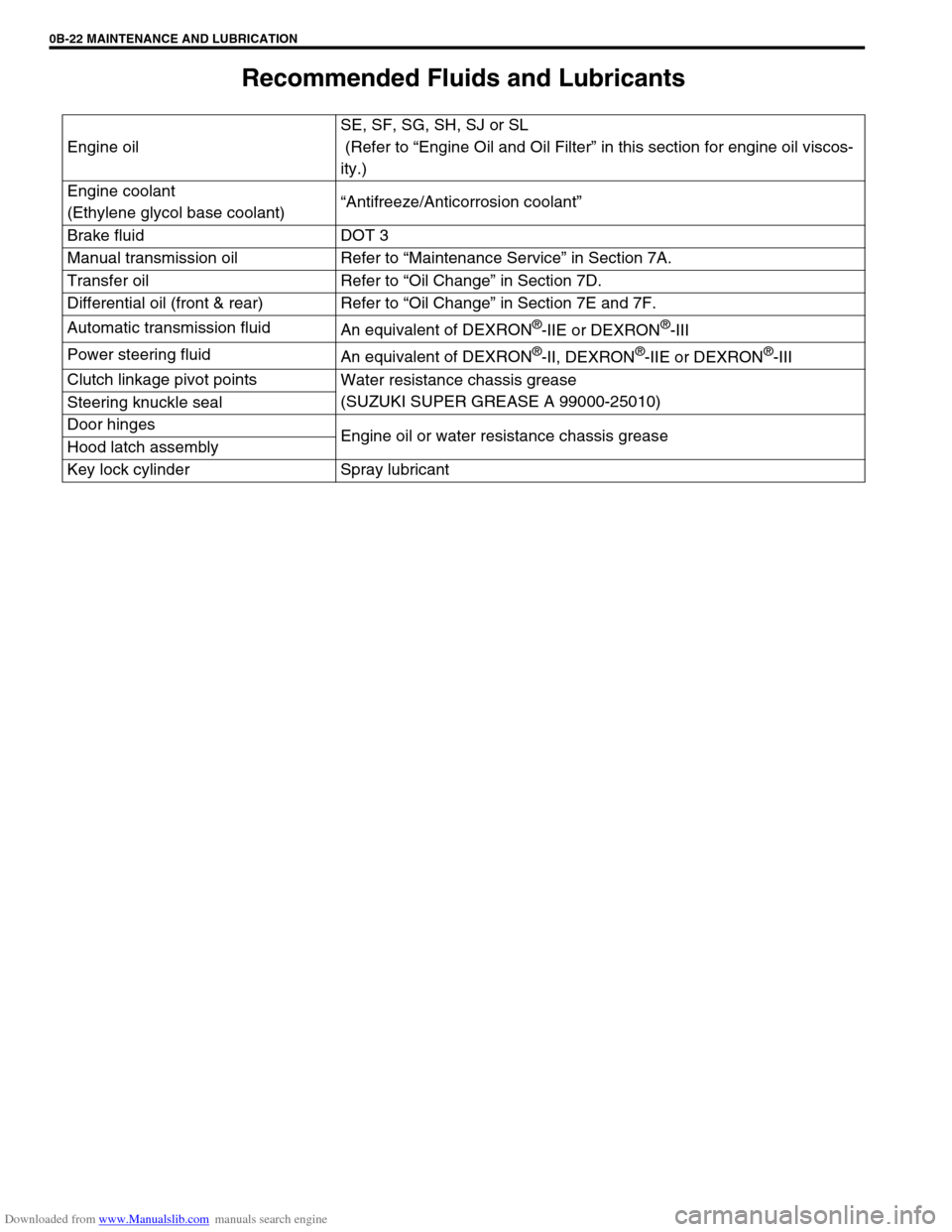

Recommended Fluids and Lubricants

Engine oilSE, SF, SG, SH, SJ or SL

(Refer to “Engine Oil and Oil Filter” in this section for engine oil viscos-

ity.)

Engine coolant

(Ethylene glycol base coolant)“Antifreeze/Anticorrosion coolant”

Brake fluid DOT 3

Manual transmission oil Refer to “Maintenance Service” in Section 7A.

Transfer oil Refer to “Oil Change” in Section 7D.

Differential oil (front & rear) Refer to “Oil Change” in Section 7E and 7F.

Automatic transmission fluid

An equivalent of DEXRON

®-IIE or DEXRON®-III

Power steering fluid

An equivalent of DEXRON

®-II, DEXRON®-IIE or DEXRON®-III

Clutch linkage pivot points

Water resistance chassis grease

(SUZUKI SUPER GREASE A 99000-25010)

Steering knuckle seal

Door hinges

Engine oil or water resistance chassis grease

Hood latch assembly

Key lock cylinder Spray lubricant

Page 54 of 687

Downloaded from www.Manualslib.com manuals search engine HEATER AND VENTILATION 1A-1

6F1

6G

1A

6K

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 1A

HEATER AND VENTILATION

CONTENTS

General Description ....................................... 1A-2

Diagnosis ........................................................ 1A-3

Diagnosis Table ........................................... 1A-3

Wiring Circuit ................................................ 1A-3

On Vehicle Service ......................................... 1A-4Heater Blower Motor .................................... 1A-4

Heater Blower Resistor ................................ 1A-5

Heater Control Lever Assembly ................... 1A-5

Heater Blower Fan Switch ........................... 1A-7

Heater Unit/Boost Ventilation ....................... 1A-7

WARNING:

For vehicles equipped with Supplement Restraint (Air Bag) System

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in Section 10B in order to confirm whether you are performing service on or

near the air bag system components or wiring. Please observe all WARNINGS and “Service Precau-

tions” under “On-Vehicle Service” in Section 10B before performing service on or around the air

bag system components or wiring. Failure to follow WARNINGS could result in unintentional activa-

tion of the system or could render the system inoperative. Either or these two conditions may result

in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

The link mechanism of the heater varies depending on the specifications.

Page 61 of 687

Downloaded from www.Manualslib.com manuals search engine 1A-8 HEATER AND VENTILATION

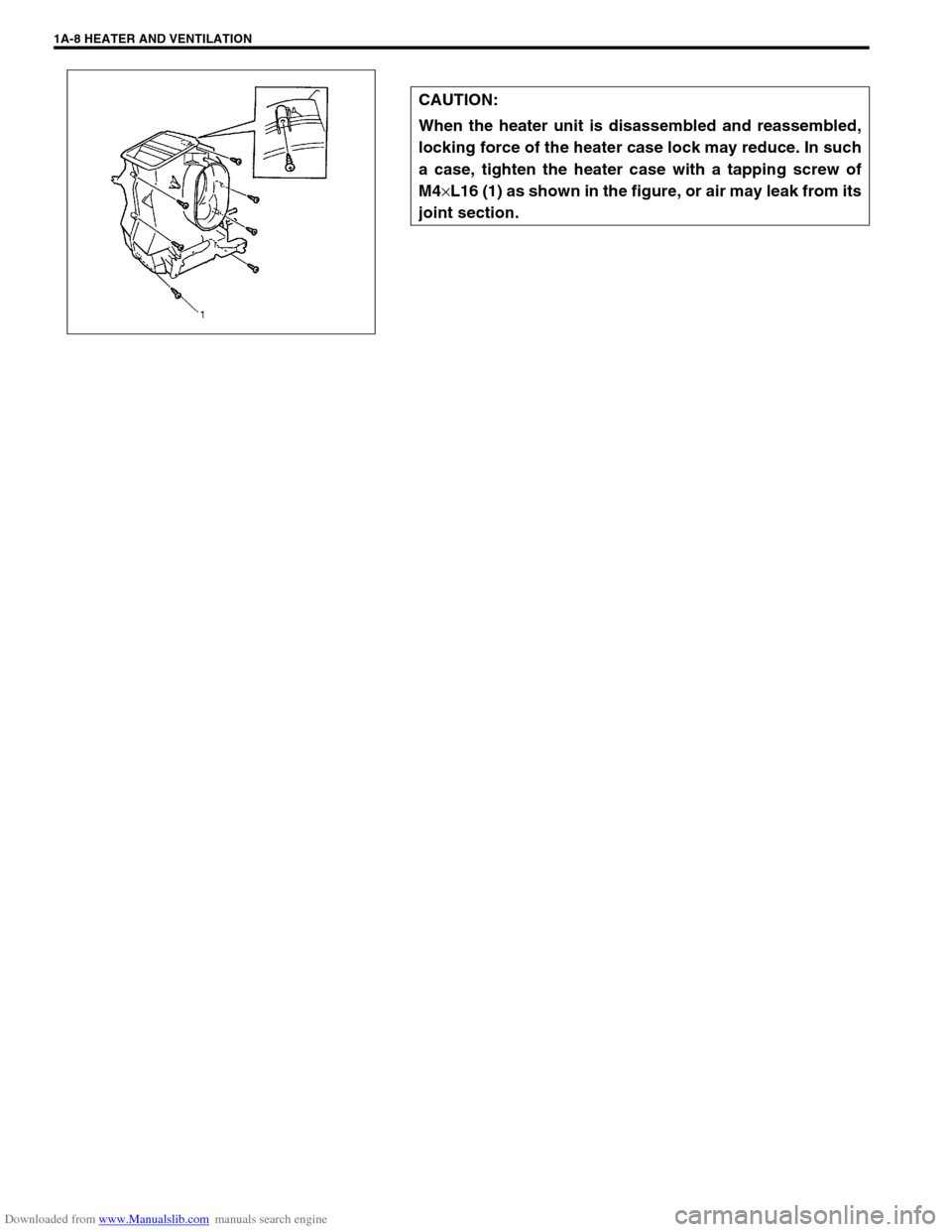

CAUTION:

When the heater unit is disassembled and reassembled,

locking force of the heater case lock may reduce. In such

a case, tighten the heater case with a tapping screw of

M4

×L16 (1) as shown in the figure, or air may leak from its

joint section.