Section 8 SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 510 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-29

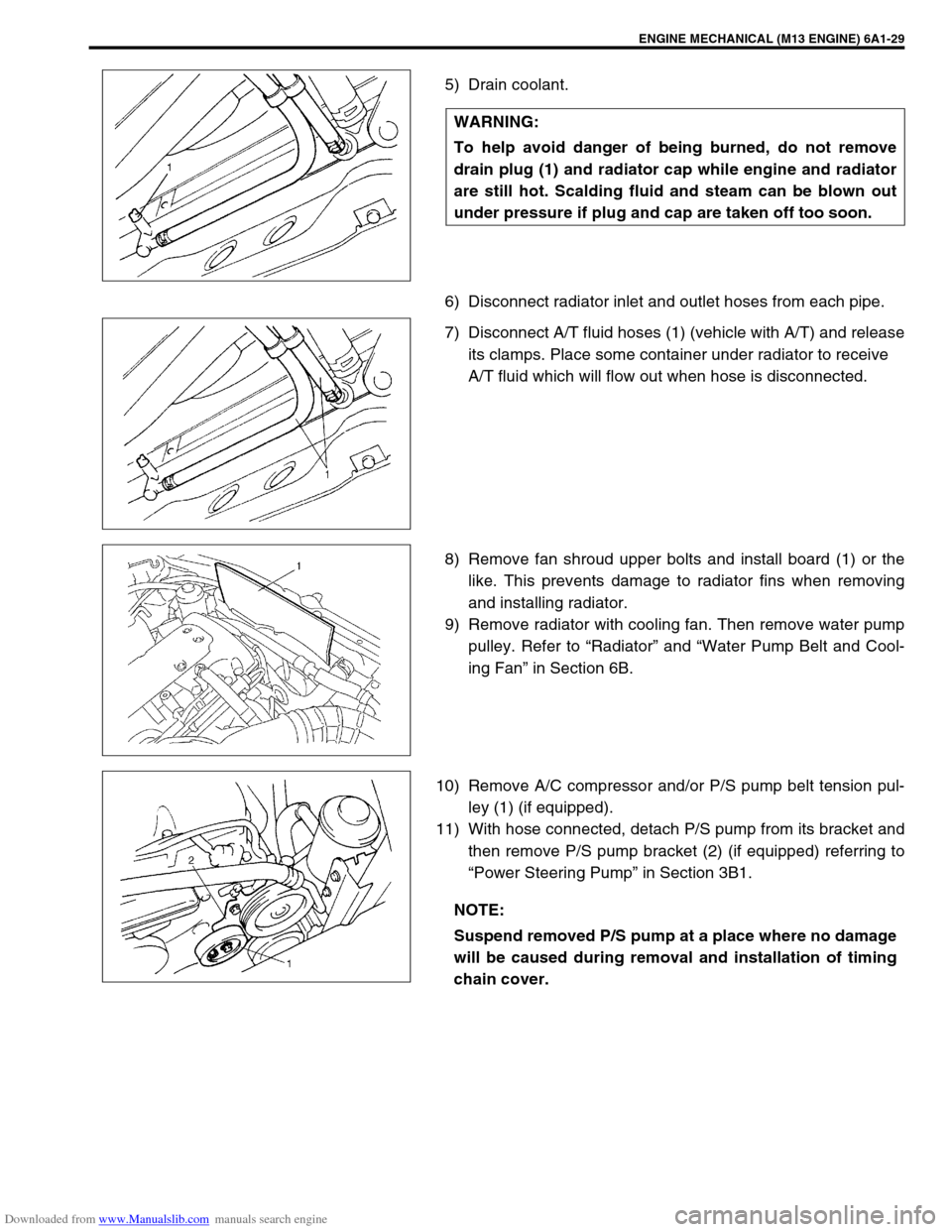

5) Drain coolant.

6) Disconnect radiator inlet and outlet hoses from each pipe.

7) Disconnect A/T fluid hoses (1) (vehicle with A/T) and release

its clamps. Place some container under radiator to receive

A/T fluid which will flow out when hose is disconnected.

8) Remove fan shroud upper bolts and install board (1) or the

like. This prevents damage to radiator fins when removing

and installing radiator.

9) Remove radiator with cooling fan. Then remove water pump

pulley. Refer to “Radiator” and “Water Pump Belt and Cool-

ing Fan” in Section 6B.

10) Remove A/C compressor and/or P/S pump belt tension pul-

ley (1) (if equipped).

11) With hose connected, detach P/S pump from its bracket and

then remove P/S pump bracket (2) (if equipped) referring to

“Power Steering Pump” in Section 3B1. WARNING:

To help avoid danger of being burned, do not remove

drain plug (1) and radiator cap while engine and radiator

are still hot. Scalding fluid and steam can be blown out

under pressure if plug and cap are taken off too soon.

NOTE:

Suspend removed P/S pump at a place where no damage

will be caused during removal and installation of timing

chain cover.

Page 511 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-30 ENGINE MECHANICAL (M13 ENGINE)

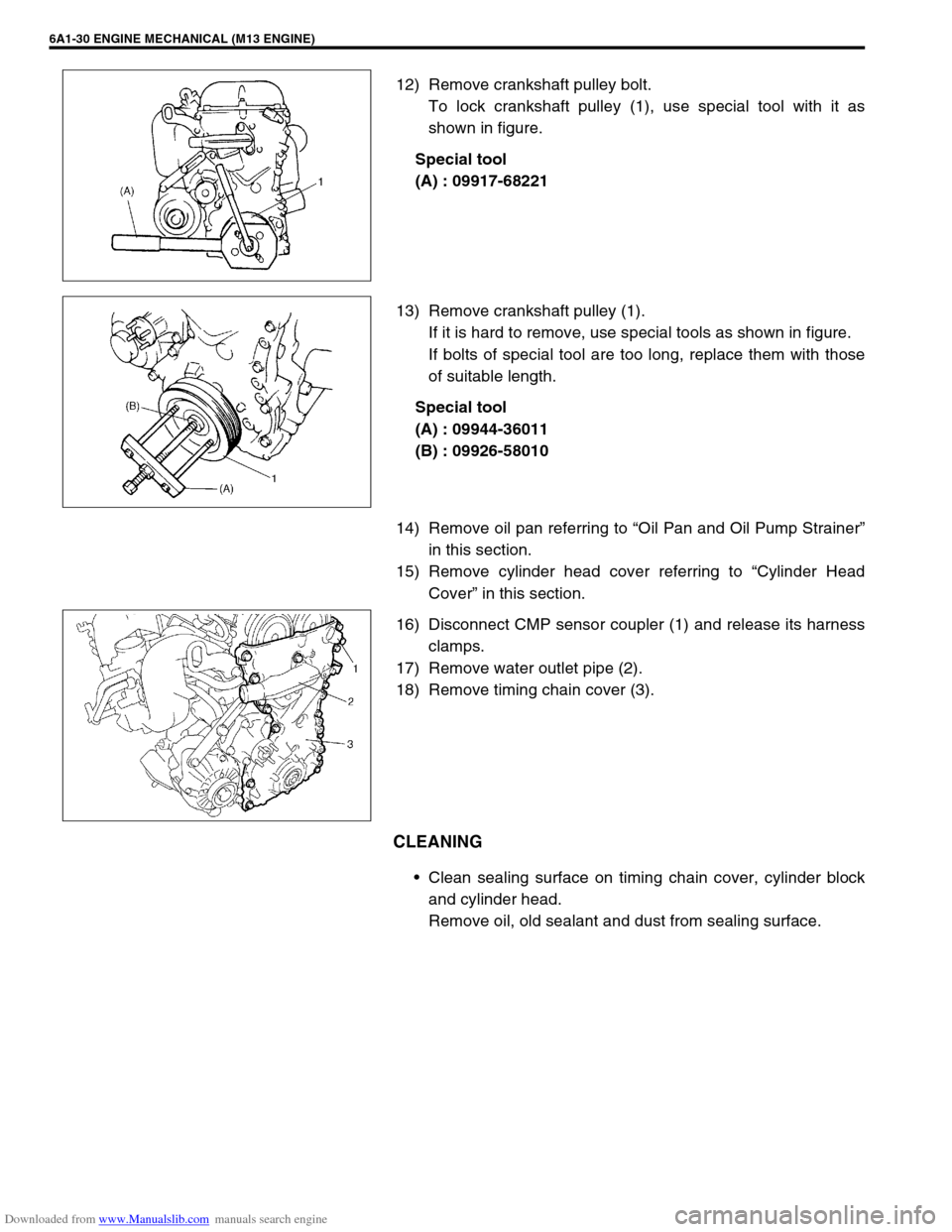

12) Remove crankshaft pulley bolt.

To lock crankshaft pulley (1), use special tool with it as

shown in figure.

Special tool

(A) : 09917-68221

13) Remove crankshaft pulley (1).

If it is hard to remove, use special tools as shown in figure.

If bolts of special tool are too long, replace them with those

of suitable length.

Special tool

(A) : 09944-36011

(B) : 09926-58010

14) Remove oil pan referring to “Oil Pan and Oil Pump Strainer”

in this section.

15) Remove cylinder head cover referring to “Cylinder Head

Cover” in this section.

16) Disconnect CMP sensor coupler (1) and release its harness

clamps.

17) Remove water outlet pipe (2).

18) Remove timing chain cover (3).

CLEANING

Clean sealing surface on timing chain cover, cylinder block

and cylinder head.

Remove oil, old sealant and dust from sealing surface.

Page 513 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-32 ENGINE MECHANICAL (M13 ENGINE)

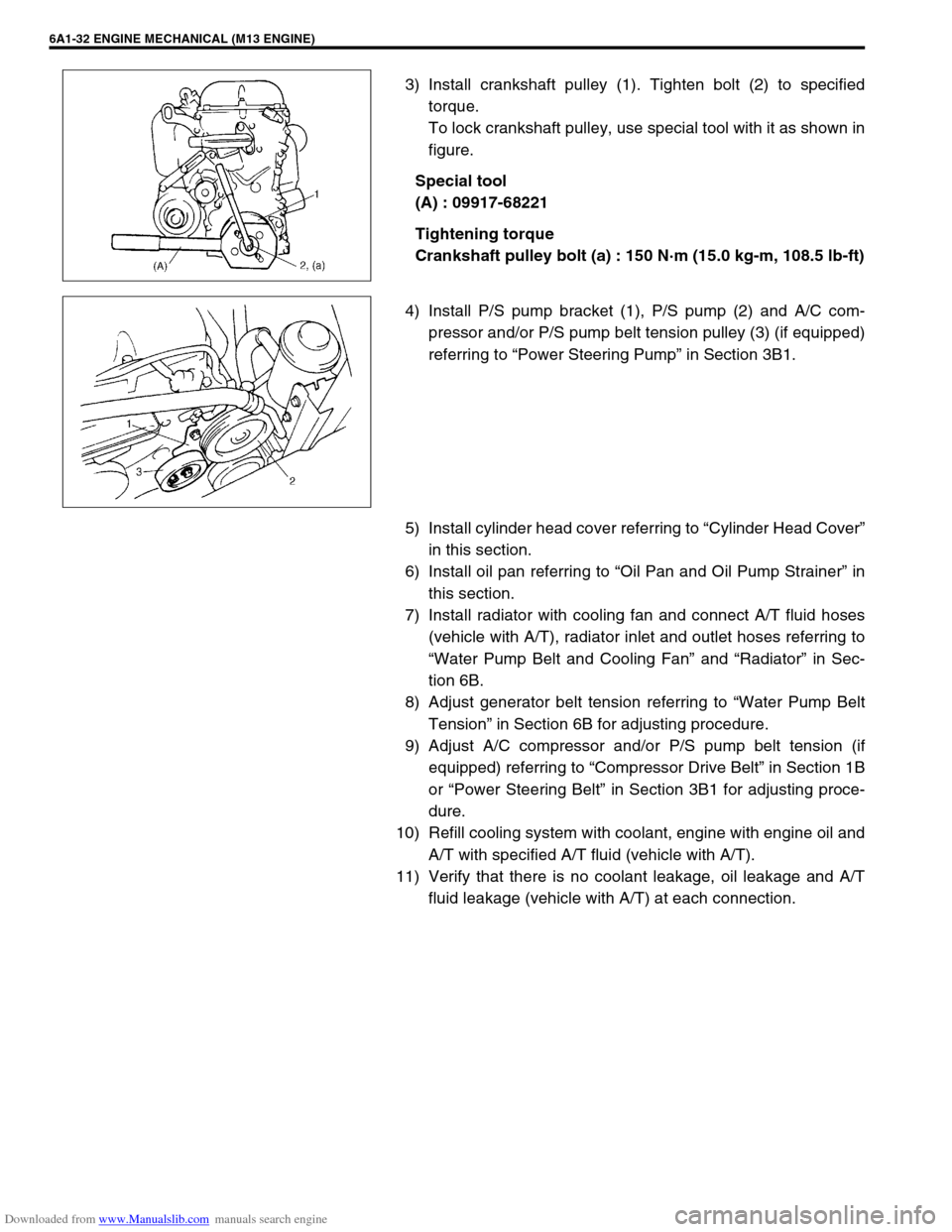

3) Install crankshaft pulley (1). Tighten bolt (2) to specified

torque.

To lock crankshaft pulley, use special tool with it as shown in

figure.

Special tool

(A) : 09917-68221

Tightening torque

Crankshaft pulley bolt (a) : 150 N·m (15.0 kg-m, 108.5 lb-ft)

4) Install P/S pump bracket (1), P/S pump (2) and A/C com-

pressor and/or P/S pump belt tension pulley (3) (if equipped)

referring to “Power Steering Pump” in Section 3B1.

5) Install cylinder head cover referring to “Cylinder Head Cover”

in this section.

6) Install oil pan referring to “Oil Pan and Oil Pump Strainer” in

this section.

7) Install radiator with cooling fan and connect A/T fluid hoses

(vehicle with A/T), radiator inlet and outlet hoses referring to

“Water Pump Belt and Cooling Fan” and “Radiator” in Sec-

tion 6B.

8) Adjust generator belt tension referring to “Water Pump Belt

Tension” in Section 6B for adjusting procedure.

9) Adjust A/C compressor and/or P/S pump belt tension (if

equipped) referring to “Compressor Drive Belt” in Section 1B

or “Power Steering Belt” in Section 3B1 for adjusting proce-

dure.

10) Refill cooling system with coolant, engine with engine oil and

A/T with specified A/T fluid (vehicle with A/T).

11) Verify that there is no coolant leakage, oil leakage and A/T

fluid leakage (vehicle with A/T) at each connection.

Page 514 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-33

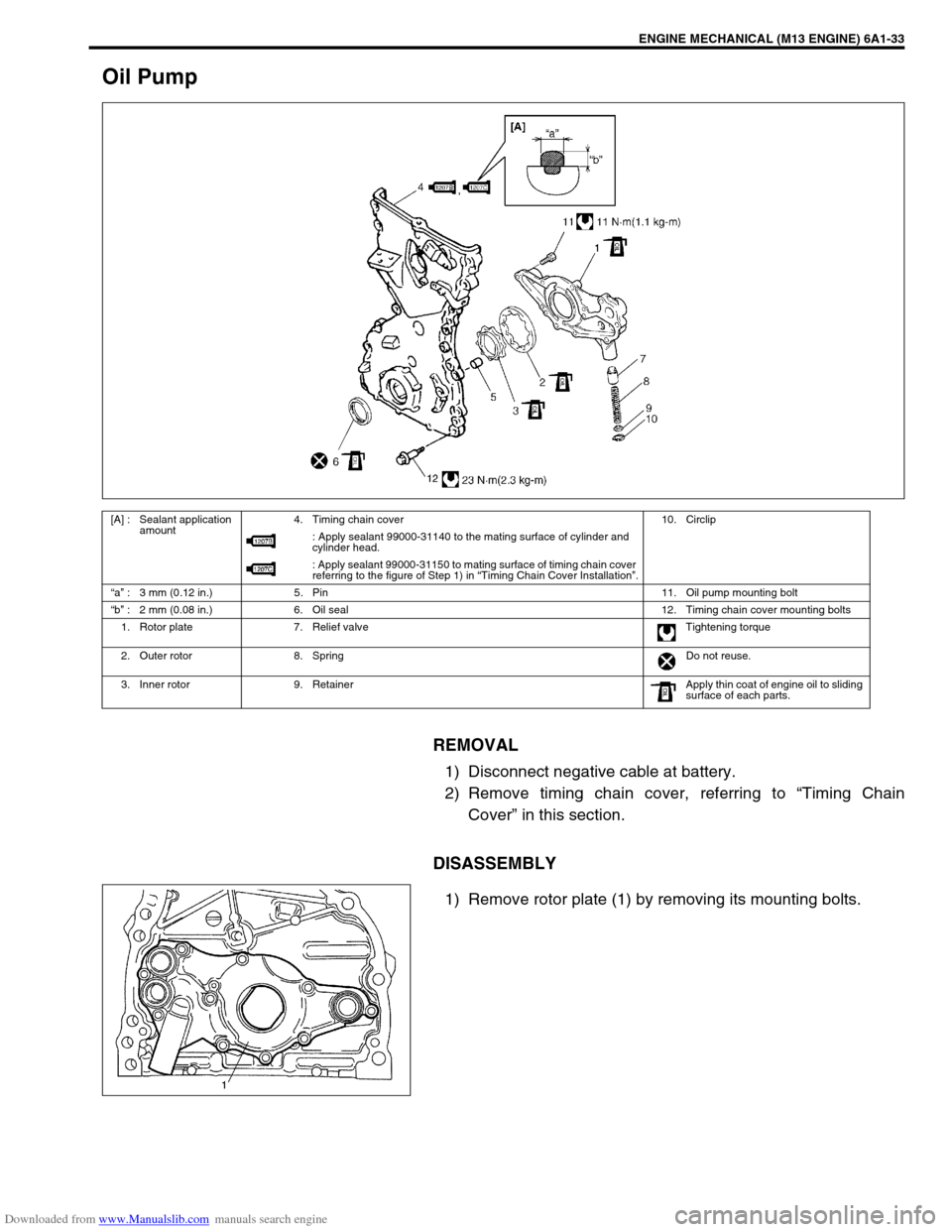

Oil Pump

REMOVAL

1) Disconnect negative cable at battery.

2) Remove timing chain cover, referring to “Timing Chain

Cover” in this section.

DISASSEMBLY

1) Remove rotor plate (1) by removing its mounting bolts.

[A] : Sealant application

amount4. Timing chain cover 10. Circlip

: Apply sealant 99000-31140 to the mating surface of cylinder and

cylinder head.

: Apply sealant 99000-31150 to mating surface of timing chain cover

referring to the figure of Step 1) in “Timing Chain Cover Installation”.

“a” : 3 mm (0.12 in.) 5. Pin 11. Oil pump mounting bolt

“b” : 2 mm (0.08 in.) 6. Oil seal 12. Timing chain cover mounting bolts

1. Rotor plate 7. Relief valve Tightening torque

2. Outer rotor 8. Spring Do not reuse.

3. Inner rotor 9. Retainer Apply thin coat of engine oil to sliding

surface of each parts.

Page 517 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-36 ENGINE MECHANICAL (M13 ENGINE)

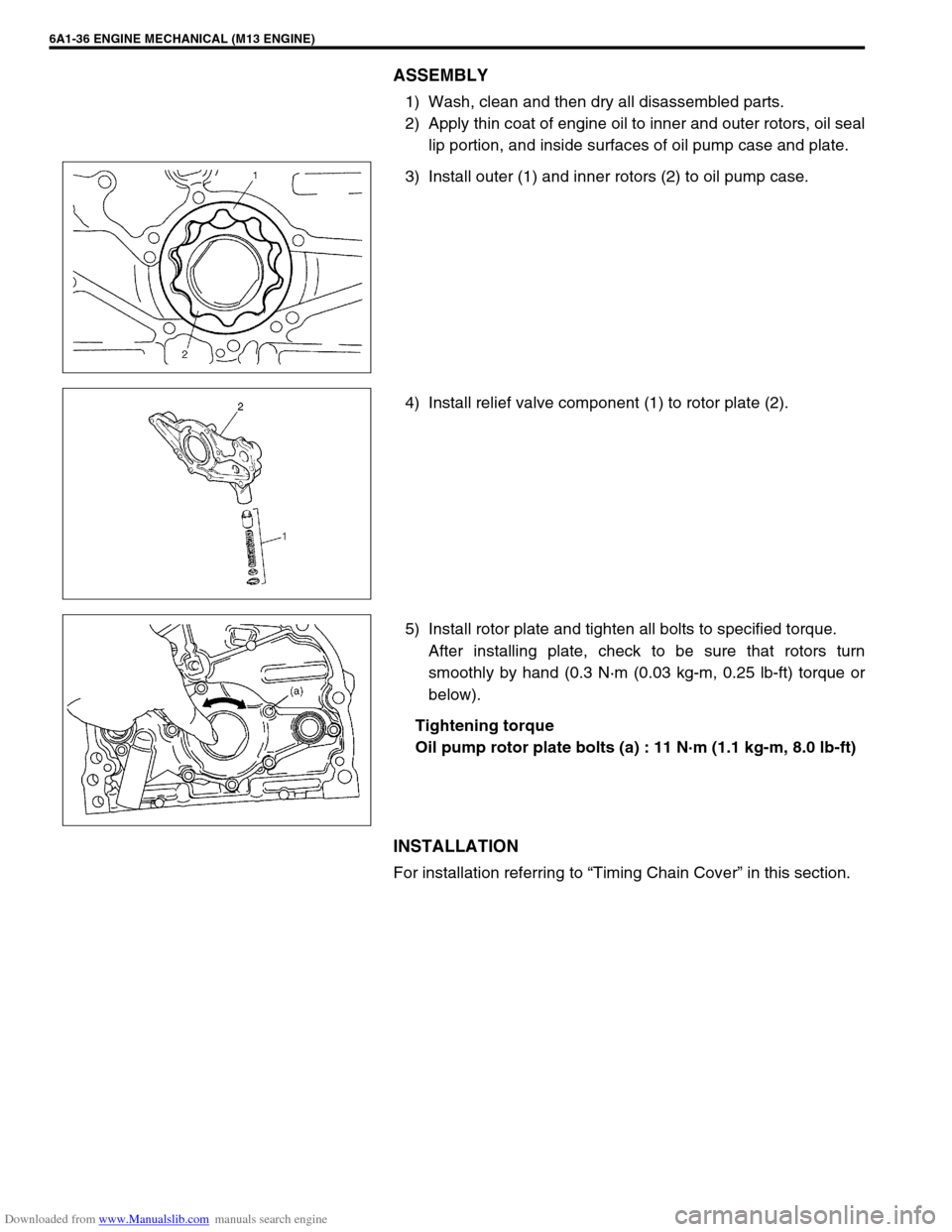

ASSEMBLY

1) Wash, clean and then dry all disassembled parts.

2) Apply thin coat of engine oil to inner and outer rotors, oil seal

lip portion, and inside surfaces of oil pump case and plate.

3) Install outer (1) and inner rotors (2) to oil pump case.

4) Install relief valve component (1) to rotor plate (2).

5) Install rotor plate and tighten all bolts to specified torque.

After installing plate, check to be sure that rotors turn

smoothly by hand (0.3 N·m (0.03 kg-m, 0.25 lb-ft) torque or

below).

Tightening torque

Oil pump rotor plate bolts (a) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

INSTALLATION

For installation referring to “Timing Chain Cover” in this section.

Page 518 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-37

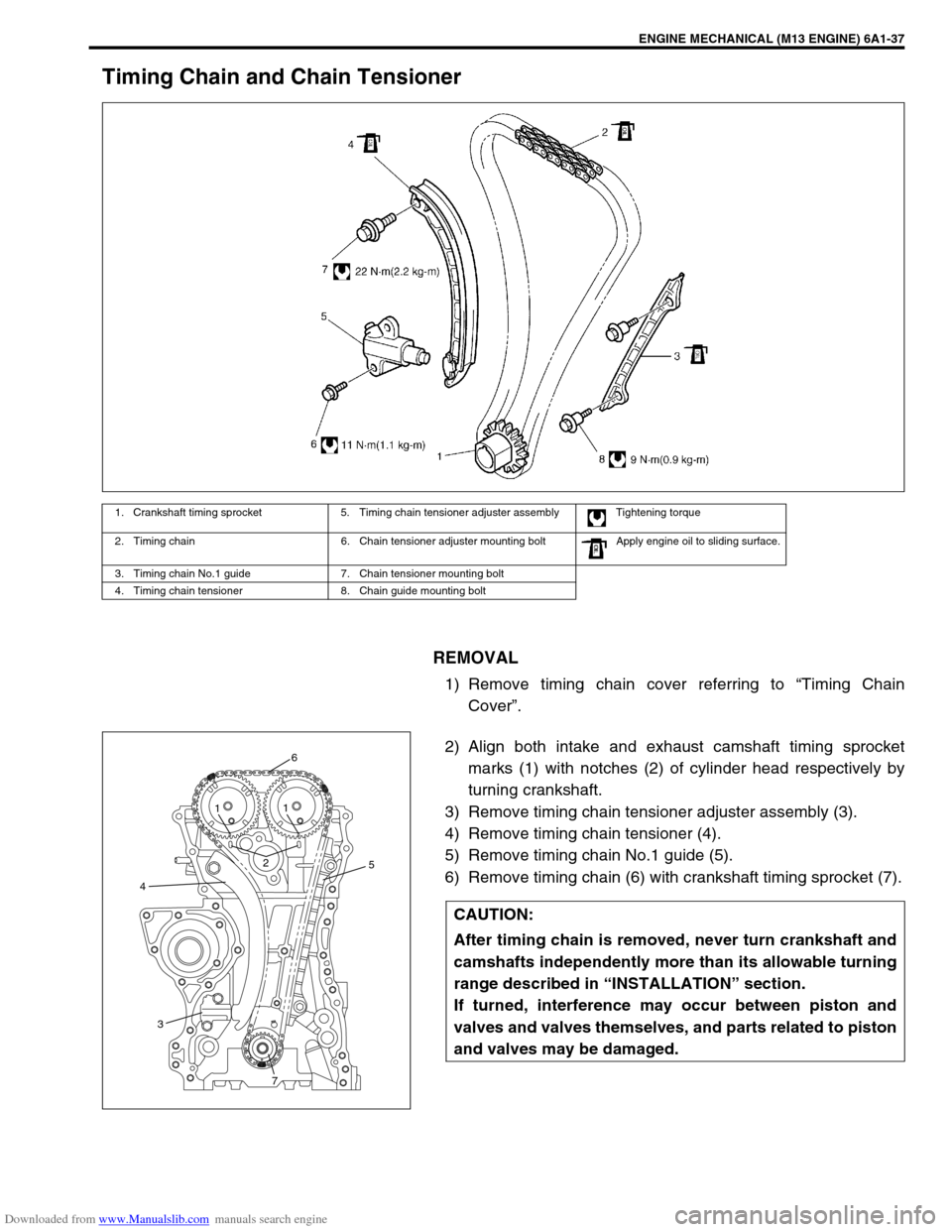

Timing Chain and Chain Tensioner

REMOVAL

1) Remove timing chain cover referring to “Timing Chain

Cover”.

2) Align both intake and exhaust camshaft timing sprocket

marks (1) with notches (2) of cylinder head respectively by

turning crankshaft.

3) Remove timing chain tensioner adjuster assembly (3).

4) Remove timing chain tensioner (4).

5) Remove timing chain No.1 guide (5).

6) Remove timing chain (6) with crankshaft timing sprocket (7).

1. Crankshaft timing sprocket 5. Timing chain tensioner adjuster assembly Tightening torque

2. Timing chain 6. Chain tensioner adjuster mounting bolt Apply engine oil to sliding surface.

3. Timing chain No.1 guide 7. Chain tensioner mounting bolt

4. Timing chain tensioner 8. Chain guide mounting bolt

CAUTION:

After timing chain is removed, never turn crankshaft and

camshafts independently more than its allowable turning

range described in “INSTALLATION” section.

If turned, interference may occur between piston and

valves and valves themselves, and parts related to piston

and valves may be damaged.

45

6

21

1

3

7

Page 522 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-41

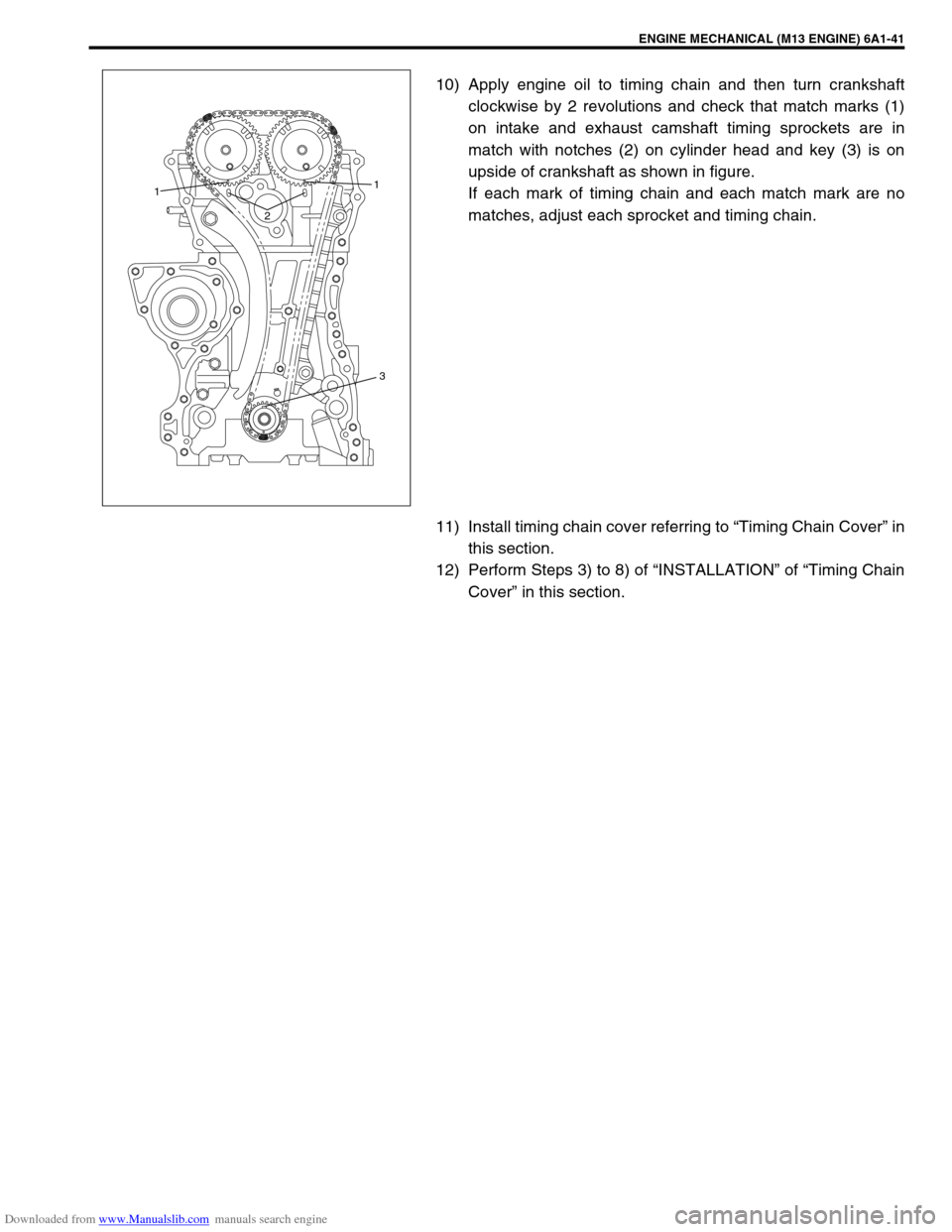

10) Apply engine oil to timing chain and then turn crankshaft

clockwise by 2 revolutions and check that match marks (1)

on intake and exhaust camshaft timing sprockets are in

match with notches (2) on cylinder head and key (3) is on

upside of crankshaft as shown in figure.

If each mark of timing chain and each match mark are no

matches, adjust each sprocket and timing chain.

11) Install timing chain cover referring to “Timing Chain Cover” in

this section.

12) Perform Steps 3) to 8) of “INSTALLATION” of “Timing Chain

Cover” in this section.

21

1

3

Page 523 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-42 ENGINE MECHANICAL (M13 ENGINE)

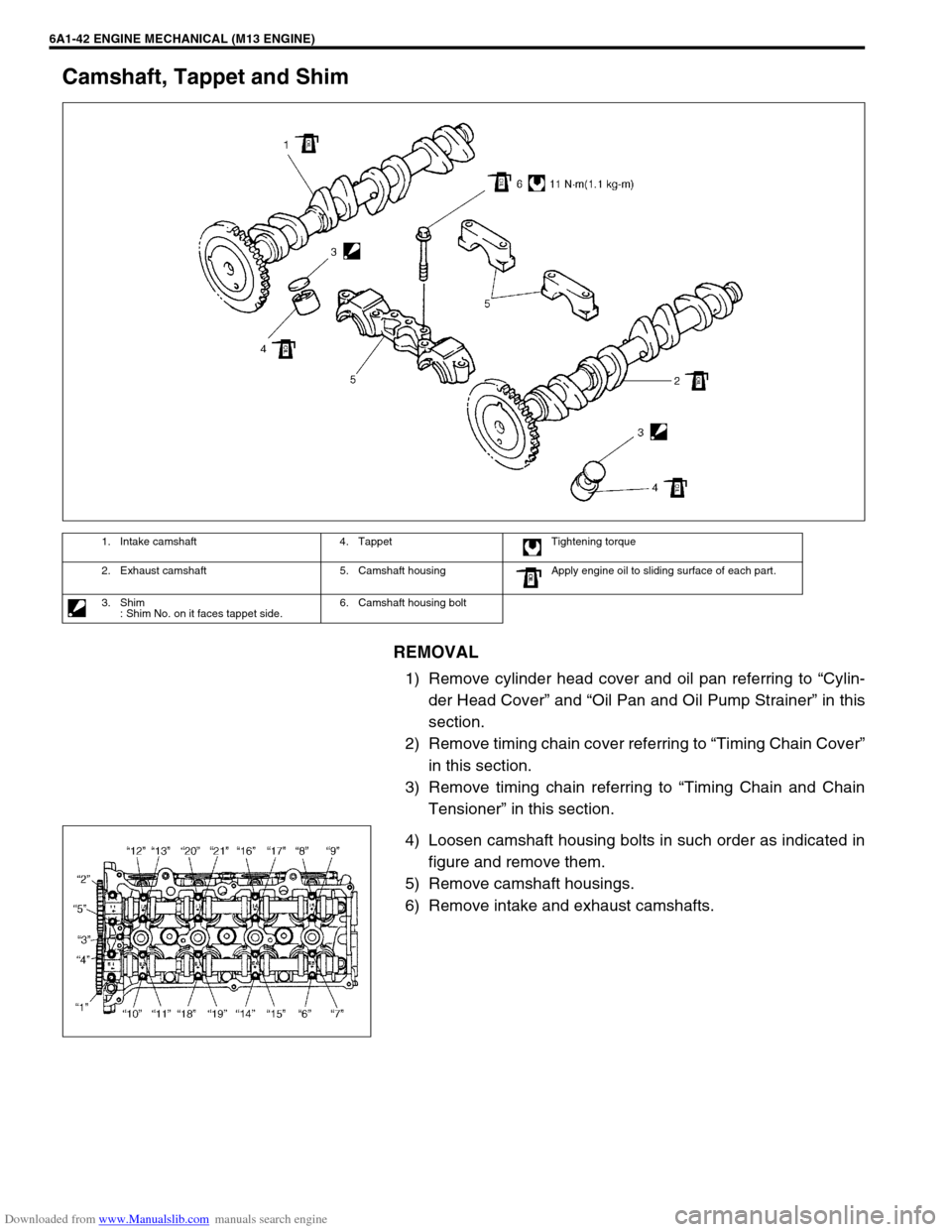

Camshaft, Tappet and Shim

REMOVAL

1) Remove cylinder head cover and oil pan referring to “Cylin-

der Head Cover” and “Oil Pan and Oil Pump Strainer” in this

section.

2) Remove timing chain cover referring to “Timing Chain Cover”

in this section.

3) Remove timing chain referring to “Timing Chain and Chain

Tensioner” in this section.

4) Loosen camshaft housing bolts in such order as indicated in

figure and remove them.

5) Remove camshaft housings.

6) Remove intake and exhaust camshafts.

1. Intake camshaft 4. Tappet Tightening torque

2. Exhaust camshaft 5. Camshaft housing Apply engine oil to sliding surface of each part.

3. Shim

: Shim No. on it faces tappet side.6. Camshaft housing bolt

Page 528 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-47

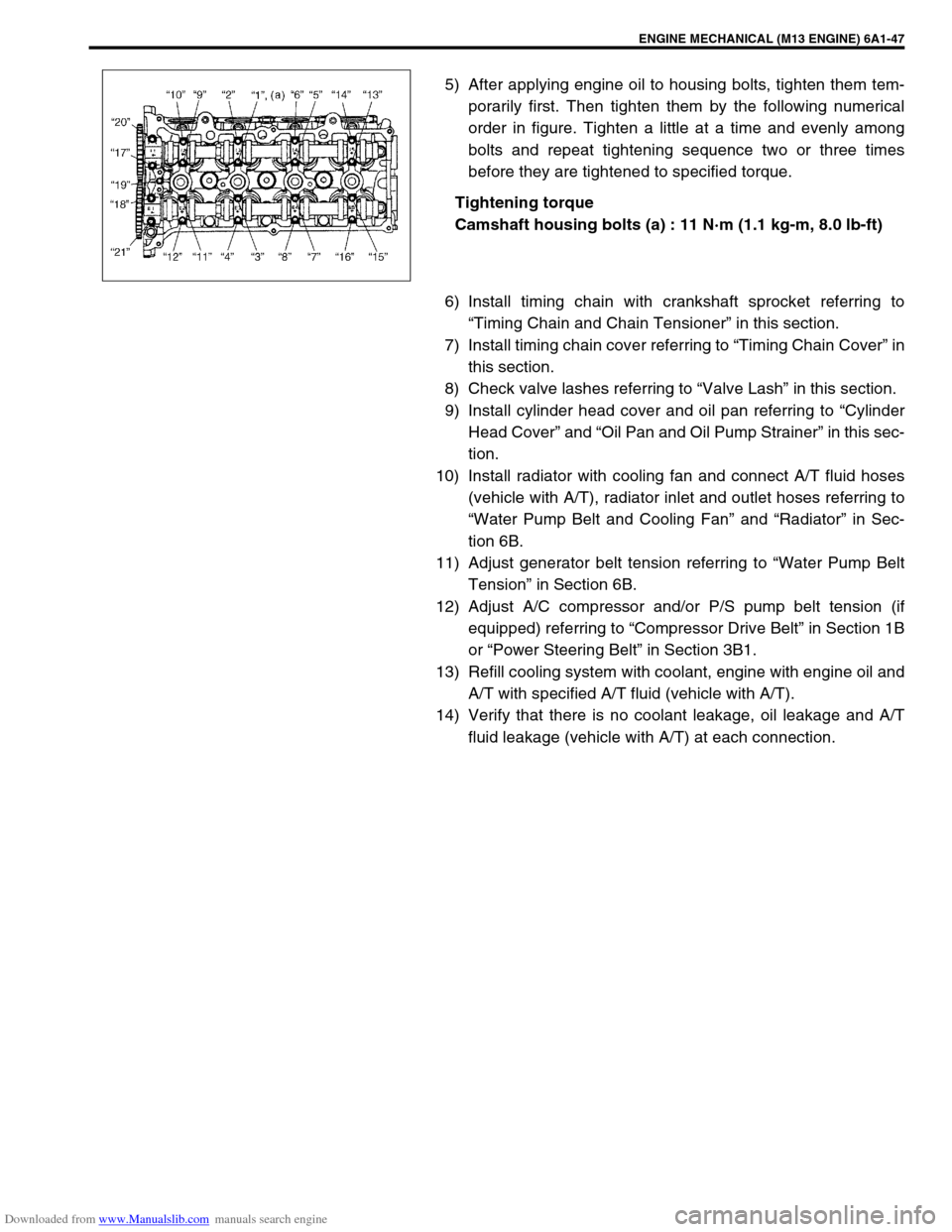

5) After applying engine oil to housing bolts, tighten them tem-

porarily first. Then tighten them by the following numerical

order in figure. Tighten a little at a time and evenly among

bolts and repeat tightening sequence two or three times

before they are tightened to specified torque.

Tightening torque

Camshaft housing bolts (a) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

6) Install timing chain with crankshaft sprocket referring to

“Timing Chain and Chain Tensioner” in this section.

7) Install timing chain cover referring to “Timing Chain Cover” in

this section.

8) Check valve lashes referring to “Valve Lash” in this section.

9) Install cylinder head cover and oil pan referring to “Cylinder

Head Cover” and “Oil Pan and Oil Pump Strainer” in this sec-

tion.

10) Install radiator with cooling fan and connect A/T fluid hoses

(vehicle with A/T), radiator inlet and outlet hoses referring to

“Water Pump Belt and Cooling Fan” and “Radiator” in Sec-

tion 6B.

11) Adjust generator belt tension referring to “Water Pump Belt

Tension” in Section 6B.

12) Adjust A/C compressor and/or P/S pump belt tension (if

equipped) referring to “Compressor Drive Belt” in Section 1B

or “Power Steering Belt” in Section 3B1.

13) Refill cooling system with coolant, engine with engine oil and

A/T with specified A/T fluid (vehicle with A/T).

14) Verify that there is no coolant leakage, oil leakage and A/T

fluid leakage (vehicle with A/T) at each connection.

Page 530 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-49

REMOVAL

1) Relieve fuel pressure referring to “Fuel Pressure Relief Pro-

cedure” in Section 6.

2) Disconnect negative cable at battery.

3) Drain engine oil.

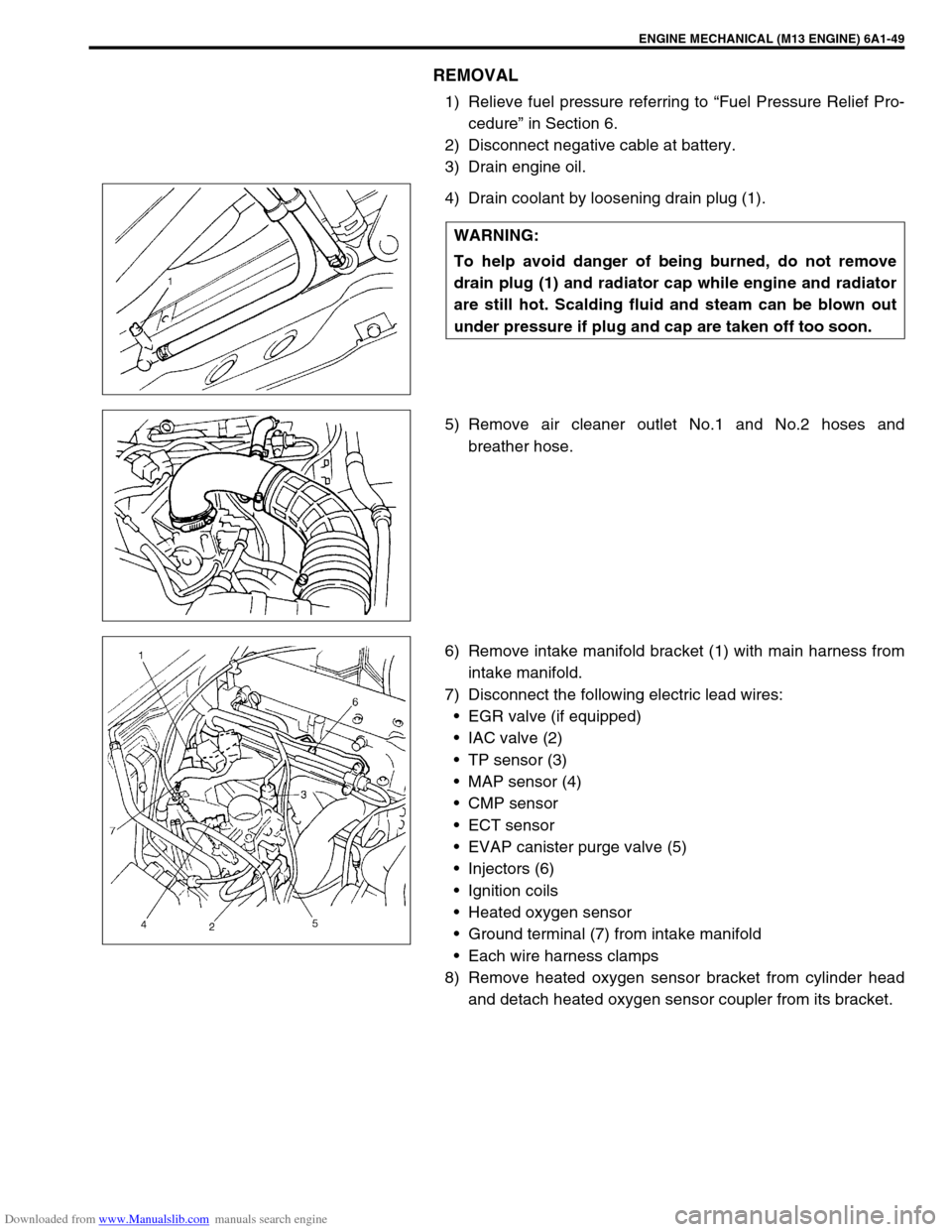

4) Drain coolant by loosening drain plug (1).

5) Remove air cleaner outlet No.1 and No.2 hoses and

breather hose.

6) Remove intake manifold bracket (1) with main harness from

intake manifold.

7) Disconnect the following electric lead wires:

EGR valve (if equipped)

IAC valve (2)

TP sensor (3)

MAP sensor (4)

CMP sensor

ECT sensor

EVAP canister purge valve (5)

Injectors (6)

Ignition coils

Heated oxygen sensor

Ground terminal (7) from intake manifold

Each wire harness clamps

8) Remove heated oxygen sensor bracket from cylinder head

and detach heated oxygen sensor coupler from its bracket. WARNING:

To help avoid danger of being burned, do not remove

drain plug (1) and radiator cap while engine and radiator

are still hot. Scalding fluid and steam can be blown out

under pressure if plug and cap are taken off too soon.