Section 8 SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 531 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-50 ENGINE MECHANICAL (M13 ENGINE)

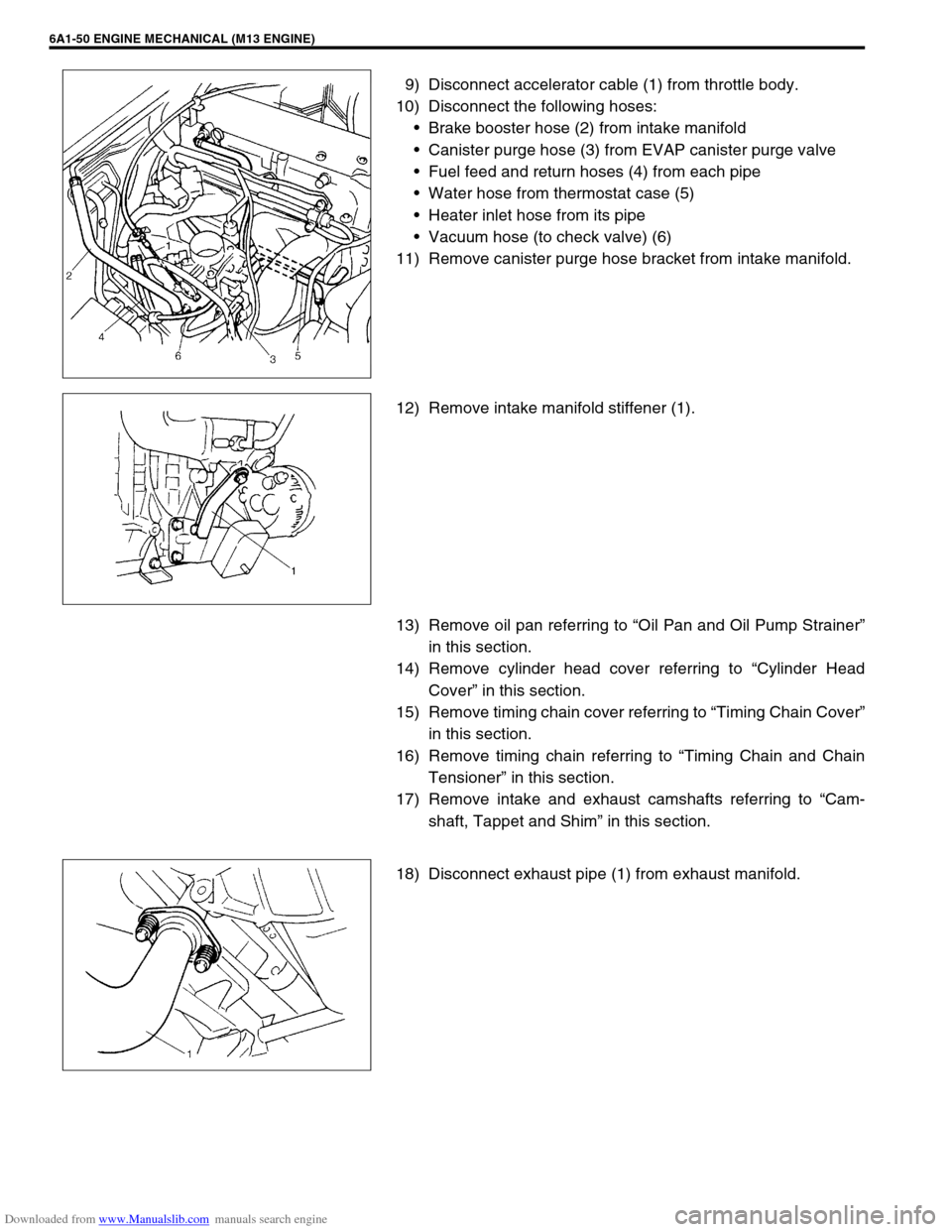

9) Disconnect accelerator cable (1) from throttle body.

10) Disconnect the following hoses:

Brake booster hose (2) from intake manifold

Canister purge hose (3) from EVAP canister purge valve

Fuel feed and return hoses (4) from each pipe

Water hose from thermostat case (5)

Heater inlet hose from its pipe

Vacuum hose (to check valve) (6)

11) Remove canister purge hose bracket from intake manifold.

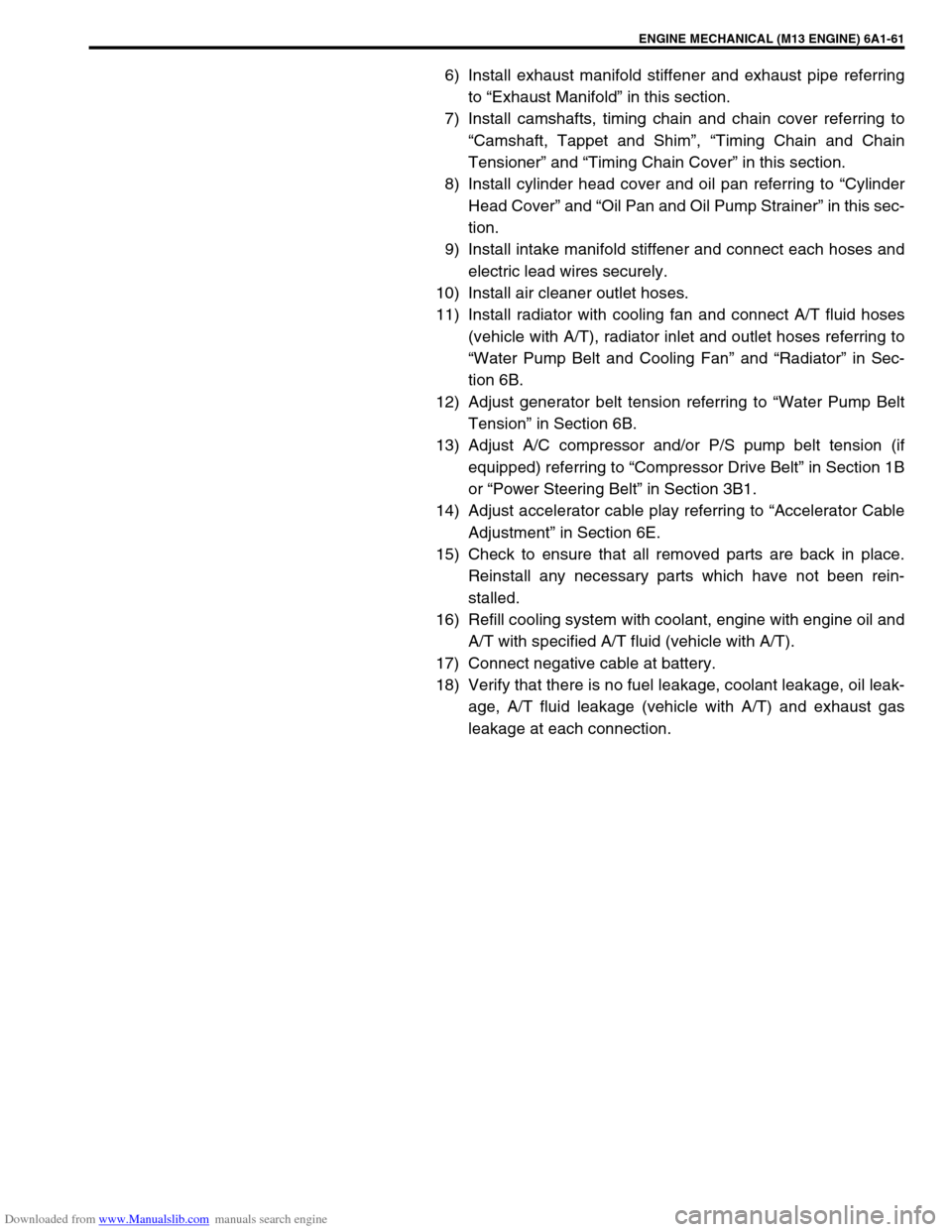

12) Remove intake manifold stiffener (1).

13) Remove oil pan referring to “Oil Pan and Oil Pump Strainer”

in this section.

14) Remove cylinder head cover referring to “Cylinder Head

Cover” in this section.

15) Remove timing chain cover referring to “Timing Chain Cover”

in this section.

16) Remove timing chain referring to “Timing Chain and Chain

Tensioner” in this section.

17) Remove intake and exhaust camshafts referring to “Cam-

shaft, Tappet and Shim” in this section.

18) Disconnect exhaust pipe (1) from exhaust manifold.

Page 542 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-61

6) Install exhaust manifold stiffener and exhaust pipe referring

to “Exhaust Manifold” in this section.

7) Install camshafts, timing chain and chain cover referring to

“Camshaft, Tappet and Shim”, “Timing Chain and Chain

Tensioner” and “Timing Chain Cover” in this section.

8) Install cylinder head cover and oil pan referring to “Cylinder

Head Cover” and “Oil Pan and Oil Pump Strainer” in this sec-

tion.

9) Install intake manifold stiffener and connect each hoses and

electric lead wires securely.

10) Install air cleaner outlet hoses.

11) Install radiator with cooling fan and connect A/T fluid hoses

(vehicle with A/T), radiator inlet and outlet hoses referring to

“Water Pump Belt and Cooling Fan” and “Radiator” in Sec-

tion 6B.

12) Adjust generator belt tension referring to “Water Pump Belt

Tension” in Section 6B.

13) Adjust A/C compressor and/or P/S pump belt tension (if

equipped) referring to “Compressor Drive Belt” in Section 1B

or “Power Steering Belt” in Section 3B1.

14) Adjust accelerator cable play referring to “Accelerator Cable

Adjustment” in Section 6E.

15) Check to ensure that all removed parts are back in place.

Reinstall any necessary parts which have not been rein-

stalled.

16) Refill cooling system with coolant, engine with engine oil and

A/T with specified A/T fluid (vehicle with A/T).

17) Connect negative cable at battery.

18) Verify that there is no fuel leakage, coolant leakage, oil leak-

age, A/T fluid leakage (vehicle with A/T) and exhaust gas

leakage at each connection.

Page 543 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-62 ENGINE MECHANICAL (M13 ENGINE)

Pistons, Piston Rings, Connecting Rods and Cylinders

REMOVAL

1) Relieve fuel pressure referring to “Fuel Pressure Relief Pro-

cedure” in Section 6.

2) Disconnect negative cable at battery.

3) Drain engine oil.

4) Drain coolant.

5) Remove cylinder head referring to “Valves and Cylinder

Head” in this section.

6) Mark cylinder number on all pistons, connecting rods and

connecting rod caps using silver pencil or quick drying paint.

7) Remove rod bearing caps.

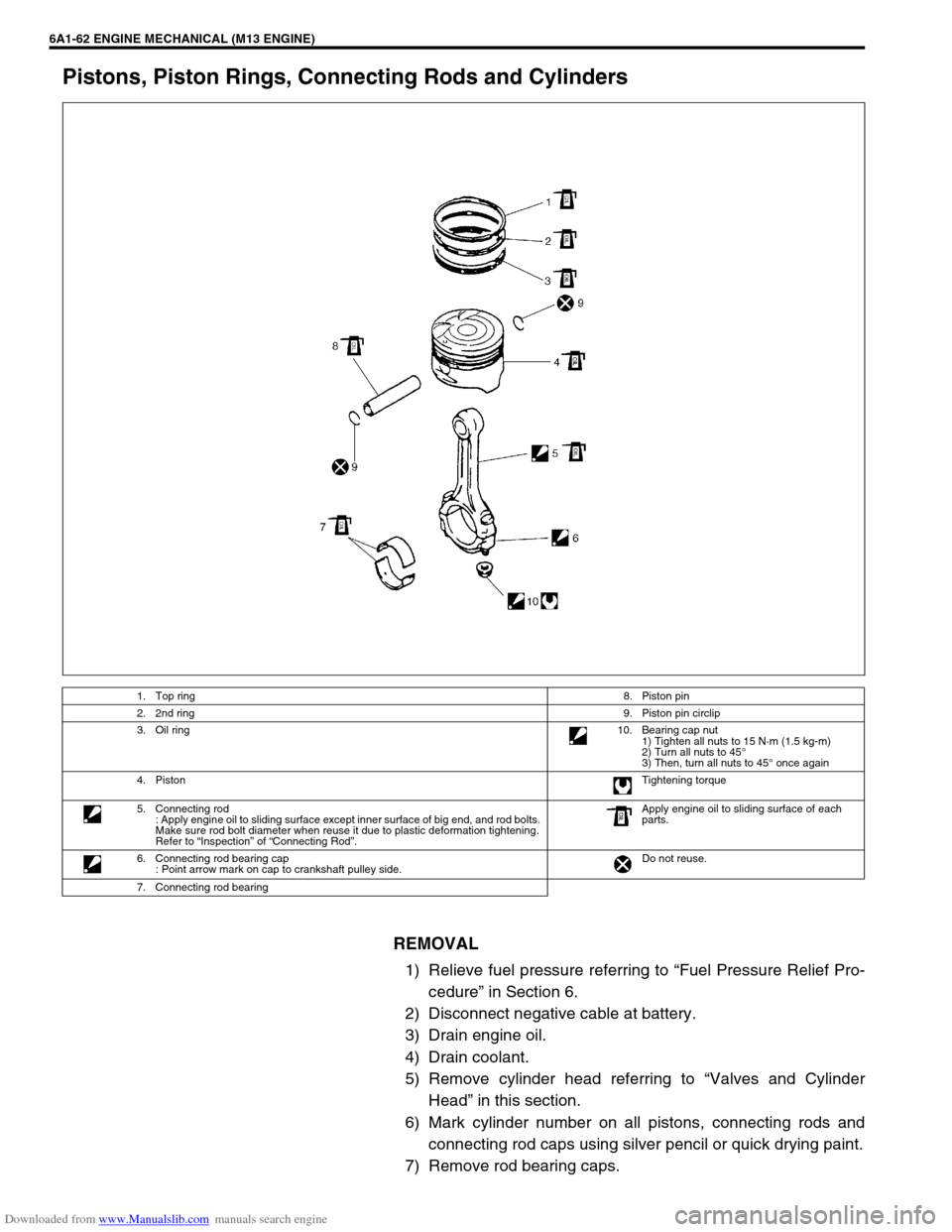

1. Top ring8. Piston pin

2. 2nd ring9. Piston pin circlip

3. Oil ring10. Bearing cap nut

1) Tighten all nuts to 15 N·m (1.5 kg-m)

2) Turn all nuts to 45°

3) Then, turn all nuts to 45° once again

4. PistonTightening torque

5. Connecting rod

: Apply engine oil to sliding surface except inner surface of big end, and rod bolts.

Make sure rod bolt diameter when reuse it due to plastic deformation tightening.

Refer to “Inspection” of “Connecting Rod”.Apply engine oil to sliding surface of each

parts.

6. Connecting rod bearing cap

: Point arrow mark on cap to crankshaft pulley side.Do not reuse.

7. Connecting rod bearing

Page 552 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-71

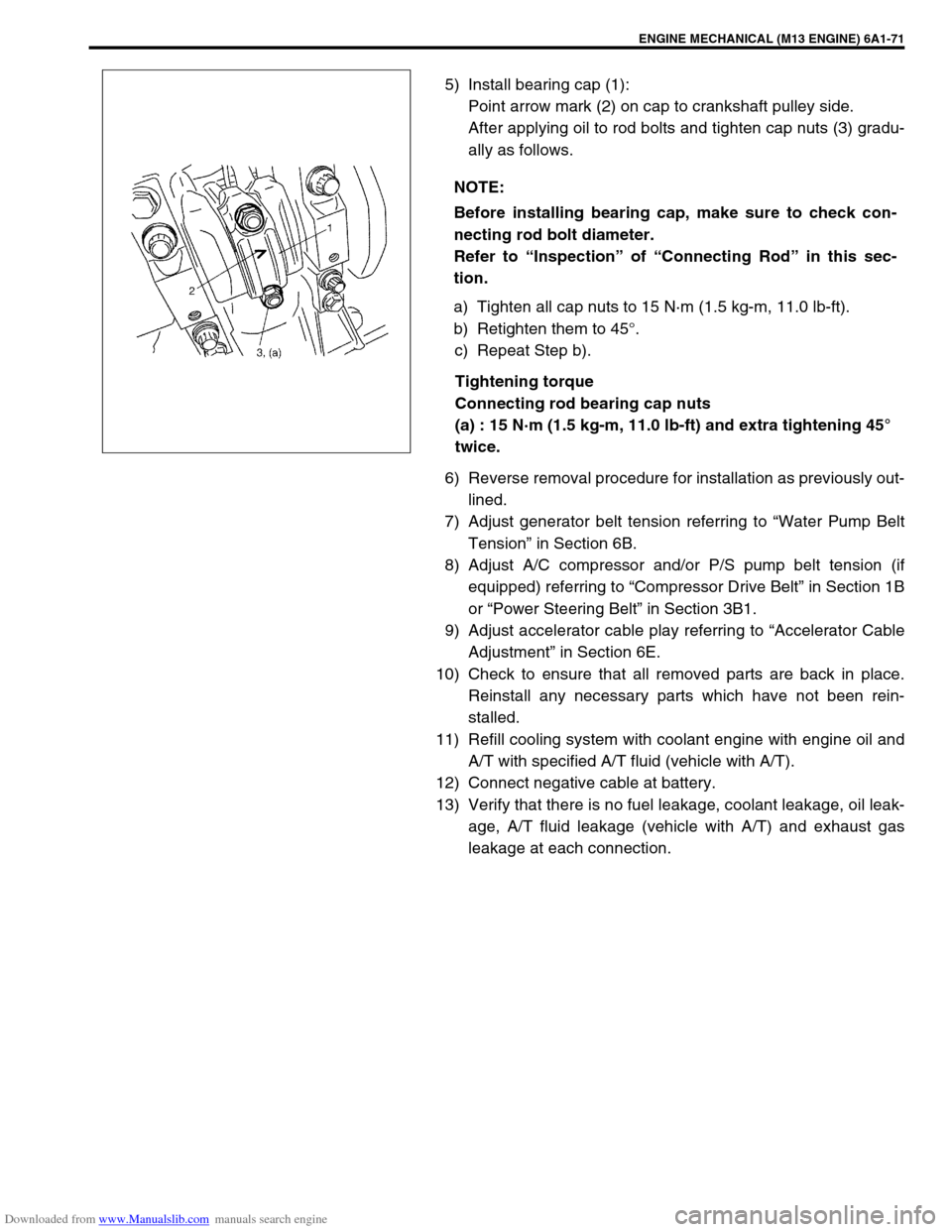

5) Install bearing cap (1):

Point arrow mark (2) on cap to crankshaft pulley side.

After applying oil to rod bolts and tighten cap nuts (3) gradu-

ally as follows.

a) Tighten all cap nuts to 15 N·m (1.5 kg-m, 11.0 lb-ft).

b) Retighten them to 45°.

c) Repeat Step b).

Tightening torque

Connecting rod bearing cap nuts

(a) : 15 N·m (1.5 kg-m, 11.0 lb-ft) and extra tightening 45°

twice.

6) Reverse removal procedure for installation as previously out-

lined.

7) Adjust generator belt tension referring to “Water Pump Belt

Tension” in Section 6B.

8) Adjust A/C compressor and/or P/S pump belt tension (if

equipped) referring to “Compressor Drive Belt” in Section 1B

or “Power Steering Belt” in Section 3B1.

9) Adjust accelerator cable play referring to “Accelerator Cable

Adjustment” in Section 6E.

10) Check to ensure that all removed parts are back in place.

Reinstall any necessary parts which have not been rein-

stalled.

11) Refill cooling system with coolant engine with engine oil and

A/T with specified A/T fluid (vehicle with A/T).

12) Connect negative cable at battery.

13) Verify that there is no fuel leakage, coolant leakage, oil leak-

age, A/T fluid leakage (vehicle with A/T) and exhaust gas

leakage at each connection. NOTE:

Before installing bearing cap, make sure to check con-

necting rod bolt diameter.

Refer to “Inspection” of “Connecting Rod” in this sec-

tion.

Page 554 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-73

Unit Repair Overhaul

Engine Assembly

REMOVAL

1) Relieve fuel pressure referring to “Fuel Pressure Relief Pro-

cedure” in Section 6.

2) Disconnect negative cable at battery.

3) Remove engine hood after disconnecting windshield washer

hose.

4) Remove A/C compressor and/or P/S pump belt (if

equipped).

5) Remove generator belt.

6) Drain engine oil.

7) Drain coolant.

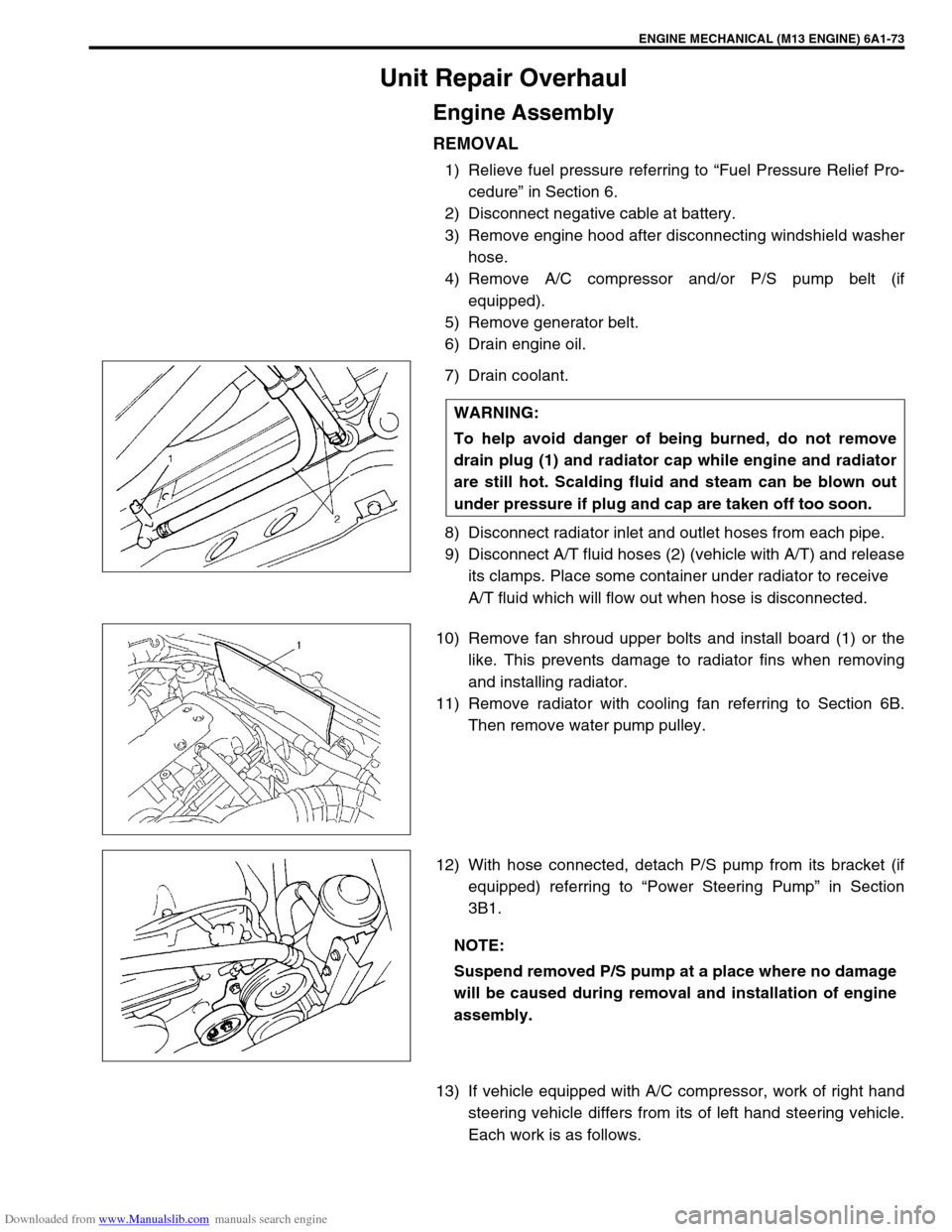

8) Disconnect radiator inlet and outlet hoses from each pipe.

9) Disconnect A/T fluid hoses (2) (vehicle with A/T) and release

its clamps. Place some container under radiator to receive

A/T fluid which will flow out when hose is disconnected.

10) Remove fan shroud upper bolts and install board (1) or the

like. This prevents damage to radiator fins when removing

and installing radiator.

11) Remove radiator with cooling fan referring to Section 6B.

Then remove water pump pulley.

12) With hose connected, detach P/S pump from its bracket (if

equipped) referring to “Power Steering Pump” in Section

3B1.

13) If vehicle equipped with A/C compressor, work of right hand

steering vehicle differs from its of left hand steering vehicle.

Each work is as follows. WARNING:

To help avoid danger of being burned, do not remove

drain plug (1) and radiator cap while engine and radiator

are still hot. Scalding fluid and steam can be blown out

under pressure if plug and cap are taken off too soon.

NOTE:

Suspend removed P/S pump at a place where no damage

will be caused during removal and installation of engine

assembly.

Page 555 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-74 ENGINE MECHANICAL (M13 ENGINE)

a) For right hand steering vehicle:

With hose connected, detach A/C compressor from its

bracket.

b) For left hand steering vehicle:

i) Recover refrigerant from refrigeration system using recov-

ery and recycling equipment.

ii) Disconnect magnet clutch lead wire.

iii) Remove suction pipe and disconnect discharge pipe from

A/C compressor.

iv) Remove A/C compressor from its bracket.

When servicing above steps, refer to “Compressor” in Section 1B.

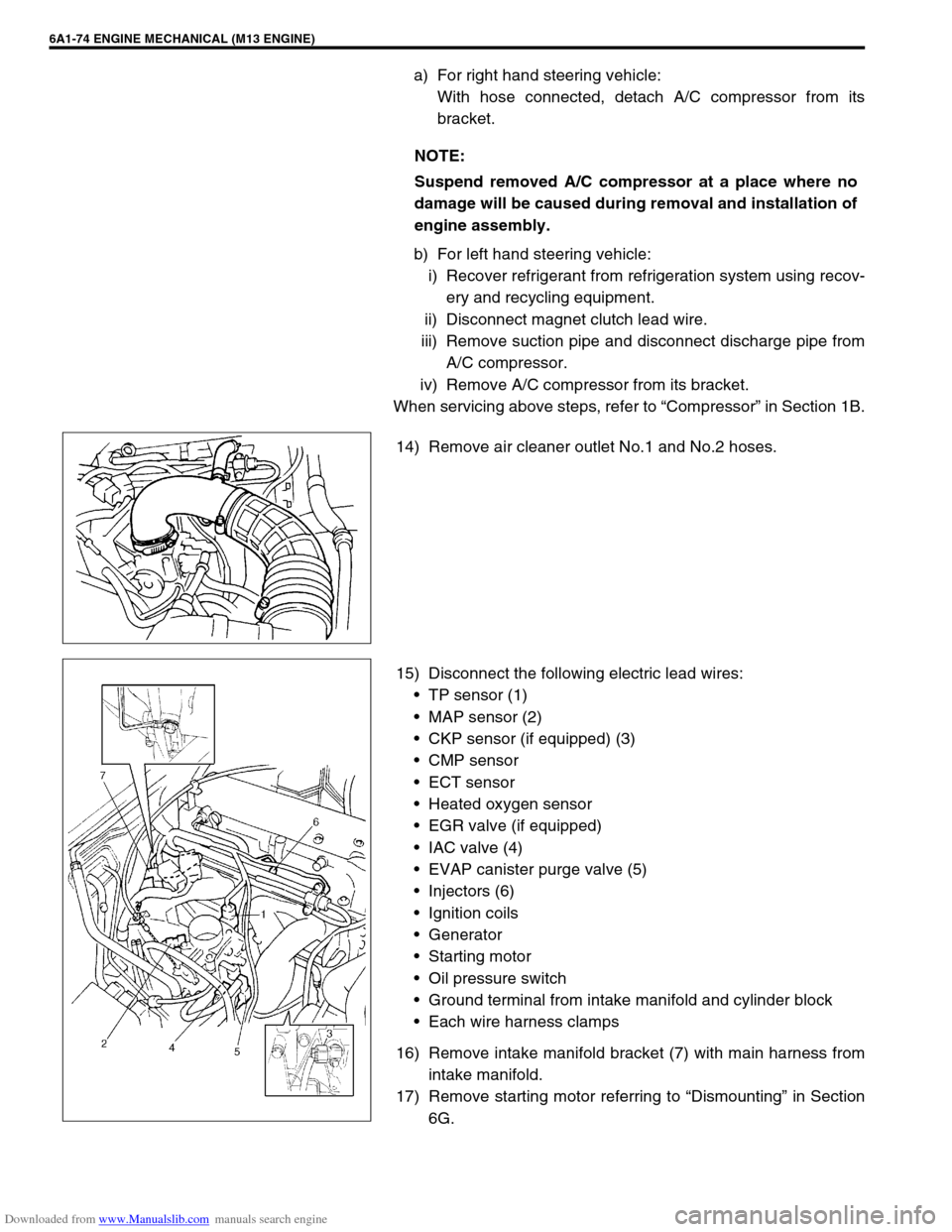

14) Remove air cleaner outlet No.1 and No.2 hoses.

15) Disconnect the following electric lead wires:

TP sensor (1)

MAP sensor (2)

CKP sensor (if equipped) (3)

CMP sensor

ECT sensor

Heated oxygen sensor

EGR valve (if equipped)

IAC valve (4)

EVAP canister purge valve (5)

Injectors (6)

Ignition coils

Generator

Starting motor

Oil pressure switch

Ground terminal from intake manifold and cylinder block

Each wire harness clamps

16) Remove intake manifold bracket (7) with main harness from

intake manifold.

17) Remove starting motor referring to “Dismounting” in Section

6G. NOTE:

Suspend removed A/C compressor at a place where no

damage will be caused during removal and installation of

engine assembly.

Page 559 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-78 ENGINE MECHANICAL (M13 ENGINE)

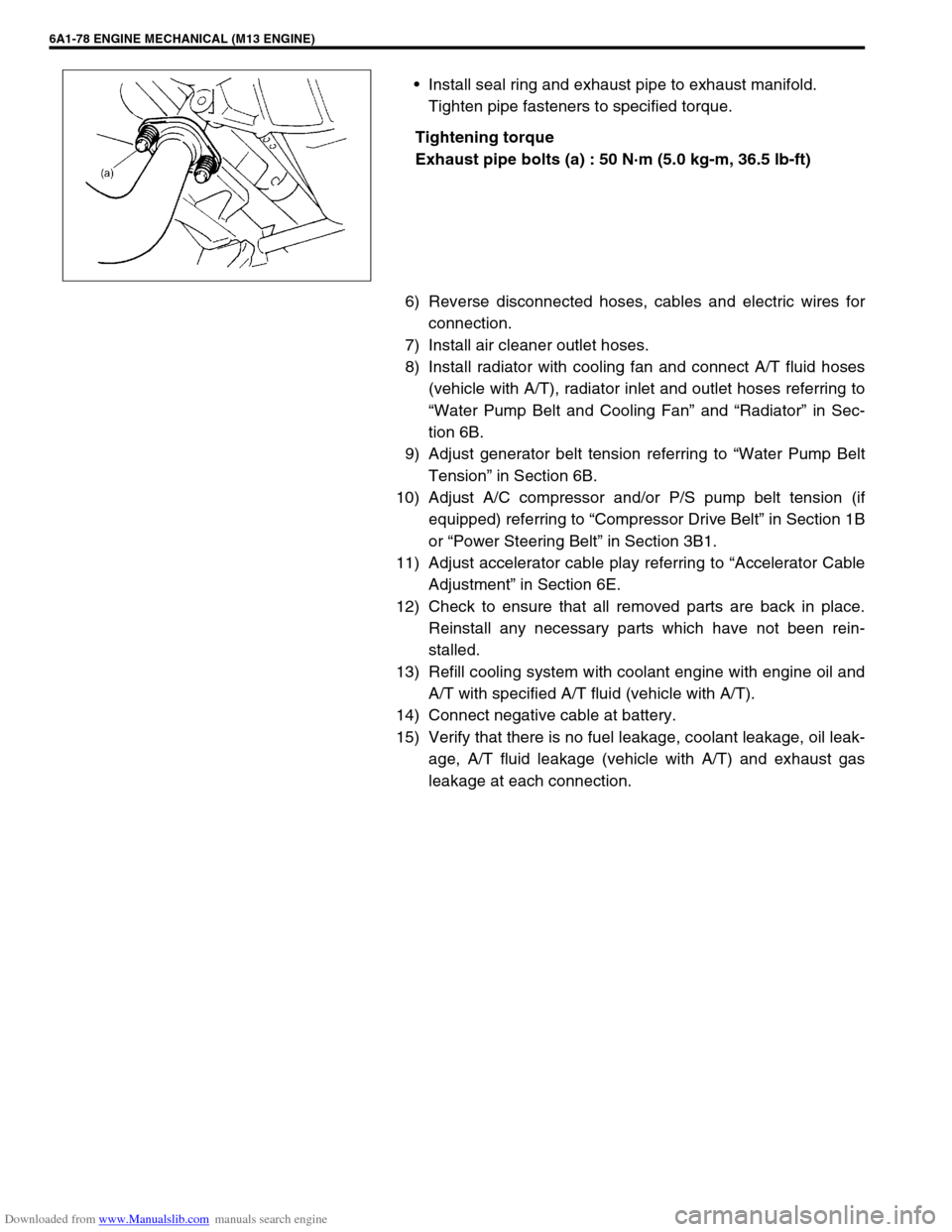

Install seal ring and exhaust pipe to exhaust manifold.

Tighten pipe fasteners to specified torque.

Tightening torque

Exhaust pipe bolts (a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

6) Reverse disconnected hoses, cables and electric wires for

connection.

7) Install air cleaner outlet hoses.

8) Install radiator with cooling fan and connect A/T fluid hoses

(vehicle with A/T), radiator inlet and outlet hoses referring to

“Water Pump Belt and Cooling Fan” and “Radiator” in Sec-

tion 6B.

9) Adjust generator belt tension referring to “Water Pump Belt

Tension” in Section 6B.

10) Adjust A/C compressor and/or P/S pump belt tension (if

equipped) referring to “Compressor Drive Belt” in Section 1B

or “Power Steering Belt” in Section 3B1.

11) Adjust accelerator cable play referring to “Accelerator Cable

Adjustment” in Section 6E.

12) Check to ensure that all removed parts are back in place.

Reinstall any necessary parts which have not been rein-

stalled.

13) Refill cooling system with coolant engine with engine oil and

A/T with specified A/T fluid (vehicle with A/T).

14) Connect negative cable at battery.

15) Verify that there is no fuel leakage, coolant leakage, oil leak-

age, A/T fluid leakage (vehicle with A/T) and exhaust gas

leakage at each connection.

Page 563 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-82 ENGINE MECHANICAL (M13 ENGINE)

Tighten bearing cap No.1 bolts (1) – (10) and No.2 bolts (11) –

(20) gradually as follows.

1) Tighten bolts (1) – (10) to 30 N·m (3.0 kg-m, 22.0 lb-ft)

according to numerical order in figure.

2) In the same manner as in Step 1), tighten them to 50 N·m

(5.0 kg-m, 36.5 lb-ft).

3) In the same manner as in step 1), retighten them to 60°.

4) Tighten bolts (11) – (20) to 22 N·m (2.2 kg-m, 16.0 lb-ft)

according to numerical order in figure.

Tightening torque

Crankshaft bearing cap No.1 bolts (1) – (10) :

50 N·m (5.0 kg-m, 36.5 lb-ft) and extra tightening 60°

Crankshaft bearing cap No.2 bolts (11) – (20) :

22 N·m (2.2 kg-m, 16.0 lb-ft)

Use a dial gauge to read displacement in axial (thrust) direction of

crankshaft.

If its limit is exceeded, replace thrust bearing with new standard

one or oversize one to obtain standard thrust play.

Crankshaft thrust play

Standard : 0.11 – 0.31 mm (0.0043 – 0.0122 in.)

Limit : 0.35 mm (0.0138 in.)

Out-of-round and taper of journals

An unevenly worn crankshaft journal shows up as a difference in

diameter at a cross section or along its length (or both). This dif-

ference, if any, is determined by taking micrometer readings. If

any one of journals is badly damaged or if amount of uneven

wear in the sense explained above exceeds its limit, regrind or

replace crankshaft.

Crankshaft out-of-round and taper

Limit : 0.01 mm (0.0004 in.)

Out-of-round : A – B

Taper : a – b

Main Bearings

General information

Service main bearings are available in standard size and

0.25 mm (0.0098 in.) undersize, and each of them has 5

kinds of bearings differing in tolerance.

NOTE:

After checking the thrust play, check for thread deforma-

tion of each bearing cap No.1 bolt according to previous

mentioned “Main Bearing Cap No.1 Bolt” once again.

Page 573 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-92 ENGINE MECHANICAL (M13 ENGINE)

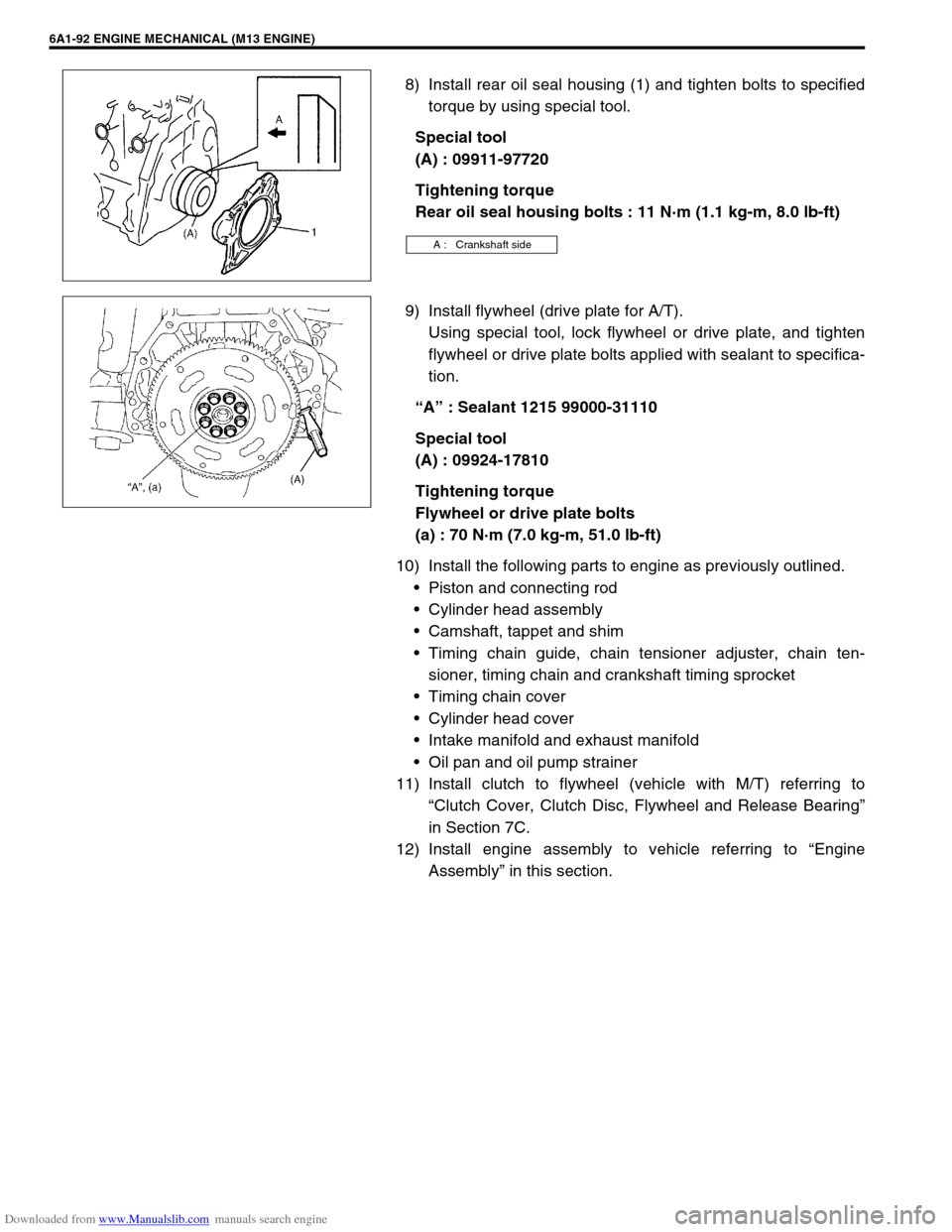

8) Install rear oil seal housing (1) and tighten bolts to specified

torque by using special tool.

Special tool

(A) : 09911-97720

Tightening torque

Rear oil seal housing bolts : 11 N·m (1.1 kg-m, 8.0 lb-ft)

9) Install flywheel (drive plate for A/T).

Using special tool, lock flywheel or drive plate, and tighten

flywheel or drive plate bolts applied with sealant to specifica-

tion.

“A” : Sealant 1215 99000-31110

Special tool

(A) : 09924-17810

Tightening torque

Flywheel or drive plate bolts

(a) : 70 N·m (7.0 kg-m, 51.0 lb-ft)

10) Install the following parts to engine as previously outlined.

Piston and connecting rod

Cylinder head assembly

Camshaft, tappet and shim

Timing chain guide, chain tensioner adjuster, chain ten-

sioner, timing chain and crankshaft timing sprocket

Timing chain cover

Cylinder head cover

Intake manifold and exhaust manifold

Oil pan and oil pump strainer

11) Install clutch to flywheel (vehicle with M/T) referring to

“Clutch Cover, Clutch Disc, Flywheel and Release Bearing”

in Section 7C.

12) Install engine assembly to vehicle referring to “Engine

Assembly” in this section.

A : Crankshaft side

Page 578 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE COOLING 6B-1

6B

SECTION 6B

ENGINE COOLING

CONTENTS

General Description ........................................6B-2

Cooling System Circulation ........................... 6B-2

Radiator Cap ................................................. 6B-3

Coolant Reservoir ......................................... 6B-3

Water Pump .................................................. 6B-4

Thermostat .................................................... 6B-4

Cooling Fan Clutch ........................................ 6B-4

Coolant (Water) Temperature Gauge............ 6B-4

Diagnosis .........................................................6B-5

Maintenance ....................................................6B-6

Coolant .......................................................... 6B-6

Coolant Level ................................................ 6B-7

Cooling System Service ................................ 6B-7Cooling System Flush and Refill ................... 6B-8

Water Pump Belt Tension ............................. 6B-9

On-Vehicle Service ....................................... 6B-10

Cooling System Component ....................... 6B-10

Coolant Draining ......................................... 6B-11

Cooling Water Pipes or Hoses .................... 6B-11

Thermostat .................................................. 6B-11

Water Pump Belt and Cooling Fan ............. 6B-13

Radiator ...................................................... 6B-14

Water Pump ................................................ 6B-15

Required Service Material ............................ 6B-17

Tightening Torque Specification ................. 6B-17